Preparation method for homopolymer or copolymer of cyclohexyl ethylene and catalyst

A cyclohexane-based ethylene and styrene copolymer technology is applied in the preparation of cyclohexane-based ethylene homopolymers or copolymers and in the field of catalysts, and can solve the problems of slow hydrogenation speed, large catalyst dosage, difficult separation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

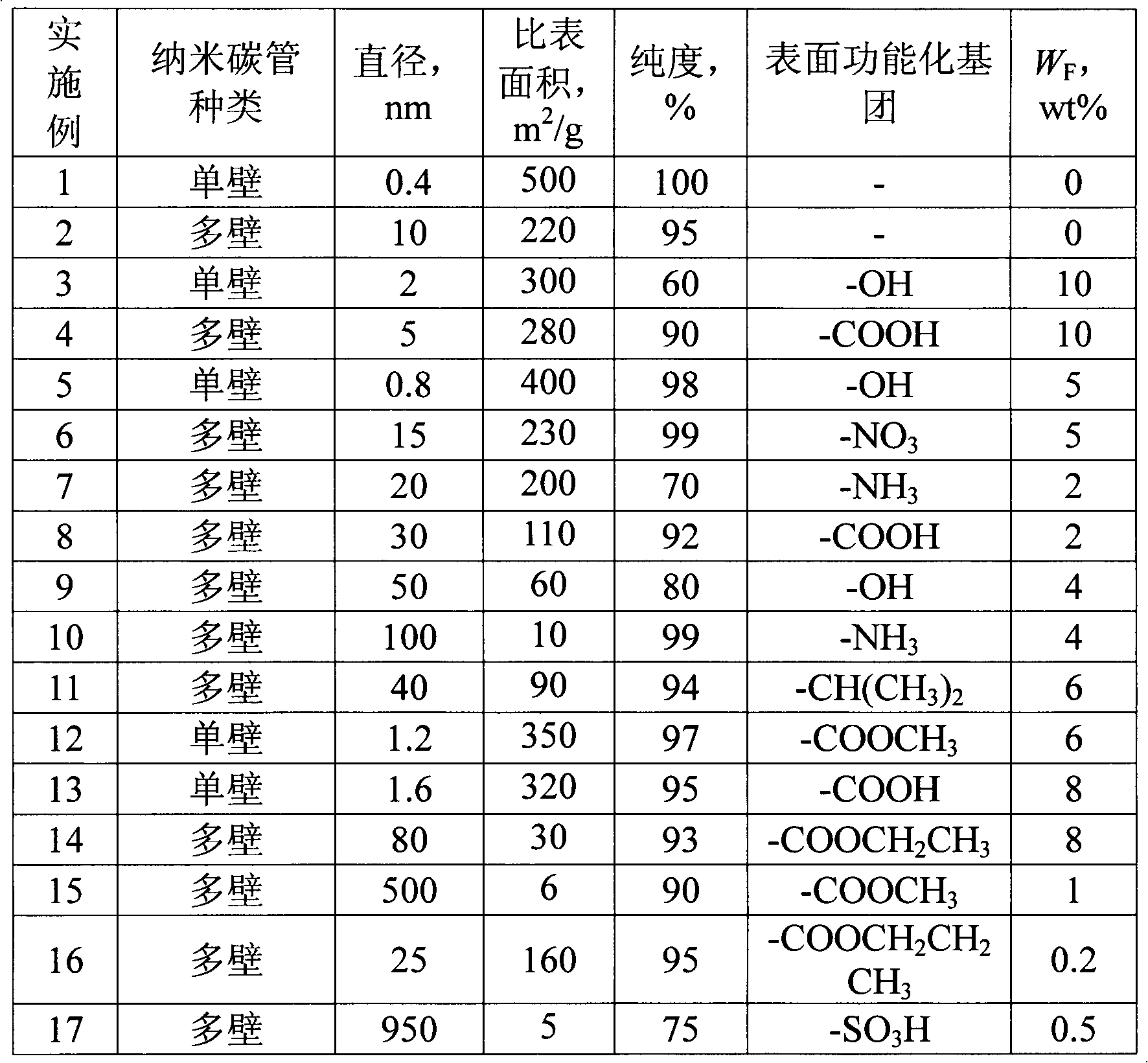

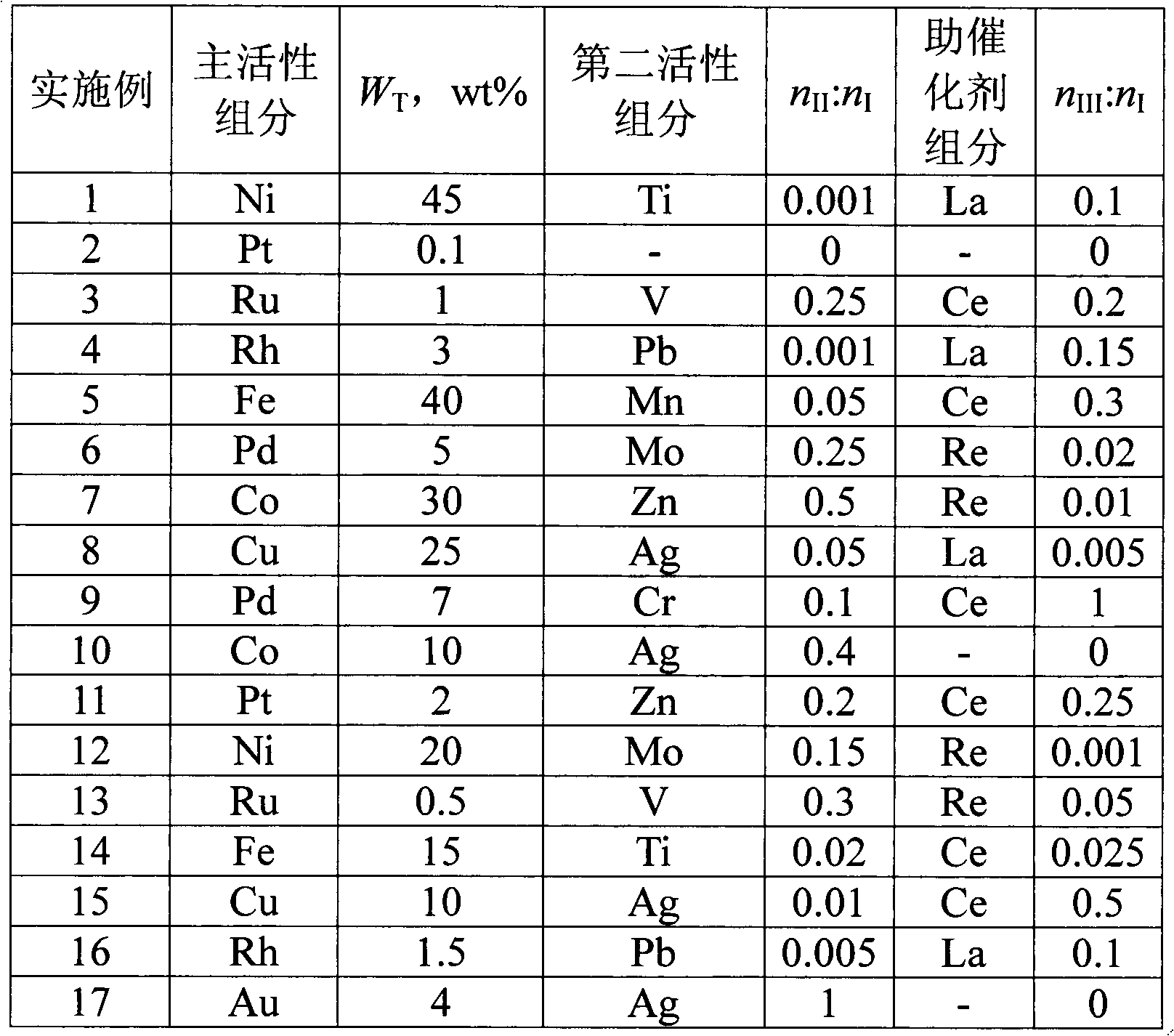

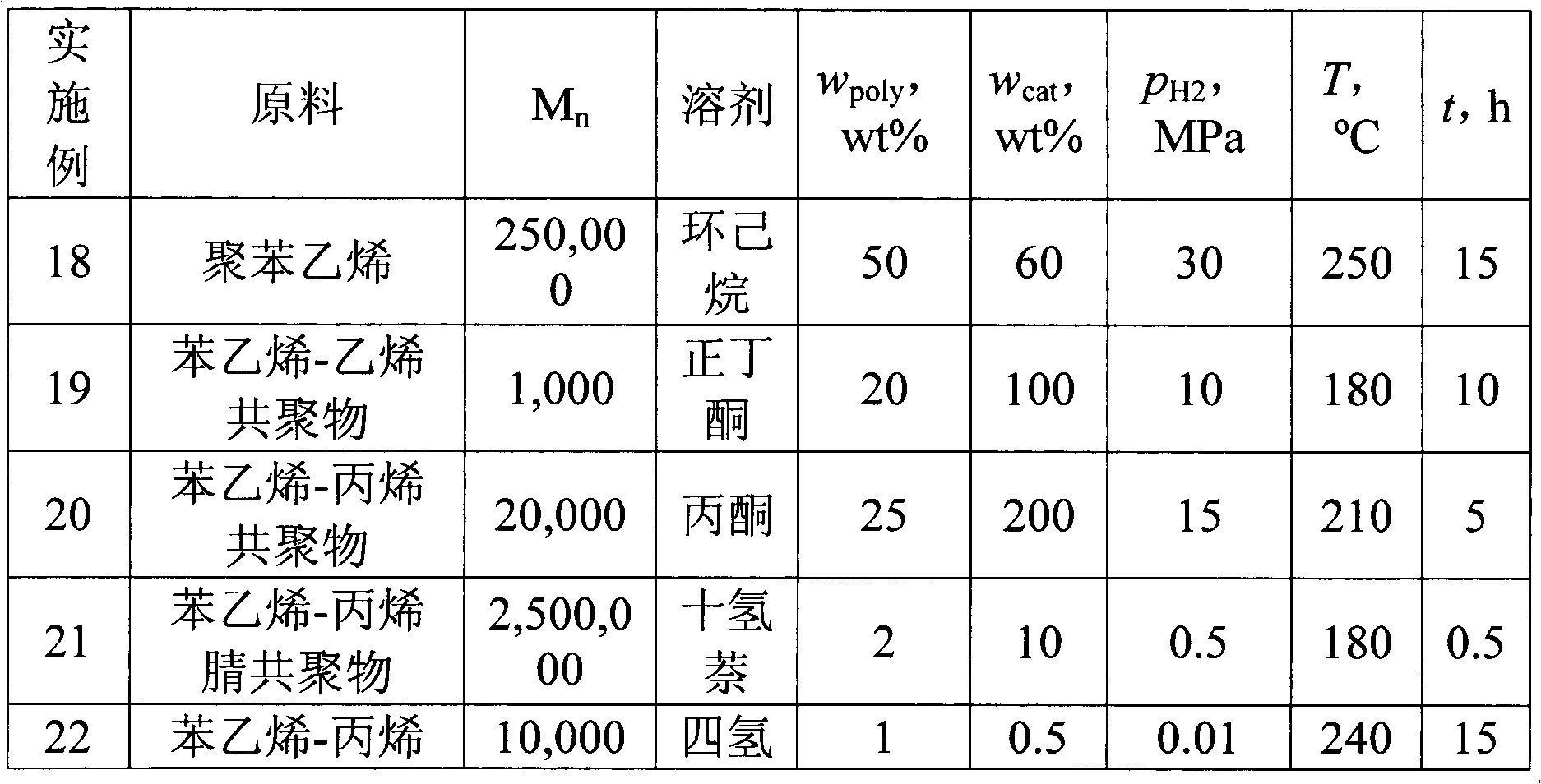

[0062] Select diameter as 0.4nm in embodiment 1 in table 2, and specific surface area is 500m 2 / g, single-walled carbon nanotubes without surface functional groups were used as the carrier, carbon nanotubes were added into ethanol, and ultrasonically dispersed for 0.2h. According to the first group of formulations in Table 3, the hydrochloride ethanol solution containing the main active component, the second active component and the cocatalyst component was added to the dispersed carbon nanotube solution, and the ultrasonic dispersion was continued for 0.5 h. Filter the impregnated carbon nanotubes, wash and dry, add NaBH 4 The reducing agent is reduced and treated at 100°C for 2 hours to obtain a supported carbon nanotube catalyst.

Embodiment 2

[0064] Select diameter as 10nm in embodiment 2 in table 2, and specific surface area is 220m 2 / g, multi-walled carbon nanotubes without surface functional groups were used as the carrier, carbon nanotubes were added into ethanol, and ultrasonically dispersed for 0.5h. Add the hydrochloride ethanol solution containing the main active component, the second active component and the cocatalyst component into the dispersed carbon nanotube solution according to the second group of formulations in Table 3, and continue ultrasonic dispersion for 2 hours. Filter the impregnated carbon nanotubes, wash and dry, add NaBH 4 The reducing agent is reduced and treated at 100°C for 2 hours to obtain a supported carbon nanotube catalyst.

Embodiment 3

[0066] Select diameter as 2nm in embodiment 3 in table 2, and specific surface area is 300m 2 / g, single-walled carbon nanotubes containing surface functional groups -OH as a carrier, carbon nanotubes were added to ethanol, and ultrasonically dispersed for 2 hours. Add the nitrate ethanol solution containing the main active component, the second active component and the cocatalyst component into the dispersed carbon nanotube solution according to the third group of formulations in Table 3, and continue ultrasonic dispersion for 2 hours. Filter, wash and dry the impregnated carbon nanotubes, add formaldehyde as a reducing agent for reduction, and treat at 160°C for 4 hours to obtain a supported carbon nanotube catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com