Method for preparing carbon nanotube-loaded nano-copper-nickel solid solution by utilizing microwave

A carbon nanotube and nano-copper technology is applied in the field of preparing a carbon nanotube-supported nano-copper-nickel solid solution, which can solve the problems of complex process, high cost, difficult control of nano-particle size, etc., and achieves simple process, low cost, and overcoming difficult storage easily oxidized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

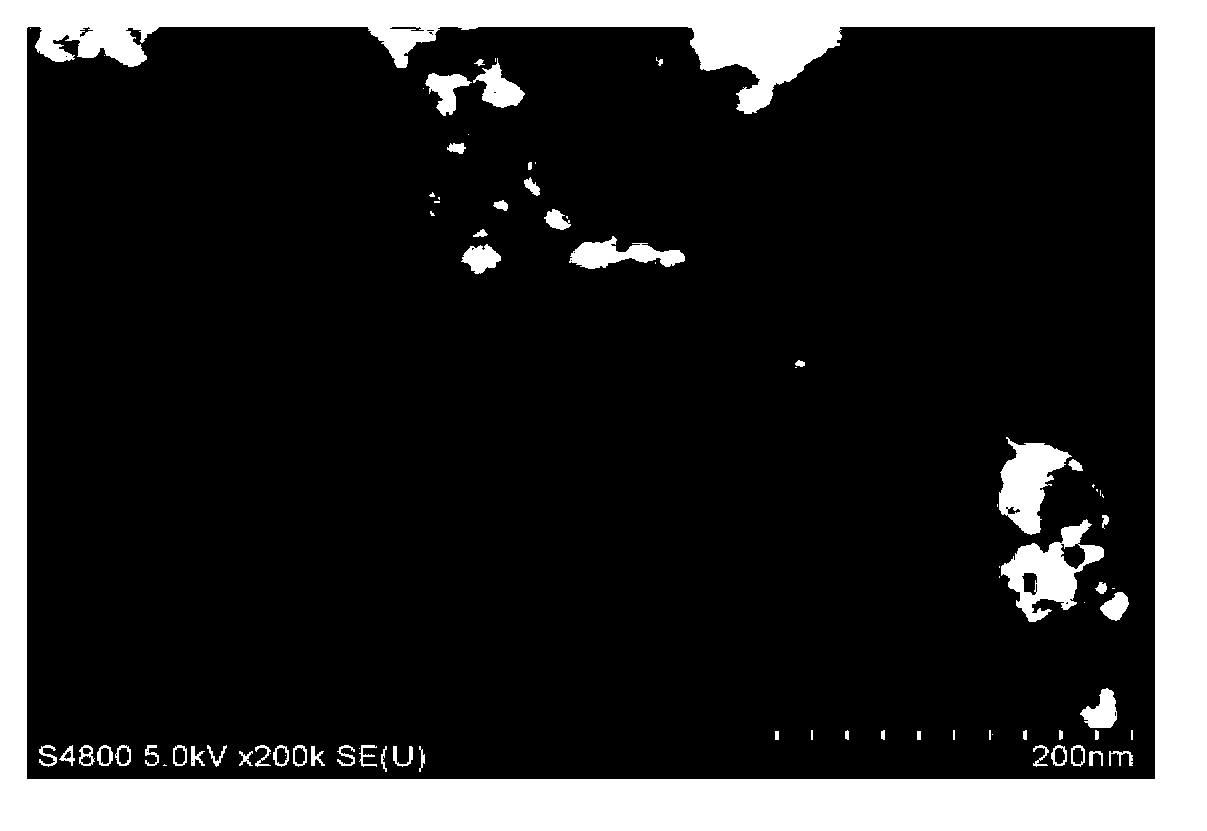

Image

Examples

preparation example Construction

[0027] 4. The preparation method of the present invention has the advantages of simple process, low cost, short reaction time and easy control of nano-copper-nickel solid solution particles.

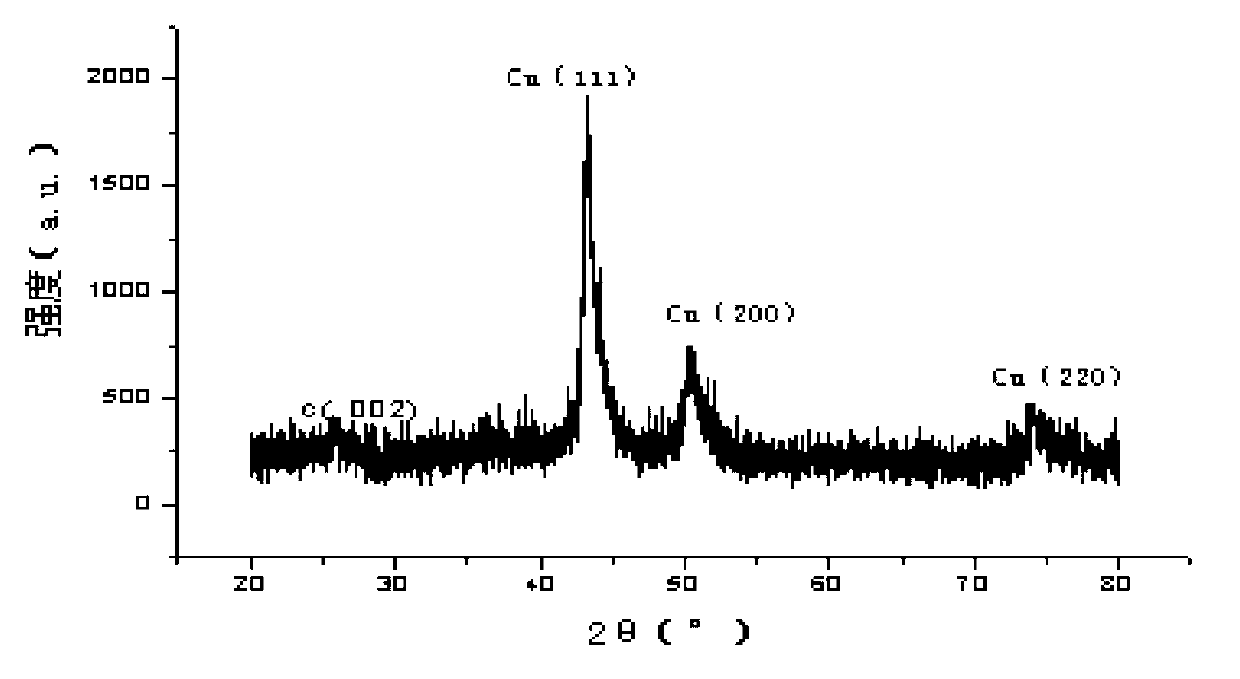

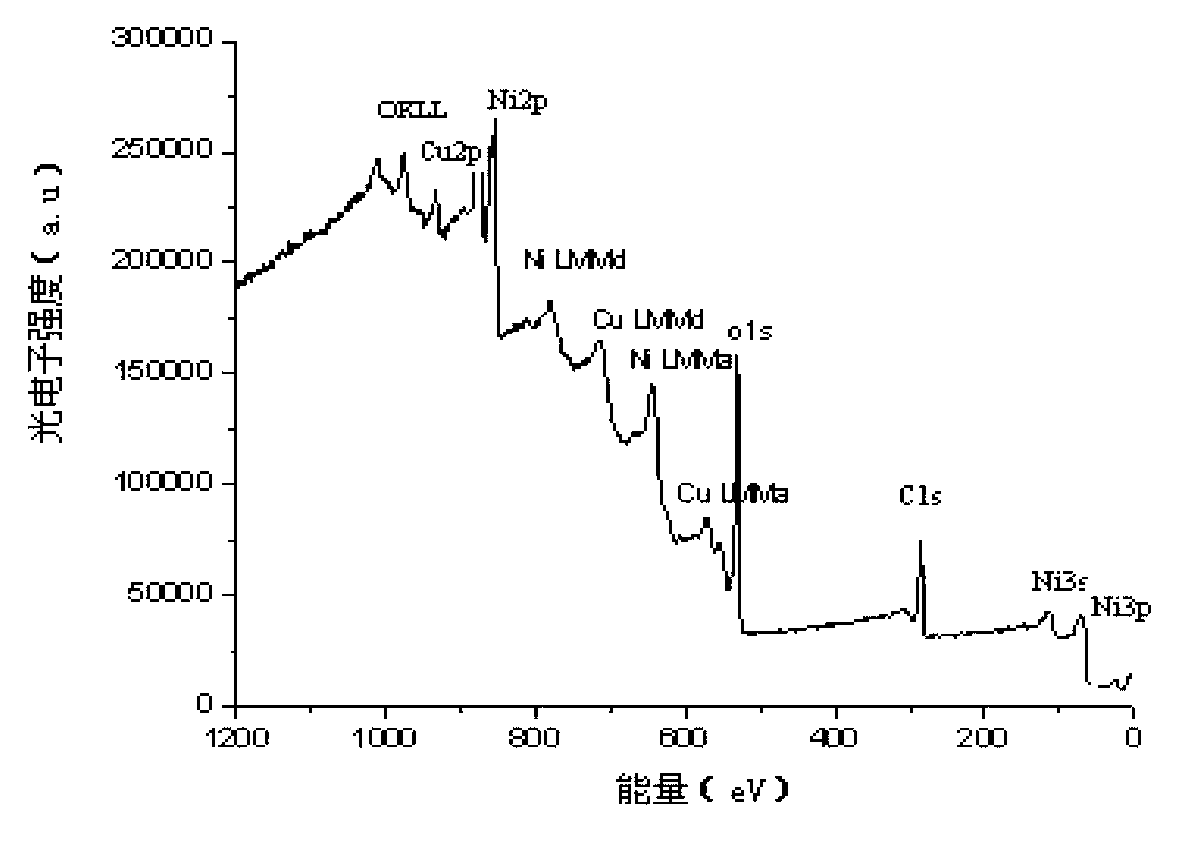

[0028] 5. The XRD spectrogram of the composite material prepared by the present invention contains diffraction peaks of copper and carbon, but no diffraction peak of nickel, but there is a nickel peak in XPS, indicating that the composite material is a carbon nanotube-loaded nano-copper-nickel solid solution.

specific Embodiment approach 2

[0029] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in step one, 0.1mol / L~0.3mol / L NiSO 4 ·6H 2 O solution and 0.1mol / L~0.4mol / L CuSO 4 ·5H 2 The O solution was mixed evenly in a ratio of 1:(2~8) by volume. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0030] Specific embodiment three: the difference between this embodiment and specific embodiment one is that 0.2mol / L NiSO 4 ·6H 2 O solution and 0.25mol / L CuSO 4 ·5H 2 The O solution was mixed uniformly at a ratio of 1:5 by volume. Other steps and parameters are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com