Patents

Literature

47 results about "P-nitrobenzyl alcohol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

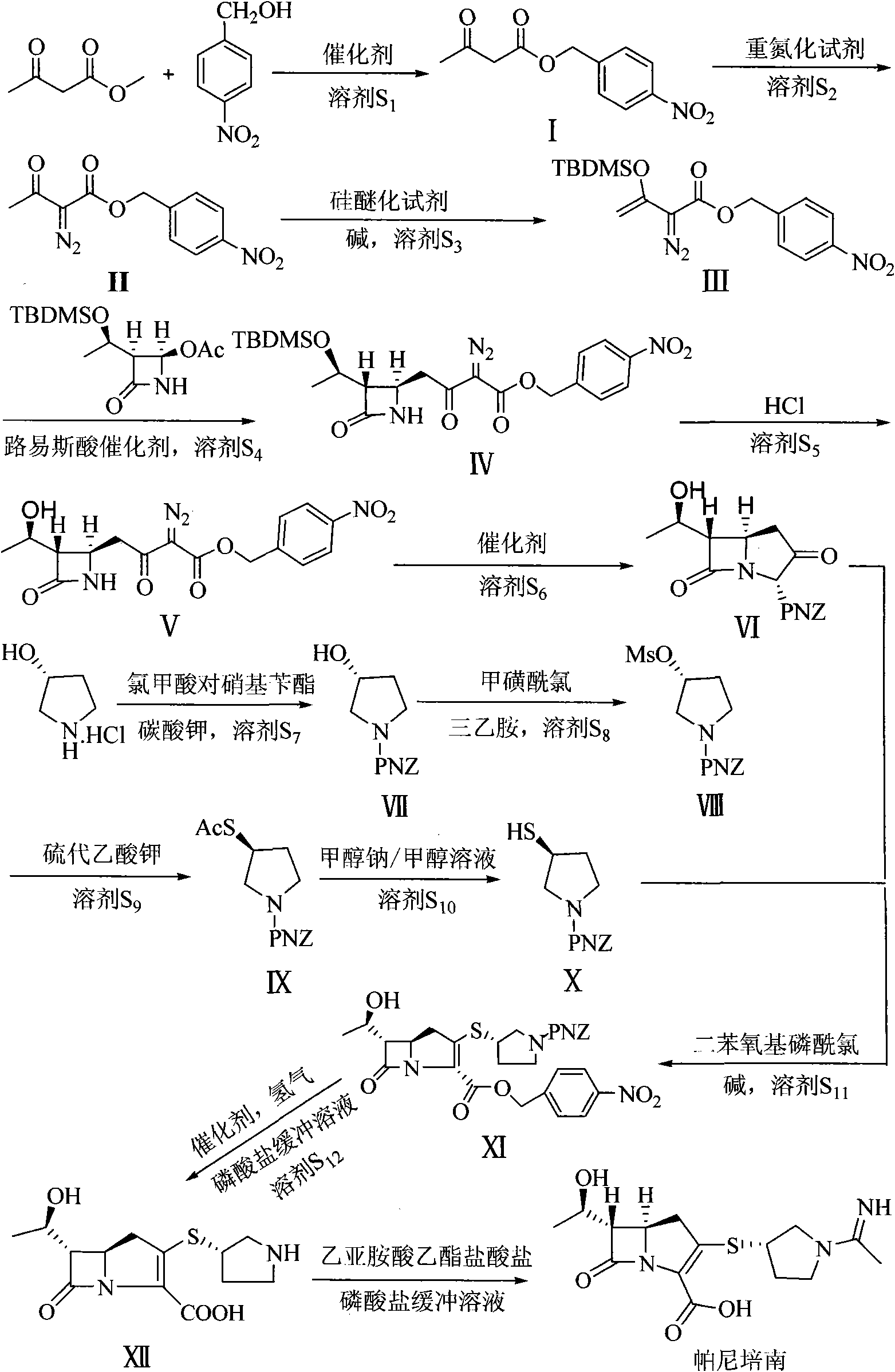

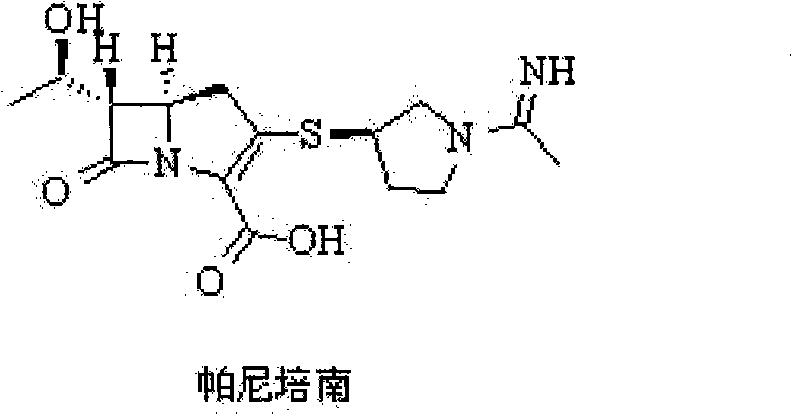

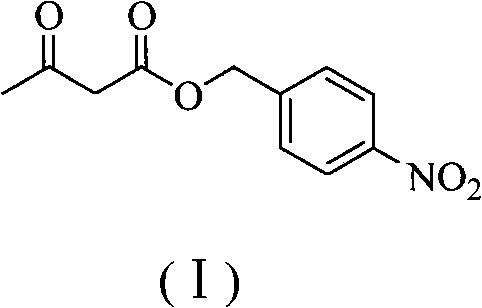

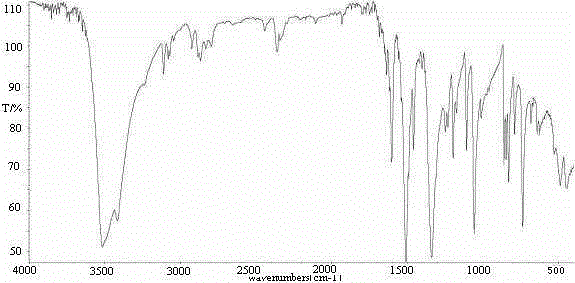

Preparation method of panipenem

The invention relates to a preparation method of panipenem. Firstly, methyl acetoacetate and p-nitrobenzyl alcohol are taken as raw materials to prepare panipenem parent nucleus by six steps of reactions: ester exchange reaction, diazo reaction, enolization reaction, substitution reaction, hydrolysis reaction and ring closing reaction; then, (3R)-3-hydroxy-pyrrolidine hydrochloride, nitrobenzyl chroformate ester are taken as raw materials to prepare panipenem side chain by amidation reaction, sulfonylation reaction, nucleophilic substitution reaction and saponification reaction; finally, the prepared panipenem parent nucleus and panipenem side chain are in butt joint by condensation and are subjected to catalytic hydrolysis and imidization to obtain panipenem. The preparation method of panipenem features simple operation, mild reaction condition, friendly environment, high yield, good product purity, low cost and better industrialized production prospect.

Owner:ZHEJIANG NORMAL UNIVERSITY

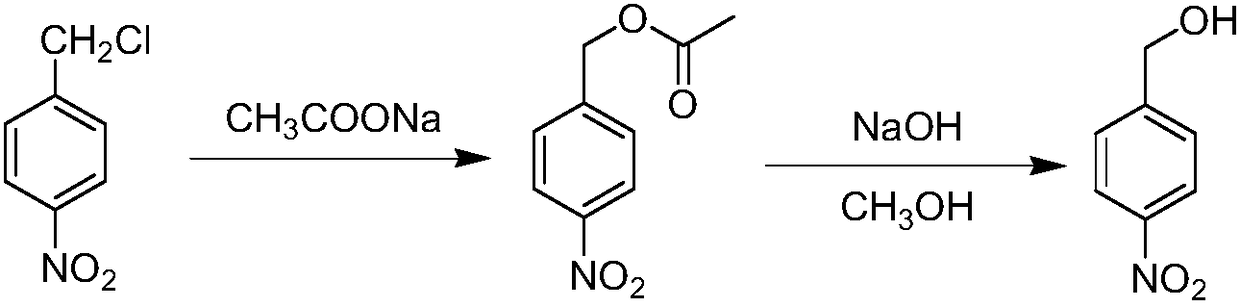

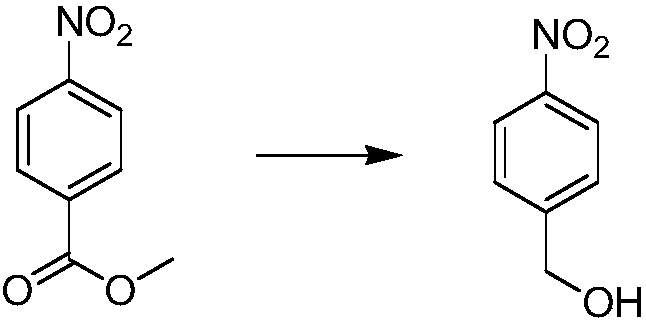

Cost-saving preparation method of p-nitrobenzyl alcohol

InactiveCN104370746ANothing producedNo production, in line with the concept of green productionOrganic chemistryOrganic compound preparationState of artP-nitrobenzyl chloride

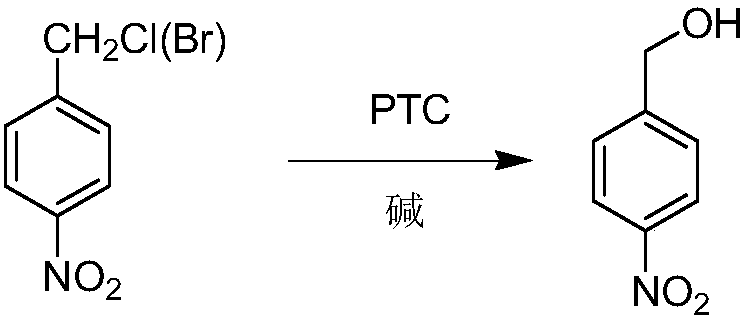

The invention discloses a cost-saving preparation method of p-nitrobenzyl alcohol. The key points of the technical scheme are as follows: according to the cost-saving preparation method of the p-nitrobenzyl alcohol, p-nitrotoluene is taken as a starting raw material and reacts with chlorine gas to obtain p-nitrobenzyl chloride, and then the p-nitrobenzyl chloride is hydrolyzed in an alkaline solution to obtain p-nitrobenzyl alcohol. Compared with the prior art, the cost-saving preparation method of the p-nitrobenzyl alcohol has the following beneficial effects: the reaction system is simple and the raw material is cheap and easily available; the preparation cost is low and no hazardous waste is generated, so that the preparation method accords with the green production ideal; the cost-saving preparation method is simple in process, simple and convenient to operate, short in reaction time, high in efficiency and suitable for large-scale production.

Owner:HENAN NORMAL UNIV

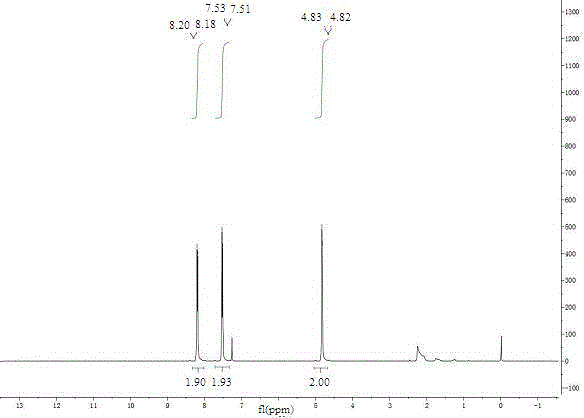

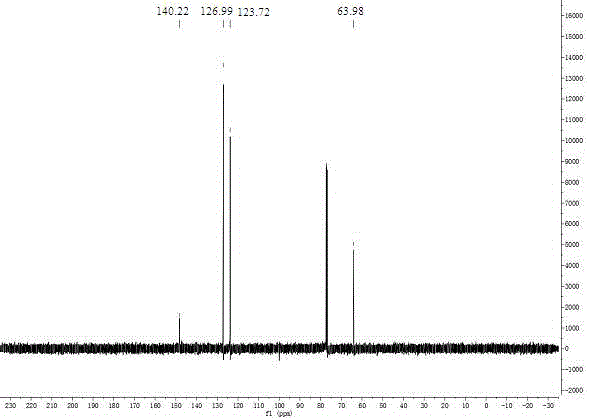

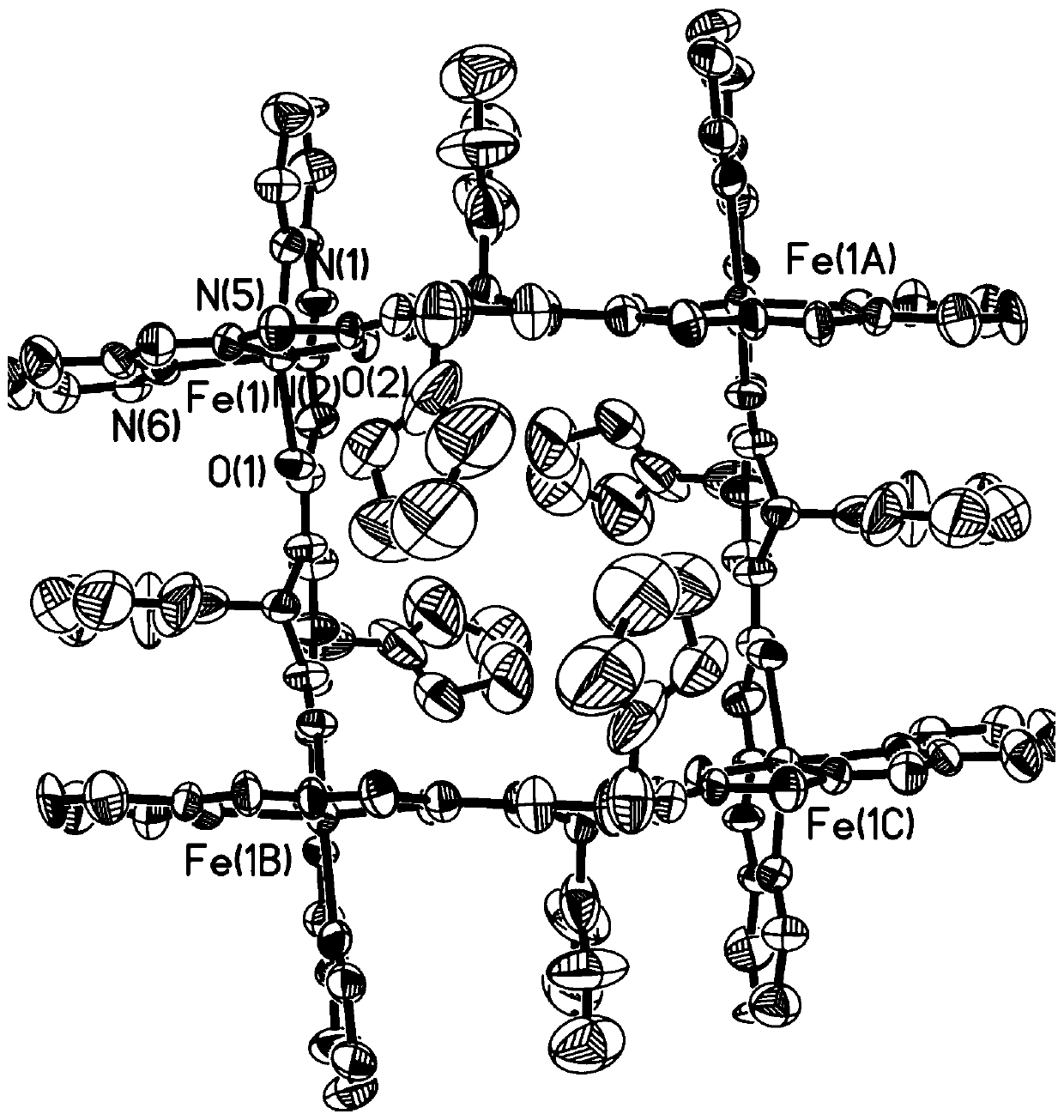

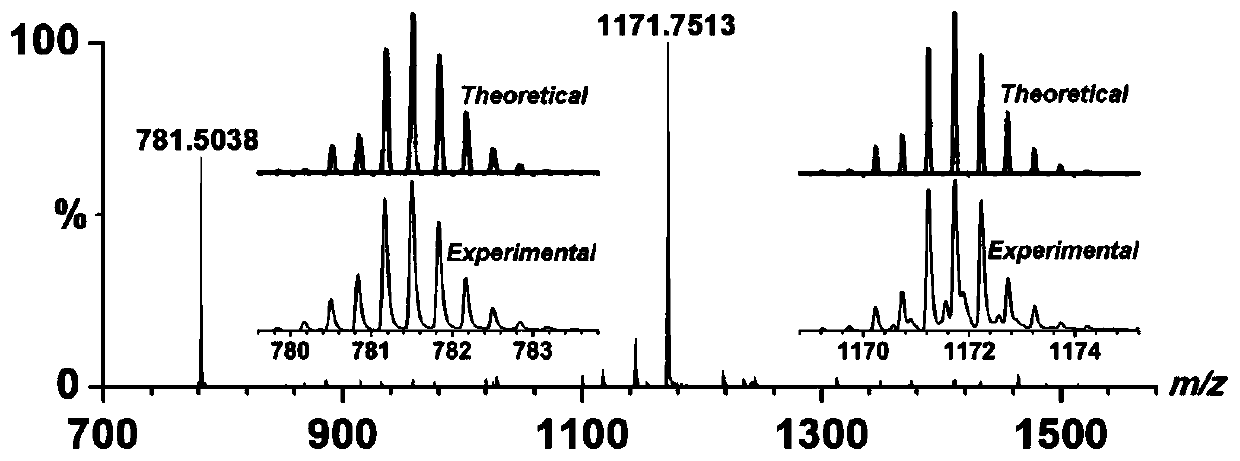

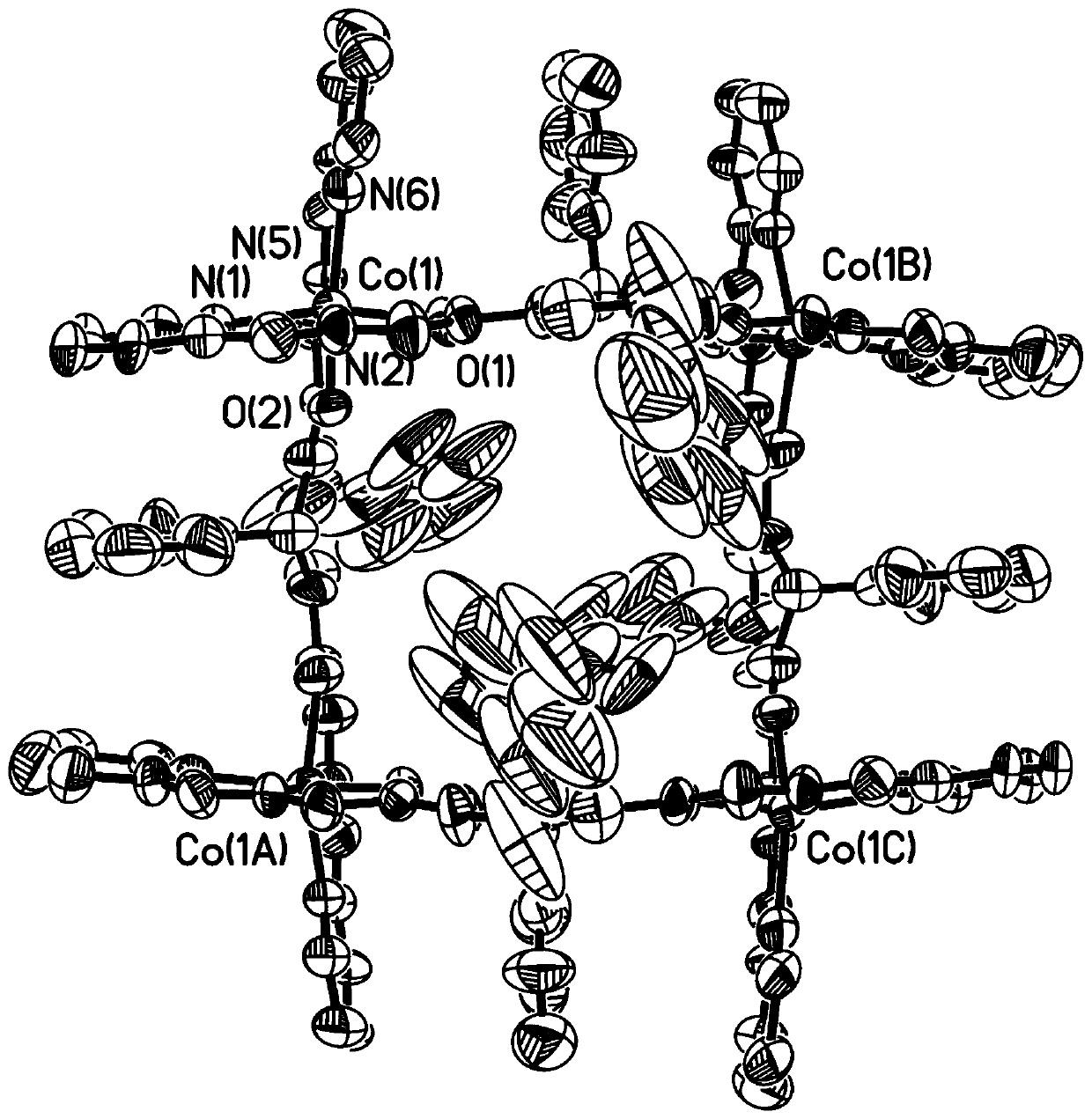

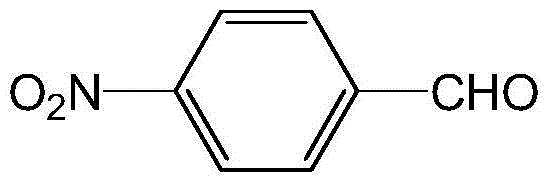

Preparation method and application of adjustable metal organic cage compound for efficiently selective catalytic reduction of nitrobenzaldehyde

InactiveCN110483585AHigh yieldChemically stableOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsTetrafluoroboratePara-nitrobenzaldehyde

The invention belongs to the technical field of fine chemical engineering. The invention relates to a preparation method and application of an adjustable metal organic cage compound for efficient selective catalytic reduction of nitrobenzaldehyde. According to the preparation method, M<2+> in a transition metal salt is used as a node and L is used as a ligand for reaction to prepare the metal organic cage compound, and the synthetic route is as follows: M<2+> + L- to M-L; wherein the ligand L is selected from H2FPB; the transition metal salt is selected from one of ferrous perchlorate, cobalttetrafluoroborate, nickel perchlorate or zinc tetrafluoroborate. The metal organic cage compound prepared by the method is low in raw material price and high in yield, and the obtained compound is stable in chemical property and easy to put into practical application. As a target compound M-FPB, the adjustable metal organic cage compound shows that the selectivity of the compound M-FPB can reach 99% in the aspects of reduction of p-nitrobenzaldehyde to prepare p-nitrobenzyl alcohol, one-step synthesis of cinnarizine by reduction catalysis of cinnamyl aldehyde and reduction of p-nitrobenzaldehyde to prepare p-aminobenzaldehyde.

Owner:DALIAN UNIV OF TECH

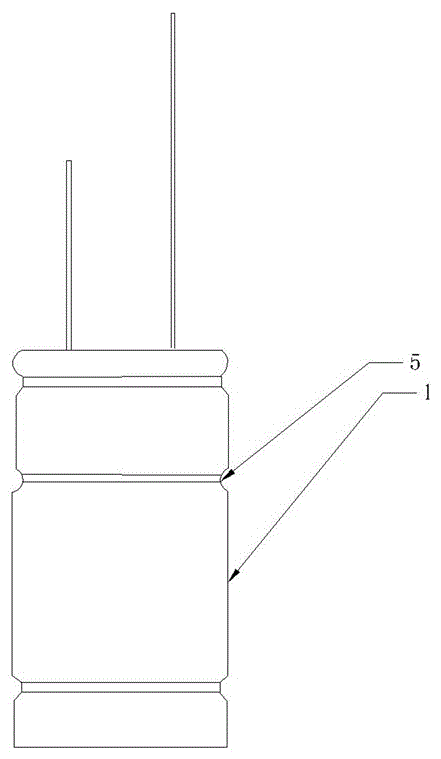

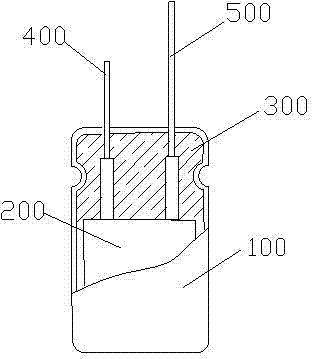

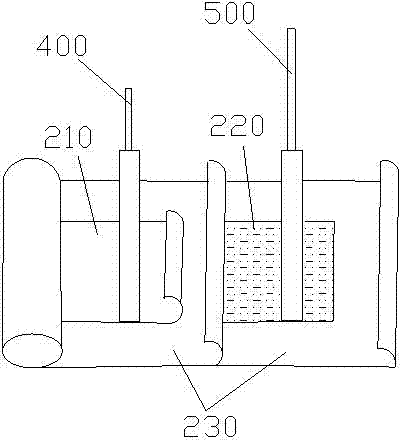

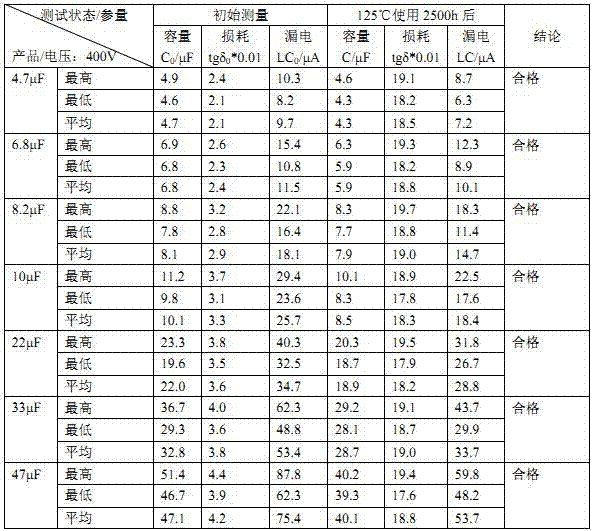

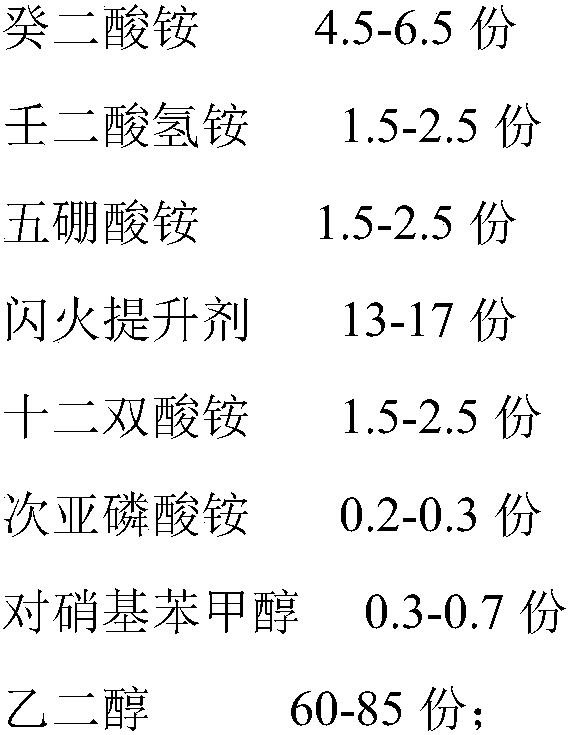

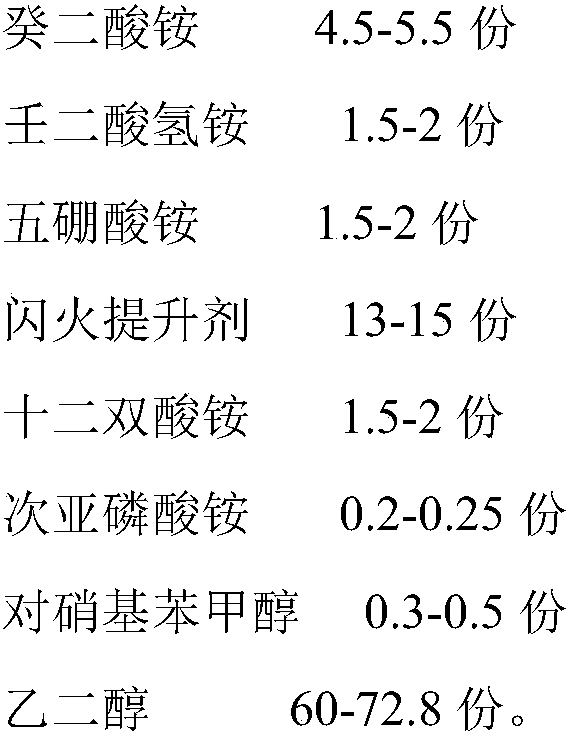

Microminiature rapid charging special-purpose aluminium electrolytic capacitor

InactiveCN106252083AGuaranteed capacityGuaranteed high withstand voltage performanceCapacitor housing/encapsulationP-nitroanisoleLightning strike

The invention provides a microminiature rapid charging special-purpose aluminium electrolytic capacitor which comprises a shell, a core bag and a rubber plug. The core bag is sealed in the shell through the rubber plug. The core bag contains electrolyte which comprises a solvent, an inorganic acid ammonium salt, an organic acid ammonium salt, and a hydrogen elimination agent. The inorganic acid ammonium salt is ammonium borate or ammonium pentaborate or the mixture of the ammonium borate or the ammonium pentaborate. The organic acid ammonium salt comprises one or more of ammonium sebacate, ammonium azelate, diammonium phthalate, and dodecyl ammonium carboxylate. The hydrogen elimination agent comprises one or more of a p-Nitrobenzyl alcohol, a p nitroanisole and p-nitrobenzoic acid. The conductivity of the electrolyte in the invention is between 2.4 ms / cm to 2.8ms / cm, the ESR value of a product can be effectively reduced, thus the ripple resistance and lightning strike resistance ability of the product are improved greatly, the flash fire voltage is above 490V, in a condition of high voltage, the breakdown of electrolytic paper caused by flash fire of the electrolyte does not appears, and thus the voltageproof performance of the product is ensured.

Owner:HUNAN AIHUA GRP

Method for synthesizing 4-nitrobenzyl chloroformate

InactiveCN1803758AEliminate production safety hazardsThe amount of three wastes is lessOrganic chemistryOrganic compound preparationOrganic solventChloroformate

The invention provides a process for synthesizing 4-Nitrobenzyl chloroformate, which comprises reacting trichloromethyl chloroformate or bis(trichloromethyl)carbonate with p-nitrobenzyl alcohol at -40-20 deg C under the action of acid-binding agent, finally carrying out post-treatment to obtain the outcome yield.

Owner:ZHEJIANG UNIV OF TECH

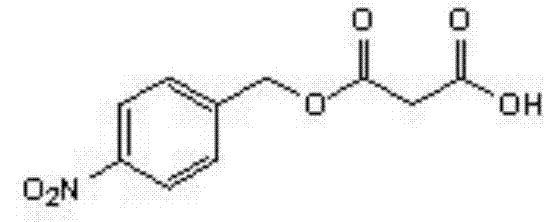

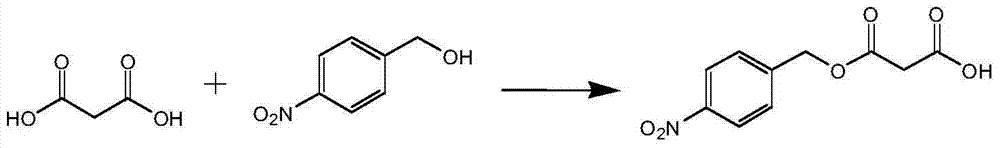

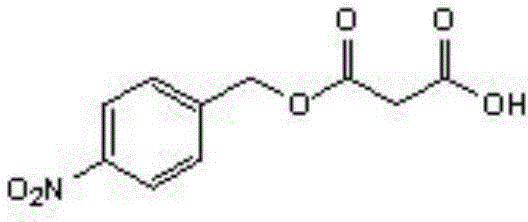

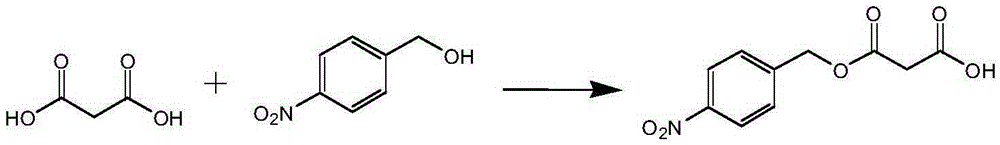

Method for enzymatic synthesis of mono-4-nitrobenzyl malonate

InactiveCN103540622AReduce the impactRaw materials are easy to getFermentationWater bathsEnzymatic synthesis

The invention relates to a method for synthesizing mono-4-nitrobenzyl malonate. The method comprises the steps of adding para-nitrobenzyl alcohol, malonic acid or malonate and a reaction solvent to a reaction flask at a mol ratio of 1: (1-10): (10-50); heating in a water bath until being balanced; adding lipase and a water absorbent to the reaction flask at a mol ratio of (0.1-1): (0-100) with the para-nitrobenzyl alcohol; controlling temperature at 30-50 DEG C, reacting for 10-48 hours, filtering to remove the lipase to obtain a reaction solution, and carrying out reduced pressure distilling on the reaction solution to remove the solvent, to obtain reaction residue; adding a mixing solution of an organic solvent and a salt solution to the reaction residue, stirring and layering, acidifying an obtained water phase, carrying out suction filtering and drying to obtain the mono-4-nitrobenzyl malonate. The method is easily available in raw materials, few in reaction step, moderate in reaction condition, few in side product, and simple and convenient to operate; the method, because the adopted organic solvent can be recycled, is low in environmental impact, simple in post-treatment, relatively high in production purity and yield, and suitable for industrial production.

Owner:NANJING UNIV OF TECH

High-sparking and anti-lightning electrolyte for aluminum electrolytic capacitor and preparation method therefor

ActiveCN105469992ASimple processEasy to operate and controlElectrolytic capacitorsDiethylene glycol monobutyl etherElectrolysis

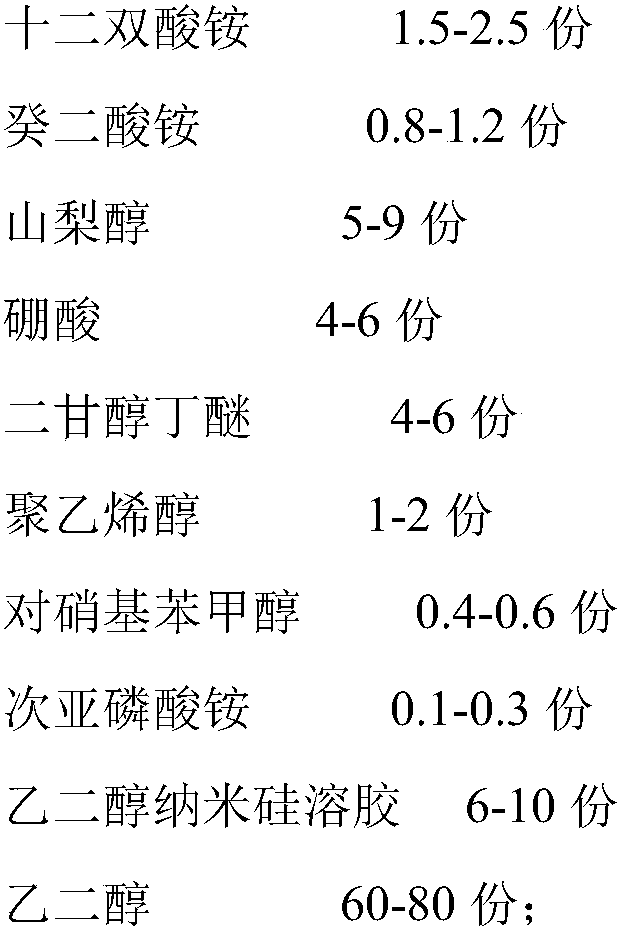

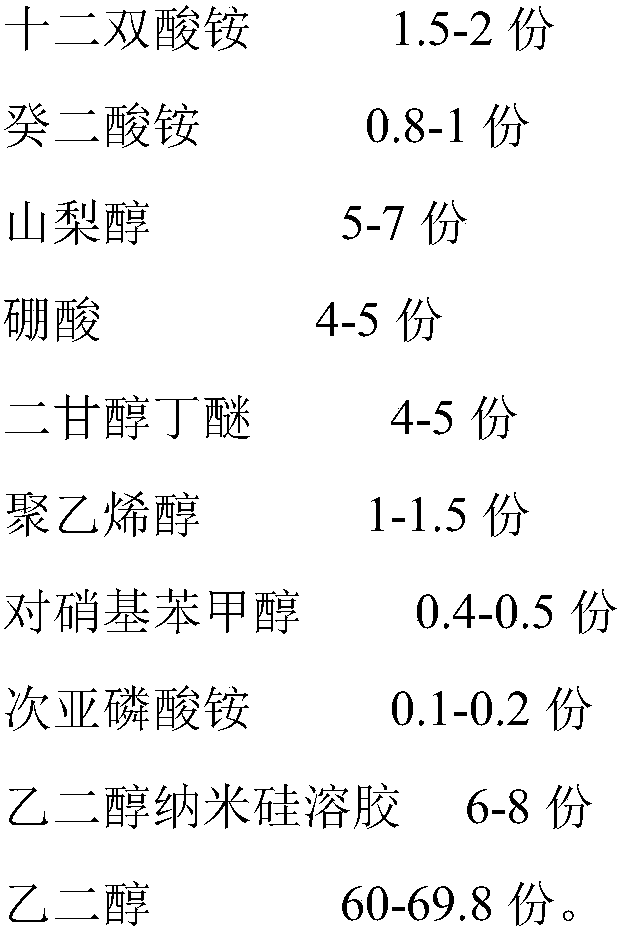

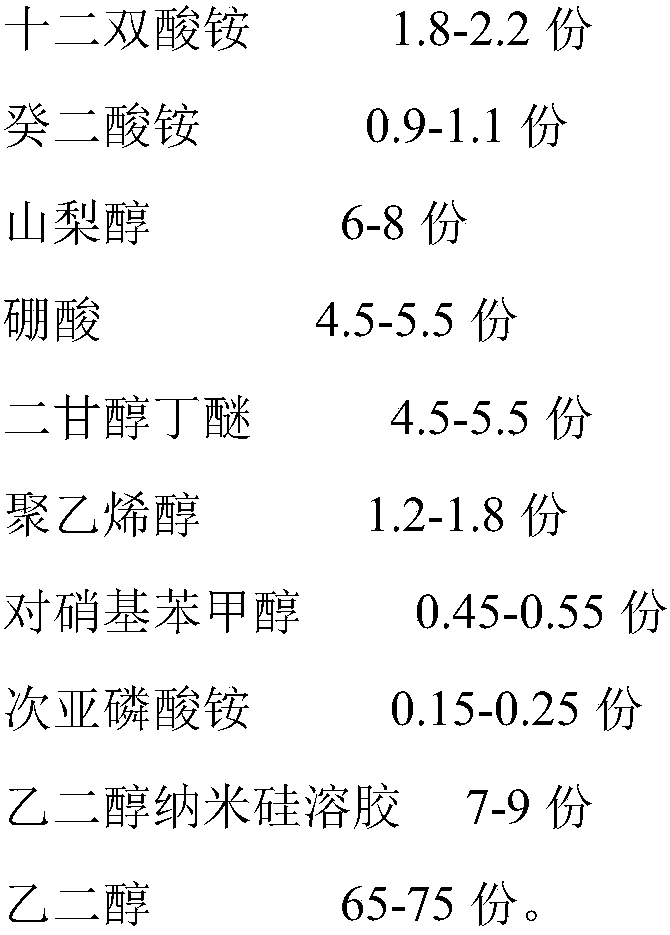

The present invention relates to the technical field of electrolytes, in particular to a high-sparking and anti-lightning electrolyte for an aluminum electrolytic capacitor and a preparation method therefor. The electrolyte comprises the following raw materials in parts by weight: 1.5-2.5 parts of ammonium dodecanedioate, 0.8-1.2 parts of ammonium sebacate, 5-9 parts of sorbitol, 4-6 parts of boracic acid, 4-6 parts of diethylene glycol monobutyl ether, 1-2 parts of polyvinyl alcohol, 0.4-0.6 part of p-nitrobenzyl alcohol, 0.1-0.3 part of ammonium hypophosphite, 6-10 parts of ethylene glycol nano silica sol and 60-80 parts of glycol. The electrolyte is prepared by means of interaction among the raw materials and by strictly controlling a weight proportion of the raw materials; the sparking voltage of the prepared electrolyte can reach 590 V and the conductivity rate of the prepared electrolyte can reach 0.5 ms / cm; and the electrolyte has good electrochemical properties, has the advantages of high sparking voltage, lightning resistance and the like, and can be applied to manufacturing of the aluminum electrolytic capacitors.

Owner:DONGGUAN JIUZHI ELECTRONICS CO LTD

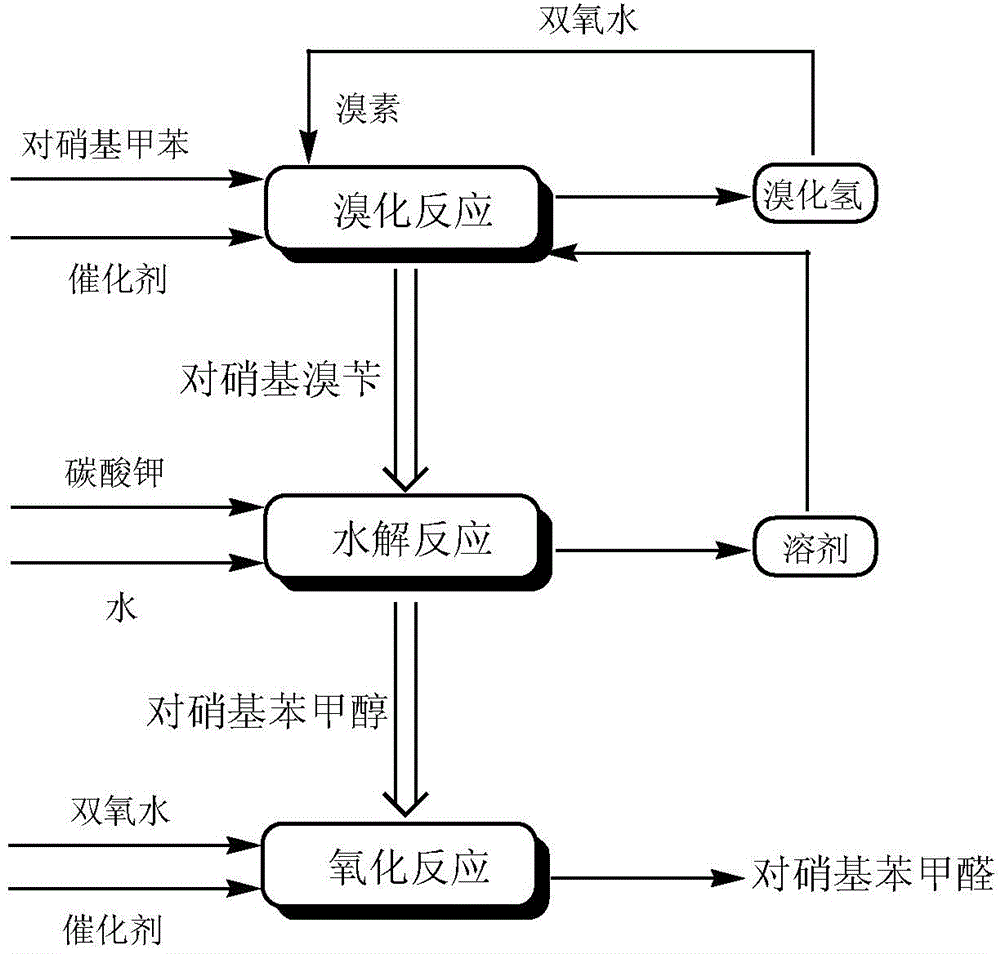

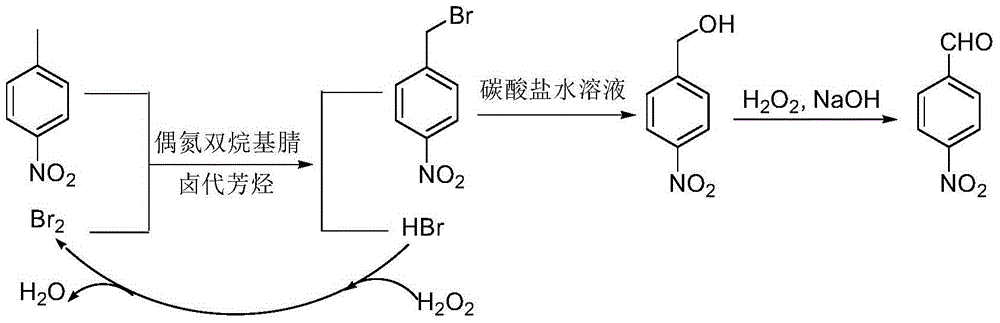

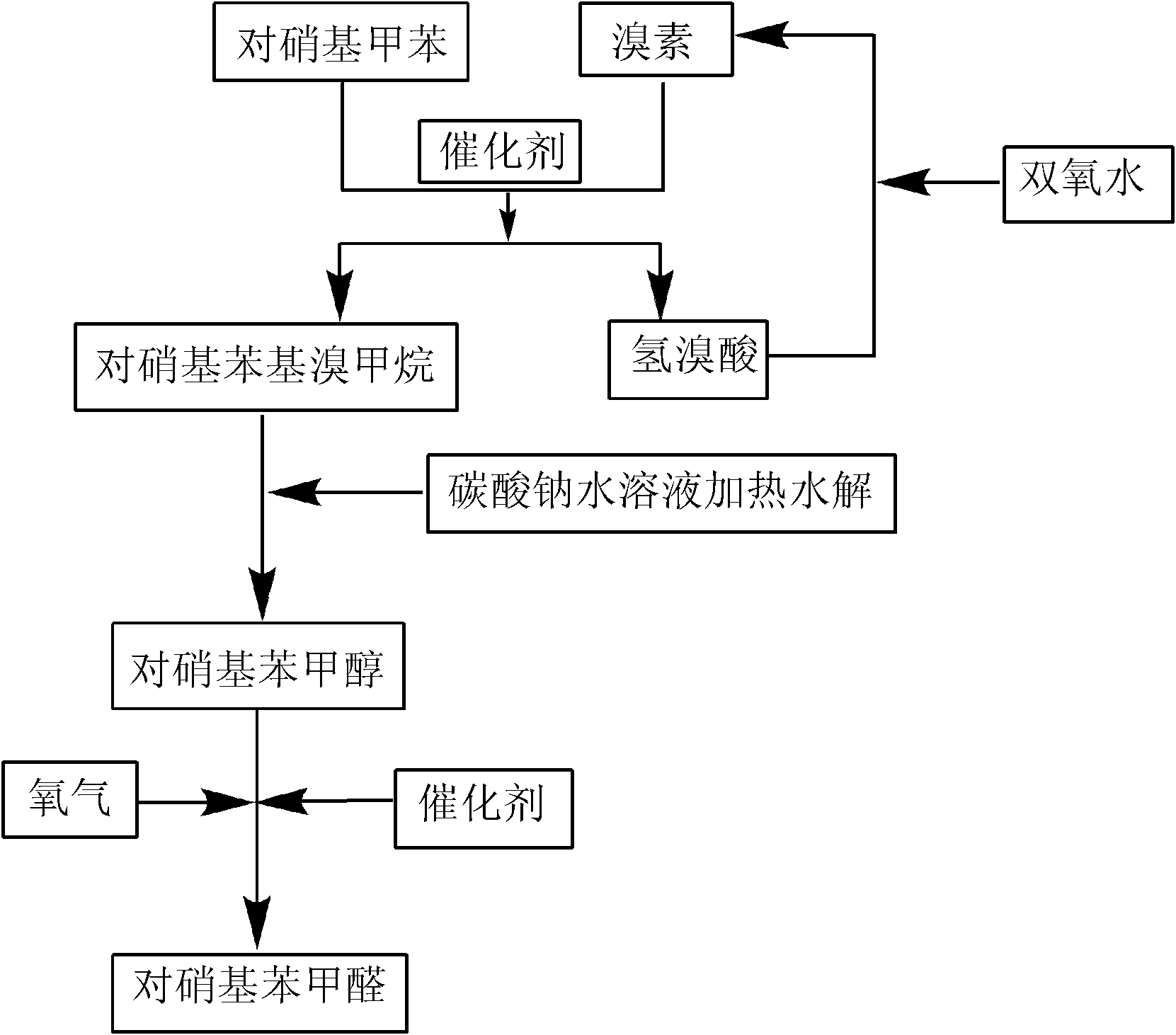

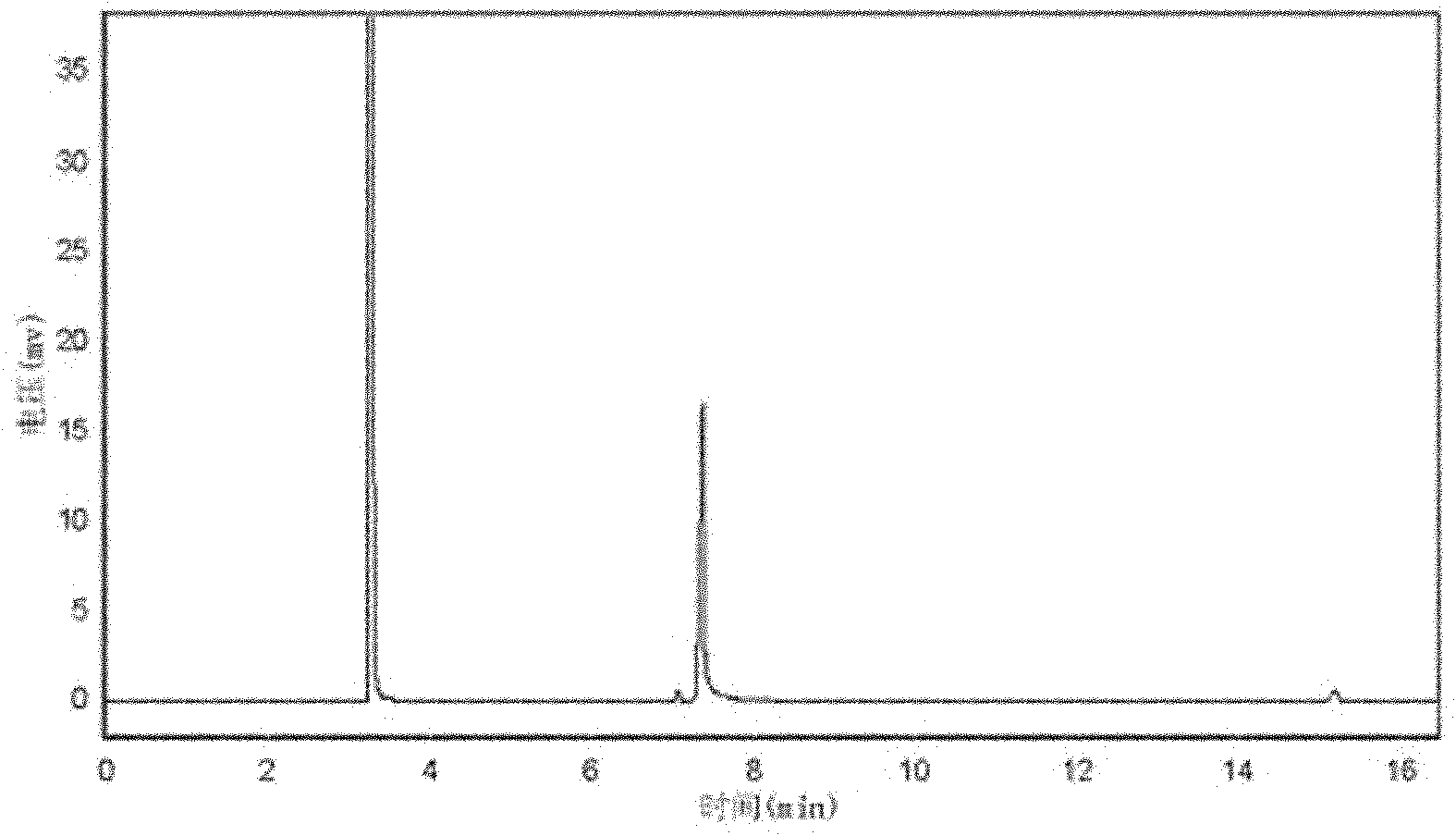

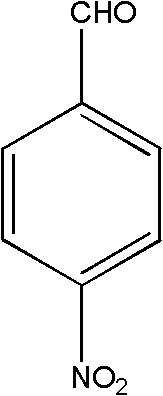

Preparation method of p-nitrobenzaldehyde

InactiveCN105348107AEasy to cleanReduce pollutionOrganic chemistryOrganic compound preparationP-nitrotolueneSolvent

The invention discloses a preparation method of p-nitrobenzaldehyde. The preparation method comprises the following steps: p-nitrotoluene, which is used as a raw material, undergoes bromine bromination under the catalysis of azo-dialkyl nitrile, so as to generate 4-nitrobenzyl bromide and hydrogen bromide; hydrolysis of 4-nitrobenzyl bromide is catalyzed by an aqueous carbonate solution to obtain p-nitrobenzyl alcohol; and hydrogen peroxide oxidation of p-nitrobenzyl alcohol is catalyzed by sodium hydroxide so as to generate a target product, namely p-nitrobenzaldehyde. According to the invention, the azo-dialkyl nitrile solid catalyst replaces a peroxycarbonate liquid phase catalyst to catalyze the bromination reaction, so as to raise operational safety of the industrial preparation reaction; by using aryl halide as a solvent medium, use of a haloalkane solvent medium is avoided, and pollution of volatile organic solvents with low boiling point is avoided; and by the hydrogen peroxide oxidation method, cleanliness of the industrial preparation reaction is raised, and environmental pollution is reduced. According to the invention, product yield is increased; yield is raised by about 3% in comparison with yield of existing traditional industrial methods; overall yield reaches 76%; and product purity reaches 99% and above.

Owner:NANJING UNIV OF SCI & TECH

400 V electrolytic capacitor and production technology thereof

ActiveCN103680980AIncrease in sizeGuaranteed to workLiquid electrolytic capacitorsCapacitor terminalsElectrolysisO-Nitroanisole

The invention discloses a 400 V electrolytic capacitor and a production technology thereof. The 400 V electrolytic capacitor comprises a shell, a core, a sealing plug, a negative wire and a positive wire, wherein the core comprises a cathode foil and an anode foil; the core further comprises insulating electrolytic paper; electrolyte is added to the insulating electrolytic paper; the electrolyte is composed of ethylene glycol accounting for 40%-50%, diethylene glycol accounting for 10%-20%, triethylene glycol accounting for 10%-20%, glycerol accounting for 10%-20%, gamma-hydroxybutyrate lactone accounting for 10%-20%, sebacic acid accounting for 1%-10%, ammonium sebacate accounting for 1%-10%, o-nitroanisole accounting for 0.1%-0.9%, p-nitrobenzyl alcohol accounting for 0.1%-0.9%, benzene accounting for 0.1%-1%, polyvinyl alcohol accounting for 0.1%-1% and citric acid accounting for 0%-0.5%. The electrolytic capacitor has good temperature tolerance and long service life, and the load life reaches to 10000-15000 hours at 105 DEG C.

Owner:FOSHAN LIMING ELECTRONICS GAOMING

High-sparking and long-service-life electrolyte for aluminum electrolytic capacitor and preparation method therefor

ActiveCN105469991AGood electrochemical propertiesIncrease the flash voltageLiquid electrolytic capacitorsCapacitor manufactureElectrolysisPhosphate

The present invention relates to the technical field of electrolytes, in particular to a high-sparking and long-service-life electrolyte for an aluminum electrolytic capacitor and a preparation method therefor. The electrolyte comprises the following raw materials in parts by weight: 3-5 parts of ammonium sebate, 1-2 parts of ammonium pentaborate, 1-2 parts of sorbitol, 1.5-2.5 parts of ammonium dodecanedioate, 8-12 parts of a sparking boosting agent, 4-6 parts of branch-chain organic acid, 0.05-0.15 part of organic phosphate, 0.4-0.6 part of p-nitrobenzyl alcohol, 0.1-0.3 part of p-nitrophenol, 5-7 parts of ethylene glycol nano silica sol, 4-6 parts of Y-butyrolactone and 55-75 parts of glycol. The electrolyte is prepared by means of interaction among the raw materials; the sparking voltage of the prepared electrolyte can reach 535 V and the conductivity rate of the prepared electrolyte can reach 1.8 ms / cm; and the electrolyte has good electrochemical properties, has the advantages of high sparking voltage and long service life, and can be applied to manufacturing of the aluminum electrolytic capacitors.

Owner:DONGGUAN JIUZHI ELECTRONICS CO LTD

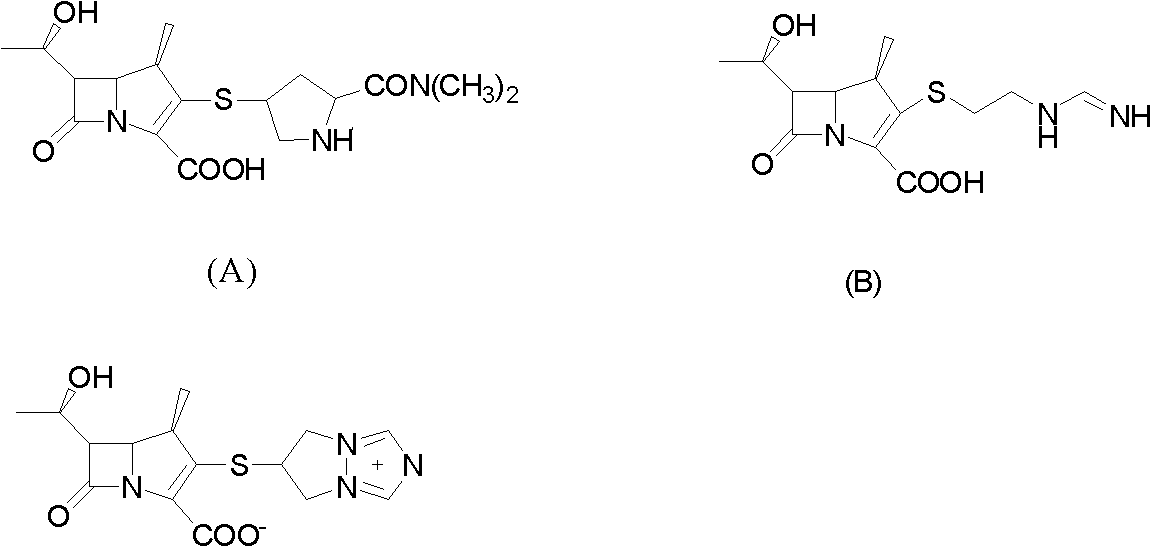

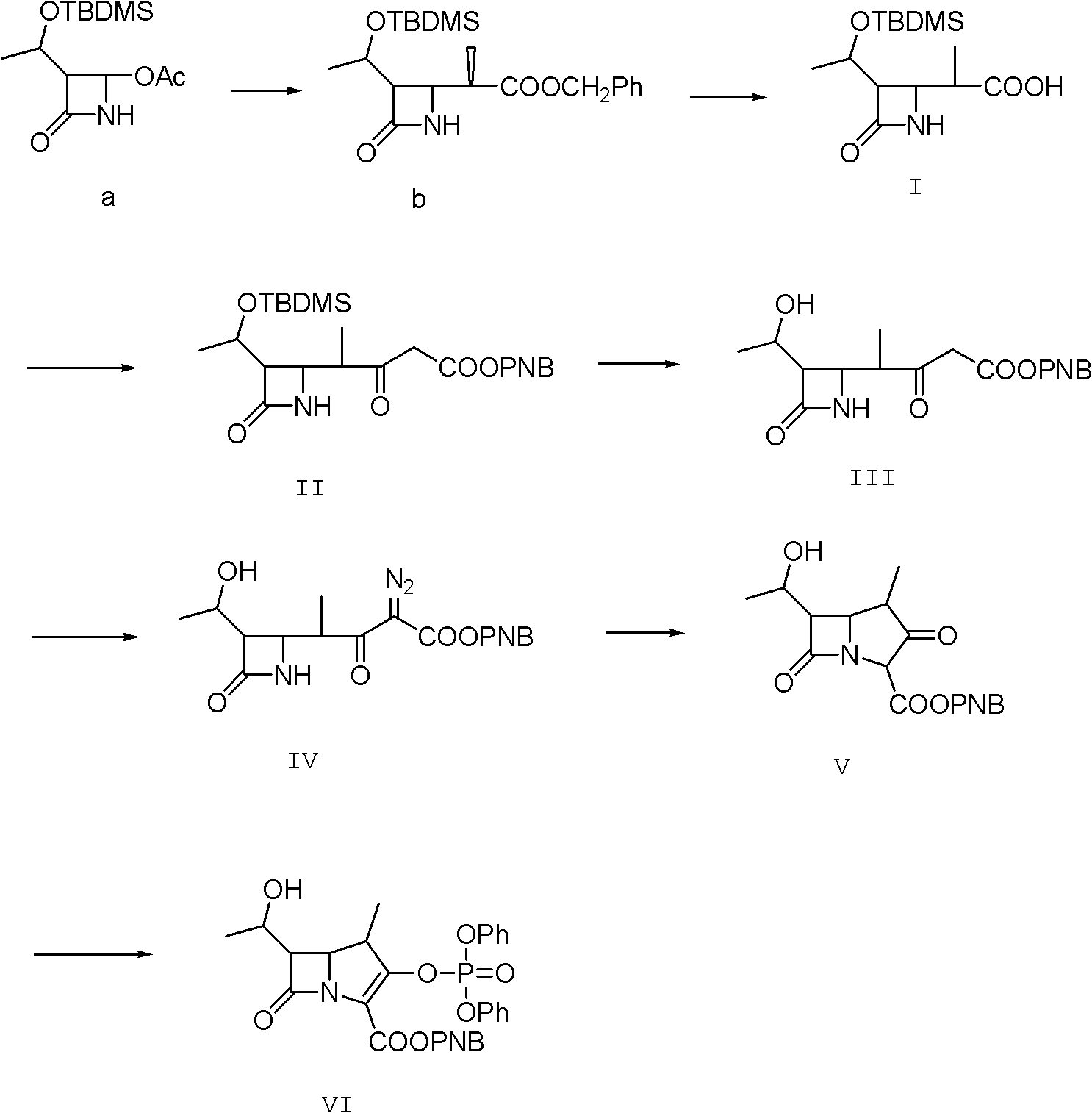

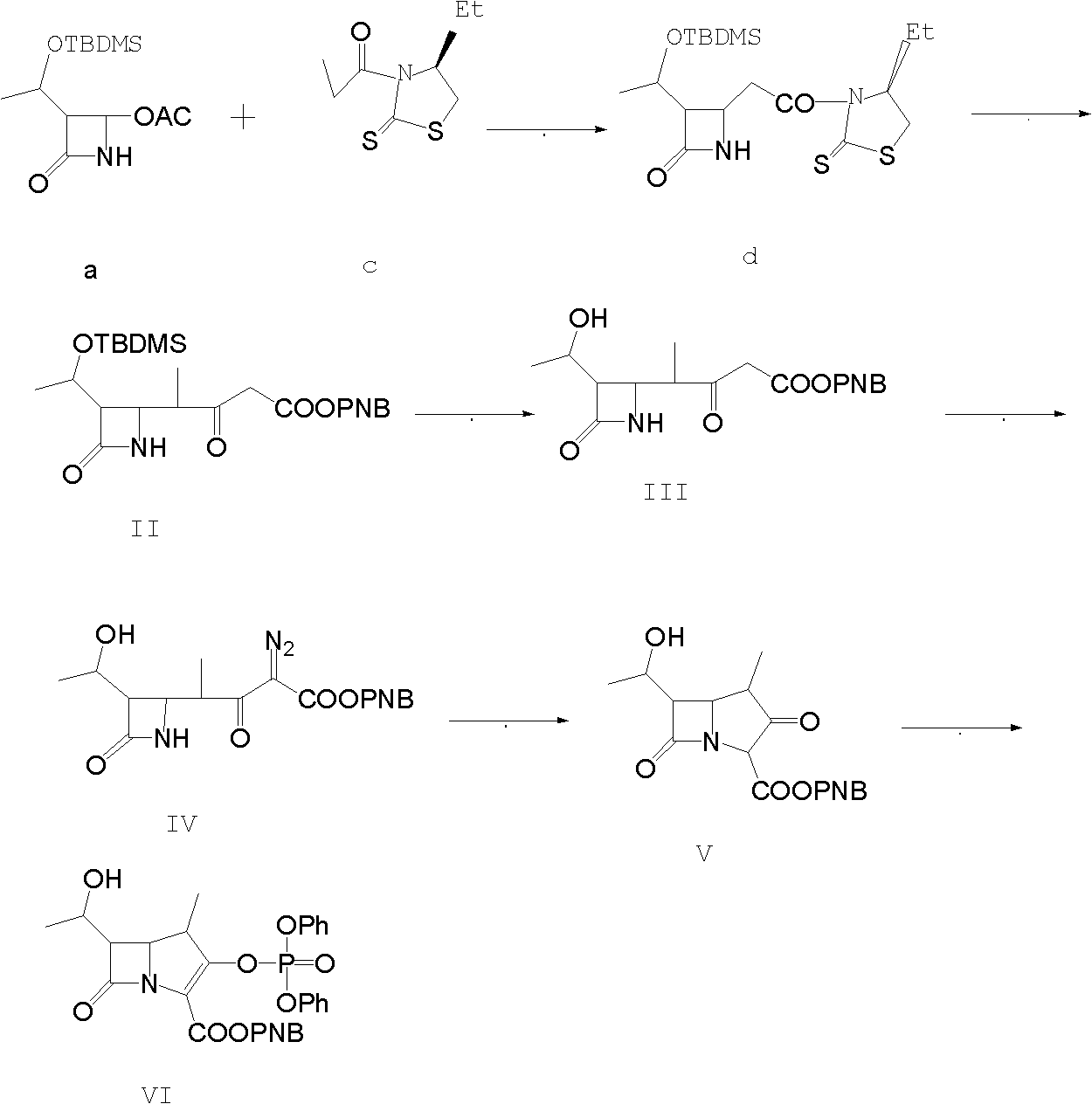

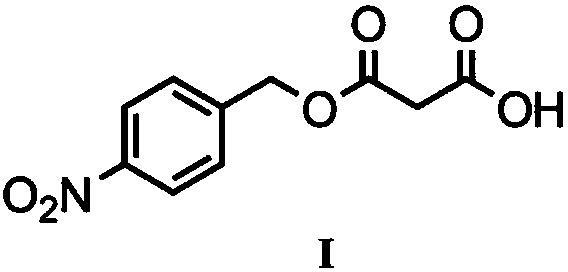

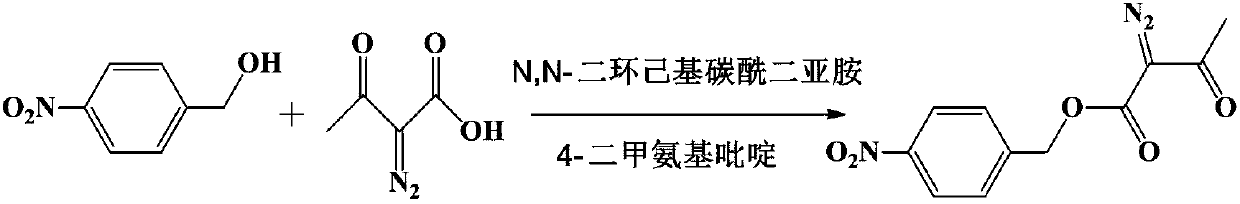

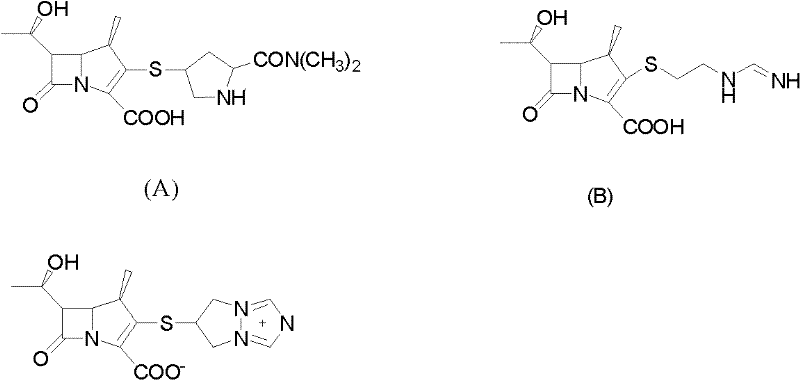

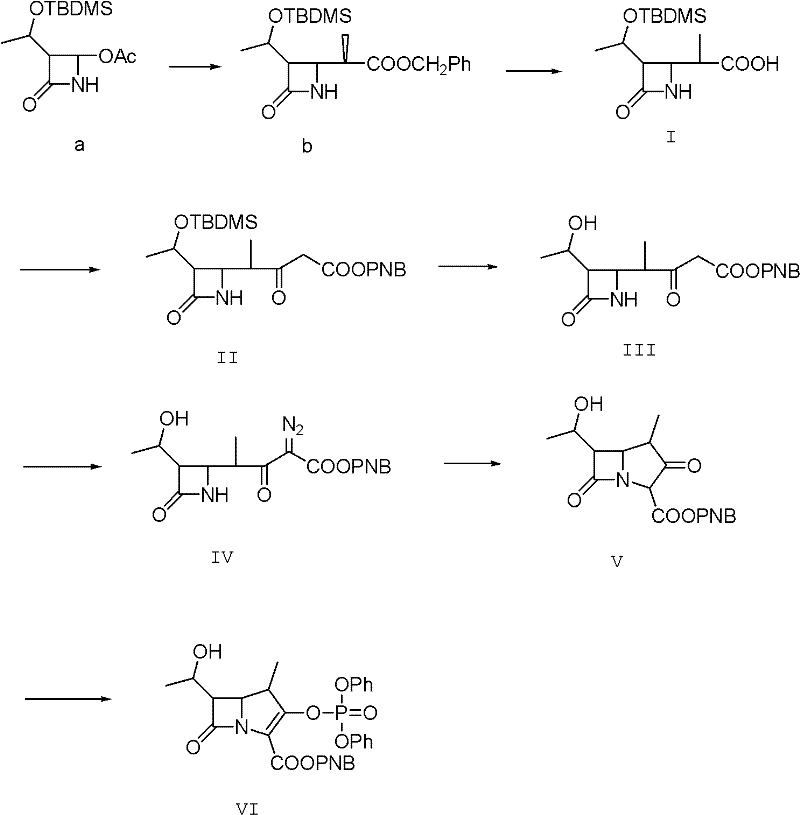

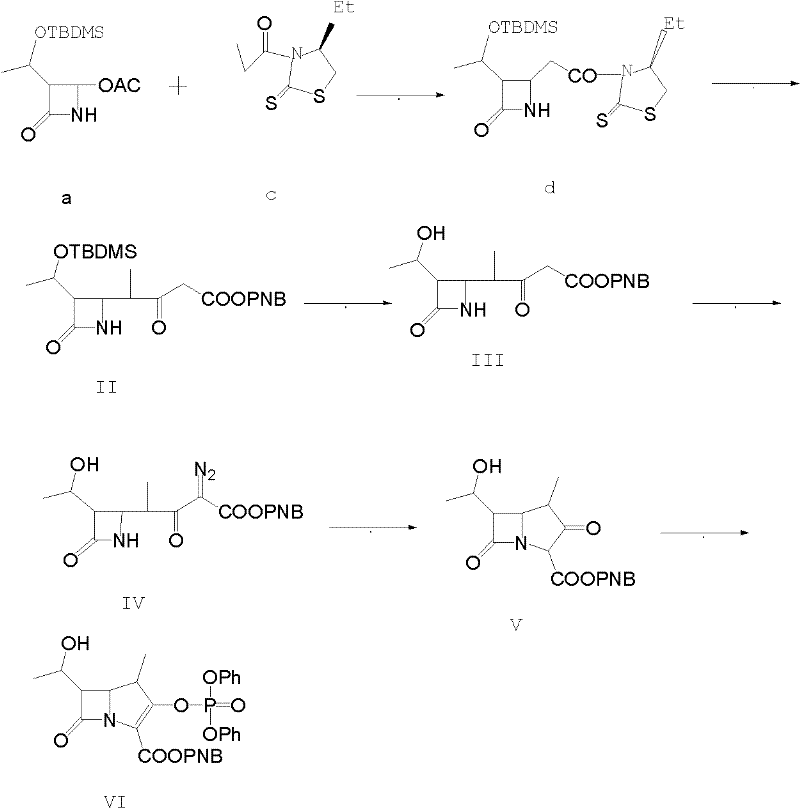

Method for preparing protected meropenem

The invention provides protected meropenem synthesized under simple conditions. In the invention, a compound (I) is reacted with mono-4-nitrobenzyl malonic acid ester and magnesium chloride to form a compound (II) product; the compound (II) is diazotized to form a compound (III) product; the compound (III) is dehydrated by methanesulfonic acid to obtain a compound (IV) product; the compound (IV) is cyclized to form a compound (V) product, and 4-dimethylaminopyridine, diphenyl chlorophosphate and N,N-diisopropylethylamine are added in turn to participate in reactions to form a product (VI) product; and N,N-diisopropylethylamine and (2S,4S)-2-dimethylaminocarbonyl-4-thio-1-(p-nitrobenzyloxycarbonyl)pyrrolidine are added to participate in a reaction to obtain a compound (VII) product. The method has the advantages that: the cost as well as 'waste gas, liquid and solid' are reduced, the operation is convenient, and the post-treatment is simple; and the total molar yield of the six-step reactions is more than or equal to 74 percent, so the method is easy to industrialize.

Owner:江西如益科技发展有限公司

Enzyme-catalyzed method for synthesizing p-nitrobenzyl alcohol malonate

InactiveCN103540622BRaw materials are easy to getFew reaction stepsFermentationWater bathsEnzymatic synthesis

The invention relates to a method for synthesizing mono-4-nitrobenzyl malonate. The method comprises the steps of adding para-nitrobenzyl alcohol, malonic acid or malonate and a reaction solvent to a reaction flask at a mol ratio of 1: (1-10): (10-50); heating in a water bath until being balanced; adding lipase and a water absorbent to the reaction flask at a mol ratio of (0.1-1): (0-100) with the para-nitrobenzyl alcohol; controlling temperature at 30-50 DEG C, reacting for 10-48 hours, filtering to remove the lipase to obtain a reaction solution, and carrying out reduced pressure distilling on the reaction solution to remove the solvent, to obtain reaction residue; adding a mixing solution of an organic solvent and a salt solution to the reaction residue, stirring and layering, acidifying an obtained water phase, carrying out suction filtering and drying to obtain the mono-4-nitrobenzyl malonate. The method is easily available in raw materials, few in reaction step, moderate in reaction condition, few in side product, and simple and convenient to operate; the method, because the adopted organic solvent can be recycled, is low in environmental impact, simple in post-treatment, relatively high in production purity and yield, and suitable for industrial production.

Owner:NANJING TECH UNIV

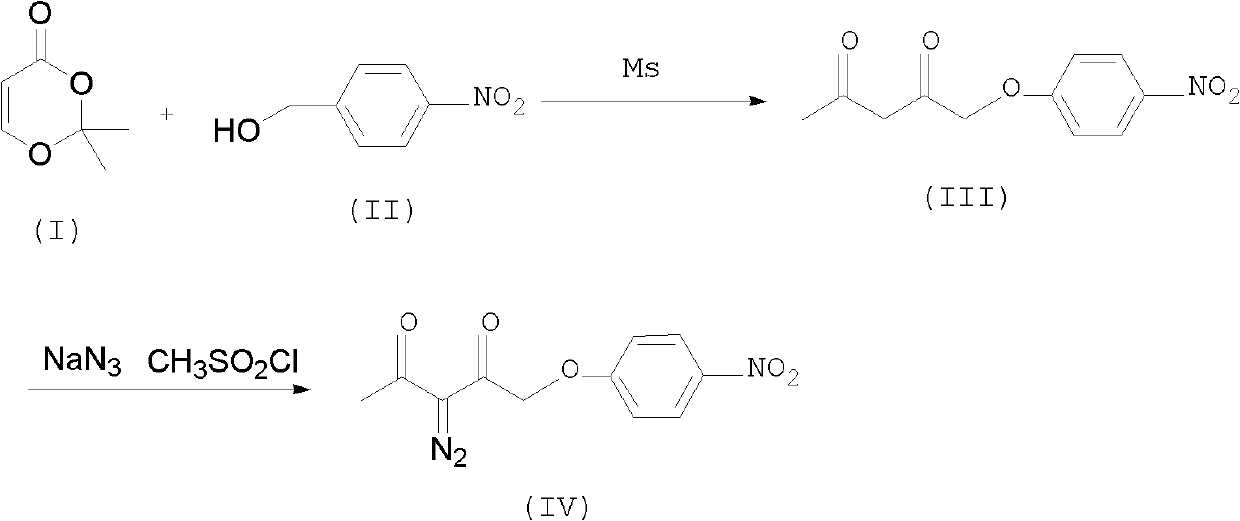

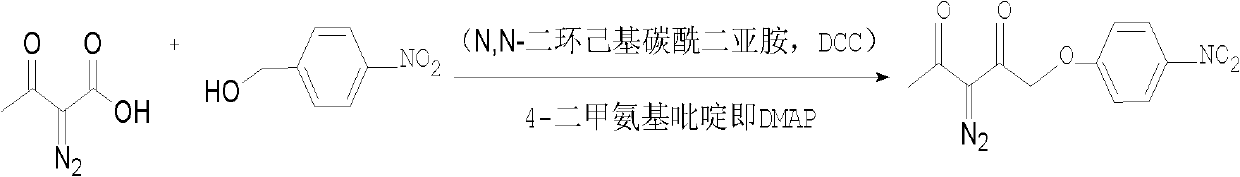

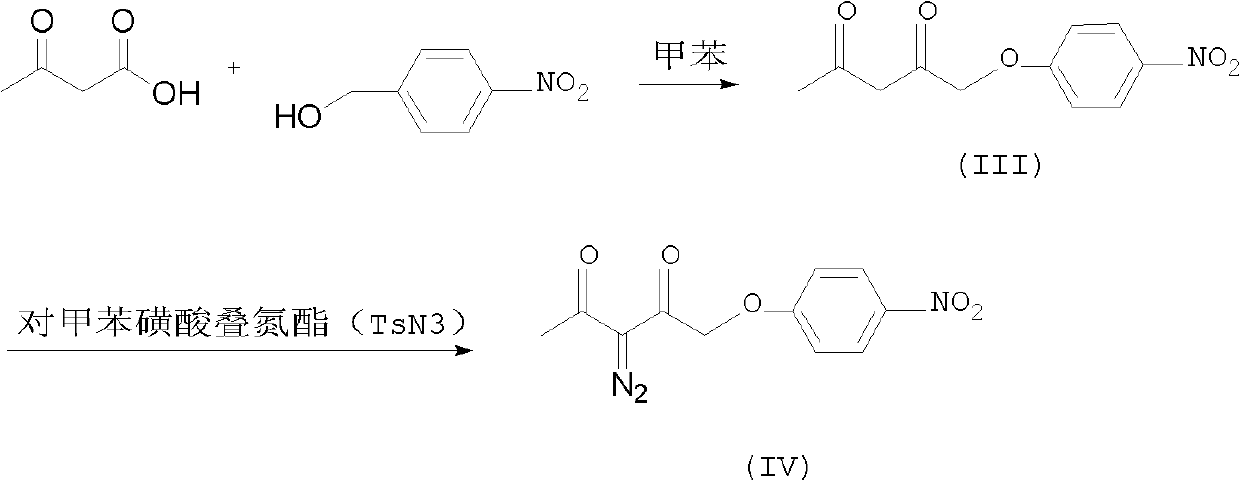

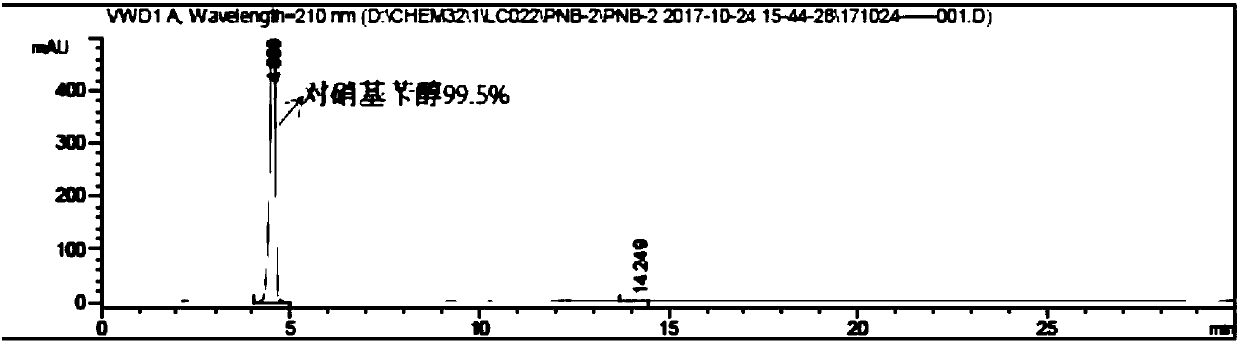

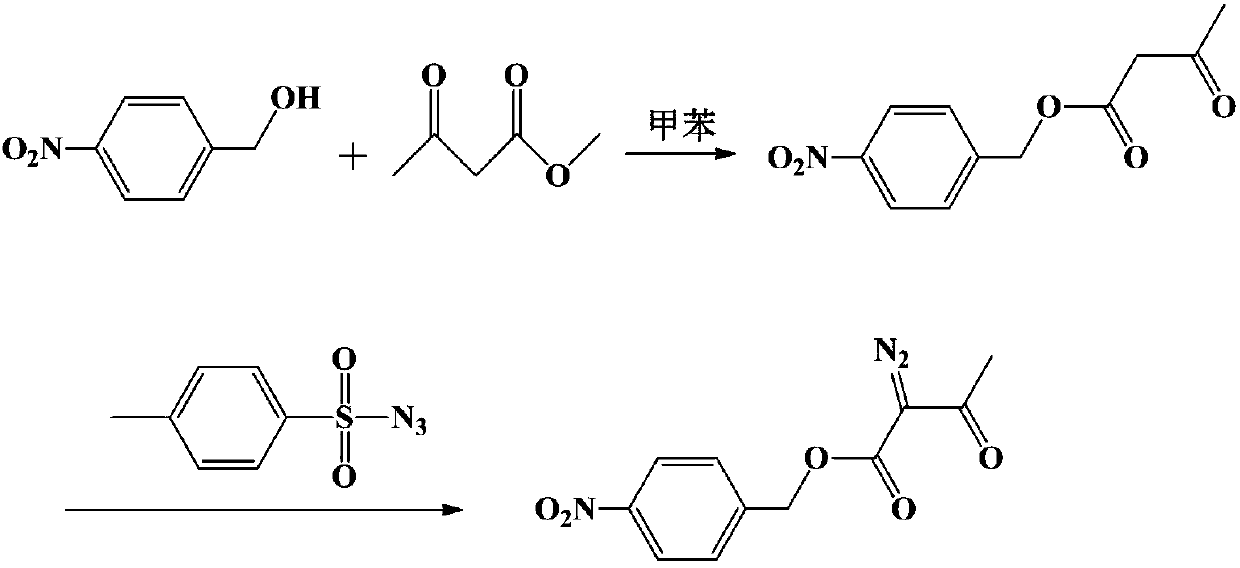

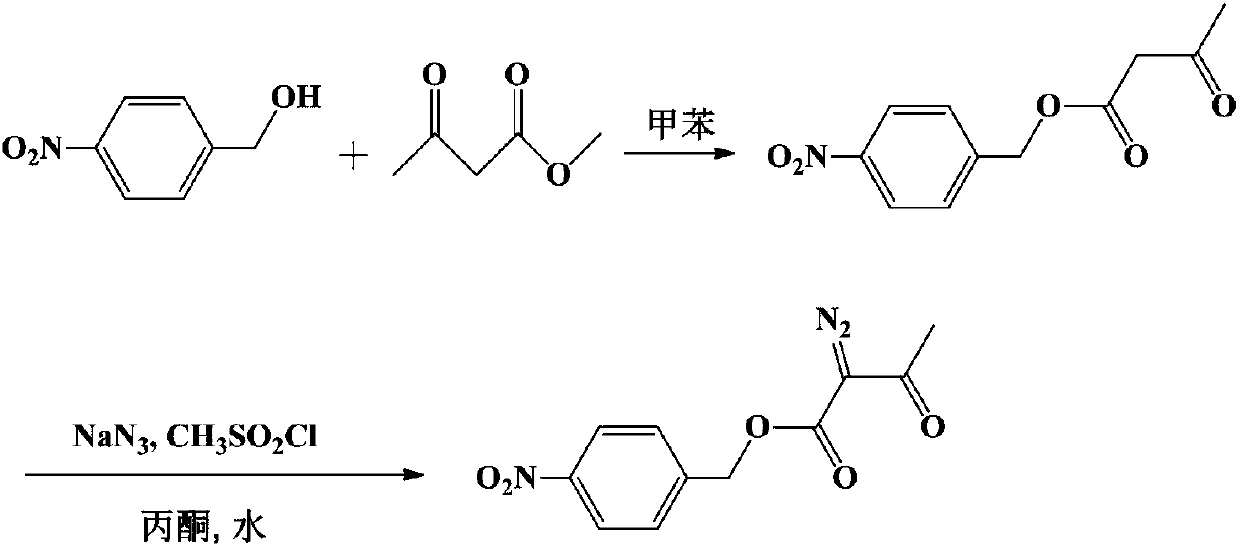

Preparation method of p-nitrobenzyl 2-diazoacetoacetate

ActiveCN101983958AEasy to operate the machineEase of industrial productionOrganic chemistryAcetic acidP-nitrobenzyl alcohol

The invention provides a preparation method of p-nitrobenzyl 2-diazoacetoacetate, wherein, the p-nitrobenzyl 2-diazoacetoacetate is made by two-step reaction. The preparation method has the advantages of simplified processing steps, easy industrialized production, lowered production cost, improved product quality and higher yield, wherein, by taking nitrobenzyl alcohol as a standard, the total mol yield reaches more than or equal to 95%, and the purity of the product compound (IV) reaches more than or equal to 99.5%.

Owner:江西如益科技发展有限公司

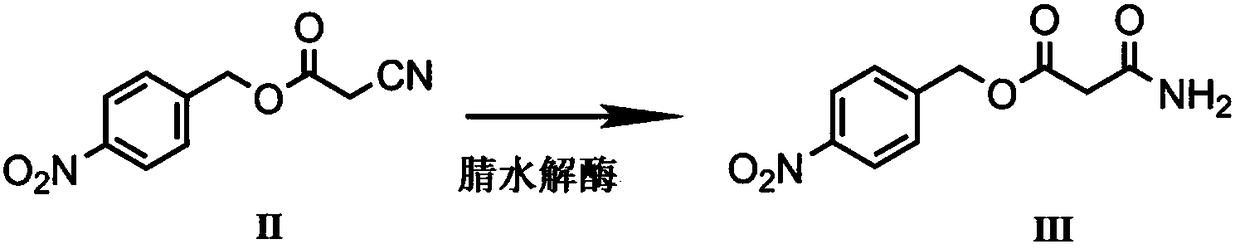

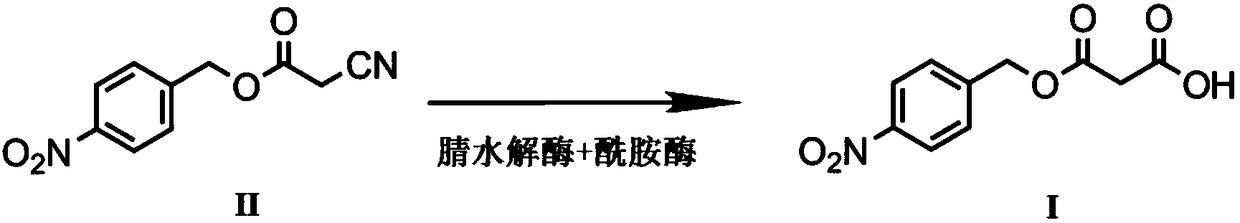

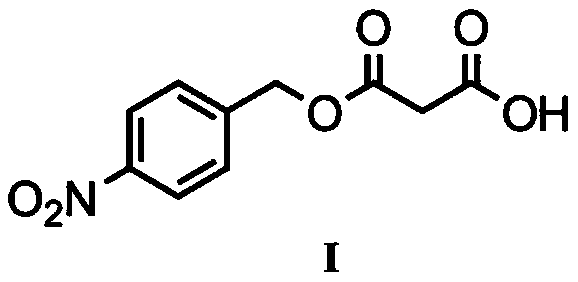

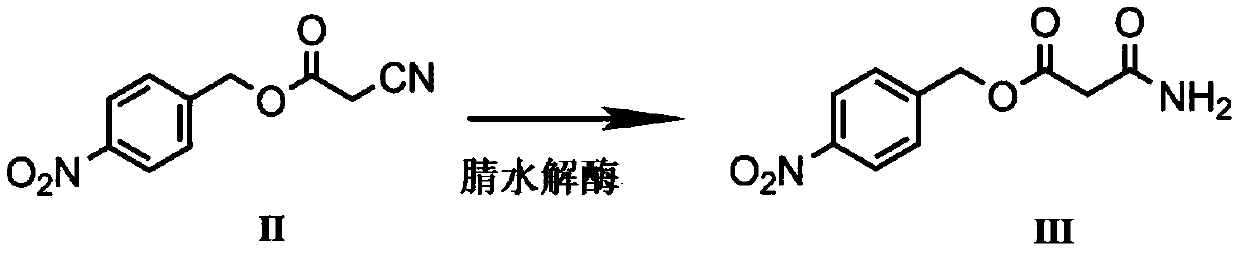

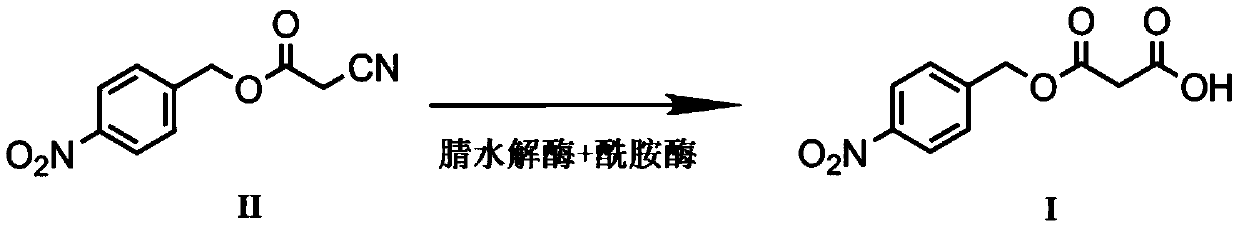

Biological preparation method of p-nitrobenzyl alcohol propandioic acid monoester

The invention provides a method for preparing p-nitrobenzyl alcohol propandioic acid monoester through double-enzyme catalysis. The method comprises the step of performing joint catalysis on 2-cyanoacetic acid-(4-nitrobenzophenone) methyl ester serving as a matrix by using alcaligenes faecalis-derived nitrilase and alcaligenes faecalis-derived amidase. The method provided by the invention is highin product yield, mild in reaction condition, low in environmental pollution and applicable to industrial production, and a small number of byproducts are produced.

Owner:TAIZHOU UNIV

Preparation method of magnesium mono-p-nitrobenzyl malonate

InactiveCN103483202AHigh yieldHigh purityOrganic chemistryOrganic compound preparationMalonateSolvent

The invention discloses a preparation method of magnesium mono-p-nitrobenzyl malonate. The preparation method comprises following steps: 1) 1-hydroxymethyl-4-nitrobenaene and malonic acid are added into a solvent, and the solution is subjected to esterification at a low temperature and in the presence of a catalyst; 2) the temperature of the reaction system is increased to 60 to 80 DEG C so as to realized crystal transition of products, and obtain mono-p-nitrobenzyl malonate; and 3) mono-p-nitrobenzyl malonate obtained in step 1) and magnesium chloride are added into water for reaction, and the reaction product is subjected to recrystallization, centrifugal separation and drying process so as to obtain magnesium mono-p-nitrobenzyl malonate. According to the preparation method, purity of intermediate mono-p-nitrobenzyl malonate is high, and can be more than 95%; yield of magnesium mono-p-nitrobenzyl malonate is high, and can be more than 80%; product clarity after dissolving is high; raw materials are easily available; reaction conditions are mild; operation is simple and convenient; by-products are few; production cost is low; and the preparation method is suitable for large-scaled industrialized production.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

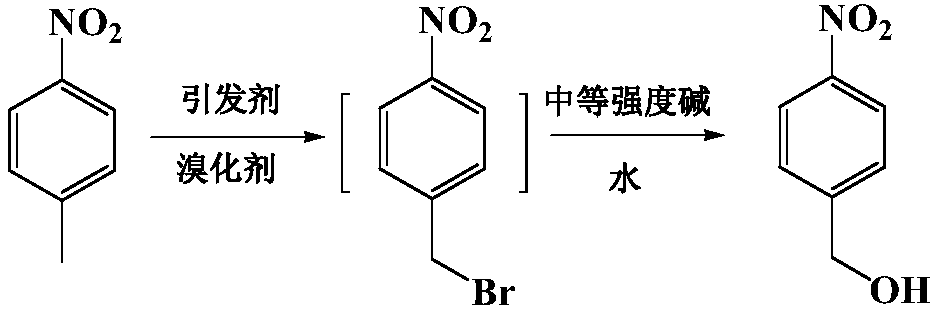

Nitrobenzy alcohol preparing method

InactiveCN109748800ALow costReduce pollutionOrganic chemistryOrganic compound preparationNitrobenzeneWastewater

The invention relates to a nitrobenzy alcohol preparing method. Specifically, the nitrobenzy alcohol preparing method takes methyl nitrobenzene as the raw material to prepare nitrobenzy alcohol through processes of bromination, hydrolysis, refining and the like. During the processes, separation and purification of intermediates are saved, reaction solvent for both bromination and hydrolysis is water and can be repeatedly recycled and reused, and meanwhile, operation is simplified, the production cost can be saved, and emission of wastewater and waste gas can be reduced. The nitrobenzy alcoholpreparing method has the advantages of being simple in operation, low in investment, green, environmentally friendly and the like and is applicable to industrial production.

Owner:台州昌霖化工科技有限公司 +1

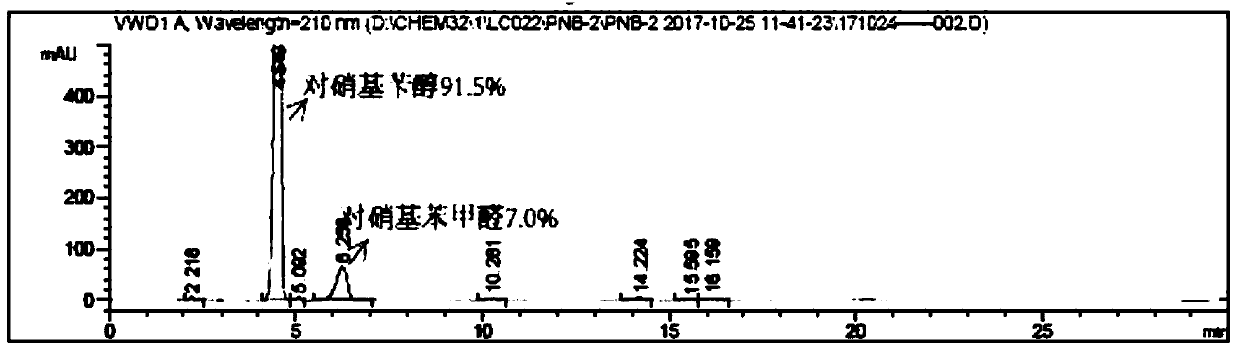

High selectivity synthesis method of p-nitrobenzaldehyde

InactiveCN102126960BReduce pollutionReduce consumptionOrganic chemistryOrganic compound preparationSynthesis methodsP-nitrotoluene

A high selectivity synthesis method of p-nitrobenzaldehyde comprises the following steps: firstly, adding p-nitrotoluene, peroxycarbonate used as catalyst and dichloroethane used as solvent in a reactor, dropping bromine at 40-50 DEG C under stirring, then reacting at 50-60 DEG C to ensure that the color of bromine fades, adding hydrogen peroxide to react at 60-70 DEG C for no less than 4 hours and prepare 4-nitrobenzyl bormide; and secondly, adding 25-35% sodium carbonate solution to hydrolyze at 80-95 DEG C and generate p-nitrobenzyl alcohol, standing to separate, and finally using oxygen as oxidant to react for no less than 25 hours in the presence of catalyst triphenylphosphine metal salt organic complex under the conditions that the temperature is 50-90 DEG C and the pressure 5.1*10<5>-1.0*10<6>. The overall yield of the method is no less than 70%, the product purity is no less than 99% and the dosage of bromine is 50-60% of the theoretical amount.

Owner:HEFEI UNIV OF TECH

Method for preparing p-nitrobenzyl 2-diazoacetoacetate

The invention relates to a method for preparing p-nitrobenzyl 2-diazoacetoacetate. The method takes p-nitrobenzyl alcohol and 2-diazoacetoacetate as raw materials, and ester exchange one-step reactionis carried out under the catalysis of acid or alkali to prepare the p-nitrobenzyl 2-diazoacetoacetate. The preparation method provided by the invention has the advantages of less investment, simplicity in operation, no highly toxic or explosive raw materials, greenness and cleanness and the like and is suitable for industrial production.

Owner:台州科金中高技术转移有限公司

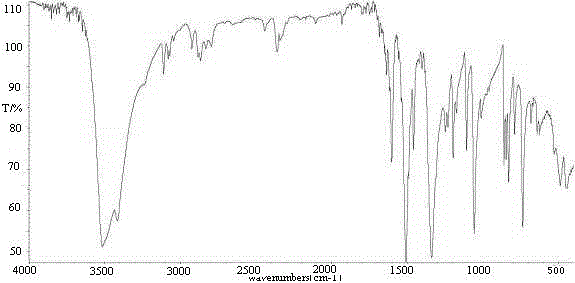

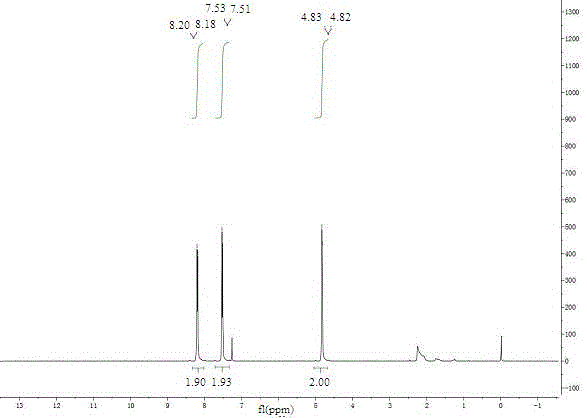

Preparation method of p-nitrobenzyl alcohol

ActiveCN108117490AHigh yieldImprove conversion rateOrganic chemistryOrganic compound preparationP-nitrobenzyl chlorideBromine

The invention discloses a preparation method of p-nitrobenzyl alcohol. The preparation method comprises the steps of with p-nitrobenzyl chloride (or bromine) as the raw material and water as a solvent, heating for hydrolysis under the catalysis of imidazole type iron liquid, and cooling for crystallization, so as to obtain a white product, namely p-nitrobenzyl alcohol. The raw material is easily available, and the preparation method good in atom economy, mild in reaction conditions, environment-friendly, simple, efficiency and suitable for industrial production.

Owner:JIANGSU YUANDA XIANLE PHARMA

Capacitor working electrolyte for ultra-high temperature LED lamps, and preparation method thereof

InactiveCN110415979AMeet the requirementsImprove electrochemical performanceElectrolytic capacitorsWorking temperaturePolyethylene glycol

The invention relates to a capacitor working electrolyte for ultra-high temperature LED lamps, comprising the following components in parts by weight: 65-70 parts of ethylene glycol, 3-5 parts of diethylene glycol, 8-15 parts XP-8, 10-15 parts of ammonium isosebacate, 10-15 parts of ammonium sebacate, 2-8 parts of polyethylene glycol 2000, 0.15-0.25 parts of ammonium hypophosphite, and 1-1.5 partsof p-nitrobenzyl alcohol. A preparation method of the capacitor working electrolyte comprises the steps of: (1) firstly mixing ethylene glycol, diethylene glycol, ammonium isosebacate, XP-8 and ammonium sebacate, heating the mixture to 115 DEG C, and performing heat preservation for 15 minutes; (2) then adding the polyethylene glycol 2000, heating to 135 DEG C, and performing heat preservation for 40 minutes; and (3) finally adding the ammonium hypophosphite, heating to 145 DEG C, performing heat preservation for 120 minutes, cooling to 85 DEG C, adding the p-nitrobenzyl alcohol, performing heat preservation for 13 minutes, finally heating to 145 DEG C, performing heat preservation for 30 minutes, and naturally cooling the product. The capacitor working electrolyte provided by the invention has good electrochemical performance and has a wide working temperature range.

Owner:WUXI TAIWEI ELECTRONICS CO LTD

A kind of preparation method of cost-saving p-nitrobenzyl alcohol

InactiveCN104370746BProduced in line withSimple reaction systemOrganic chemistryOrganic compound preparationState of artP-nitrobenzyl chloride

Owner:HENAN NORMAL UNIV

A kind of electrolytic solution for aluminum electrolytic capacitor with high conductance and high flash fire and preparation method thereof

ActiveCN105469988BReliable continuous workThere is no cracking or burningElectrolytic capacitor manufactureElectrochemistryDodecanedioate

Owner:DONGGUAN JIUZHI ELECTRONICS CO LTD

Preparation method of electronic-grade p-nitrobenzyl alcohol

InactiveCN108164420AHigh yieldHigh purityOrganic chemistryOrganic compound preparationHydrolysateFiltration

The invention relates to the field of medical intermediate and discloses a preparation method of electronic-grade p-nitrobenzyl alcohol. The preparation method comprises the steps: dissolving p-nitrotoluene and bromine into water, adding the mixed solution into a reaction kettle, and adding an initiator for an initiation reaction at 45-55 DEG C until red is faded; dropwise adding hydrogen peroxide, adding the initiator according to a reaction condition, and carrying out a reaction at 80-85 DEG C after the dropwise adding operation is ended until the red is faded to obtain a bromide; adding liquid caustic soda and water, and keeping the temperature of 75-80 DEG C for 6-8h to obtain a hydrolysate; adding water and methyl alcohol, keeping the temprature of 60-65 DEG C for 1h, separating out an oil layer, carrying out cooling for crystallization, and when the temperature is reduced to 0 DEG C, carrying out centrifugation to obtain a crude product of p-nitrobenzyl alcohol; and adding methylbenzene, keeping the temperature of 70-75 DEG C for 30min, and carrying out pressure filtration, cooling and crystallization to obtain an electronic-grade p-nitrobenzyl alcohol product. A dichloroethane organic solvent is not needed, no hazards to operating personnel are caused, and the product conforms to the standard of an electronic-grade product.

Owner:GUANNAN YISITE CHEM

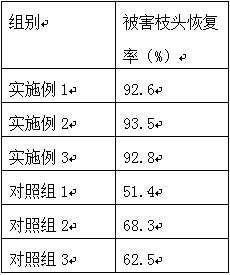

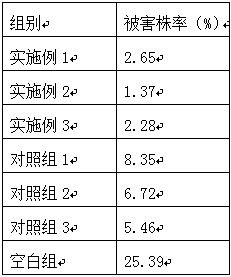

Method for preventing and treating Rhbdophaga salics Schrank for wickerwork

InactiveCN109006107ASafe and harmless to growGood control effectBiocideAnimal repellantsTreatment managementTherapeutic effect

The invention belongs to the technical field of willow planting for wickerwork, and particularly relates to a method for preventing and treating Rhbdophaga salics Schrank for wickerwork. The method includes cottage management and prevention and treatment management. An insecticidal liquid comprises, the following raw materials in parts by weight, 24-28 parts of burkhoderia pseudomallei fermentation material, 6-10 parts of compound peptide nucleic acid, 3-5 parts of berberine, 1-3 parts of p-nitrobenzyl alcohol, 0.2-0.6 parts of emulsion stabilizer, and 100 parts of complex solvent. Compared with the prior art, the method has the following advantages that after the burkhoderia pseudomallei is fermented and then reacts with the compound peptide nucleic acid, berberine and p-nitrobenzyl alcohol, so that the obtained insecticidal liquid has a good prevention and treatment effect on Rhbdophaga salics Schrank of salix integra, and the percentage of damaged trees can be greatly reduced by reasonable management. The damaged tree crowns can be recovered, and the method is safe and harmless to the growth of salix integra. The method is remarkable in economic benefit and suitable for popularization and application.

Owner:阜南县明强柳编工艺品有限公司

Method for synthesizing 4-nitrobenzyl chloroformate

InactiveCN100439322CEliminate production safety hazardsThe amount of three wastes is lessOrganic chemistryOrganic compound preparationOrganic solventChloroformate

Owner:ZHEJIANG UNIV OF TECH

A kind of biological preparation method of p-nitrobenzyl alcohol malonate monoester

The invention provides a method for preparing p-nitrobenzyl alcohol malonate monoester by double-enzyme catalysis, comprising the steps of: using 2-cyanoacetic acid-(4-nitrophenyl) methyl ester as a substrate, using It is obtained through combined catalysis of nitrilase derived from Alcaligenes faecalis and amidase derived from Alcaligenes faecalis. The method of the invention has high product yield, few by-products, mild reaction conditions and little environmental pollution, and is suitable for industrialized production.

Owner:TAIZHOU UNIV

Capacitor electrolyte solution and capacitor using electrolyte solution

ActiveCN107731534ASuppresses saturation vapor pressure increaseAvoid contactLiquid electrolytic capacitorsHazardous substancePhosphate

The invention belongs to the field of electrochemistry, and discloses a capacitor electrolyte solution and a capacitor using the electrolyte solution. Ethylene glycol, ammonium formate, deionized water, organic high molecular compound, phosphate, tributylamine, polyvinyl alcohol, p-nitrobenzyl alcohol, carboxylic acid, phosphorous pentoxide and p-nitrobenzyl alcohol are mixed according to a certain mass ratio to prepare the capacitor electrolyte solution. Through addition of the organic high molecular compound, water molecules are fixed, the situation that water and the other harmful substances are in direct contact with dielectric film is prevented, improvement of saturated vapor pressure is inhibited, and hydration and corrosion are prevented. Parameters of the capacitor electrolyte solution are as follows, the conductivity (35 degrees) = 3.8 + / - 0.5 ms / cm, the pH value 6.5 + / - 1 and the broken voltage > 600 V. The capacitor electrolyte solution and the capacitor using the electrolyte solution have good electromagnetic compatibility and lightening resistance, can be widely applicable to the fields of mobile phone chargers and the like, and have very high economic value.

Owner:NANTONG JIANGHAI CAPACITOR CO LTD

Preparation method of p-nitrobenzyl alcohol

InactiveCN108129324AHigh yieldHigh purityOrganic chemistryOrganic compound preparationHydrolysateP-nitrotoluene

The invention relates to the field of medical intermediates, and discloses a preparation method of p-nitrobenzyl alcohol. The method comprises the steps of dissolving p-nitrotoluene and bromine into water, adding the mixed solution into a reaction kettle, adding an initiator at the temperature of 45-55 DEG C into the reaction kettle for an initiation reaction until red fades; dropwise adding hydrogen peroxide and adding the initiator as appropriate; after addition is finished, carrying out a reaction at the temperature of 80-85 DEG C until red fades so as to obtain bromides; adding sodium carbonate and water, and carrying out heat preservation for 6-8h at the temperature of 90-100 DEG C to obtain hydrolysate; adding water and methanol, carrying out heat preservation for 1h at the temperature of 60-65 DEG C, separating out an oil layer, cooling and crystallizing, and centrifuging when the temperature drops to 0 DEG C so as to obtain a crude p-nitrobenzyl alcohol product; adding methylbenzene, carrying out heat preservation for 30min at the temperature of 70-75 DEG C, carrying out filter pressing, cooling, and crystallizing to obtain the p-nitrobenzyl alcohol product. A dichloroethane organic solvent does not need to be used in the method, so that the method is harmless to an operator, and the purity of the product is higher.

Owner:GUANNAN YISITE CHEM

Method for preparing protected meropenem

The invention provides protected meropenem synthesized under simple conditions. In the invention, a compound (I) is reacted with mono-4-nitrobenzyl malonic acid ester and magnesium chloride to form a compound (II) product; the compound (II) is diazotized to form a compound (III) product; the compound (III) is dehydrated by methanesulfonic acid to obtain a compound (IV) product; the compound (IV) is cyclized to form a compound (V) product, and 4-dimethylaminopyridine, diphenyl chlorophosphate and N,N-diisopropylethylamine are added in turn to participate in reactions to form a product (VI) product; and N,N-diisopropylethylamine and (2S,4S)-2-dimethylaminocarbonyl-4-thio-1-(p-nitrobenzyloxycarbonyl)pyrrolidine are added to participate in a reaction to obtain a compound (VII) product. The method has the advantages that: the cost as well as 'waste gas, liquid and solid' are reduced, the operation is convenient, and the post-treatment is simple; and the total molar yield of the six-step reactions is more than or equal to 74 percent, so the method is easy to industrialize.

Owner:江西如益科技发展有限公司

A kind of electrolytic solution for high flash fire anti-lightning stroke aluminum electrolytic capacitor and preparation method thereof

ActiveCN105469992BReliable continuous workThere is no cracking or burningElectrolytic capacitorsDiethylene glycol monobutyl etherElectrolysis

The present invention relates to the technical field of electrolytes, in particular to a high-sparking and anti-lightning electrolyte for an aluminum electrolytic capacitor and a preparation method therefor. The electrolyte comprises the following raw materials in parts by weight: 1.5-2.5 parts of ammonium dodecanedioate, 0.8-1.2 parts of ammonium sebacate, 5-9 parts of sorbitol, 4-6 parts of boracic acid, 4-6 parts of diethylene glycol monobutyl ether, 1-2 parts of polyvinyl alcohol, 0.4-0.6 part of p-nitrobenzyl alcohol, 0.1-0.3 part of ammonium hypophosphite, 6-10 parts of ethylene glycol nano silica sol and 60-80 parts of glycol. The electrolyte is prepared by means of interaction among the raw materials and by strictly controlling a weight proportion of the raw materials; the sparking voltage of the prepared electrolyte can reach 590 V and the conductivity rate of the prepared electrolyte can reach 0.5 ms / cm; and the electrolyte has good electrochemical properties, has the advantages of high sparking voltage, lightning resistance and the like, and can be applied to manufacturing of the aluminum electrolytic capacitors.

Owner:DONGGUAN JIUZHI ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com