Nitrobenzy alcohol preparing method

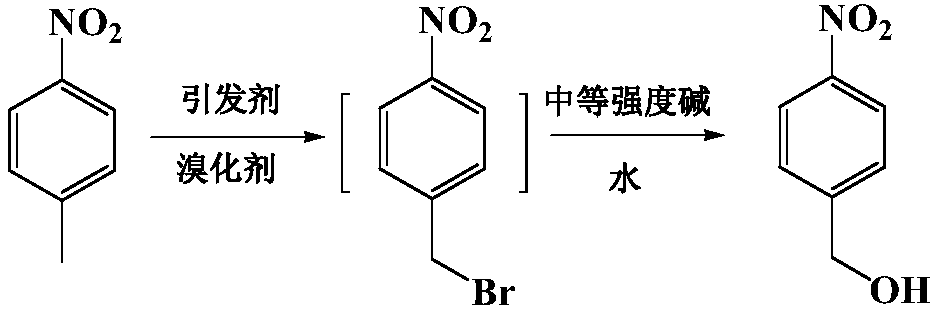

A technology for p-nitrobenzyl alcohol and p-nitrotoluene is applied in the field of preparation of p-nitrobenzyl alcohol, and can solve the problems of large amount of water used as a solvent for hydrolysis reaction, difficulty in recovering halogenated aromatic hydrocarbon solvent, difficulty in recovering organic solvent, and the like, Achieve high bromine content, simplified operation and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

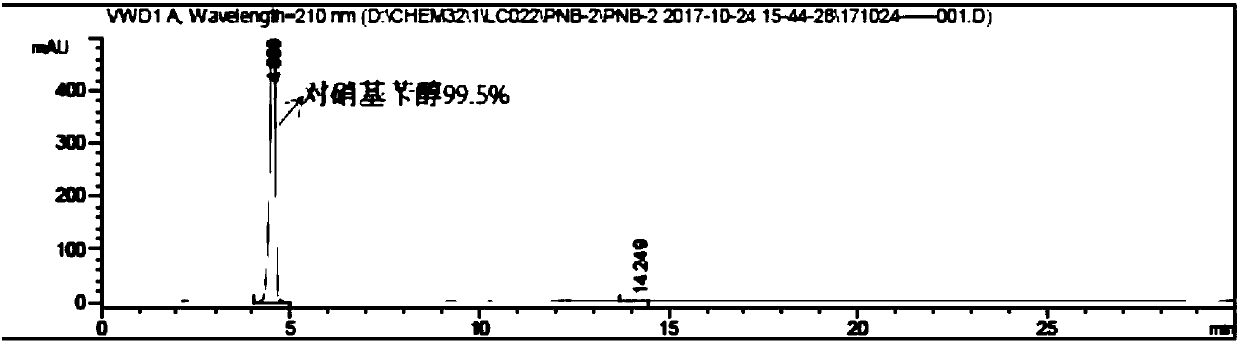

[0028] Put 400 kg of p-nitrotoluene and 400 kg of water into a 5000L reactor, raise the temperature to 58-60°C, add 8 kg of benzoyl peroxide, add 246 kg of bromine dropwise, and continue to add 30% hydrogen peroxide dropwise 175 kg, reacted until the color of the reaction solution faded, allowed to stand for stratification, and took out the supernatant water layer while it was hot (the water layer was inserted into the next batch of bromination reaction). Add 3200 kilograms of water and 155 kilograms of sodium carbonate, heat up and reflux, after the hydrolysis is over, let stand for stratification, take out the supernatant water layer while it is hot (the water layer is inserted into the next batch of hydrolysis reaction while it is hot), add 1200 kilograms of toluene to the organic layer while it is hot , heated up to 60-70°C to dissolve, lowered to 10-20°C to crystallize, filtered, and dried to obtain 357 kg of p-nitrobenzyl alcohol with a yield of 79.9% and a liquid phase p...

Embodiment 2

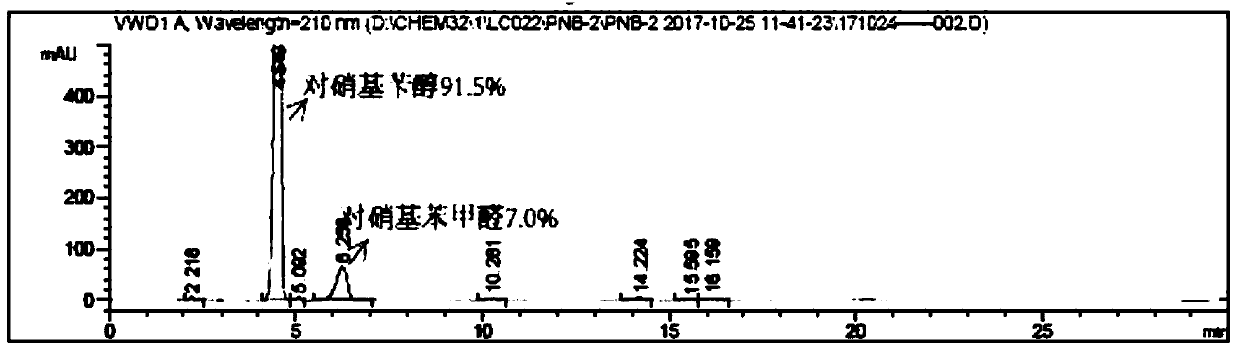

[0034] Put 400 kg of p-nitrotoluene and 400 kg of water into a 5000L reactor, raise the temperature to 51-55°C, add 8 kg of azobisisoheptylcyanide, add 235 kg of bromine dropwise, and continue to add 30% dropwise 200 kg of hydrogen peroxide, reacted until the color of the reaction solution faded, allowed to stand for stratification, and took out the supernatant water layer while it was hot (the water layer was applied mechanically to the next batch of bromination reaction). Add 2800 kilograms of water and 270 kilograms of sodium bicarbonate to the organic layer, heat up and reflux, after the hydrolysis is over, let it stand for stratification, take out the supernatant water layer while it is hot (the water layer is inserted into the next batch of hydrolysis reaction while it is hot), and add the organic layer while it is hot 1,200 kg of toluene was heated up to 60-70°C to dissolve, then crystallized at 10-20°C, filtered, and dried to obtain 335 kg of p-nitrobenzyl alcohol, with...

Embodiment 3

[0036] Put 400 kg of p-nitrotoluene and 800 kg of water into a 5000L reactor, raise the temperature to 56-58°C, add 6 kg of azobisisobutyronitrile, add 257 kg of bromine dropwise, and continue to add 30% dropwise 175 kg of hydrogen peroxide was reacted until the color of the reaction solution faded, and the layers were left to stand, and the supernatant water layer was taken out while it was hot (the water layer was applied mechanically to the next batch of bromination reactions). Add 2000 kilograms of water and 139 kilograms of sodium carbonate to the organic layer, heat up and reflux, after the hydrolysis ends, let stand to separate layers, take out the supernatant water layer while hot (the water layer is inserted into the next batch of hydrolysis reaction while hot), and add acetic acid to the organic layer while hot 1,600 kg of ethyl ester was heated to 60-70°C to dissolve, then crystallized at 0-10°C, filtered, and dried to obtain 331 kg of p-nitrobenzyl alcohol, with a y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com