Preparation method of p-nitrobenzyl alcohol

A technology for p-nitrobenzyl alcohol and p-nitrobenzyl chloride is applied in the field of preparation of p-nitrobenzyl alcohol, can solve the problems of many by-products, large environmental pollution and high cost, and achieves good product quality, enhanced solubility, and improved The effect of hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

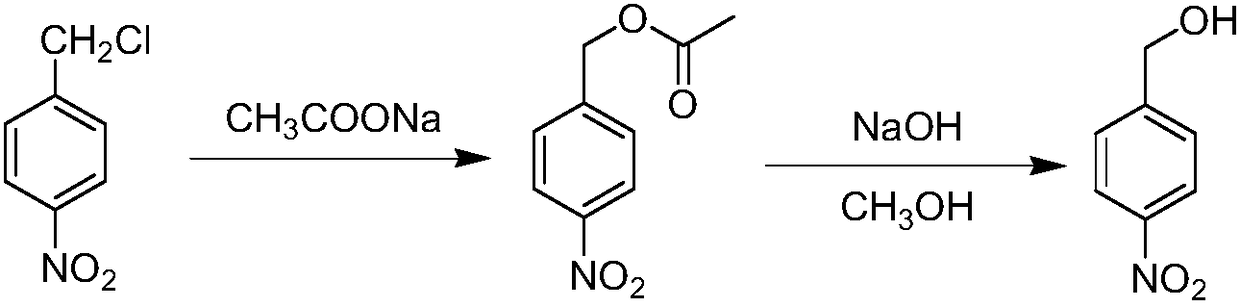

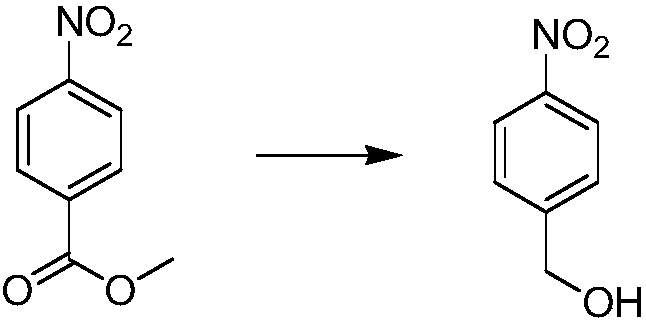

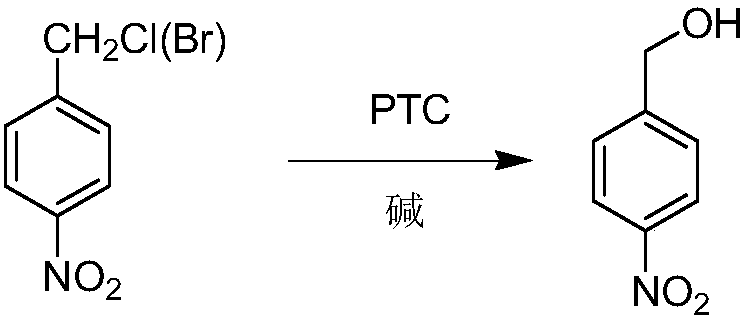

Method used

Image

Examples

Embodiment 1

[0039] Add p-nitrobenzyl chloride (171.6g, 1mol), water (1.8L), 1-butyl-3-methylimidazolium chloride (1.75g, 0.01mol) and ZnCl to a 3000mL reaction flask 2 (1.36g, 0.01mol), start stirring, raise the temperature to 100°C, and react for 7h. After testing, the reaction of the raw materials is completed, and the temperature is lowered to 5°C. The material is discharged, centrifuged, washed with water, and dried to obtain 145.5g of white product with a yield of 95 %, the centrifuged mother liquor and the first small amount of washing liquid are collected and recycled.

Embodiment 2

[0041] Add p-nitrobenzyl bromide (216.0g, 1mol), water (4.3L), 1-eicosyl-3-methylimidazolium bromide (8.88g, 0.02mol) and ZnBr to a 10000mL reaction flask 2 (13.5g, 0.06mol), start stirring, raise the temperature to 95°C, and react for 4.5h. After testing, the reaction of raw materials is completed, and the temperature is lowered to 30°C. The material is discharged, centrifuged, washed with water, and dried to obtain 140.9g of white product. The yield is 92%, the centrifuged mother liquor and the first small amount of washing liquid are collected and recycled.

Embodiment 3

[0043] Add p-nitrobenzyl bromide (216.0g, 1mol), water (3.3L), 1-dodecyl-3-methylimidazolium bromide (16.6g, 0.05mol) and ZnBr to the 10000mL reaction flask 2 (22.5g, 0.1mol), start stirring, raise the temperature to 90°C, and react for 3h. After testing, the reaction of the raw materials is completed, and the temperature is lowered to 20°C. The material is discharged, centrifuged, washed with water, and dried to obtain 147g of white product with a yield of 96%. , centrifuge the mother liquor and collect the first small amount of washing solution for recycling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com