400 V electrolytic capacitor and production technology thereof

A technology of electrolytic capacitors and electrolytic paper, which is applied in the direction of electrolytic capacitors, liquid electrolytic capacitors, capacitors, etc., can solve the problems of short load life, etc., and achieve the effects of prolonging life, increasing overall volume, and improving temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

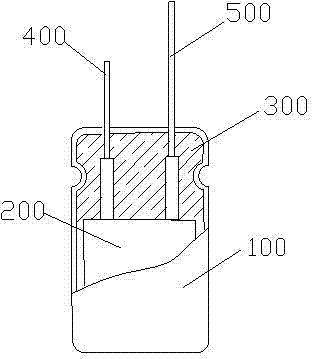

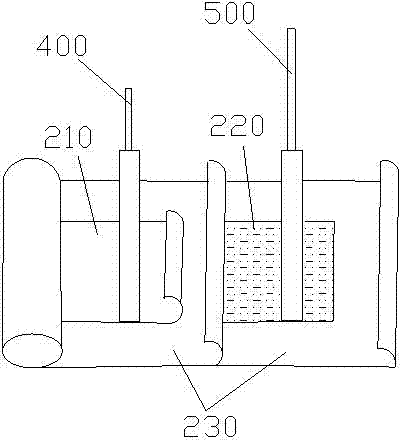

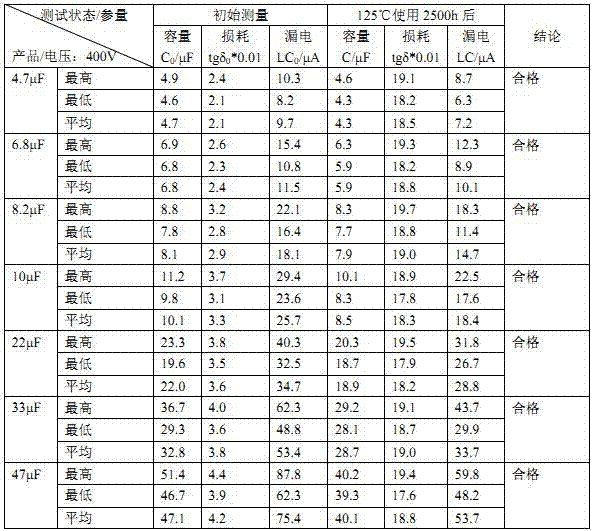

[0051] Take cathode foil and anode foil: electrocorrode cathode foil and anode foil, oxidize cathode foil and anode foil after electrocorrosion, and form an oxide film on the surface of cathode foil and anode foil; cut cathode foil, anode foil and insulating electrolytic paper, respectively The lead wire is connected with the cathode foil and the anode foil to form the negative electrode lead and the positive electrode lead, and the insulating electrolytic paper, the cathode foil and the anode foil are wound; the electrolyte is added, and the electrolyte is impregnated on the insulating electrolytic paper; the final assembly and crimping are carried out , charging, aging test and parameter detection.

[0052] In this embodiment, the composition of the electrolyte includes: 40% ethylene glycol, 20% diethylene glycol, 10% triethylene glycol, 10% glycerol, 10% gamma-hydroxybutyrolactone, sebacic acid 2.2%, ammonium sebacate 6.1%,: o-nitroanisole 0.9%, p-nitrobenzyl alcohol 0.1%, ...

Embodiment 2

[0056] This example is basically the same as Example 1, except that in this example, the composition of the electrolyte includes: 50% ethylene glycol, 10% diethylene glycol, 10% triethylene glycol, and 10% glycerol , γ-hydroxybutyrolactone 10%, sebacic acid 4.9%, ammonium sebacate 3%, o-nitroanisole 0.1%, p-nitrobenzyl alcohol 0.9%, benzene 0.1%, polyvinyl alcohol 1% .

[0057] In this embodiment, the voltage of the cathode foil is 5V, the capacity of the electrolytic capacitor is 6.8 μF, the diameter of the bottom surface of the housing is 13 mm, and the height is 20 mm.

Embodiment 3

[0059] This example is basically the same as Example 1, except that in this example, the composition of the electrolyte includes: 40% ethylene glycol, 10% diethylene glycol, 18.5% triethylene glycol, and 10% glycerol , γ-hydroxybutyrolactone 10%, sebacic acid 5%, ammonium sebacate 4.5%, o-nitroanisole 0.5%, p-nitrobenzyl alcohol 0.4%, benzene 0.3%, polyvinyl alcohol 0.3% , citric acid 0.5%.

[0060] In this embodiment, the voltage of the cathode foil is 3V, the capacity of the electrolytic capacitor is 8.2 μF, the diameter of the bottom surface of the housing is 13 mm, and the height is 21 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com