Patents

Literature

104results about How to "Thorough cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

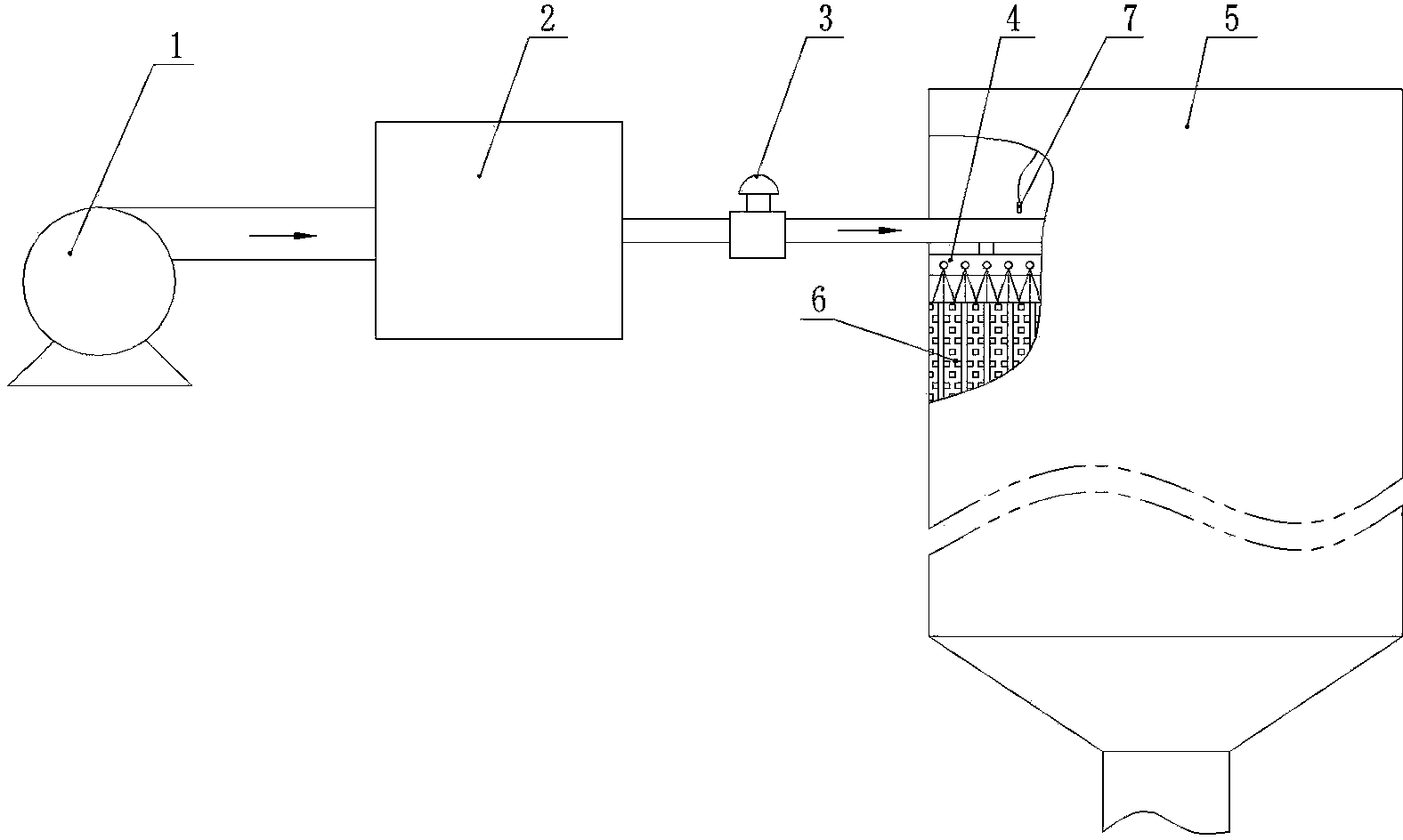

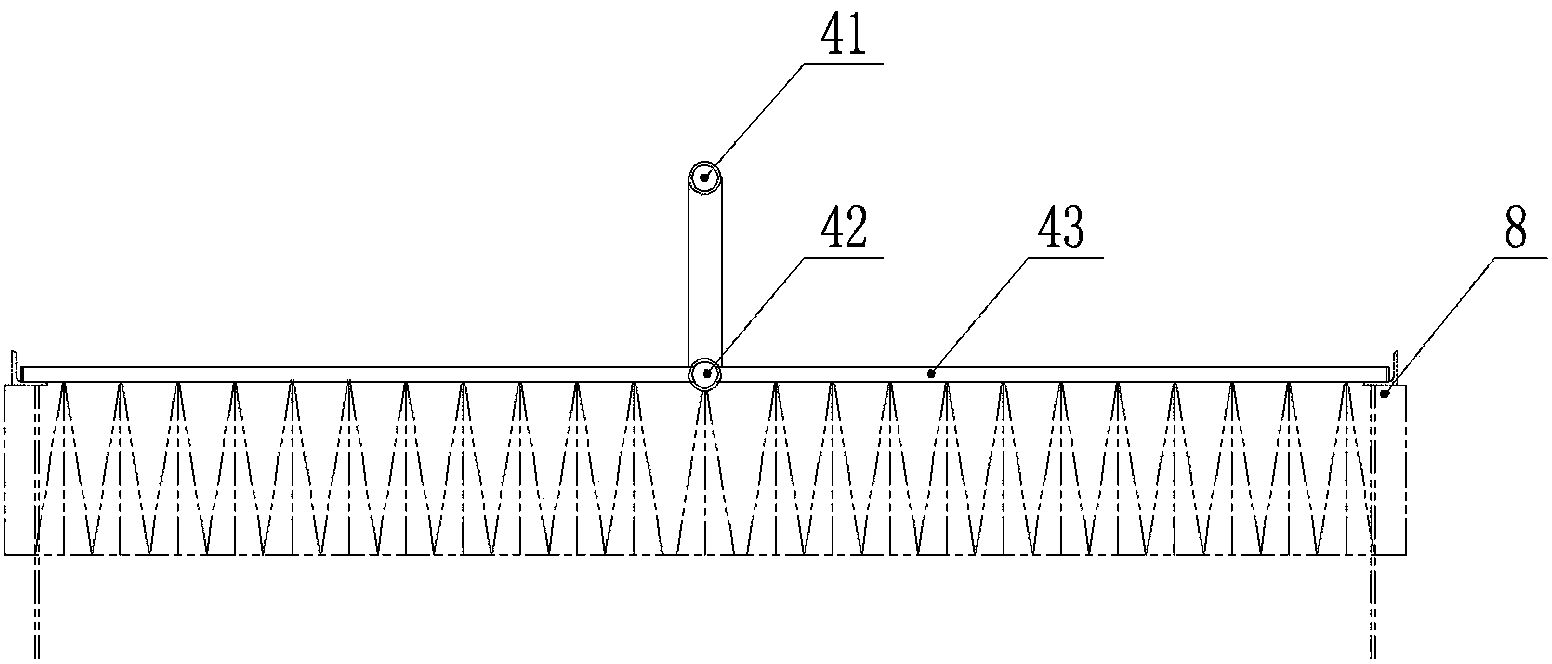

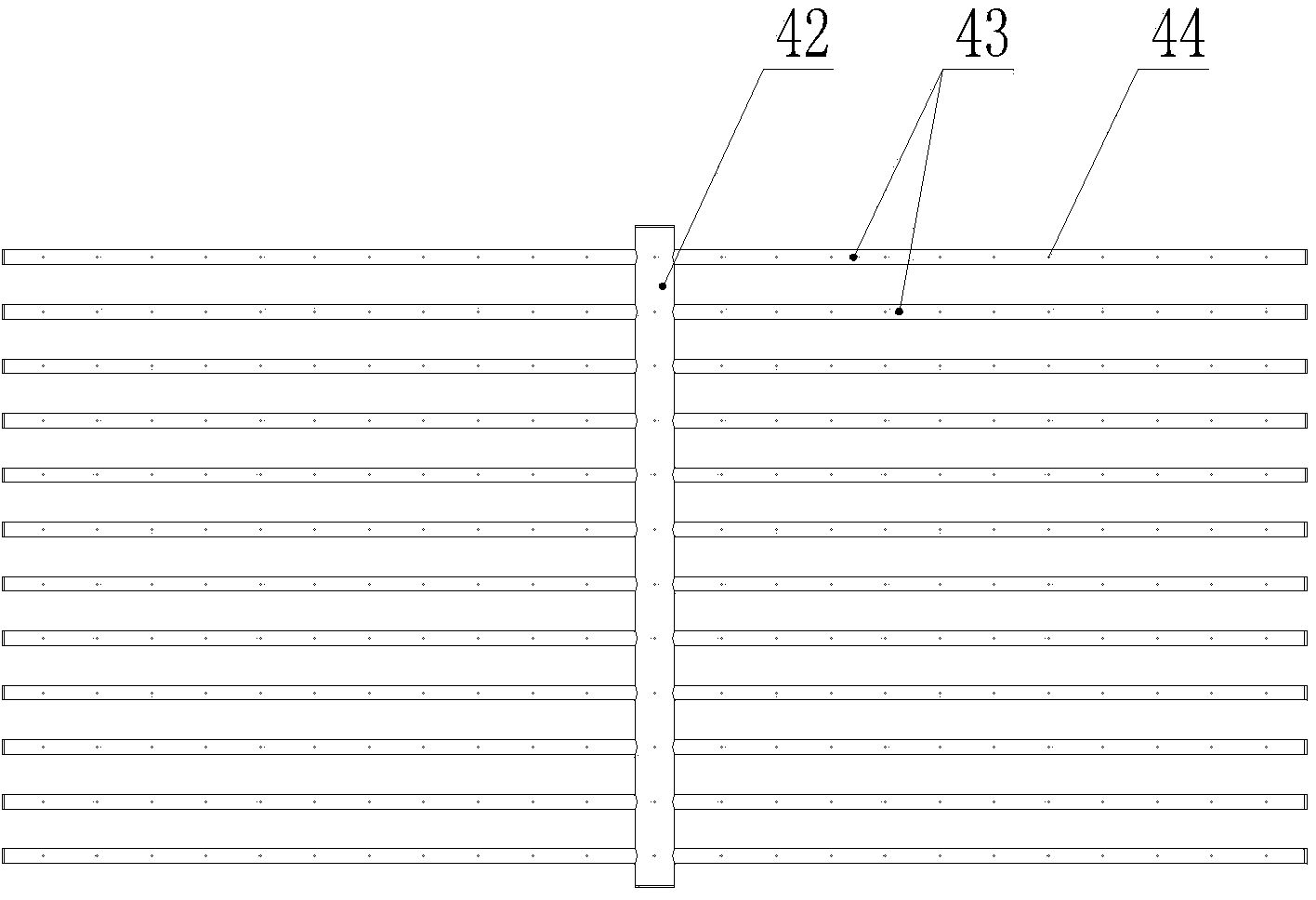

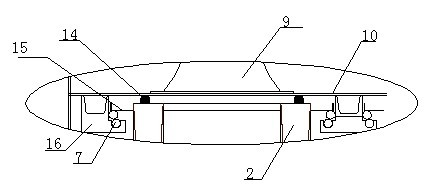

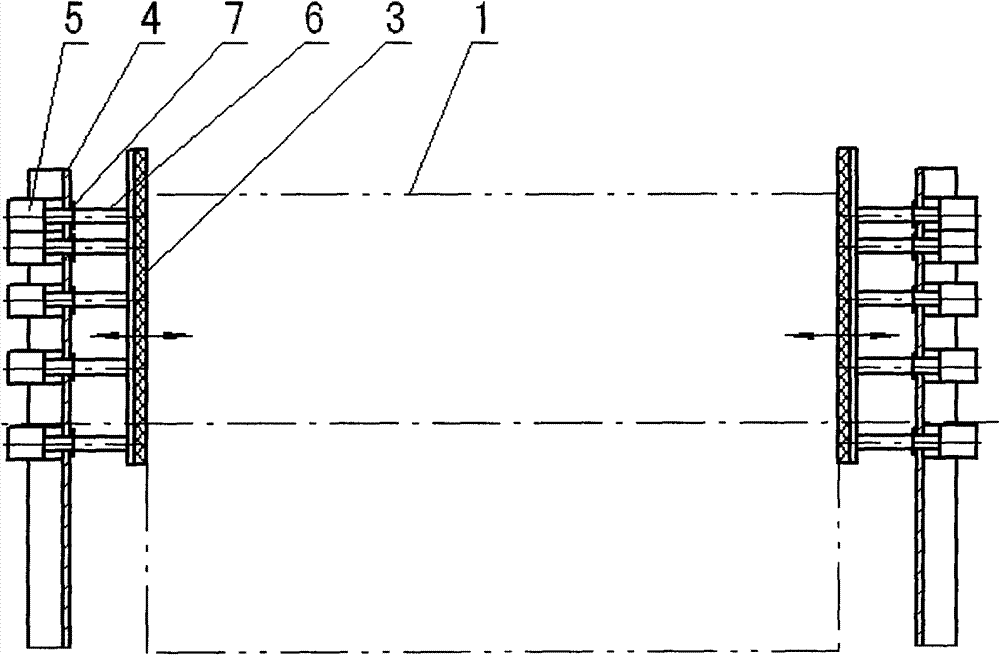

Dust blowing device for selective catalytic reduction (SCR) denitration reactor

InactiveCN103432904ASoot blowing forceThorough cleaningDispersed particle separationBuffer tankSolenoid valve

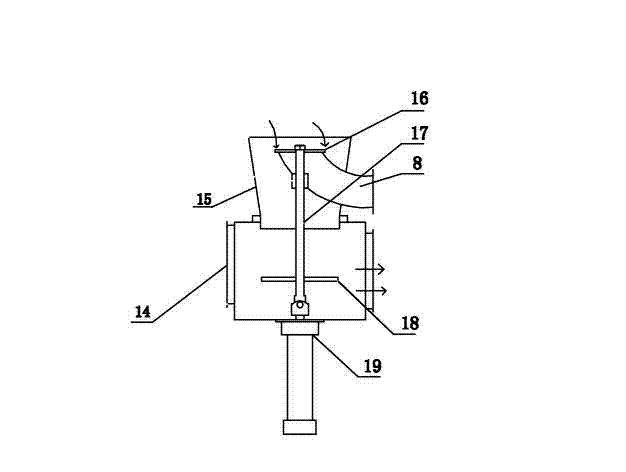

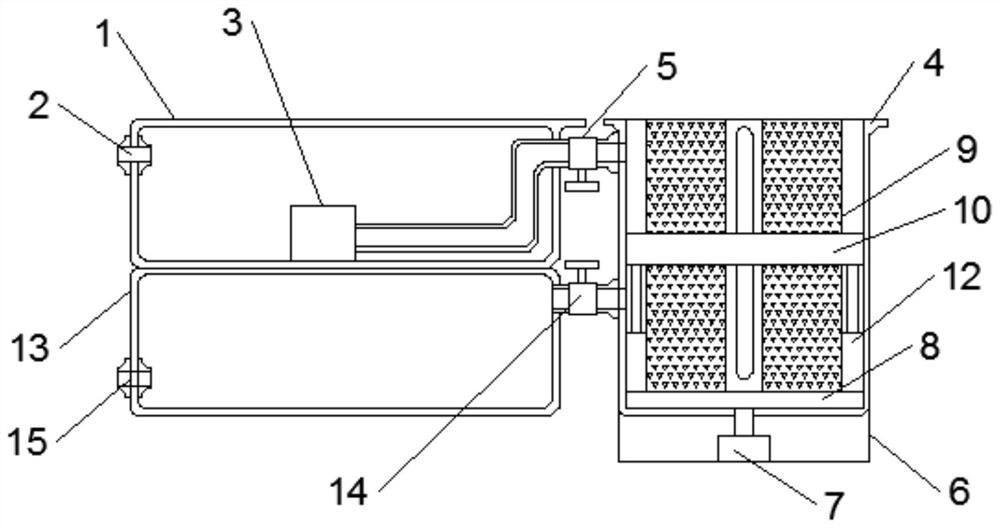

The invention discloses a dust blowing device for a selective catalytic reduction (SCR) denitration reactor. The dust blowing device comprises an air compressor, a buffer tank, a solenoid valve and jet pipe network unit module which are communicated in sequence; the jet pipe network unit module is positioned on catalyst units positioned in the SCR denitration reactor and jet pipes in the jet pipe network unit module are in one-to-one correspondence with the catalyst units. In the dust blowing device, a dust blowing air source is provided for the jet pipe network unit module by utilizing the air compressor; compressed air is stored and released by utilizing the buffer tank; the opening and the closing of the buffer tank is controlled by utilizing the solenoid valve; the jet pipes which are in the jet pipe network unit module and are in one-to-one correspondence with the catalyst units blow away dust in a manner of being dead against catalysts. The dry compressed air serves as a dust blowing medium, so that the normal work of the catalyst in a dry state is guaranteed. The dust blowing device has no vibration, no high temperature, no dead angle or no gathered dust residue, and has a large coverage surface when the gathered dust is cleaned by the compressed air; the service life of the catalysts is prolonged; the replacement cycle of the catalysts is prolonged; the denitration efficiency is effectively improved; an energy resource is saved.

Owner:HUNAN LUNAN DESULFURIZATION & DENITRATION TECH

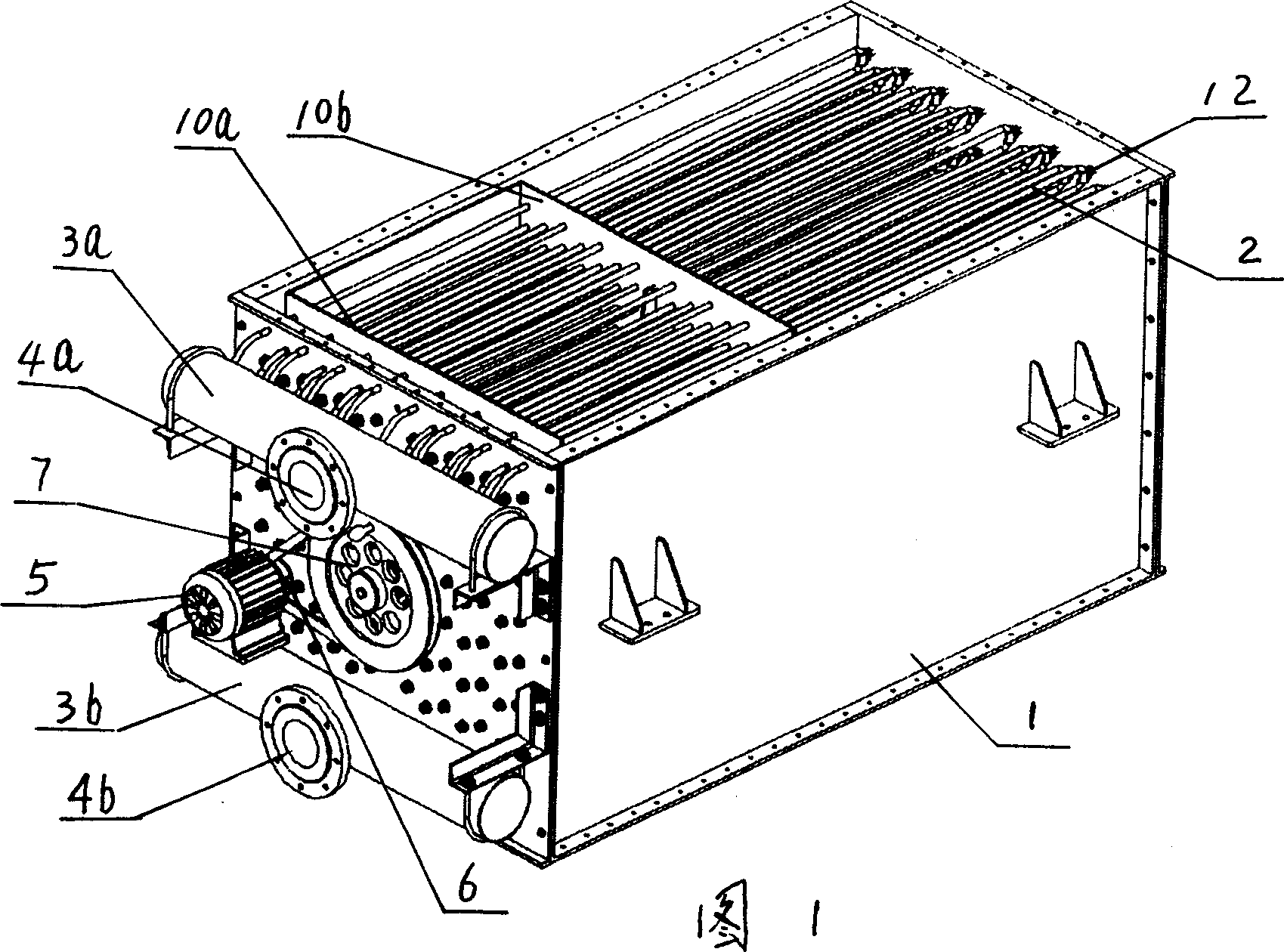

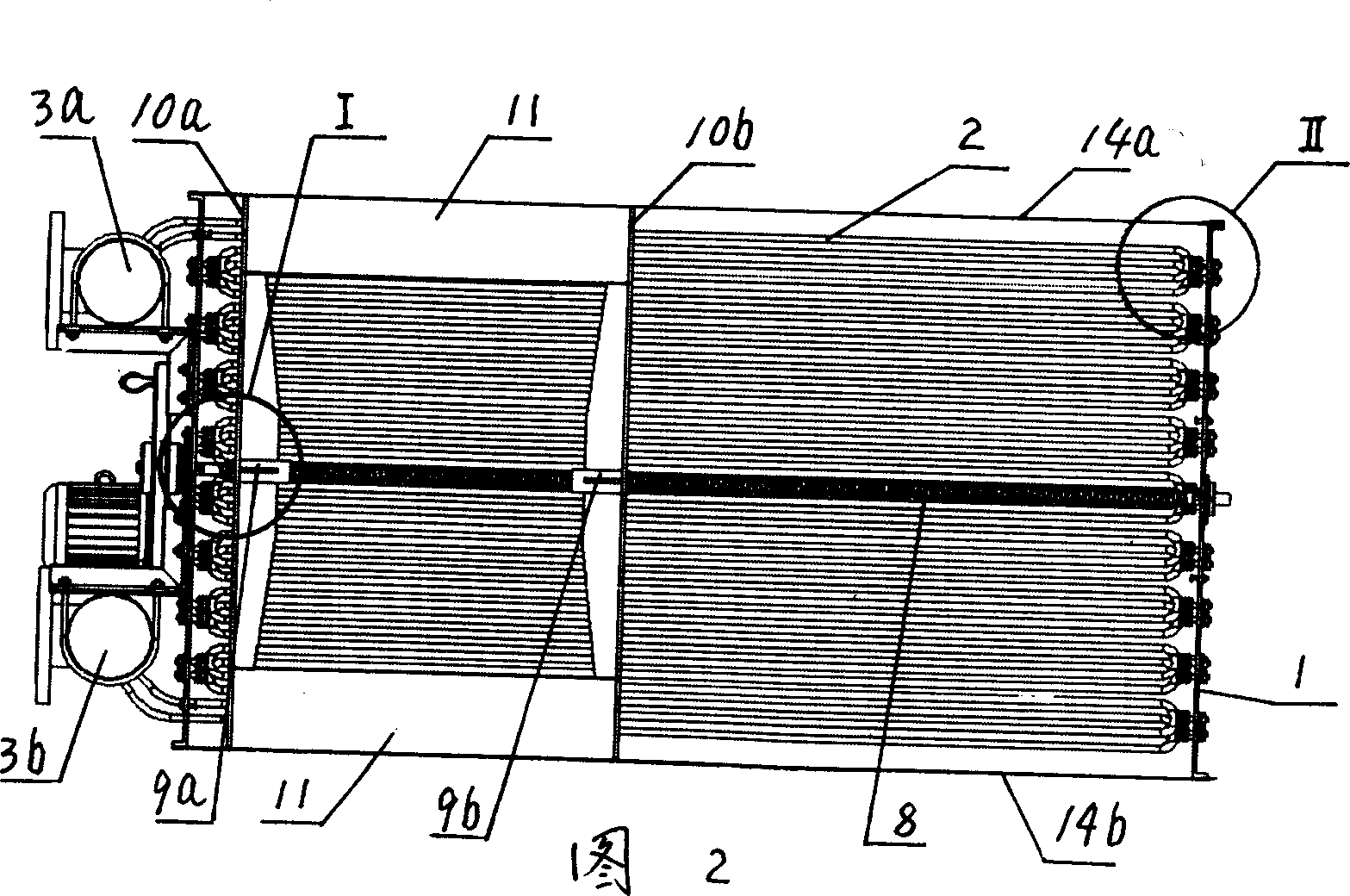

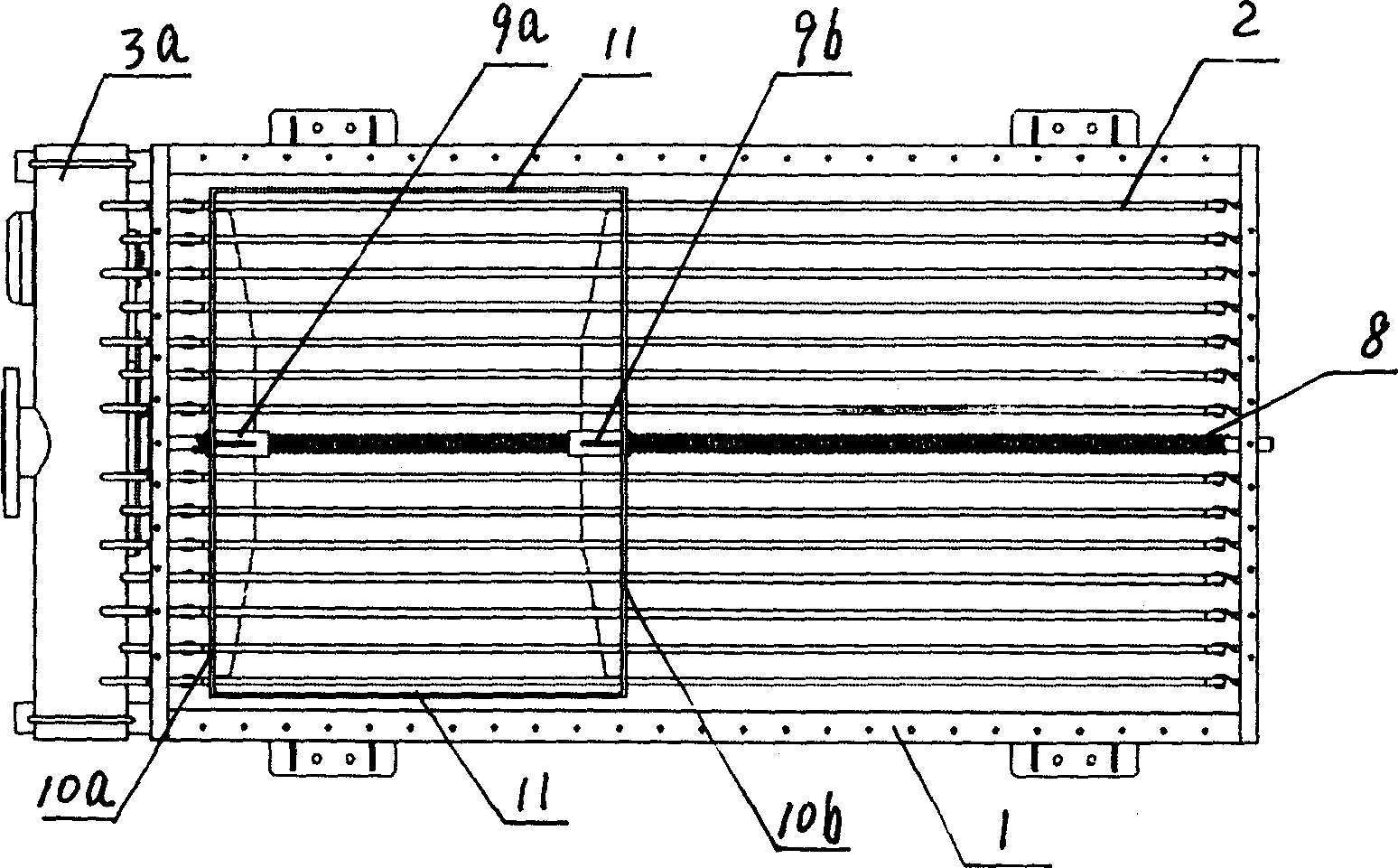

Ash-scraping waste-heat-recovering coal-saving device

InactiveCN1851382APrevent adhesionHigh recovery rateStationary tubular conduit assembliesNon-rotary device cleaningDrive wheelEngineering

The invention relates o a recycling device for boiler smoking waste heat that includes box. The smoke mouth A and B are set on the up end and the down end. Snake shaped pipe bundle is installed on the box, and the two ends connect to A and B. The feature is that it has dust shaving device. Shaving board is covering on the pipe bundle, and the bolt is set on the box that could fix the board by nuts. The shaving board driving device contains dynamo. The driving wheel of the dynamo is connected to the driven wheel of the bolt. The invention has the advantages of simple structure, low cost, easy to maintain, good dust cleaning effect, high heat recovery efficiency, etc.

Owner:NORTHEAST DIANLI UNIVERSITY

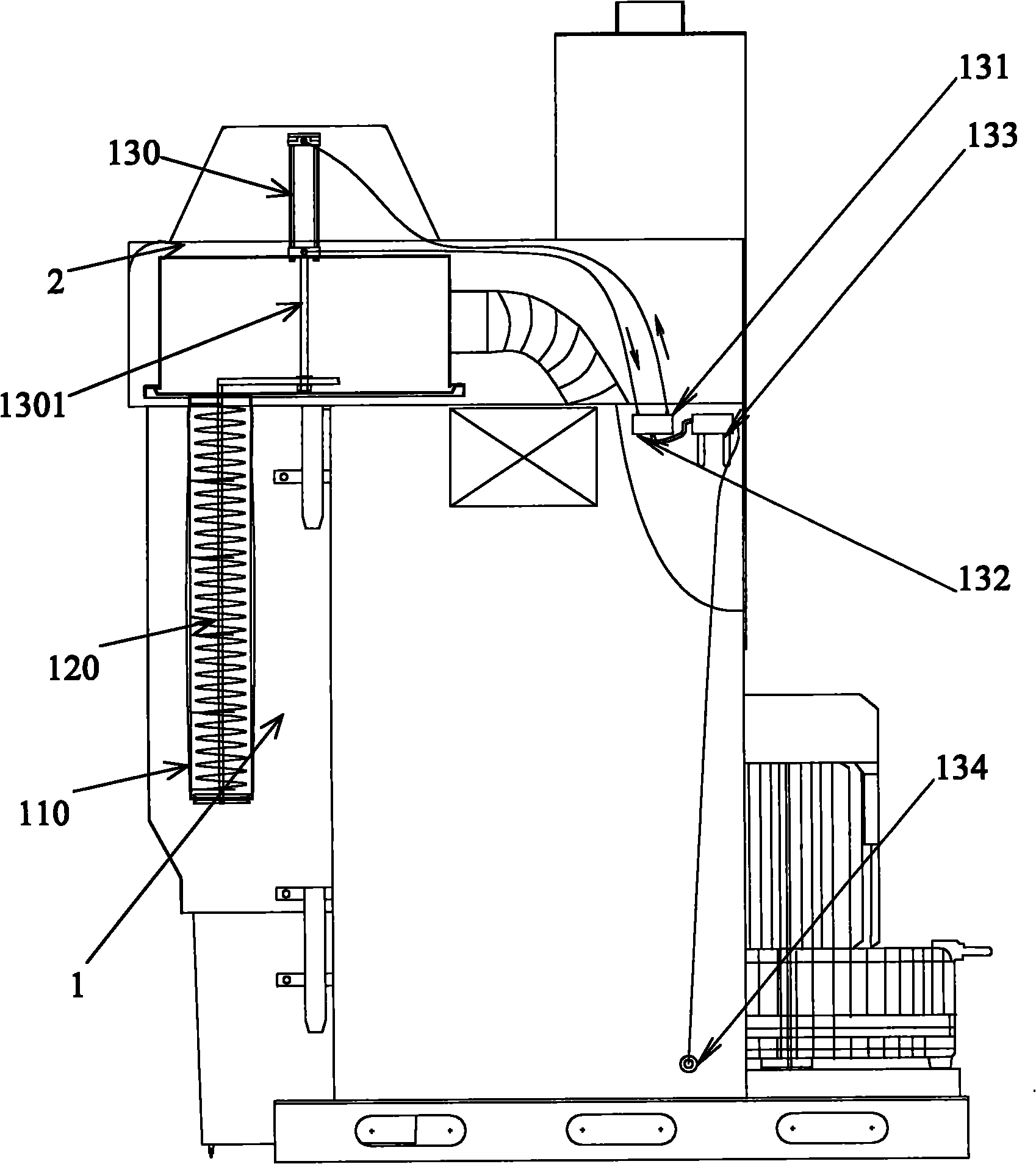

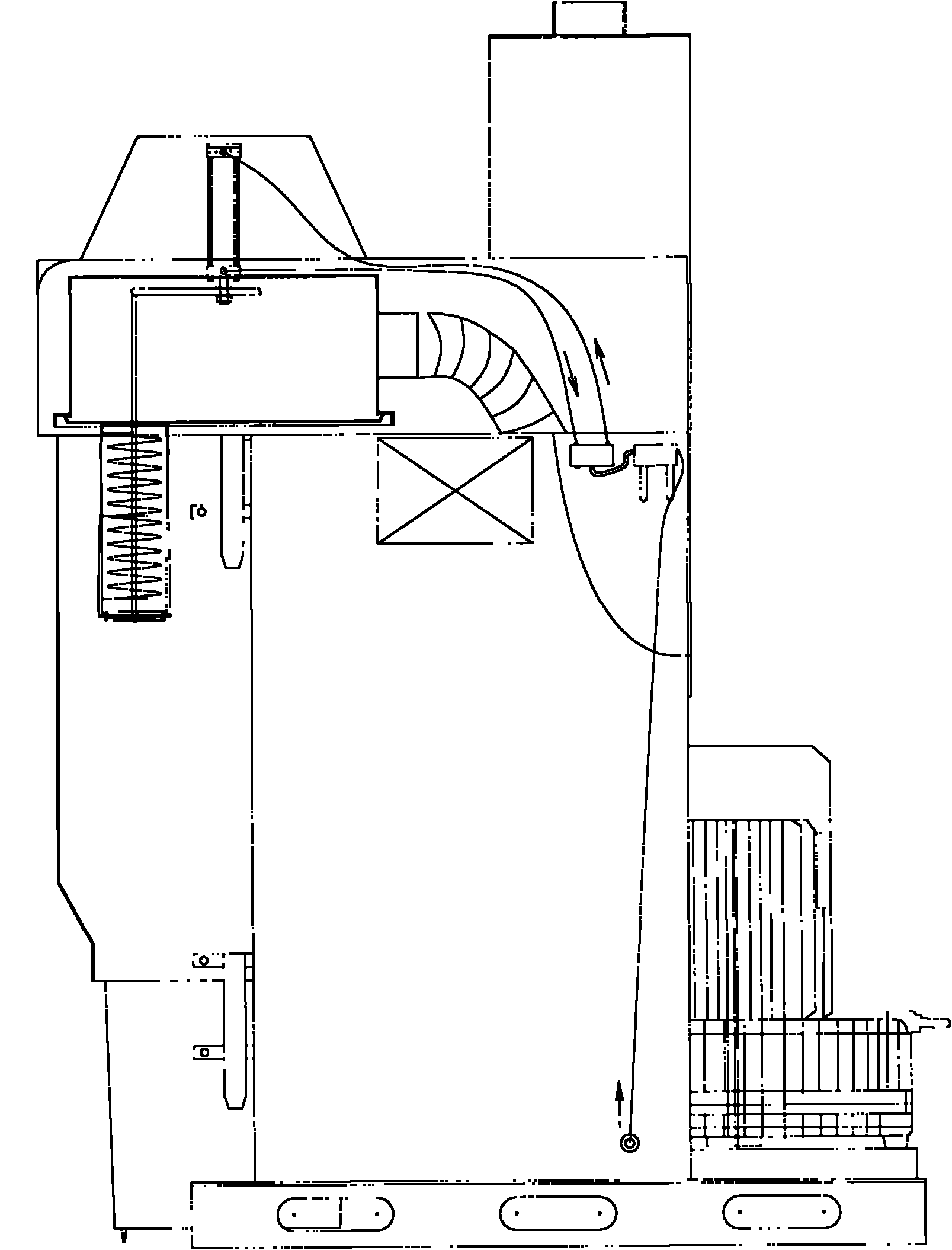

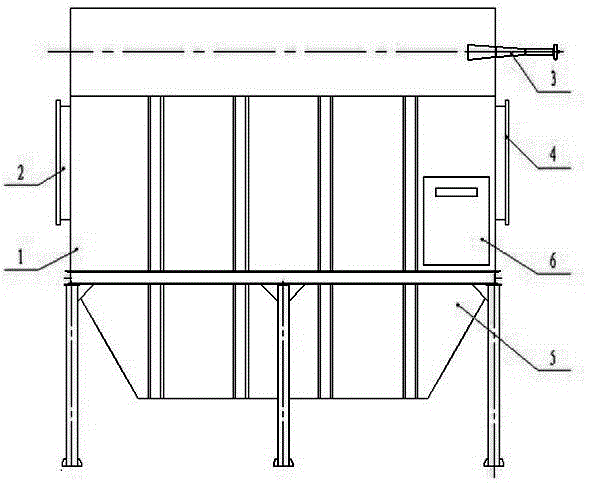

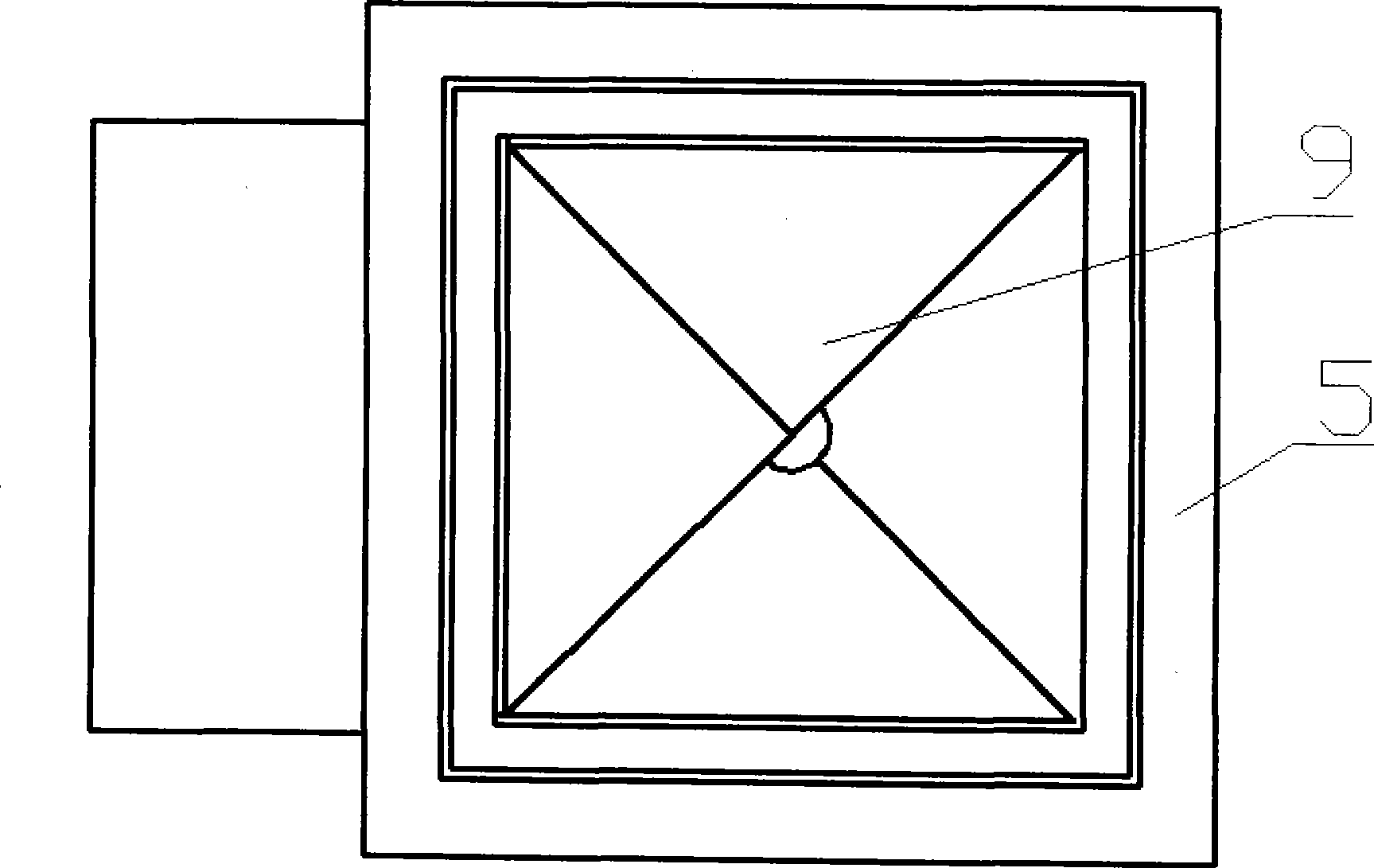

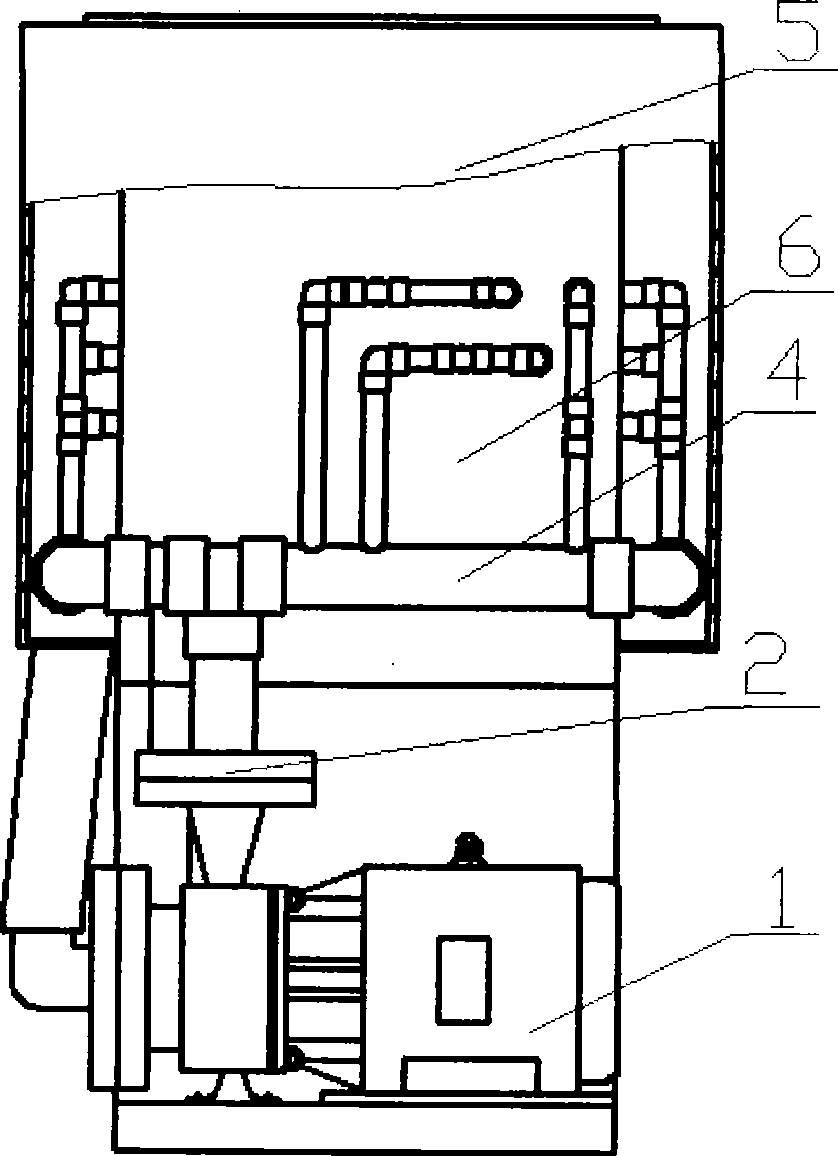

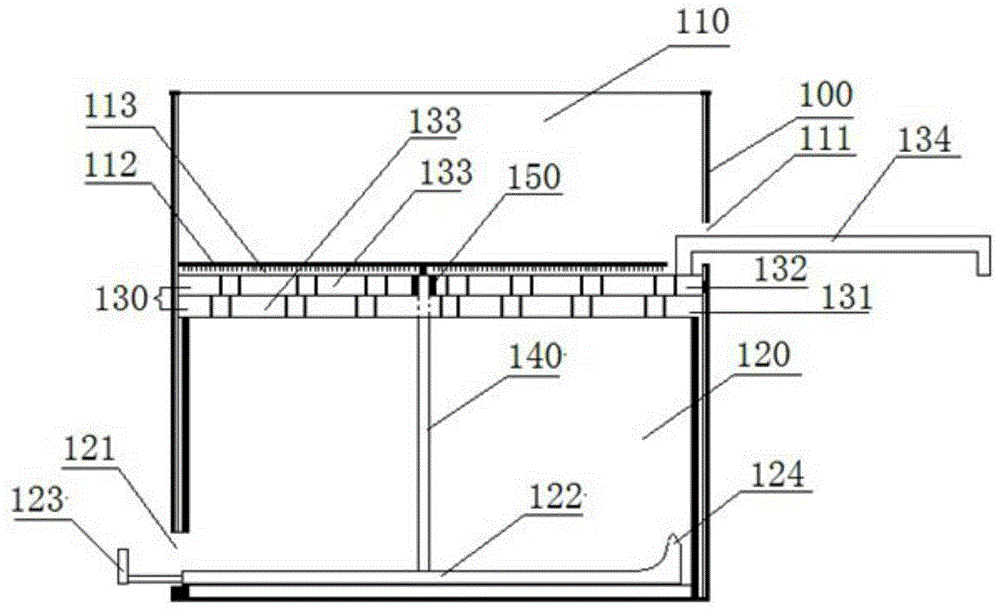

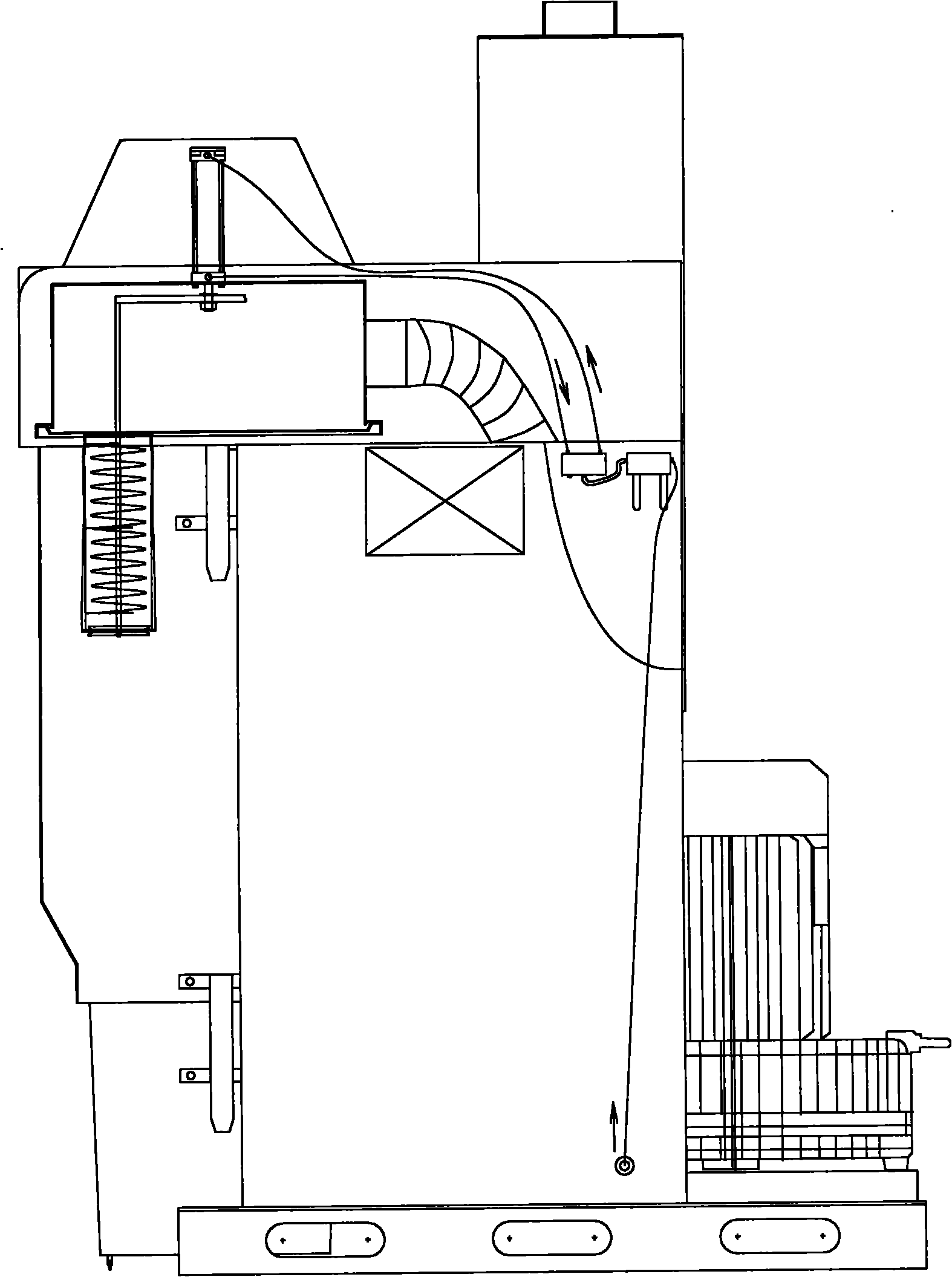

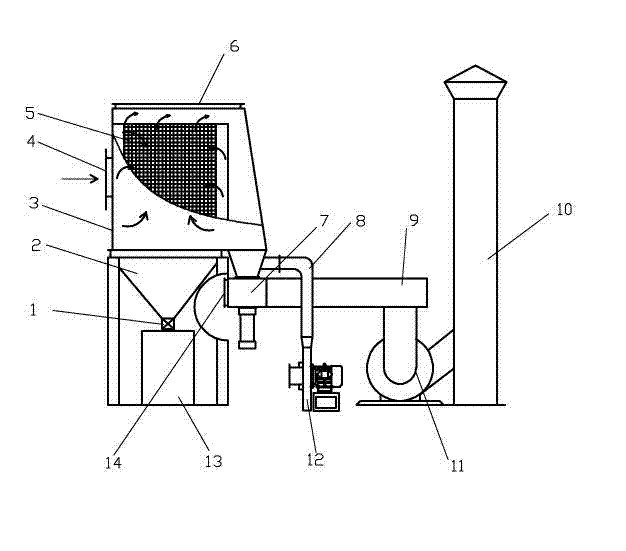

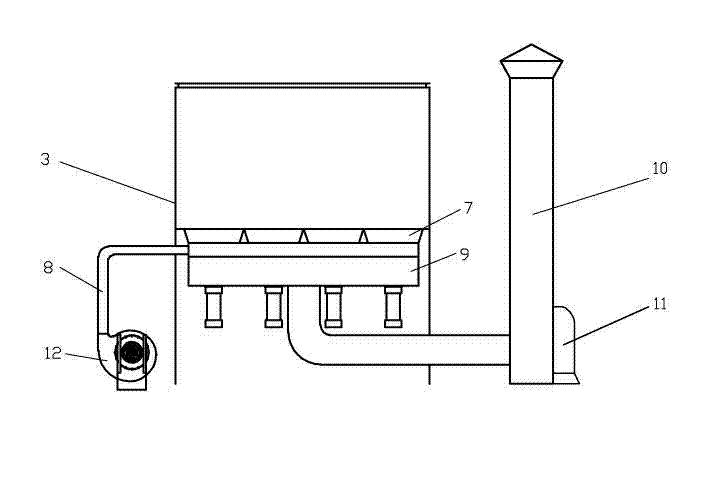

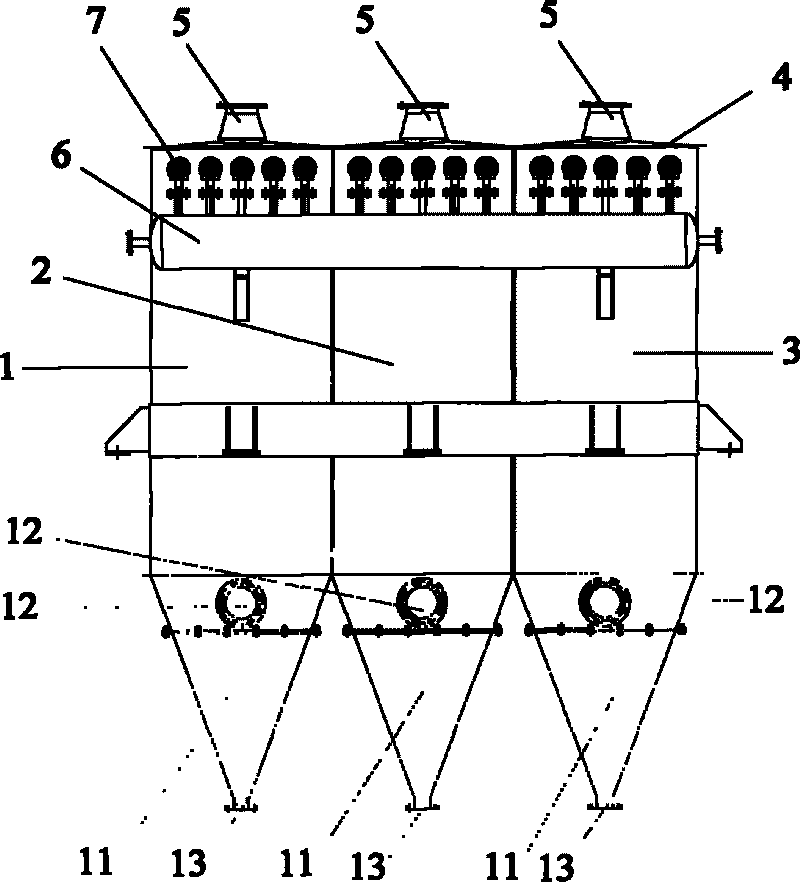

Pneumatic dust-cleaning device of bag-type dust remover and dust-cleaning method thereof

InactiveCN101884866AImprove cleanlinessThorough cleaningDispersed particle filtrationBaghouseEngineering

The invention discloses a pneumatic dust-cleaning device of a bag-type dust remover and a dust-cleaning method thereof. The pneumatic dust-cleaning device comprises a mechanical part and a pneumatic part, wherein the mechanical part comprises a filter bag, a drawing rod and a cylinder; the filter bag is a constituent part of the bag-type dust remover, and a piston rod of the cylinder is connected with the filter bag by the drawing rod. When the mechanical part is started to enter a dust-cleaning program by the pneumatic part, the dust-cleaning method is carried out in such a way that: the piston rod of the cylinder moves upwards to drive the drawing rod to move upwards and the filter bag is lifted by the drawing rod to change the filter bag from an expanding state into a pursing state; after moving upwards to the limit position of the cylinder, the piston rod of the cylinder moves downwards to drive the drawing rod to move downwards; and the filter bag is pushed downwards by the drawing rod so that the filter bag is restored to the expanding state. Because a cylinder oscillating type cleaning way is adopted in the dust-cleaning device of the bag-type dust remover in a purifying dust removing bin, the dust-cleaning device has better cleaning effect and enable dust-cleaning to be more thorough.

Owner:南通克莱克空气处理设备有限公司

Thermal equipment operation cleaning agent and its application

ActiveCN102312244AEmission reductionBroad prospects for commercial applicationFatty amineProcess engineering

The invention provides an application of alicyclic amine, such as octadecylamine, cetylamine, tetradecy lamine and dodecylamine, in thermal equipment operation cleaning as a cleaning agent. The invention further provides an application of a mixture of any two or three or four components selected from octadecylamine or cetylamine or tetradecy lamine or dodecylamine at random mass ratio in thermal equipment operation cleaning as a cleaning agent. According to the invention, insoluble peeling descaling replaces soluble descaling, thus not dissolving and corroding metal, eradicating the harm of traditional cleaning technologies to equipment and accomplishing the production mode of cleaning thermal equipment during operation, protecting during cleaning and efficiently operating during protection. Powder units are always in cleaning state, therefore making powder units to operate safely and stably and reaching the purpose of energy saving and emission reduction. The cleaning agent provided by the invention is a grate breakthrough in traditional cleaning technologies. In addition, the medicine addition condition of using octadecylamine as a thermal equipment outage anticorrosion protective agent is changed, the film forming quality and anticorrosion effect are guaranteed, and the function of outage anticorrosion is reinforced.

Owner:BEIJING CHINA POWER LONG YUAN ENVIRONMENTAL PROTECTION TECH

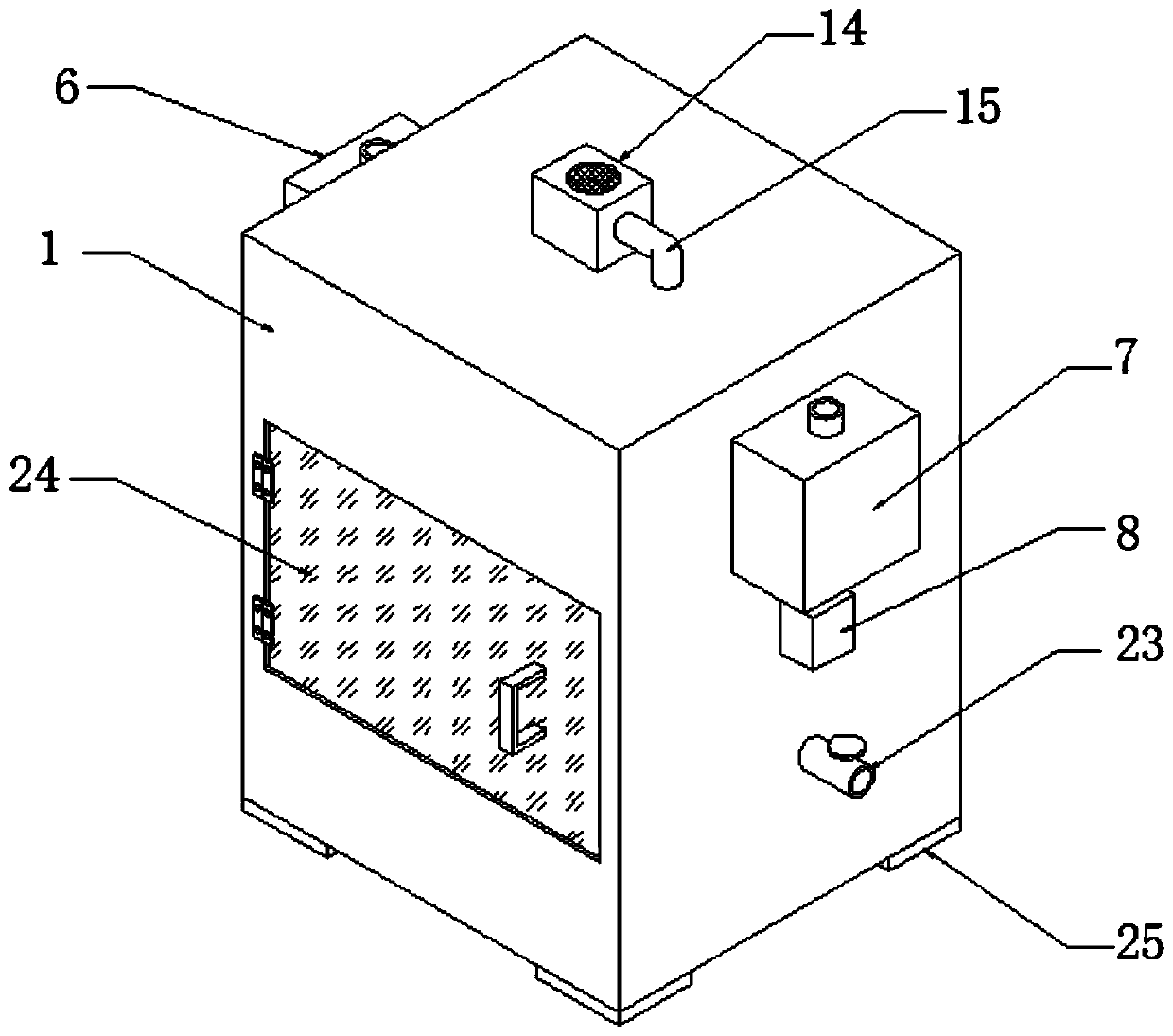

Acoustic deashing and dedusting device

InactiveCN103909016AGood cleaning effectAvoid erosionDispersed particle filtrationElectrodes cleaningElectricityFilter material

The invention relates to a deduster and discloses an acoustic deashing and dedusting device. The acoustic deashing and dedusting device comprises a box, an air inlet, an air outlet, an ash bucket arranged below the box and a negative pressure draught fan connected with the air outlet. The acoustic deashing and dedusting device is characterized by further comprising an acoustic transmitter. According to the invention, acoustic deashing technology is employed, and dust accumulated on pole plates and pole wires of an electric precipitator or on the filter material of a bag filter can be effectively removed. The acoustic deashing and dedusting device can remove dust accumulated on the surface of the pole plates or filter material and has the advantages of a good deashing effect, a simple structure, high purifying efficiency, long service life, safe and reliable operation and a high degree of automation.

Owner:ZHEJIANG JITIAN ENVIRONMENTAL PROTECTION TECH

Jet type scallop rim cleaning device

The invention relates to a machine of cleaning shirt rims of seashells, more specifically to a jet type scallop shirt rim cleaning device, composed of a motor, a centrifugal pump, a filter screen, a seawater circulation pipe, a housing, a case, a jet hole, a screen and a baffle. The seawater circulation pipe communicates with inner of the case through the jet hole on the walls of the case, water is circled between the pipe and the case through the motor to drive the centrifugal pump, and jet flow is generated on the jet hole of the walls of the case causing water body to form vortex, finally the shirt rims of seashells are cleaned. The device is low in cost, simple in structure, free of expertise and skills in use and maintenance, stable and reliable in working, and fast and thoroughly completes cleaning of the shirt rims of seashells.

Owner:獐子岛集团大连轮船有限公司

Filter drum deduster

ActiveCN102553365ADecreased filtration rateReduce the load of filtration and purificationDispersed particle filtrationFiltrationEmission standard

The invention is an improvement of a filter drum deduster. The deduster is characterized in that a rigid non-compression eccentric rotating interference compressing piece is used for compressing between an air-out end surface of the filter drum and an overhung pore plate; a cushion space which is not less than 30cm is reserved between the bottom of the filtering drum and the bottom plane of a filtering drum box body; and a filtering air inlet is arranged in the cushion space at the lower part of the filtering drum. According to the deduster provided by the invention, over-diameter particles are ensured not to exist in the filtered gas, the filtering material is prevented from being damaged effectively, the service life of the filtering drum is prolonged, two main defects which are hard to solve by a traditional filtering drum deduster are solved completely, and the effective service life of the filtering drum is prolonged from originally maximum twelve months to eighteen months. A frame type filter is added above a filtering drum air outlet by being connected with a transition section interval, the filter precision of the frame type filter is higher than the filter grade of the lower filtering drum, thereby forming secondary filtration of upper and lower inter-phase serial connection; the minimum filtering precision can be 0.1 microns; the filter drum deduster provided by the invention can be used in the lead-acid battery industry for filtering lead dust and fume, and the dust content of the filtered gas is not more than 0.07mg / m<3>, which is far less than the national emission standard; the filtration resistance is increased by more or less than 10% on the basis of previous grade, so that the contradiction between the filtering precision and the filtering resistance is balanced well.

Owner:江苏二环环保科技有限公司

Furnace

InactiveCN104633717ABurn fullyClear in timeDomestic stoves or rangesLighting and heating apparatusCombustionEngineering

The invention discloses a furnace which comprises a furnace body. The furnace body comprises a combustion cavity and a ventilation cavity. The combustion cavity and the ventilation cavity are separated by a grate plate. The grate plate comprises a fixed grate plate body and a rotary grate plate body which are attached to each other. The fixed grate plate body is fixedly installed in the furnace body. The rotary grate plate body is installed on the upper portion of the fixed grate plate body. The main body of the rotary grate plate body and the main body of the fixed grate plate body are each provided with a plurality of through holes. The overlapped portions of the through holes in the fixed grate plate body and the through holes in the rotary grate plate body form grate plate through holes. The size of the grate plate through holes can be adjusted by rotating the rotary grate plate body. Compared with the prior art, due to the fact that the grate plate is divided into the fixed grate plate body and the rotary grate plate body which are attached to each other, the grate plate through holes in the grate plate can be adjusted according to the size of combusting fuel, it is ensured that the fuel can be sufficiently combusted in the furnace, completely-combusted fuel ash can be rapidly removed in time, no pollution is produced in the ash removing process, and operation is easy and convenient.

Owner:XUZHOU JIAGU ENVIRONMENTAL PROTECTION TECH

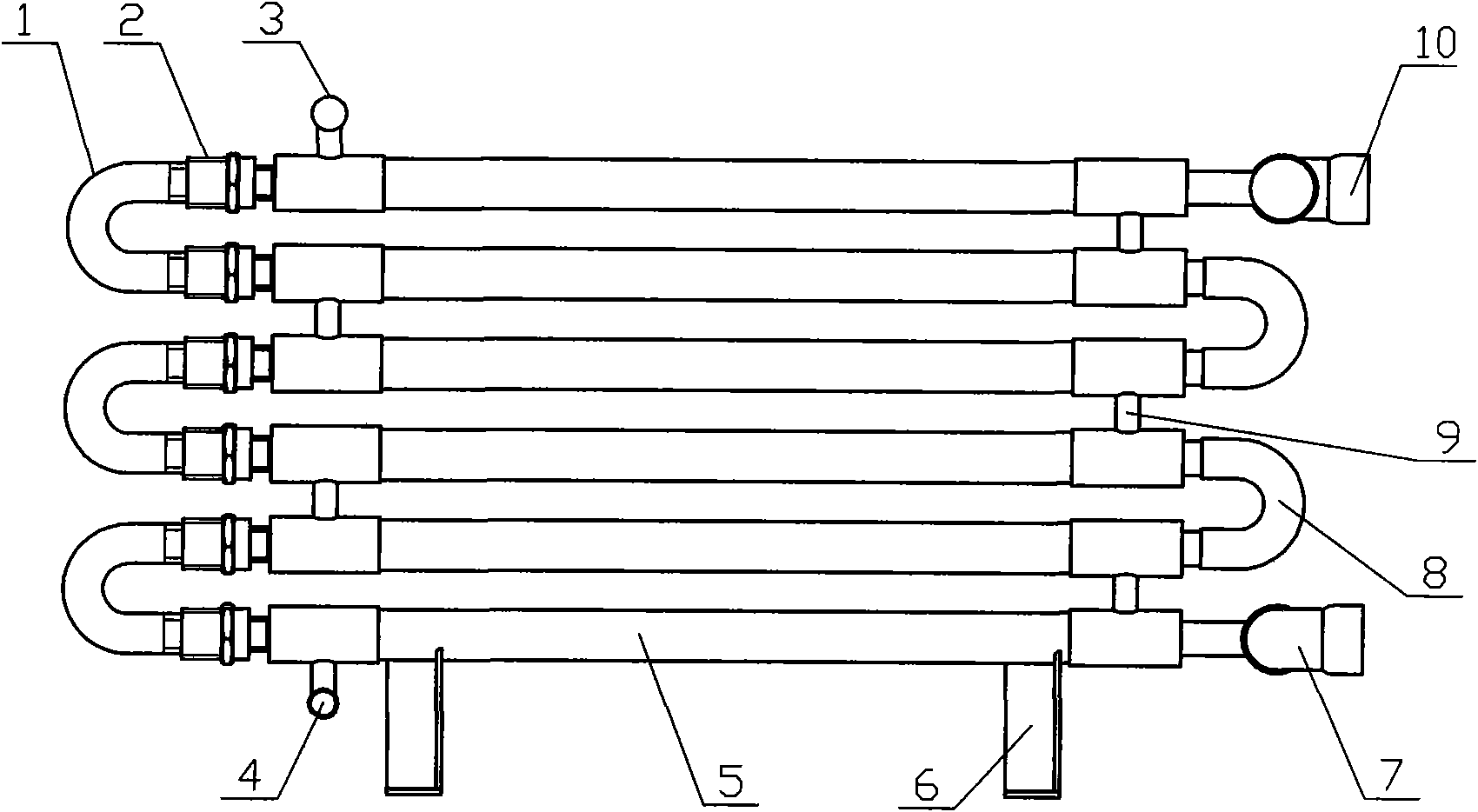

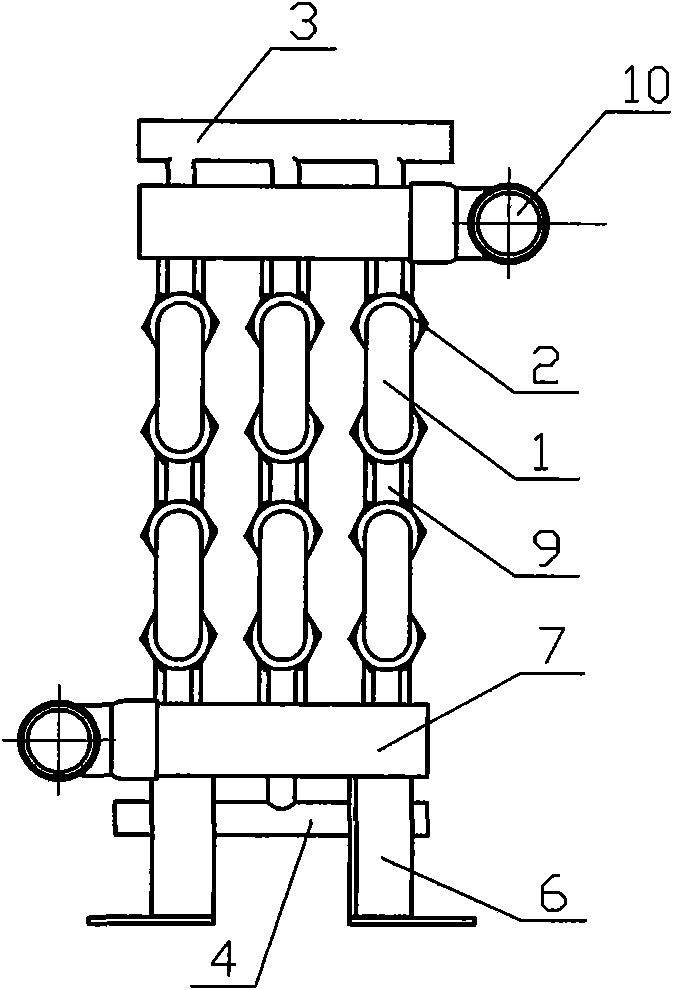

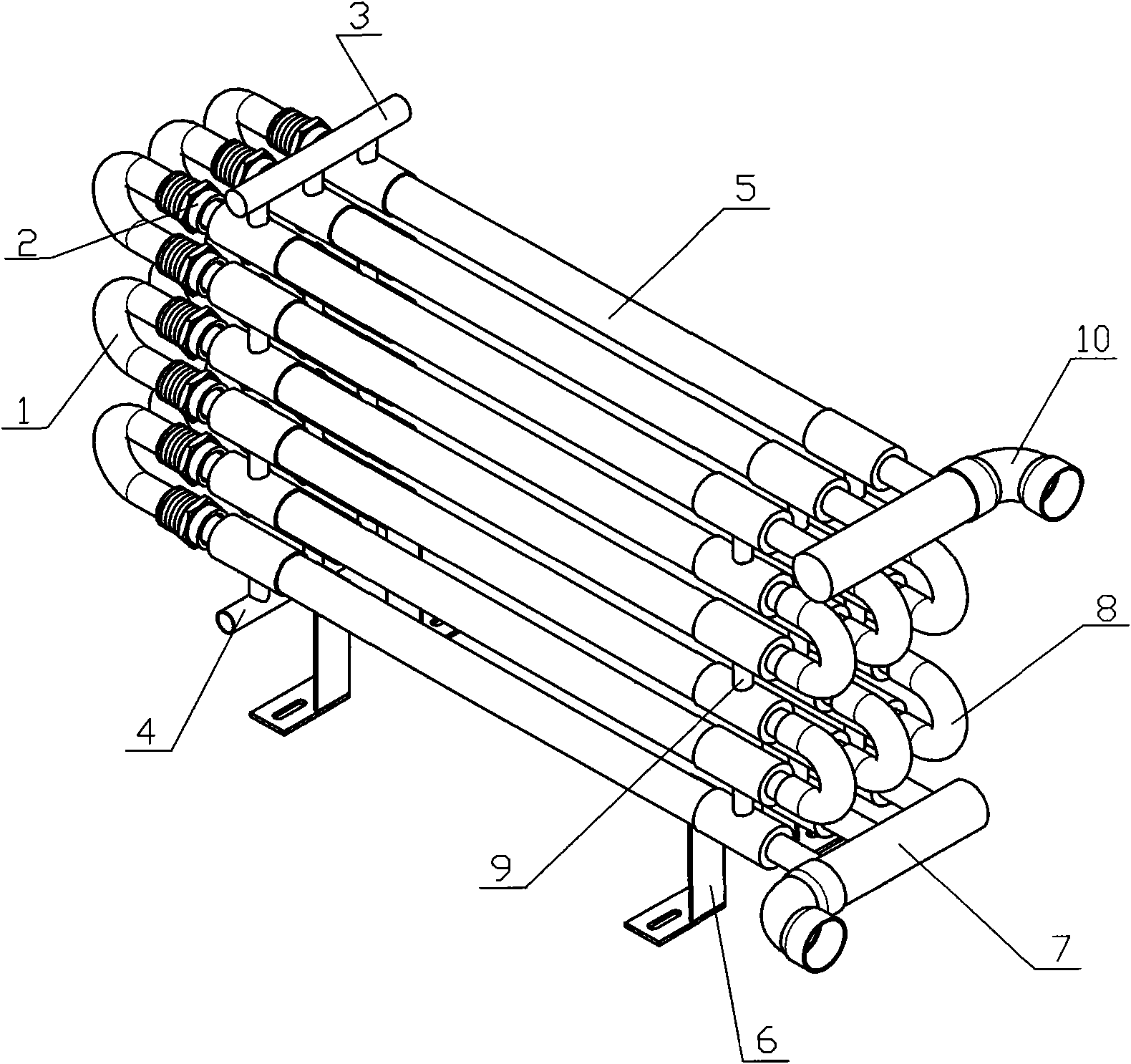

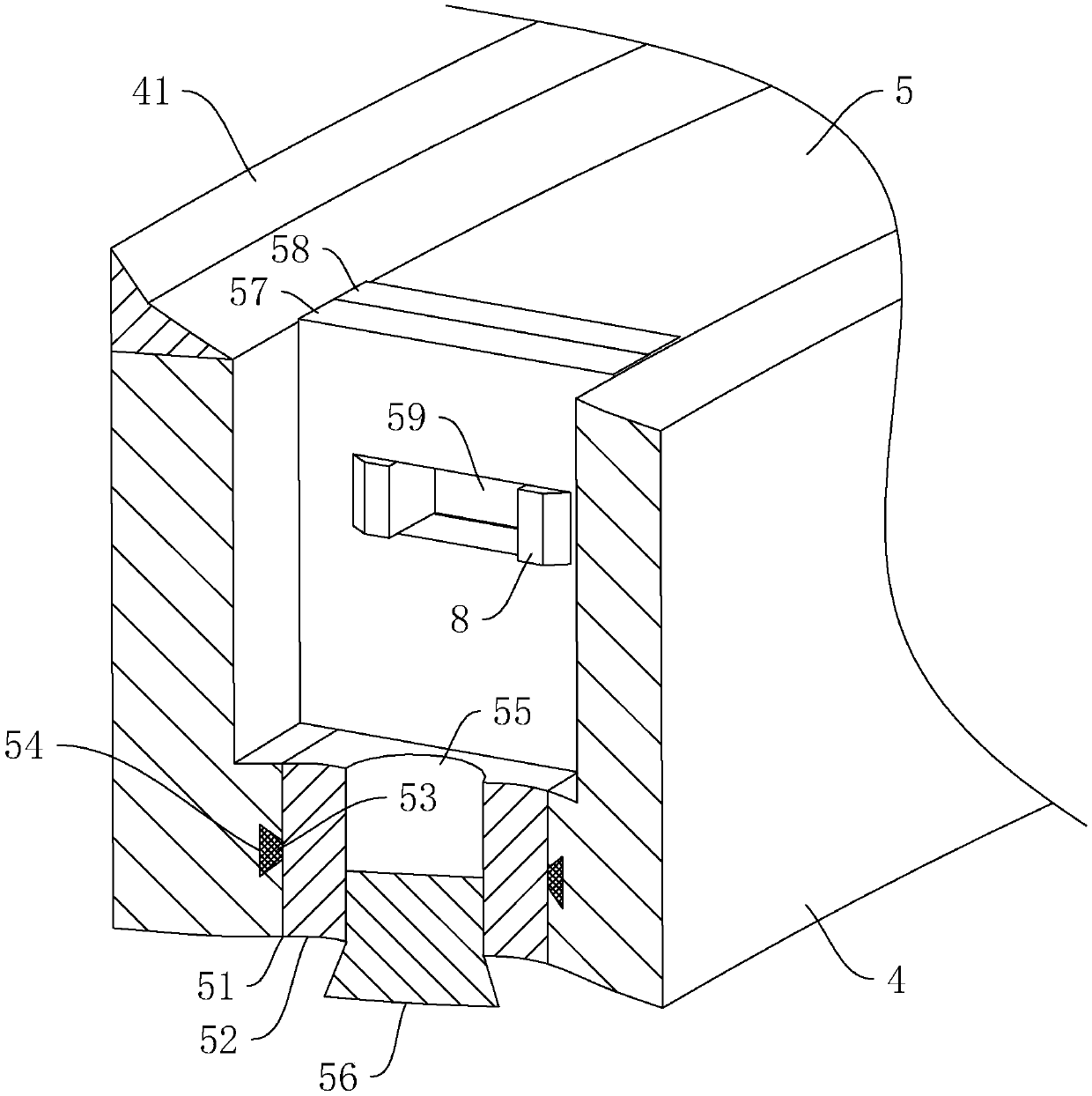

Row-line type integrated jacket pipe heat exchanger detachable scale clean structure

InactiveCN101586922AEasy to installImprove sealingHeat exchanger casingsStationary tubular conduit assembliesCoolantHeat exchanger

The invention discloses a row-line type integrated jacket pipe heat exchanger detachable scale clean structure, includes a transversely disposed jacket pipe composed by connecting an U shaped connection pipe to a C shaped connection pipe in sequence, and a short pipe, a coolant inlet pipe, a coolant exit port, a water inlet pipe, a water outlet pipe and a footing. The connector between the two interfaces of the U shaped connection pipe and the left end of the jacket pipe is a screw connection structure, the connector is locked in common situation that is in sealed connection situation. After a period of time operation, heat exchange efficiency is reduced because of accumulated scale, so proceeding maintenance of cleaning scale in shutdown situation, first unscrewing related connector and demounting the u shaped pipe and cleaning inner pipe of the jacket pipe, then installing the u shaped connection pipe and the operation is recovered. The invention can install and uninstall the u shaped connection pipe by connector of screw connection structure that is convenient for physical scale cleaning operation without drawing off coolant which reduces cost of scale clean maintenance greatly.

Owner:JIANGYAN TAIYI METAL BRAID SLEEVING

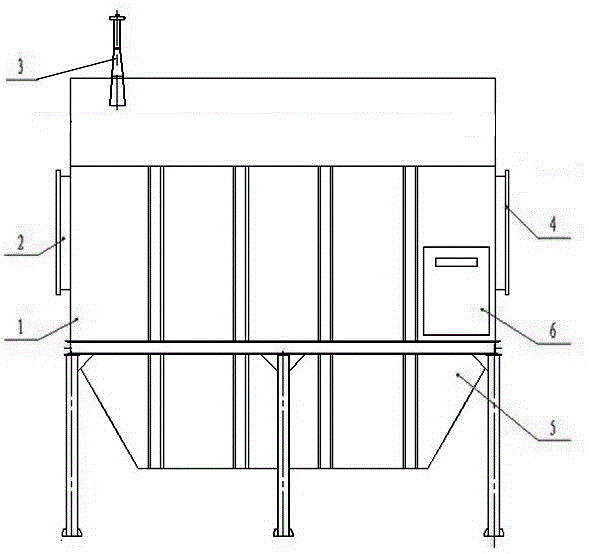

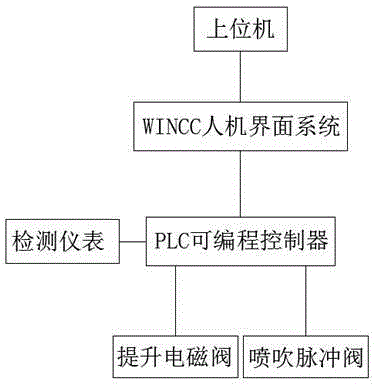

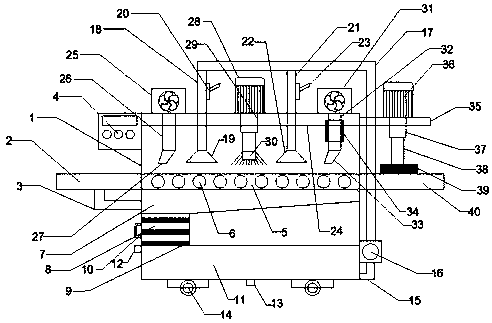

WINCC-based bag filter control system and control method

InactiveCN105169828ARealize automatic operationThorough cleaningDispersed particle filtrationControl systemProgrammable logic controller

The invention discloses a WINCC-based bag filter control system and a control method. The WINCC-based bag filter control system comprises a host computer, a WINCC human-computer interface system, a PLC (programmable logic controller), a detection meter, a lifting solenoid valve and a jetting pulse valve; the host computer is connected with the WINCC human-computer interface system via ethernet; the input port of the PLC is connected with the signal output terminal of the detection meter, and the output port of the PLC is connected with the lifting solenoid valve, the jetting pulse valve and a coil of a relay; and the lifting valve and the jetting pulse valve are connected with a power supply via a normally open contact via the relay. By employing the PLC, timed or constant-resistance automatic blowing for cleaning ash is performed, gas consumption is small and ash is cleaned thoroughly. By combining with the WINCC human-computer interface system, the labor efficiency is improved.

Owner:HANDAN XINXING SPECIAL TUBING CO LTD

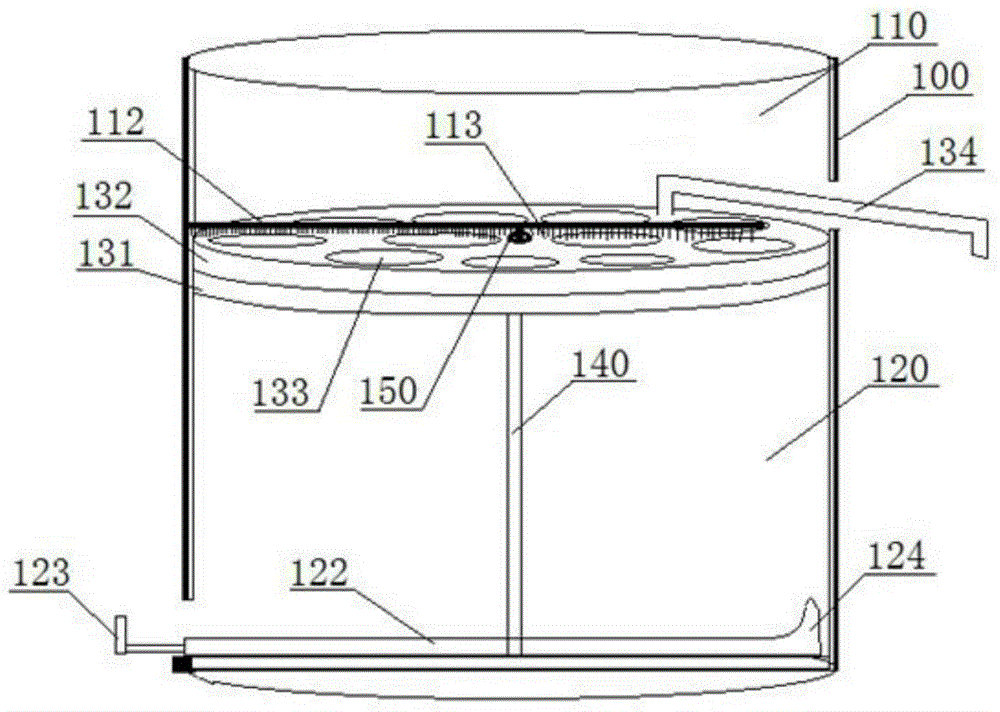

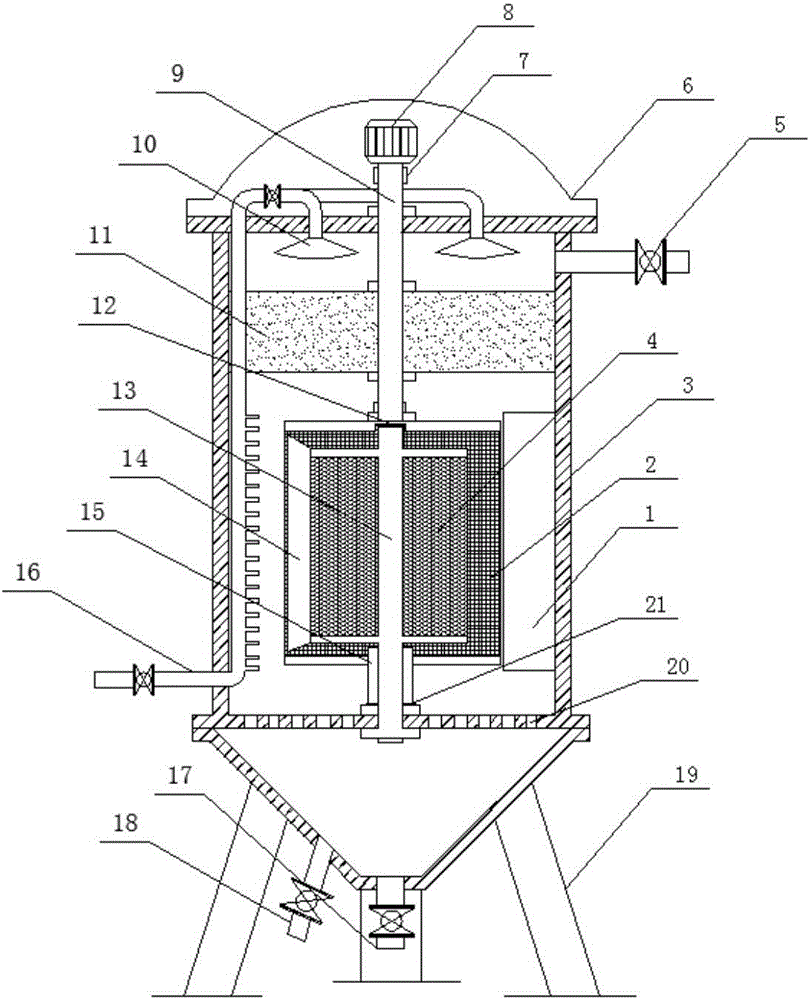

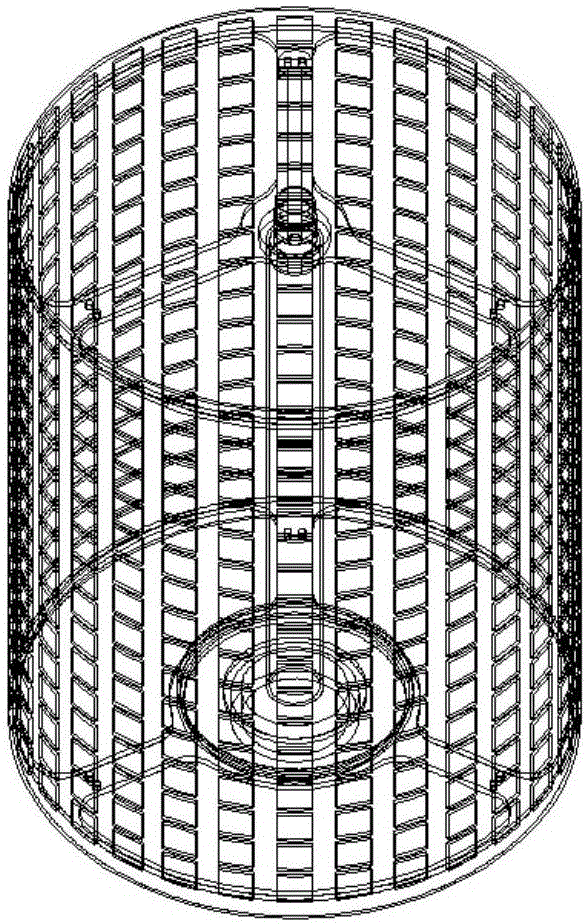

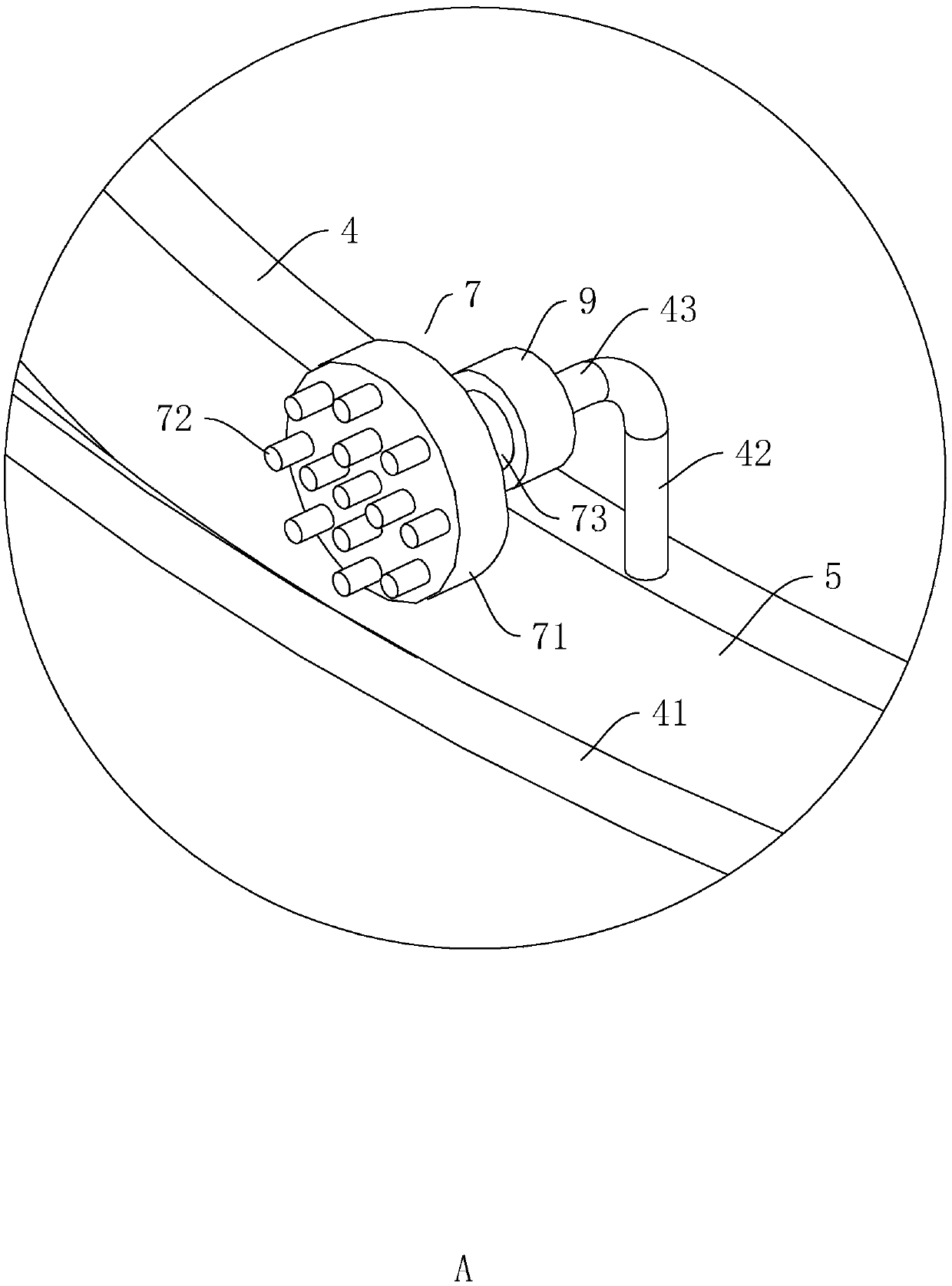

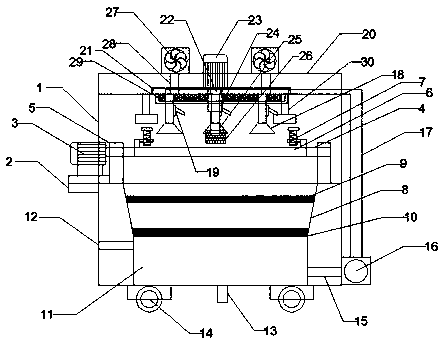

Automatic circulating water electrolysis descaling device and method

PendingCN106554090ASuitable for descaling and anti-corrosionThorough cleaningWater softeningWater/sewage treatment apparatusSlagCorrosion prevention

The invention relates to an automatic circulating water electrolysis descaling device and method. The device comprises a reaction box body, a water inlet and control valve, a water outlet and control valve, a slag discharging outlet and control valve, a first scraper, a filtering packing layer, a back washing structure, a box body top cover and a support. The device is further provided with a cathode and assembly, an anode and assembly and a washing structure. The cathode and assembly and the anode and assembly are concentrically installed inside the reaction box body. A washing structure pipeline is fixed to the inner wall of the reaction box body. The box body top cover on the upper portion of the reaction box body is of a sphere crown shape, and the bottom of a cone shape. A fixed plate with small uniform holes and sliding rails is arranged at the connecting position of the lower end of a cylindrical body of the reaction box body and the cone-shaped bottom edge. By the adoption of net tube-shaped electrodes, the scale removing method with automatic mechanical scale scrapping and washing being conducted at the same time is adopted to be combined with the filtering packing layer, so that scale removing is thorough, yielding water is made cleaner, and the automatic circulating water electrolysis descaling device and method are suitable for scale removing and corrosion prevention of circulating water.

Owner:沈阳瀚威科技有限公司

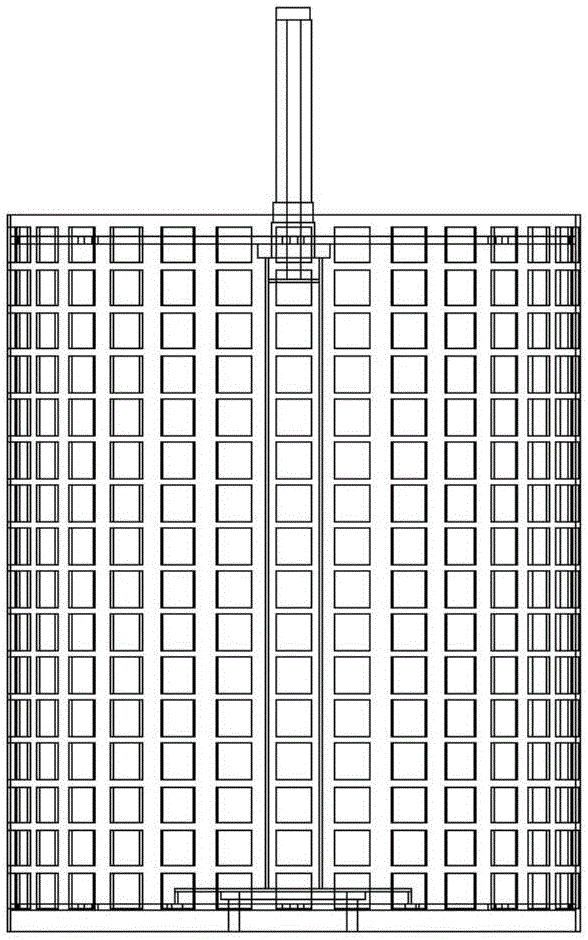

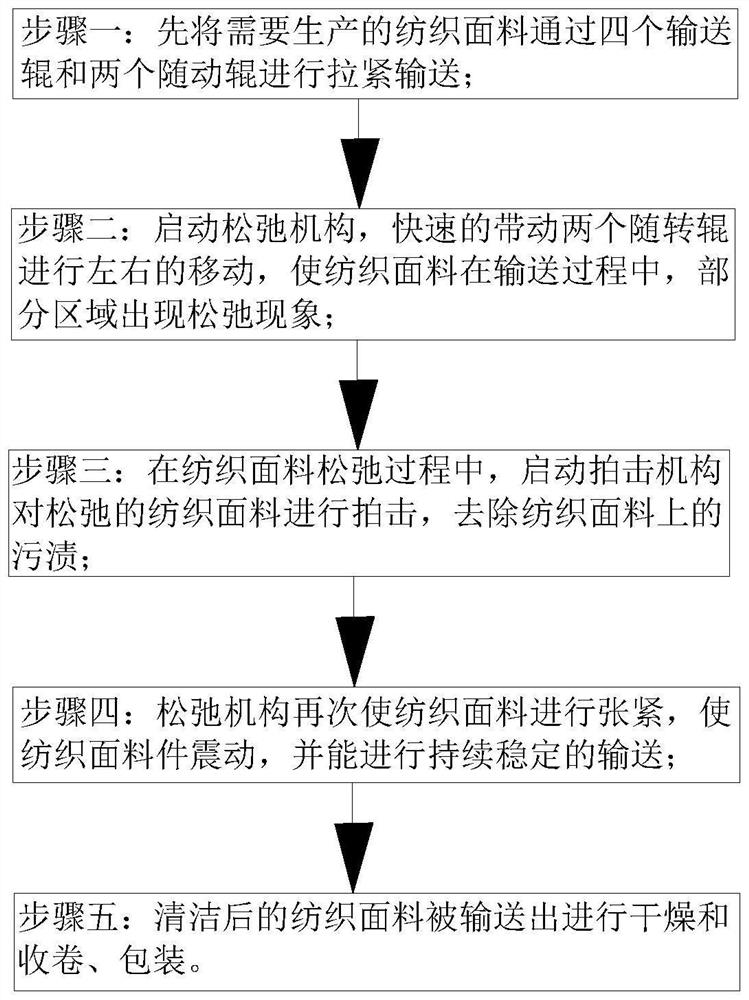

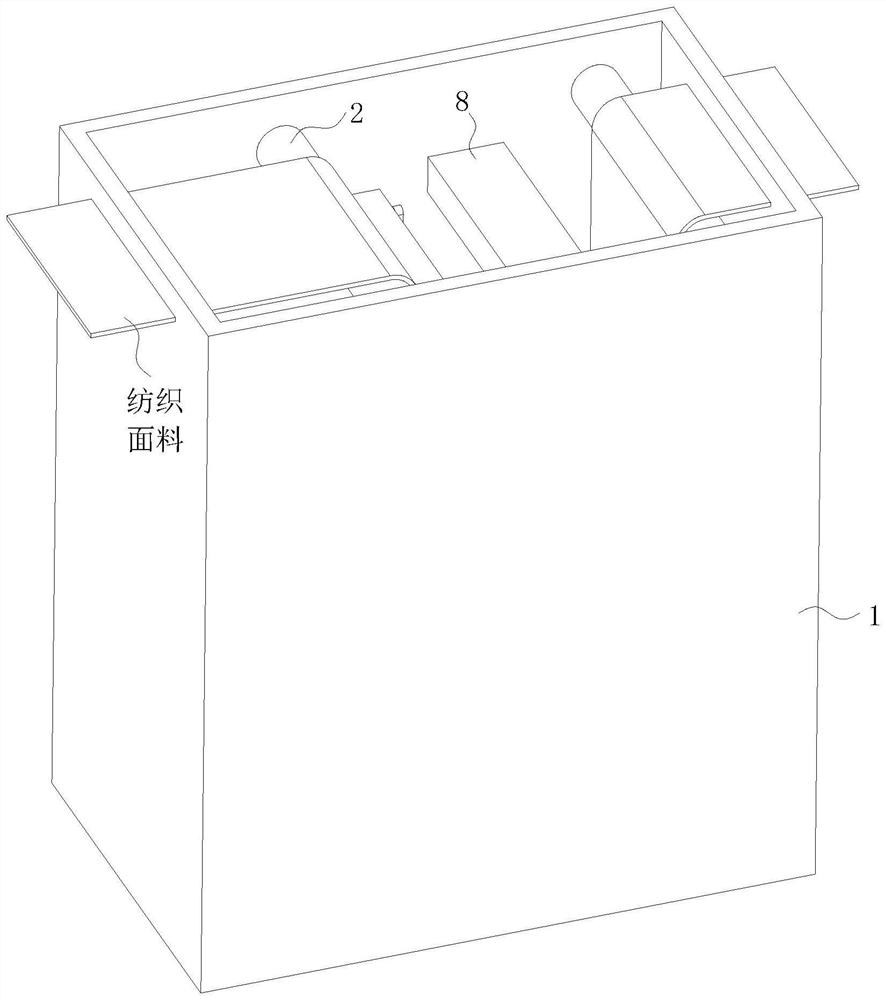

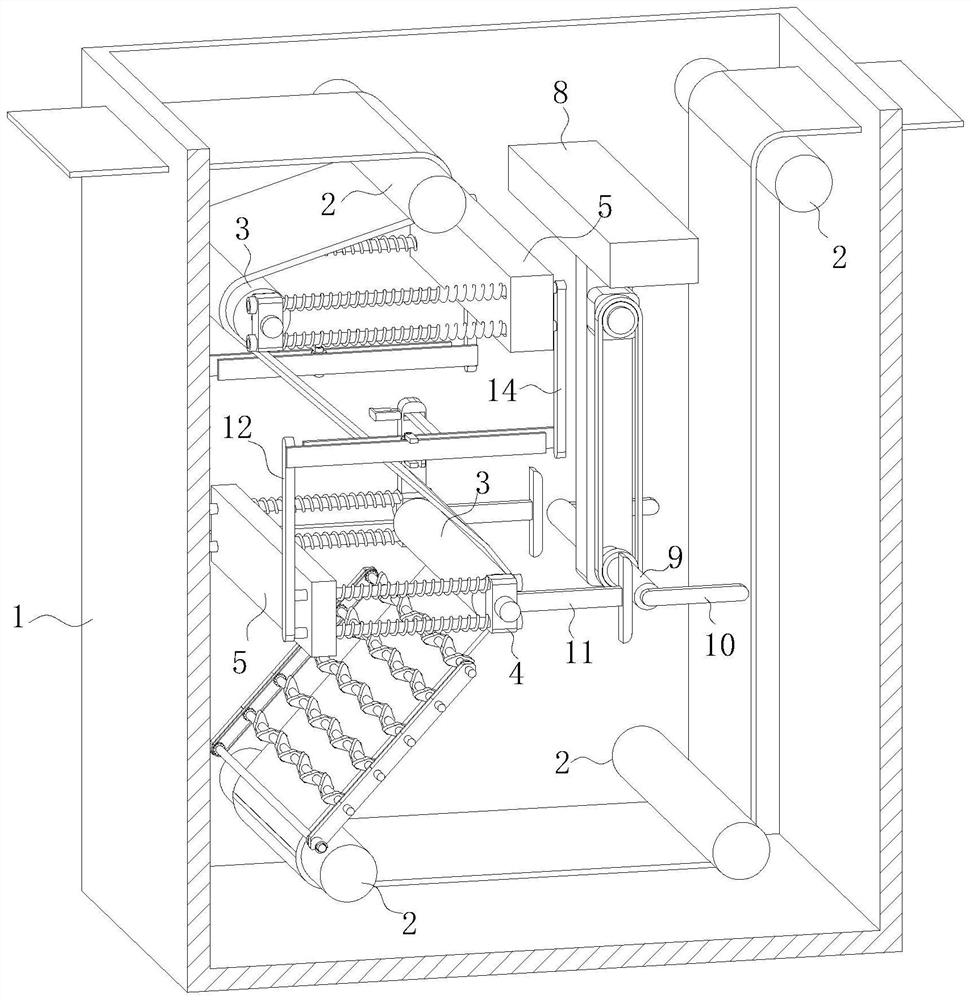

Textile fabric cleaning device and cleaning method for textile production

ActiveCN114457530AEasy dischargeEasy to cleanLiquid/gas/vapor treatment machines driving mechanismsTextile treatment machine arrangementsTextile productionMechanical engineering

The invention discloses a textile fabric cleaning device and method for textile production in the technical field of textile fabric cleaning, and the textile fabric cleaning device comprises a cleaning box, and the inner side of the cleaning box is provided with a conveying device used for conveying a textile fabric in the cleaning box; a loosening mechanism for bending, tensioning and loosening the textile fabric is arranged on the inner side of the conveying device; when the produced textile fabric needs to be cleaned every time, the textile fabric is tensioned through the conveying mechanism and the relaxation mechanism, the textile fabric is relaxed through the relaxation interval in the textile fabric conveying process, the slapping mechanism is matched for slapping and cleaning the relaxed fabric in the cleaning box, the fabric is softer, and the cleaning efficiency is improved. By means of the device, stains in the textile fabric can be more thoroughly slapped and cleaned, the textile fabric is continuously loosened and tensioned in the conveying process, the inner side of the textile fabric is vibrated, and the stains on the inner side of the textile fabric can be better discharged in a vibrating mode.

Owner:嘉兴市鸣竣纺织有限公司

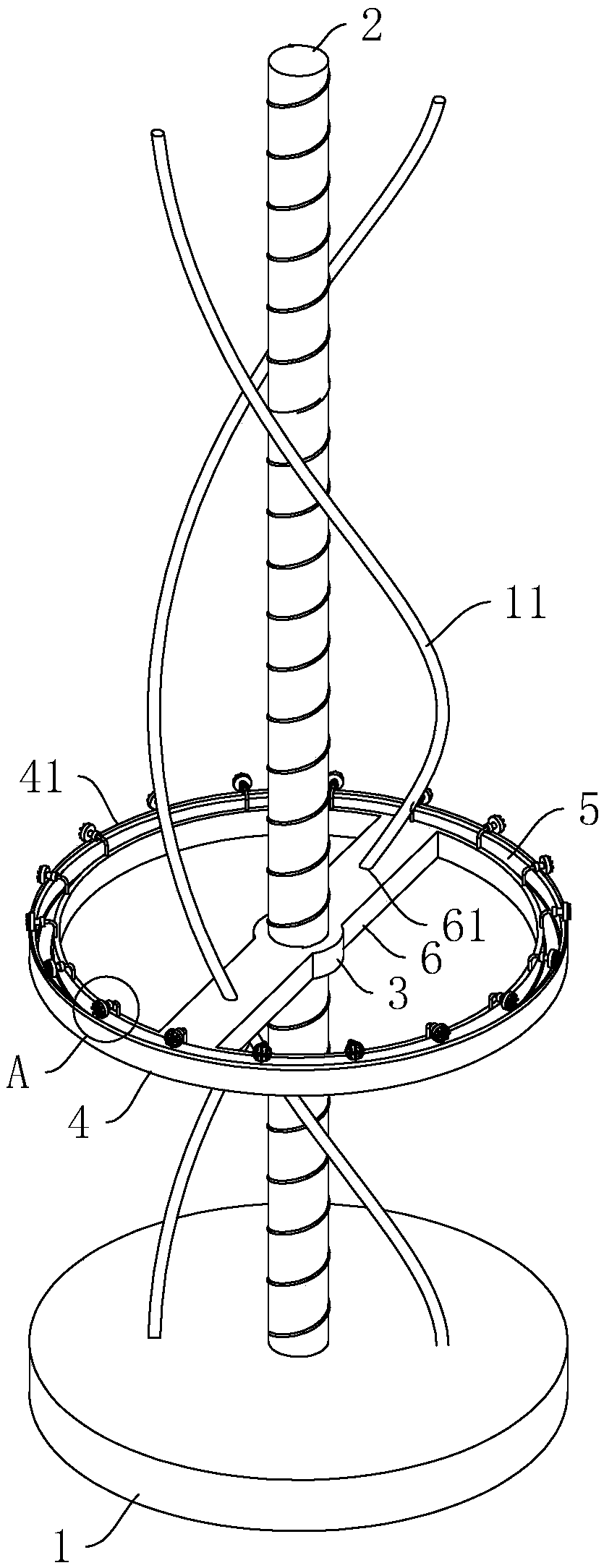

Ash clearing device for boiler flue

The invention discloses an ash clearing device for a boiler flue and relates to the field of power supplying boilers. The device comprises a base, and a transmission lead screw vertically and rotationally connected to the middle portion of the base; the outer wall of the transmission lead screw is sleeved with a nut, and the transmission lead screw and the nut form a lead screw pair; the device further comprises an installing ring, and a pair of supporting plates are arranged in front of the inner wall of the installing ring and the outer wall of the nut; a circle of scraping plate used for tightly abutting against the interior of the flue is arranged at the outer edge position of the upper end face of the installing ring, and the upper end face of the installing ring is further provided with a circle of containing groove; a pair of guiding rods are vertically arranged on the base; and the pair of supporting plates are each provided with a guiding hole for the corresponding guiding rodto penetrate through. The ash clearing device for the boiler flue has the following beneficial effects that by arranging the high-automatic device to achieve automatic movement of the scraping plate,the scraping plate is utilized for scraping and stripping oil stains on the inner wall of the flue, the clearing effect of the inner wall of the flue is effectively improved, so that the ash clearingprocess of the flue is more thorough, and the cleanness degree of the inner wall of the flue is improved.

Owner:杭州航民江东热电有限公司

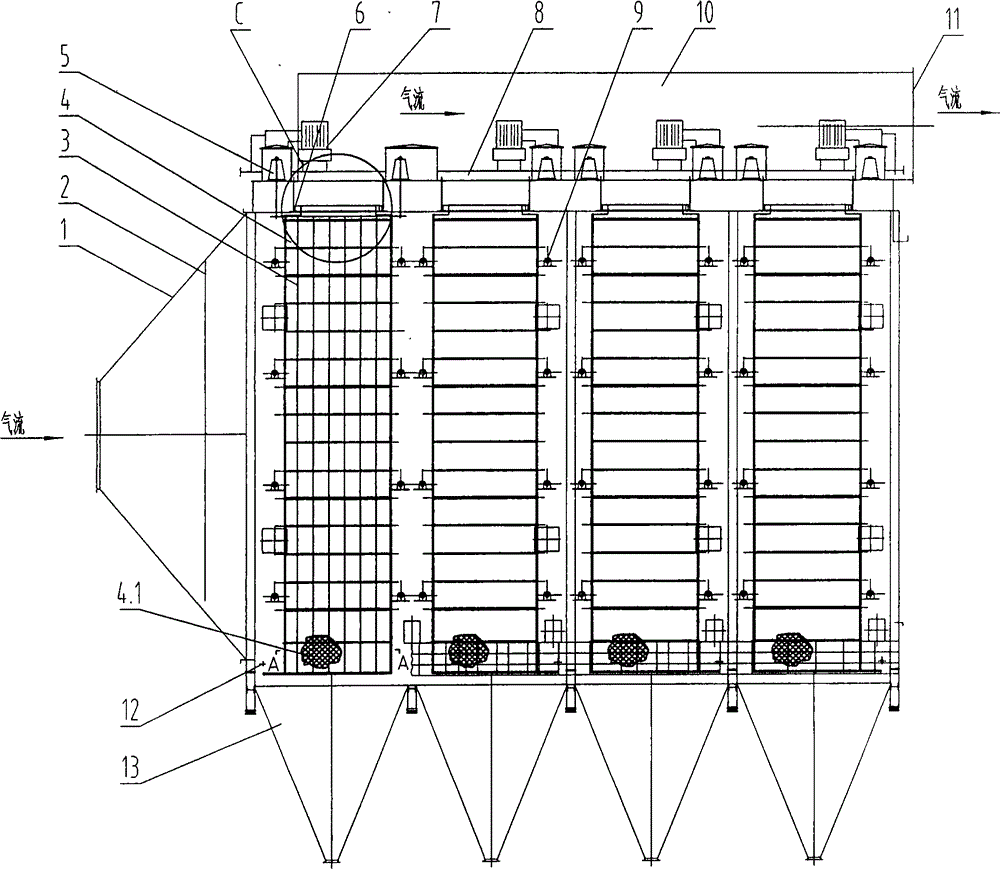

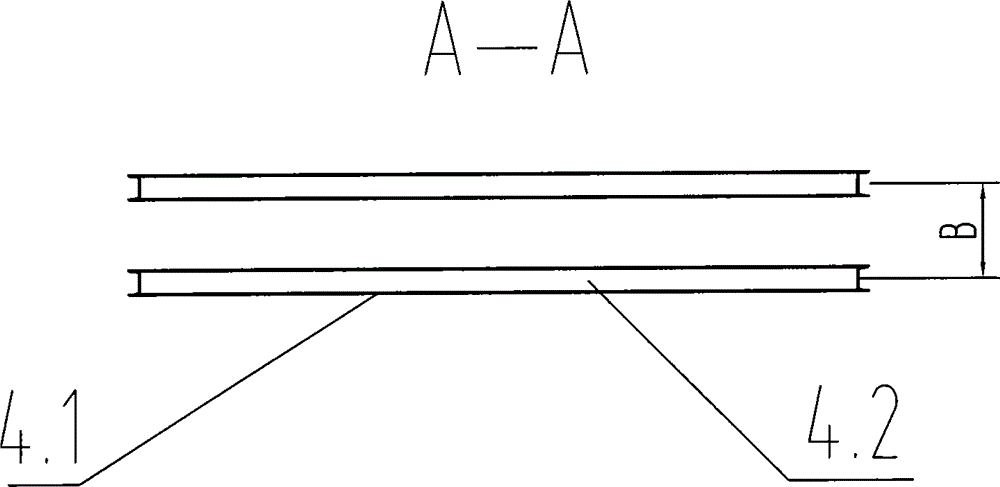

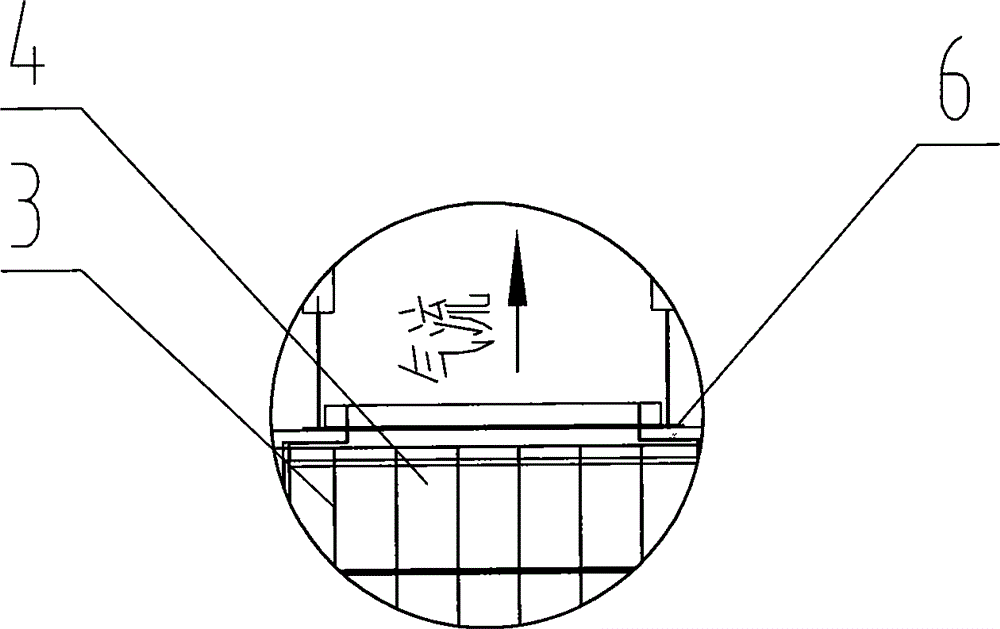

Filter plate type electrostatic precipitator

InactiveCN104668096APlay a filtering roleIncrease collection speedElectrode constructionsElectrodes cleaningElectric fieldAirflow

The invention relates to a filter plate type electrostatic precipitator. An anode row of the precipitator consists of a plurality of parallelly arranged box type filter plates; the box type filter plates are suspended on a suspending beam in a precipitator shell and are in alternative arrangement with a discharge electrode row, so that the filter plate box bodies configured in the shell and the discharge electrode row suspended among the filter plates form positive and negative electrode systems of the electrostatic precipitator; rapping devices are arranged at two sides of the cathode row and the anode row for rapping the cathode row configured at the electrode interval B and the filter plate box bodies periodically; upper opening ends of the filter plate air ducts are communicated with the air exhaust channels at the top of the precipitator; an electric field and a metal filter plate form a composite dust precipitation chamber, and dust attached to the outer surface of the filter plate falls into a dust hopper. According to the invention, the bidirectional dust precipitation under the action of electric field power and air flow power does not generate secondary dust flying; the system resistance is relatively low, and is less than or equal to 500Pa; the dust filtering and precipitation speed is improved by 60 times; the service life of a filter cartridge can reach 10 years; the dust precipitation efficiency Eta is greater than or equal to 99.95%; the absorption of fine dust (not greater than 1 micron) can meet the PM2.5 emission requirement.

Owner:BODI WEAPON MAKES

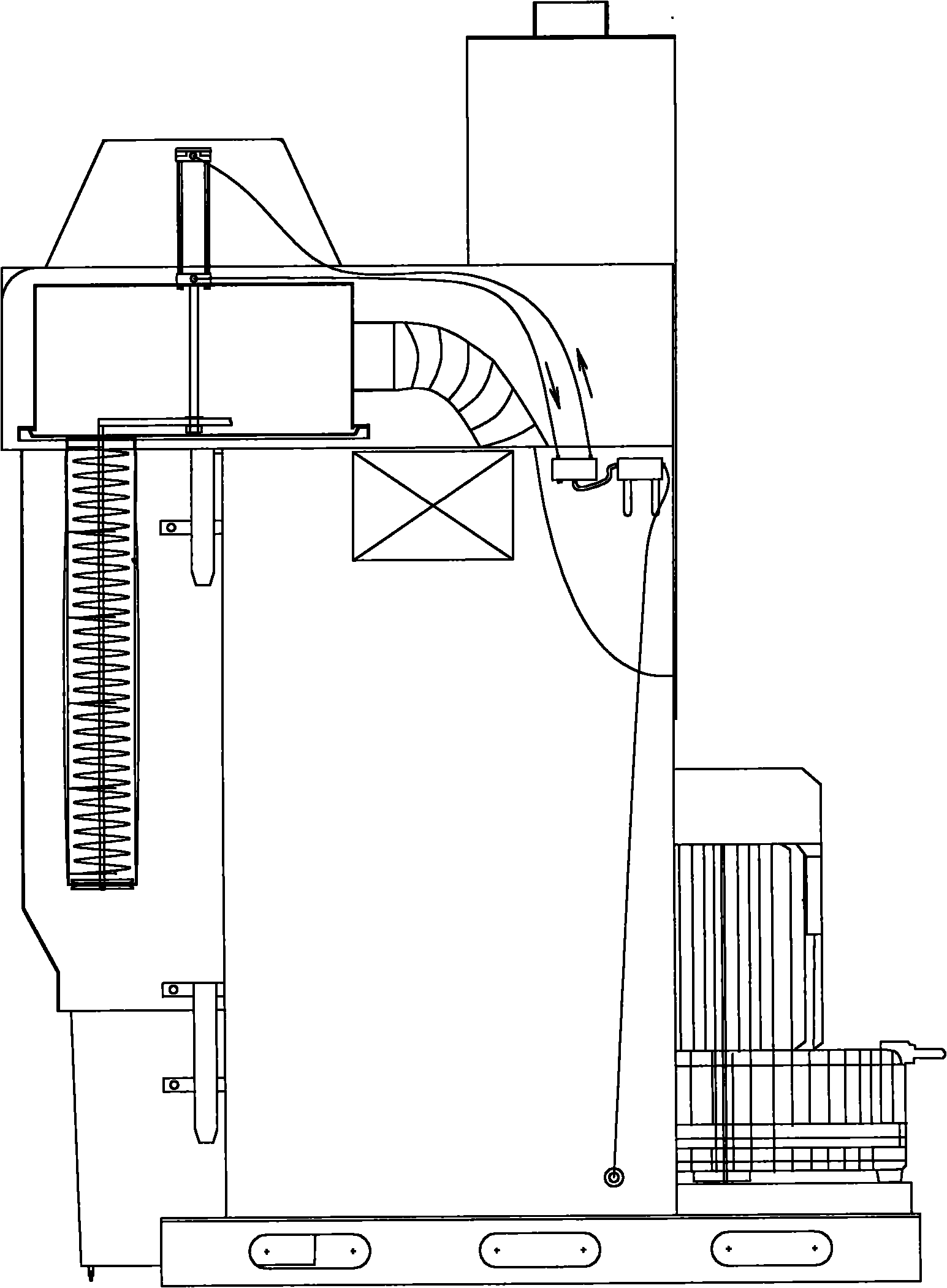

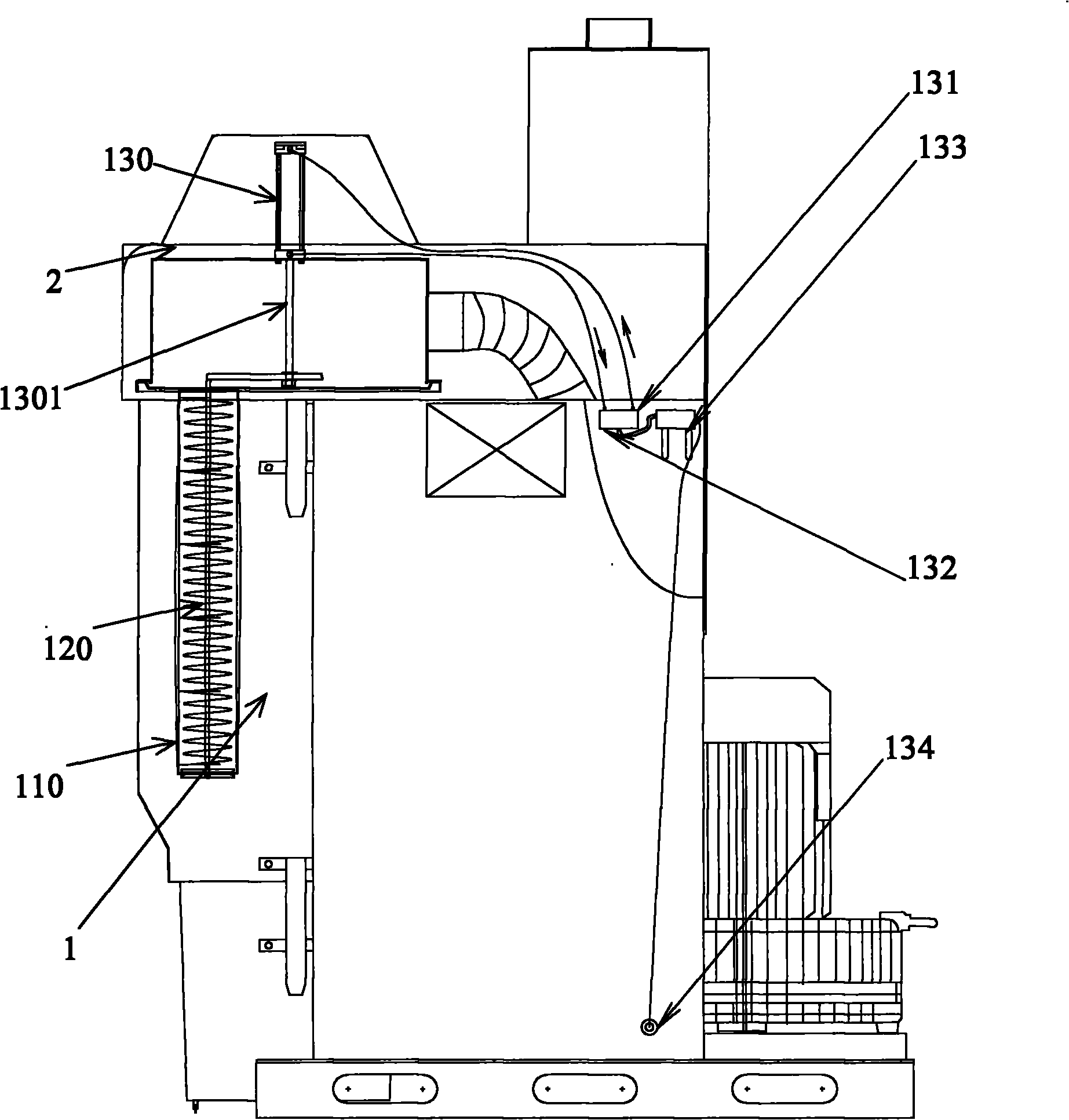

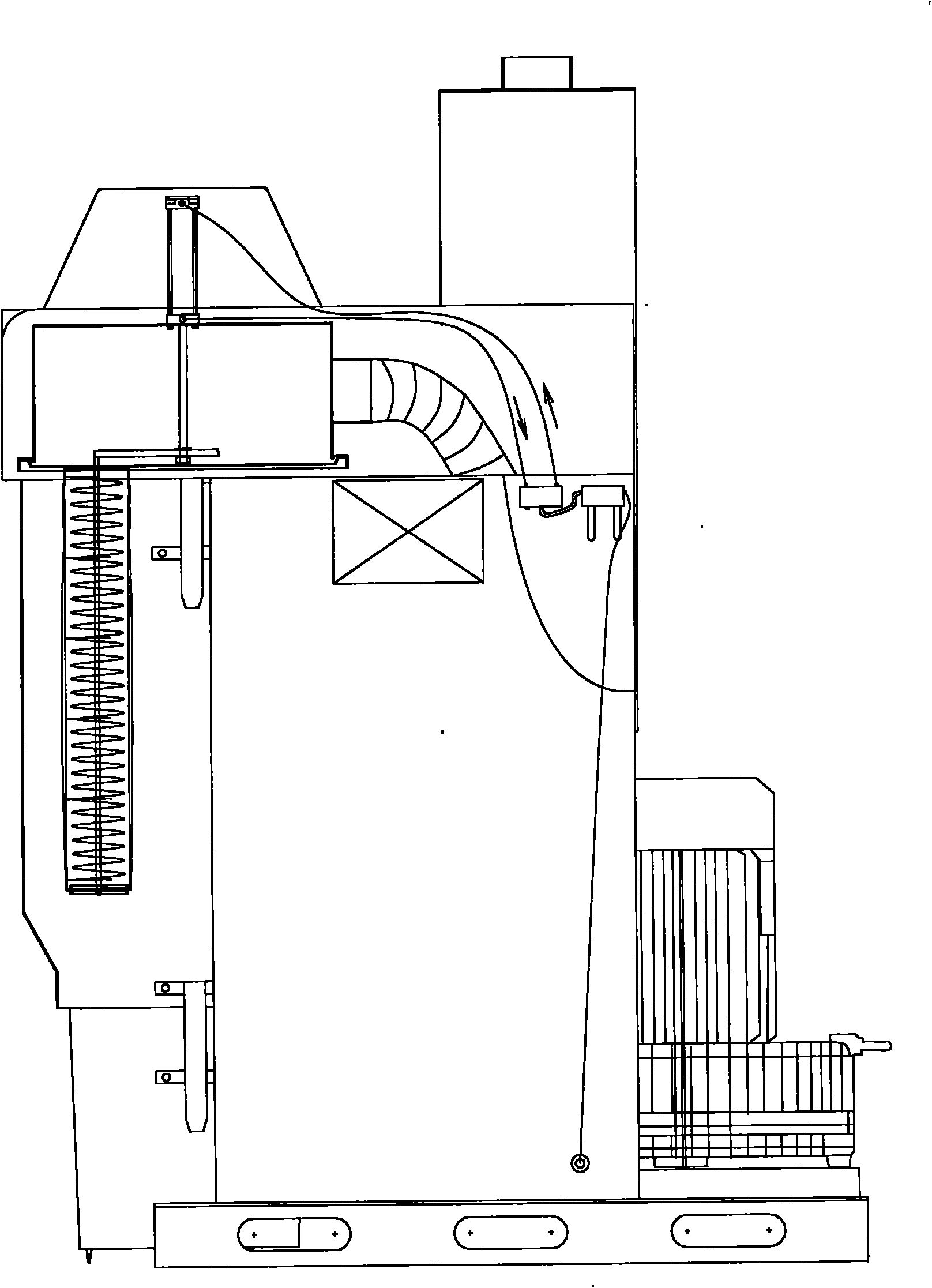

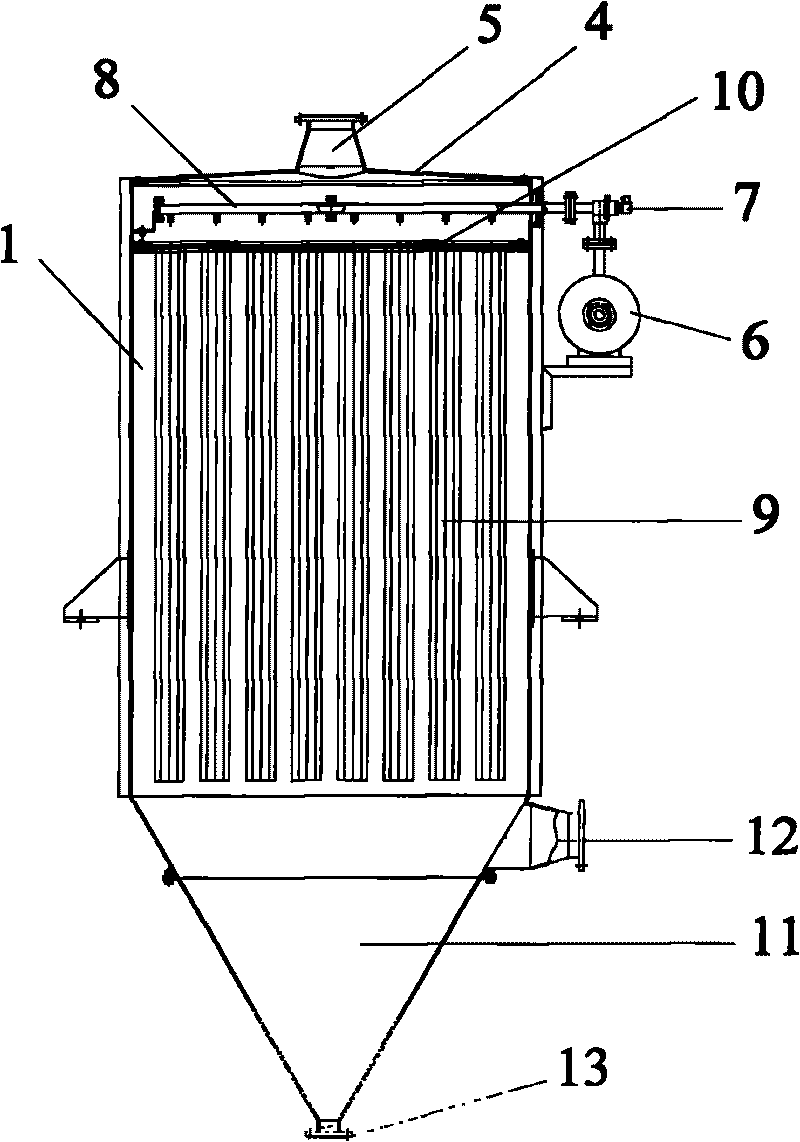

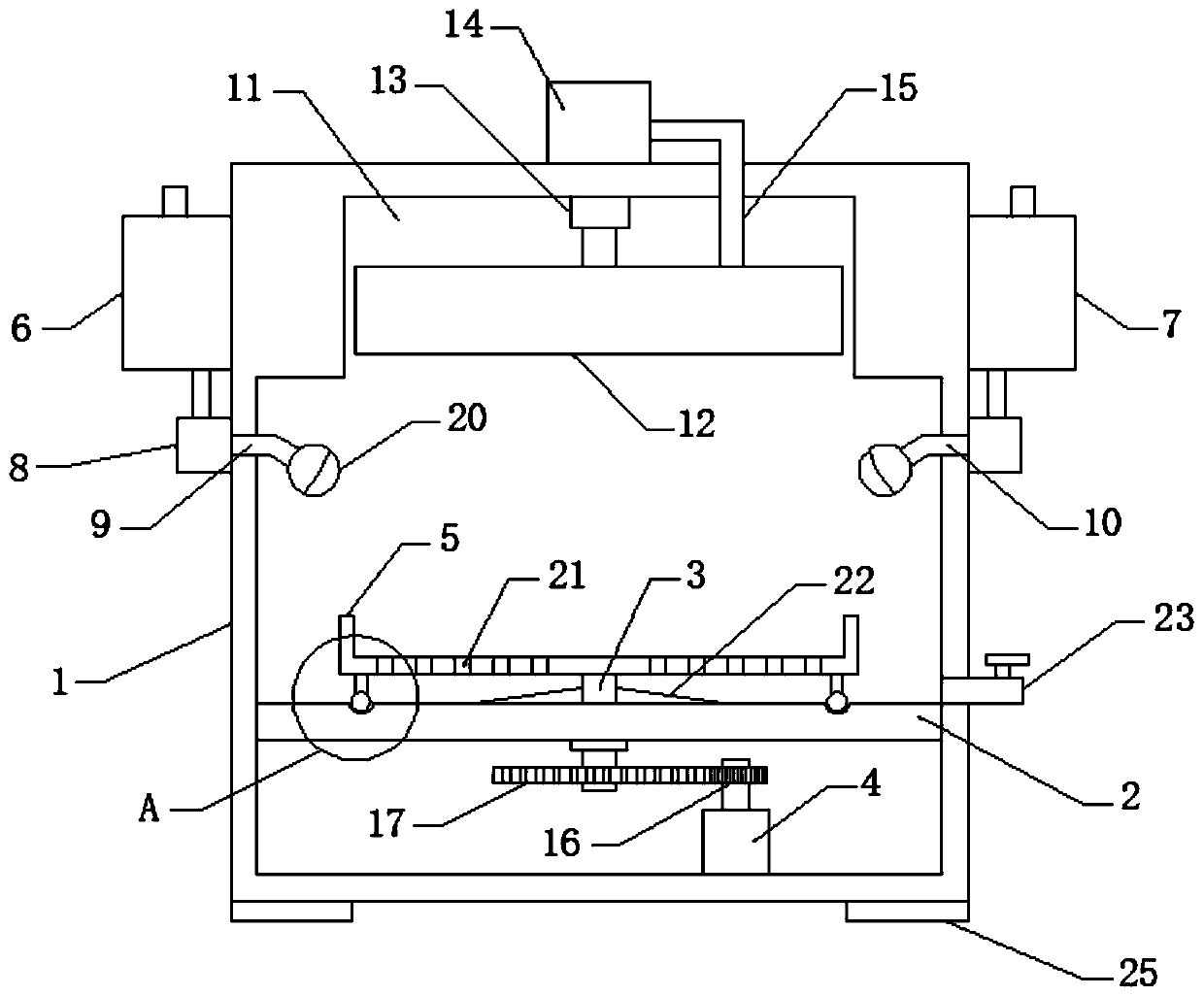

High negative pressure welding smoke dust purification device and deashing method thereof

InactiveCN101966634AImprove cleanlinessThorough cleaningDispersed particle filtrationWelding/cutting auxillary devicesBaghouseEngineering

The invention discloses a high negative pressure welding smoke dust purification device and a deashing method thereof. A purifying and dust removing bin inside the high negative pressure welding smoke dust purification device comprises a bag-type dust remover; the bag-type dust remover comprises a pneumatic deashing part; the pneumatic deashing part comprises a mechanical part and a pneumatic control part, wherein the mechanical part comprises a filter bag, a pull rod and an air cylinder, wherein the filter bag is a constituent part of the bag-type dust remover, and a piston rod of the air cylinder is connected with the filter bag through the pull rod. When the mechanical part is started to enter a deashing procedure by the pneumatic control part, the deashing method comprises the following steps that: the piston rod of the air cylinder moves upwards to drive the pull rod to move upwards, and the pull rod lifts the filter bag so that the filter bag is changed from an unfolding state to a folding state; the piston rod of the air cylinder moves downwards to drive the pull rod to move downwards after moving upwards to the limit position of the air cylinder, and the pull rod pushes downwards the filter bag so that the filter bag is restored to the opening state. The invention has better deashing effect and more thorough deashing because the deashing part adopts an air cylinder vibrating type deashing mode.

Owner:南通克莱克空气处理设备有限公司

Environmentally friendly glass cleaning and drying machine

InactiveCN109107986AImprove mobilitySimple structureDrying solid materials without heatDrying gas arrangementsWater storageWater filter

The invention discloses an environmentally friendly glass cleaning and drying machine. The cleaning and drying machine includes a machine frame; a feeding plate is arranged on the left side of the machine frame; a workbench is arranged in the middle part of the machine frame and provided with a conveying device; a draining bin is arranged under the conveying device; a water filtering device is arranged below the left side of the draining bin and is provided with filtering plates; a handle is arranged on the left side of the water filtering device; a water storage bin is arranged under the water filtering device; the top of the machine frame is provided with a crossbeam; a first fan is arranged on the upper left side of the crossbeam; a first gas pipe is arranged under the first fan; a first wind gun is arranged under the first gas pipe; a first motor is arranged on the right side of the first fan; a first output main shaft is arranged under the first motor; and a hairbrush is arrangedunder the first output main shaft. The cleaning and drying machine is simple in structure and convenient in operation; and used sewage can be conveyed to the water storage bin for reuse after being filtered by the water filtering device, and therefore, recycling effects and environmentally friendly and saving functions can be achieved.

Owner:黄清平

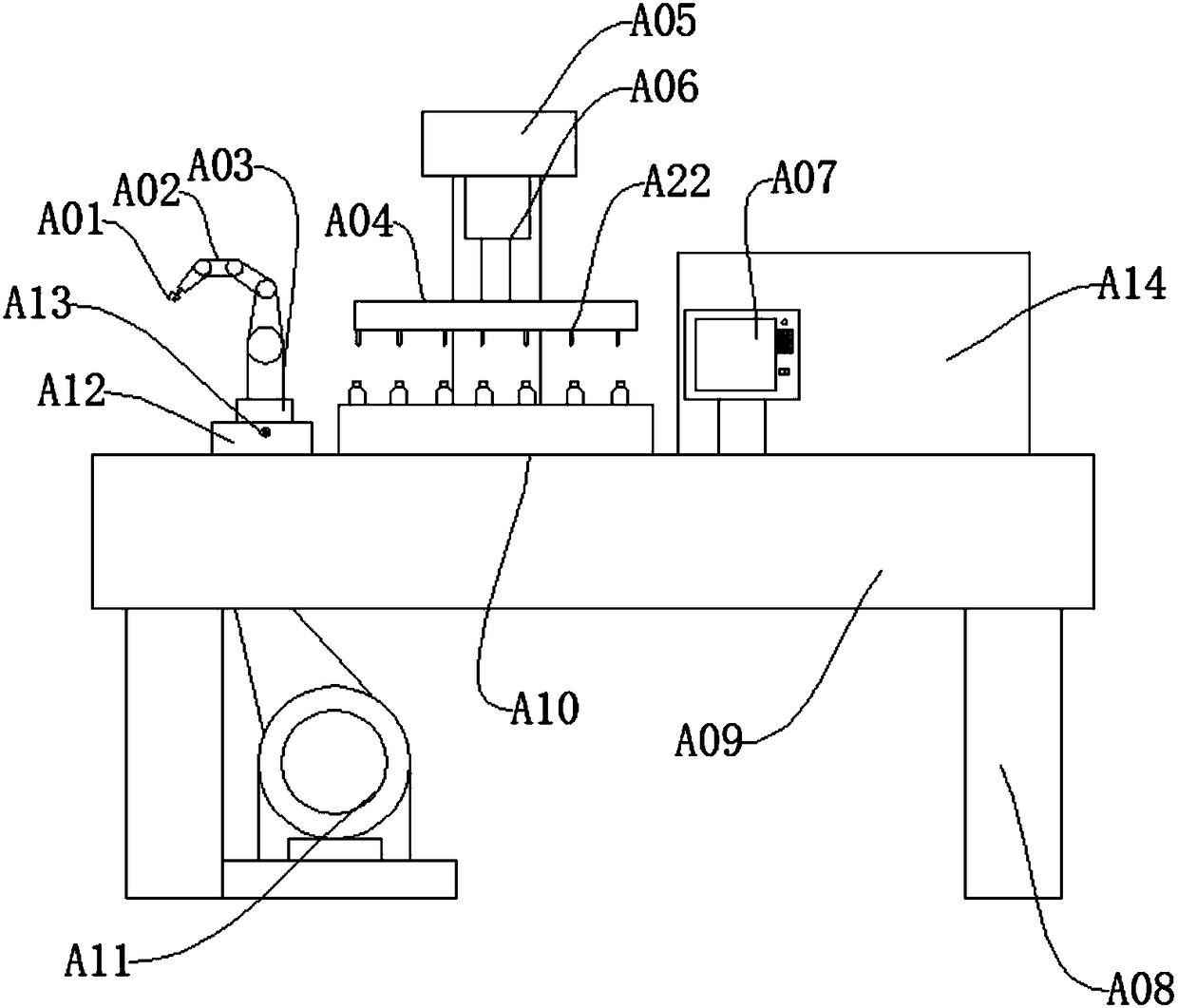

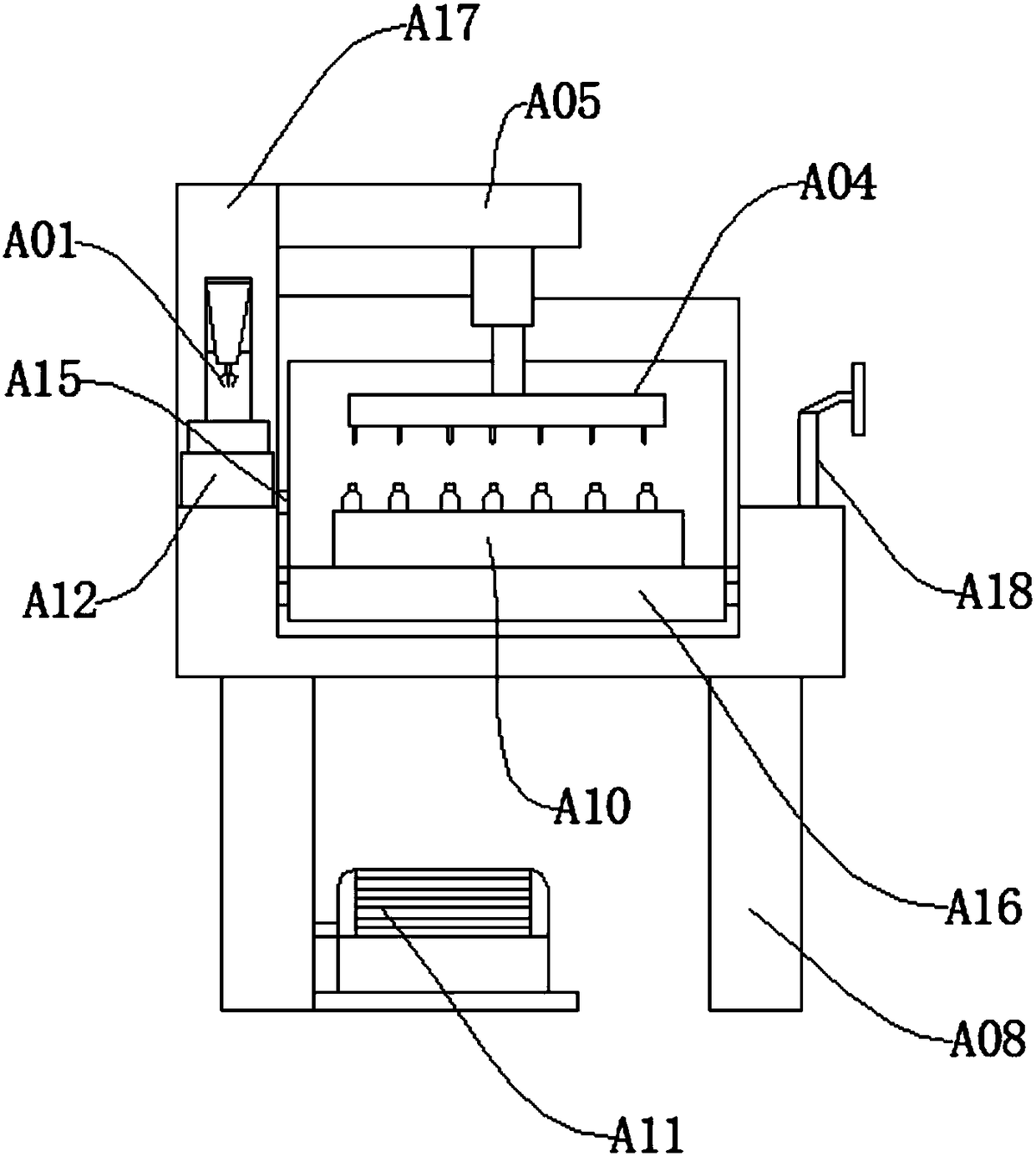

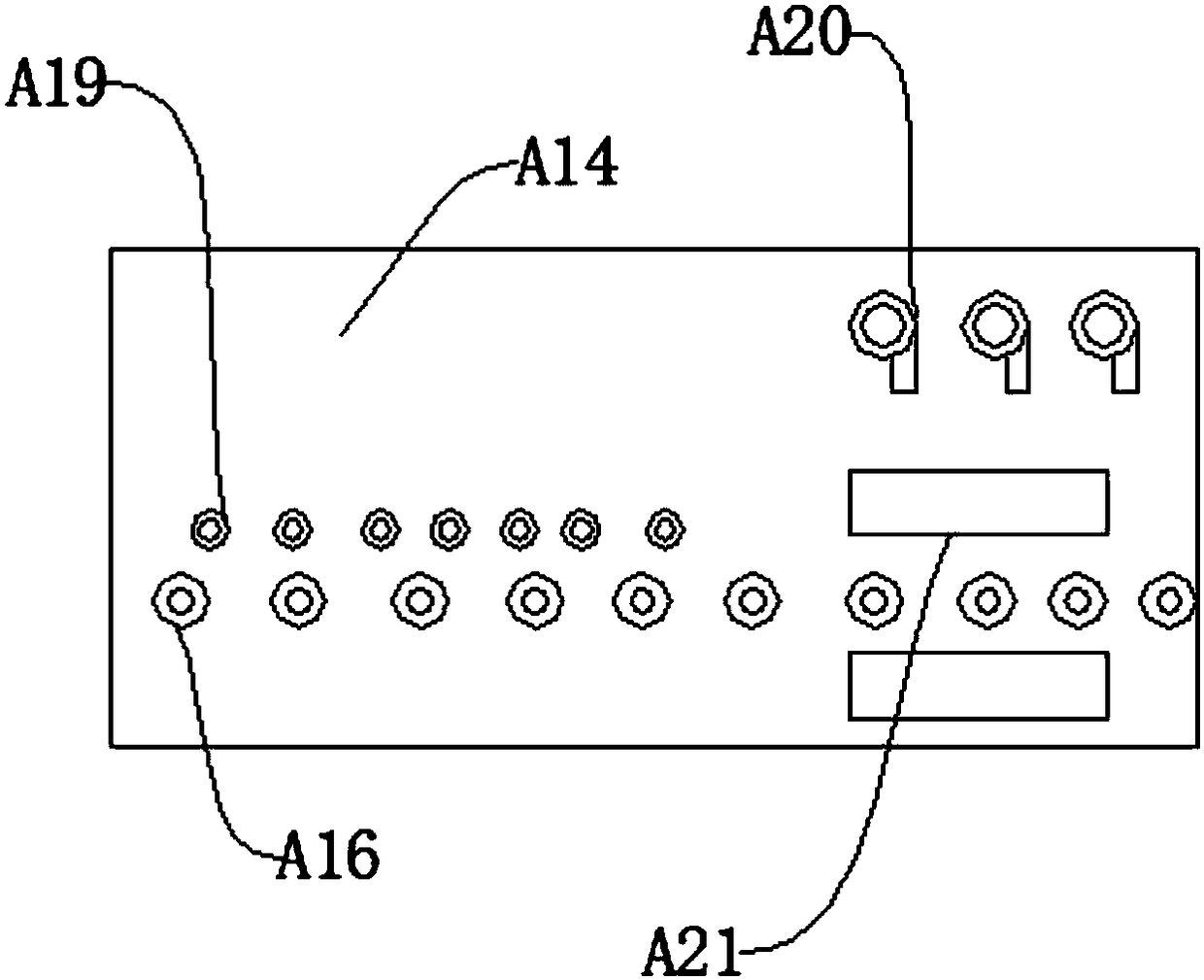

Perfume packaging bottle inspection cleaning device and use method thereof

InactiveCN108262321AImprove cleaning efficiencyImprove cleaning qualityHollow article cleaningSortingBiochemical engineeringSpray nozzle

The invention provides a perfume packaging bottle inspection cleaning device and a use method thereof. The perfume packaging bottle inspection cleaning device comprises a machine tool, a work box, anupright post and a laser sensor, wherein a wheel roller conveying frame is arranged on the machine tool; a packaging bottle conveying box is arranged on the wheel roller conveying frame; an in-bottleflushing device is arranged above the packaging bottle conveying box; a flushing spray head is arranged at the lower part of the in-bottle flushing device; a telescopic rod is arranged above the in-bottle flushing device; the work box is arranged above the telescopic rod, and is arranged on the upright post; an ultrasonic wave generator is arranged on the upright post. The cleaning device has theadvantages that ultrasonic waves are used for inspecting perfume packaging bottles; tiny spray nozzles go deep into the bottom of the packaging bottles for flushing; a drying device is arranged; the perfume packaging bottles are subjected to a series of operation such as inspection, cleaning and drying; the cleaning efficiency and the quality of the perfume packaging bottles are improved to a great degree.

Owner:安吉美庭纺织品贸易有限公司

Reverse blowing bag type dust remover

InactiveCN102895826ASuitable for dust removalImprove ventilationDispersed particle filtrationReciprocating motionWaste management

The invention provides a reverse blowing bag type dust remover comprising an upper box body and a lower box body. A dust removing chamber is arranged inside the upper box body; the dust removing chamber is communicated with the outside through an air inlet on the upper box body; a dust removing bag is arranged inside the dust removing chamber; the opening of the dust removing bag is arranged on the lateral wall of the dust removing chamber; the dust removing chamber is divided into a plurality of relatively independent sub dust removing chambers; an air purifying chamber is divided into a plurality of relatively independent sub air purifying chambers; a combined air duct valve is connected with the lower part of each air purifying chamber; the composite air duct valve is a three-way valve and is connected with two air ducts of a reverse blowing air duct and a mixed air outlet channel; a sealing board is designed inside the combined air duct valve; and the sealing board does reciprocating motion to respectively seal and block the reverse blowing air duct and the mixed air outlet channel. The reverse blowing bag type dust remover provided by the invention is wide in application range and is suitable for removing dust in various heavy-dust fields. The reverse blowing bag type dust remover uses the sub chambers to efficiently reversely remove dust without stopping and removing the dust, and can be used for entirely removing the dust.

Owner:枣庄市邦众环保设备有限公司

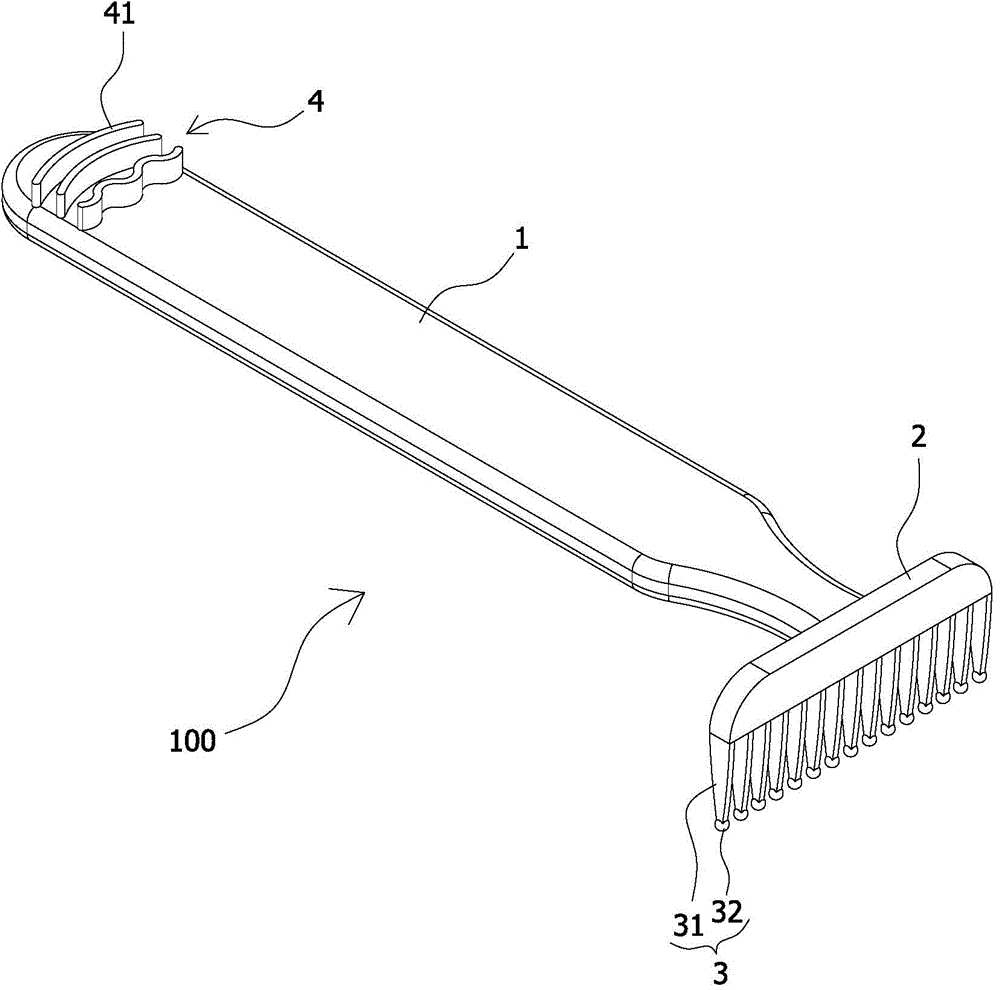

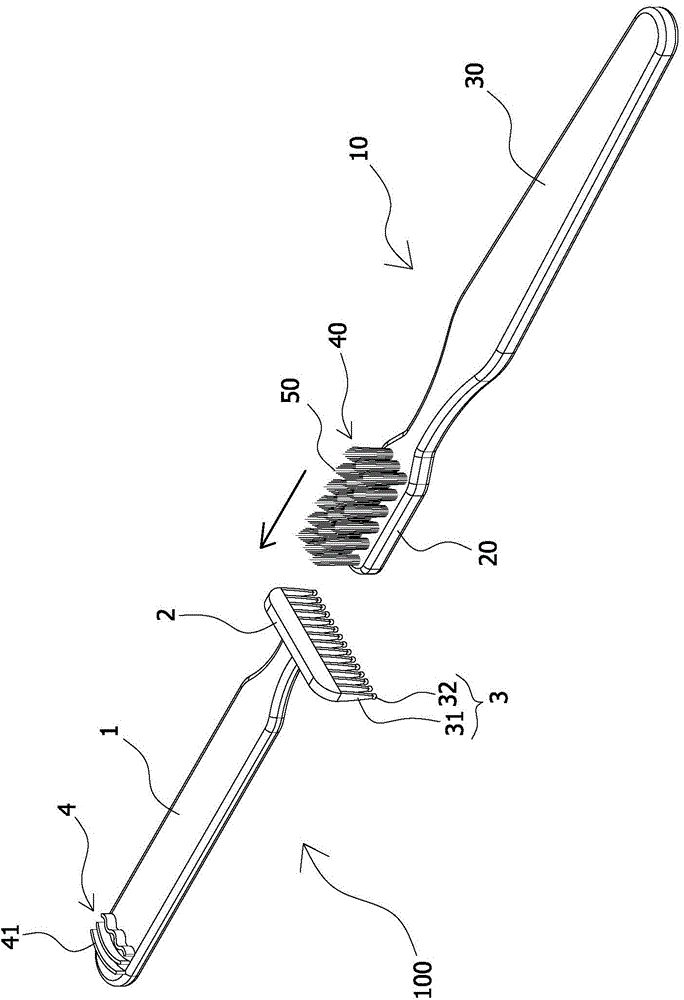

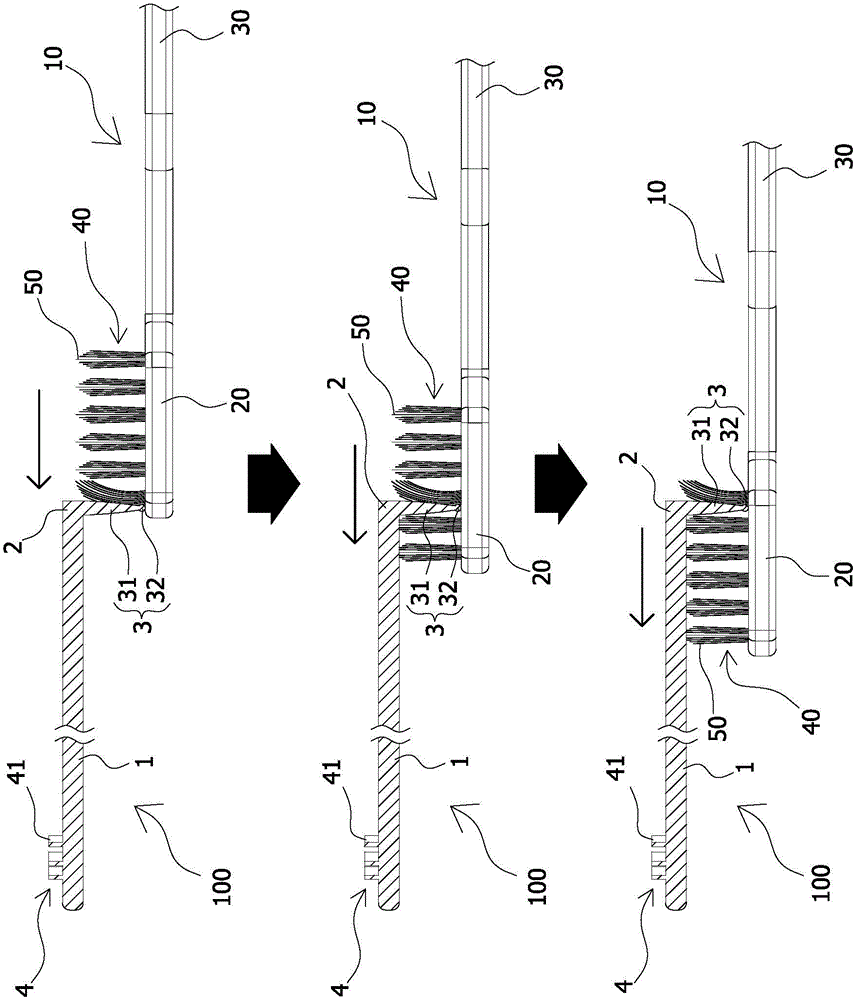

Quick cleaning device of hairs of toothbrush

The invention provides a quick cleaning device of hairs of a toothbrush. The cleaning device is convenient to use and capable of quickly cleaning hairs of a toothbrush, and comprises a handle part for a user to hold, a head which is arranged on one side of the hold part and kept horizontal, and at least one row of cleaning brushes arranged on the bottom side face of the head. The cleaning brushes comprise multiple brush rods which are provided with tenacity and arranged at equal intervals. The lengths of the brush rods are less than that of the hairs of the toothbrush. The cleaning brushes are capable of thoroughly pressing and cleaning the hairs of the toothbrush so as to keep the hairs clean all the time, thereby extending service lifetime of the toothbrush and preventing disease from entering the mouth.

Owner:刘国祯

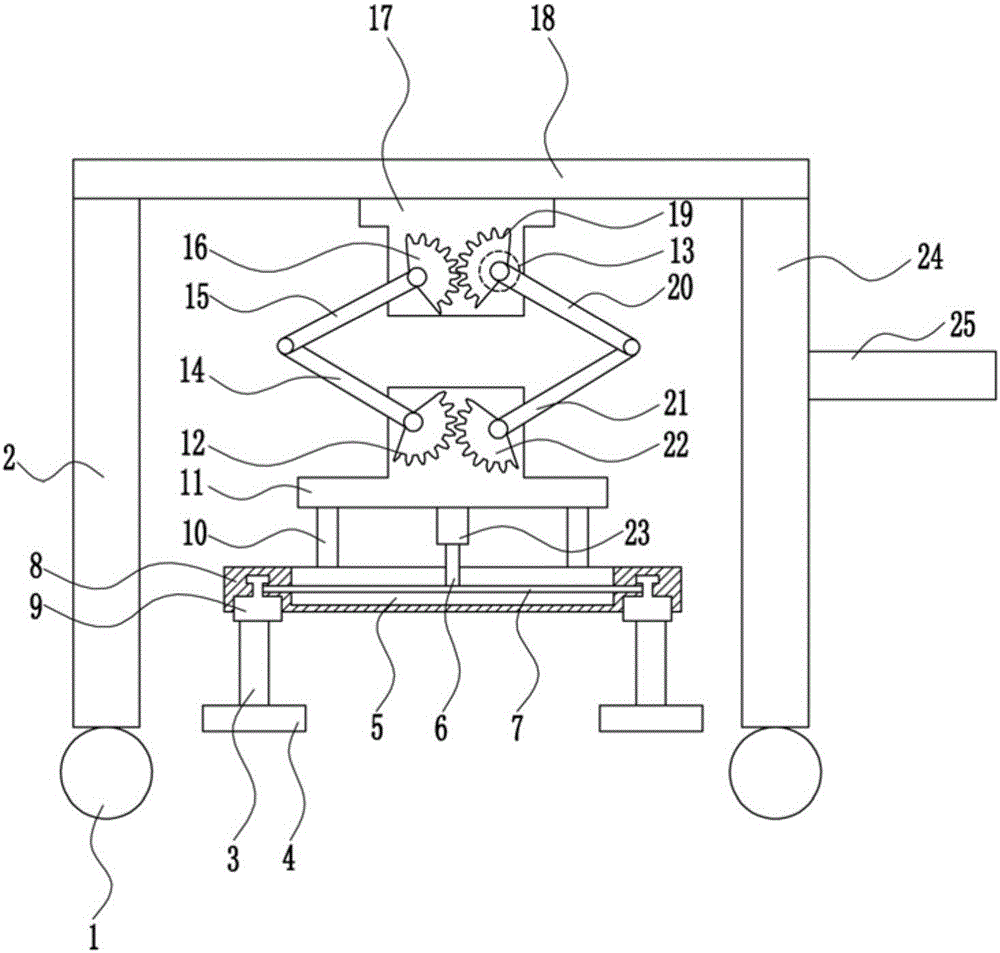

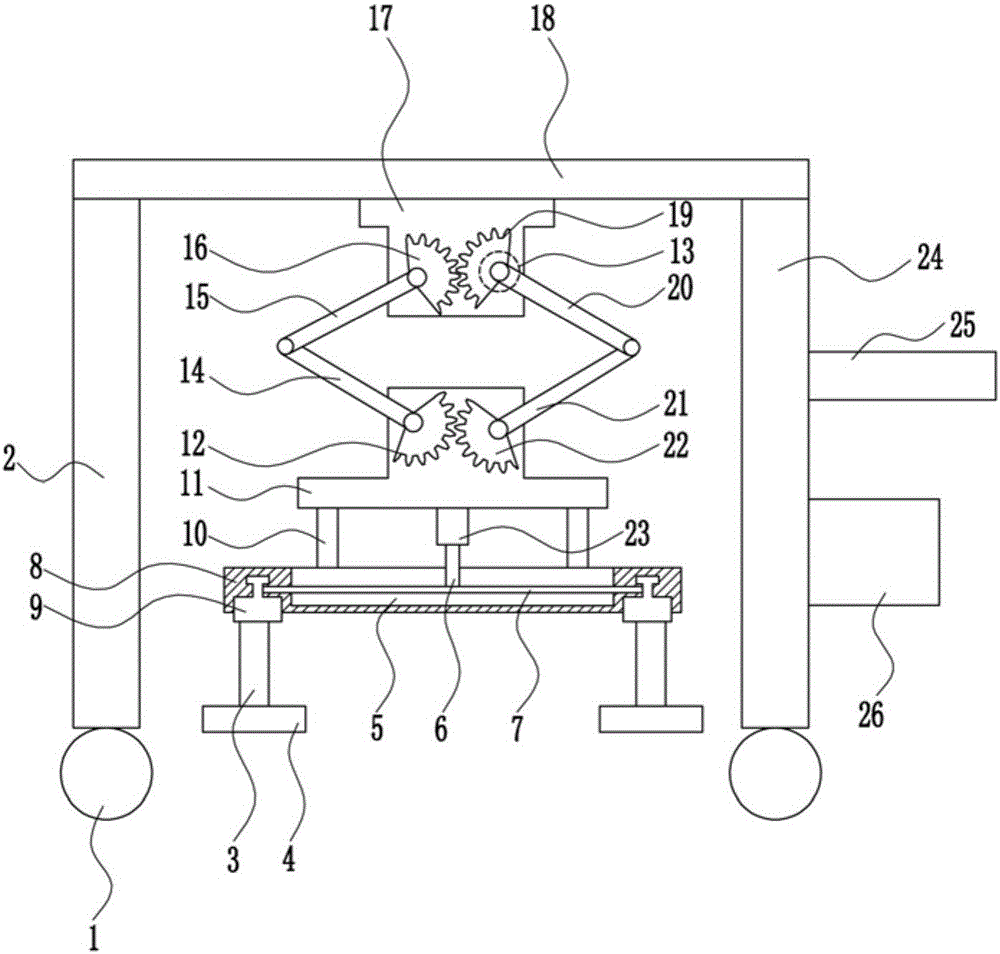

Road dust cleaning device for expressway

The invention relates to a road dust cleaning device, in particular to a road dust cleaning device for an expressway, and aims to solve the technical problem to provide a road dust cleaning device for the expressway, which can clean dust thoroughly and is high in dust cleaning speed and convenient to operate. In order to solve the technical problem, the invention provides the road dust cleaning device for the expressway. The road dust cleaning device comprises wheels, a left frame, a supporting rod, a dust collector, a cavity, a rotating rod, a connection rod, a circular sliding rail, a sliding block, a fixed rod, a first fixed seat, a first gear, a first motor, a first link rod, a second link rod, a second gear, a second fixed seat, a top plate, a third gear, a third link rod, a fourth link rod, a fourth gear, a second motor, a right frame and a push handle, wherein the wheels are arranged at the bottoms of the left frame and the right frame; the top plate is arranged at the tops of the left frame and the right frame; the second fixed seat is arranged at the center of the bottom of the top plate. The road dust cleaning device for the expressway achieves the effects of thorough dust cleaning, high dust cleaning speed and convenience in operation.

Owner:安徽兴元建设集团有限公司

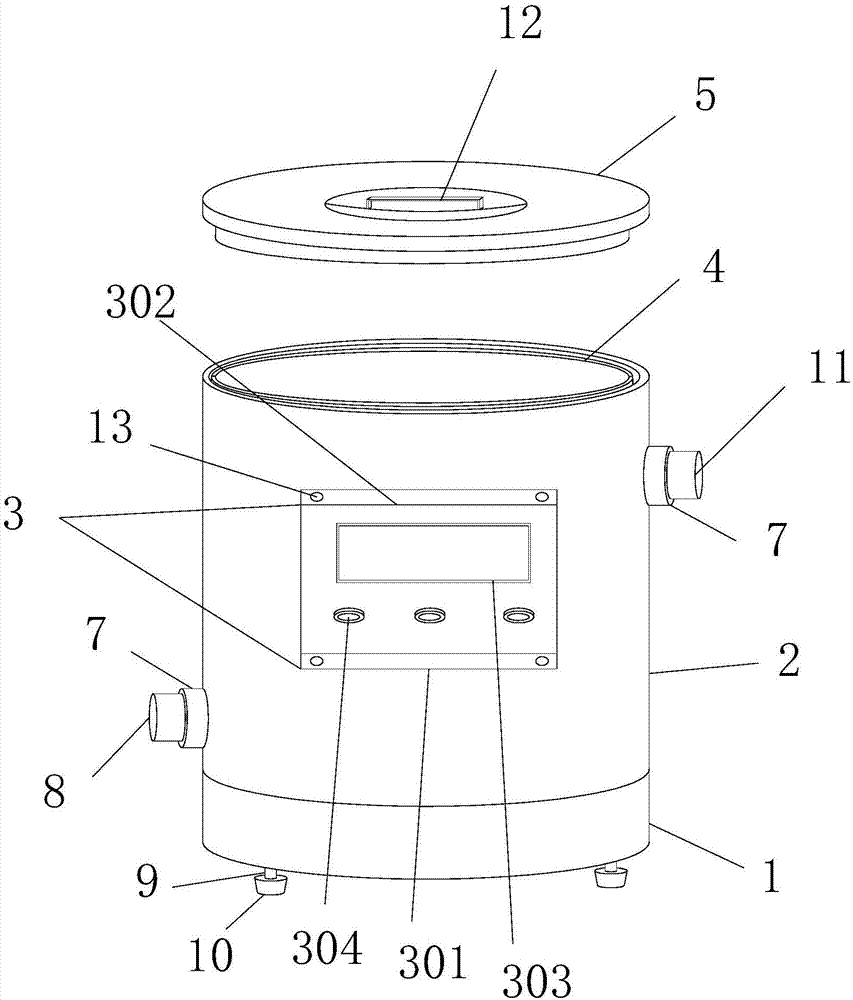

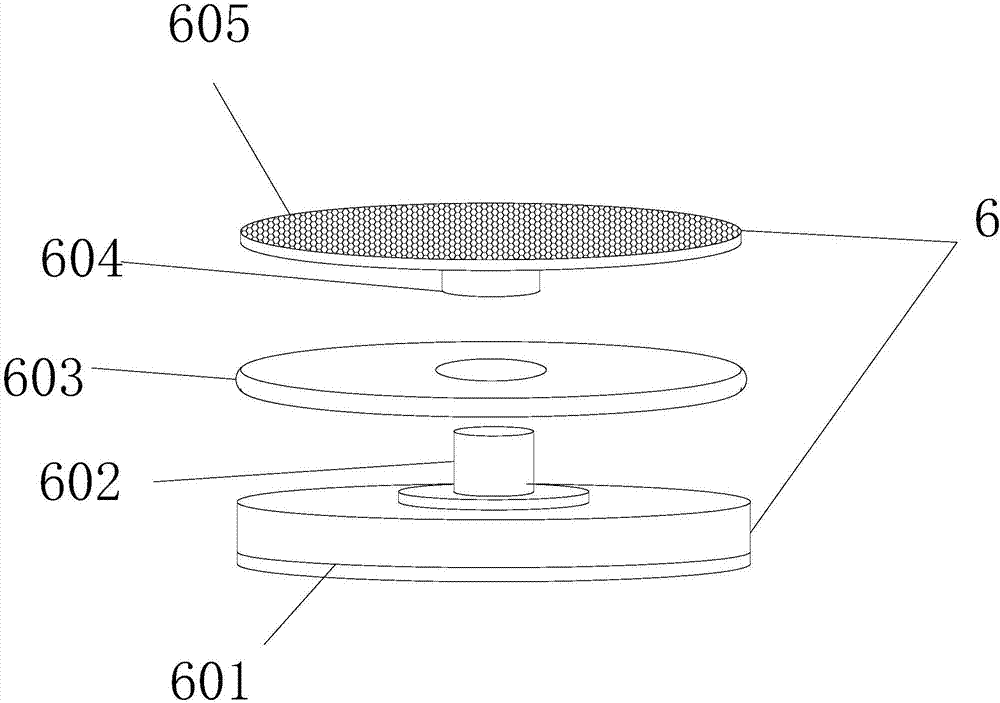

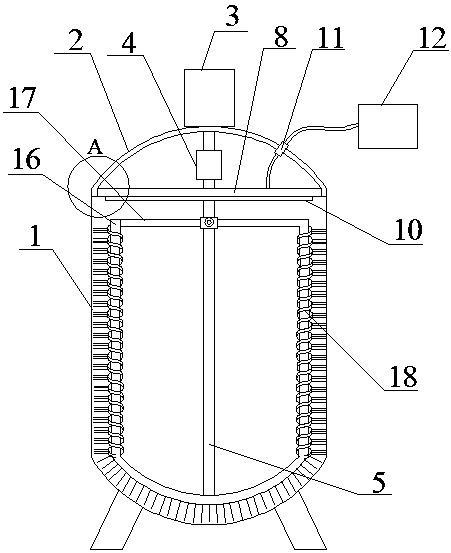

Artificial diamond cleaning device

The invention discloses an artificial diamond cleaning device. The structure of the artificial diamond cleaning device comprises a base, a barrel body, an ultrasonic controller, an inner barrel, an upper cover, a rotary cleaning device body, a closing valve, a water outlet pipe, screws, supporting feet, a water inlet pipe, a handle and screws. The barrel body is arranged above the base and internally provided with the inner barrel. The base is connected with the upper cover through the barrel body. The handle is welded to the upper cover. The artificial diamond cleaning device has the beneficial effects that the ultrasonic controller is arranged and composed of a machine base, a control panel, a display screen and control buttons, the equipment is controlled to conduct ultrasonic cleaning on artificial diamond in the inner barrel through the control buttons, and the rotary cleaning device body is matched, so that the cleaning work is more thorough.

Owner:ANQING KAILI DIAMOND TECH

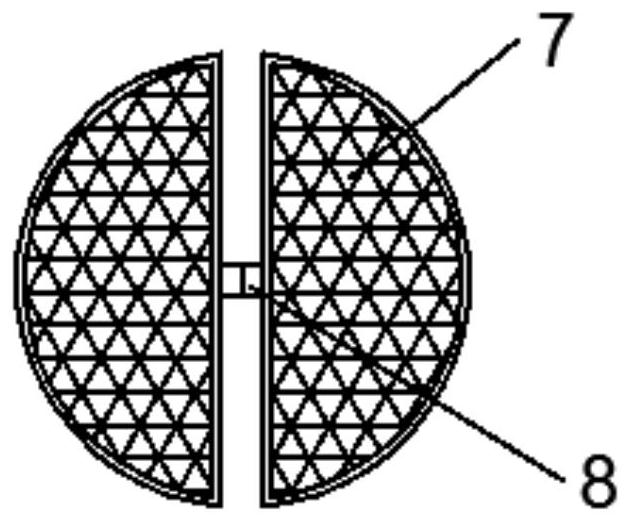

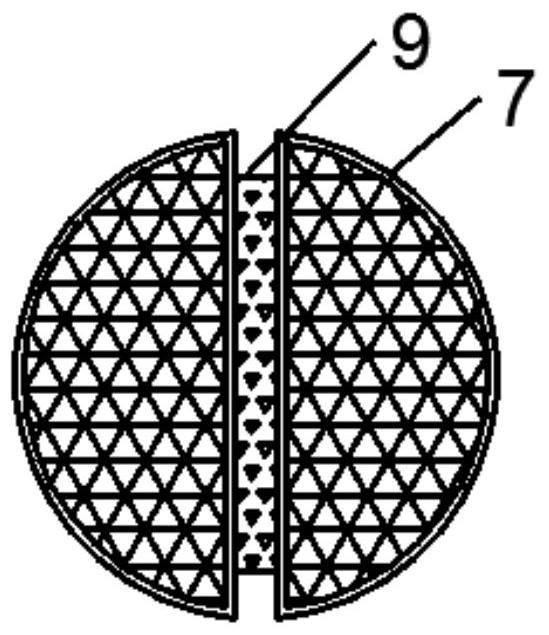

Algae scum treatment device based on special ceramic microspheres

ActiveCN112807856APurify thoroughlyEvenly distributedEnergy based wastewater treatmentFiltration separationMicrosphereElectric machine

The invention discloses an algae scum treatment device based on special ceramic microspheres. The device comprises: a first sewage tank which is internally provided with a first water pump; a filter box, wherein a through hole is formed in the bottom of the filter box, and the filter box communicates with the first water pump; a first base which is arranged at the bottom of the filter box, wherein a rotating motor is arranged in the first base, and a rotating shaft of the rotating motor penetrates through the through hole; a second base, wherein the bottom surface of the second base is connected with the rotating shaft; a filter which is a box body of which the surface is hollowed out and the interior is filled with special ceramic microspheres, wherein the filter is connected with the second base, and a vertical through groove is formed in the vertical center line position of the filter; two semicircular filter screens arranged horizontally and symmetrically, wherein the round edges of the two semicircular filter screens deviate from each other, the straight edges of the two filter screens are connected through a connecting rod, and the connecting rod is connected with the through groove in an up-down sliding mode; two first telescopic rods which are arranged on the second base, wherein the extension end of each first telescopic rod is connected with one filter screen; and a water purifying tank which is communicated with the second water pump. The special ceramic microspheres in the filter of the device have a good adsorption effect on algae scum.

Owner:JINGDEZHEN UNIV

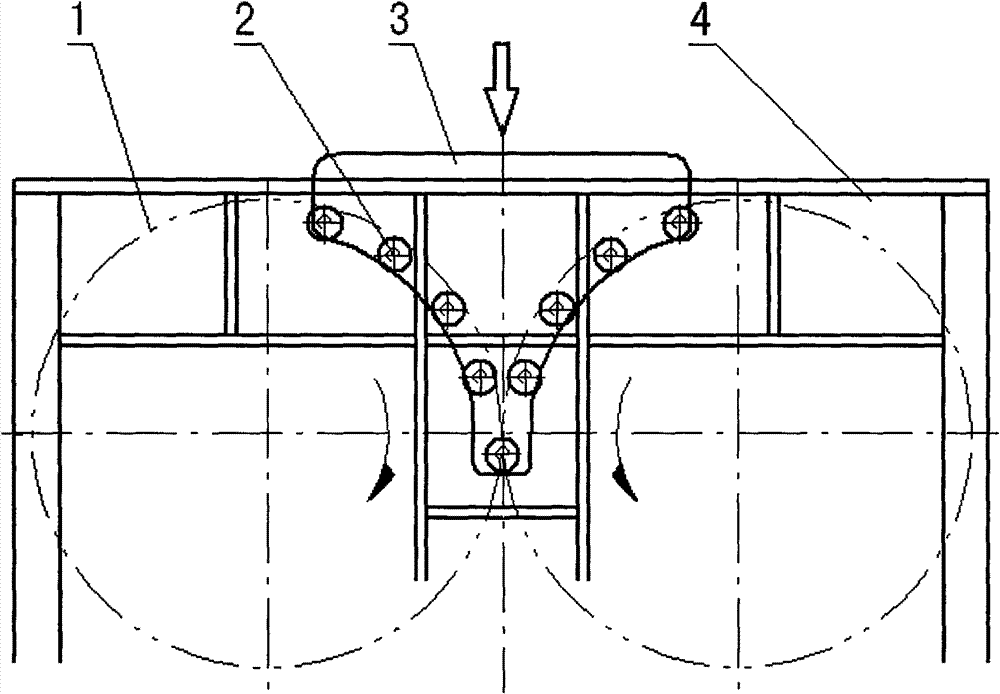

Moveable side striker plate for double-drum drier material pond

InactiveCN102772908APrevent leakage of raw material liquidEasy to checkEvaporator accessoriesEngineeringLinear motion

The invention discloses a moveable side striker plate for a double-drum drier material pond, comprising a side striker plate, an end wallboard, a sealing unit and a plurality of push rod assemblies with same structure, wherein the side striker plate is produced by compounding two kinds of materials with different properties; the end wallboard is fixedly arranged at the outer side of the end surfaces of two drums of the double-drum drier; each set of the push rod assembly comprises a push rod drive unit and a push rod, wherein the push rod drive unit is fixedly arranged on the outer side plate surface of the end wallboard, one end of the push rod is fixedly connected with the side striker plate, and the other end of the push rod is movably connected with the matched push rod drive unit through the through holes of the sealing unit and the end wallboard. According to the invention, the moveable side striker plate disclosed in the invention can make a bidirectional horizontal linear motion under control, can timely adjust the clearance between the moveable side striker plate and the end surfaces of two drums and effectively prevent the leakage of raw material fluids, is convenient for checking and changing easily damaged parts, and is beneficial for thoroughly cleaning the device.

Owner:无锡捷尔机械有限公司

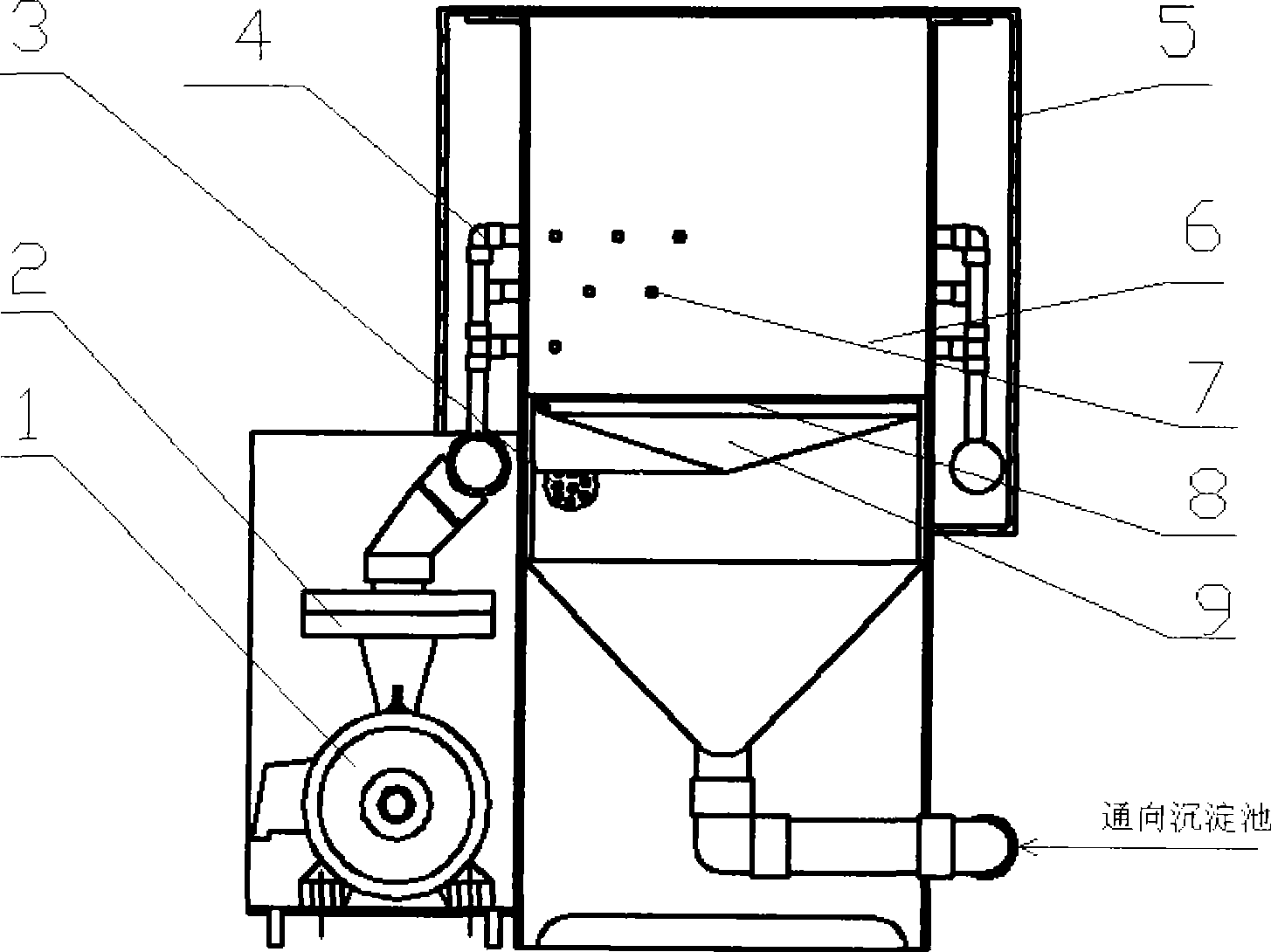

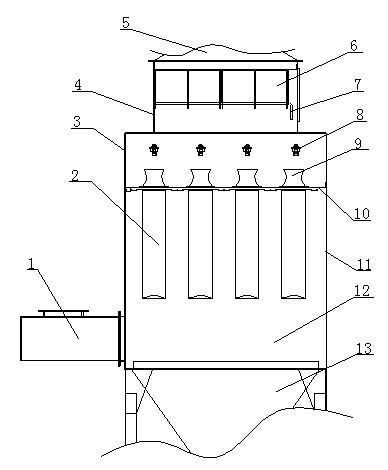

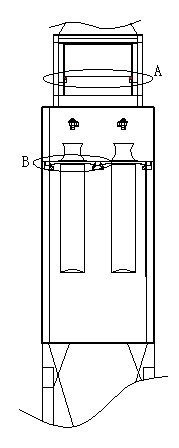

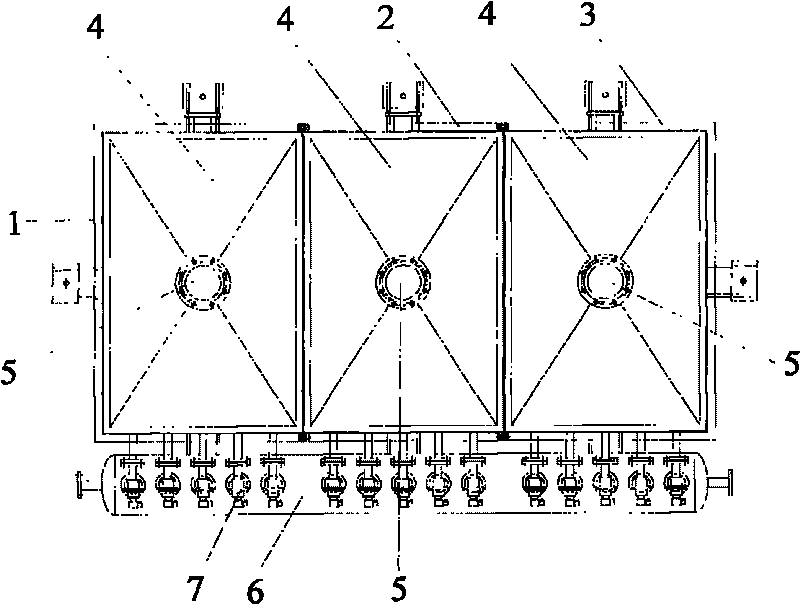

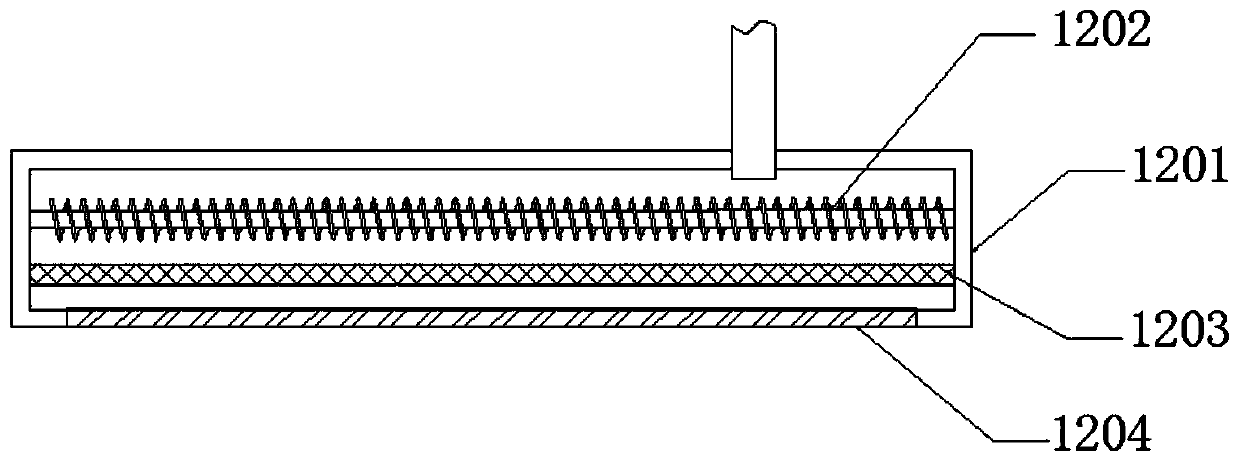

Air box pulse bag deduster

InactiveCN101711936AImprove cleanlinessImprove dust removal efficiencyDispersed particle filtrationBuffer tankEngineering

The invention relates to an air box pulse bag deduster. The deduster is formed by parallelly connecting a left box, a middle box and a right box, wherein the top of the box is provided with an upper cover plate; an air outlet is formed on the upper cover plate; the side part of the box is provided with an air buffer tank. The air buffer tank is connected with an air blowpipe via a pulse electromagnetic valve; and the air blowpipe is arranged on the upper part of the box, the interior of the box is provided with a filter bag, the upper part of the filter bag is connected with the box via a filter bag card, the lower part of the box is connected with a dust hopper, the upper part of the dust hopper is provided with an air inlet, and bottom of the dust hopper is provided with a dust discharge opening. Compared with the prior art, the air box pulse bag deduster overcomes shortcomings of conventional pulse dedusters and section reverse dedusters, and achieves the aim of completely removing dust by blowing once. The air box pulse bag deduster has advantages of strong chemical resistance, high filter efficiency, low discharge, large processing air flow, low pressure drop and long service life.

Owner:上海竟茨环保科技有限公司

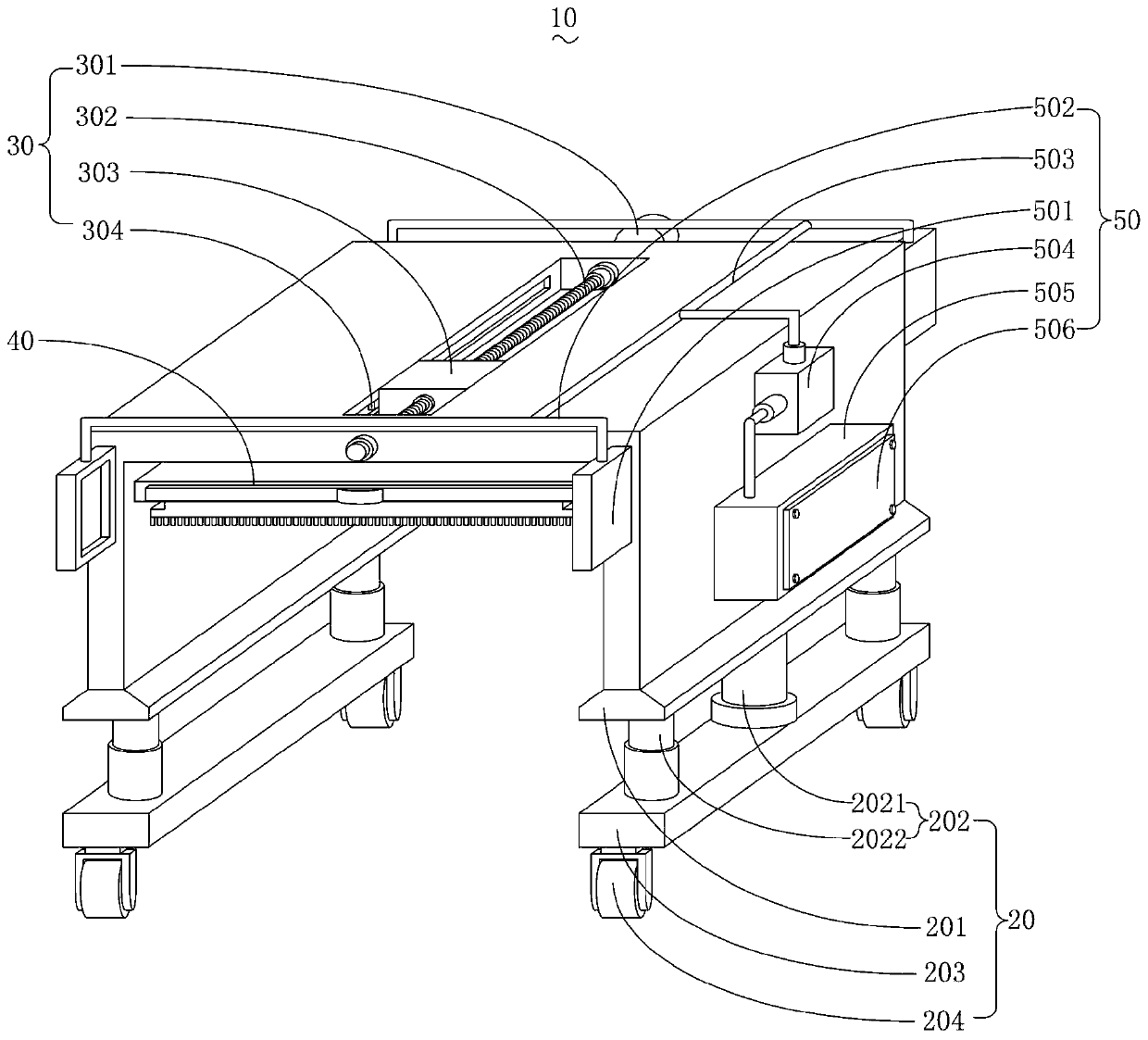

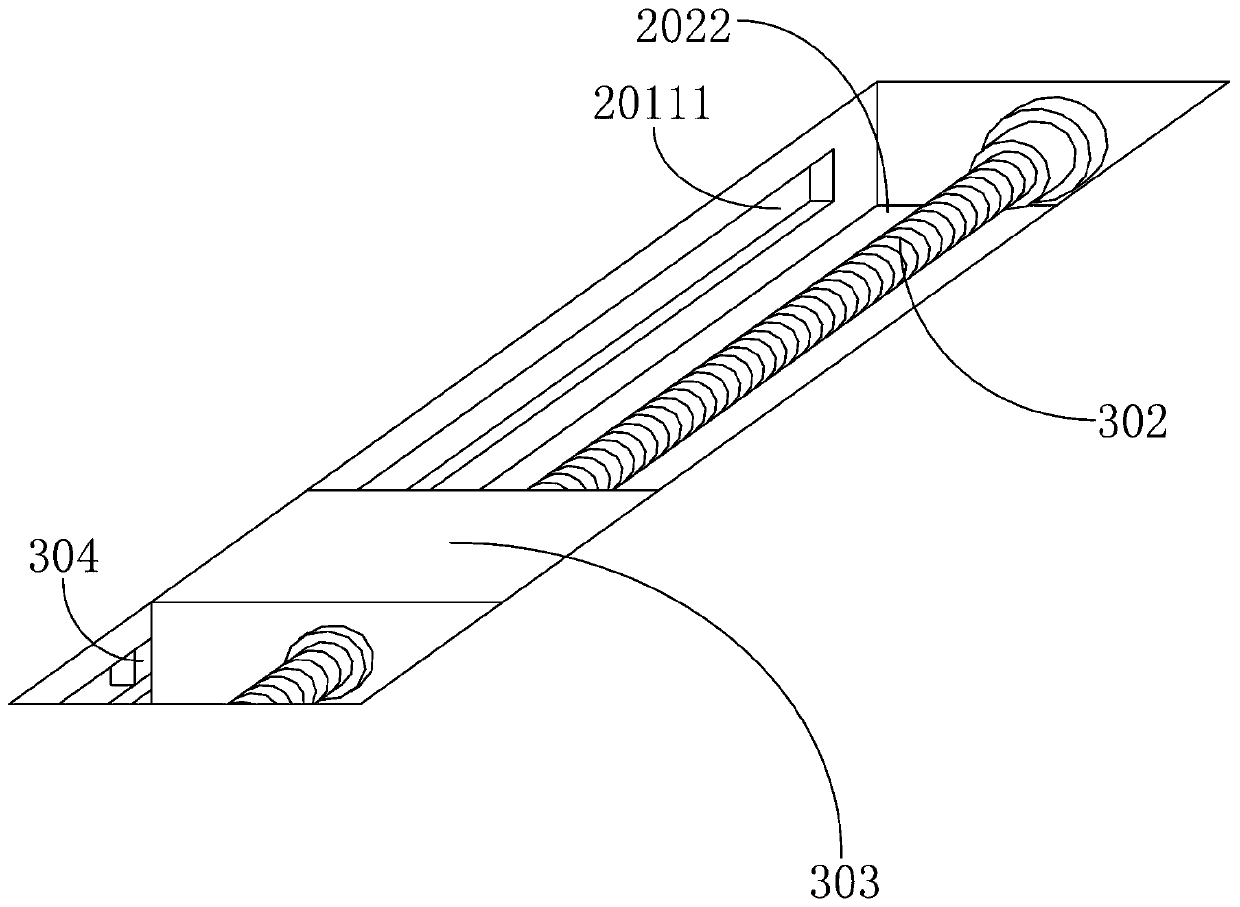

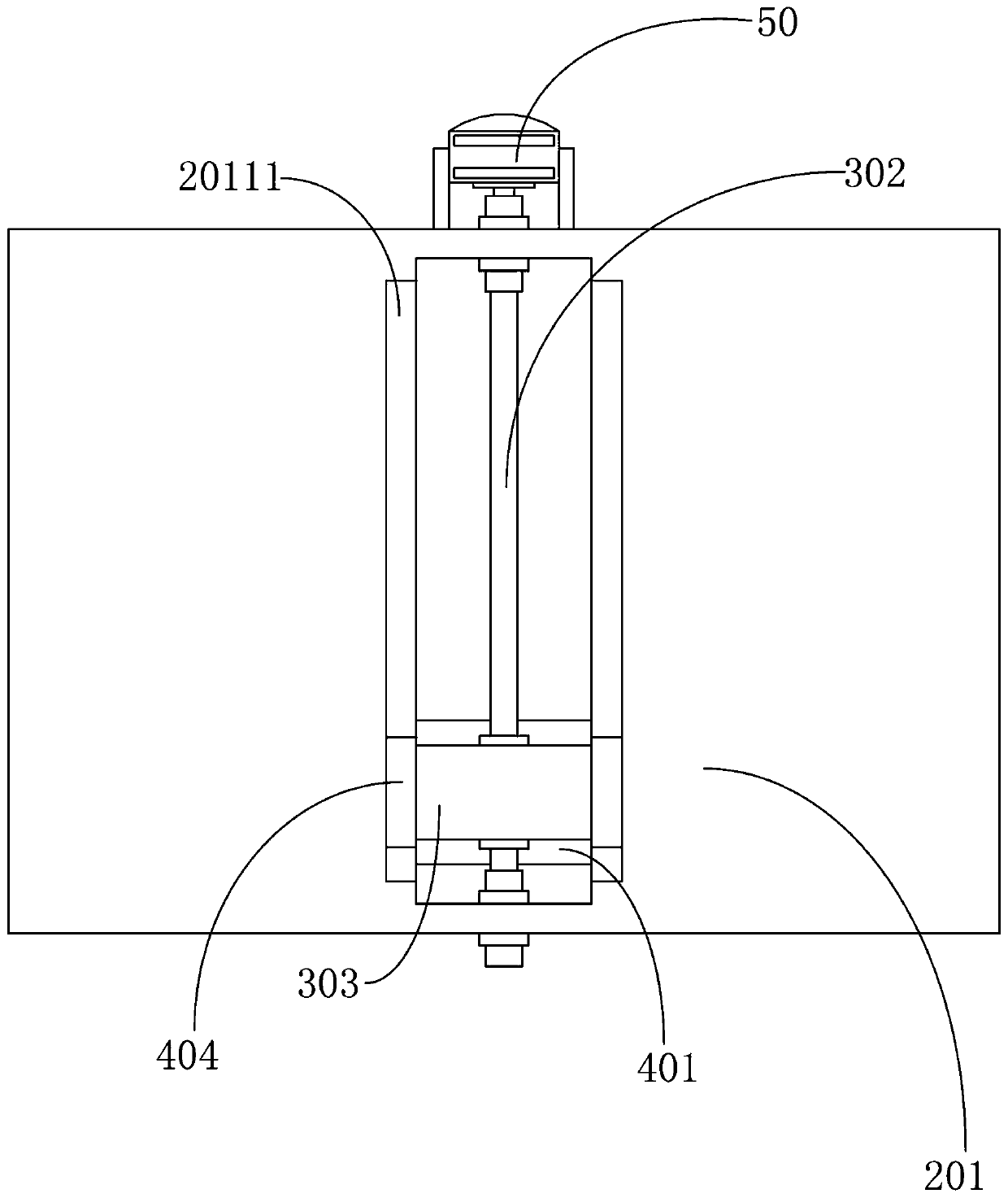

Dust removal device for substation transformer bearing base

PendingCN111229662AThorough cleaningDispersed particle filtrationCleaning using toolsTransformerReciprocating motion

A dust removal device for a substation transformer bearing base comprises a movable supporting frame, a driving device, a sweeping device and a dust collecting device. The driving device and the dustcollecting device are arranged on the movable supporting frame. The upper end of the sweeping device is detachably connected with the driving device. The movable supporting frame comprises a U-shapedframe, a lifting mechanism, a supporting base and universal wheels. The upper end of the U-shaped frame is fixedly connected with the sweeping device and the dust collecting device. The sweeping device is located on the top of the U-shaped frame and used for sweeping away dust on the bearing base. The dust collecting device is located on the side face of the U-shaped frame and used for absorbing and storing the dust. The lower end of the U-shaped frame is fixedly connected with the upper end of the lifting mechanism. The lifting mechanism drives the U-shaped frame to move up and down. The lower end of the lifting mechanism is fixedly connected with the upper end of the supporting base. The lower end of the supporting base is fixedly connected with the universal wheels. In work, the sweeping device is driven by the driving device to reciprocate so as to remove the dust on the bearing base of a transformer, and therefore the dust can be thoroughly swept away.

Owner:YINCHUAN POWER SUPPLY COMPANY OF STATE GRID NINGXIA ELECTRIC POWER

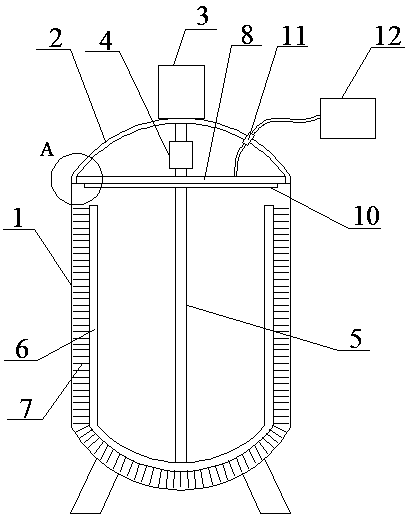

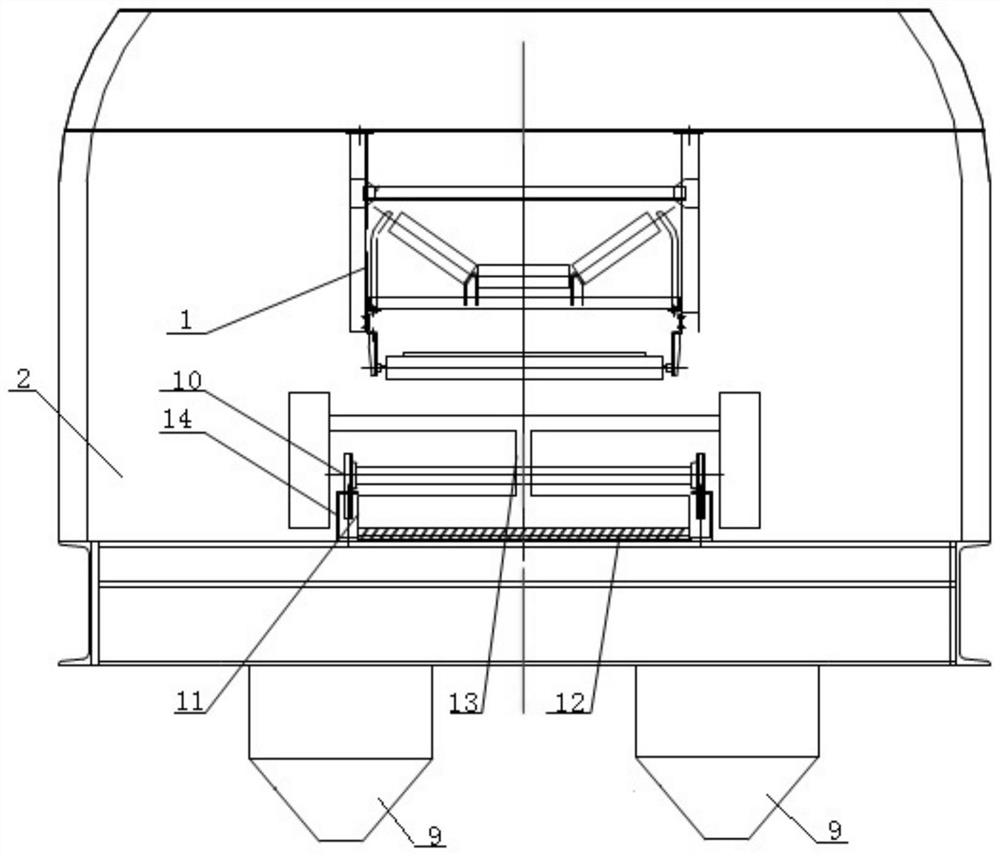

Chemical reaction kettle dirt clearing device

ActiveCN109107517AEasy to useThorough cleaningHollow article cleaningChemical/physical/physico-chemical stationary reactorsHigh pressureCircular disc

The invention discloses a chemical reaction kettle dirt clearing device, and belongs to the technical field of chemical reaction kettle maintenance equipment. The device comprises a reaction kettle, wherein the reaction kettle comprises a kettle body and a kettle cover, a motor is arranged on the kettle cover, a rotating shaft of the motor is arranged on the inner side of the kettle cover, the rotating shaft of the motor is connected with a dirt clearing mechanism through a coupler, and a spraying mechanism is arranged on the inner side of the kettle cover; the dirt clearing mechanism comprises a vertical rod and a U-shaped rod connected with the lower end of the vertical rod, wherein bristles are arranged on the outer side of the U-shaped rod, the spraying mechanism comprises a disk, a through hole for allowing the vertical rod to penetrate through is formed in the center of the disk, a spraying pipe is arranged on the bottom surface of the disk, a spraying pipe connector is arrangedon the kettle cover, the spraying pipe and the spraying pipe connector are communicated, and the other side of the spraying pipe connector is communicated with a water pump through a high pressure hose. By means of the chemical reaction kettle dirt clearing device, the reaction kettle is cleared comprehensively and thoroughly, and the cleaning efficiency is high.

Owner:ZHENGZHOU INST OF TECH

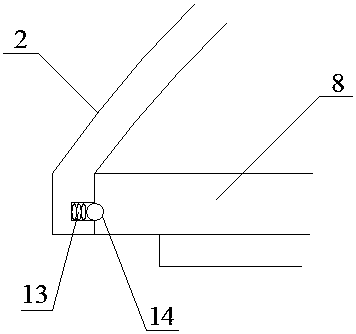

Dust removal device for closed corridor of suspension type belt conveyor

The invention relates to a dust removal device for a closed corridor of a suspension type belt conveyor. The dust removal device comprises a running rail, a running trolley, a dust hood, rolling brushes, a connection pipeline and a dust processing device; the running rail is arranged in the closed corridor, and the running trolley can move along the running rail; the bottom of the running trolleyis provided with the dust hood, the two sides of a dust suction inlet of the dust hood are provided with the rolling brushes correspondingly, and the rolling brushes make rolling contact with the ground of the closed corridor; the top of the suction hood is connected with the dust processing device arranged on the running trolley through the connection pipeline; and the dust processing device comprises a primary filter, a secondary filter, an induced draft fan and an air exhaust device in sequence. According to the dust removal device, the upper suspension type belt conveyor is adopted, the running trolley carries the dust processing device to continuously sweep the ground of the closed corridor along the working path of the belt conveyor, the problem that dust is accumulated on the groundof the closed corridor of the belt conveyor can be effectively solved, unsafe factors caused by manpower cleaning are eliminated, and the purposes of automatically and efficiently removing dust and improving the operation environment are achieved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Cleaning device for medical surgical instruments

PendingCN110974447AThorough disinfectionThorough cleaningDiagnosticsSurgeryElectric machinerySurgical instrument

The invention relates to the technical field of surgical instrument cleaning equipment, and especially relates to a cleaning device for the medical surgical instruments, which comprises a device body,the middle part of a supporting plate is movably connected with a rotating shaft through a bearing; a motor is in transmission connection with the rotating shaft through a reduction gear set, a trayis fixedly mounted at the top of the rotating shaft, a disinfectant tank and a cleaning water tank are fixedly mounted on the two sides of the surface of the device body correspondingly, a groove is formed in the inner top wall of the device body, a drying device is arranged in the groove, a draught fan is fixedly installed at the top of the device body, an air pipe is arranged on one side of thedraught fan, and one end of the air pipe is fixedly connected with the drying device. Through the cooperative design of a motor, the reduction gear set, the rotating shaft and the tray, the instrumentcan be comprehensively and thoroughly disinfected and cleaned when rotating, the cleaning efficiency and the cleaning effect are improved, and the instrument can be dried through the arrangement of the drying device.

Owner:杭州华慧医药科技有限公司

Rotary type glass cleaning and drying machine

InactiveCN109127625ASimple structureEasy to operateDrying gas arrangementsFlexible article cleaningAgricultural engineeringDrive motor

The invention discloses a rotary type glass cleaning and drying machine. The rotary type glass cleaning and drying machine comprises a machine frame, a motor cushion block is arranged outside the leftside of the machine frame, a servo motor is arranged on the motor cushion block, the servo motor is connected with an output shaft, the output shaft is fixed on a supporting frame, a glass fixing plate is arranged outside the output shaft, a drainage bin is arranged below the supporting frame, a water storage bin is arranged below the drainage bin, a water supply pipe is arranged on the right side of the water storage bin, the water supply pipe is connected with the water pump, the water pump is connected with a cleaning spray head through an L-shaped water delivery pipe, a sliding groove isformed in a cross beam, a sliding block is arranged in the sliding groove, the sliding block is connected with a driving motor, an output rotating shaft is arranged below the driving motor, a telescopic rod is arranged below the output rotating shaft, a washing wheel is arranged below the telescopic rod, fans are arranged on the left side and the right side of the driving motor respectively, and the fans are connected with an air knife through an air conveying pipe. The rotary type glass cleaning and drying machine is simple in structure, the servo motor is matched with the glass fixing plate,so that the glass can be cleaned by 360 degrees without dead angle during cleaning, and the cleaning quality and the cleaning efficiency are improved.

Owner:黄清平

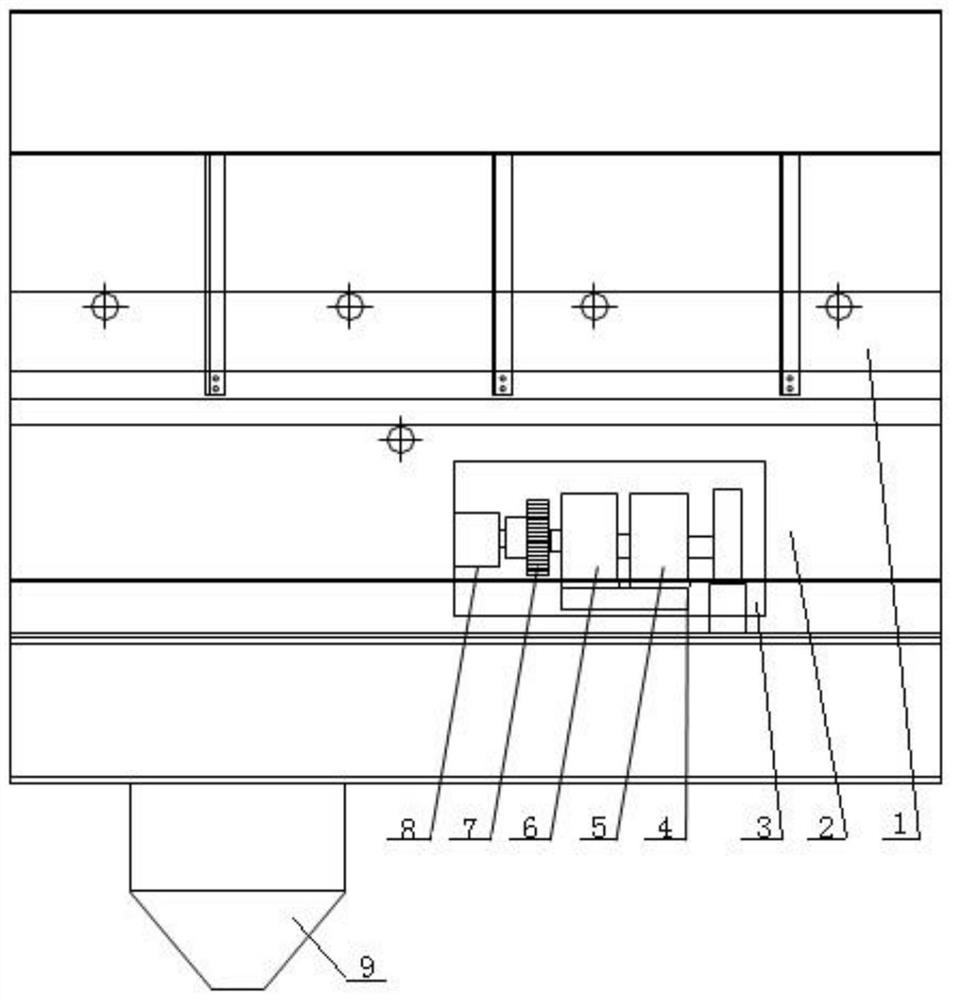

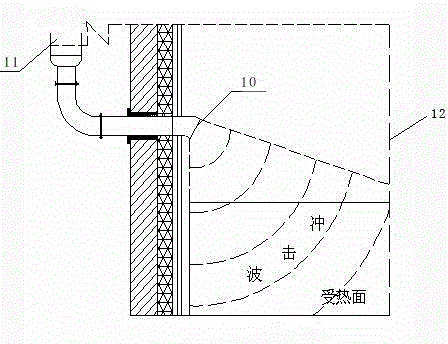

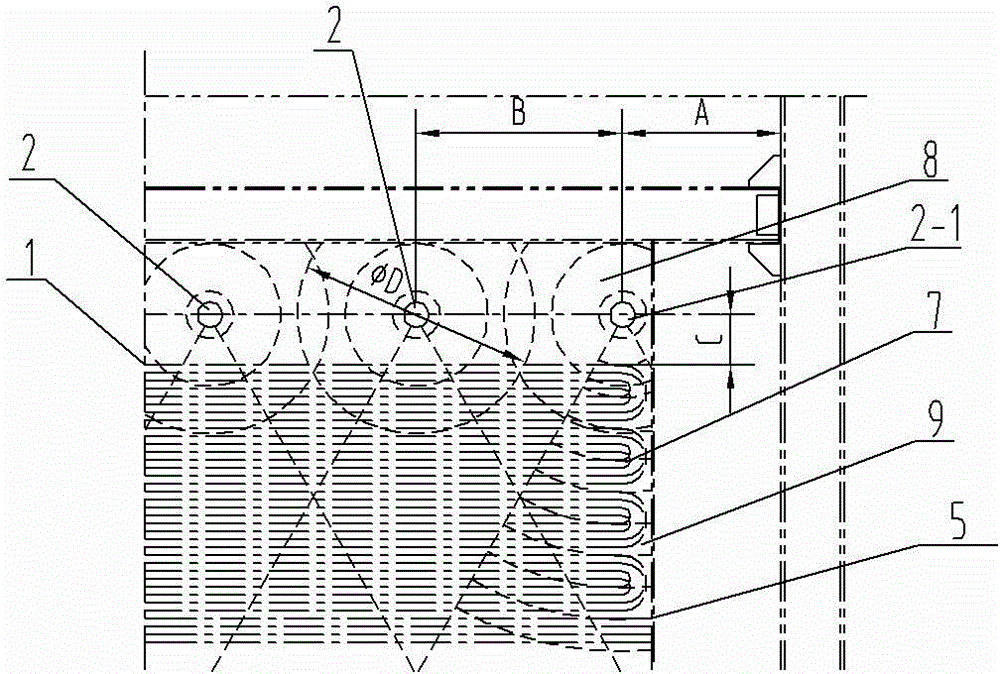

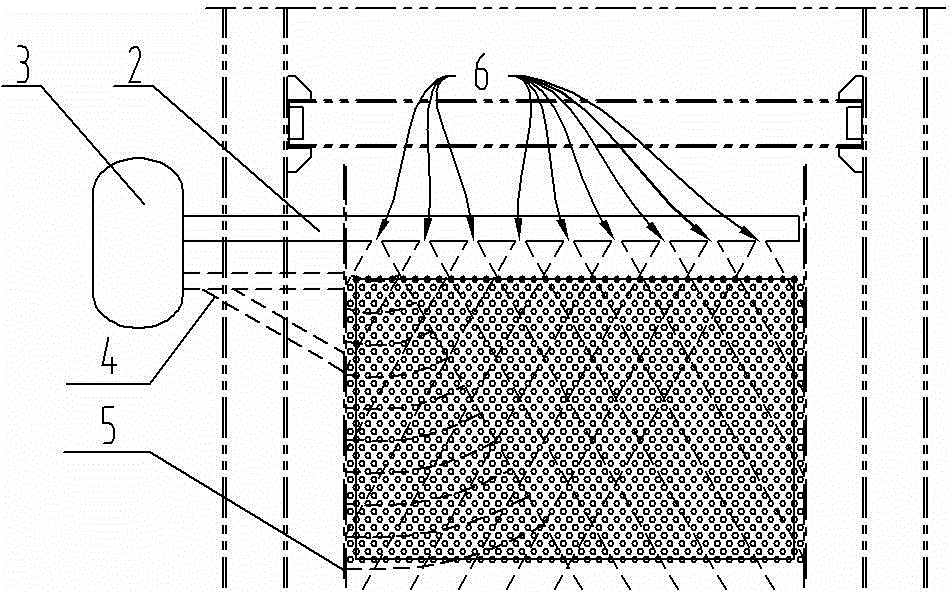

Arrangement structure of shock wave ash blower of vertical waste heat boiler

InactiveCN104456589AGuaranteed soot blowing effectIncrease the areaSolid removalShock waveHeat transfer efficiency

The invention provides an arrangement structure of a shock wave ash blower of a vertical waste heat boiler. The arrangement structure can solve the problem that an existing arrangement structure of the nozzle-type shock wave ash blower is narrow in shock wave space and poor in ash blowing effect, and therefore high heat transfer efficiency of the heating surfaces of the boiler can be effectively guaranteed. A row of shock wave ash blowing tubes transversely penetrating through the chamber of the vertical waste heat boiler are horizontally arranged above each stage of heating surface of the vertical waste heat boiler, each shock wave ash blowing tube is independently connected with a shock wave pulse generator, each shock wave pulse generator is installed on a side plate of a box of the vertical waste heat boiler through an installation support, and the wall of each shock wave ash blowing tube is provided with a plurality of downward ash blowing holes uniformly in the length direction.

Owner:JIANGSU TAIHU BOILER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com