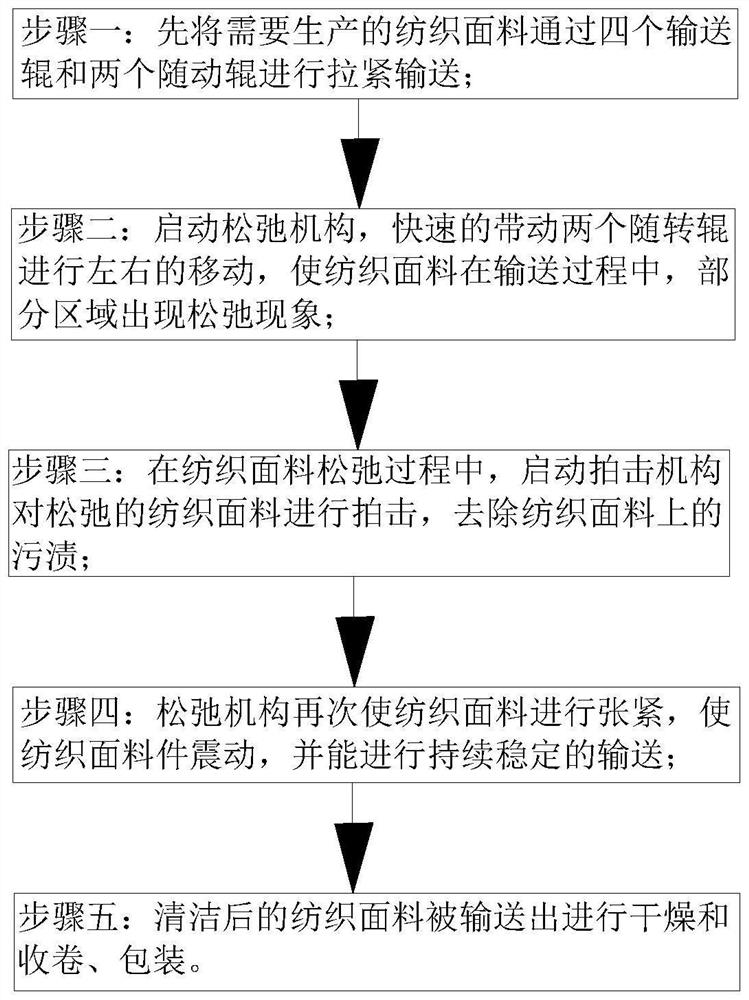

Textile fabric cleaning device and cleaning method for textile production

A technology for textile fabrics and cleaning devices, which is applied in the direction of textile material processing equipment configuration, textile material processing, and textile material carrier processing, etc. It can solve the problems of textile fabric pilling, textile fabric production quality reduction, and fluff breakage, etc., to achieve thorough cleaning. cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

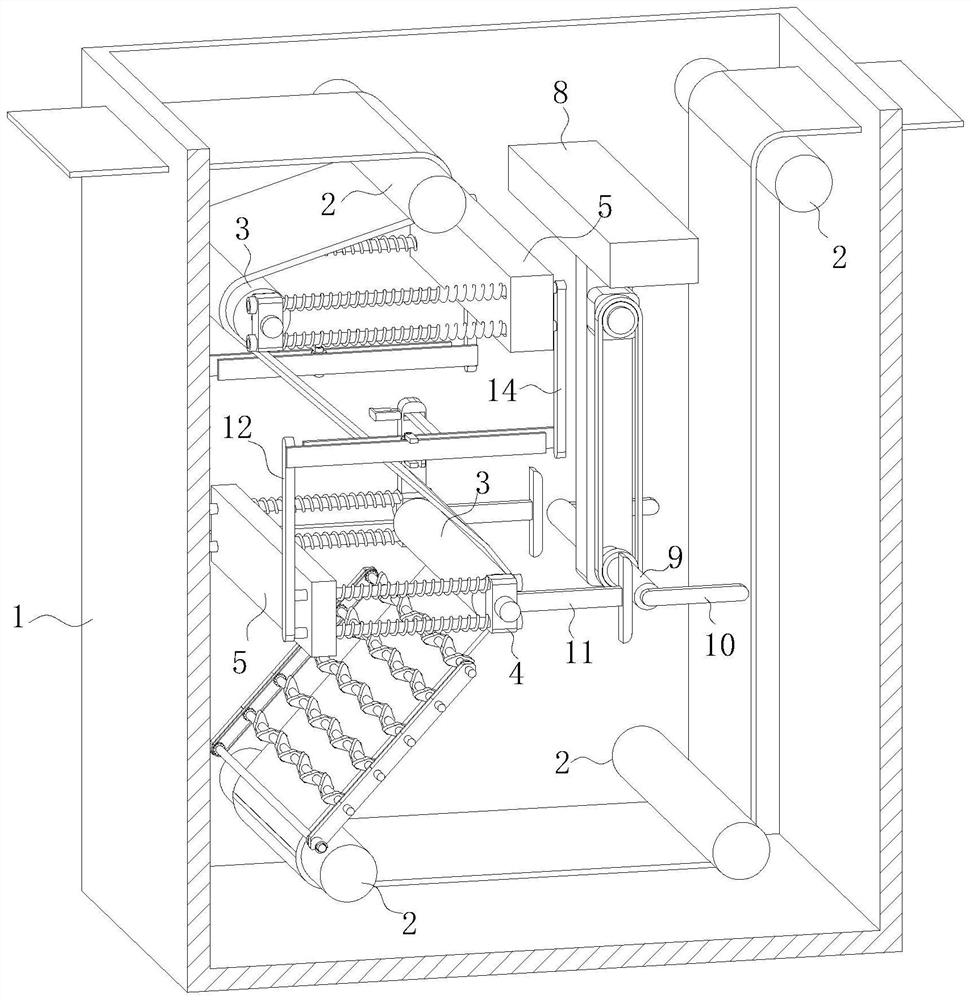

[0036] see Figure 1-10 , the present invention provides a technical solution: a textile fabric cleaning device for textile production, including a cleaning box 1, the inner side of the cleaning box 1 is provided with a conveying device for transporting the textile fabric in the cleaning box 1, and the inner side of the conveying device is provided. The relaxation mechanism is used for bending, tightening and relaxing the textile fabric. The relaxation mechanism is used to periodically relax and tighten the textile fabric in the middle part of the textile fabric. The slapping mechanism for slapping can follow the offset of the textile fabric;

[0037] The conveying mechanism includes four conveying rollers 2, and the four conveying rollers 2 are all rotatably connected to the inner wall of the cleaning box 1. The four conveying rollers 2 are arranged up and down in a prismatic shape, and the four conveying rollers 2 tighten the textile fabric. delivery;

[0038]The relaxatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com