Automatic circulating water electrolysis descaling device and method

An automatic descaling and circulating water technology, applied in chemical instruments and methods, water softening, water/sewage treatment, etc., can solve problems such as increasing energy consumption, affecting heat exchange efficiency, affecting device efficiency, etc., and achieves clean water output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

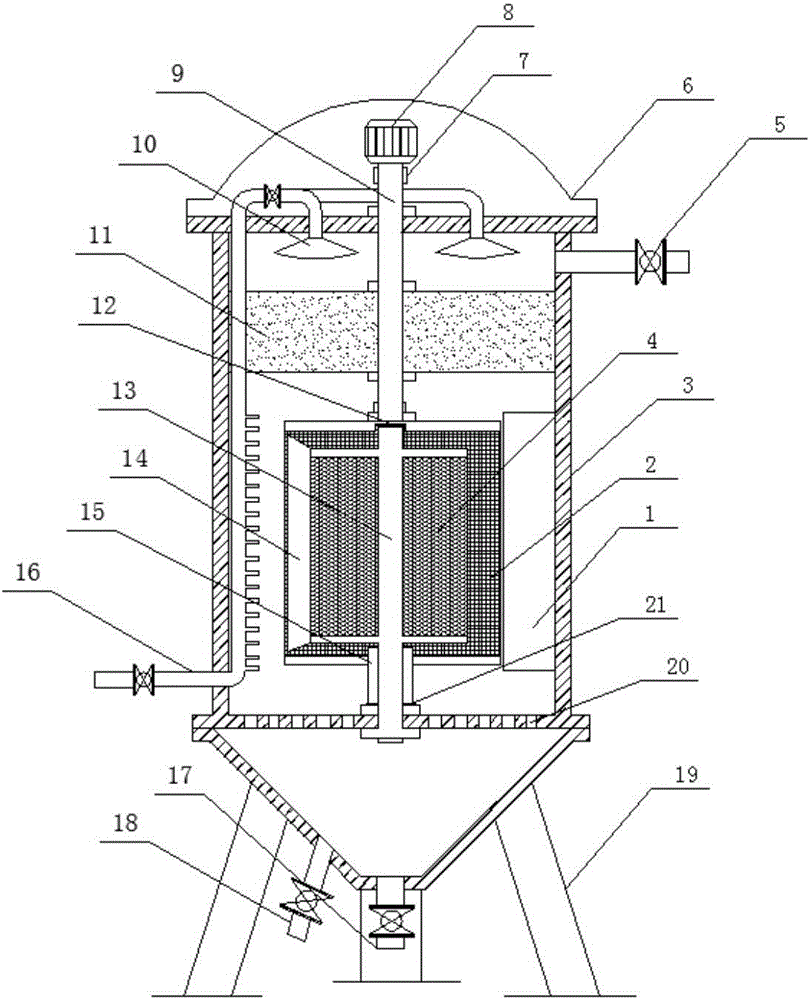

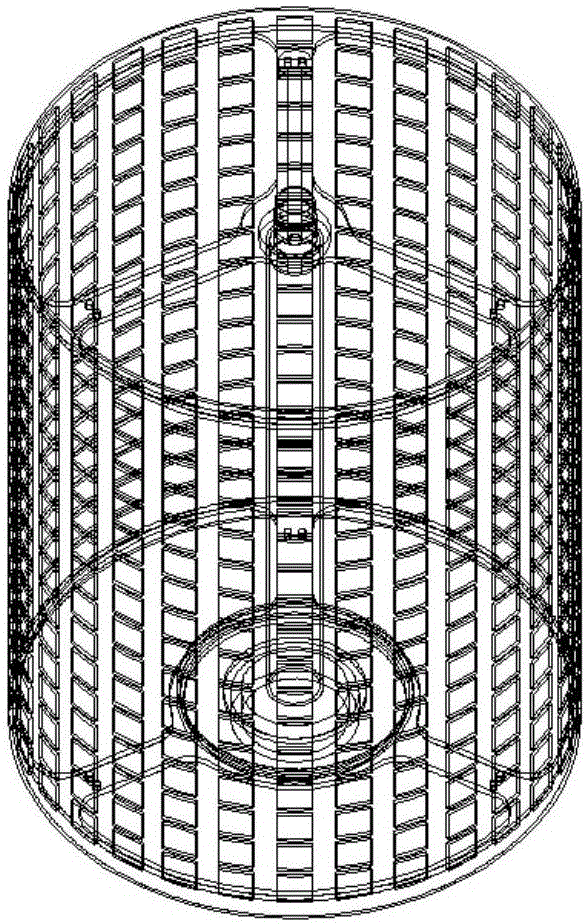

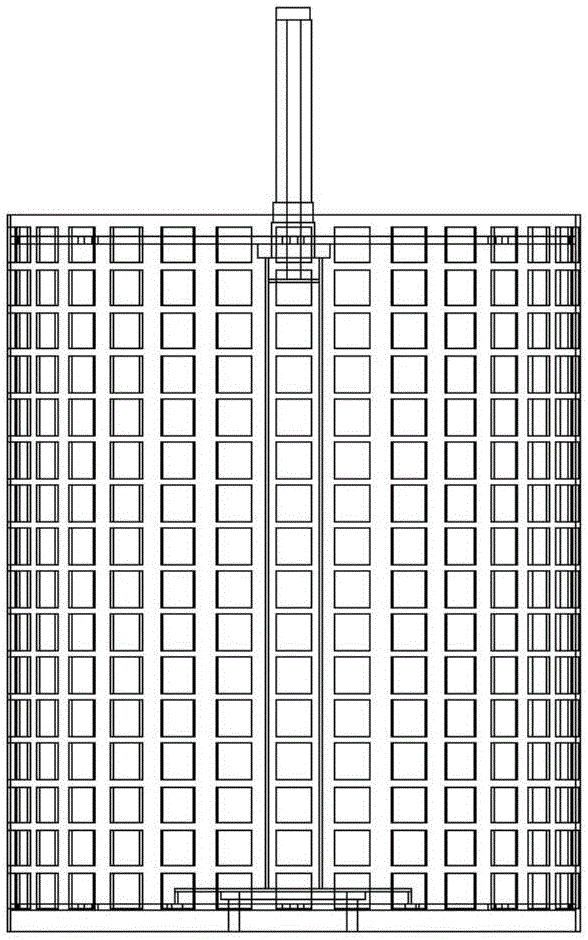

[0027] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

[0028] like figure 1 As shown, the circulating water electrolysis automatic descaling device of the present invention includes a reaction box 3, a water inlet and a control valve 18, a water outlet and a control valve 5, a slag discharge port and a control valve 17, a first scraper 1, and a filter packing layer 11 , backwashing structure 10, casing top cover 6 and support 19; Also have cathode and component 2, anode and component 4 and flushing structure 16, wherein cathode and component 2, anode and component 4 are concentrically installed in reaction box 3, The flushing structure 16 pipeline is fixed on the inner wall of the reaction box 3; the box top cover 6 on the top of the reaction box 3 is in the shape of a spherical crown, which is not easy to accumulate water and dust, and the bottom is conical, made of metal, and its lining is electricall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com