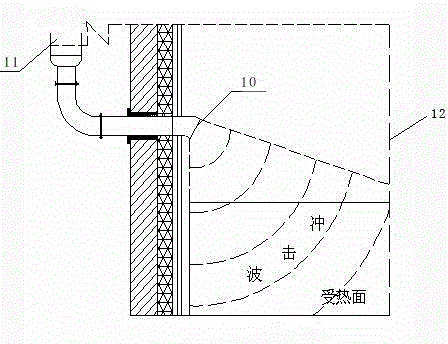

Arrangement structure of shock wave ash blower of vertical waste heat boiler

A shock wave soot blower and waste heat boiler technology, which is applied in the field of boiler ash removal and vertical waste heat boiler ash removal, can solve the problems of narrow shock wave space and poor soot blowing effect, so as to increase the effective area and ensure the Effect, the effect of improving the efficiency of soot blowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

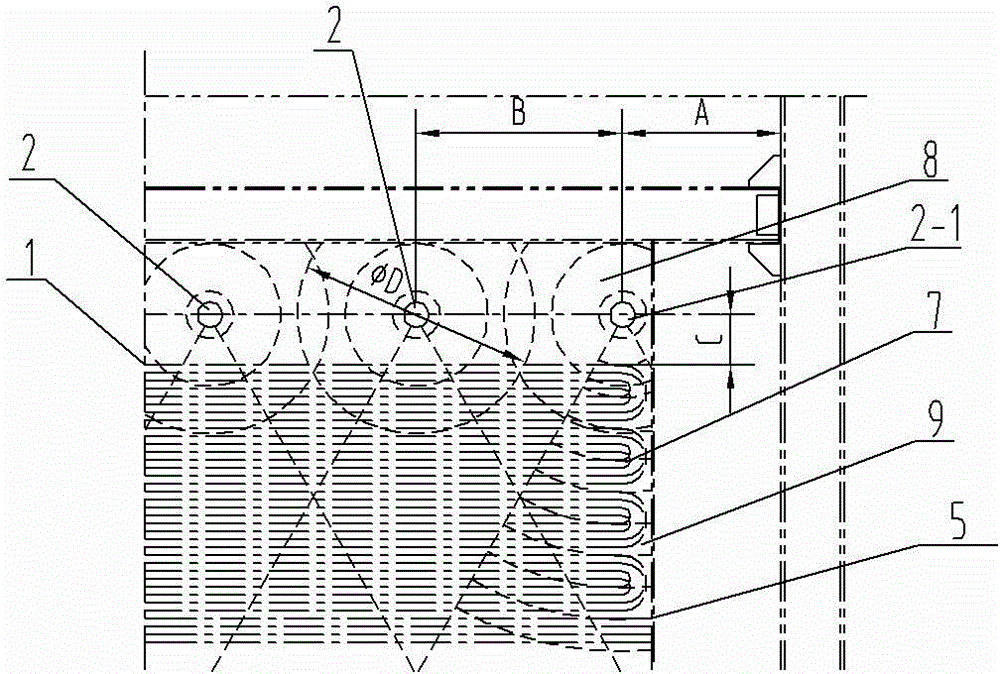

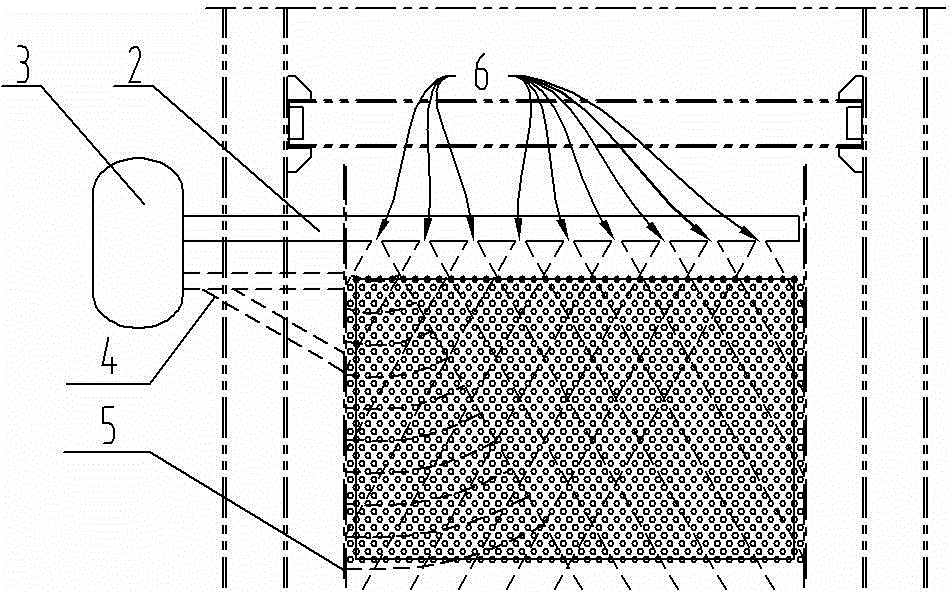

[0016] The arrangement structure of the shock wave sootblower of a vertical waste heat boiler, see figure 2 with image 3 Above each level of heating surface 1 of the vertical waste heat boiler, a row of shock wave soot blowing pipes 2 that cross the furnace of the vertical waste heat boiler is horizontally arranged, and each shock wave soot blowing pipe 2 is individually connected with one Shock pulse generator 3, each shock pulse generator is installed on the side plate 5 of the box body of the vertical waste heat boiler through the mounting bracket 4, and the shock wave soot blowing tube 2 is uniformly opened along the length direction. Several downward soot blowing holes 6; and just above the serpentine tube elbow end 7 of each stage of the vertical waste heat boiler is provided with a shock blowing soot tube 2-1, the shock blowing soot blowing tube 2-1 The distance from the inner wall of the side wall is A, and the size of A is determined according to the distance between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com