Oxyhydrogen shock wave soot blowing system capable of controlling soot blowing intensity

A soot blowing system and hydrogen-oxygen technology, which are applied in the treatment of combustion products, combustion methods, and removal of solid residues, etc., can solve the problems of insufficient flexibility and affect the soot blowing effect, so as to avoid waste and ensure the soot blowing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

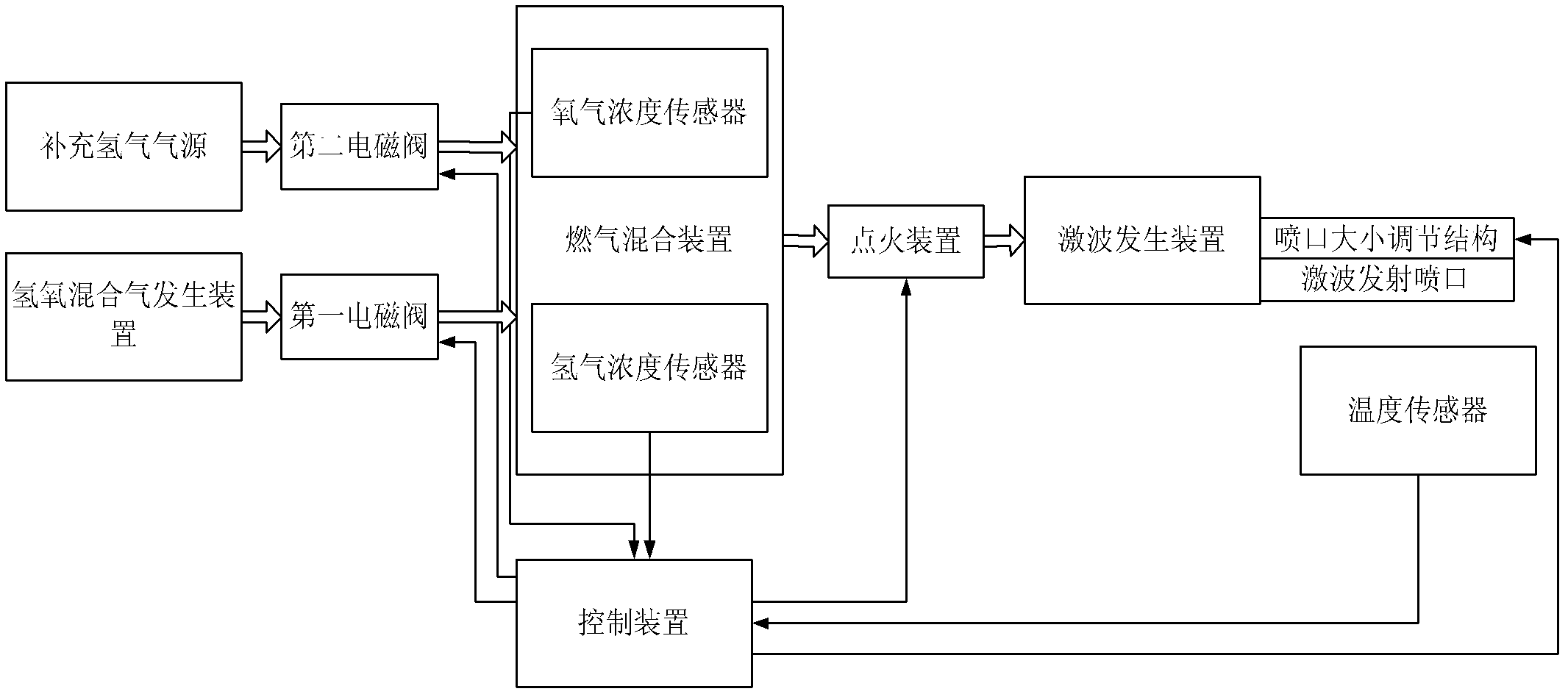

[0021] Such as figure 1 As shown, the present invention provides a hydrogen-oxygen shock wave sootblowing system capable of controlling the sootblowing intensity, including: a hydrogen-oxygen mixture generating device; a gas mixing device, which is connected to the hydrogen-oxygen mixture generating device, and a The supplementary hydrogen gas source is connected, and a first electromagnetic valve is arranged on the gas pipeline between the gas mixing device and the hydrogen-oxygen mixture generator, and the gas pipeline between the gas mixing device and the supplementary hydrogen gas source A second electromagnetic valve is arranged on the gas mixing device, a hydrogen concentration sensor and an oxygen concentration sensor are arranged in the gas mixing device; a shock wave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com