Denitration system in favor of blowing deposited ash and catalyst arrangement method of denitration system

A technology of catalyst and soot blowing device, which is applied to chemical instruments and methods, separation methods, and separation of dispersed particles, etc., to achieve the effects of reducing wear, reducing clogging, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

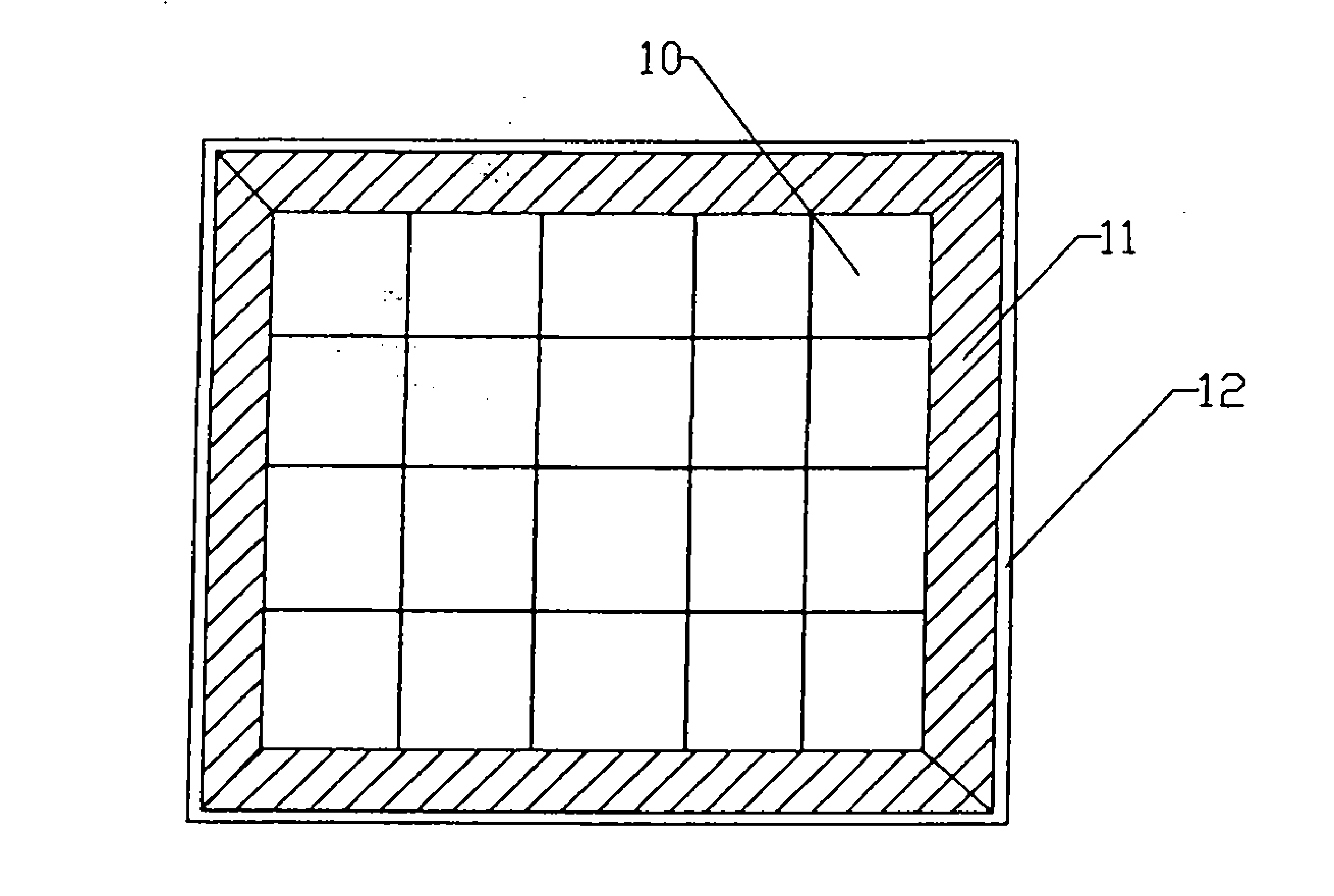

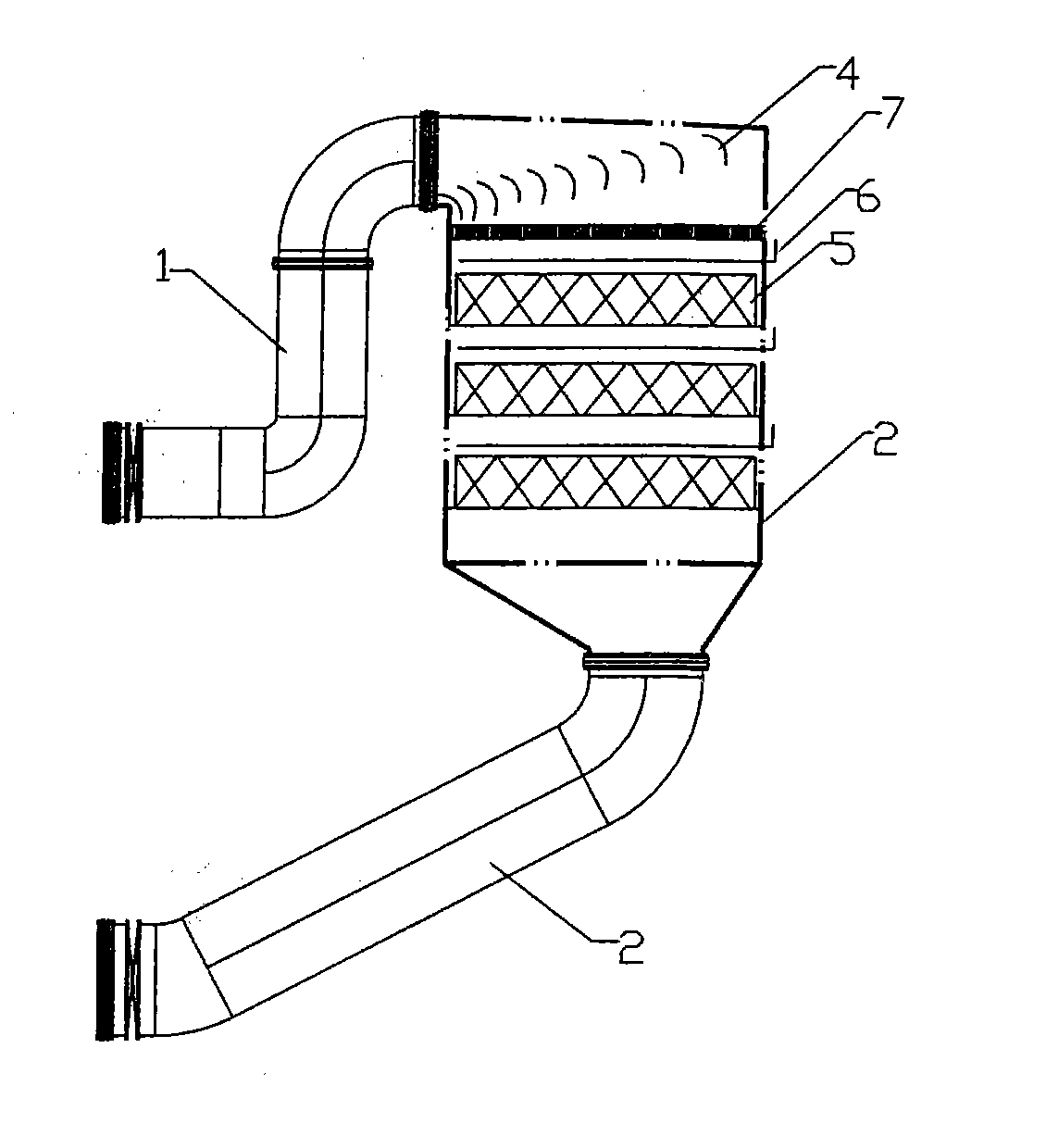

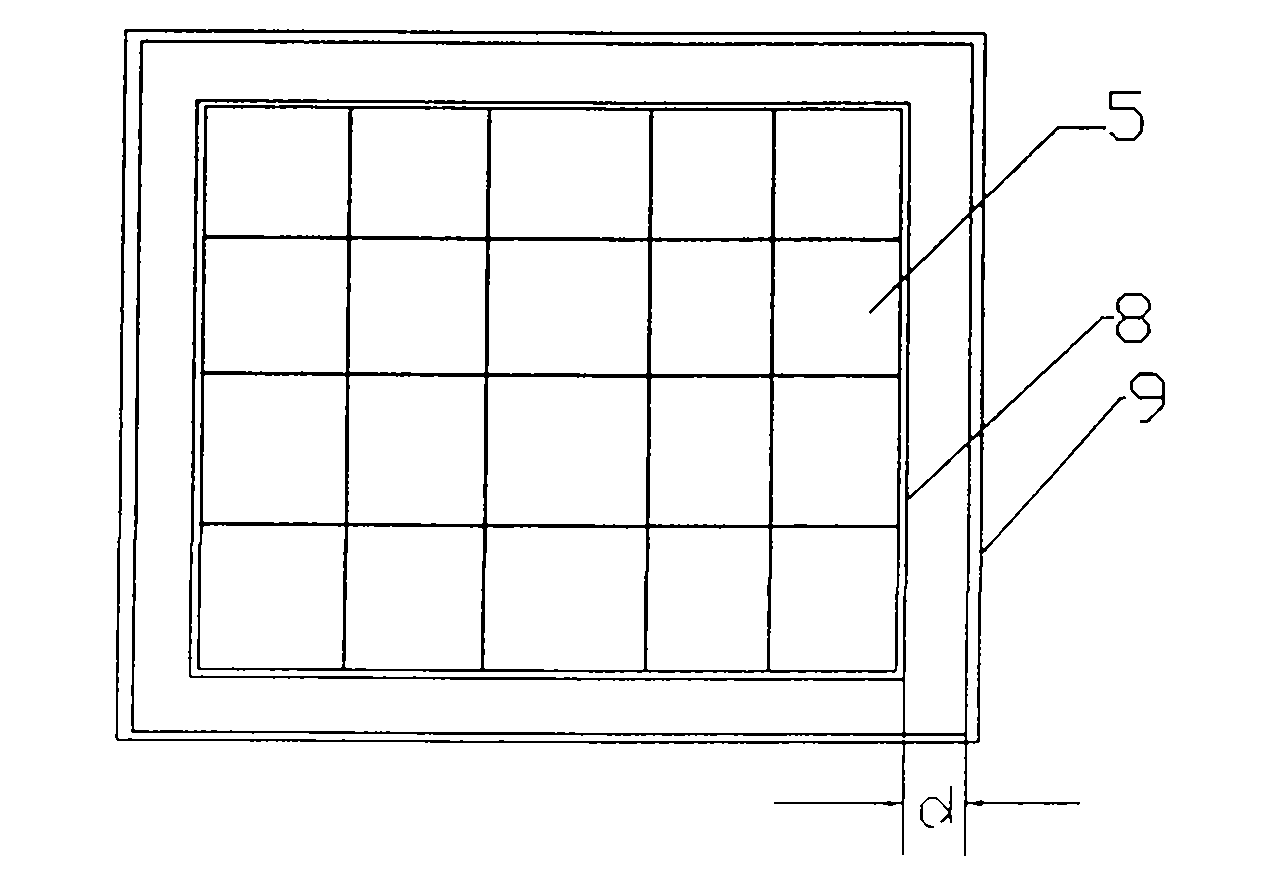

[0024] Such as figure 2 and image 3 As shown, the denitrification system of the present invention, which is beneficial to purging and depositing dust, includes an inlet flue 1, a reactor 2 and an outlet flue 3, and the inside of the reactor 2 is provided with a spoiler 4 and a rectifier 7, and the rectifier 7 There are also three horizontally placed catalyst combination modules 5 below, and the three catalyst combination modules 5 are arranged in the inside of the reactor 2 in layers along the longitudinal direction of the denitrification system reactor 2, wherein each layer of catalyst combination modules 5 is Corresponding positions are provided with soot blowing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com