Patents

Literature

88results about How to "Improve soot blowing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

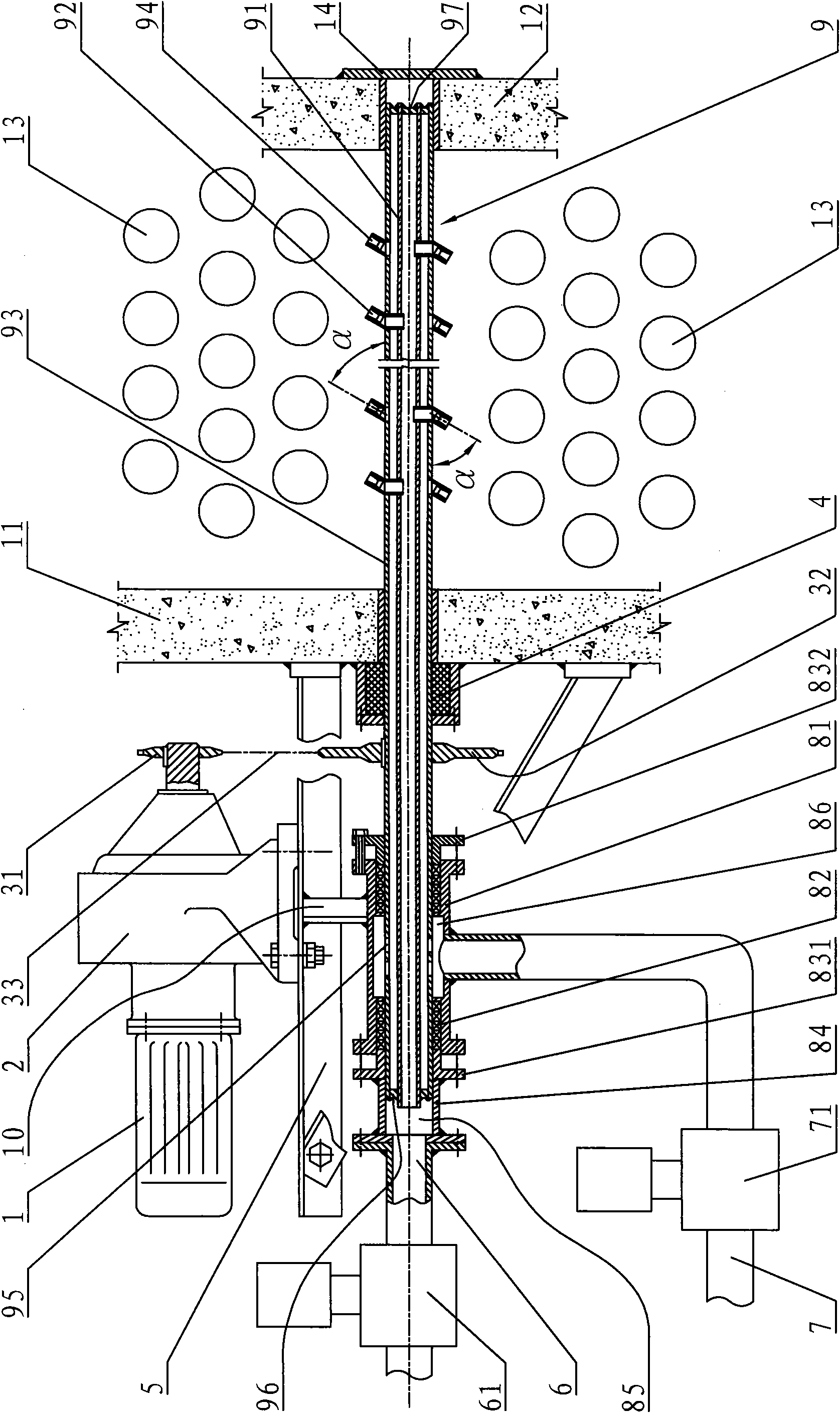

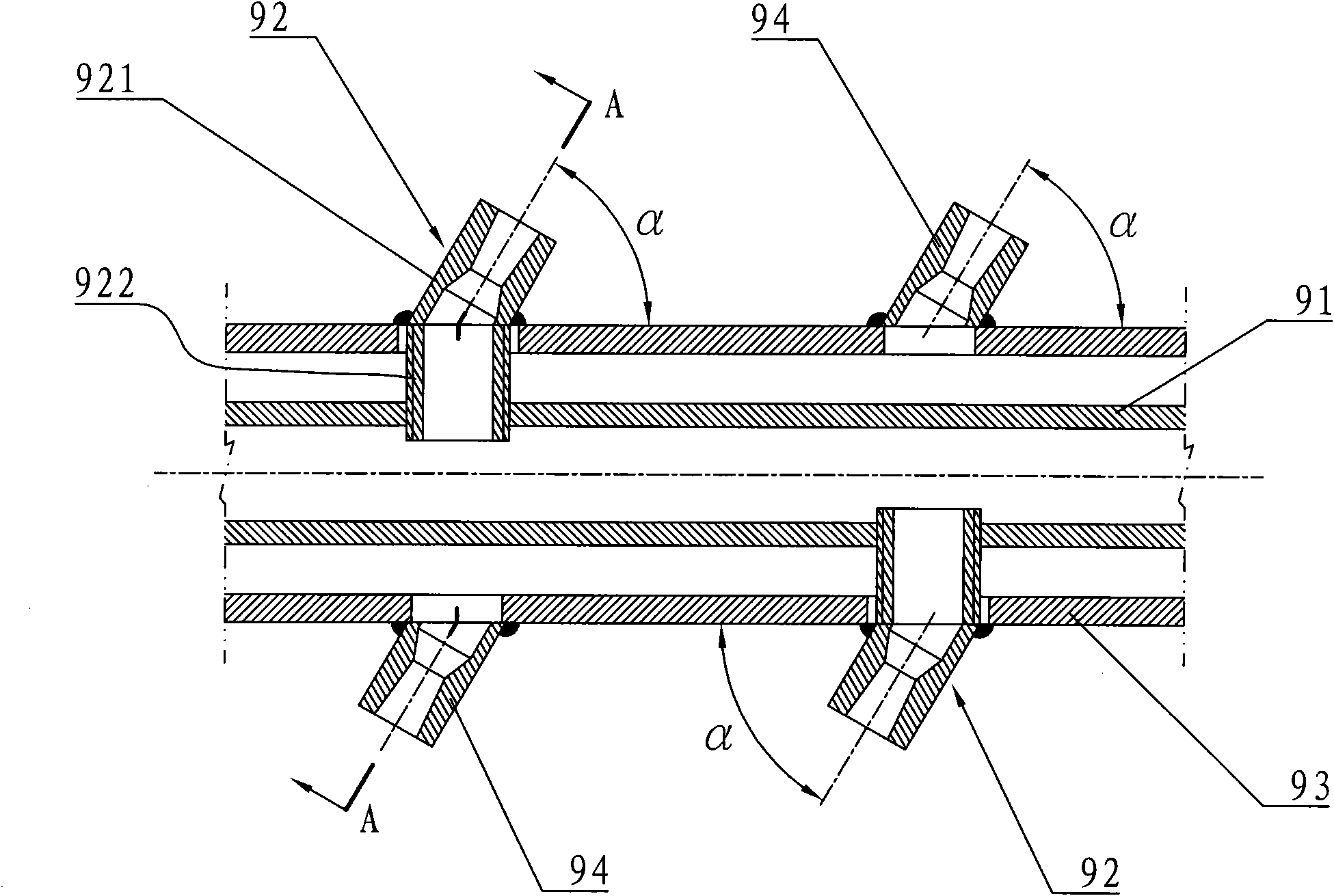

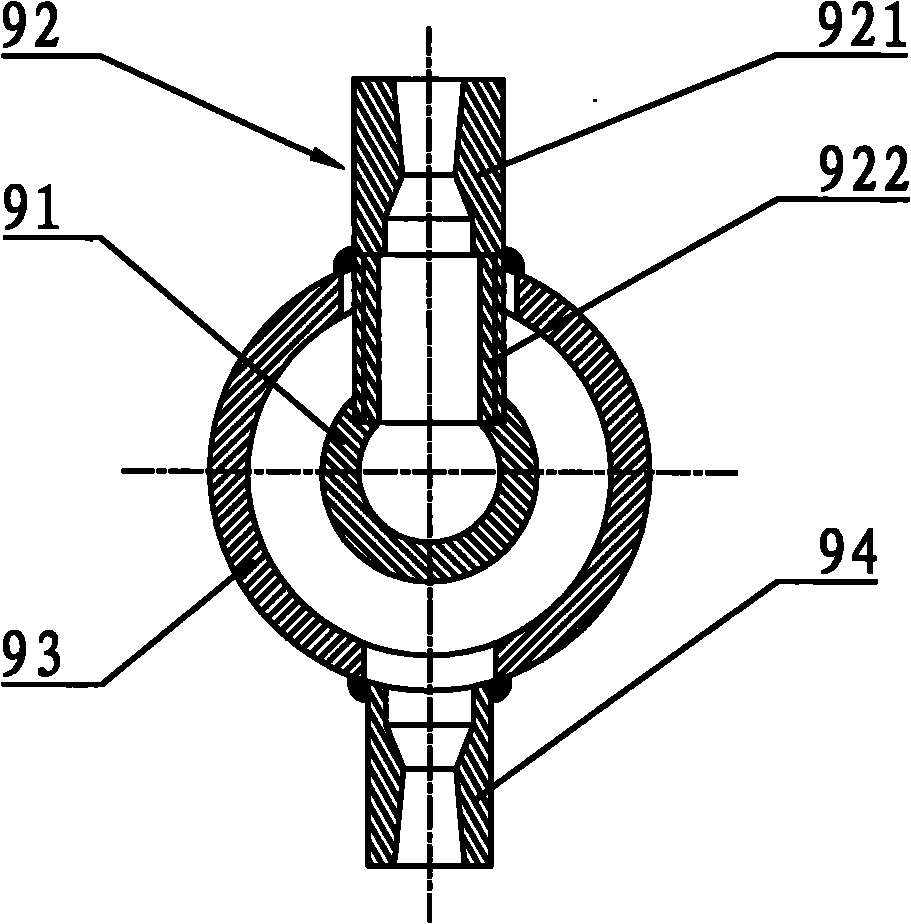

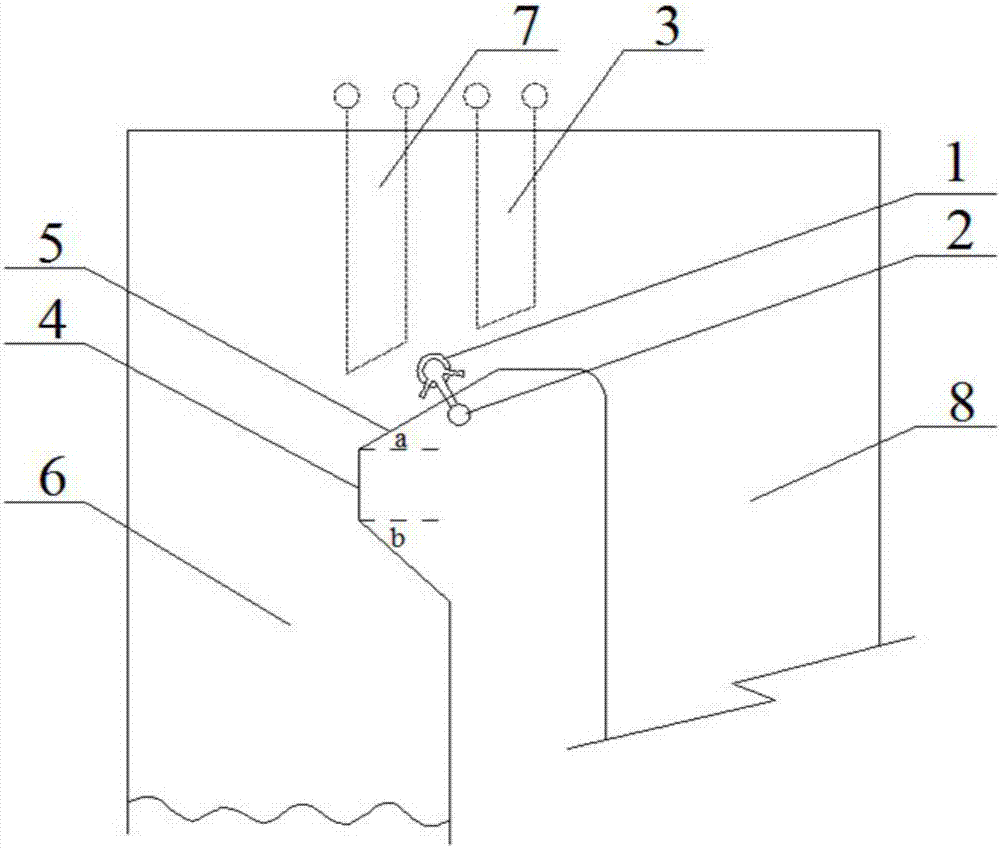

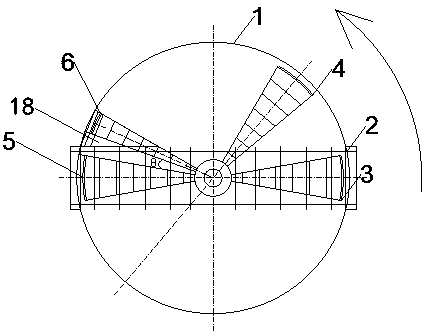

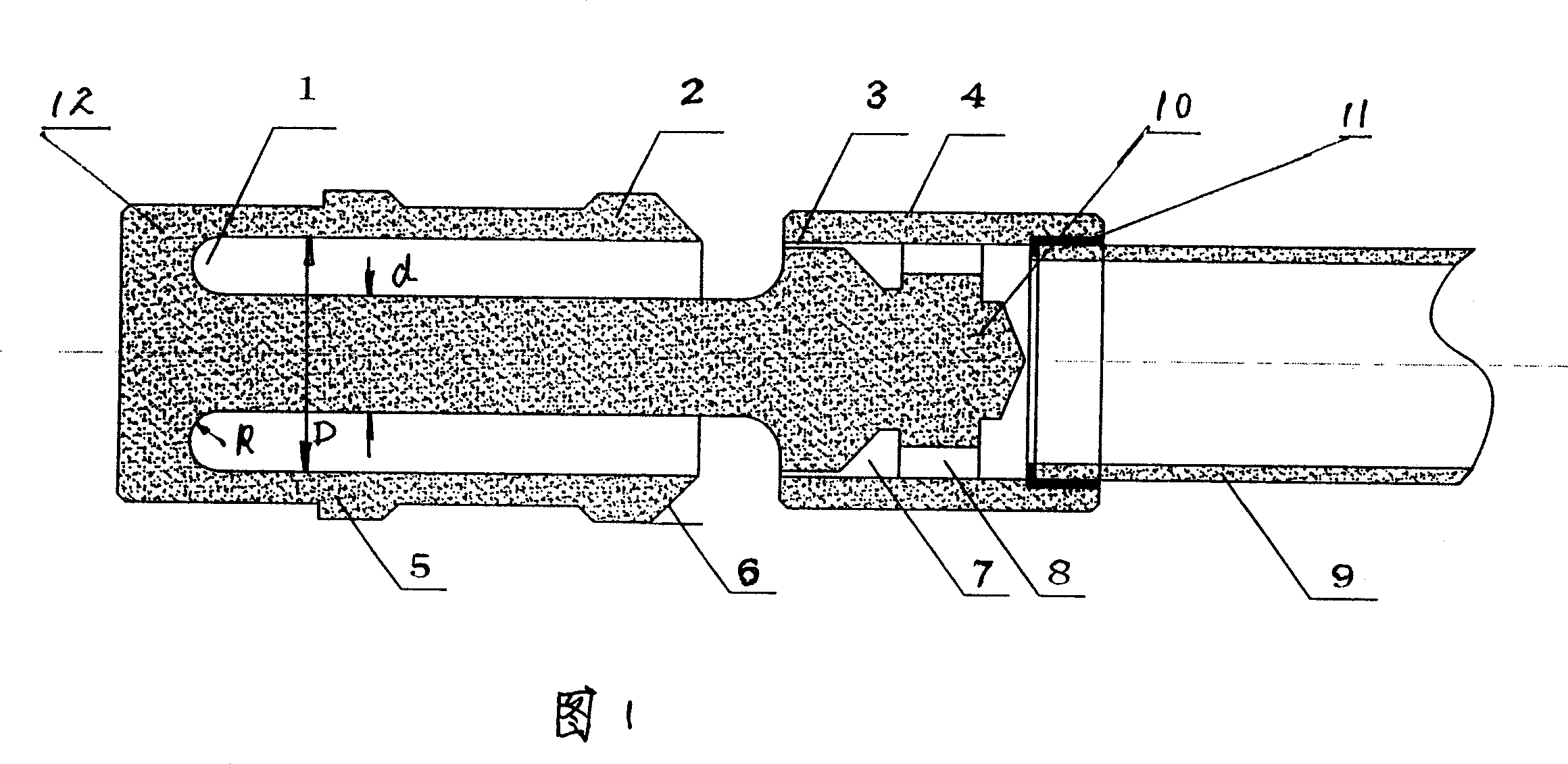

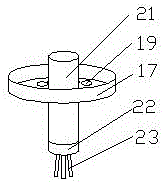

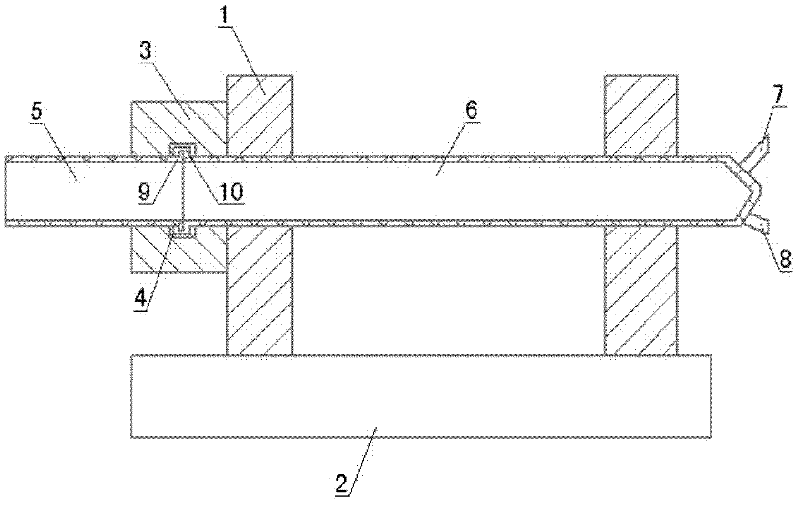

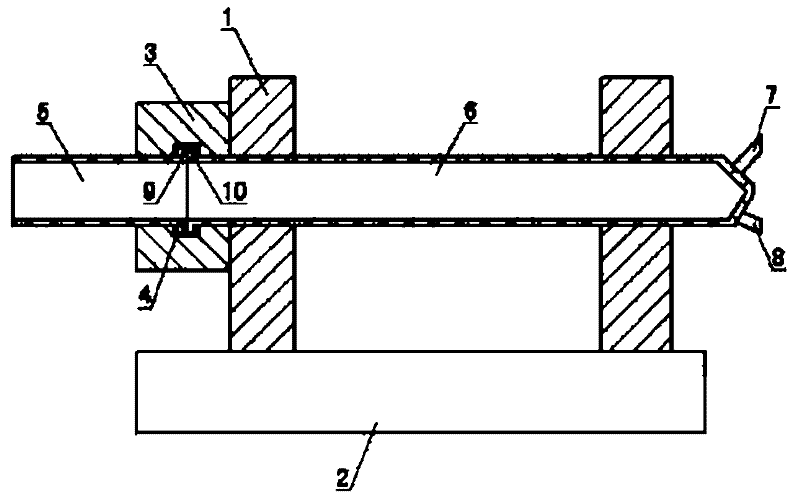

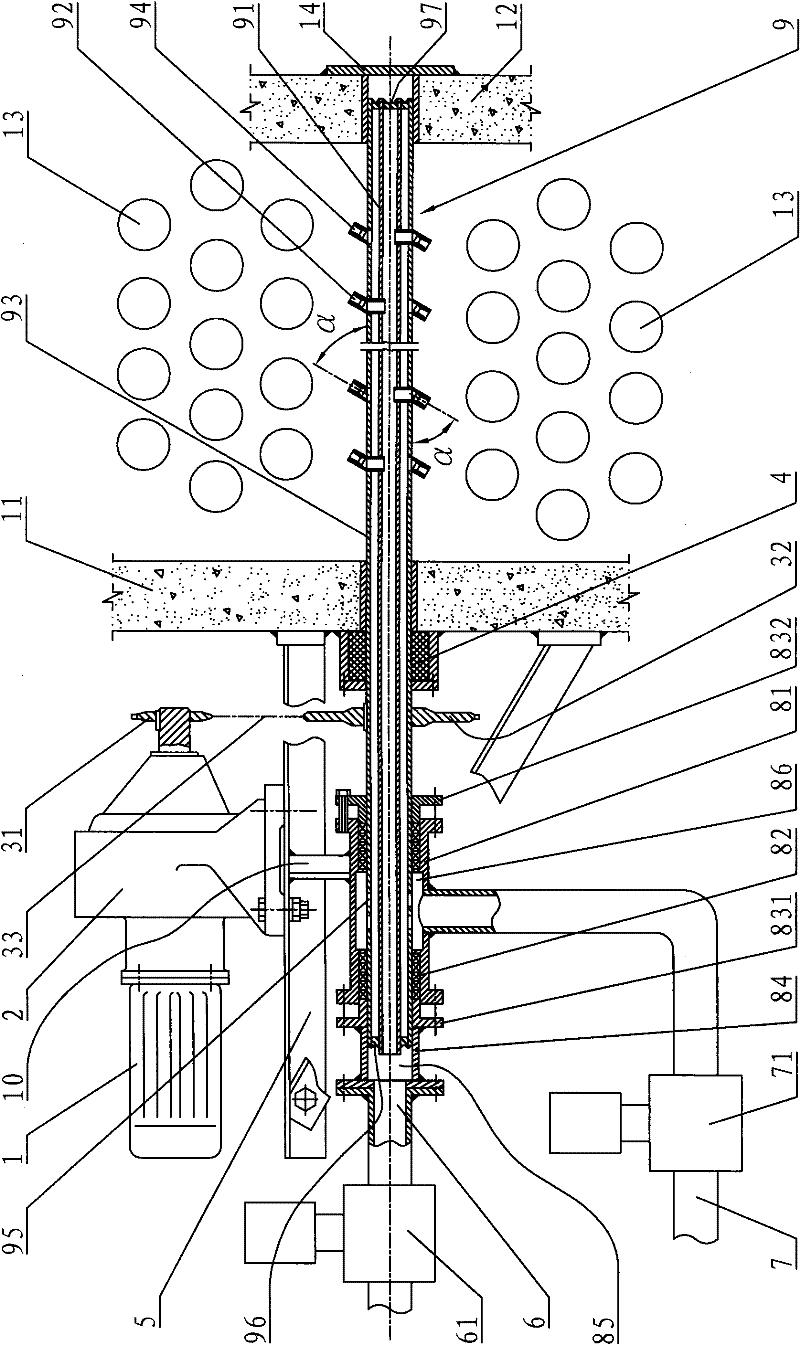

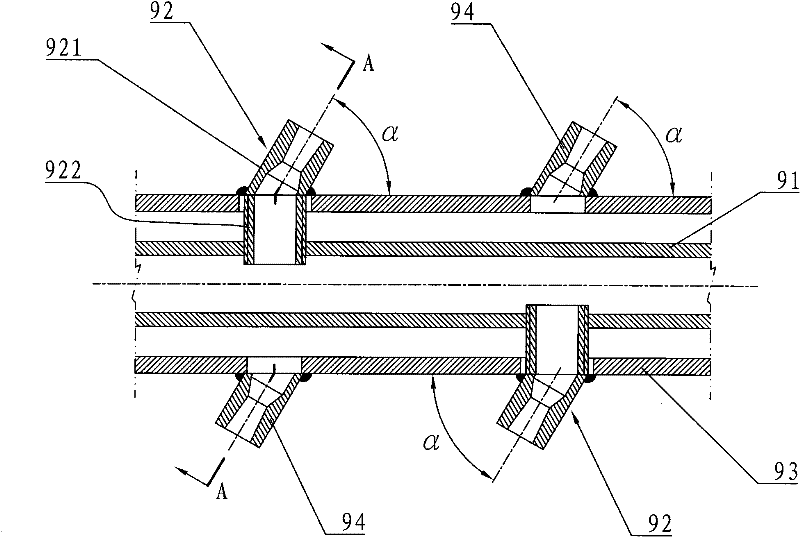

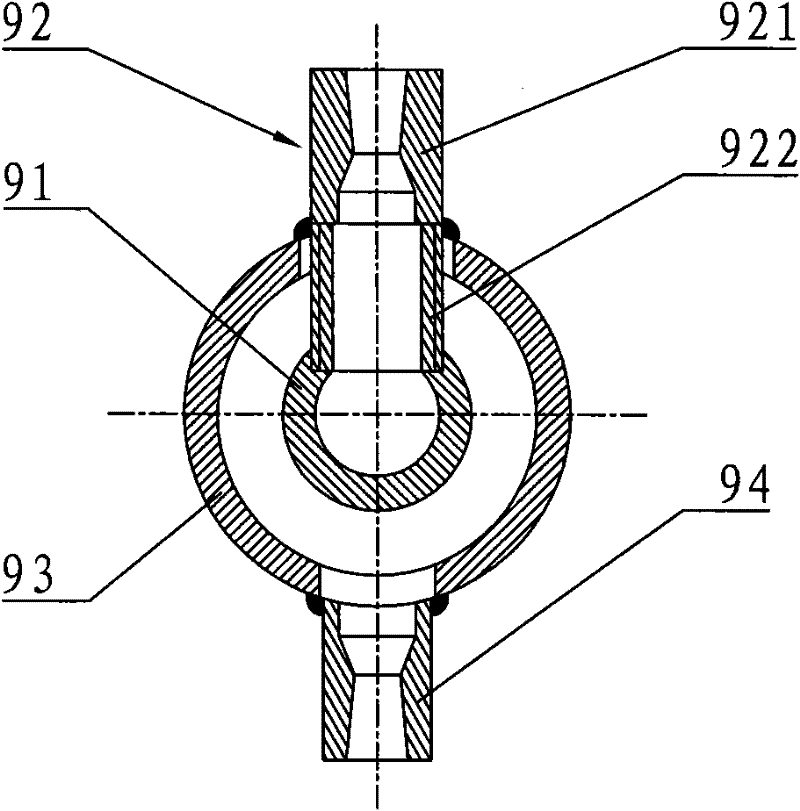

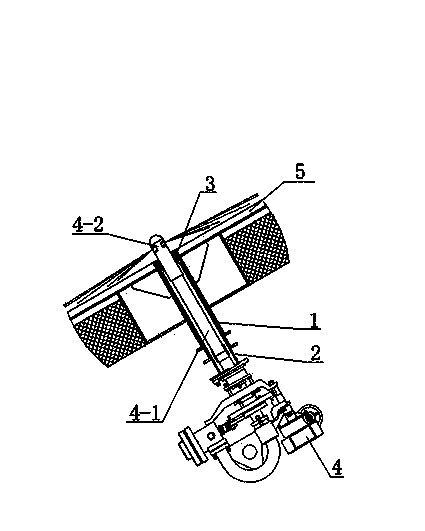

Soot blower

The invention discloses a soot blower in order to solve the problems that the existing soot blower has higher operating failure rate, unreachable blowing area and poor blowing effect. The transmission system of the soot blower of the invention comprises a motor, a reducer and a chain transmission device, wherein the reducer is particularly a cycloidal pin-wheel reducer. The soot blower is provided with an internal soot blower and an external soot blower, and an internal soot blower nozzle and an external soot blower nozzle are arranged on the internal soot blower and the external soot blower respectively; the inclined section of the internal soot blower nozzle is arranged in a way that the inclined section thereof is inclined relative to the axis of the soot blower; an air inlet is formed on the inlet section of the external soot blower; the air inlet system of the soot blower is provided with an air inlet tube, and a second air inlet chamber arranged in the middle of the air inlet tube is communicated with the air inlet and a second air inlet pipe; a first air inlet chamber is arranged at the end part of the inlet section of the internal soot blower and communicated with the end part of the inlet section of the internal soot blower and the first air inlet pipe; a first electromagnetic valve is arranged on the first air inlet pipe; and a second electromagnetic valve is arranged on the second air inlet pipe. The invention is mainly applicable to tubular heating furnaces in the field of petroleum refining and petroleum chemical engineering.

Owner:CHINA PETROCHEMICAL CORP +1

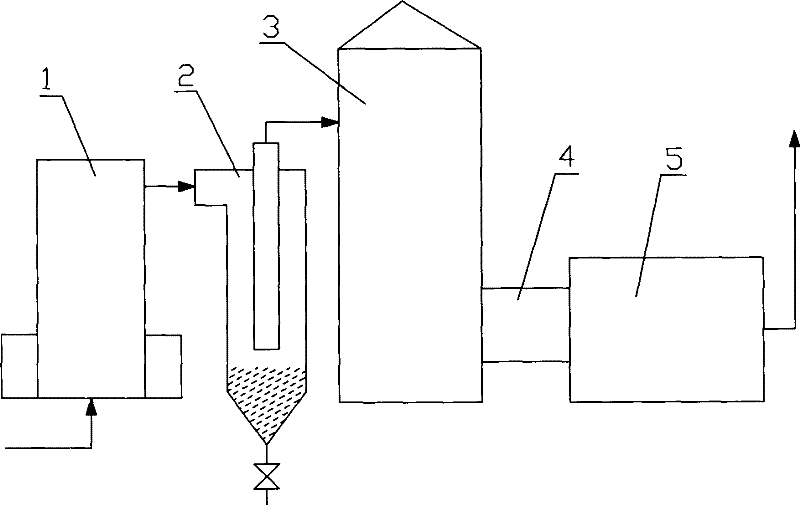

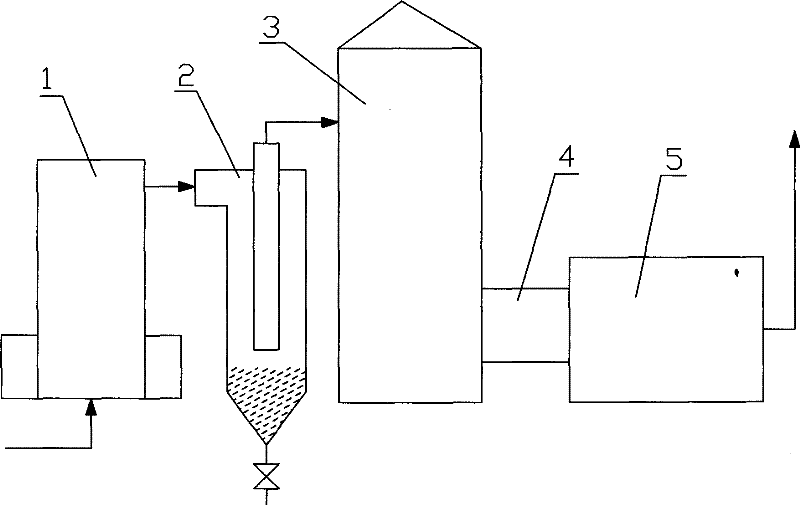

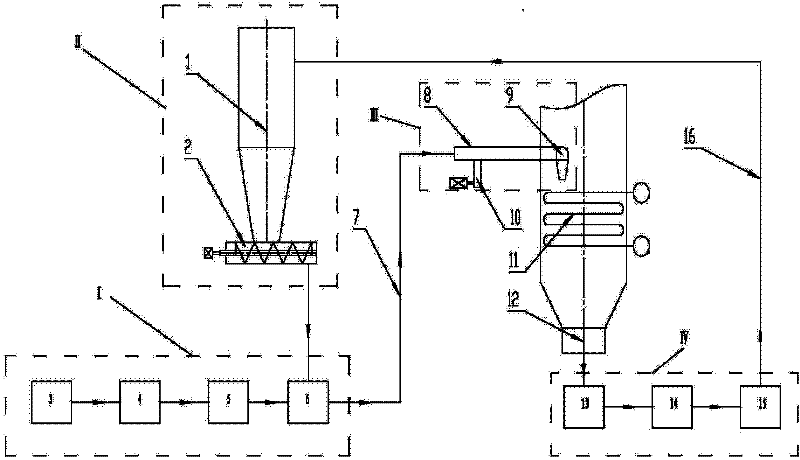

Method for blowing soot for waste heat boiler by using waste

The invention provides a method for blowing soot for a waste heat boiler by using waste, relating to a soot blowing method of a heat exchange pipe of a waste heat boiler. The method comprises the following steps: blown gas of a gas producer enters a cyclone dust collector and gas flow at an exhaust port of the cyclone dust collector enters an exhaust gas waste heat boiler. The method is characterized in that the cyclone dust collector collects deposited pulverized coal after being separated, and when the height of accumulated pulverized coal is close to a lower orifice of a central exhaust pipe of the cyclone dust collector, the accumulated pulverized coal is driven by blown gas is discharged from the exhaust port of the cyclone dust collector and enters a burner of the exhaust gas waste heat boiler; and particles produced after the combustion of blown gas and carrying coarse pulverized coal enters the boiler through a smoke channel to perform soot blowing on a heat exchange pipe bundle. The method has the advantages that blown gas, waste residues, waste soot and the like can be used as additives of coarse particulate pulverized coal soot, low-grade heat value in the waste residues and waste soot can be recycled, the utilization rate can be improved and a very good soot blowing effect can also be reached; therefore the method is an economical, efficient, convenient and quick technology.

Owner:ZHISHENG CHEM

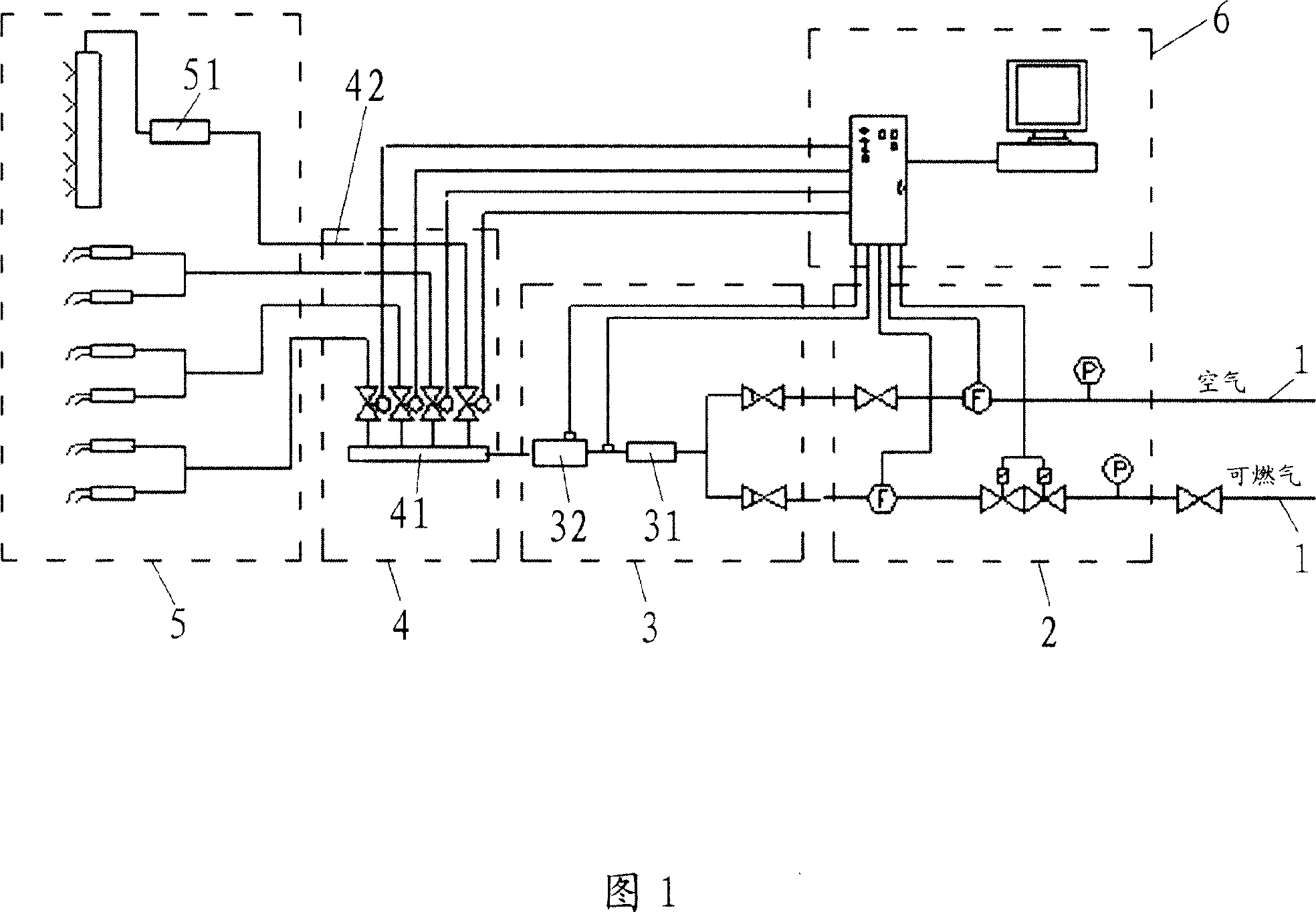

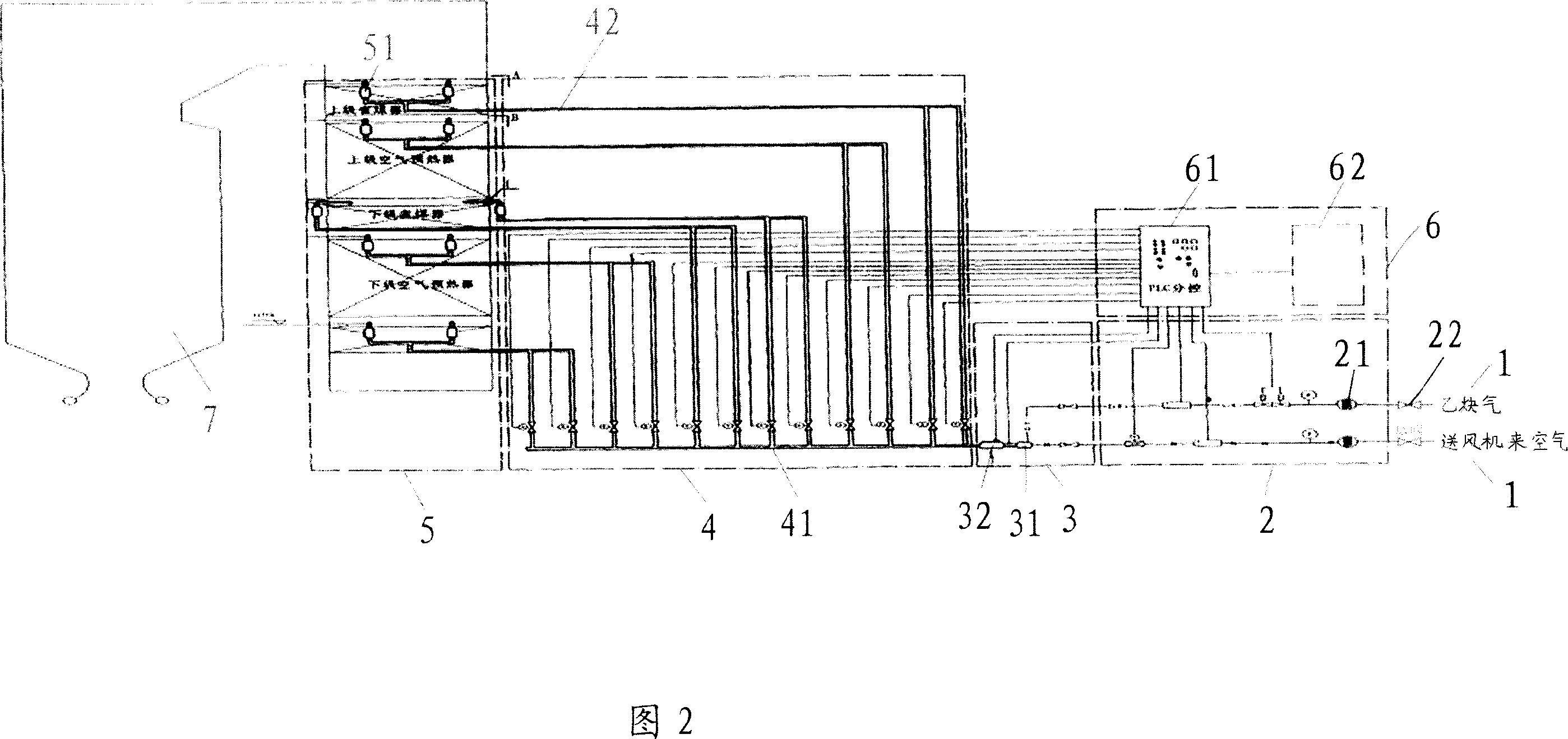

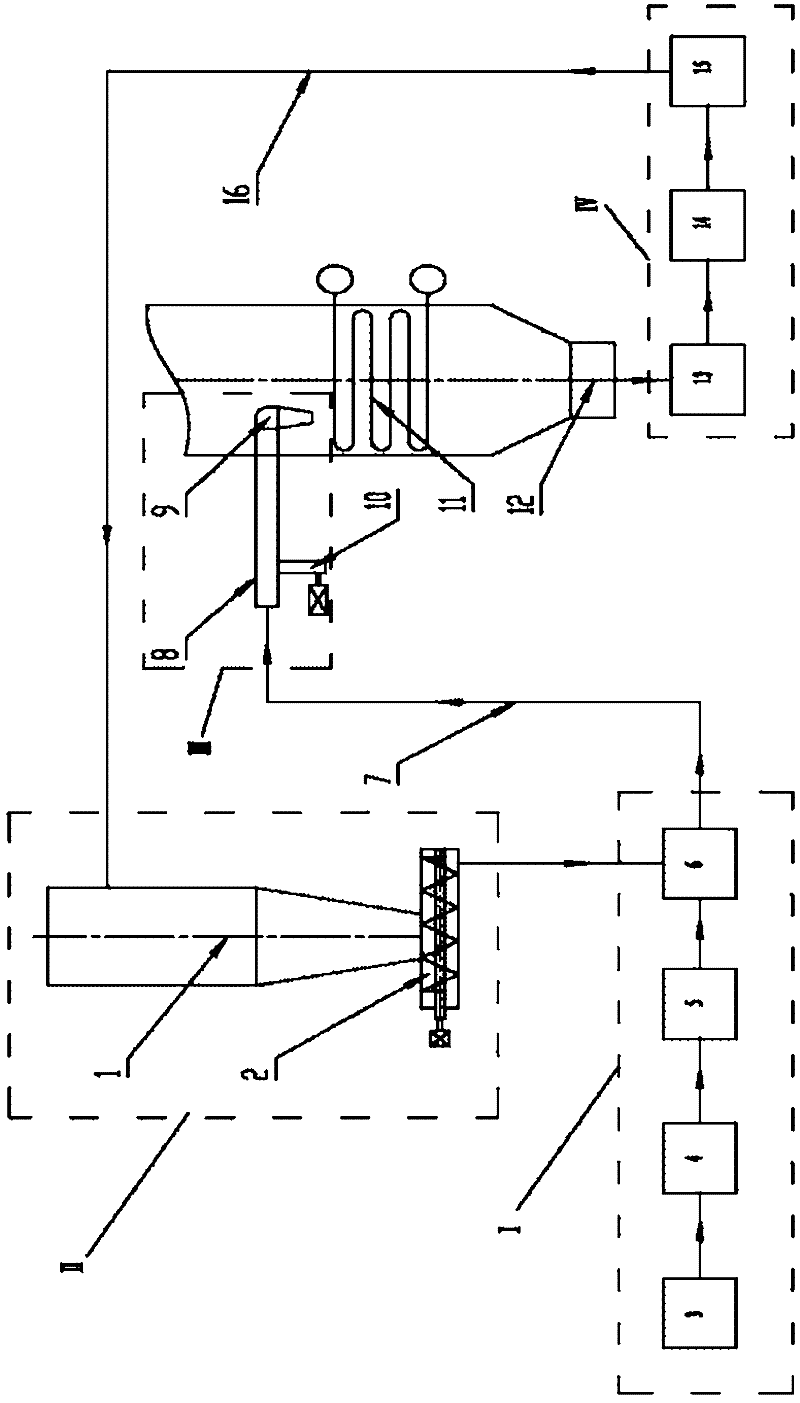

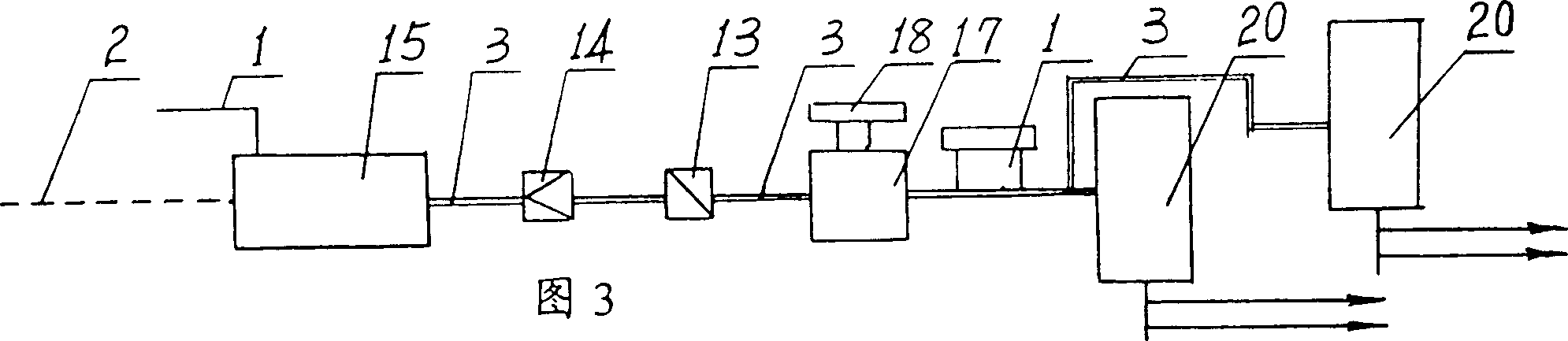

Ash injector fo gas pulsing weak-explosion wave

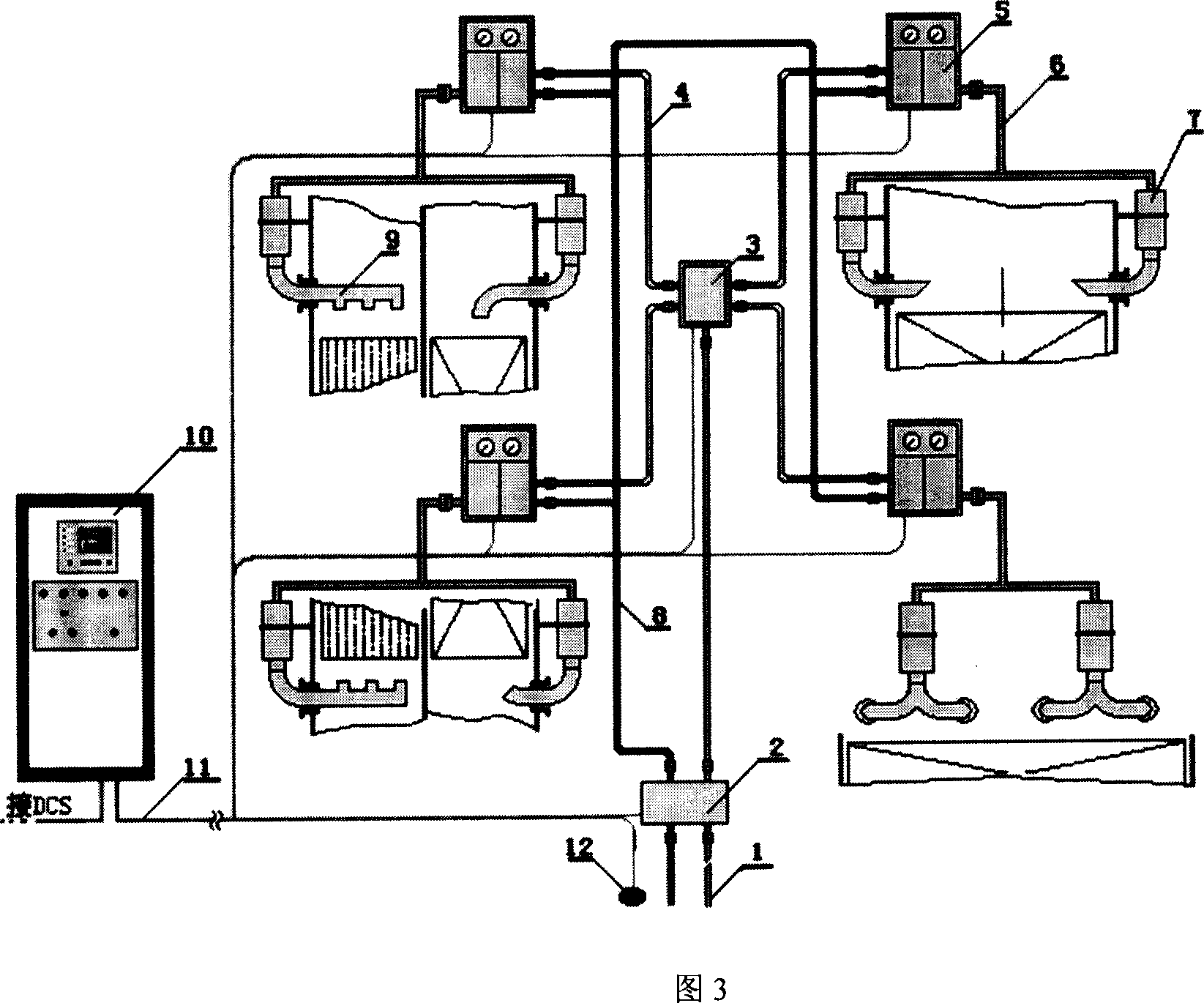

The invention comprises a combustible gas source, a flow-measuring unit for controlling the ratio of the premix gas, a mixing ignition unit for mixing the premix gas uniformly and lighting the premix gas to produce weak explosive wave high-speed jet, a soot-blowing power unit for speeding-up the spread of the gas flow flame and transmitting the spherical shock wave to the heating surface needing soot-blowing and a soot-blowing control unit for realizing automatically all kinds of soot-blowing operations according to the requirement of the given working process by collecting the field switch quantity signal and the analog quantity signal.

Owner:CHINA SHENHUA ENERGY CO LTD

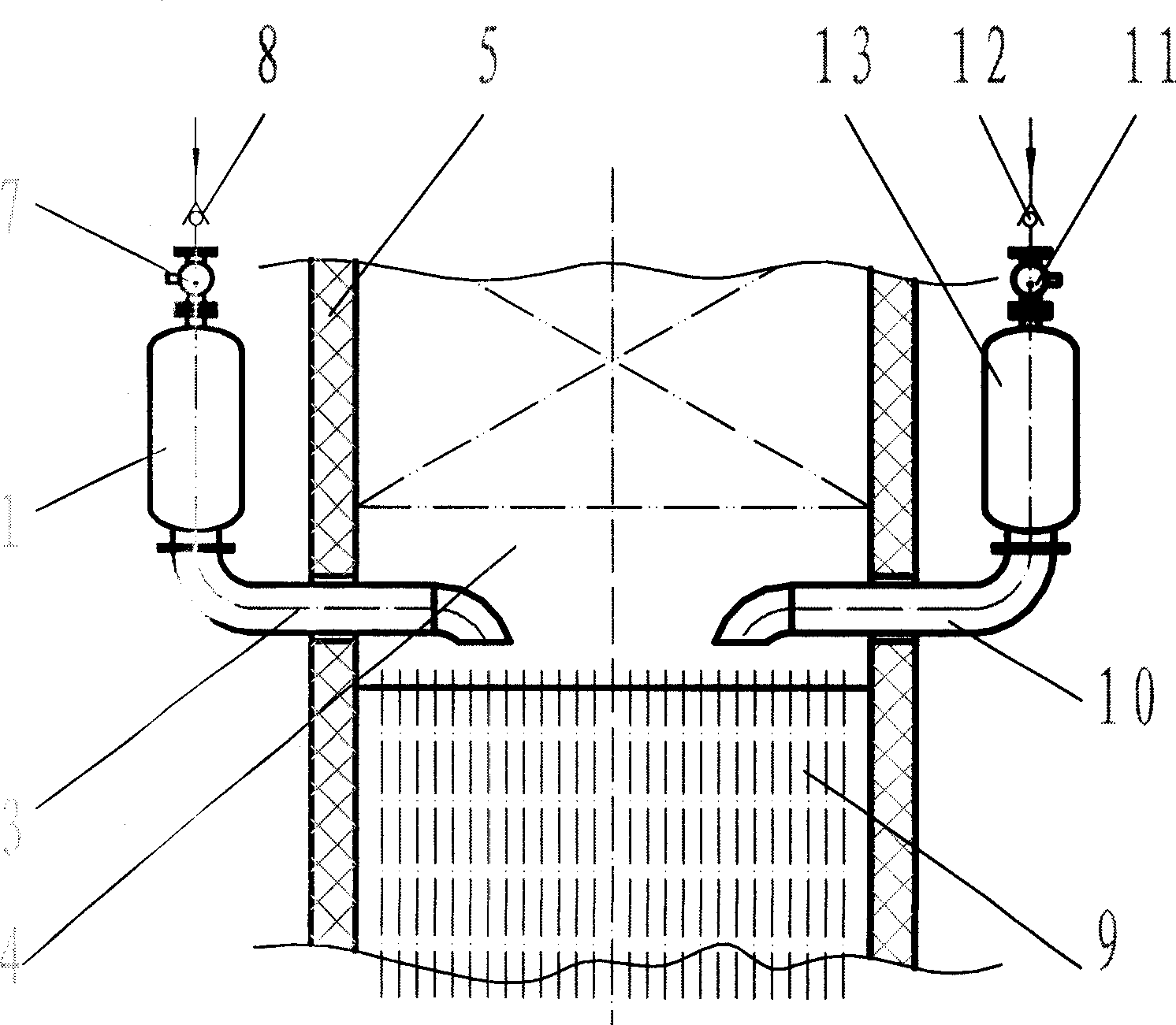

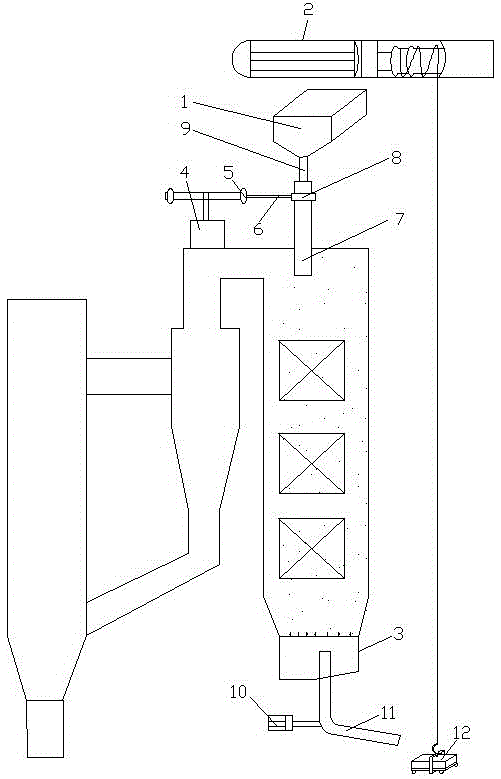

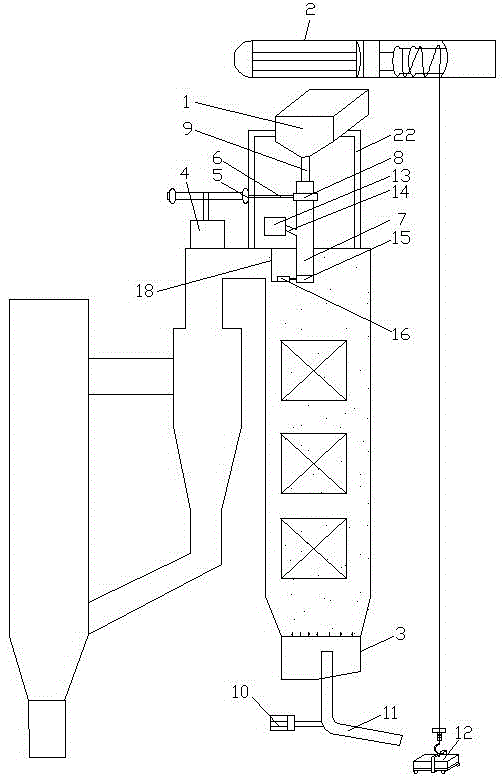

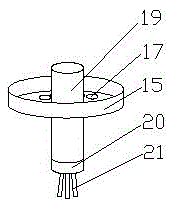

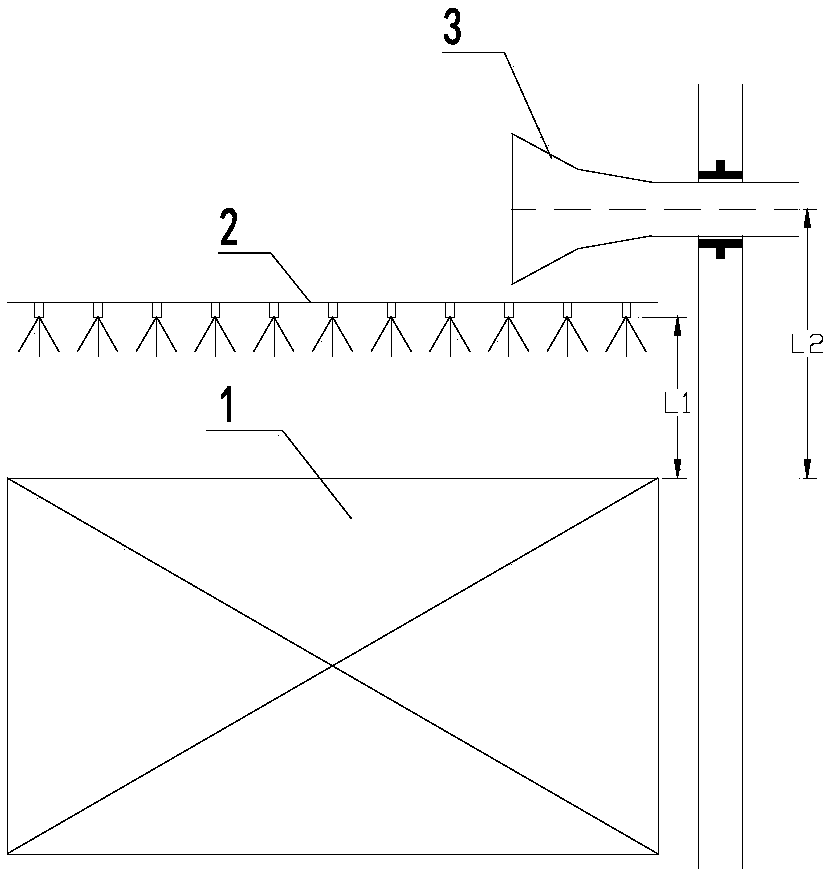

Soot blowing system and method for pi-shaped boiler furnace arch

The invention discloses a soot blowing system and method for a pi-shaped boiler furnace arch. The soot blowing system utilizes a pneumatic and steam-driven fluidization principle, and overcomes the friction of accumulated soot on the upper slope of the furnace arch, thus enabling the accumulated soot to separately flow to a hearth and a horizontal flue to be discharged. A hood-shaped soot blower is mounted on a diaphragm of the upper slope of the furnace arch, arranged between a high temperature superheater and a high temperature reheater, penetrates through the upper slope of the furnace arch, and is connected with a soot blowing media pipeline. The shapes of a first soot blowing pipe and a second soot blowing pipe of the hood-shaped soot blower are telescopic pipes, thereby improving thespeed of soot blowing airflow, and enhancing the soot blowing effect. During the soot blowing process, compressed air firstly blows the accumulated soot on the upper slope of the furnace arch, and then steam blows residual accumulated soot hard to clear, so that an excellent soot blowing effect can be achieved by a compound blowing mode. The soot blowing system can effectively clear the accumulated soot on the upper slope of the boiler furnace arch, avoids the occurrence of excessive blowing loss and pipe explosion of the furnace arch and the wall face of the superheater and saves the energyconsumption of blowing soot.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

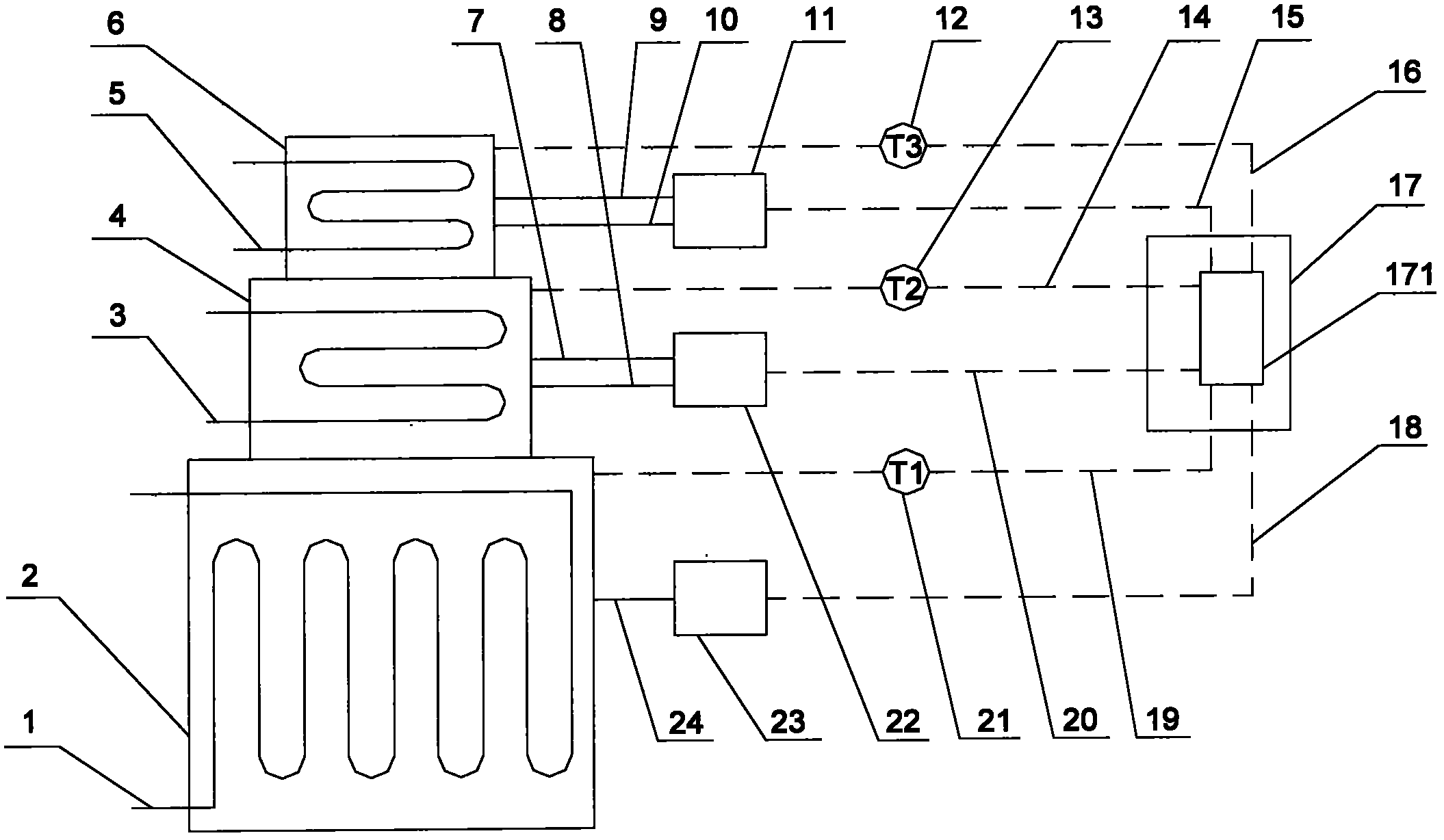

Soot blowing method of heating furnace

InactiveCN102840591AIncreased surface thermal resistanceExtended service lifeSolid removalAir preheaterFlue gas

The invention discloses a soot blowing method of a heating furnace. The method comprises the following steps: A, outlet flue gas temperature values T1, T2 and T3 of a radiation section, a convection section and an air preheater of the heating furnace are respectively measured by a thermoelectric couple, and are transmitted to a control cabinet; B, the control cabinet compares the outlet flue gas temperature values T1, T2 and T3 with preset outlet flue gas temperature values TC1, TC2 and TC3 of the radiation section, the convection section and the air preheater of the heating furnace which is normally operated, so as to obtain a signal for determining whether the radiation section, the convection section and the air preheater of the heating furnace are required to carry out soot blowing and a signal of soot blowing time according to difference values DeltaT1, DeltaT2 and DeltaT3; C, soot blowing machines of the radiation section, the convection section and the air preheater of the heating furnace accomplish soot blowing operation according to a soot blowing signal of the control cabinet; and D, steps A, B and C are repeated. The soot blowing method can perform blowing operation according to the practical soot accumulated state on the surface of a furnace tube or a heat exchange tube and perform timed and designated area blowing, and the phenomenon of over-blowing or under-blowing can not occur.

Owner:CHINA PETROLEUM & CHEM CORP +1

Soot blowing explosion wave method

InactiveCN1810388AHigh strengthImprove soot blowing effectGaseous fuelsGaseous fuel burnerEngineeringSoot

The present invention belongs to the field of soot blowing explosion wave technology, and is especially one method of blowing soot with the explosion wave produced with the burning and exploding pre-mixed gas of fuel and combustion assisting gas. The pre-mixed gas of fuel and combustion assisting gas, which is oxygen, is made to burn and explode inside the explosion tank communicated via nozzle with flue. Compared with available technology, the present invention has even high explosion wave strength, raised soot blowing effect, greatly reduced volume of the explosion tank, low cost and saving in fuel.

Owner:BEIJING FANYUANXING SCI & TECH

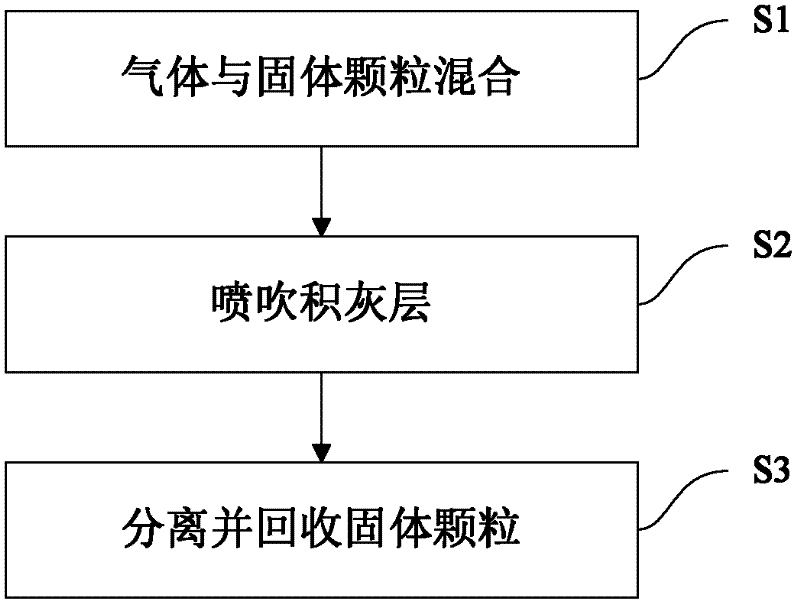

Dust deposition removing method and system

InactiveCN102313288AApparent density can be adjustedEasy to recycleSolid removalNon-rotary device cleaningParticle mixingAirflow

The invention discloses a dust deposition removing method and a system. The method comprises the following steps: gas and solid particles are mixed into dust blowing medium flow; and the dust blowing medium flow is sprayed onto a dust deposition layer. The system comprises a gas transmission device, a particle supply device, a gas and particle mixing device, a particle separation and recycle device and a dust blowing gun. In the method, the dust deposition layer on a heating surface is broken and peeled off through the continuous strike of the solid particles and dust deposition can be removed thoroughly by combining the blowing and sweeping action of air current, in particular to the highly cohesive dust deposition on the surface of the heating surface of a boiler. The dust deposition on the surfaces of a horizontal heating surface and a vertical heating surface can be effectively removed through the system provided by the invention.

Owner:BEIJING JIAOTONG UNIV

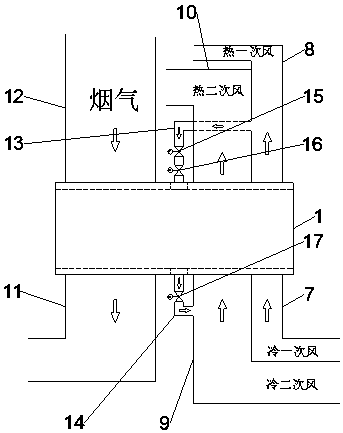

Device and method for relieving blockage of rotary air pre-heater by means of hot primary air preheating and heat storage elements

PendingCN111306568AIncrease wall temperatureFlexible layoutCorrosion preventionIndirect carbon-dioxide mitigationCold airThermodynamics

The invention discloses a device and method for relieving blockage of a rotary air pre-heater by means of hot primary air preheating and heat storage elements. The device structurally comprises a hotprimary air guiding-out pipeline, an adjusting air door, a turning-off air door, a preheating bin hot-end sector plate, a preheating bin cold-end sector plate, a preheating cold air guiding-out pipeline and the like. An independent heat storage element preheating bin is formed between the preheating bin hot-end sector plate and the preheating bin cold-end sector plate and is located in front of anair distribution bin before the rotary air pre-heater is turned to a flue gas branch bin and the flue gas branch bin, the heat storage element is preheated from top to bottom by the aid of hot primary air, and the temperature of the heat storage element entering the flue gas branch bin is increased, so that the purpose of reducing the ammonium bisulfate (ABS) deposition area is achieved, the ABSdeposition area can be cleared by the aid of a soot blower more easily, and the problem that the air pre-heater is blocked seriously due to the fact that ABS adheres to the rotary air pre-heater of aboiler of a coal-fired power plant is solved.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

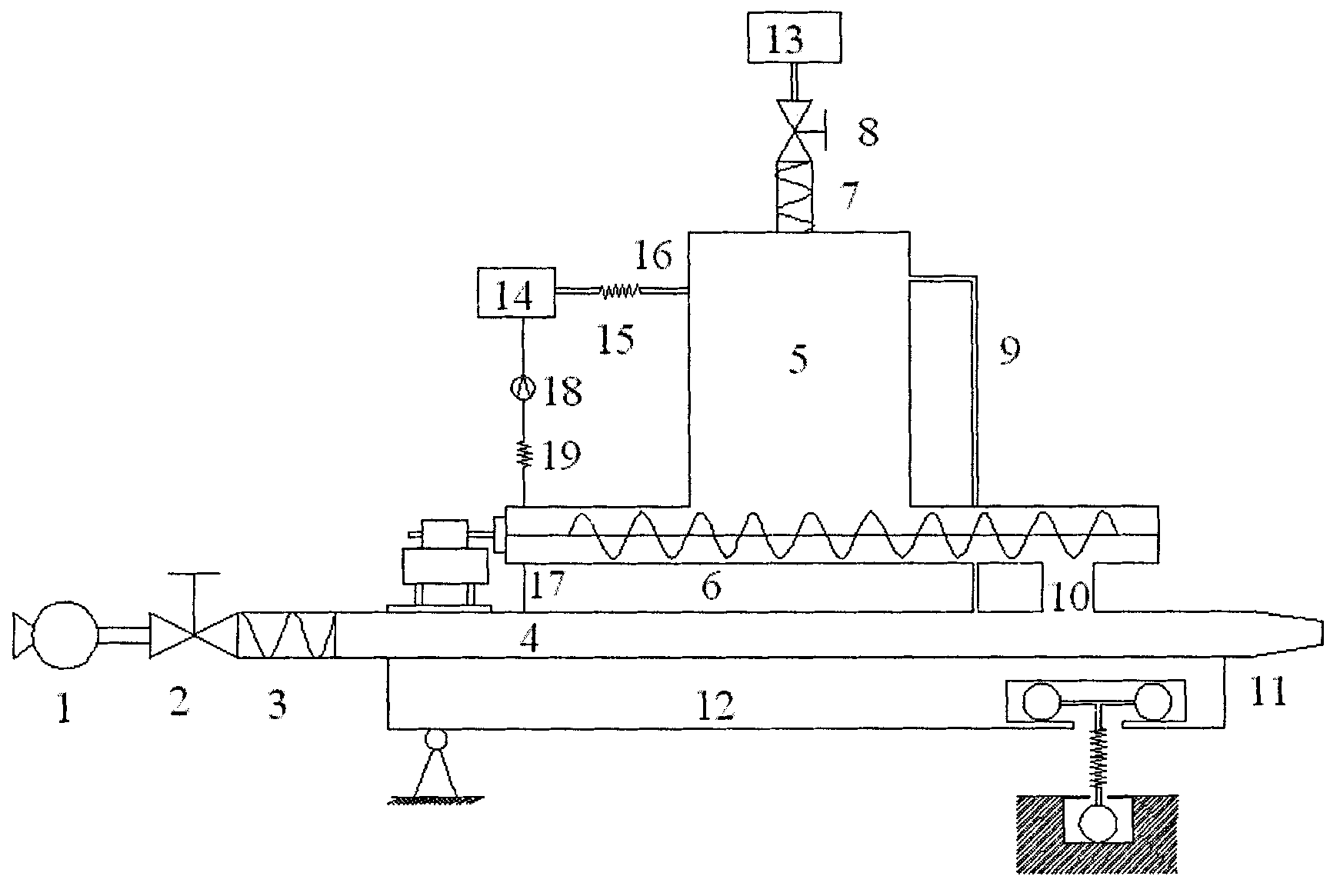

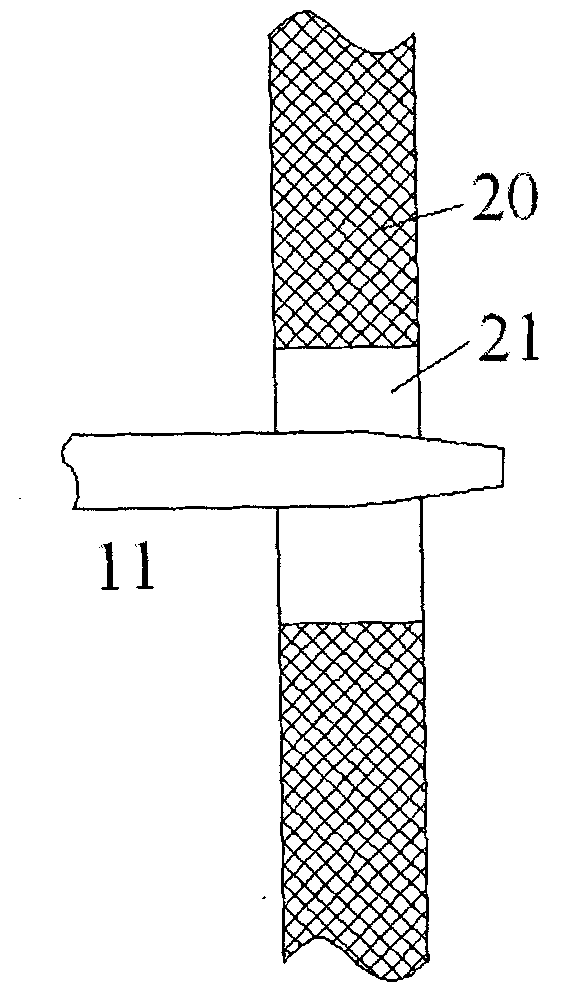

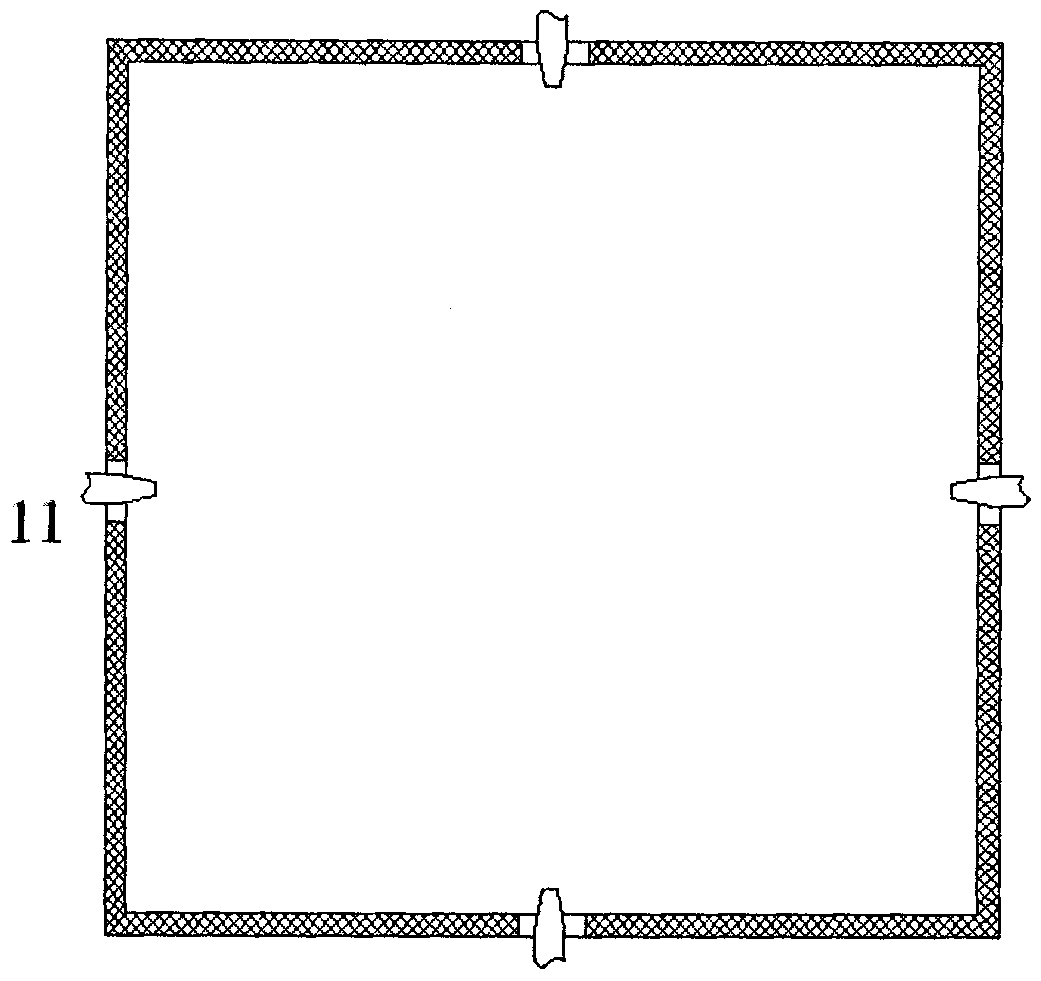

Hearth soot blower

InactiveCN101922720AReduce the temperatureThere will be no melting and bonding phenomenonLighting and heating apparatusCold airHearth

The invention discloses a hearth soot blower which is composed of a Roots blower, a volume regulating valve, a transmitting tube front hose, a transmitting duct, an ice bunker, a spiral conveyer, a scanning platform, an ice pellet machine, an air cooler, a cold air hose, a cold air inlet pipe, a cold air outlet pipe, a recirculating blower, a cold air return hose and the like, wherein the Roots blower pressurizes air into the transmitting duct; the prefabricated ice pellets are filled into the ice bunker; the ice pellets are continuously and quantitatively added into the transmitting duct through the spiral conveyer and a blanking port so as to form the air-particle two-phase mixture; the mixture accelerates at the jet port to form a high-speed jetted ice pellet particle group; and the high-speed jetted ice pellet particle group is transmitted into the hearth and impacts the opposite hearth soot deposit wall surface to realize the soot blowing operation after short-time flying. The invention uses high speed ice pellets to realize soot blowing, has the advantages of low mass of soot blowing medium and favorable soot blowing effect, can greatly relieve the problems of thermal shock, load, efficiency and the like, basically eliminates dead spaces of soot blowing, is convenient to install and operate, and is applicable to hearth soot blowing (deslagging) of a station boiler.

Owner:NANJING UNIV OF SCI & TECH

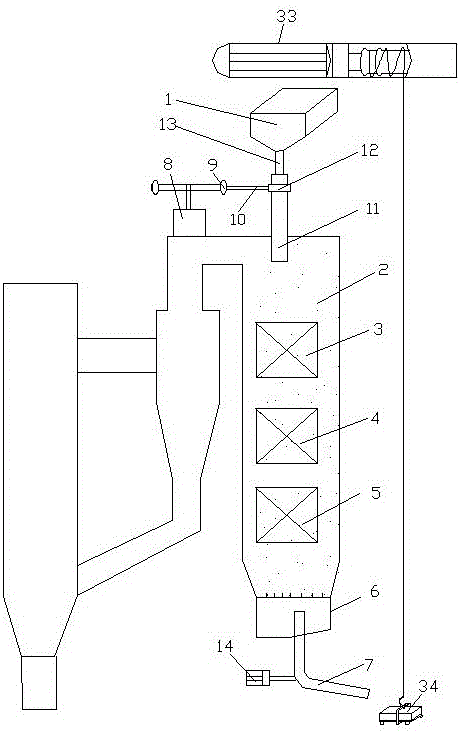

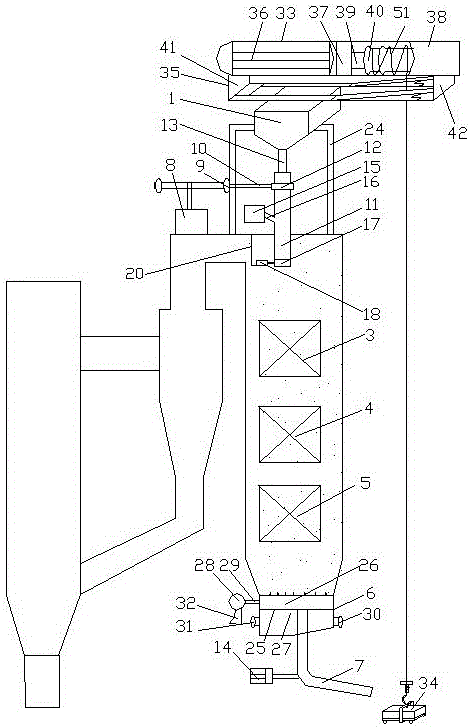

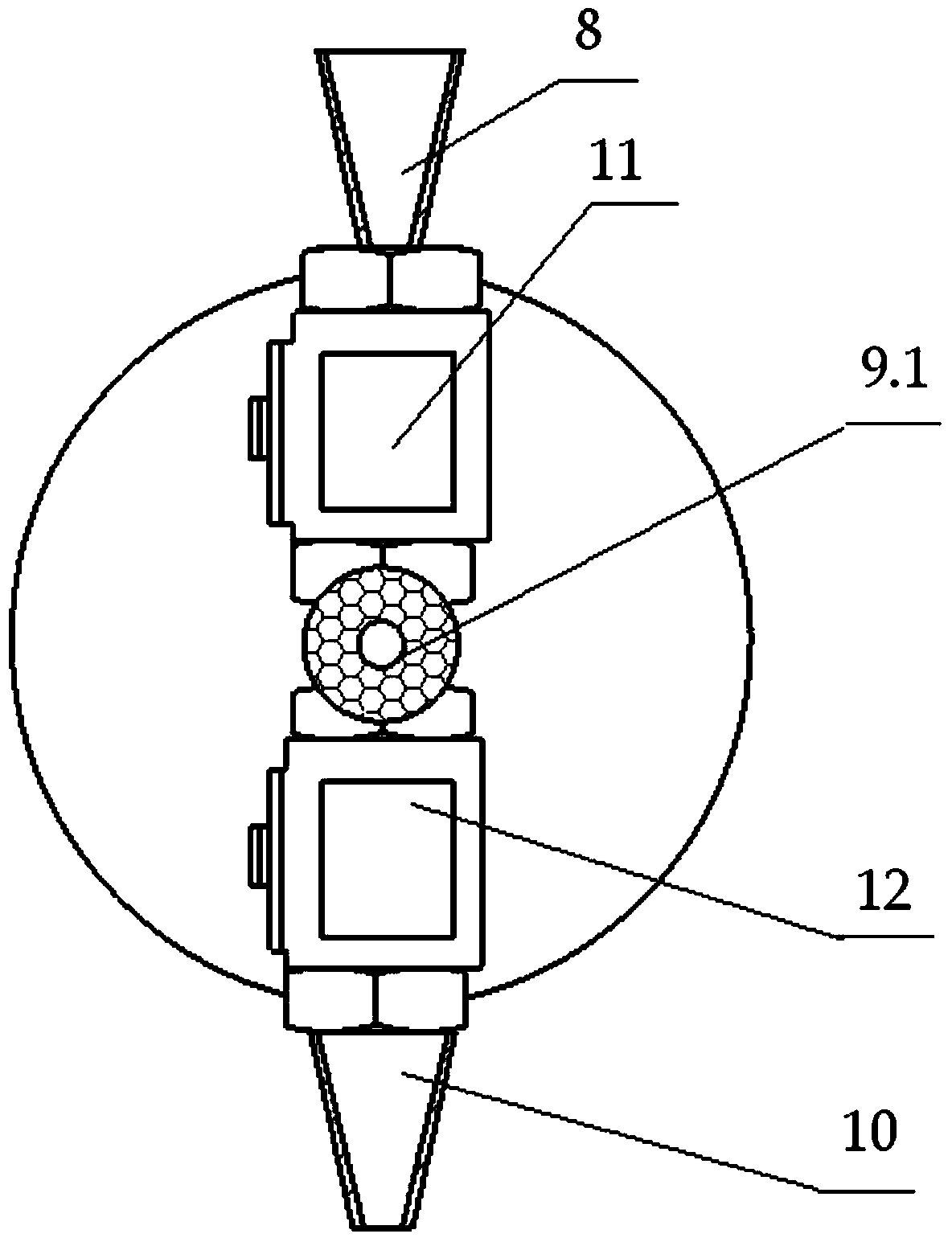

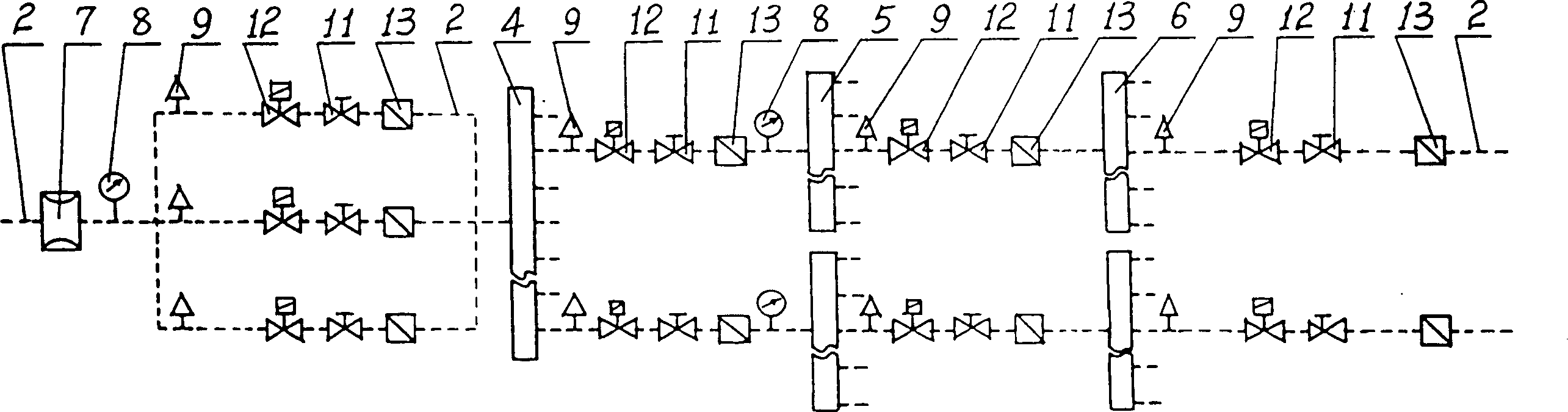

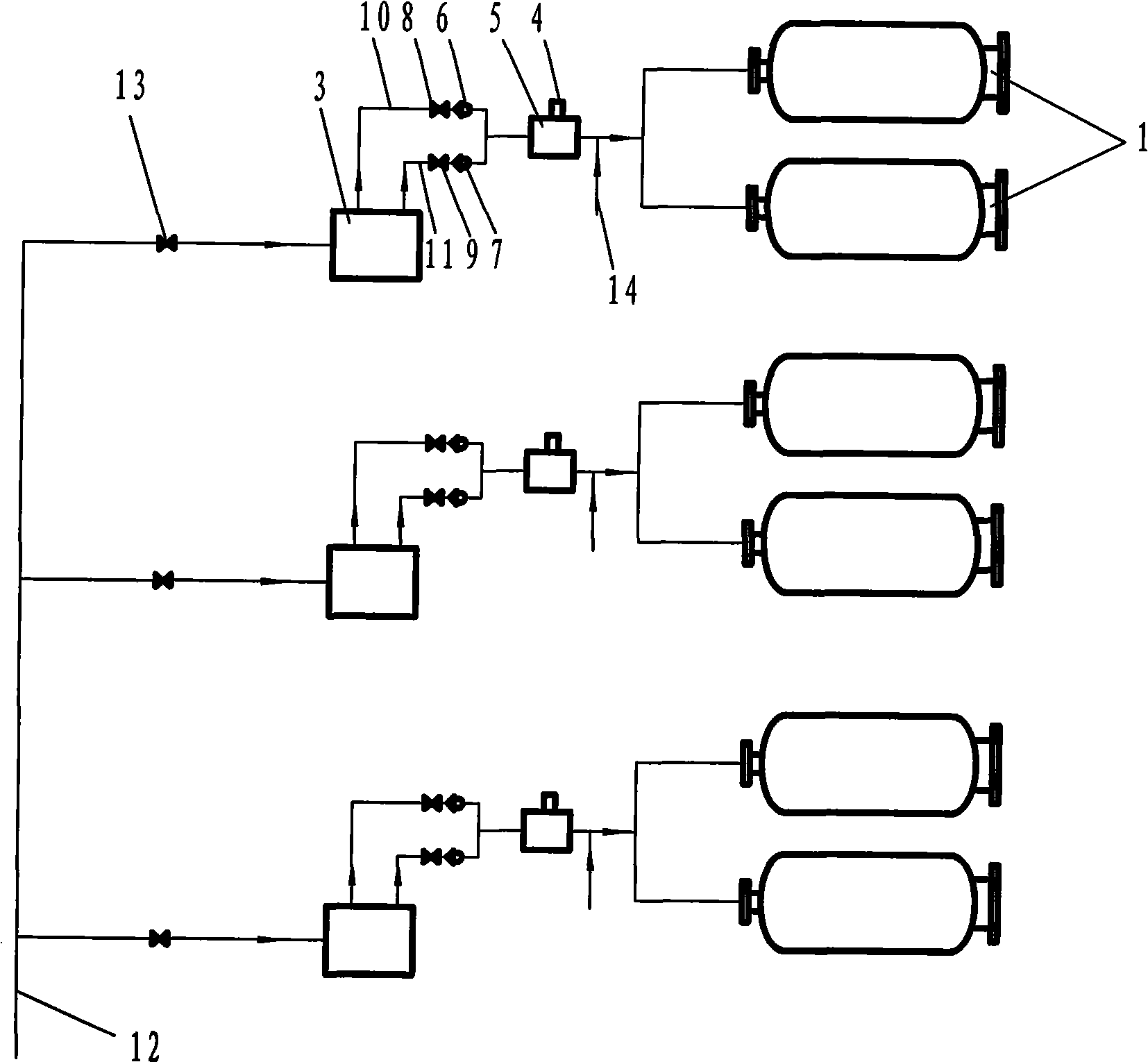

Unit individual type gas impulse ash blower

InactiveCN1920385AEasy maintenance and operationExtended service lifeSolid removalProcess engineeringEngineering

The invention relates to a unit fuel gas impulse ash blower, which comprises: a gas source distributor, a fuel gas distributor, an impulse initiator, an impulse generator, and an ejector, wherein each ejector has one impulse generator to form one ash blower; each 2-4 ash blowers are one group to be mounted on the position needing to blow ash inside the boiler; each ash blowing point via mixing gas tube is connected to one impulse initiator; the fuel gas via gas distributor is connected to the fuel gas tube and fuel gas distributor; the fuel gas distributor via tubes is connected to each impulse initiator; the air tube via gas distributor is connected to the impulse initiator; and the gas distributor is connected to the controller. The invention can avoid interference, prolong the service life, and improve the safety.

Owner:哈尔滨瑞尔能源技术有限公司

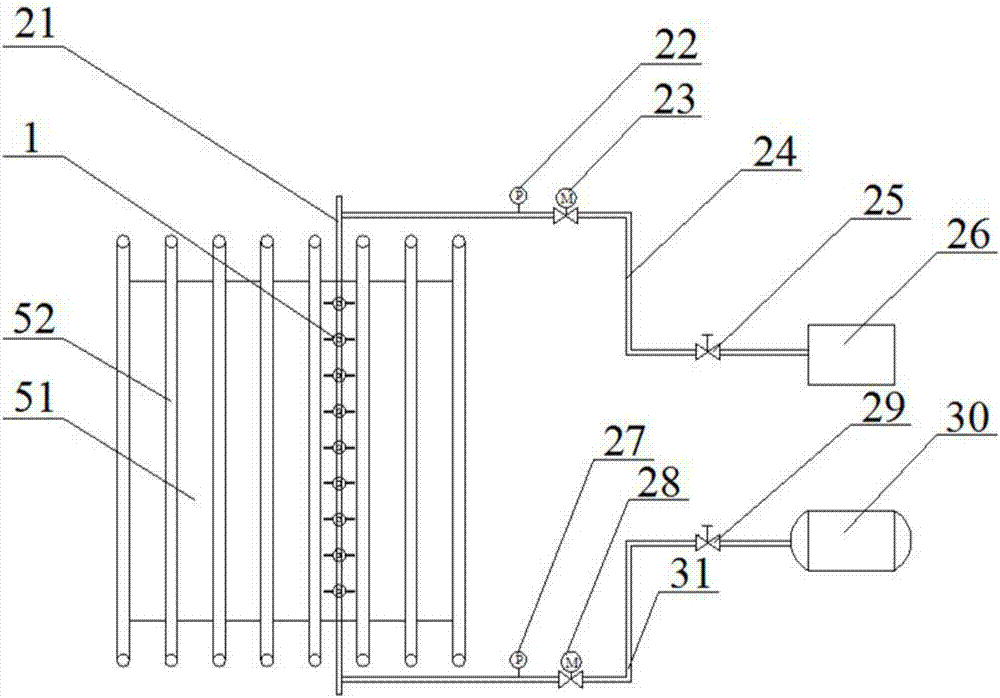

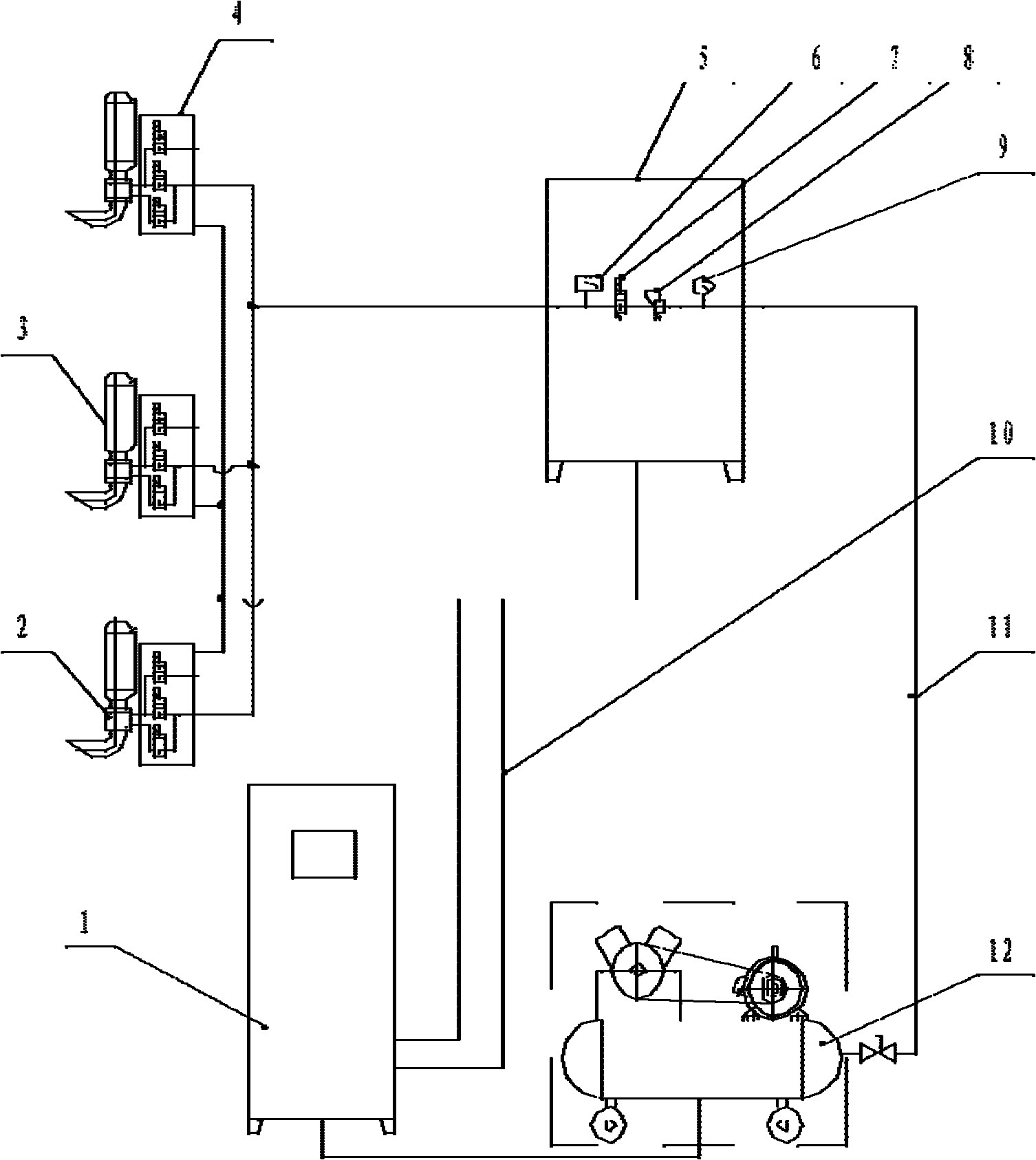

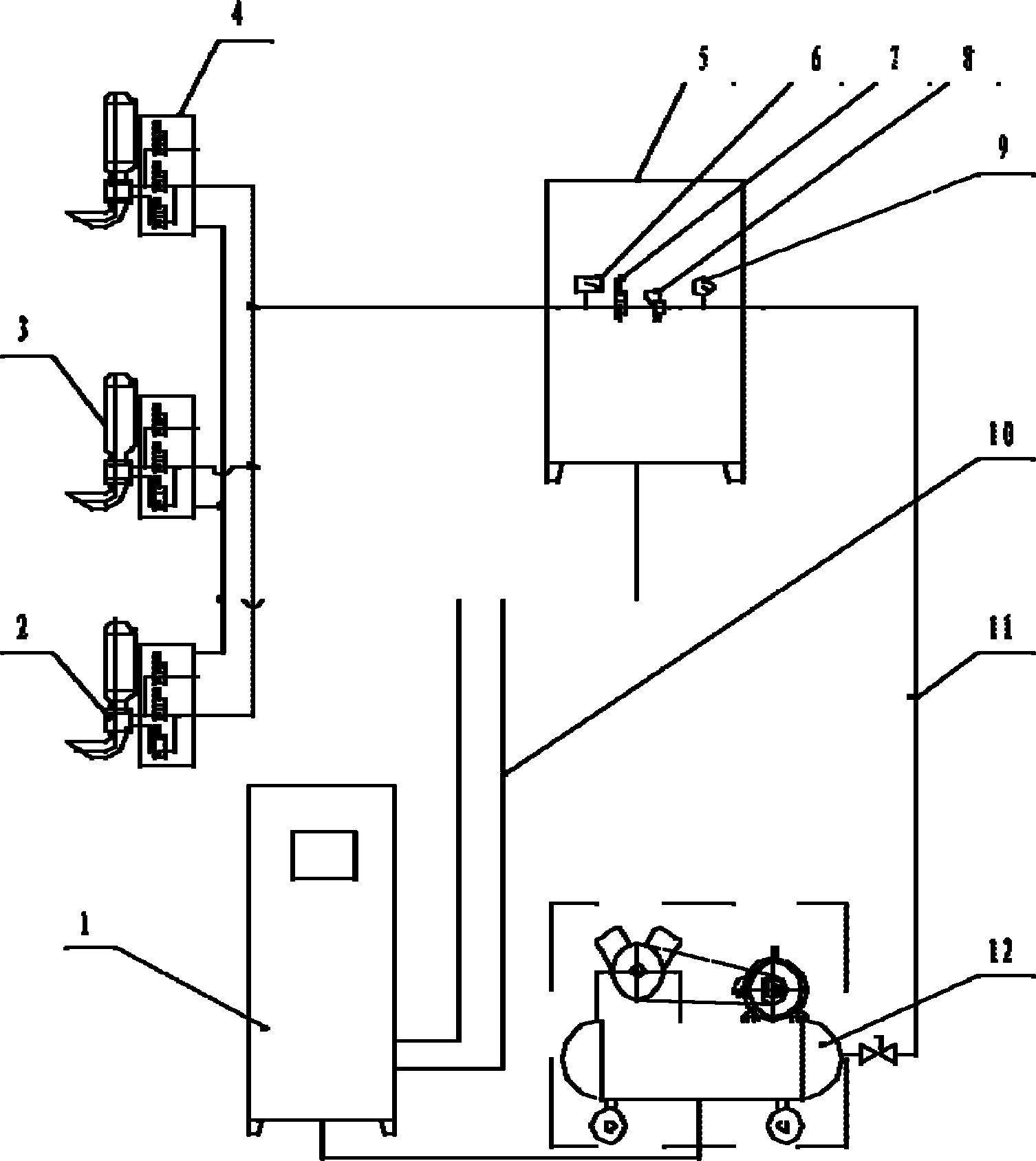

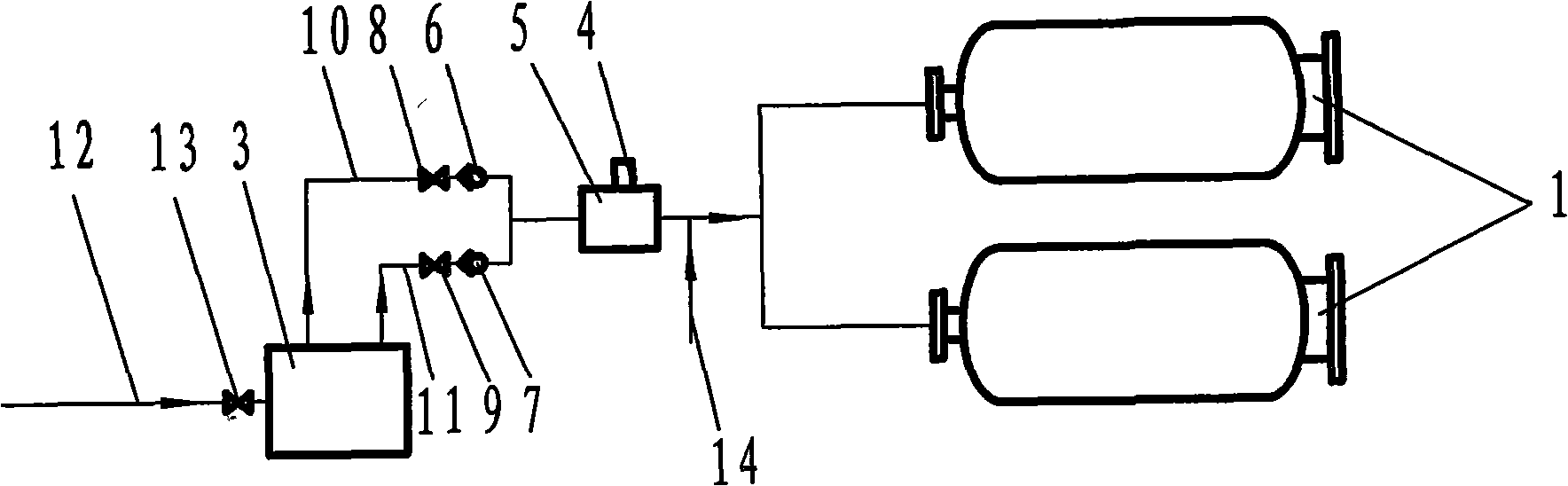

Gas energy pulse soot blower utilizing compressed gas

The invention discloses a gas energy pulse soot blower utilizing compressed gas, which comprises a plurality of groups of pulse shock wave generators, wherein each group of pulse shock wave generator comprises a solenoid valve for controlling the group of gas supply branch circuit to switch on / off, a pulse tank for generating shock waves, and a releaser for releasing the shock waves, and each group of gas supply branch circuit is communicated with a compressed gas generating device through a gas transmission pipeline. The gas energy pulse soot blower utilizing the compressed gas disclosed by the invention takes the compressed gas as the gas energy for boiler soot blowing, the cost is lower, the generated shock wave energy is larger, the soot blowing effect is more obvious, and the soot blower has a simple structure, low failure rate and is safer and more reliable.

Owner:BEIJING FANYUANXING SCI & TECH

Device for improving fullness of combustible gas in shock wave generation tank

The invention discloses a device for improving fullness of combustible gas in a shock wave generation tank and belongs to the technical field of boiler soot blowing. The device comprises an air inlet connecting port, a seal head, a first partition plate, a second partition plate, a generator tank body and a nozzle. The air inlet connecting port is fixedly connected with one end of the generator tank body, the other end of the generator tank body is fixedly connected with the nozzle, and the second partition plate and the first partition plate are sequentially arranged in the generator tank body close to the air inlet connecting port end according to the air inlet direction and are parallelly arranged. The air inlet connecting port is provided with a plurality of inclined holes, the first partition plate is provided with a center through hole and inclined holes evenly distributed around the center through hole along the circumference, and the second partition plate is provided with a center through hole, inclined holes evenly distributed around the center through hole along the circumference and strip-shaped through holes. According to the device, mixed gas can evenly rapid fill the generator tank body, energy of gas shock waves is maximized, and the gas utilization rate of a shock wave generation system and the soot blowing effect are improved.

Owner:BEIJING GUANGHUA TEXTILE GRP +1

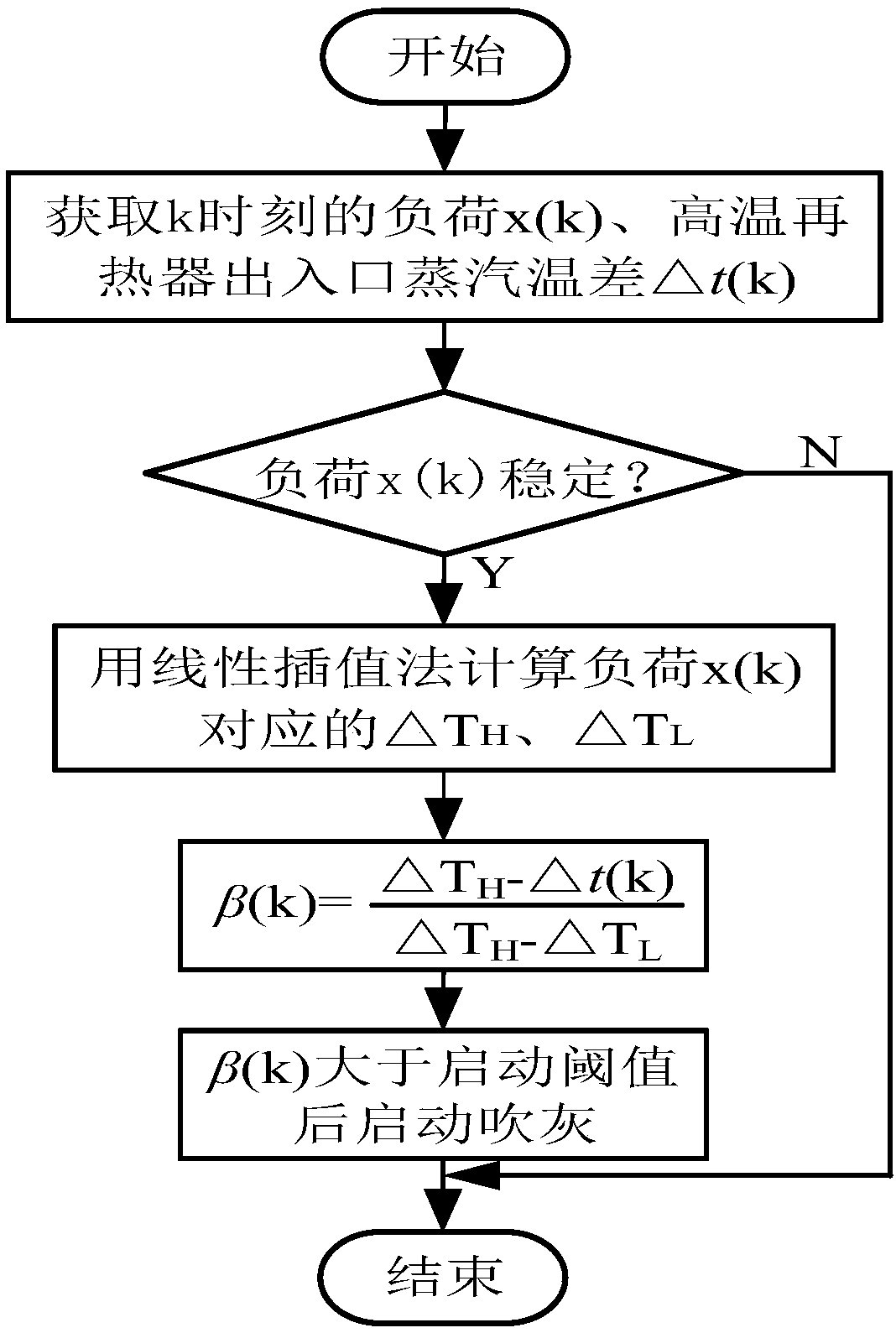

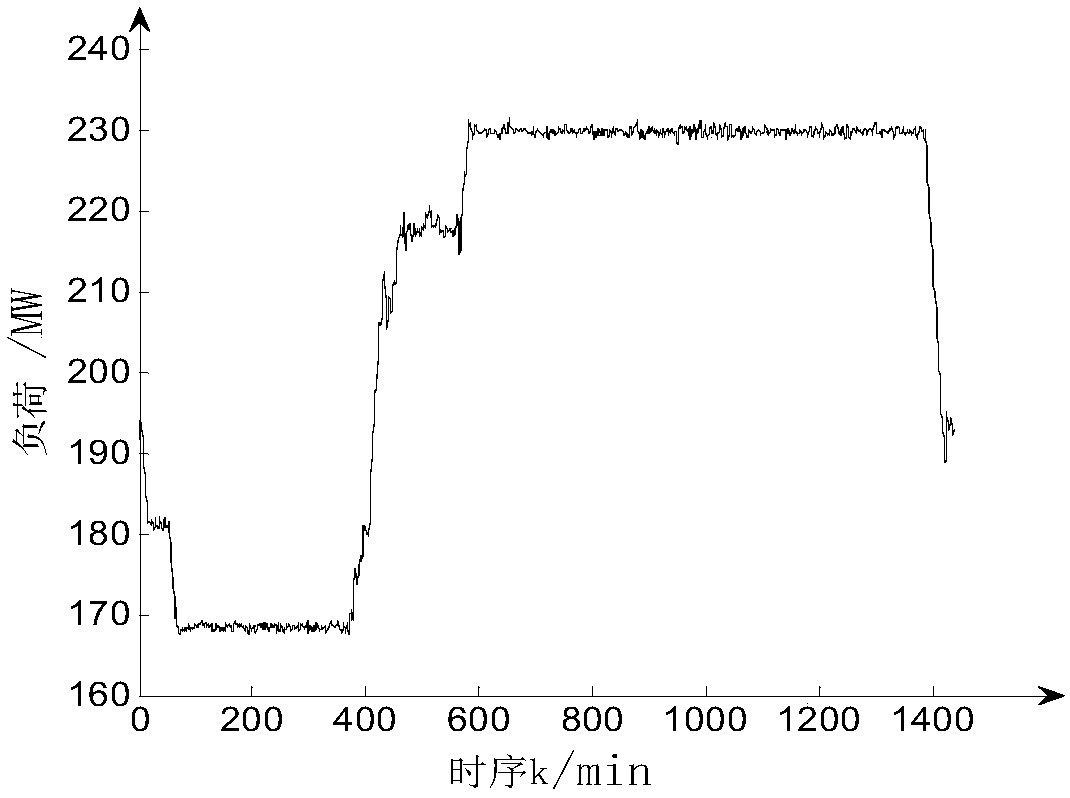

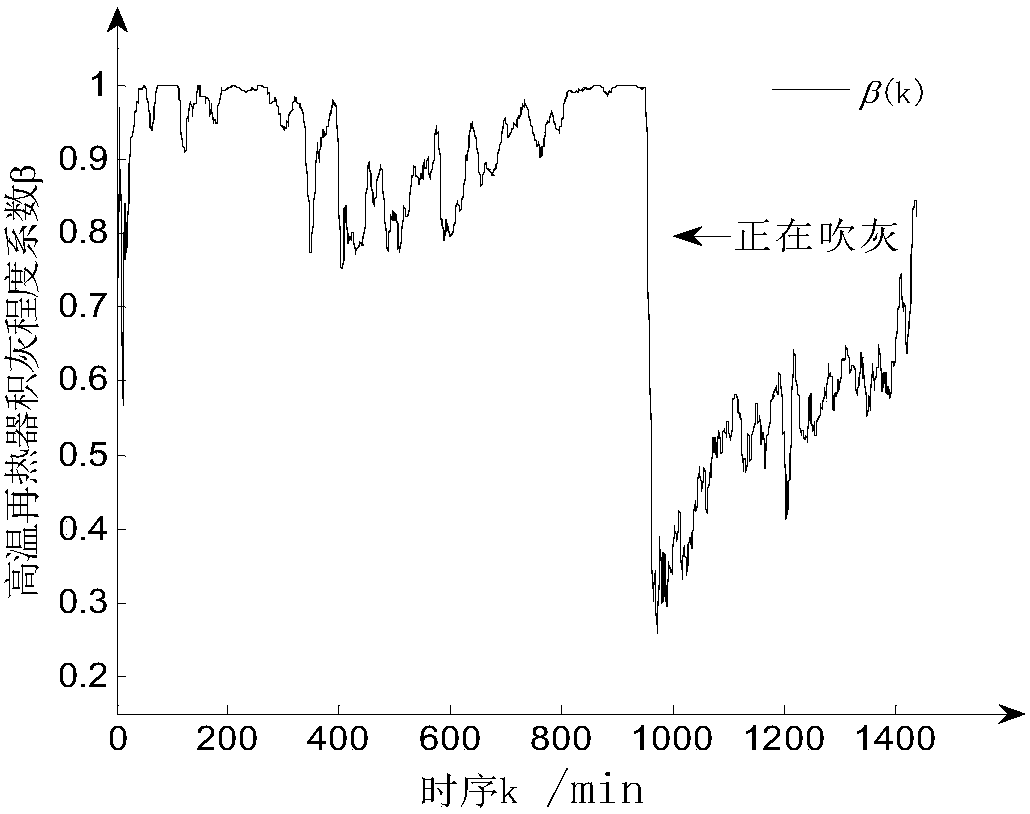

Soot blowing method for high-temperature reheater of coal-fired boiler

ActiveCN108278625ASoot blowing effect is goodAccurate and reliable ash accumulation coefficientSolid removalEngineeringCoal fired

The invention relates to a soot blowing method for a high-temperature reheater of a coal-fired boiler. The method comprises the following steps: (1) acquiring the temperature difference of steam at the inlet and the outlet of the high-temperature reheater; (2) acquiring a soot accumulation degree coefficient according to the temperature difference of the steam at the inlet and the outlet of the high-temperature reheater; and (3) when the soot accumulation degree coefficient is higher than a start threshold value, starting soot blowing until the soot accumulation degree coefficient is reduced below the start threshold value. Compared with the prior art, the method provided by the invention realizes that the soot accumulation degree coefficient can accurately reflect the soot accumulation degree of the high-temperature reheater so that accurate and reliable soot blowing can be implemented and a good soot blowing effect is achieved.

Owner:HUANENG POWER INTERNATIONAL +1

High-frequency high voice and strong sound wave blower

ActiveCN1928433AImprove soot blowing effectProduces a non-contact cleaning effectSound producing devicesSolid removalSoot blowerAirflow

The invention relates to an acoustic soot blower with high frequency and sound intensity, belonging to boiler equipment technological area. The blower comprises resonance cavity cap, gas-ring cover and air duct. They are concentrically installed in turn. On the outside of resonance cavity cap integral ring for resonance cavity is set and the end of resonance cavity cap is turbulent flow ring. One supporting concentric bar is set on the center of resonance cavity cap and circular resonance cavity, whose bottom is arc-shaped, is formed by the roof of the bar and the inner of resonance cavity cap. The frontal end of the supporting concentric bar extends into the end of gas-ring cover and circular gap, air room and diversion hole are formed by the supporting concentric bar and the inside of gas-ring cover. The end of air duct extends into the other end of gas-ring cover. In the invention, there are no any rotary parts and no need to e maintained in industrial scene. Dried saturated steam or compressed air is used as the driving source for acoustic soot blower. The soot blower is set on the furnace wall of boiler or in the boiler so as to reach optimal soot-blowing performance.

Owner:北京中电慧能国际电力科技有限公司

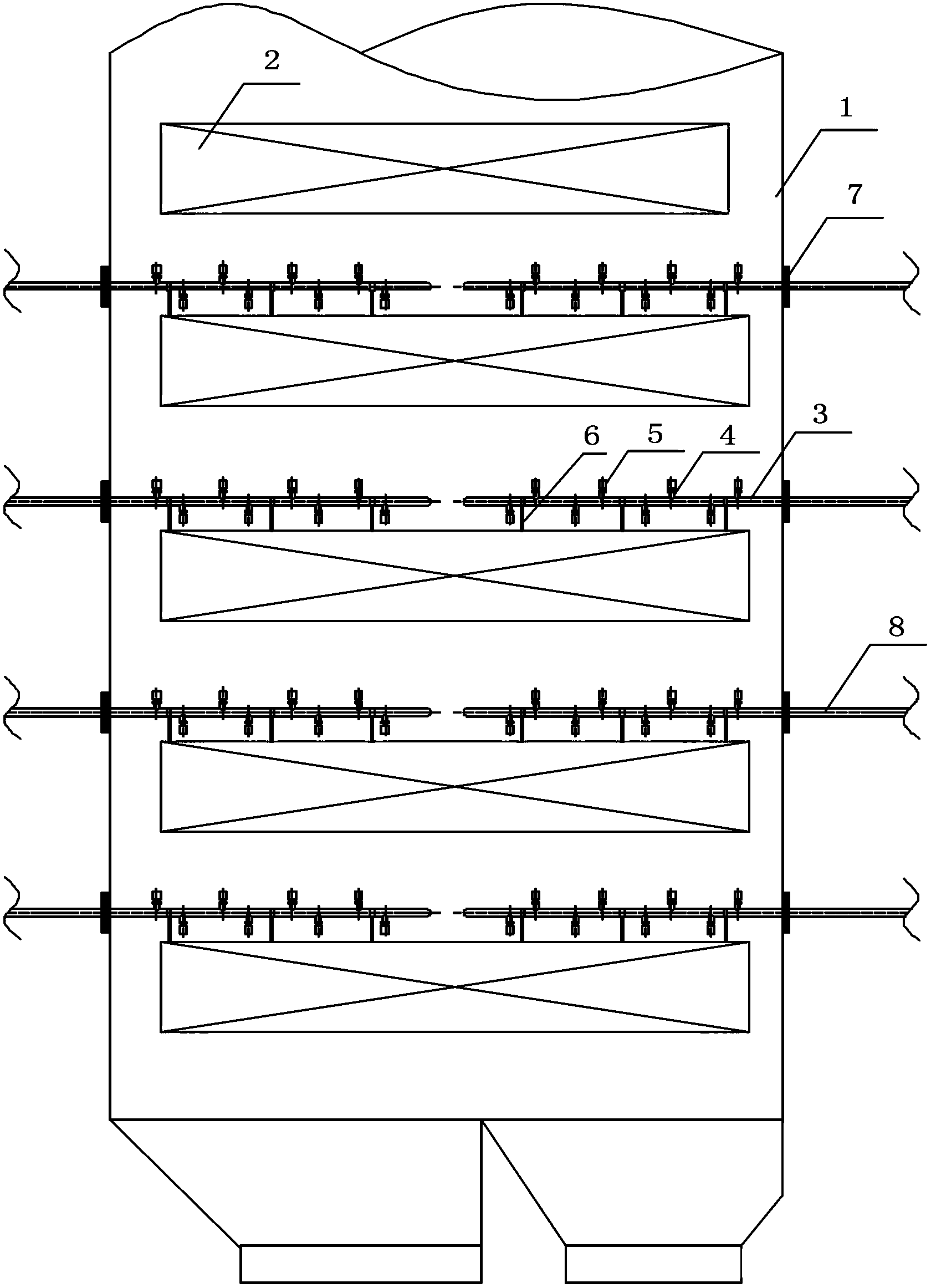

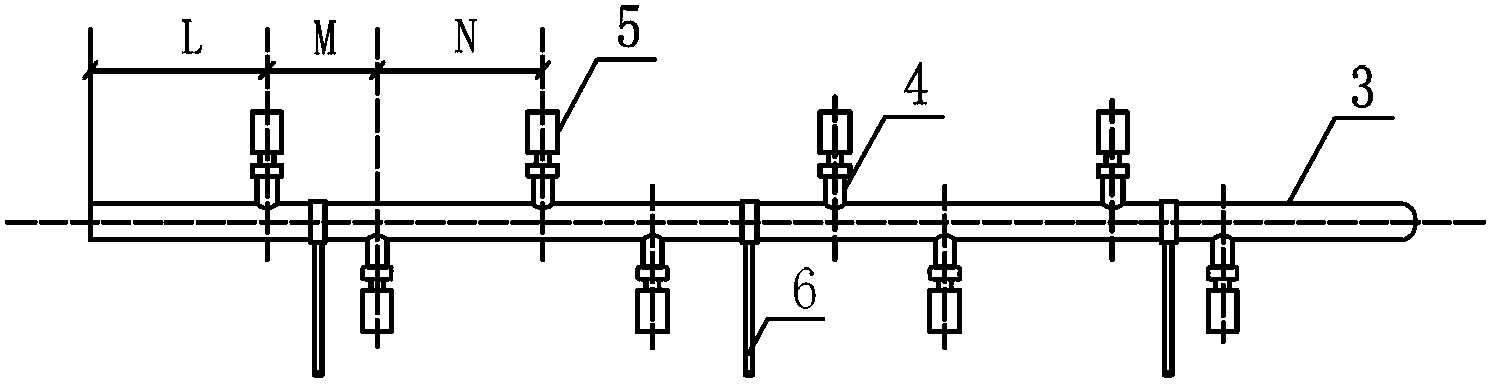

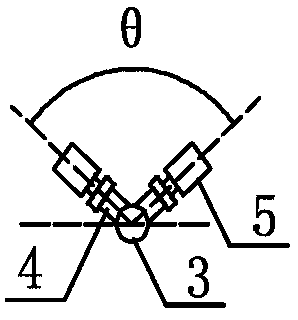

Coal-fired boiler shaft flue with sonic soot blowers

The invention relates to a coal-fired boiler shaft flue with sonic soot blowers and belongs to the technical field of coal-fired boilers. The coal-fired boiler shaft flue with the sonic soot blowers comprises heat exchangers, a plurality of pairs of primary pipes and the sonic soot blowers, wherein the pairs of primary pipes are evenly distributed along the cross section of a boiler, one end portions of each pair of primary pipes are opposite to each other and located in the center of the boiler, the other end portions of each pair of primary pipes extend out of the wall of the boiler respectively, and the end portions, extending out of the wall of the boiler, of the primary pipes are connected with steam supplying primary pipes outside the boiler in a welding mode. The heat exchangers and the pairs of primary pipes are installed in the shaft flue in a mutually spaced mode, and the primary pipes are fixed opposite to the heat exchangers through primary pipe supports. The sonic soot blowers are installed on the primary pipes through base pipes. The coal-fired boiler shaft flue has the advantages of being efficient, safe and energy-saving, promotes safety of the boiler, and can be free from daily tedious maintenance work. The sonic soot blowers are arranged in the boiler, and are free of rotating components and reliable in sealing.

Owner:张晨

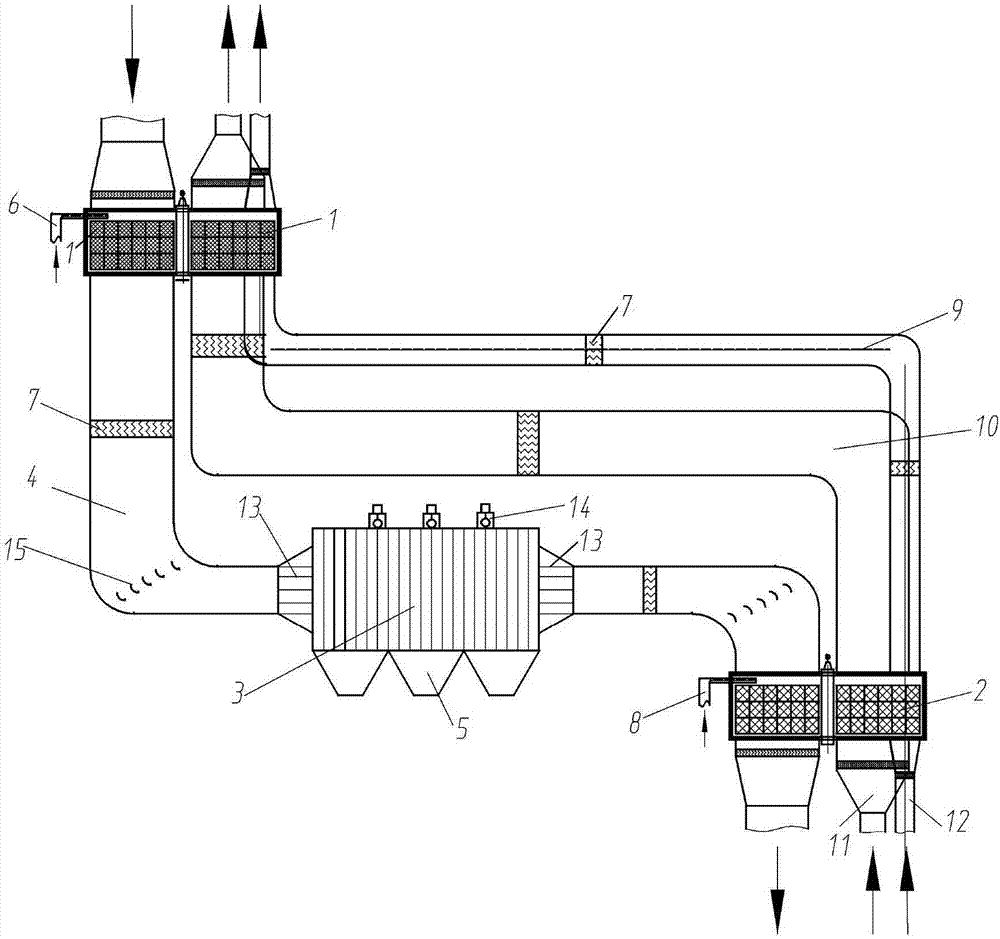

Anti-blocking segmented arrangement system for air pre-heaters

PendingCN106996577AImprove the operating environmentSolve the problem of cloggingCombustion processIndirect carbon-dioxide mitigationFlueElectrostatic precipitator

An anti-blocking segmented arrangement system for air pre-heaters comprises a high-temperature air pre-heater arranged behind a selective catalytic reduction (SCR) denitration device of a flue at the tail of a boiler; flue gas at the outlet of the high-temperature air pre-heater enters a high-temperature electrostatic precipitator through a flue; flue at the outlet of the high-temperature electrostatic precipitator enters a low-temperature air pre-heater through the flue for heat exchange; cold primary air enters the low-temperature air pre-heater through a cold primary air duct; supplied air enters the low-temperature air pre-heater through an air supply pipe; and the cold primary air and the supplied air absorb flue gas heat in the low-temperature air pre-heater and then enter a primary air side inlet and a supplied air side inlet of the high-temperature air pre-heater through an intermediate-temperate primary air pipeline and an intermediate-temperate air supply pipeline respectively. With the system, the problem of clogging of the air pre-heaters can be solved fundamentally, so that the temperature of the discharged flue gas can be effectively reduced, the temperature of the primary air and the temperature of secondary air can be increased, and the heat efficiency of the boiler can be improved.

Owner:XIAN THERMAL POWER RES INST CO LTD

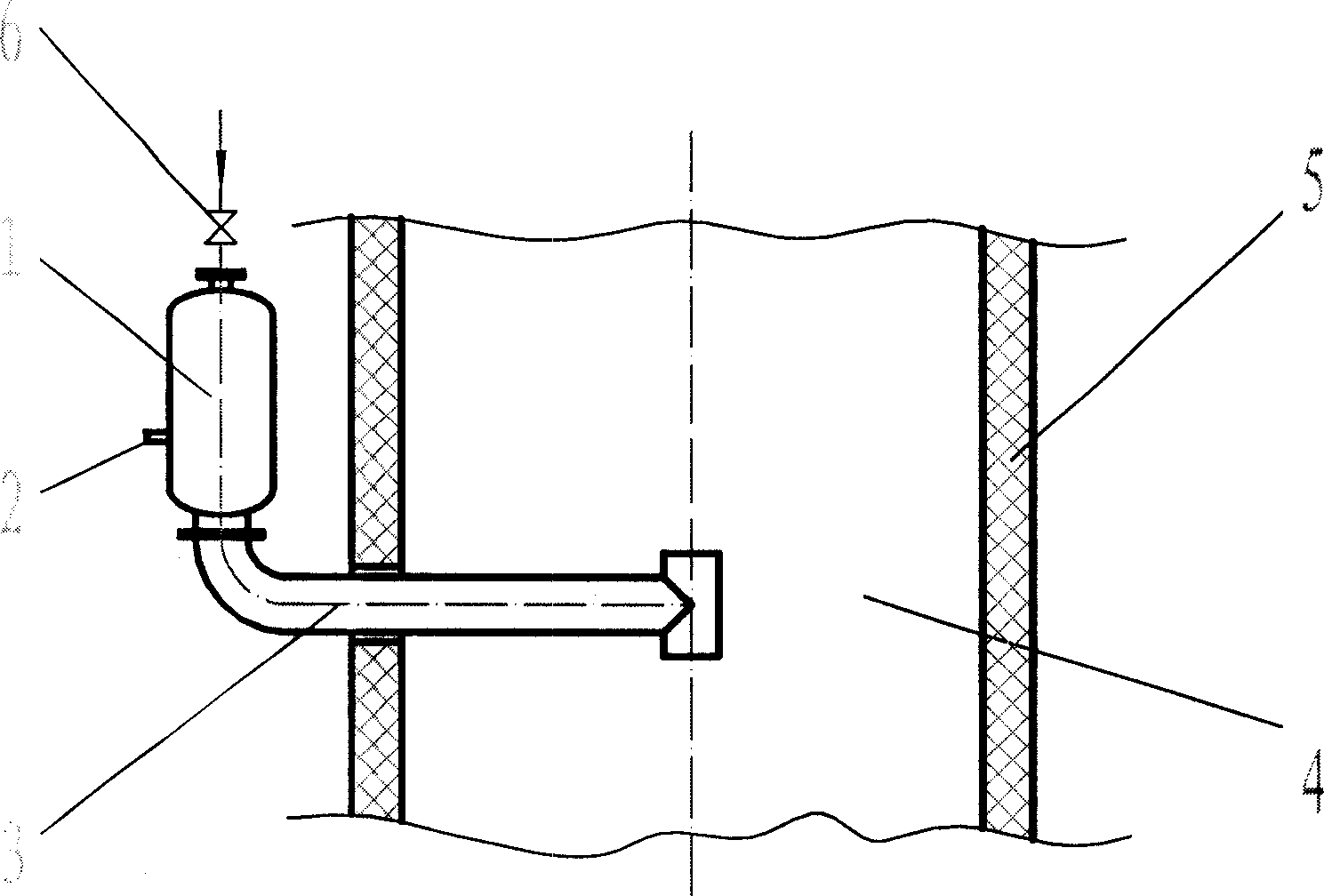

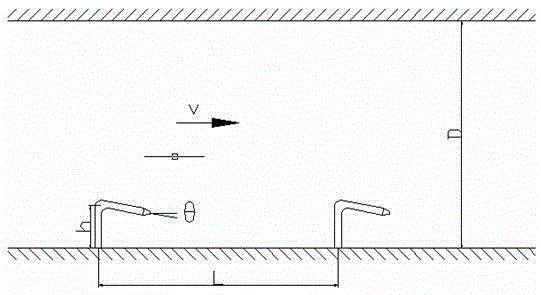

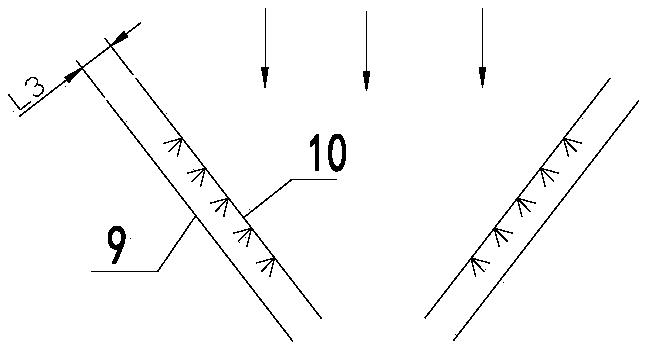

Soot blowing device used for circular flue of coal-fired power plant

The invention discloses a soot blowing device used for a circular flue of a coal-fired power plant. The soot blowing device comprises a plurality of nozzles arranged on the inclined surface inside the circular flue; the included angle between the spraying direction of the output end of each nozzle and the inclined surface is 0-5 degrees; the height of the nozzles is 0.02-0.1 time the diameter of the circular flue; the diameter of the nozzles is greater than or equal to 0.01 time that of the circular flue; the distance between the adjacent nozzles is smaller than or equal to 0.9 time the diameter of the circular flue. The soot blowing device is designed for the circular flue of the coal-fired power plant, and is simple in structure, low in energy consumption, low in economic cost, and remarkable in soot blowing effect through experimental verification, and the problem of accumulated soot in the flue can be effectively solved.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

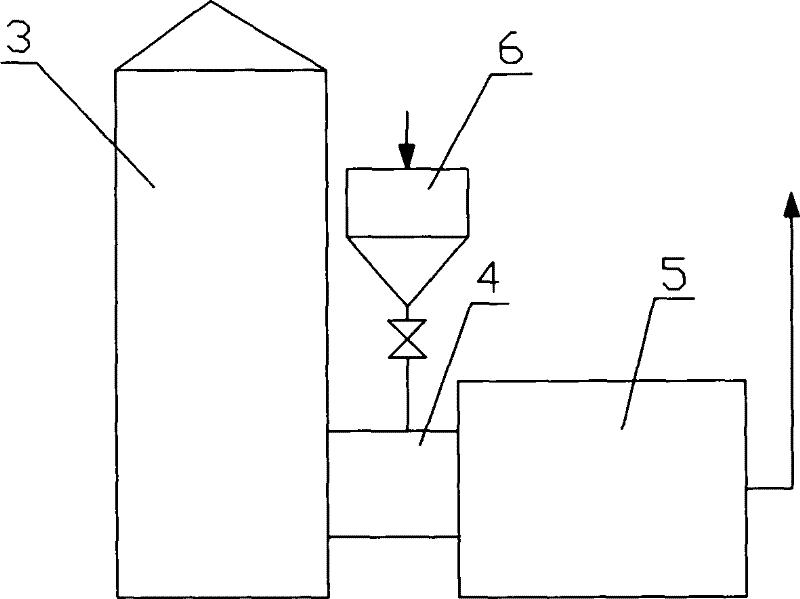

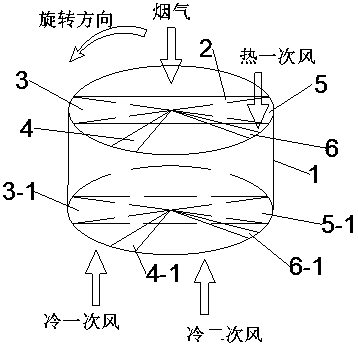

Circular ash removing method suitable for fluidized bed boiler

ActiveCN105737143AEffective flushingAvoid damageFluidized bed combustionSolid removalSand blastingFluidized bed

The invention discloses a circular ash removing method suitable for a fluidized bed boiler, and belongs to the technical field of ash removal of boiler equipment. The circular ash removing method suitable for the fluidized bed boiler comprises a sand loading step and a recycling step, and is characterized in that in the sand loading step, sand is loaded in a sand hopper of a circular sand ash blower; in a sand blasting step, the sand in the sand hopper is placed in a sandblast, and is sprayed in a shaft at the tail by the sandblast; in the recycling step, after scouring a superheater, an economizer and an air pre-heater, the sand sprayed in the shaft at the tail flows into a fluidized bed of the circular sand ash blower, and is recycled via an auger connected to the fluidized bed; and in a sand lifting step, the sand recycled by the auger is elevated and moves to a position above the sand hopper through an electric hoist, and is discharged into the sand hopper through a sand discharging trolley to form a circular ash removal cycle. By the circular ash removing method suitable for the fluidized bed boiler, the sand can be circularly used to remove ash on a heat exchange component in the shaft at the tail, the heat exchange efficiency is improved, and boiler steam rate is increased. The circular ash removing method suitable for the fluidized bed boiler has the features of low energy consumption and good ash removal effect.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

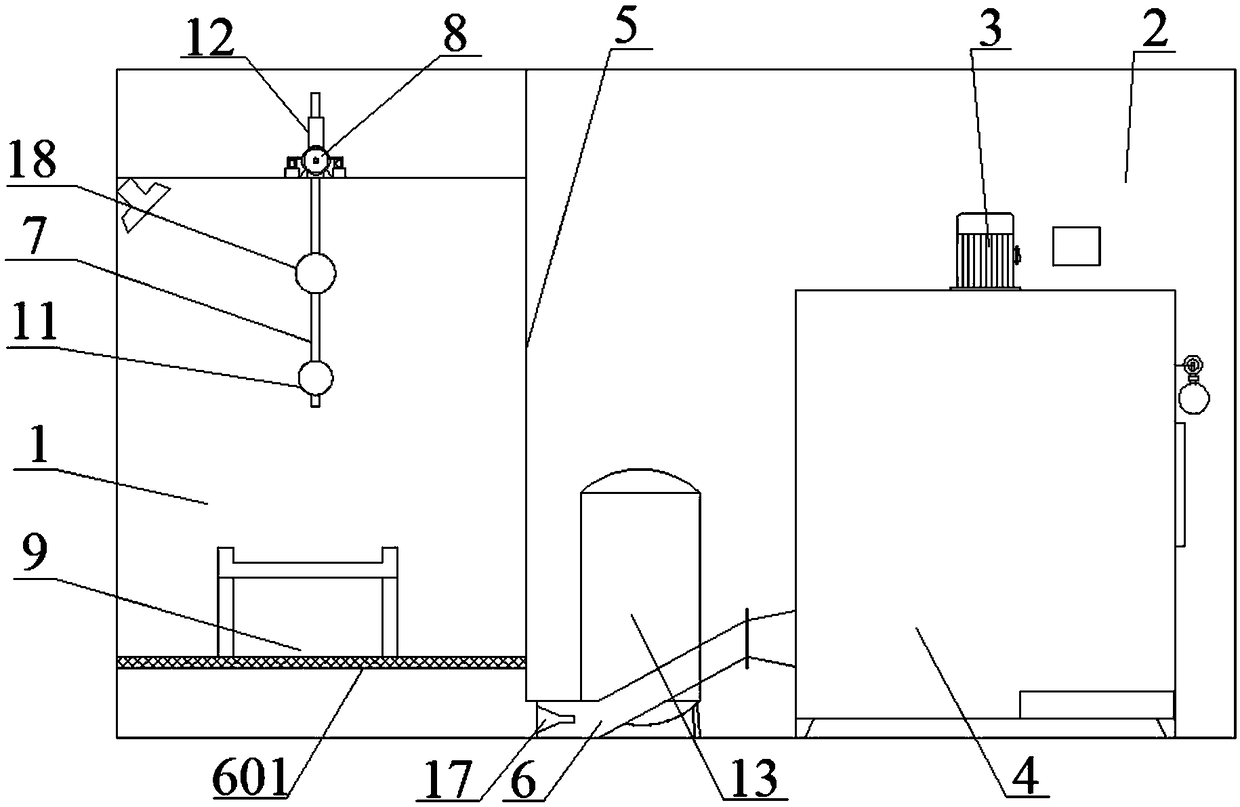

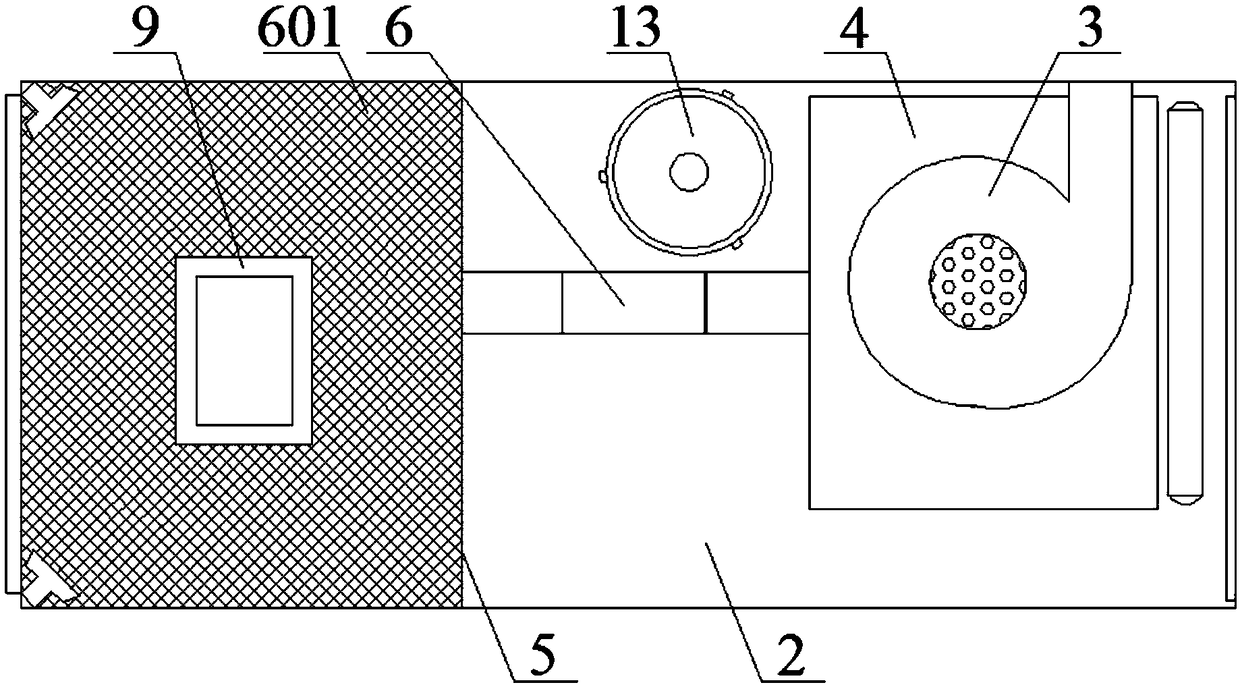

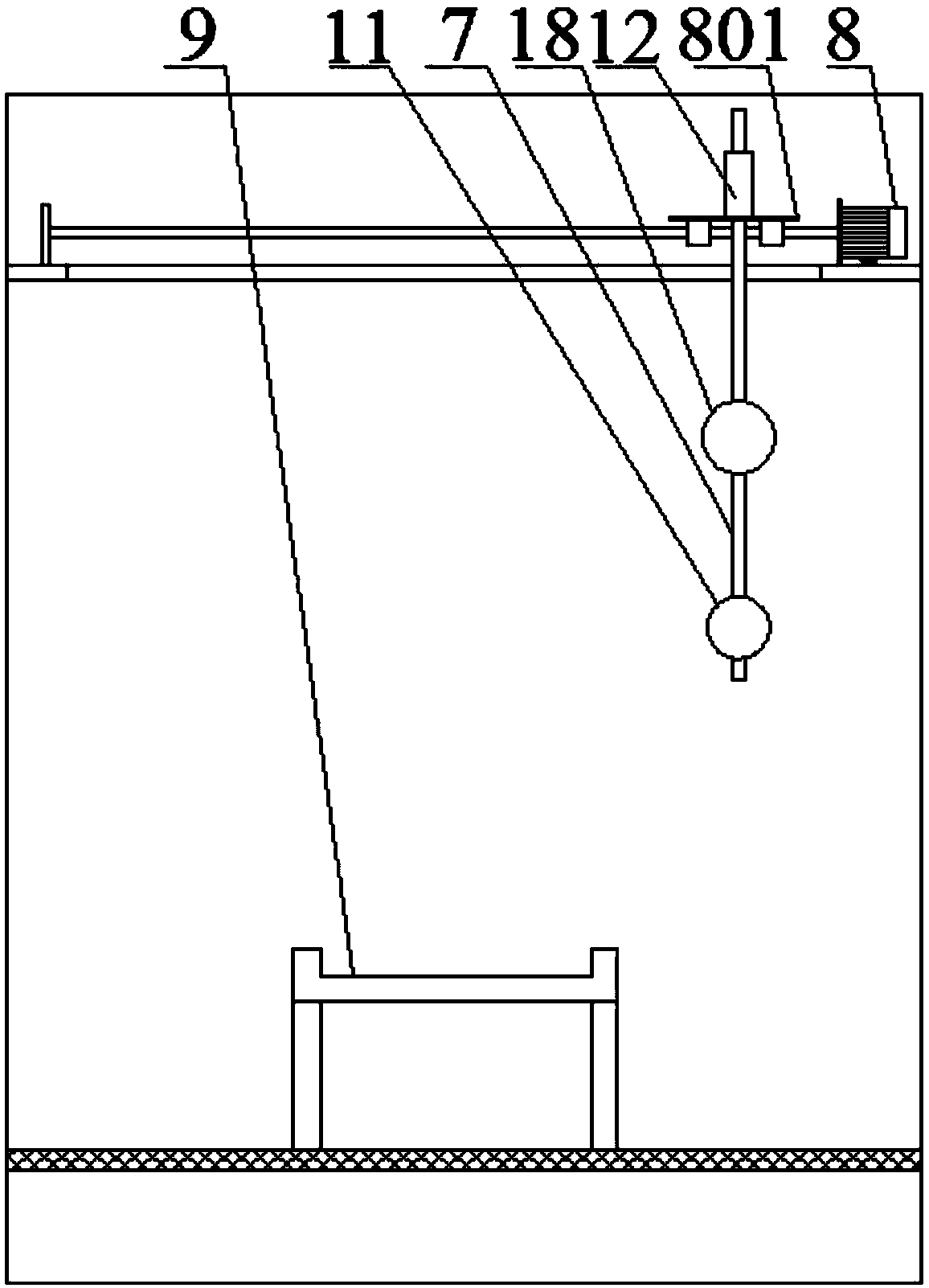

Circulating sand dust blowing device

ActiveCN105570913AImprove heat transfer efficiencyEfficient removalSolid removalFluidized bedEngineering

The invention discloses a circulating sand dust blowing device, and belongs to the technical field of boiler dust removing equipment. The circulating sand dust blowing device comprises a sand hopper and an electric hoist connected to a boiler top. The circulating sand dust blowing device is characterized in that a sand blower connected to the top of a tail vertical well and a fluidized bed connected to the bottom of the tail vertical well are further included; the sand blower comprises a speed regulation motor, a belt wheel, a transmission belt, a sand blowing pipe and a bearing connected to the sand blowing pipe; the sand hopper is connected with the sand blowing pipe through a sand inlet pipe; a motor shaft of the speed regulation motor is in transmission connection with the belt wheel; the belt wheel is in transmission connection with the bearing through the transmission belt; the sand blowing pipe communicates with the tail vertical well; a packaging auger driven through a motor is connected to the fluidized bed; and a sand discharge trolley is connected to the electric hoist. According to the circulating sand dust blowing device, dust on a heat exchange component in the tail vertical well can be effectively removed, heat exchange efficiency is improved, and the circulating sand dust blowing device has the beneficial effects of being low in energy consumption, good in dust blowing effect and high in use safety.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

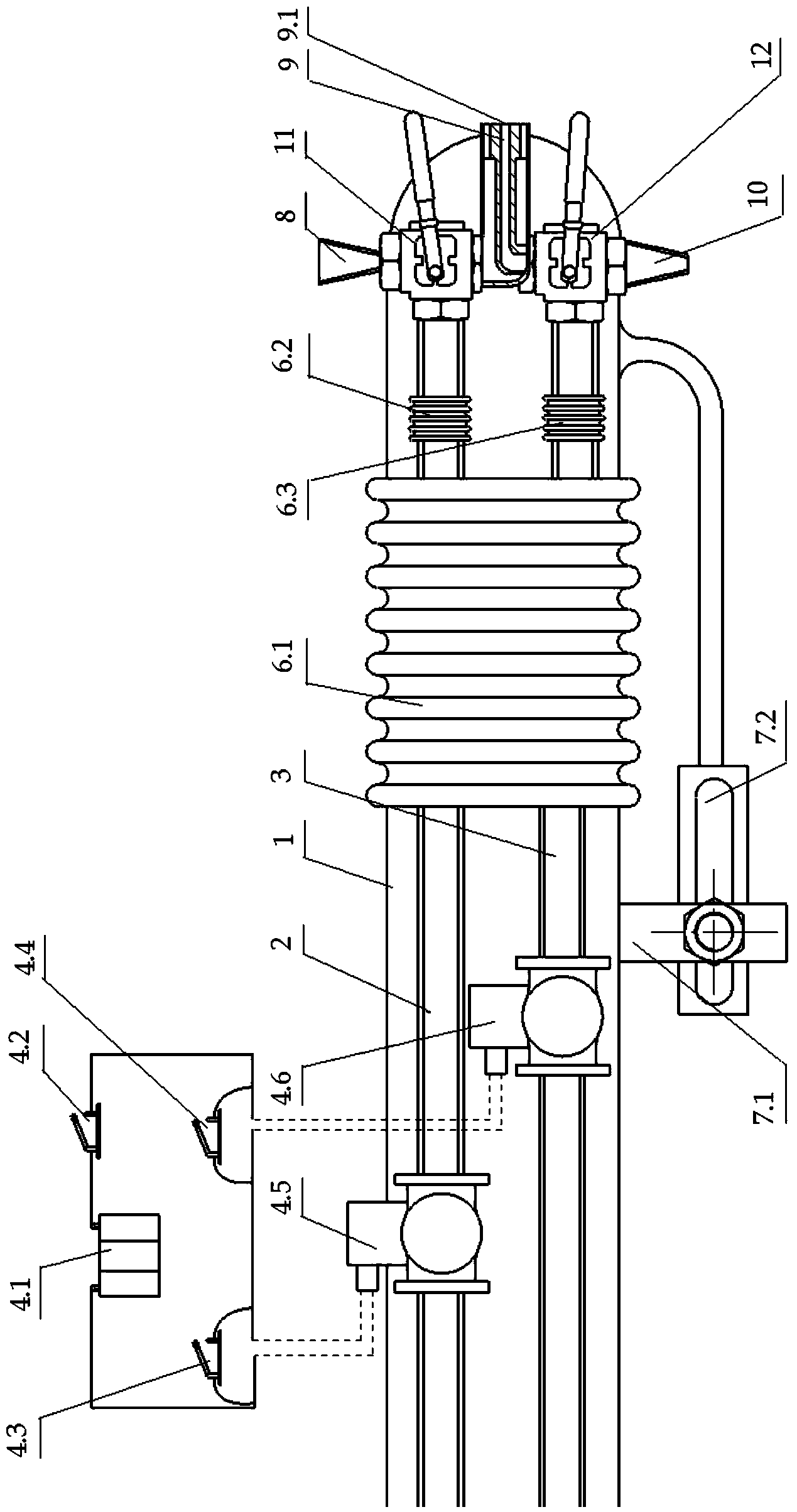

Steam soot blower of novel multifunctional blowing tube

The invention relates to a steam soot blower, in particular to a steam soot blower of a novel multifunctional blowing tube. The steam soot blower of the novel multifunctional blowing tube is characterized in that the steam soot blower of the novel multifunctional blowing tube comprises the blowing tube, a fluid switch control unit, an angle adjusting device and a blowing tube nozzle assembly. Two parallel conveying tubes are wrapped by the blowing tube, wherein the two parallel conveying tubes are a steam conveying tube and a high-temperature water conveying tube. The fluid switch control unit comprises a power source, a steam switch solenoid valve, a high-temperature water switch solenoid valve, a first switch, a second switch and a third switch. The angle adjusting device comprises a metal bellows assembly and an adjusting support assembly, wherein the metal bellows assembly comprises a metal bellows I mounted on the blowing tube, a metal bellows II mounted on the steam conveying tube and a metal bellows III mounted on the high-temperature water conveying tube, and the adjusting support comprises a fixed assembly and an adjusting assembly. The blowing tube nozzle assembly comprises a steam blowing tube nozzle, a combined blowing tube nozzle and a high-temperature water blowing tube nozzle, and the blowing tube assembly is connected with the steam conveying tube and the high-temperature water conveying tube through a tee joint ball valve. According to the steam soot blower of the novel multifunctional blowing tube, multiple blowing modes and multiple blowing angles can be obtained, the blowing area can be enlarged, high blowing full scale can be achieved, no blowing dead angles can be left, effective spraying can be improved, and the blowing effect is improved.

Owner:WUHAN SANYU MACHINE CO LTD

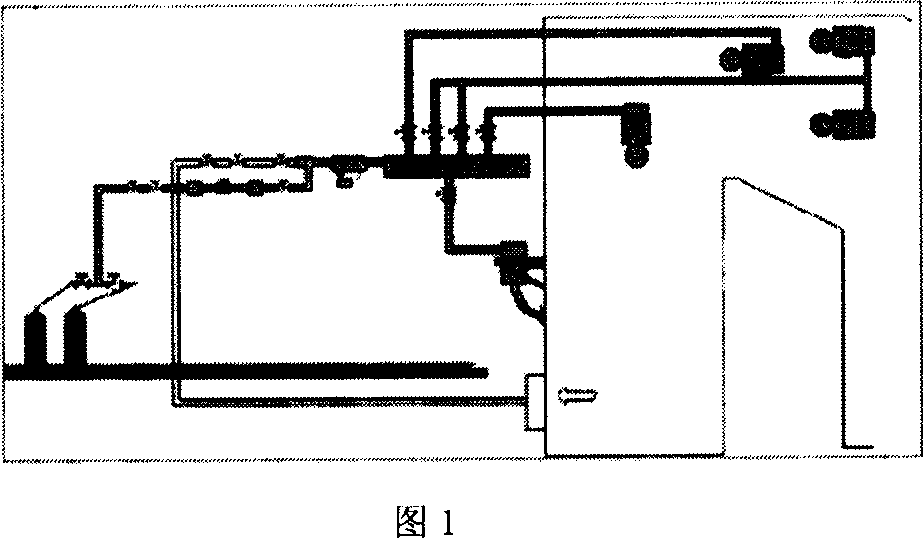

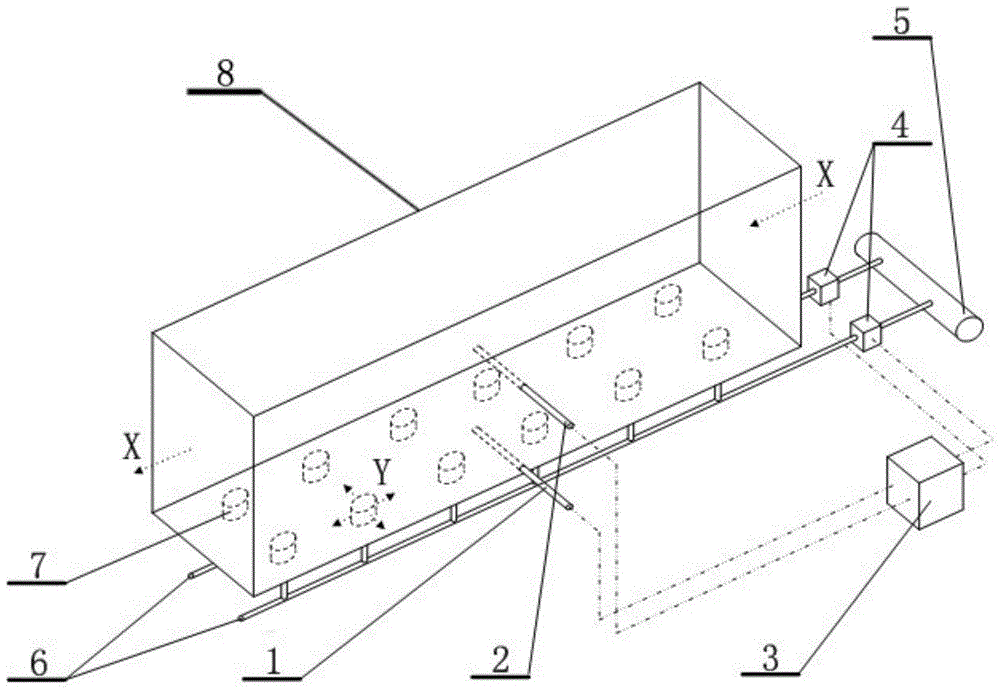

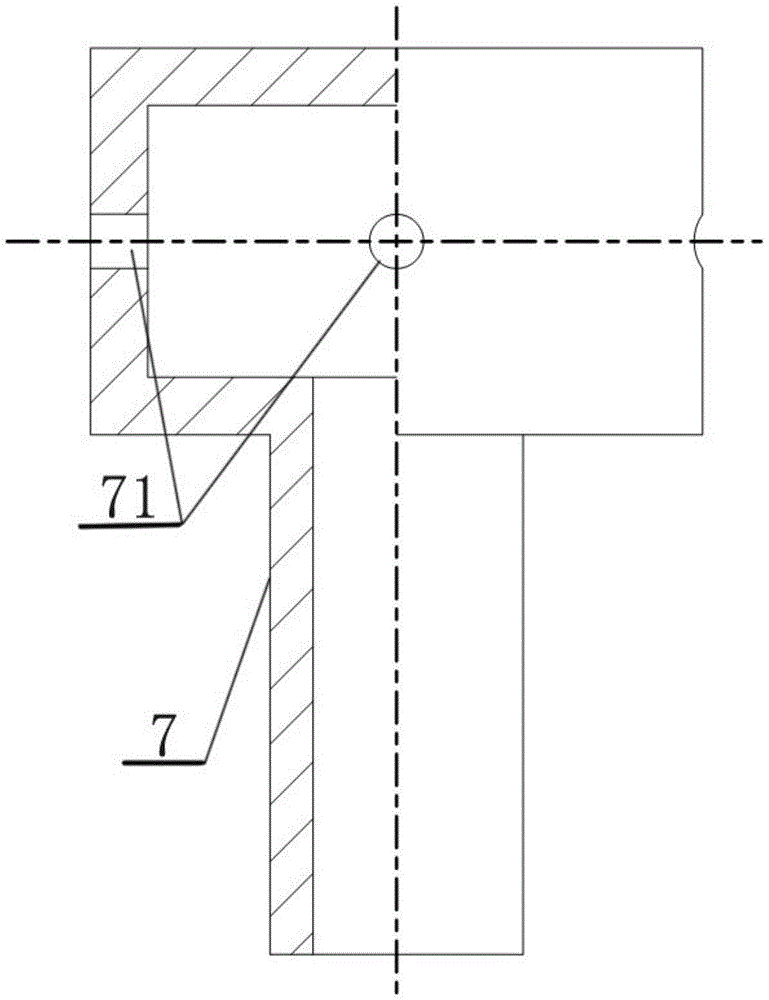

Soot blowing method and device for horizontal flue of π-shaped boiler

ActiveCN104180379BAvoid the continuous "overblowing" of the infinite loopFewer cases of continuous "overblowing" of dead loopsSolid removalSolenoid valveEngineering

The invention relates to a soot blowing method and device for a horizontal flue of a π-shaped boiler, which consists of a temperature measurement system, a control module and a soot blowing system. The temperature measurement system includes a first temperature detection device arranged on the flue wall device and a second temperature detector, the soot blowing system includes an air supply pipe, a solenoid valve arranged on the air supply pipe, and a wind cap connected with the air supply pipe and arranged on the bottom wall of the flue, and the wind cap is evenly distributed; the The first temperature detector and the second temperature detector are connected to a control module, and the control module is connected to an electromagnetic valve. It is a soot blowing method and device for a horizontal flue of a π-shaped boiler that can automatically complete the dust removal work, effectively reduce "overblowing" or "underblowing", and accurately monitor the flue dust accumulation.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

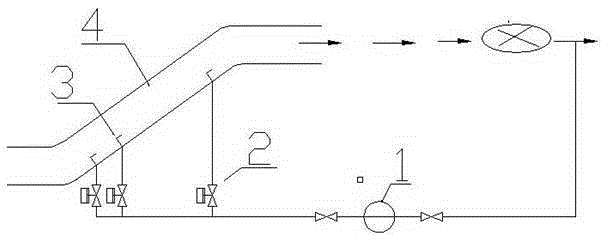

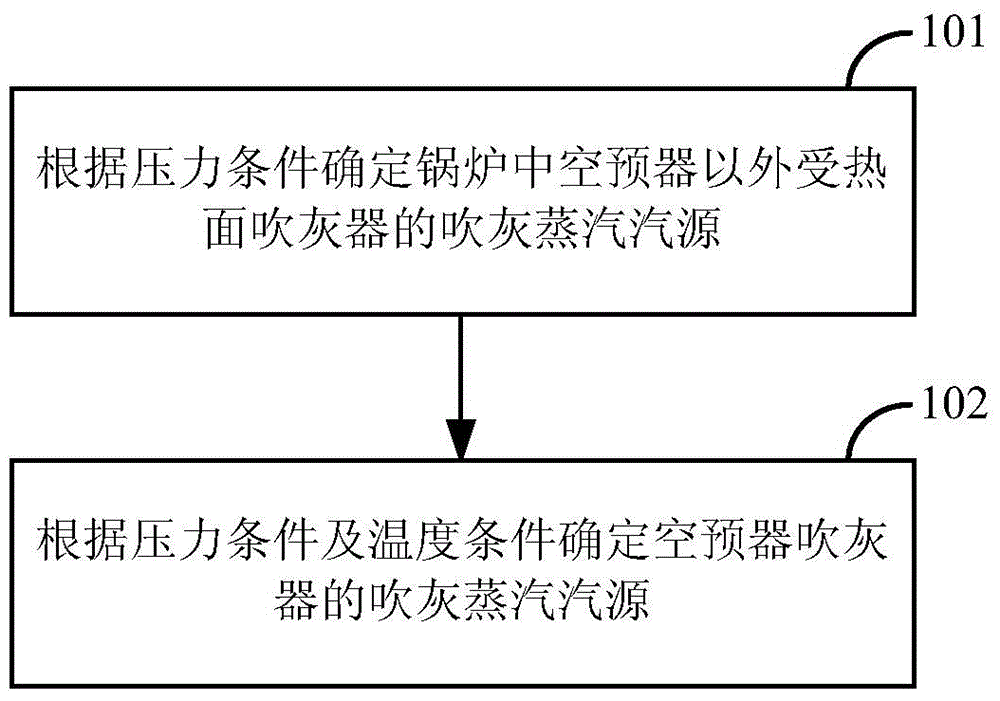

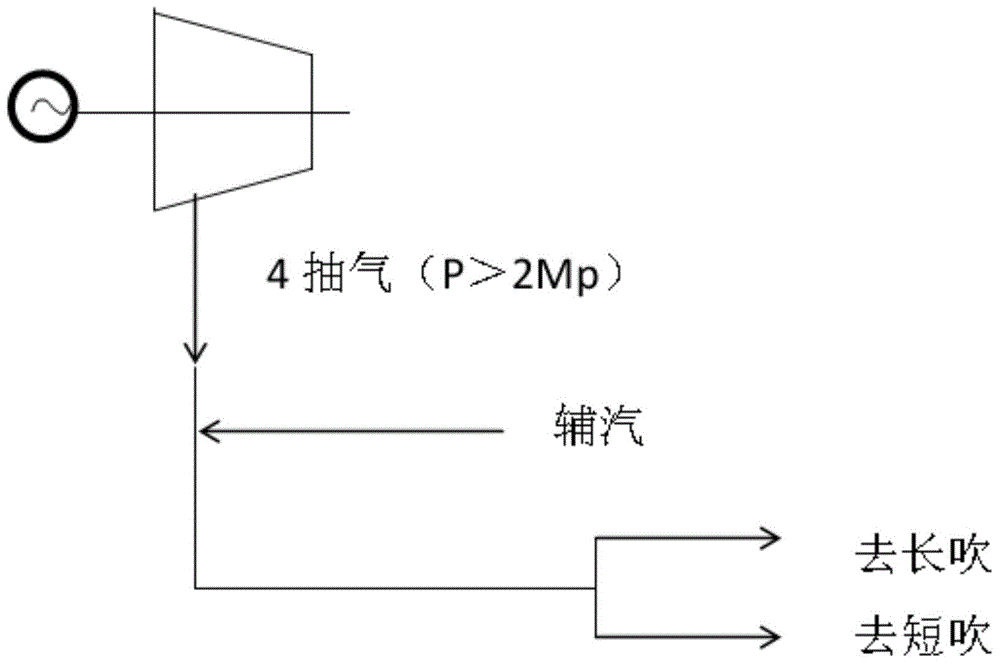

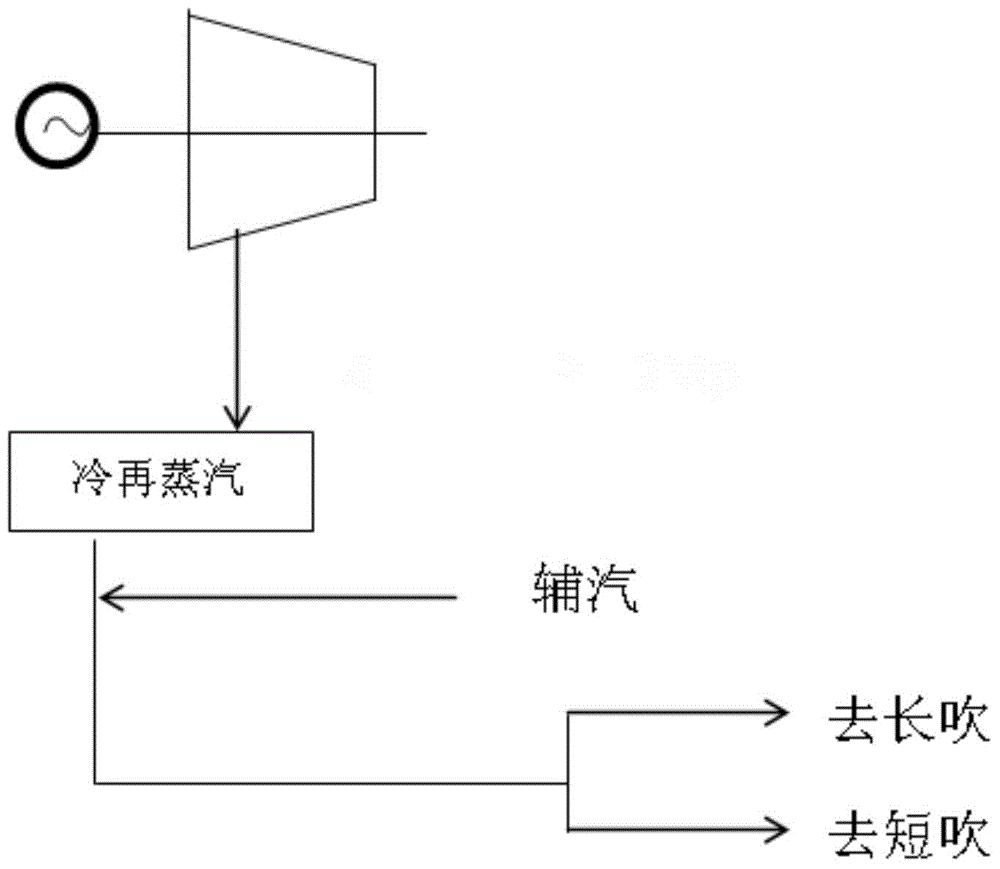

Soot blowing steam source determining method

The invention discloses a soot blowing steam source determining method. The method includes the steps that according to the pressure condition, a soot blowing steam source of a heated face soot blowing device outside an air preheater in a boiler is determined according to the pressure condition; a soot blowing steam source of an airpreheater soot blowing device is determined according to the pressure condition and temperature condition. According to the soot blowing steam source determining method, the energy level of the boot blowing steam is utilized to the maximum degree while the good soot blowing effect is achieved, steam consumption is reduced, and thus the optimum economical efficiency is reached.

Owner:NORTH CHINA ELECTRICAL POWER RES INST +1

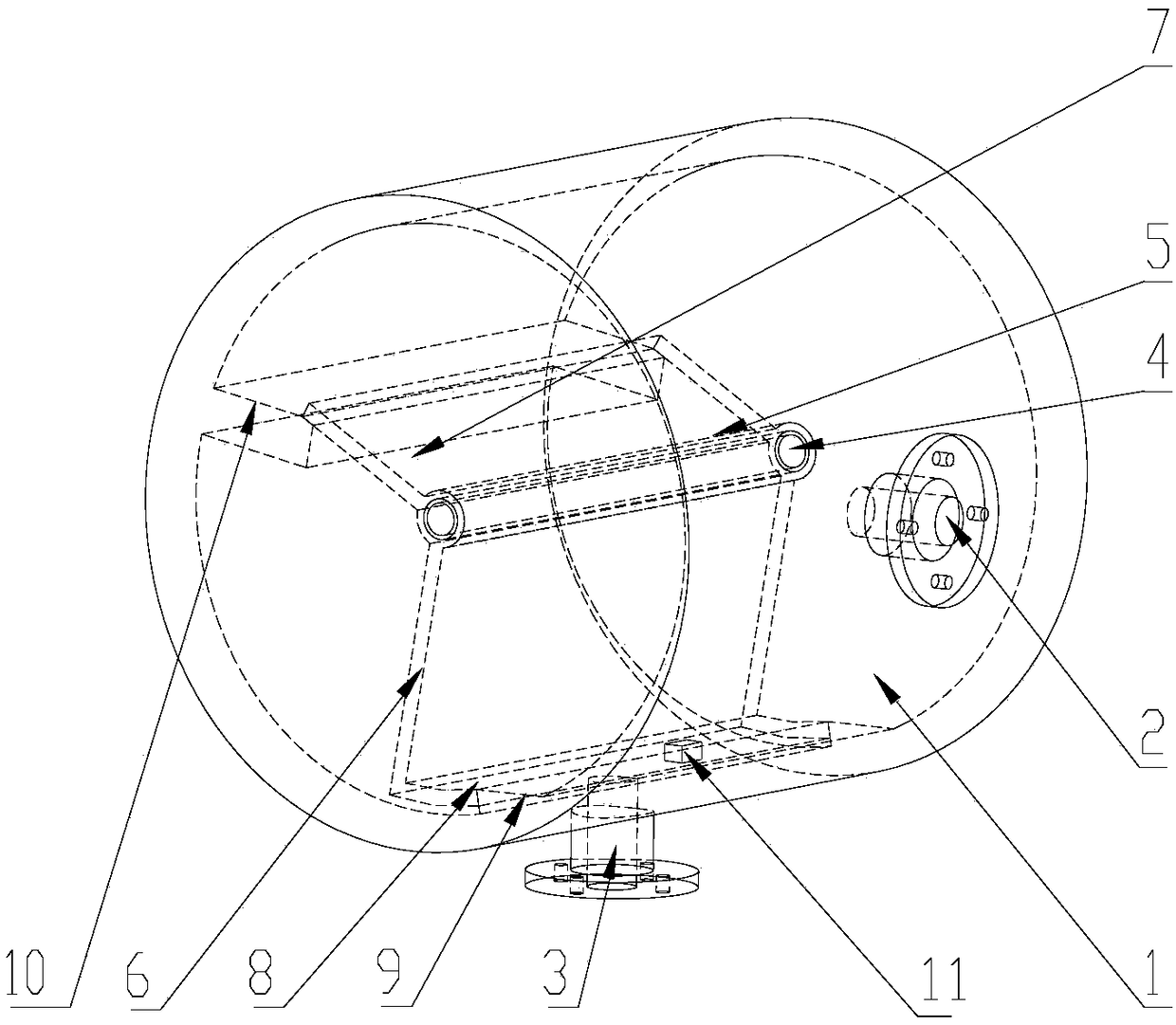

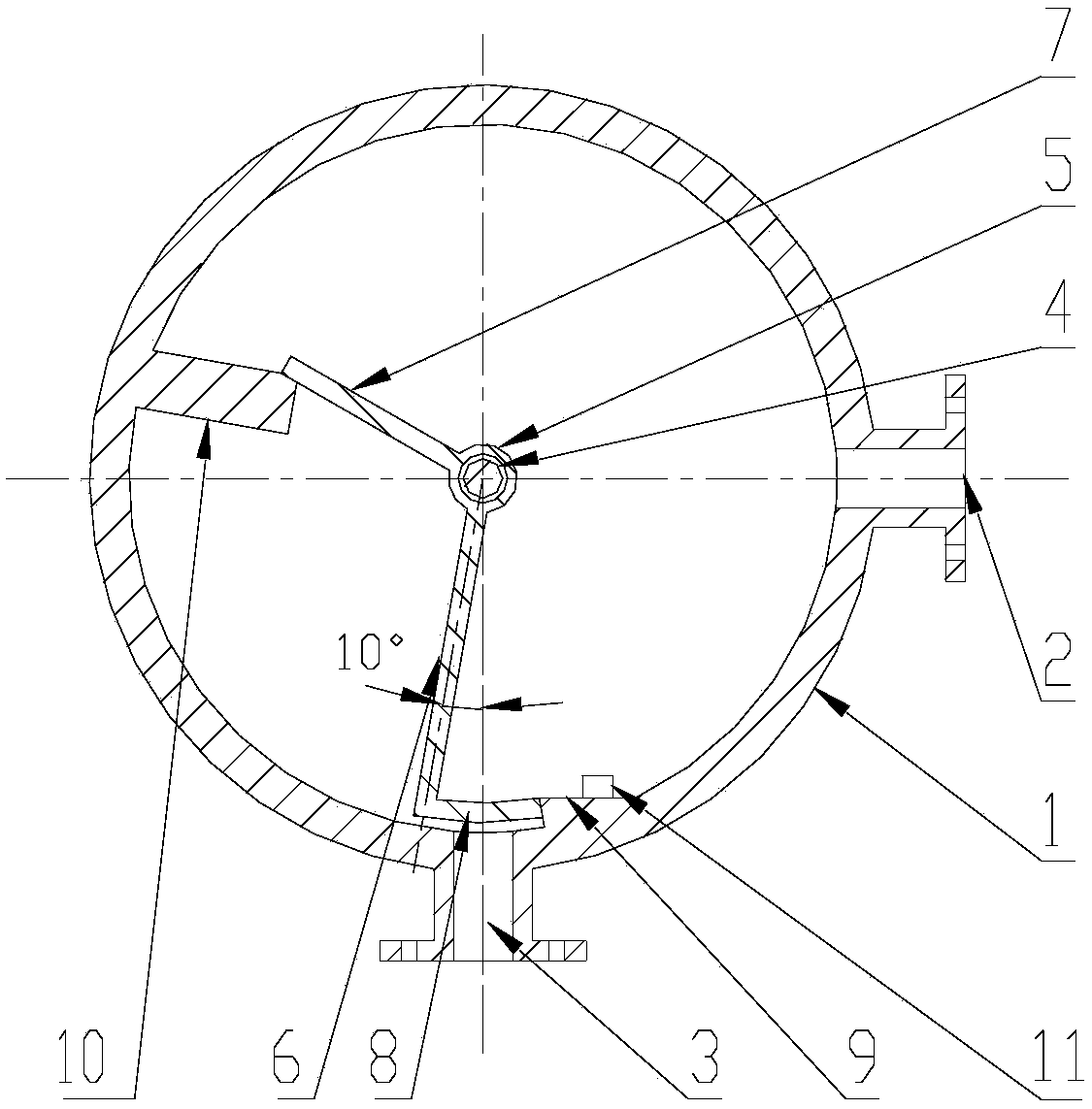

Ash blowing explosion tank with rotatable partition plates

PendingCN108224453AImprove soot blowing effectPrevent low temperature dew point corrosionSolid removalCorrosionEngineering

The invention discloses an ash blowing explosion tank with rotatable partition plates. The ash blowing explosion tank comprises a tank body, an air inlet, an air outlet and an ignition device, and ischaracterized by further comprising a shaft, a sleeve pipe, the first partition plate, the second partition plate, an arc plate, a first boss and a second boss. In the natural state, due to the actionof gravity, the arc plate welded to the tail end of the first partition plate is attached to the first boss, the second partition plate is attached to the second boss, the air outlet is closed, a sealed cavity is formed, the fullness and pressure of mixed gas in the cavity are increased advantageously, and the situation that furnace hearth smoke enters the explosion tank and corrosion is caused can be prevented. When the explosion tank is ignited for explosion, the partition plates and the arc plate are impacted and can rotate clockwise, thus, the air outlet is opened, the first partition plate is impacted and collides with the second boss after rotating clockwise by 90 degrees, ash deposits on the inner wall face of the explosion tank is loosened favorably through sound waves and vibration which are caused by collision, the air inlet is blocked by the second partition plate during explosion, and the air inlet is kept communicating with the tank body cavity all the time.

Owner:XI AN JIAOTONG UNIV

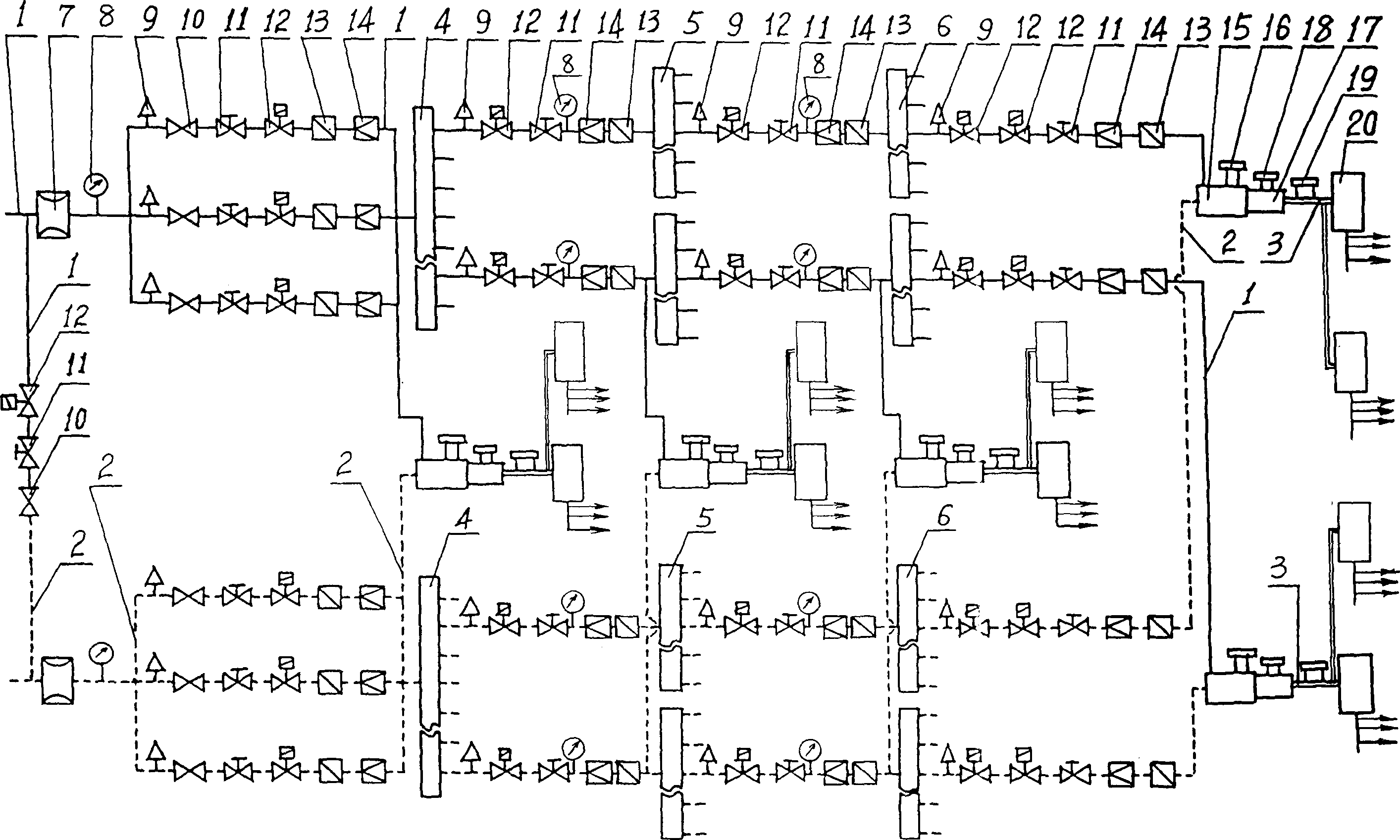

Method for coorperating distributor and mixer of gas soot blower

InactiveCN1657829AExtended service lifePrevent backfireGaseous fuel burnerSolid removalEngineeringDistributor

The invention relates to a method which admeasure device of the gas blower adapts with complex device. It includes: air channel interchange device consists of gas, air pipe and impulse, adjusting and main valve; gas or air conducting device consists of flowmeter, pressure sensor, pressure regulating valve, impulse valve, adjusting valve, main valve, backflow valve and fire retardant or air pipe; tertiary gas or air conducting device consists of primary and secondary gas or air channel conducting device consist of pressure regulating, impulse, adjusting valve and fire retardant and pressure sensor and gas or air pipe; pressure regulating, double impulse, adjusting and fire retardant device, backflow valve all connected by gas or air pipe. Gas and air channel conducting device connects with blending cavity and primary admeasuring device, so does the primary gas and air channel conducting device the mixing cavity and secondary admeasuring device, secondary gas or air channel conducting device the mixing cavity and tertiary admeasuring device. The tertiary gas and air conducting device connects with mixing cavity linked with temperature sensor, igniting cavity linked with igniter, combusting blending pipe, status monitor, and initiator. The furnace is for blowing the ashes.

Owner:北京嘉德兴业科技有限公司

High-efficiency soot blowing device for SCR (selective catalytic reduction) denitration catalyst

ActiveCN109200821AGood removal effectIncrease removal pressureDispersed particle filtrationEngineeringSoot

The invention relates to a high-efficiency soot blowing device for an SCR (selective catalytic reduction) denitration catalyst. The high-efficiency soot blowing device for the SCR denitration catalystcomprises a purging chamber and a dust removing chamber which are separated by a partition plate, wherein a placing platform is positioned in the purging chamber, and a purging unit is arranged at the top of the purging chamber; a negative pressure unit comprises an air suction channel which is provided with an upward air inlet and positioned below the placing platform, and a screen plate is arranged at the air inlet; the air suction channel penetrates through the partition plate and is connected with the negative pressure unit, and the purging unit comprises a purging pipe which is fixedly arranged at the top of the purging chamber by a horizontal moving mechanism; the tail end of the purging pipe is provided with a circular cavity, and a turret is arranged in the circular cavity; sealing rolling balls which are matched with an air outlet of the circular cavity are uniformly distributed on the circumference of the turret, and the sealing rolling balls are arranged on the turret by anelastic bracket; a funnel tube is arranged in the air suction channel, and the funnel tube forms an opening and closing unit of the air suction channel by the air pressure change of the purging chamber. The device adopts the combination of various forms of pressure multi-change, positive and negative pressure change, and sudden change to remove dust from the catalyst, and the soot blowing effectis significantly improved.

Owner:HEBEI HANTANG HONGYUAN ENVIRONMENT PROTECTION TECH

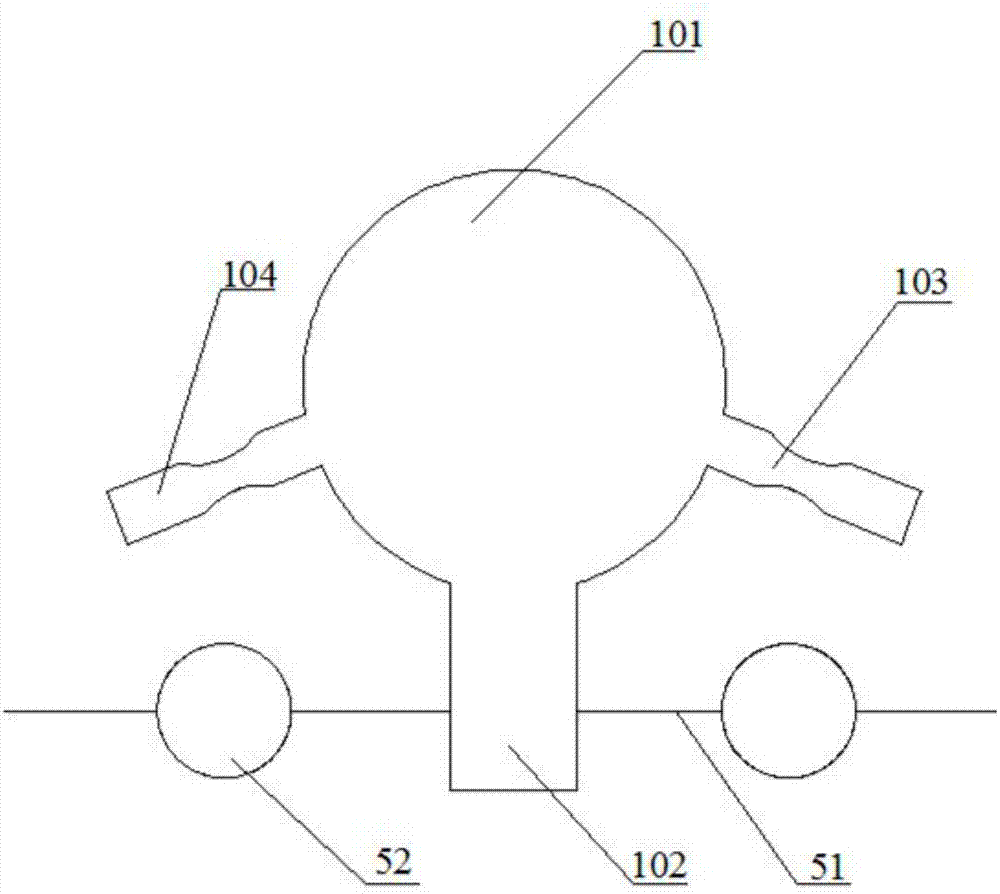

Air energy soot blower with automatic rotation head

The invention discloses an air energy soot blower with an automatic rotation head. The air energy soot blower comprises a soot blowing pipeline, wherein a rotation section is arranged at the end of the soot blowing pipeline, and multiple soot blowing outlets are arranged at the front end of the rotation section. In the air energy soot blower with an automatic rotation head disclosed by the invention, as a rotatable rotation section with multiple soot blowing outlets is arranged at the front end of the soot blowing pipeline, the rotation section can rotate by use of the recoil and the inclination angle of the soot blowing outlets in the soot blowing process, and the soot blowing outlets can cover a wider soot blowing area so as to obtain a good soot blowing effect.

Owner:BEIJING FANYUANXING SCI & TECH

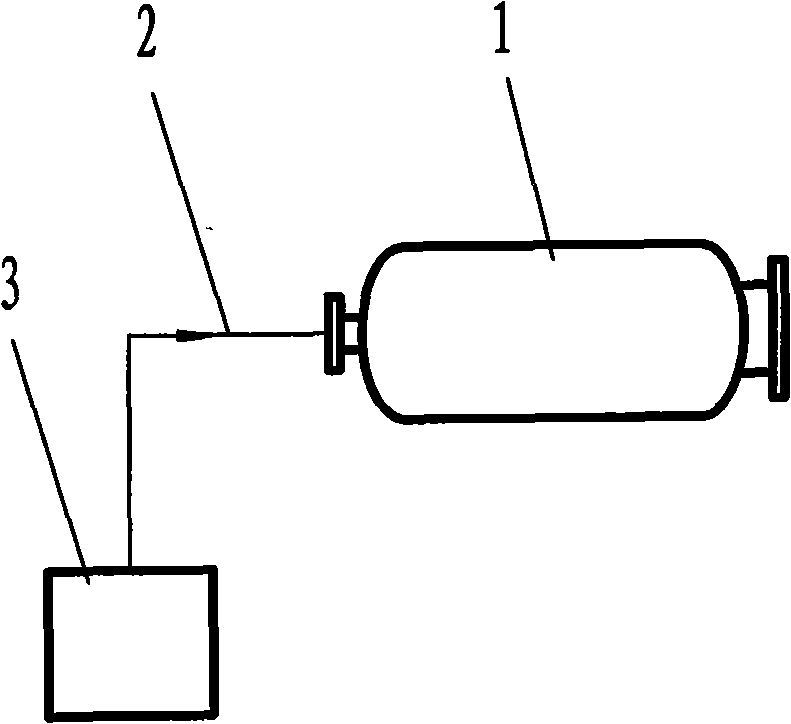

Hydrogen-oxygen heat exploding pulse sootblower

The invention belongs to the thermal explosion pulse soot blowing technical field, in particular relating to an oxyhydrogen thermal explosion pulse soot blower, which mainly comprises a pulse generator and a water electrolysis oxyhydrogen generator. An air outlet of the water electrolysis oxyhydrogen generator is connected with an inlet of the pulse generator. The pulse soot blower has the main advantages of only water and electric energy consumption, safety and reliability, and good soot blowing effect.

Owner:BEIJING GAOZHAN SCI & TECH

Soot blower

Owner:CHINA PETROCHEMICAL CORP +1

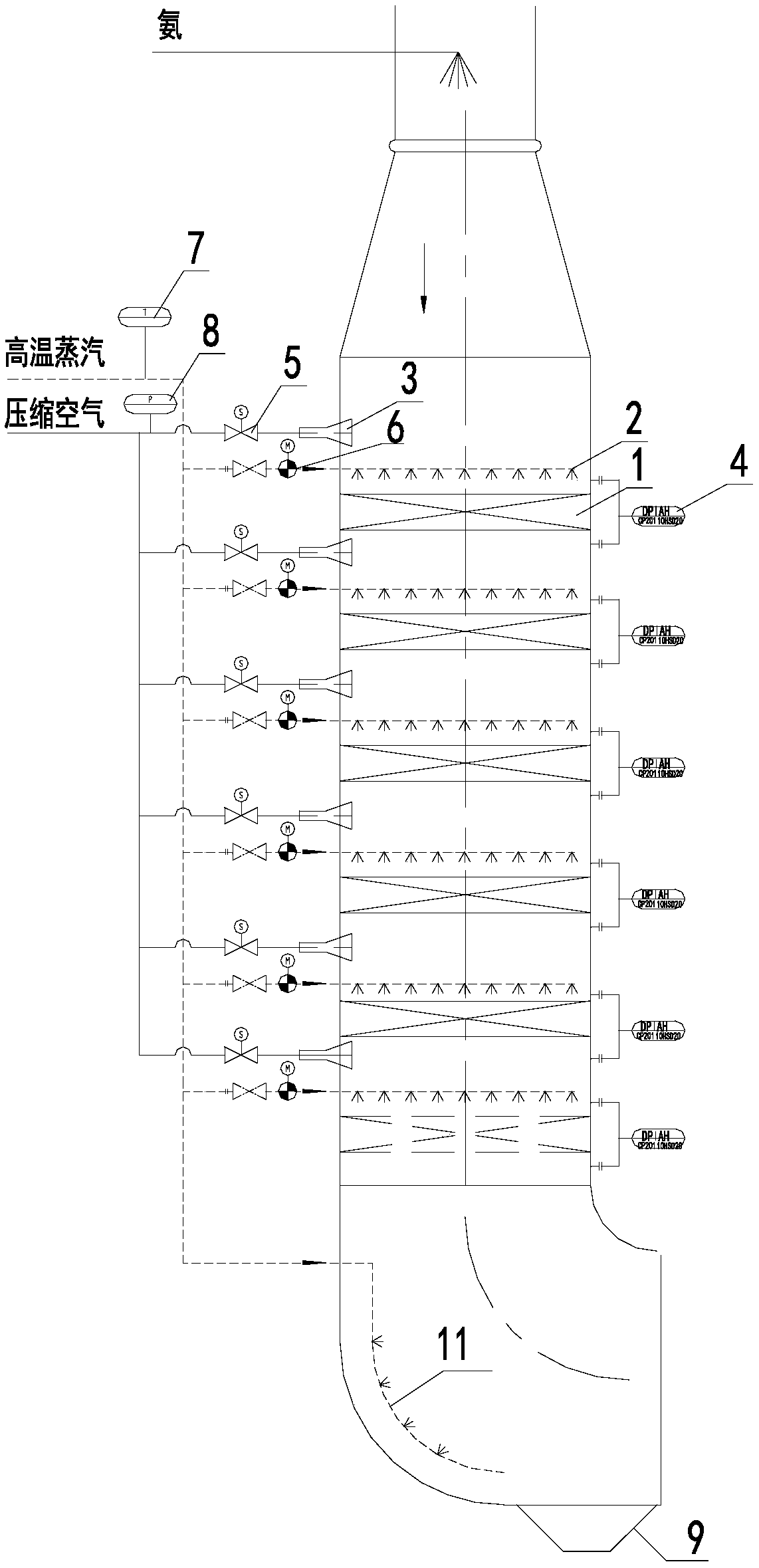

SCR denitration method and device with combined soot blowing function

ActiveCN109603545AAvoid stickingAvoid problems such as dust and scalingGas treatmentDispersed particle separationParticulatesThermal energy

The invention discloses an SCR denitration method and device with a combined soot blowing function. The device comprises an SCR reactor, wherein steam soot blowers and sonic soot blowers are arrangedin sequence in the counter-smoke flow direction above each catalyst bed layer in the reactor; differential pressure transmitters are arranged between the upper and lower portions of the catalyst bed layers; all steam soot blowers are connected in parallel and then externally connected with an high-temperature steam source, each parallel pipeline is provided with a high-temperature steam electric valve respectively, and a main pipe is provided with a temperature sensor; all acoustic sensors are connected in parallel and then externally connected with a compressed air source, each parallel pipeline is provided with a compressed air electric valve respectively, and the main pipe is provided with a pressure transmitter; the device further comprises a controller, the temperature sensor, the pressure transmitter and all differential pressure transmitters are connected with the controller separately, and all high-temperature steam electric valves and compressed air electric valves are connected with the controller separately. The SCR denitration method and device with the combined soot blowing function solves the problems that the content of denitrated particulate matters of the SCR in acement kiln is large, large granular particles in soot cannot be removed, and the thermal energy loss is large due to the steam consumption of a pure steam scoot blower.

Owner:ZHEJIANG UNIV

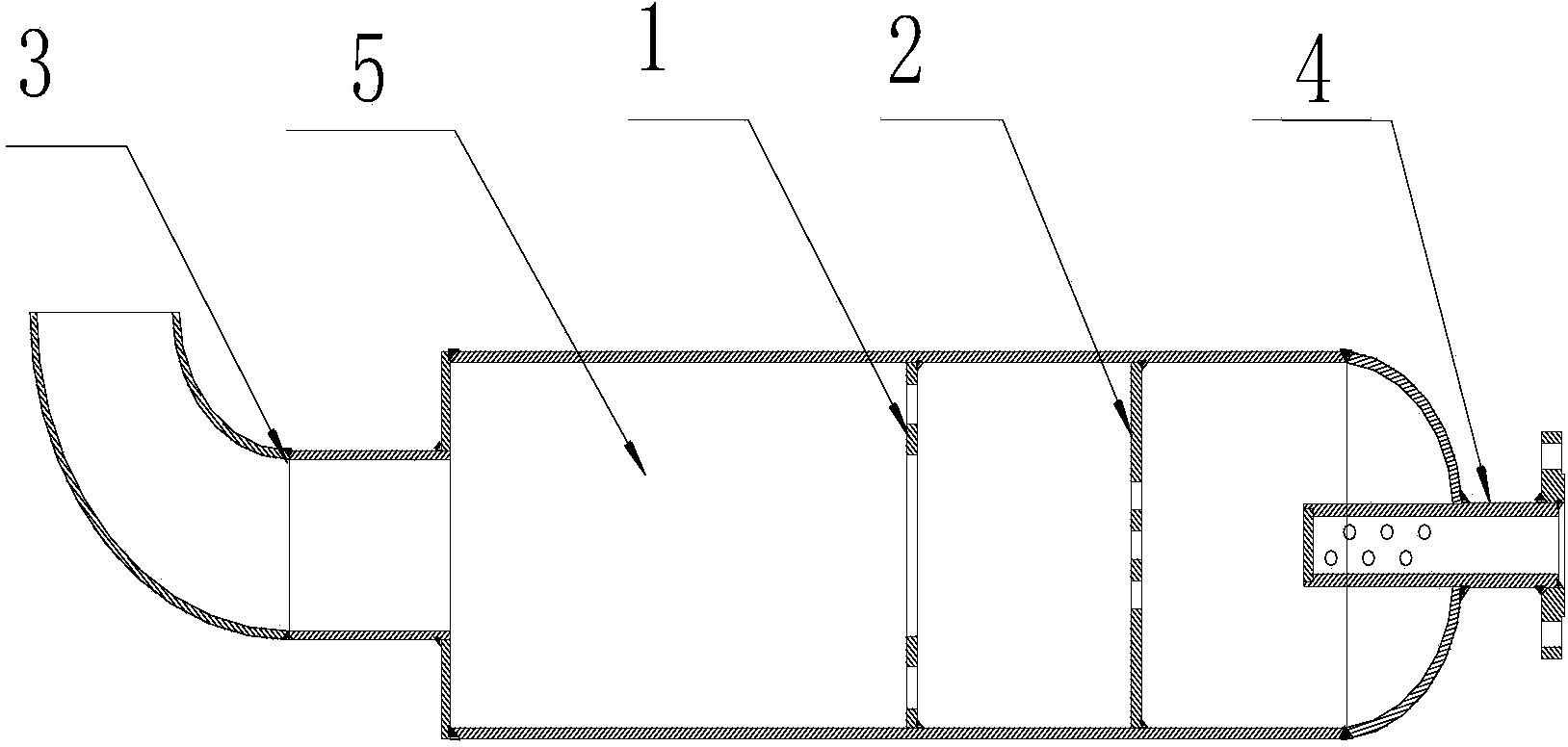

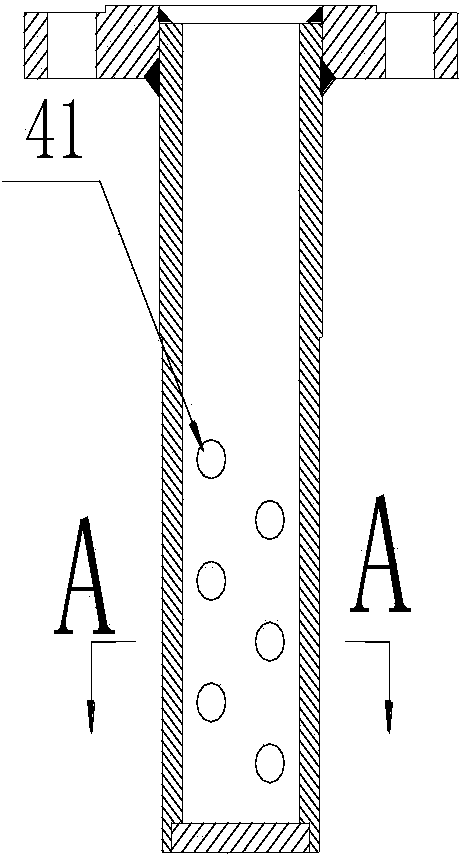

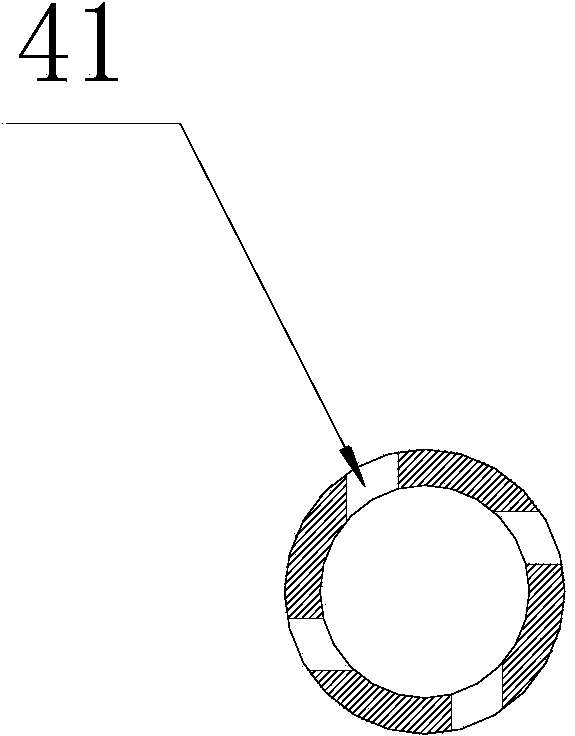

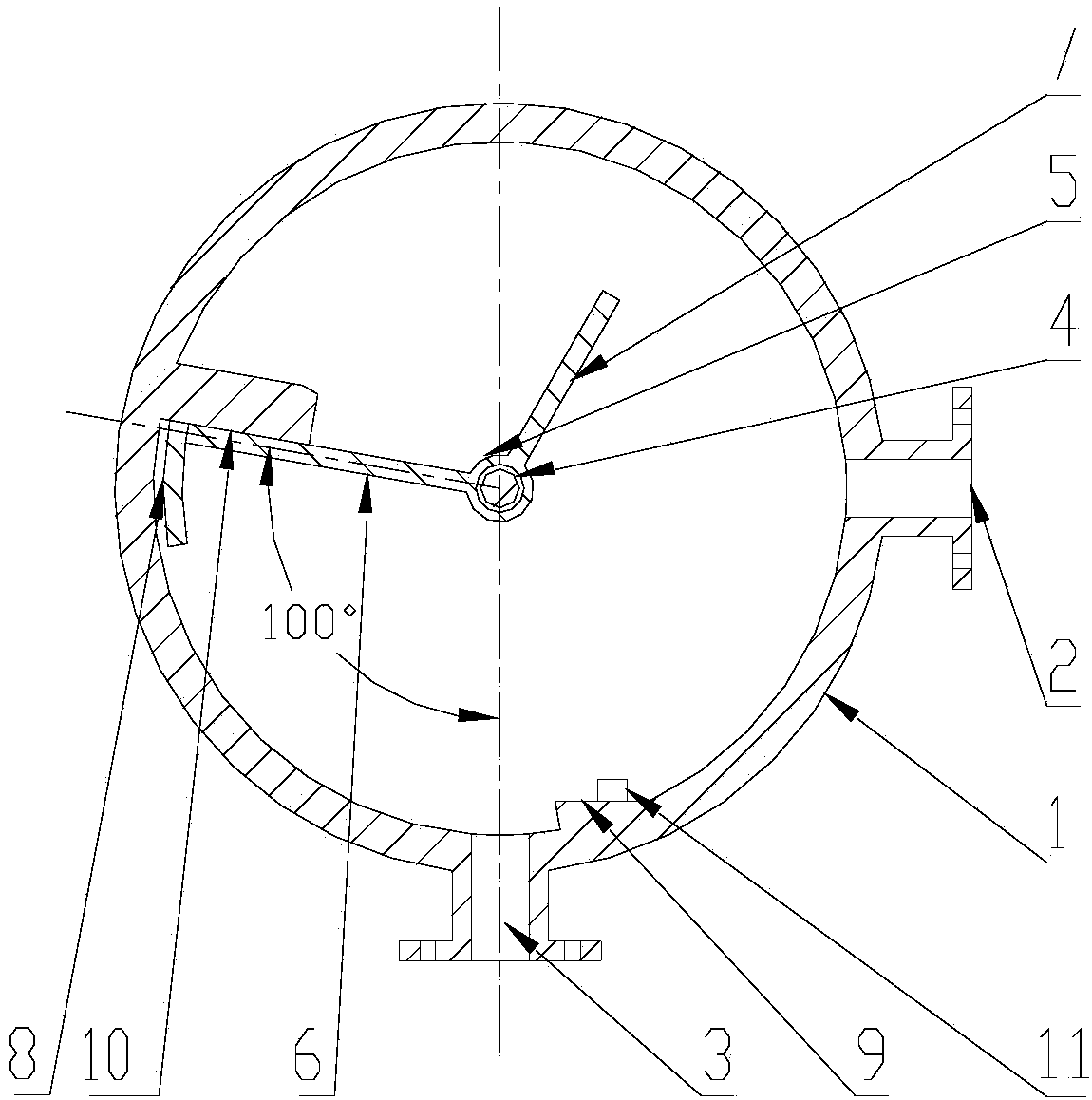

Fixed rotary type soot blower for large-size power station boiler furnace arch

InactiveCN103672926ASolve the sealing problemSoot blowing effect is goodLighting and heating apparatusCombustion chamberBoiler furnace

A fixed rotary type soot blower for a large-size power station boiler furnace arch is composed of an outer sleeve (1), an inner sleeve (2), a sealing ring (3) and a fixed rotary type soot blower body (4). The fixed rotary type soot blower for the large-size power station boiler furnace arch has the advantages that the single-injector fixed rotary type soot blower is arranged to be perpendicular to a slope surface, a gun tube is made of heat-resisting materials, the fixed rotary type soot blower stretches into a combustion chamber at a proper distance, is mounted and fixed and then blows soot in a rotary mode, and the angle of the injector, soot blowing pressure and the flow rate are calculated theoretically and then are adjusted on site to achieve the optimal soot blowing effect. The fixed rotary type soot blower for the large-size power station boiler furnace arch further has the advantages that sealing of the connecting portion of the soot blower and a furnace wall is achieved, and the fixed rotary type soot blower for the large-size power station boiler furnace arch can bear temperature higher than 1000 DEG C.

Owner:HUBEI HUAXIN MACHINERY DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com