Patents

Literature

46results about How to "Eliminate dust accumulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

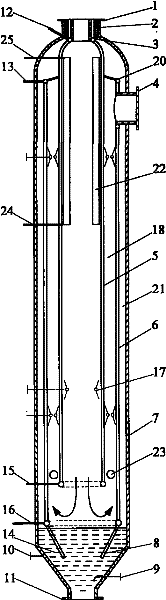

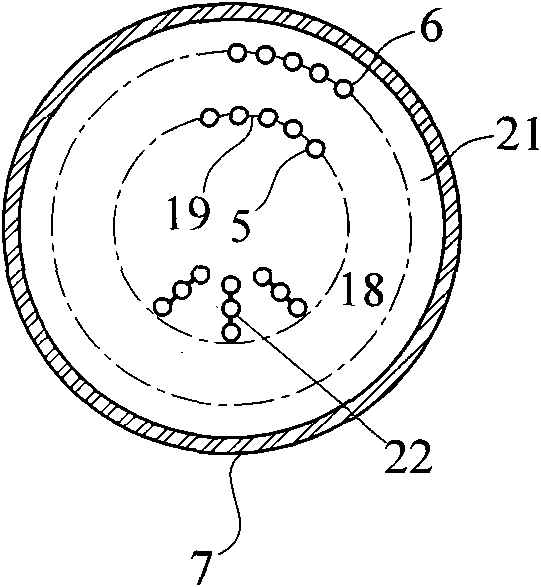

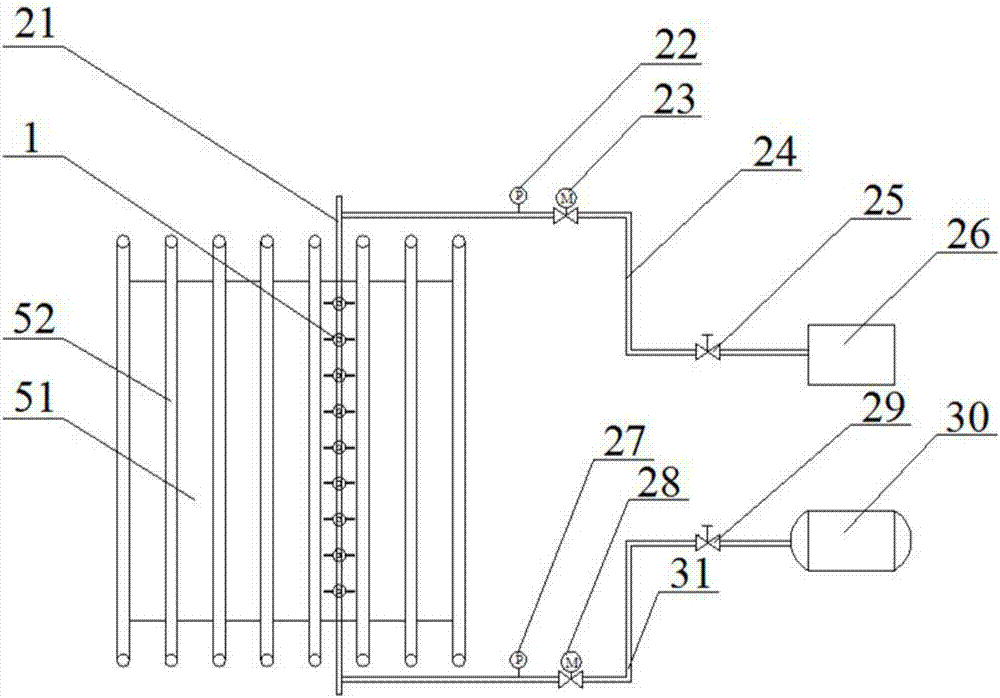

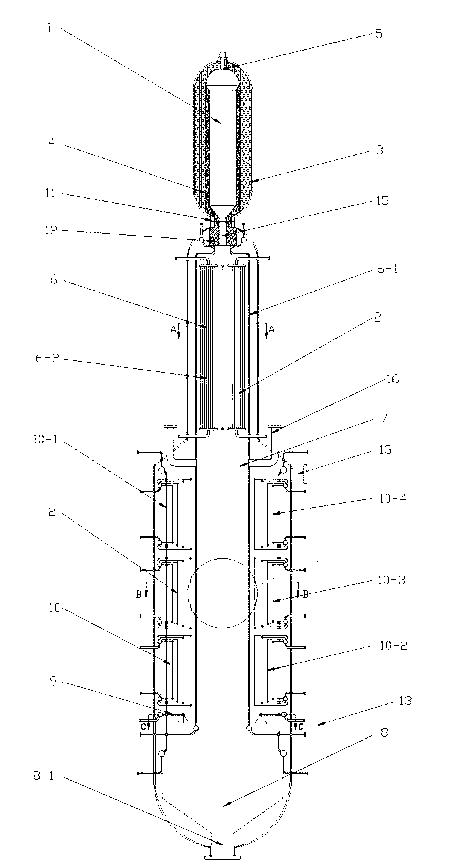

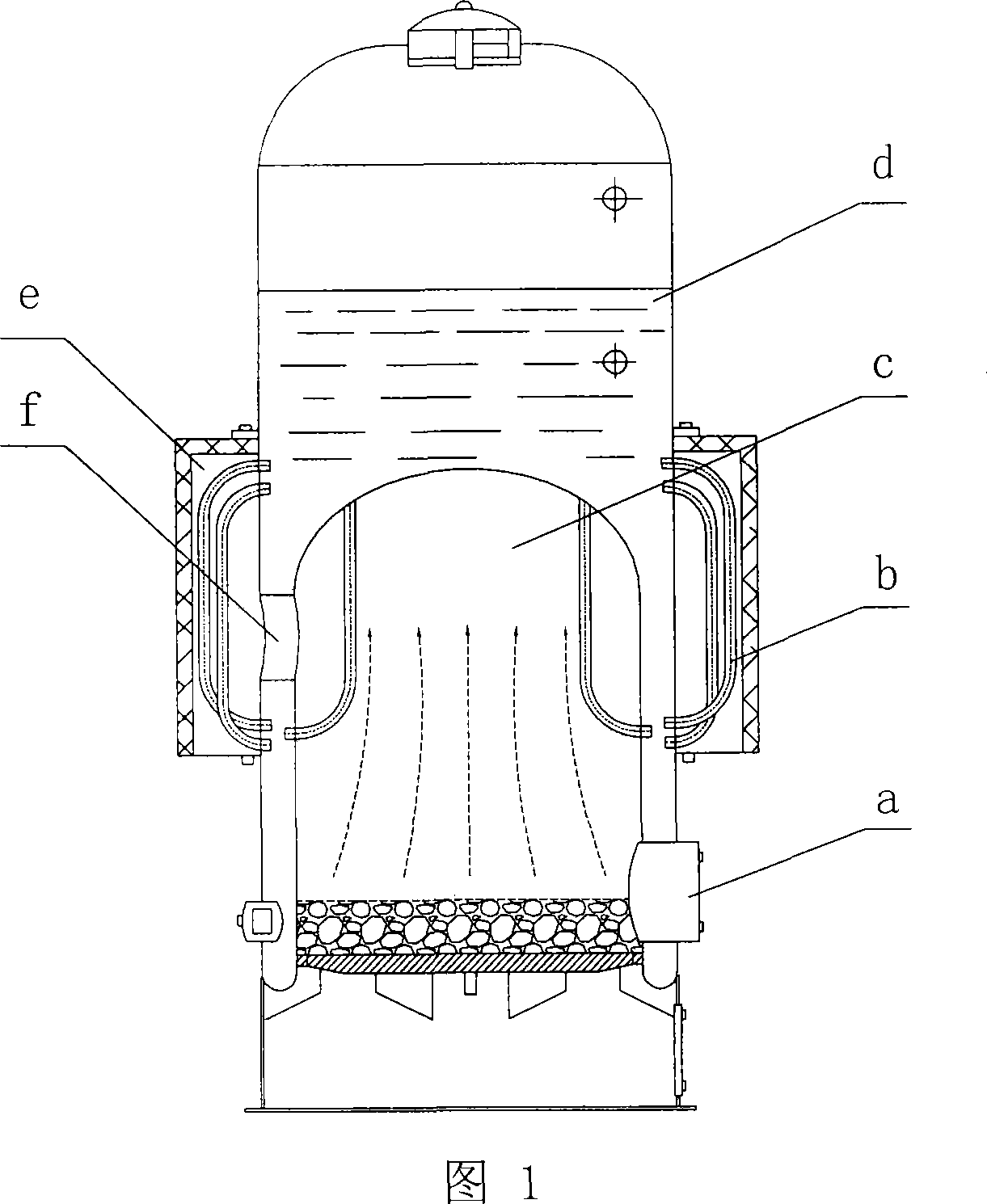

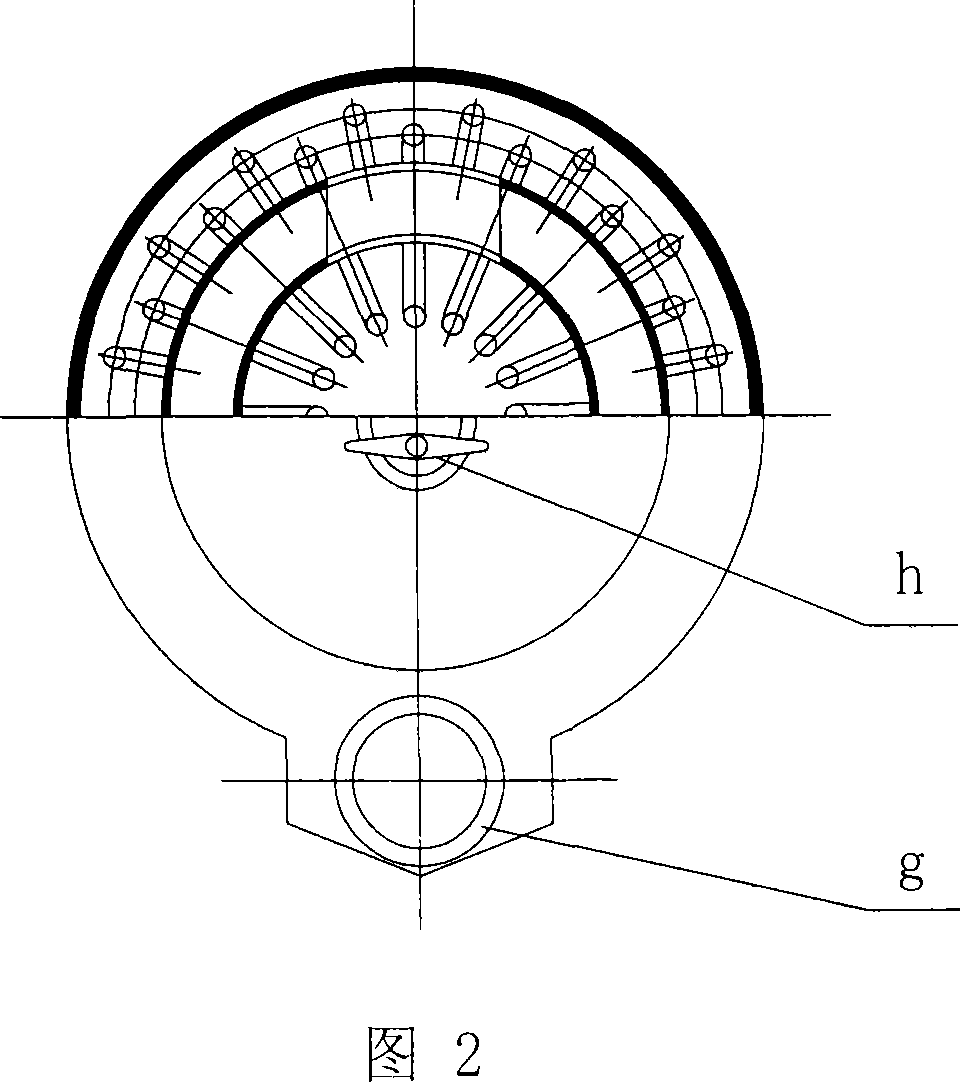

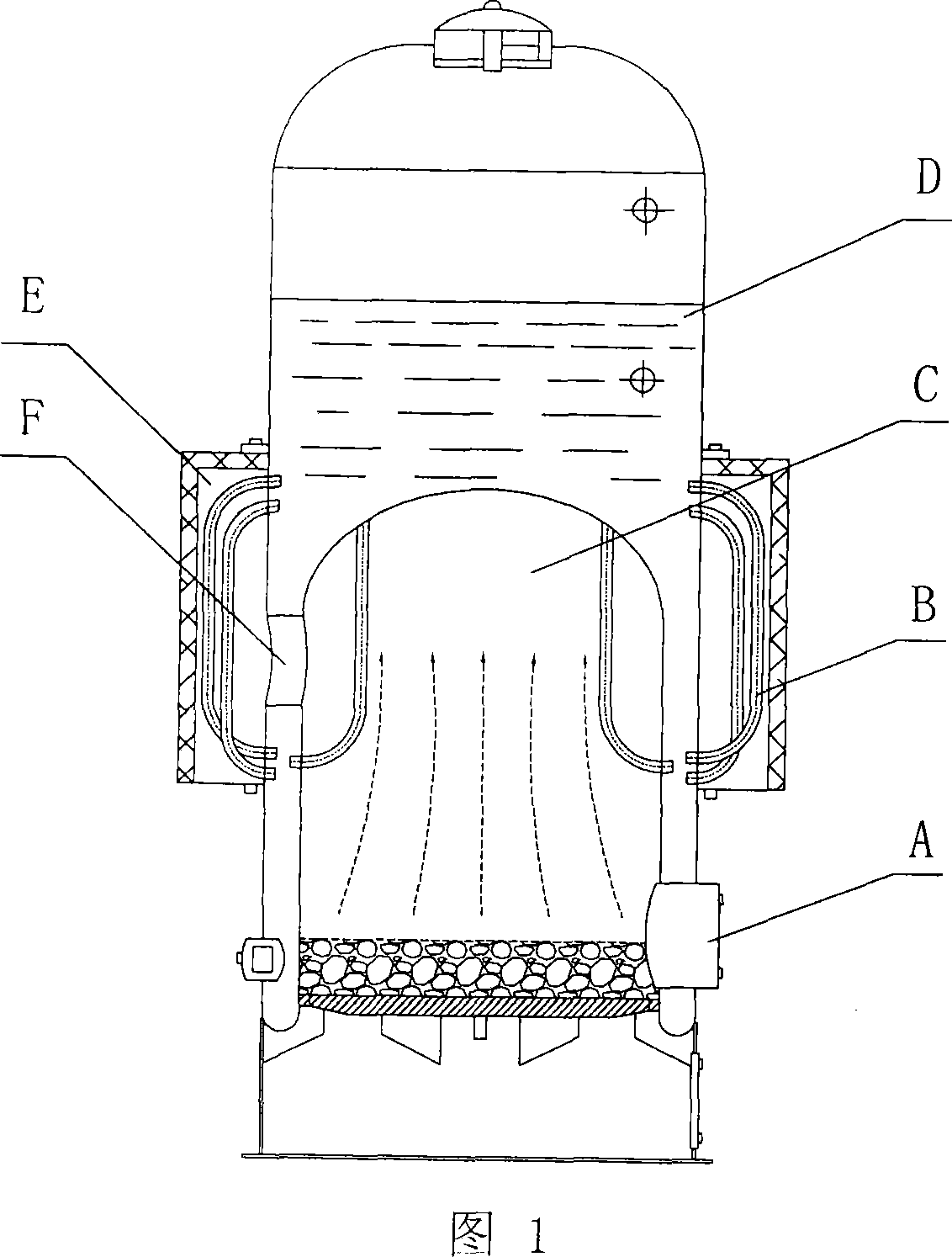

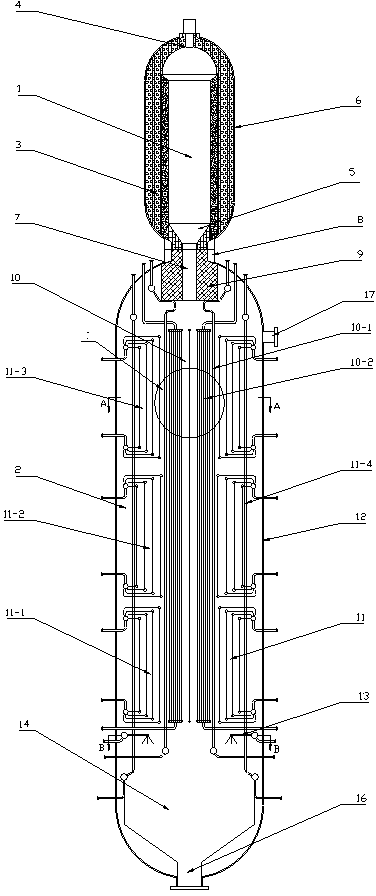

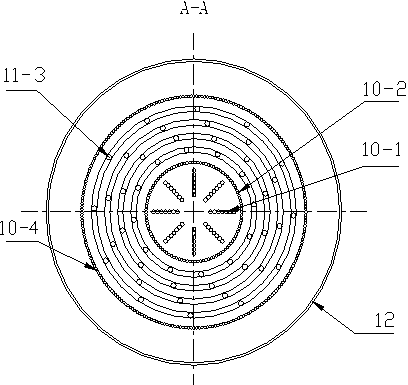

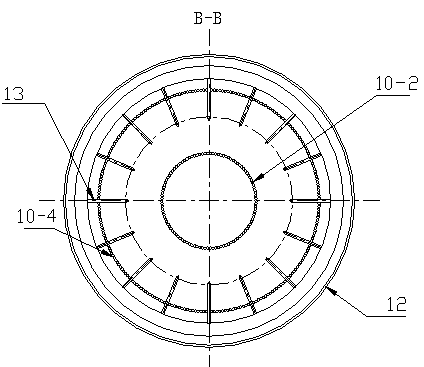

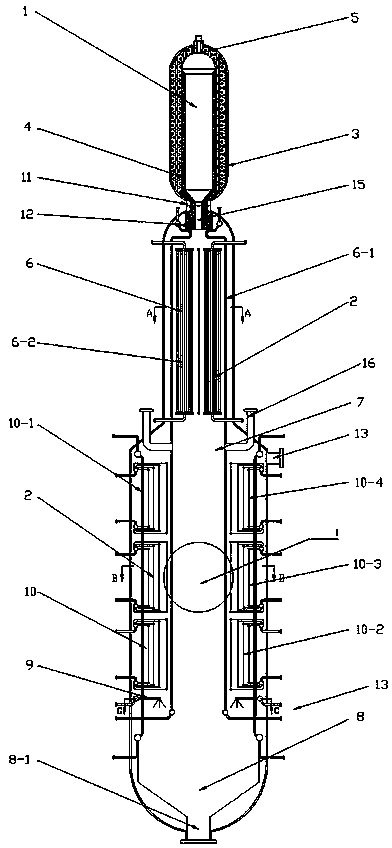

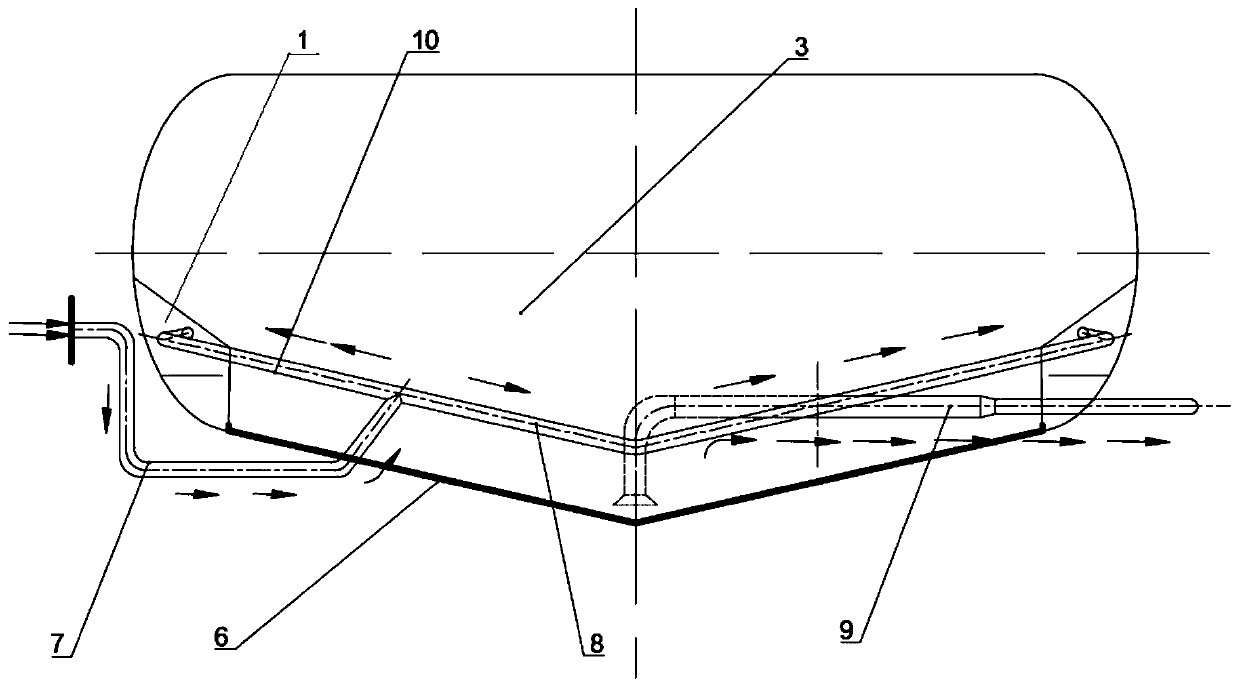

Double-barrel water cooled wall type radiation waste boiler with adjusting function and industrial application thereof

InactiveCN102213409AImprove utilization efficiencySmall sizeSteam boilersSteam boilers componentsSlagHigh pressure water

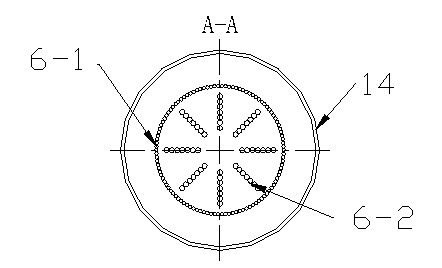

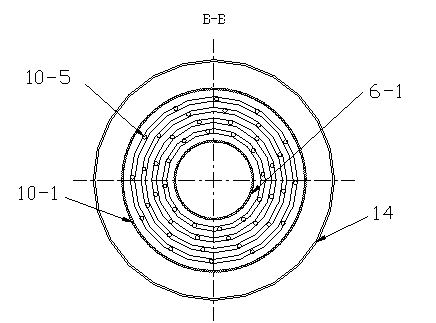

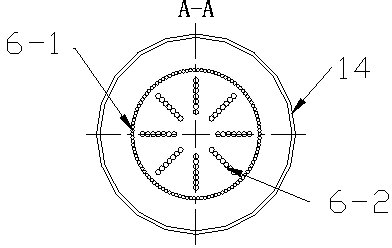

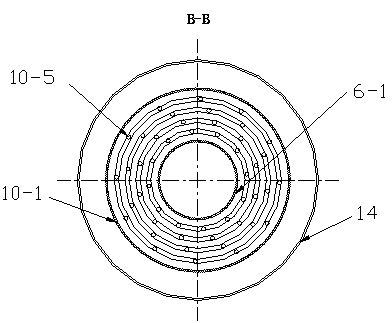

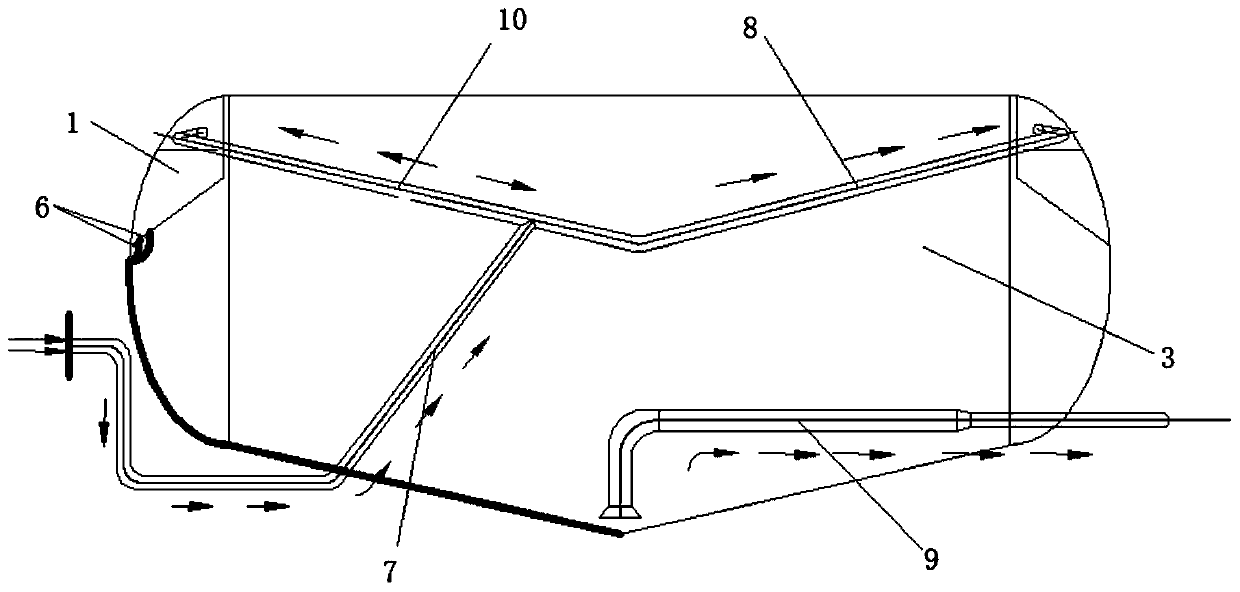

The invention discloses a recycling technology for sensible heat of high-temperature and high-pressure gasified products which are coal-gasified by an entrained flow bed, is particularly applicable for a waste boiler flow gasification furnace or a half waste boiler flower gasification furnace of a gasification island of an integrated gasification combined cycle (IGCC) power generation system, and provides a double-barrel water cooled wall type radiation waste boiler with an adjusting function. The double-barrel water cooled wall type radiation waste boiler consists of a flange connected with the gasification furnace, a shell for bearing high temperature and high pressure, an inner-layer water cooled wall, an outer-layer water cooled wall, a screen type water cooled wall, a soot blower and a slag pool positioned at the bottom, and comprises a water-spraying temperature reduction device with the adjusting function. Dust and slag which are carried by most air flows are caught and collected by the slag pool, and synthesized gas flows out from the single side of the radiation waste boiler. High-pressure water entering the radiation waste boiler recycles the sensible heat of the high-temperature and high-pressure gasified products and is converted into saturated high-pressure steam discharged from the outlet of the water cooled wall. By the double-barrel water cooled wall type radiation waste boiler, the high-position sensible heat of the gasified products can be recycled effectively, so the whole energy utilization efficiency can be improved; the double-barrel water cooled wall type radiation waste boiler has the characteristics of safe running, reliability and controllability, and is a clean and efficient energy recycling technology.

Owner:EAST CHINA UNIV OF SCI & TECH

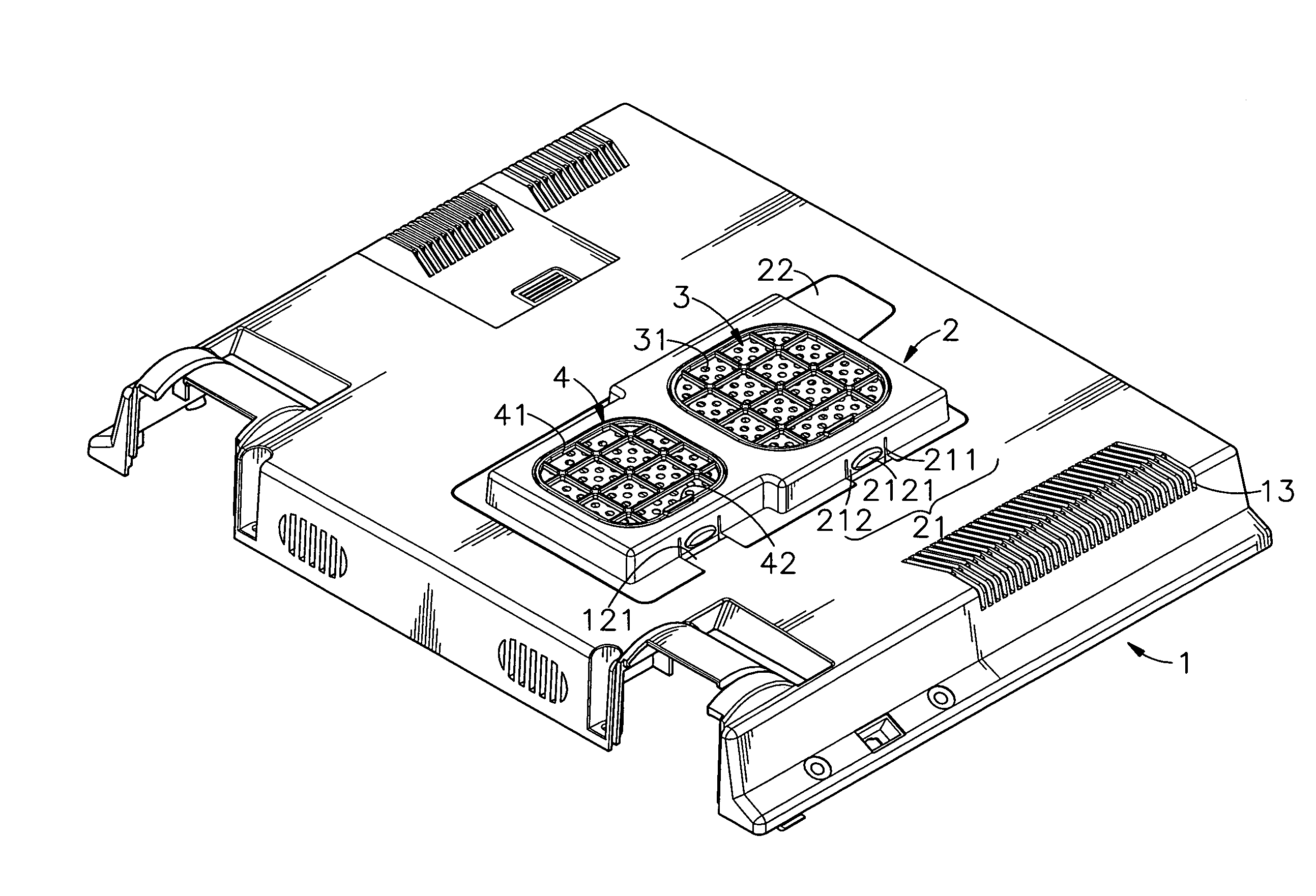

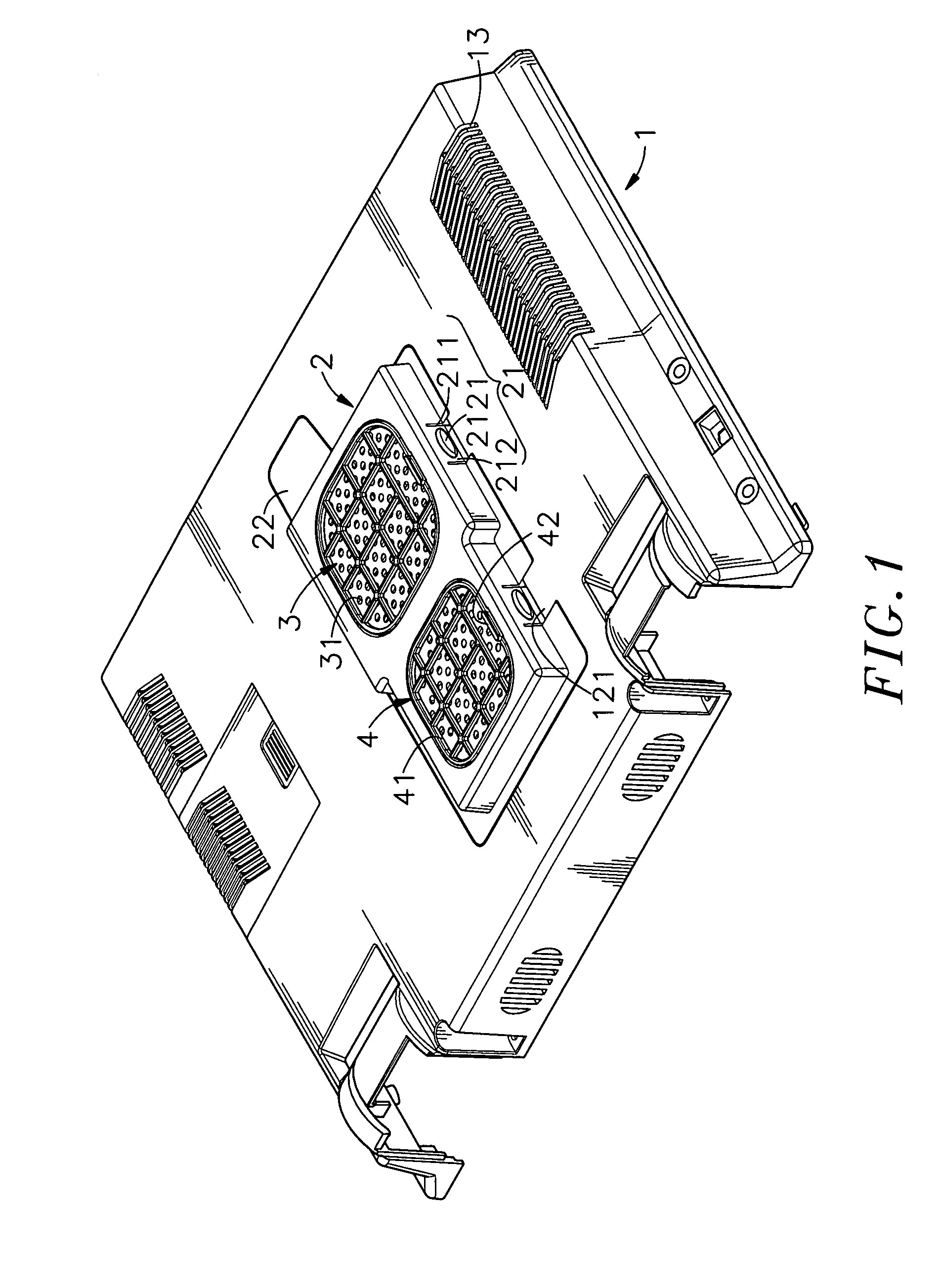

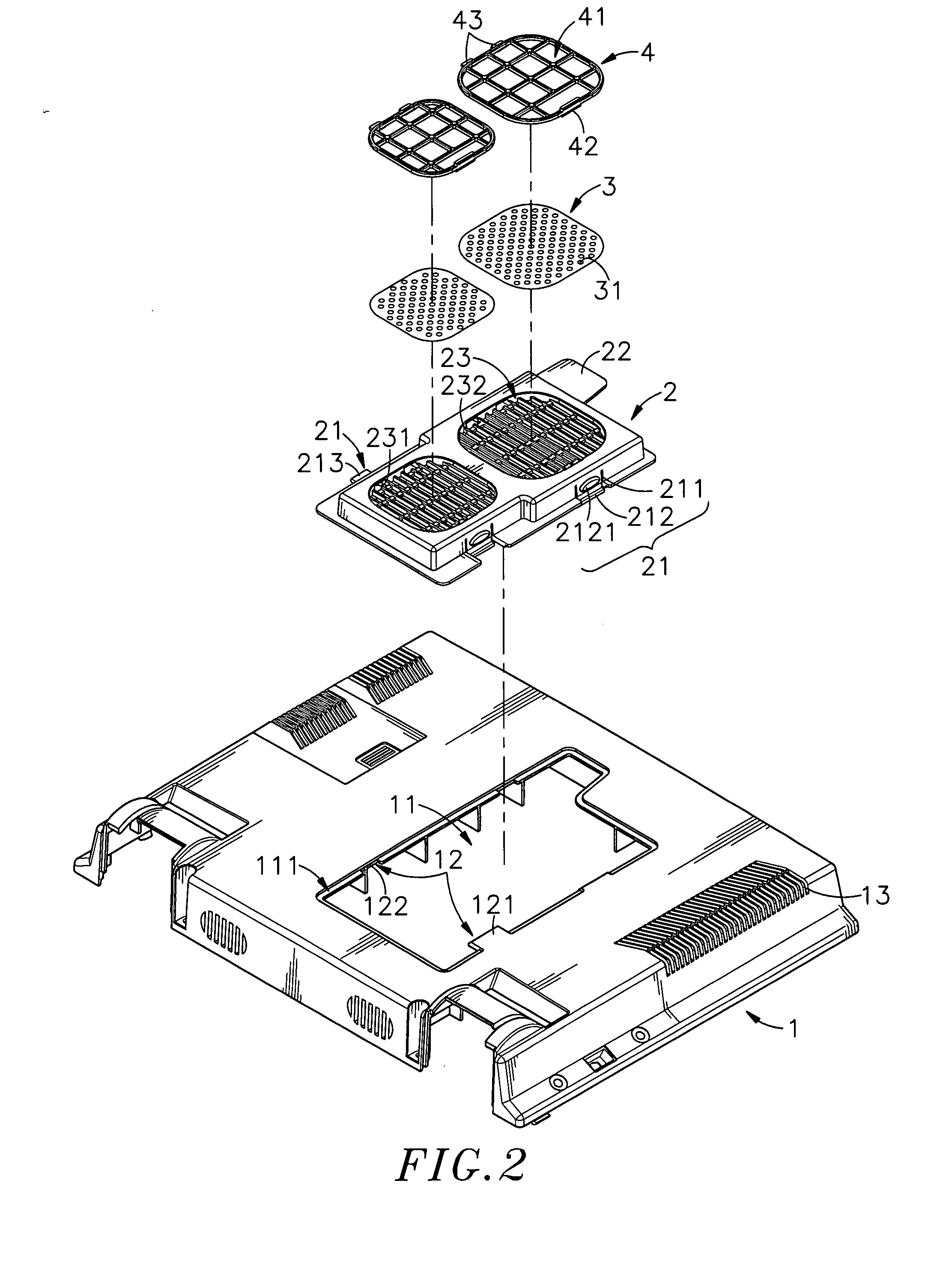

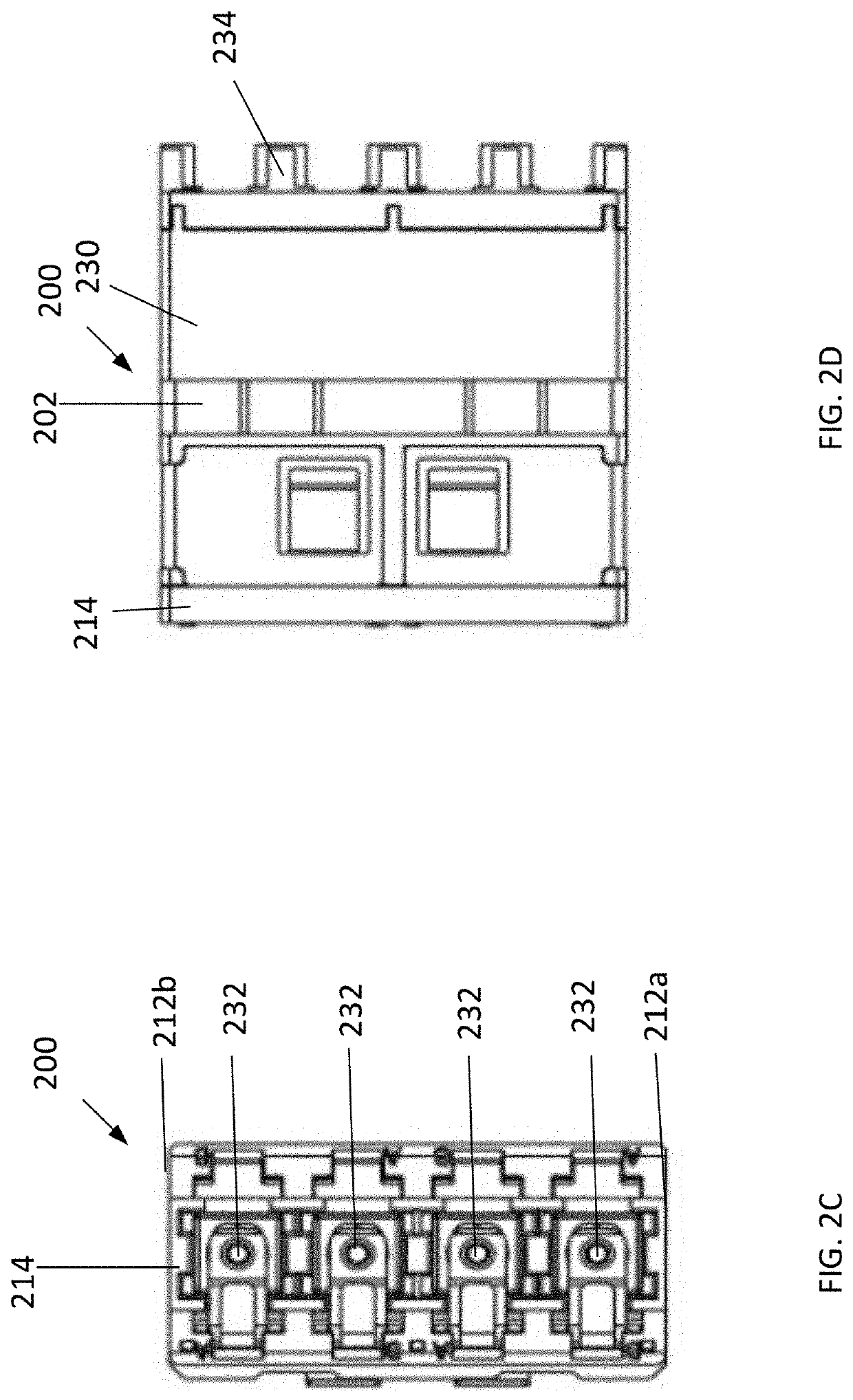

Display panel

InactiveUS20090021126A1Quick releaseEasy to cleanCasings/cabinets/drawers detailsFurniture partsEngineeringFlange

A display panel is disclosed having a panel frame that holds cooling fans in an accommodation opening thereof and is provided with a locating groove and an engagement structure around the accommodation opening, a cover frame that has a locating flange fitted into the locating groove of the panel frame and an engagement structure detachably fastened to the engagement structure of the panel frame by hand without tools to lock the cover frame to the panel frame and ventilation ports corresponding to the cooling fans in the accommodation opening of the panel frame, filter members respectively mounted in the ventilation ports and held in place by respective positioning members for removing dust from air passing through.

Owner:DATAVAN INT

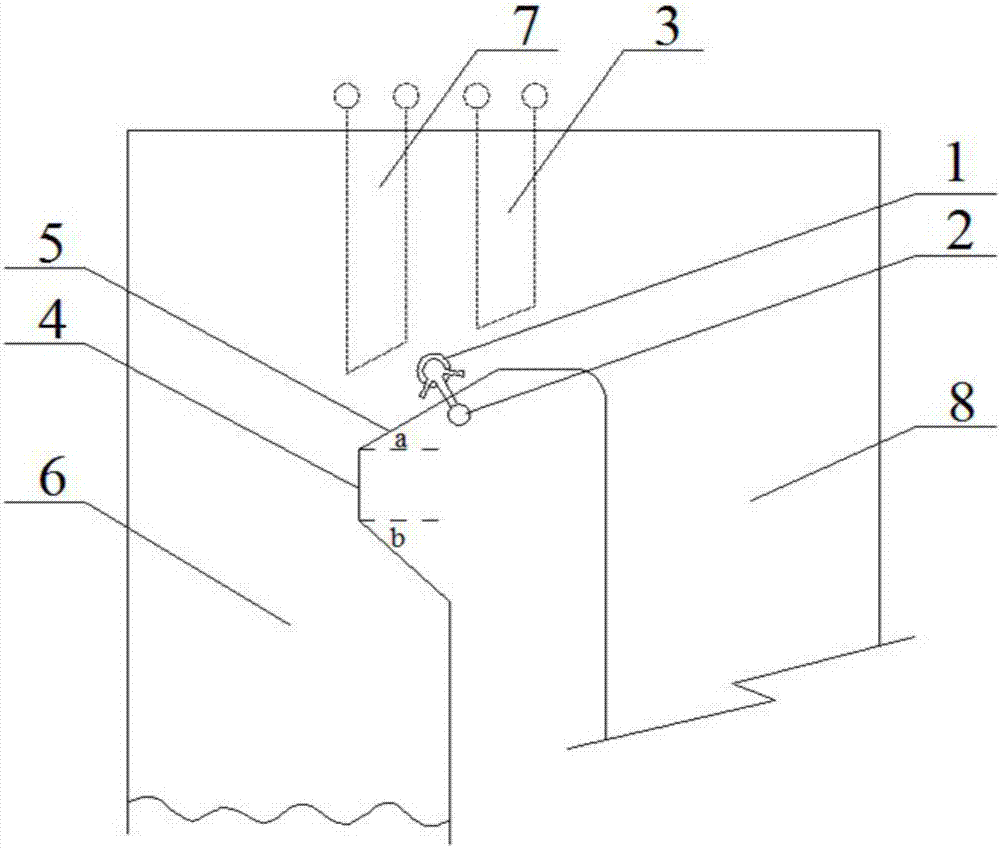

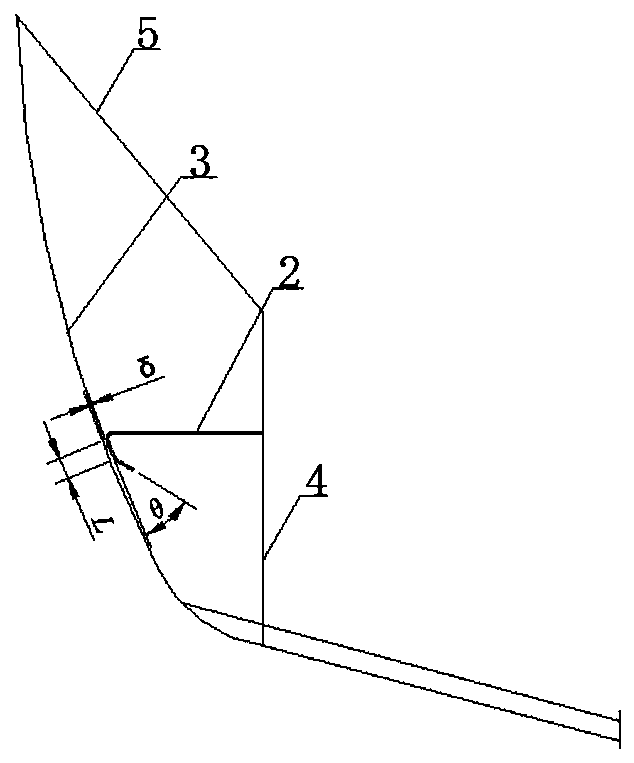

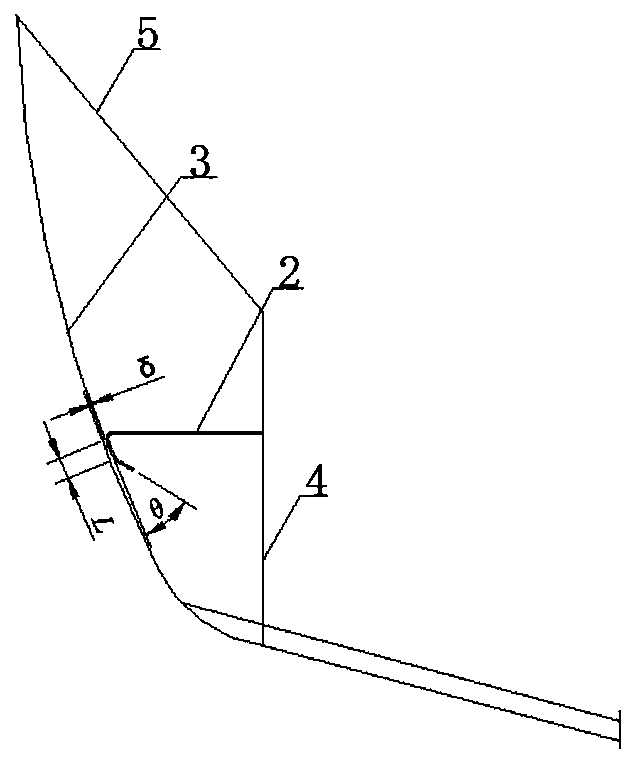

Soot blowing system and method for pi-shaped boiler furnace arch

The invention discloses a soot blowing system and method for a pi-shaped boiler furnace arch. The soot blowing system utilizes a pneumatic and steam-driven fluidization principle, and overcomes the friction of accumulated soot on the upper slope of the furnace arch, thus enabling the accumulated soot to separately flow to a hearth and a horizontal flue to be discharged. A hood-shaped soot blower is mounted on a diaphragm of the upper slope of the furnace arch, arranged between a high temperature superheater and a high temperature reheater, penetrates through the upper slope of the furnace arch, and is connected with a soot blowing media pipeline. The shapes of a first soot blowing pipe and a second soot blowing pipe of the hood-shaped soot blower are telescopic pipes, thereby improving thespeed of soot blowing airflow, and enhancing the soot blowing effect. During the soot blowing process, compressed air firstly blows the accumulated soot on the upper slope of the furnace arch, and then steam blows residual accumulated soot hard to clear, so that an excellent soot blowing effect can be achieved by a compound blowing mode. The soot blowing system can effectively clear the accumulated soot on the upper slope of the boiler furnace arch, avoids the occurrence of excessive blowing loss and pipe explosion of the furnace arch and the wall face of the superheater and saves the energyconsumption of blowing soot.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

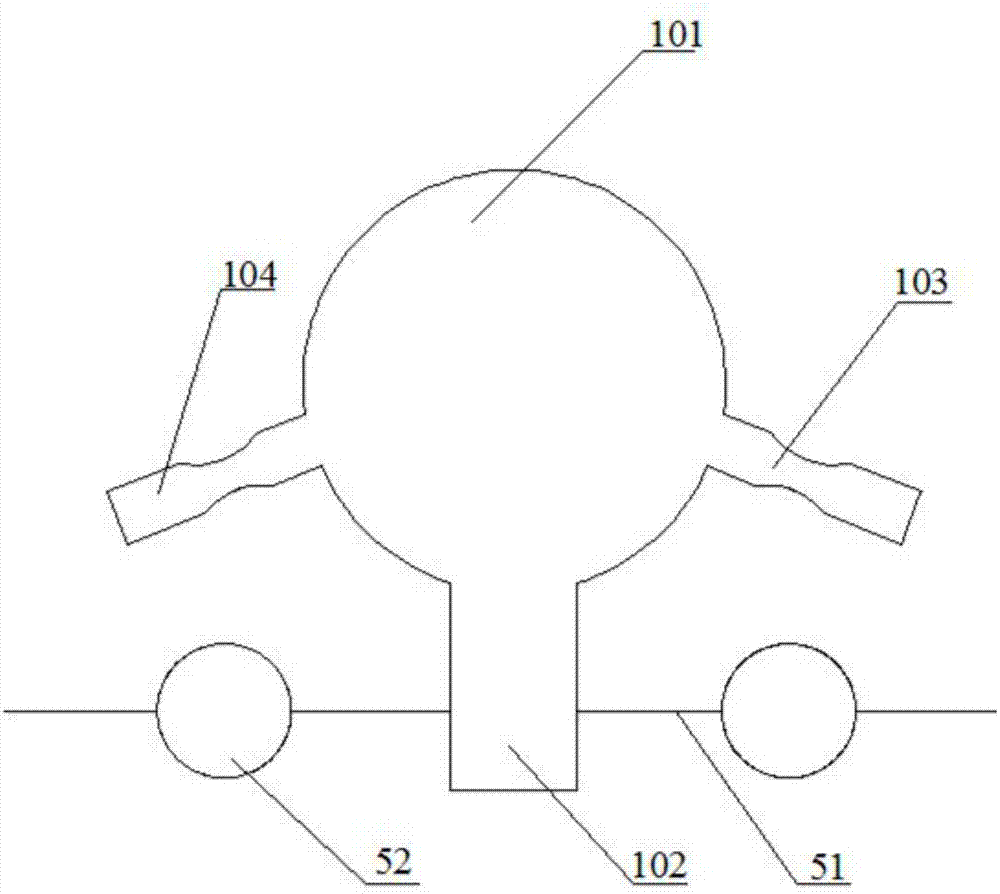

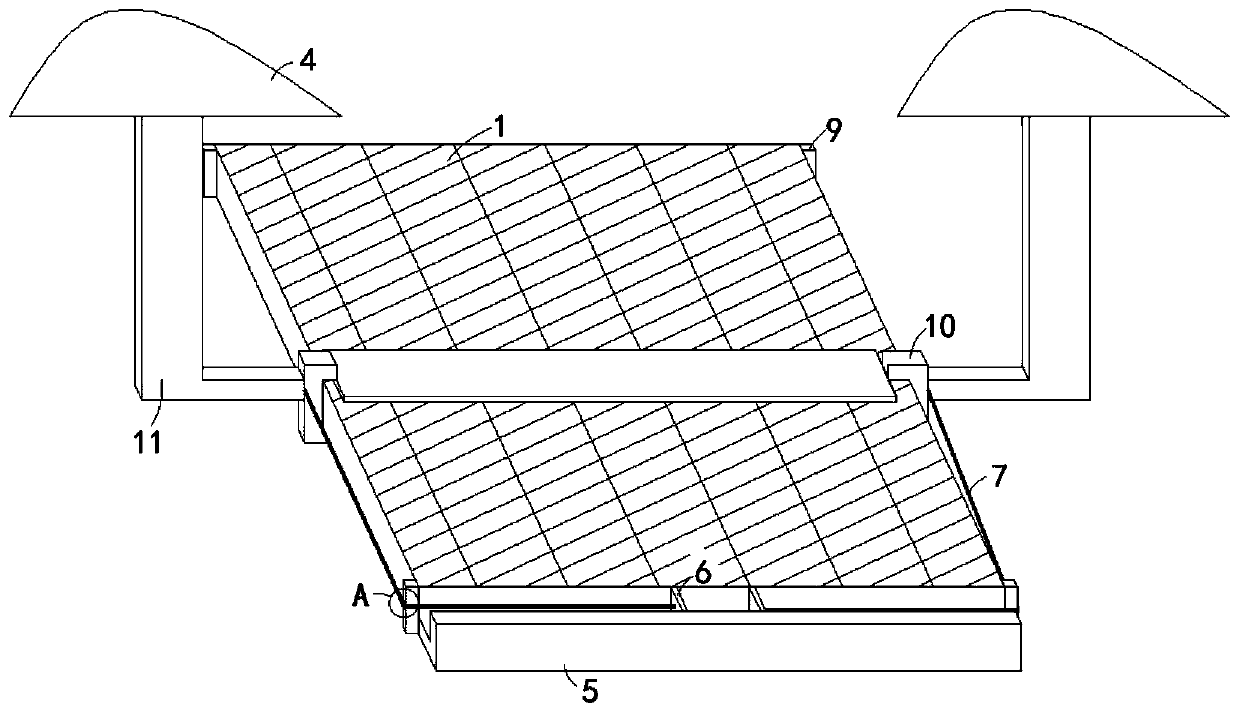

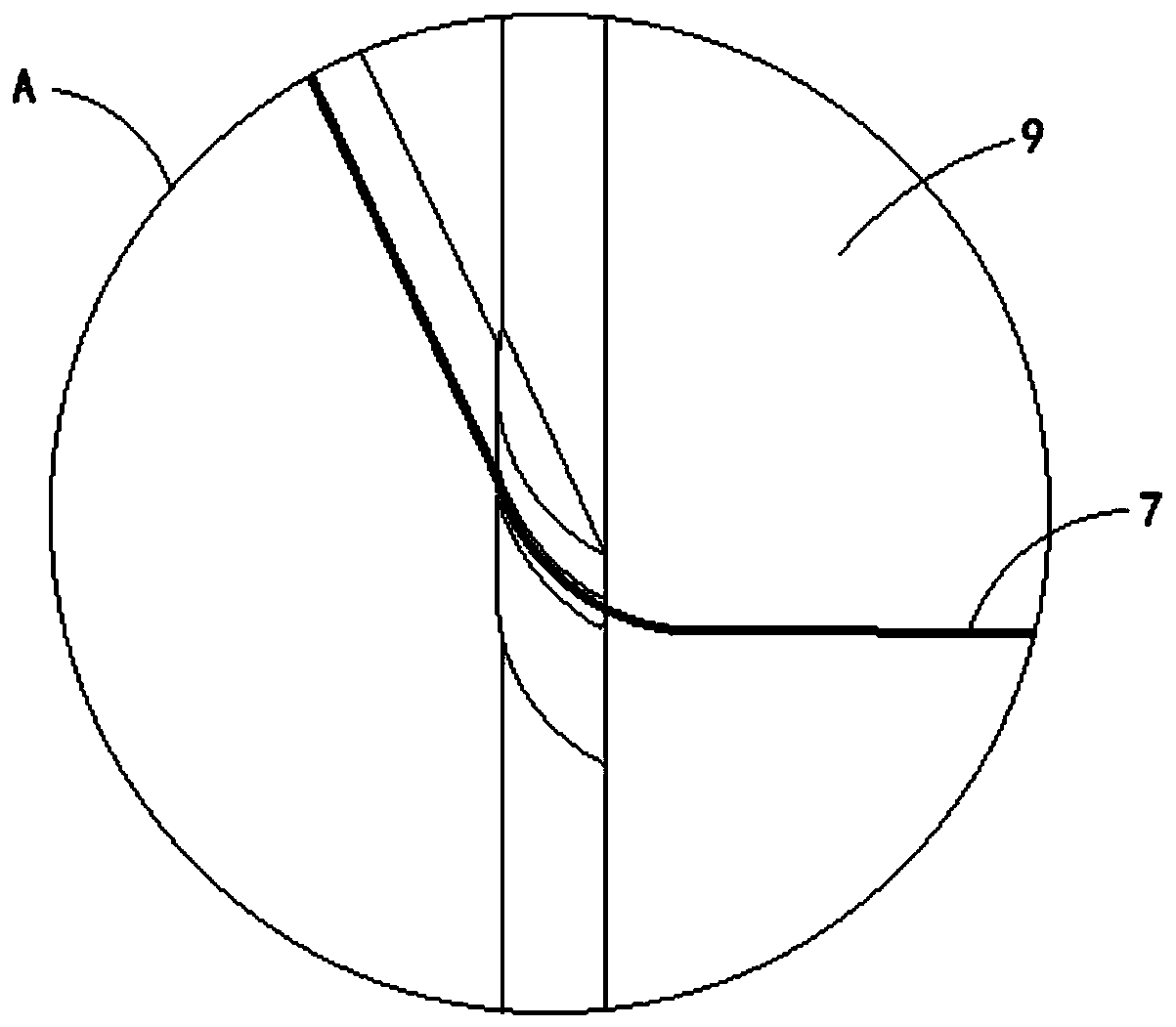

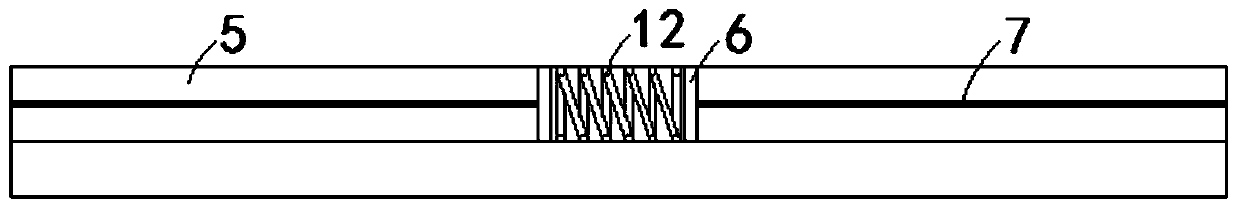

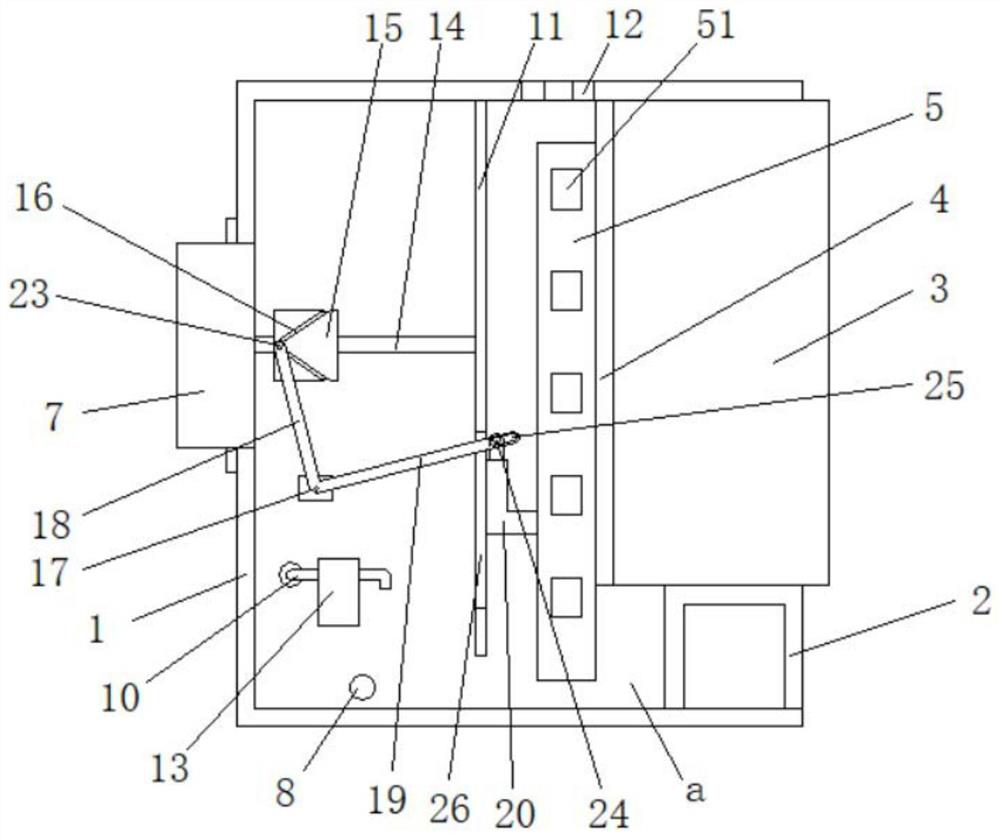

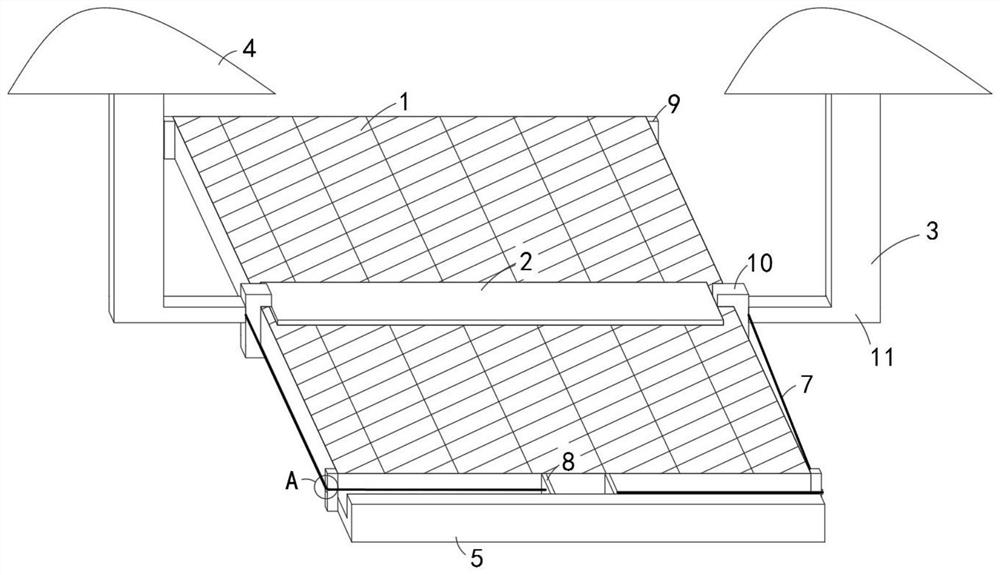

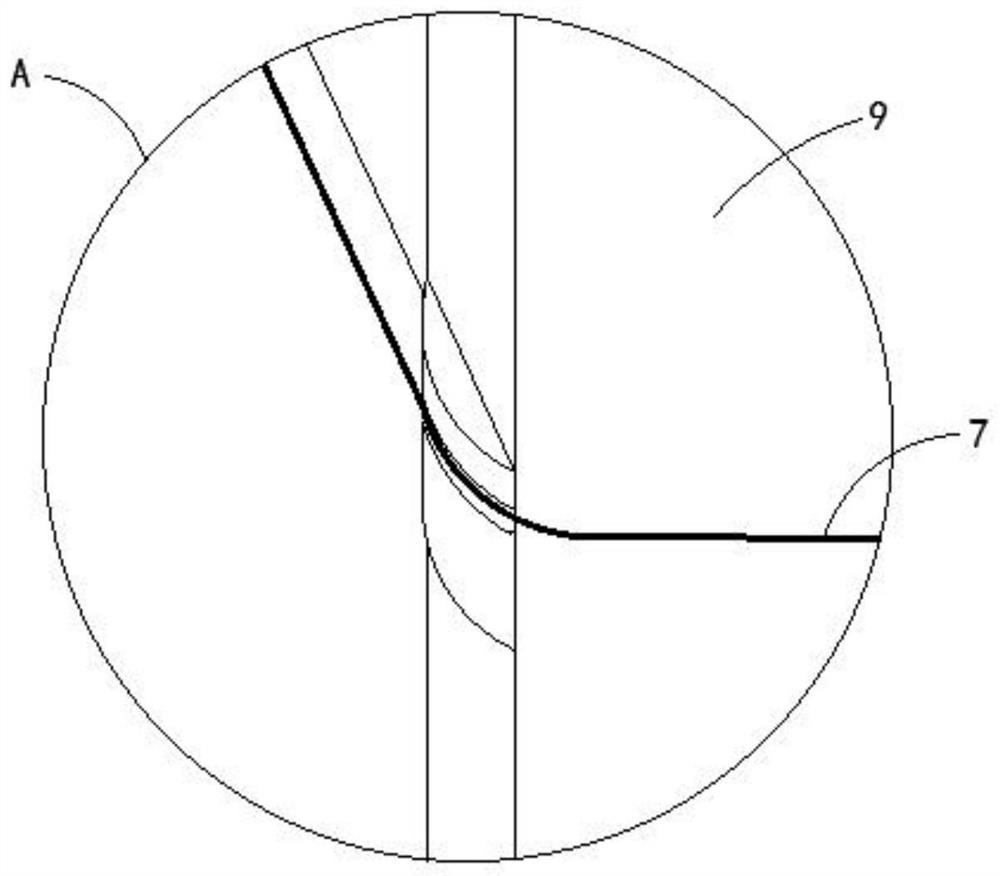

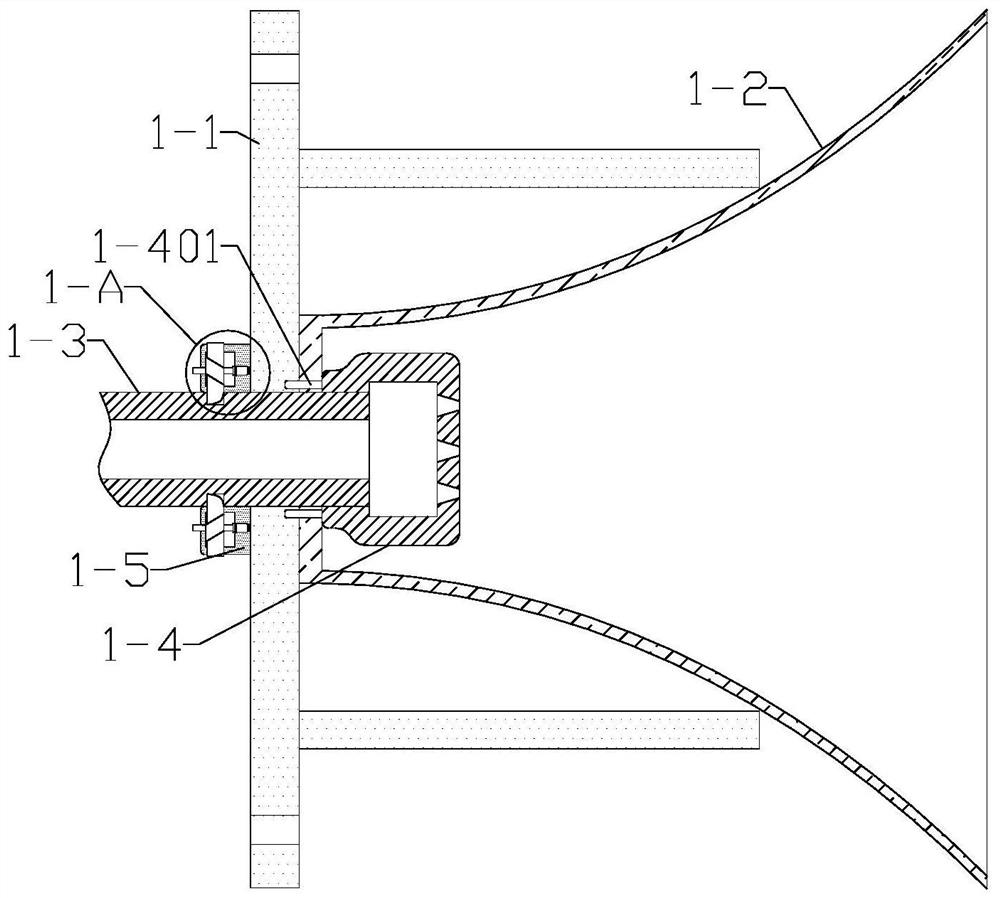

New energy self-cleaning solar panel

ActiveCN110336532AEasy to cleanRealize one-way cleaningPhotovoltaicsPhotovoltaic energy generationExternal energyNew energy

The invention belongs to the technical field of new energy equipment and in particular to a new energy self-cleaning solar panel, comprising a solar panel. The upper side wall of the solar panel is slidably connected with a brush plate. The left and right ends of the brush plate are fixedly connected with sliding mechanisms. Wing plates are fixedly connected to the other ends of the sliding mechanisms. A dust receiving tank is fixedly connected to the lower side of the solar panel. Two dust scraping plates are slidably connected in the dust receiving tank. The side walls of the two dust scraping plates away from each other are both connected to connecting ropes. The other end of each connecting rope is fixedly connected with the corresponding sliding mechanism. A reset mechanism is arranged between the two dust scraping plates. The four corners of the solar panel are fixedly connected with stopping blocks. The wind energy is fully utilized by the wing plates, so that the brush plate slides up and down under the indirect driving of the wind energy so as to remove the dust from the surface of the solar panel, thereby improving the absorption of light energy by the solar panel. Further, this process utilizes clean and renewable wind energy and requires no external energy supply so as to achieve a clean and environment-friendly effect.

Owner:中宏京(天津)智能科技有限公司

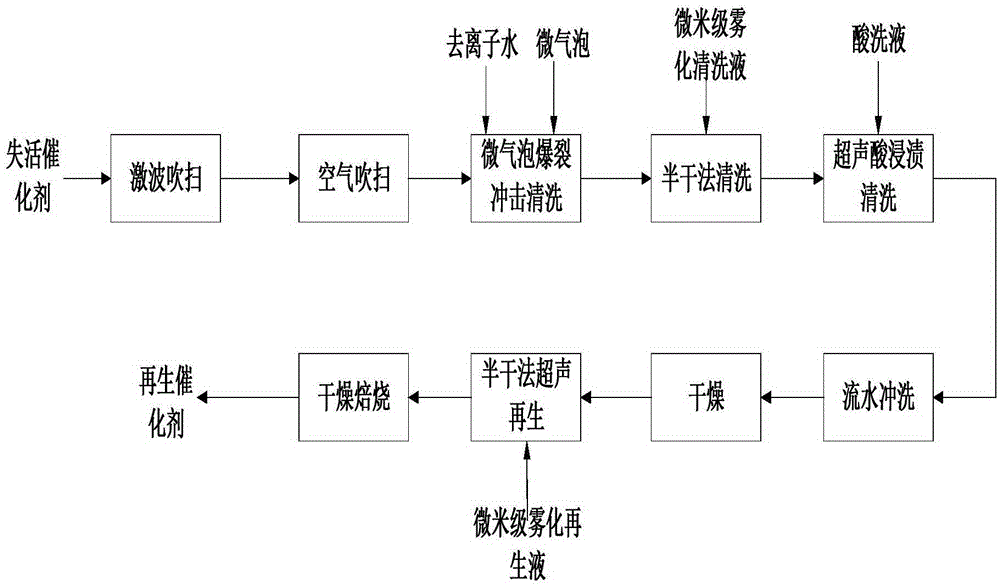

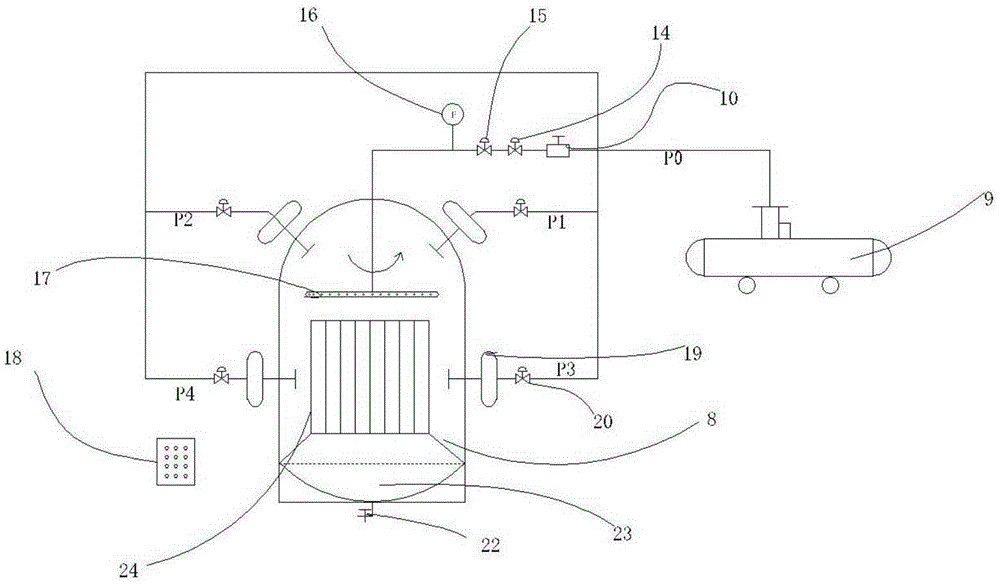

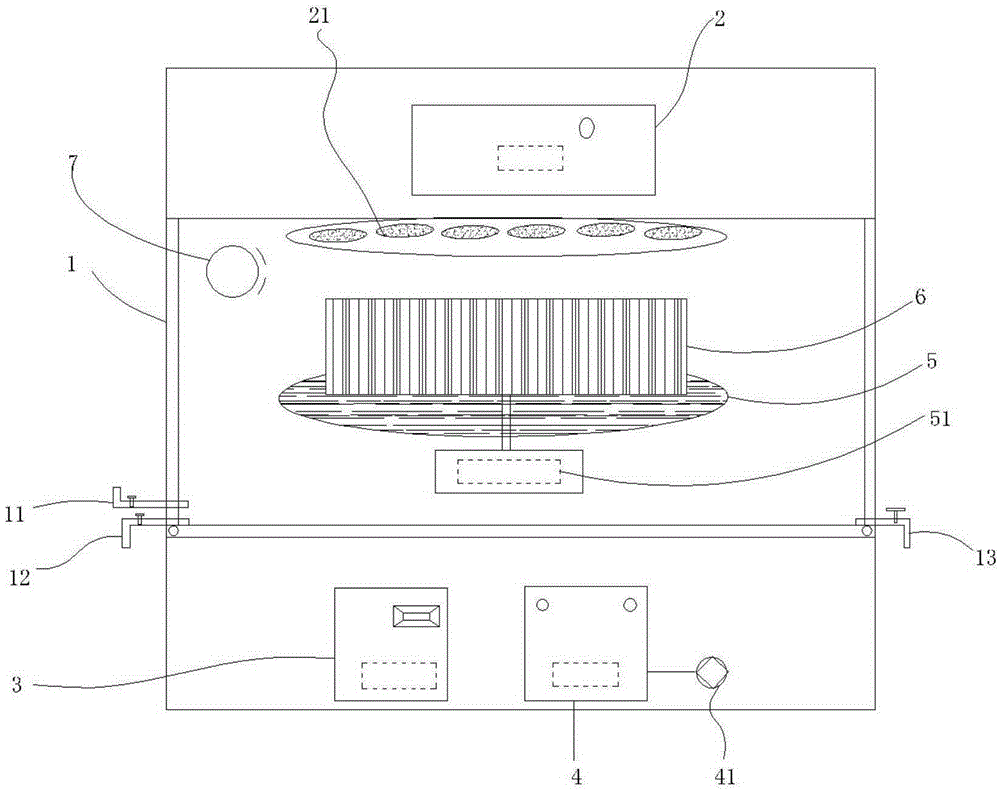

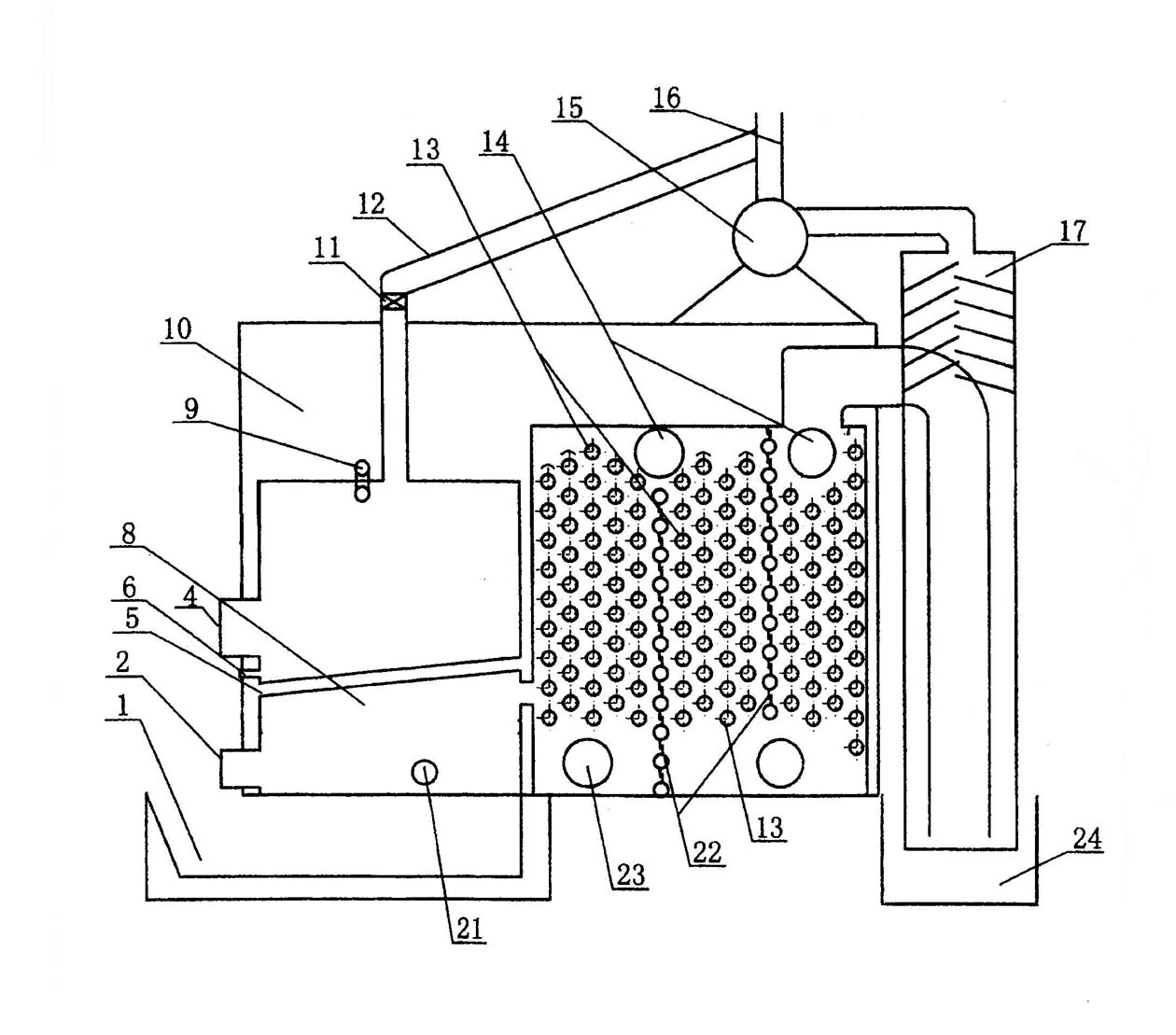

Deactivated SCR denitration catalyst purging device, activation device and regeneration system and corresponding methods

InactiveCN105381716AAchieve activationAchieve regenerationDispersed particle separationCatalyst regeneration/reactivationEngineeringBiological activation

The present invention relates to a deactivated SCR denitration catalyst purging device, an activation device and a regeneration system and corresponding methods, the activation device includes a regeneration main body tank, an ultrasonic atomization device, a catalyst rotating turntable and a micro negative pressure suction device; and the regeneration system includes the purging device, a cleaning device, a first drying device and the activation device which are connected in turn. The regeneration system can achieve deactivated catalyst regeneration, and compared with the normal regeneration process, the process is more thorough in purging and more complete in cleaning, also greatly improves the utilization ratio of a cleaning solution and a regeneration solution, and maximizes recovery of surface and pore structure of a deactivated catalyst.

Owner:FUJIAN ZIJIN ENVIRONMENT ENG TECH +1

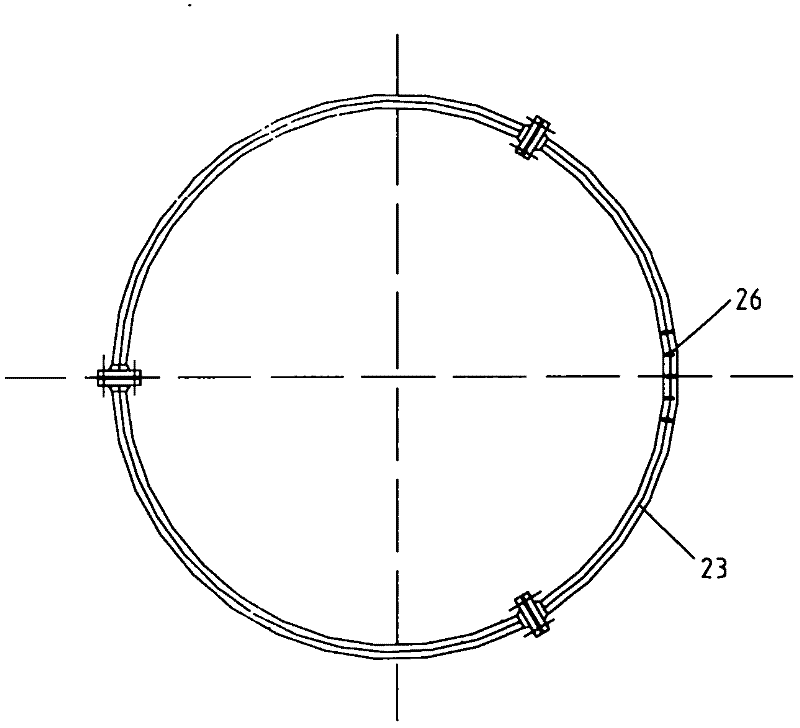

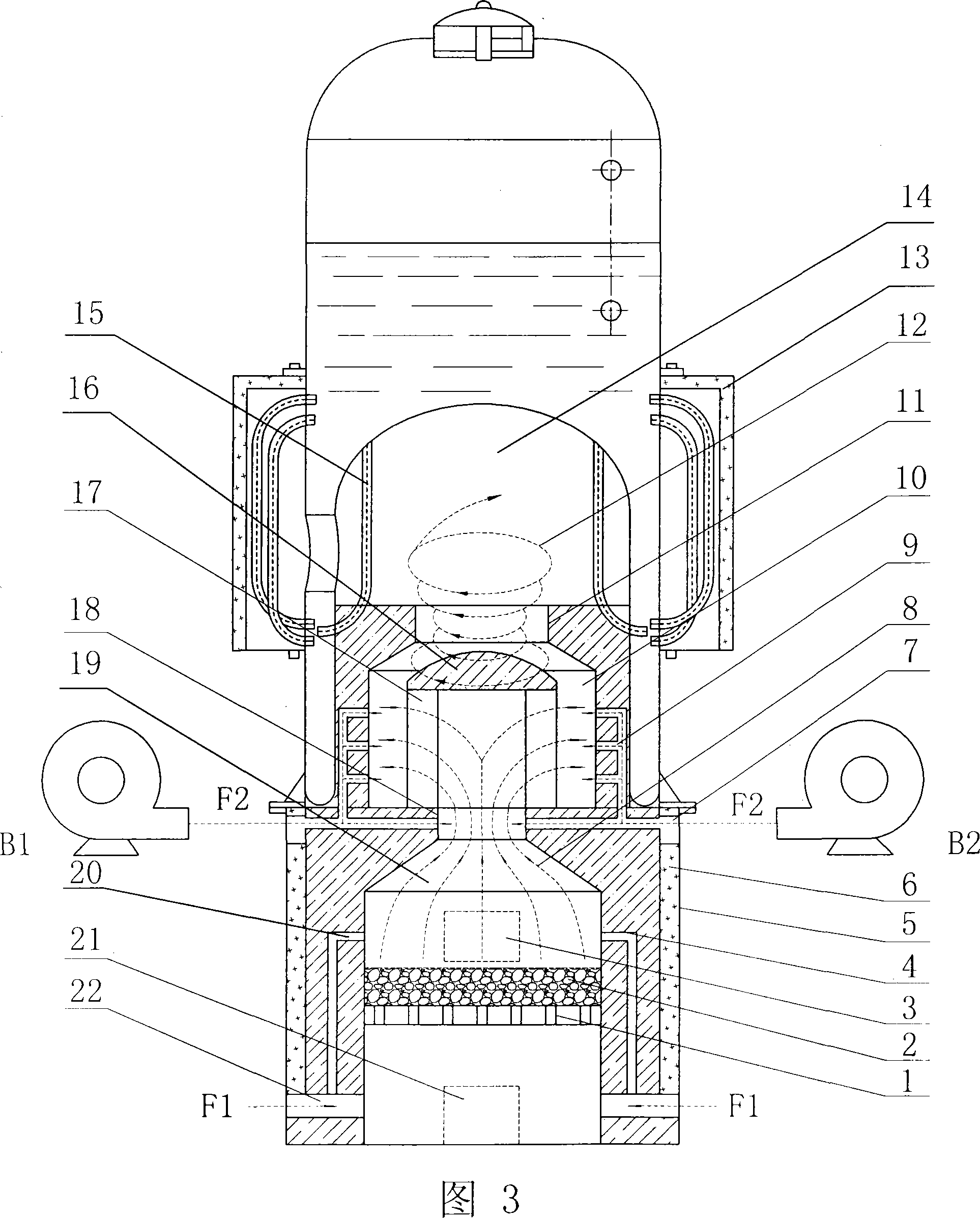

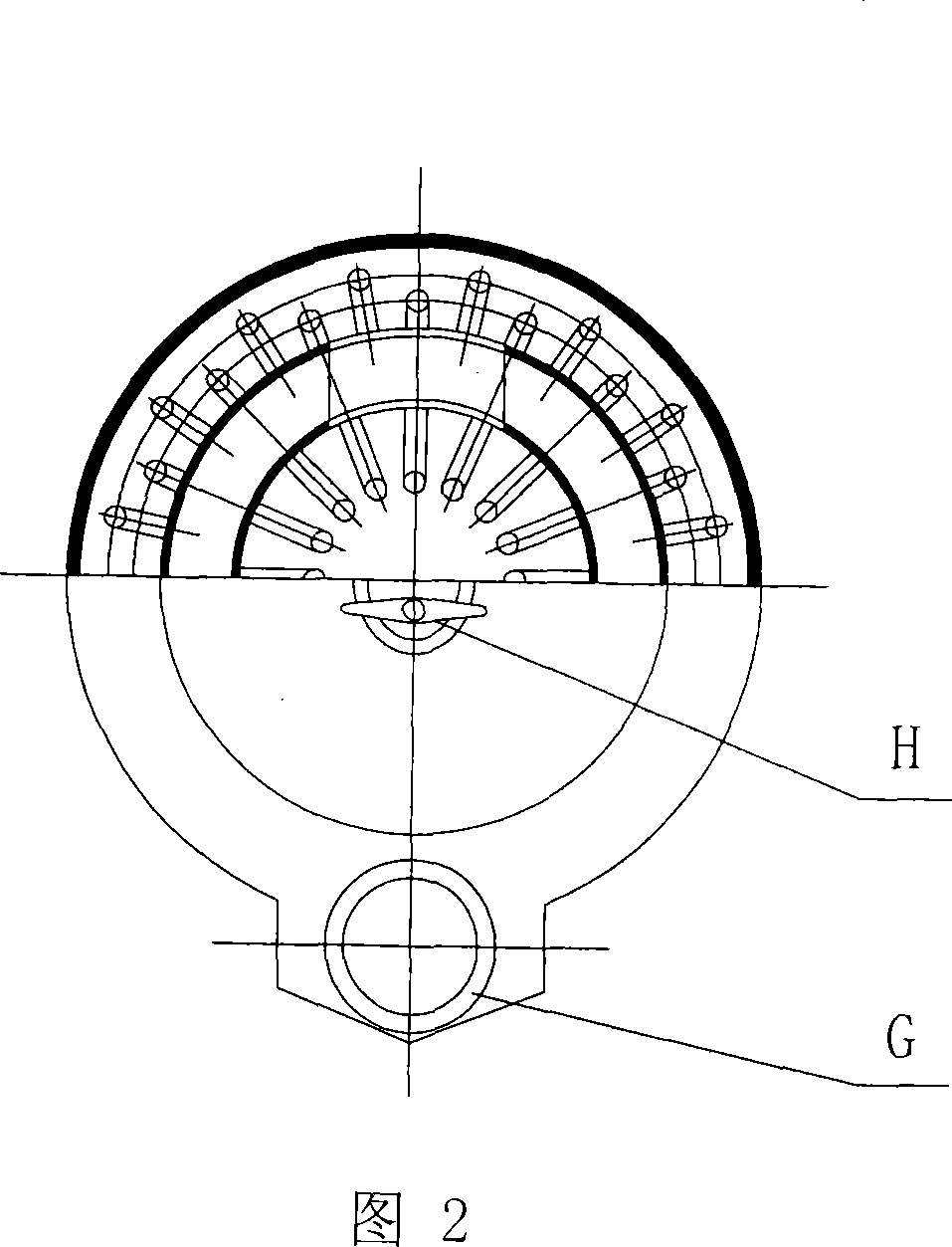

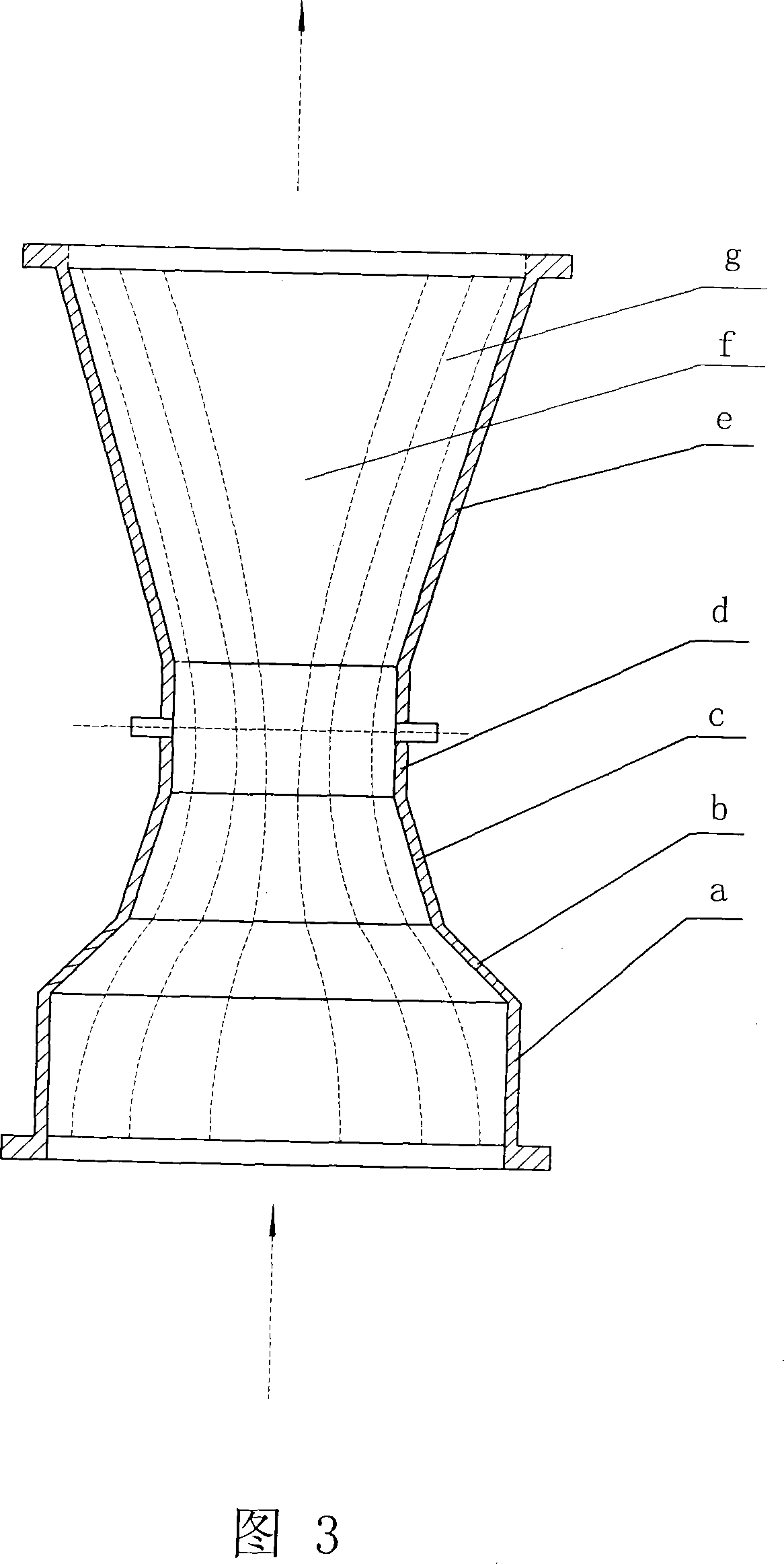

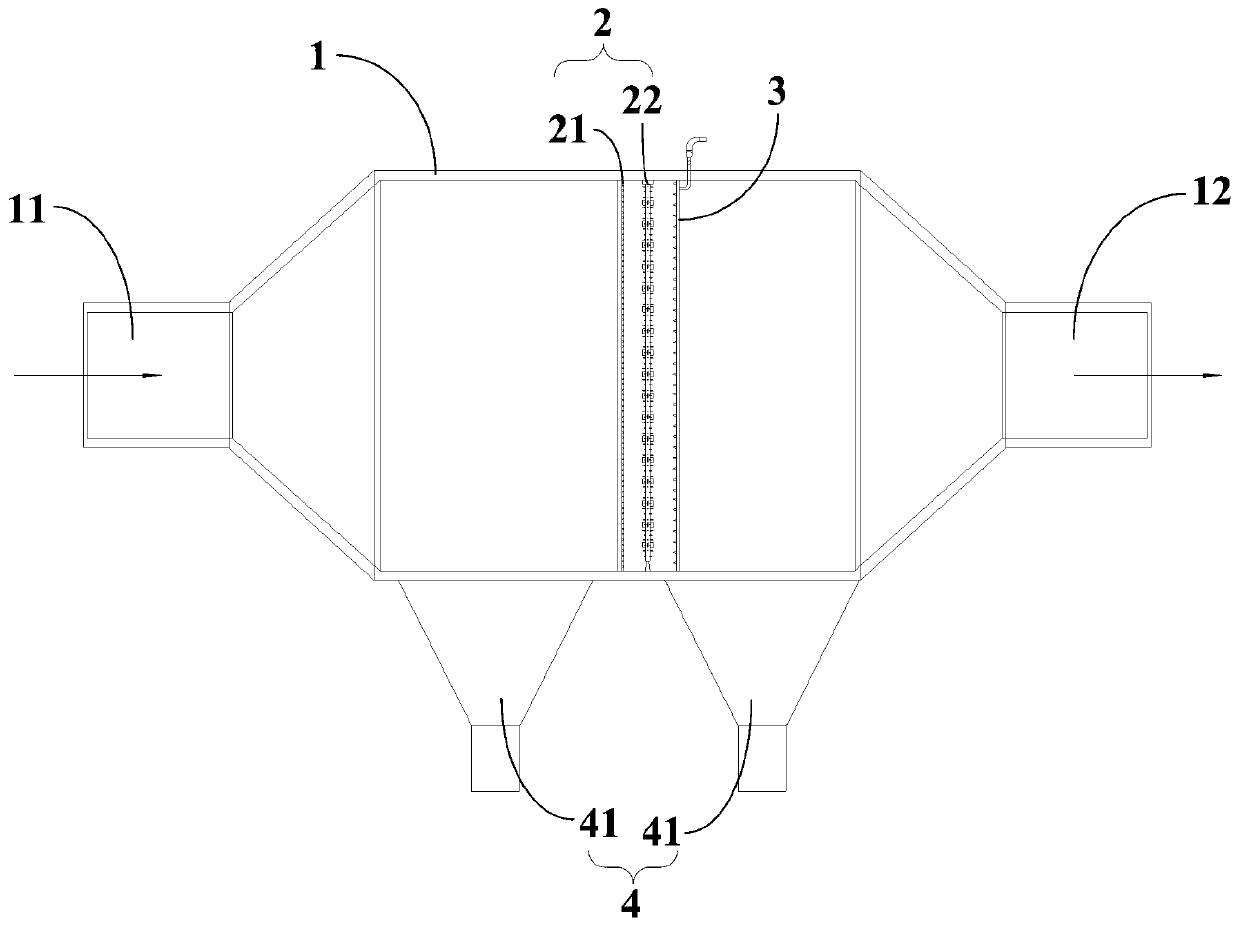

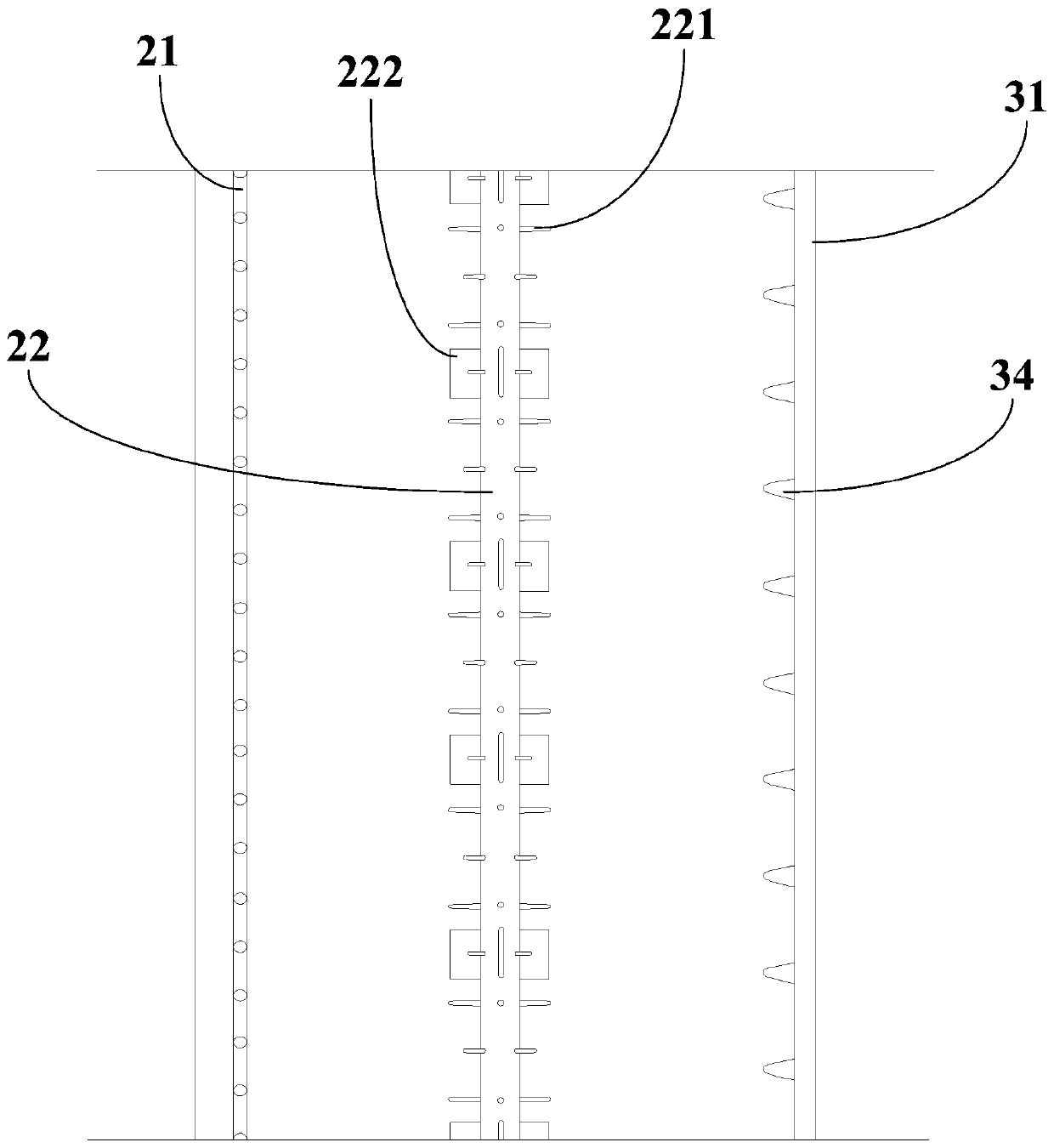

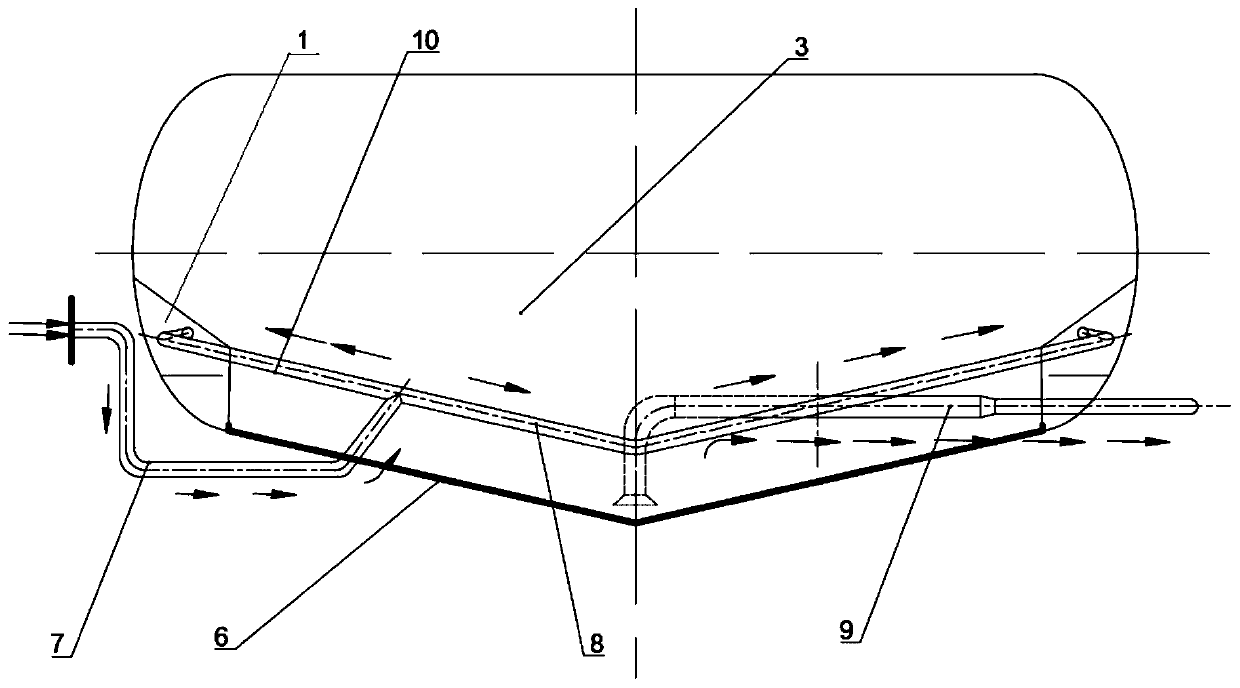

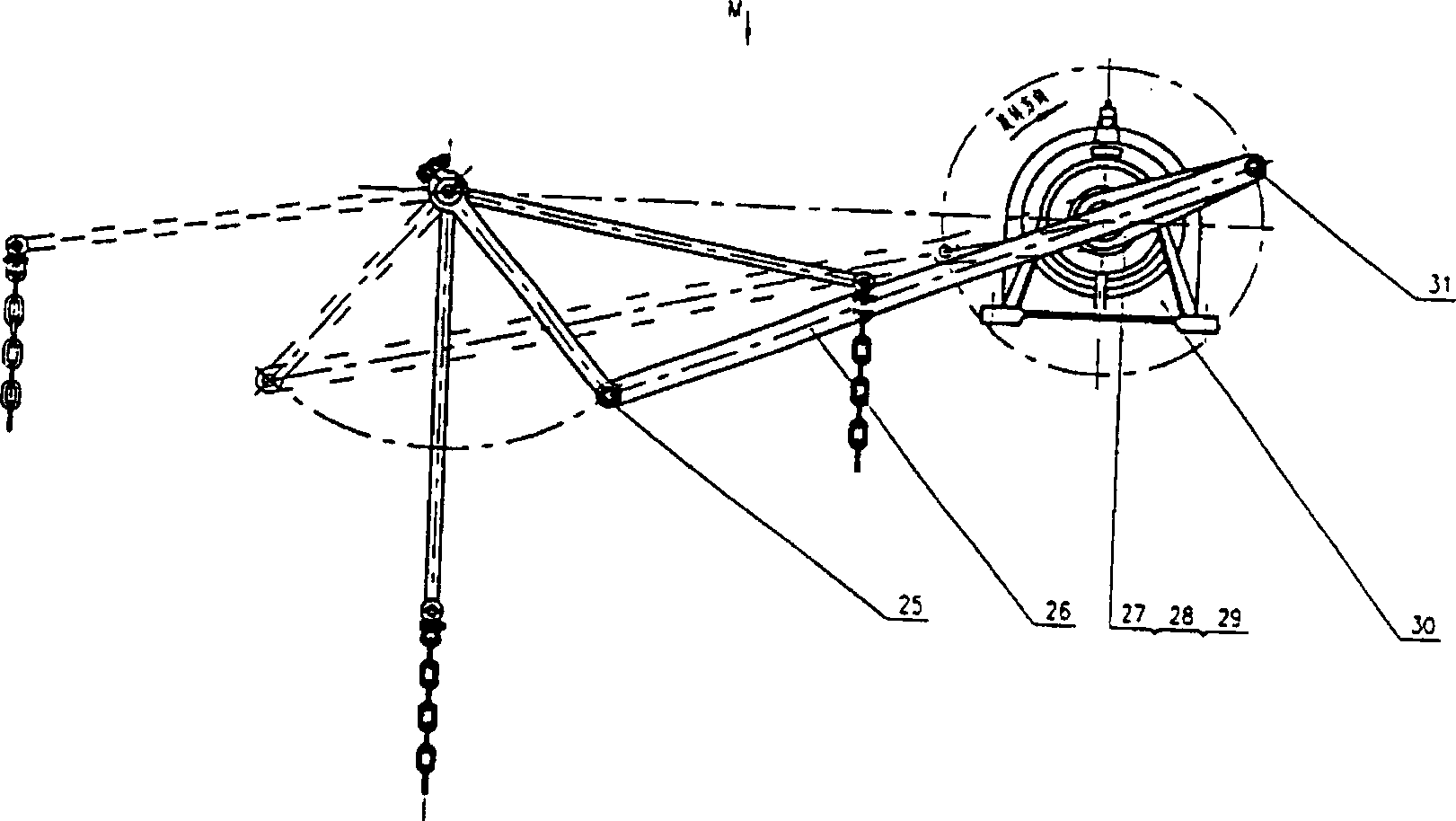

Integral rotational radiation preheating mixing energy utilization device with flue gas chilling

ActiveCN103013577AReduce slaggingGuaranteed safe operationEnergy inputCombined combustion mitigationSlagEnergy recovery

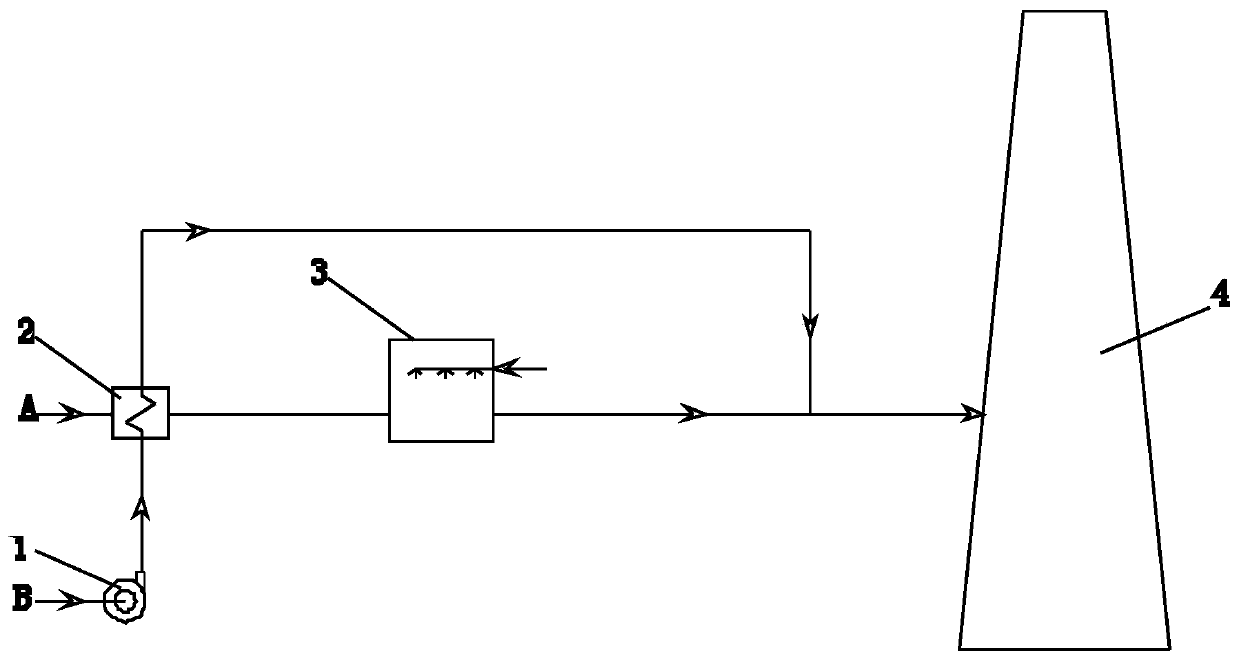

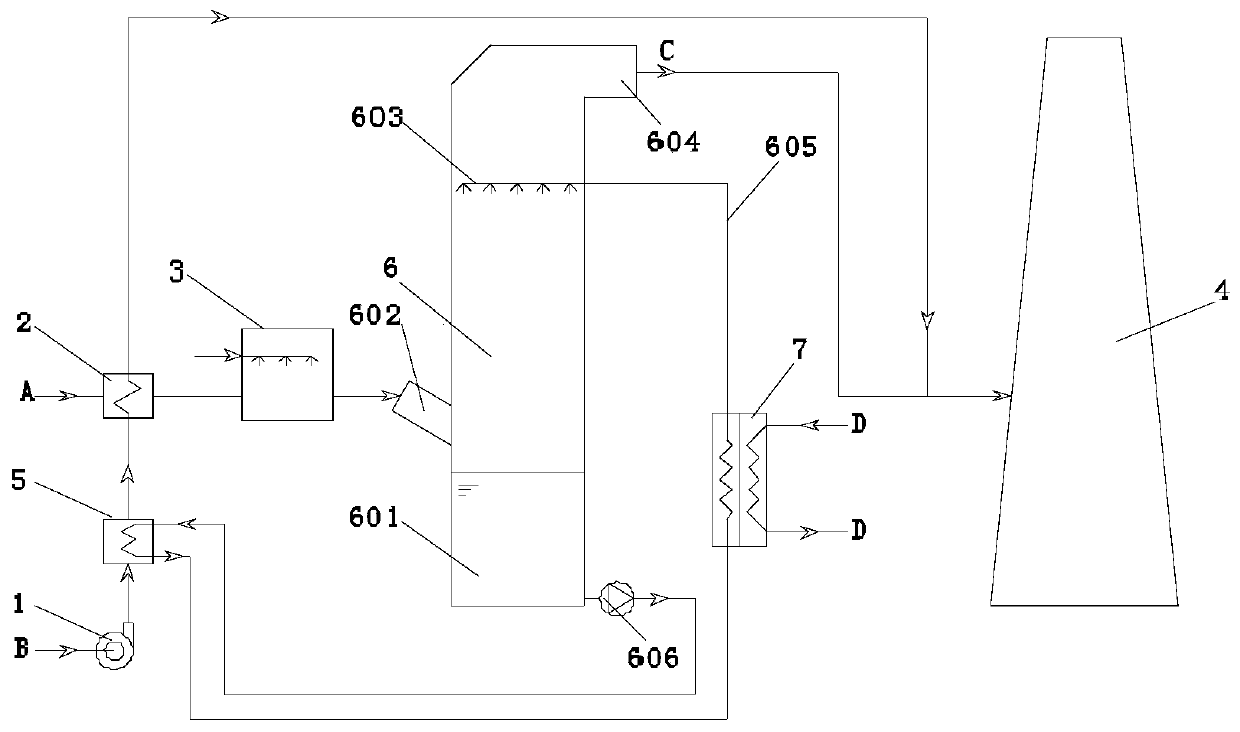

The invention relates to an integral rotational radiation preheating mixing energy utilization device with flue gas chilling. The device comprises a gasification furnace body and a heat recovery unit, which are connected with each other through a flange; the heat recovery unit comprises a pressurized shell, a syngas inlet, a radiation heat exchange component, a flue gas chilling component, a convection heat transfer component, an attemperator component, a slag tank and a syngas outlet; the gasification furnace body is communicated with the heat recovery unit through the syngas inlet; syngas is subjected to radiation heat exchange and then chilling for temperature reduction, and then liquid slag falls into the slag tank for discharge; and the syngas reversely flows up, and is subjected to convection heat transfer for temperature reduction. The device integrates radiation heat exchange, flue gas chilling and convection heat transfer effectively, and can be used for an IGCC (Integrated Gasification Combined Cycle) power generation system, the sensible heat of crude syngas is absorbed to produce high-pressure steam or medium-pressure steam to generate power, the entire energy utilization rate is increased greatly, the energy recycling rate is high, the overall dimension of a waste-heat recovery boiler is reduced effectively, the manufacturing, transporting and installing are more convenient, and the problem of dust stratification on convection heat transfer surface can be eliminated.

Owner:DONGFANG ELECTRIC CORP LTD

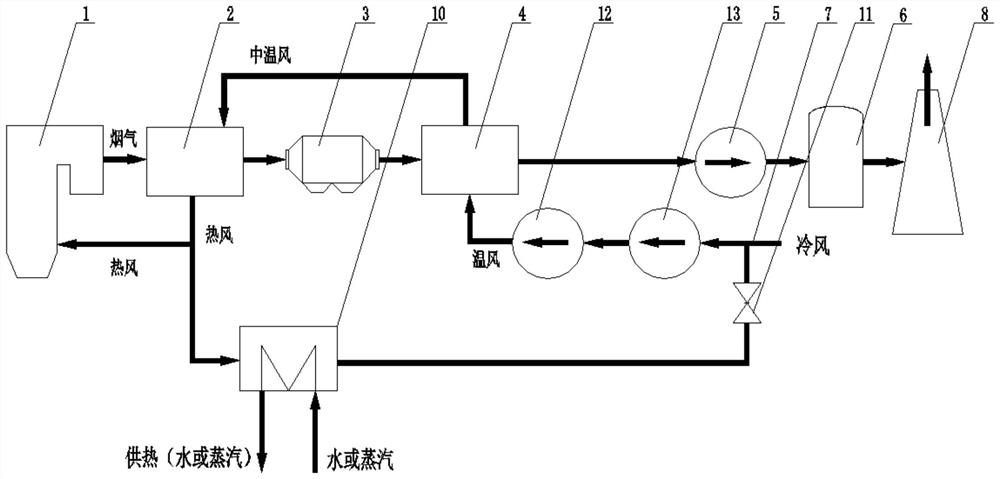

Furnace kiln wet flue gas white-elimination system

PendingCN110180335AReduce the temperatureImprove waste heat recovery efficiencyGas treatmentRecuperative heat exchangersSocial benefitsProcess systems

The invention discloses a furnace kiln wet flue gas white-elimination system, and relates to a white-elimination process of a wet flue gas after spray cooling of furnace kiln flue gas. The system comprises a gas-gas heat exchanger, a flue gas spray cooling apparatus and a fan. A flue gas and air are subjected to heat exchange, the flue gas after cooling enters the flue gas spray cooling apparatus,the wet flue gas after cooling is mixed with hot air to obtain a mixture, the mixture is heated and dehumidified, and then discharging is carried out through a chimney, and thus the white-eliminationrequirement is realized. The process system is simple, emission of air pollution and secondary pollutants is reduced while the consumption of a spray cooling liquid is reduced during a flue gas cooling process, and at the same time, the demand of flue gas white elimination is solved, so that the system has multiple purposes. Moreover, the implementation cost is low, and economic and social benefits are remarkable.

Owner:TIANJIN HUASAIER HEAT TRANSFER EQUIP

Conical guide smokeless vertical steam boiler

InactiveCN101074768AReasonable structureSolve the problem of black smokeSolid fuel combustionSteam boilersCombustion chamberEngineering

This invention relates to a diversion cone smokeless vertical steam boiler, a thermal equipment, including shell, curved pipes and combustion devices, on the top of the combustion chamber has narrow high temperature gas export, above the high temperature gas export is the secondary combustion chamber, the cross section of the secondary combustion chamber is circular, in the corresponding of the high temperature gas export has diversion cone in the secondary combustion chamber, diversion cone is formed by the vertical, circular and radial distribution of the tilt set high-temperature gas plate and the top of the roof plate, secondary combustion chamber has secondary combustion tuyere, secondary combustion tuyere correspond circular cross section of the secondary combustion chamber tangent direction, and with the high temperature smoke plate of airflow direction consistent , on the top of secondary combustion chamber has high temperature gas export, high temperature gas export connect hot gas chamber. A rational structure, solve the problem of coal-smoke emission, carry out smokeless combustion gas emission, high thermal efficiency, conservation of coal resources and the environment.

Owner:王树洲

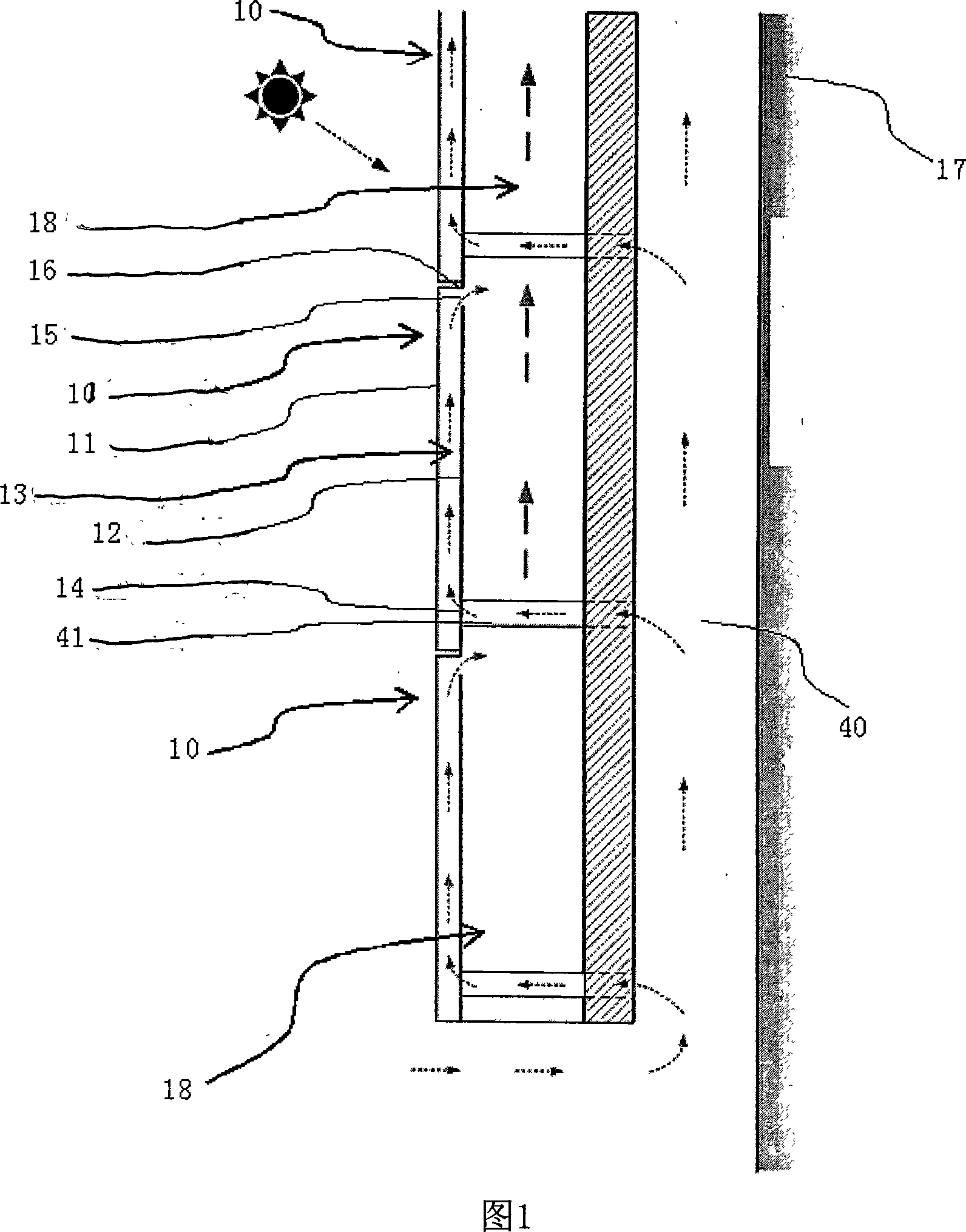

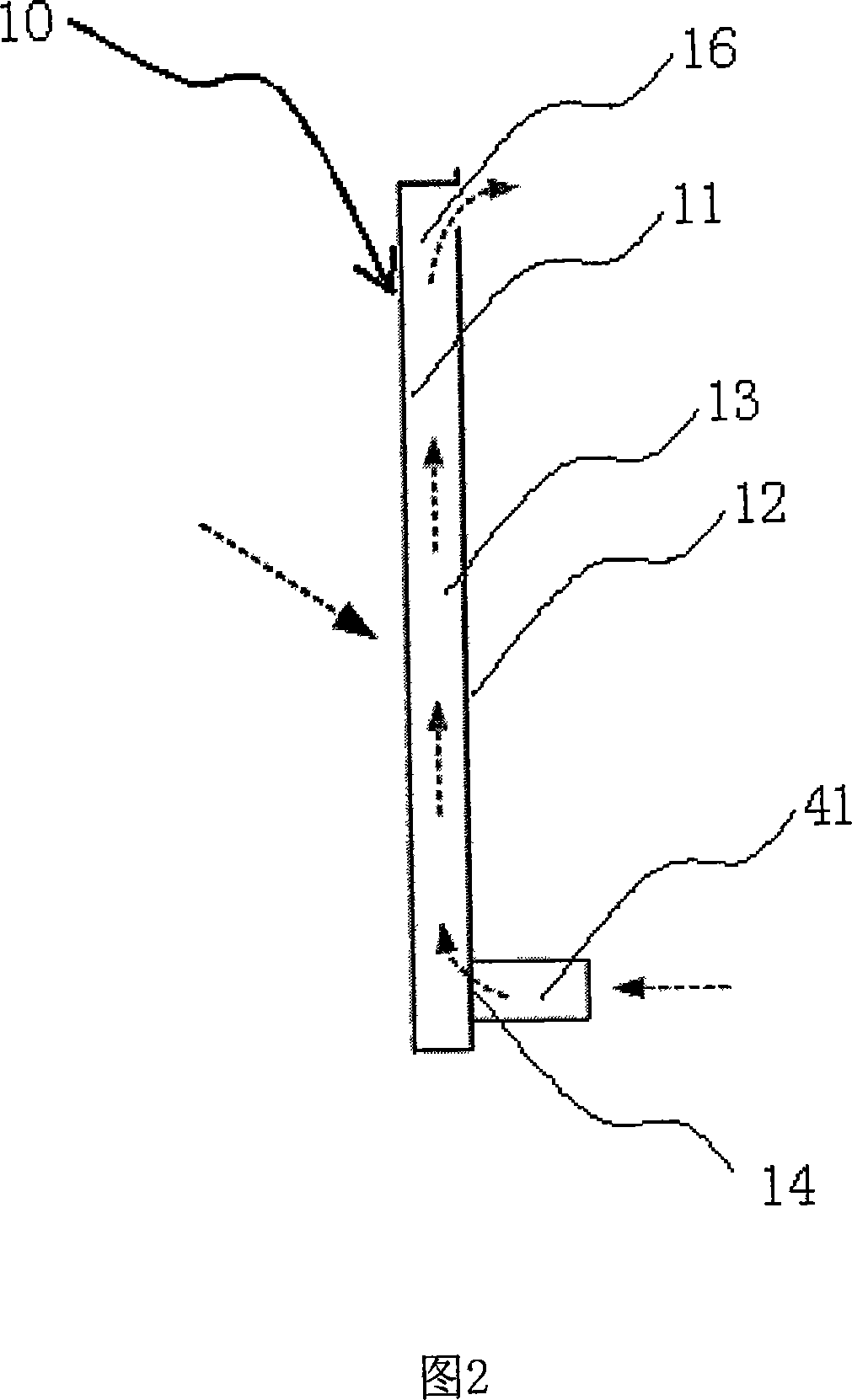

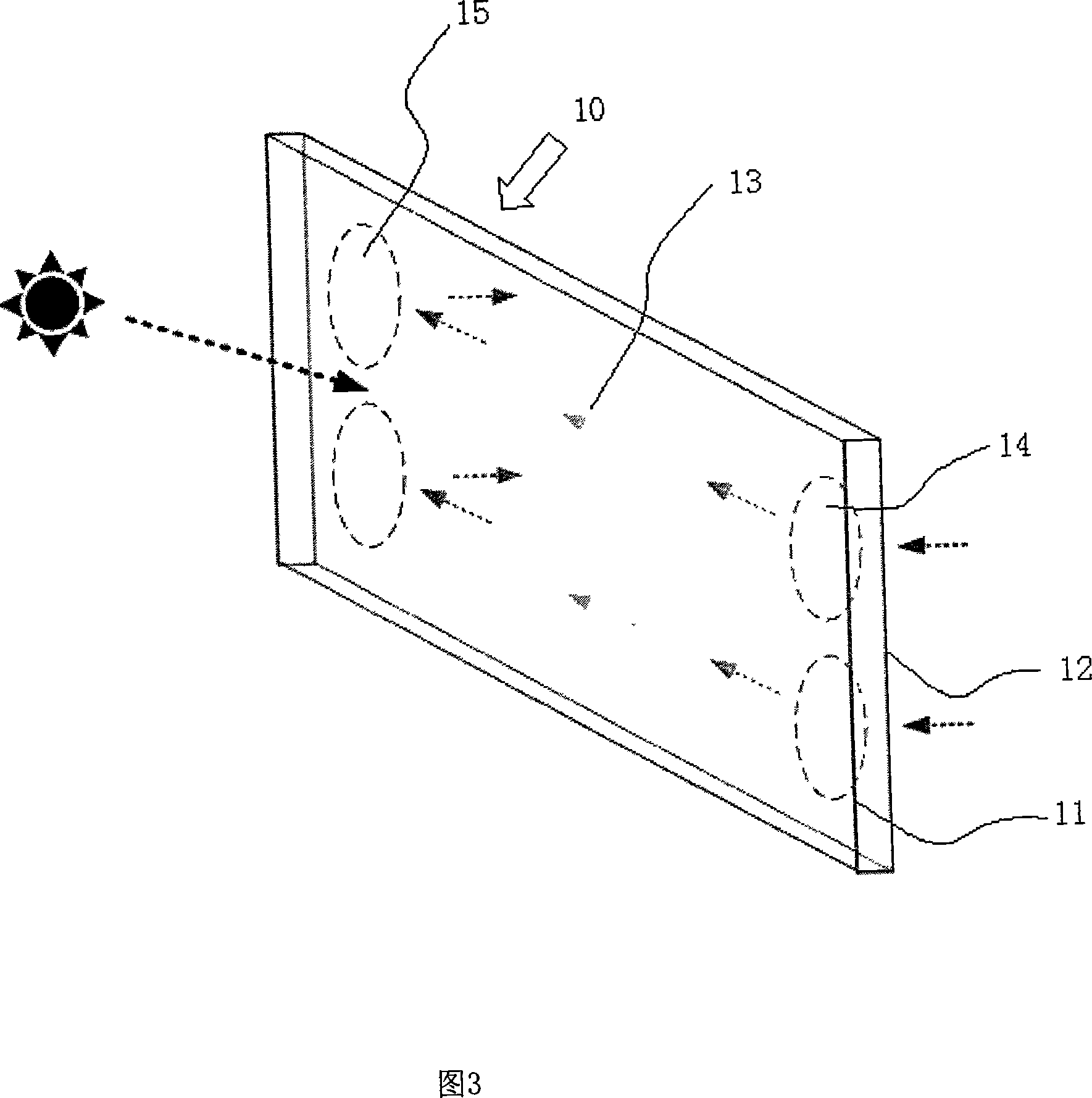

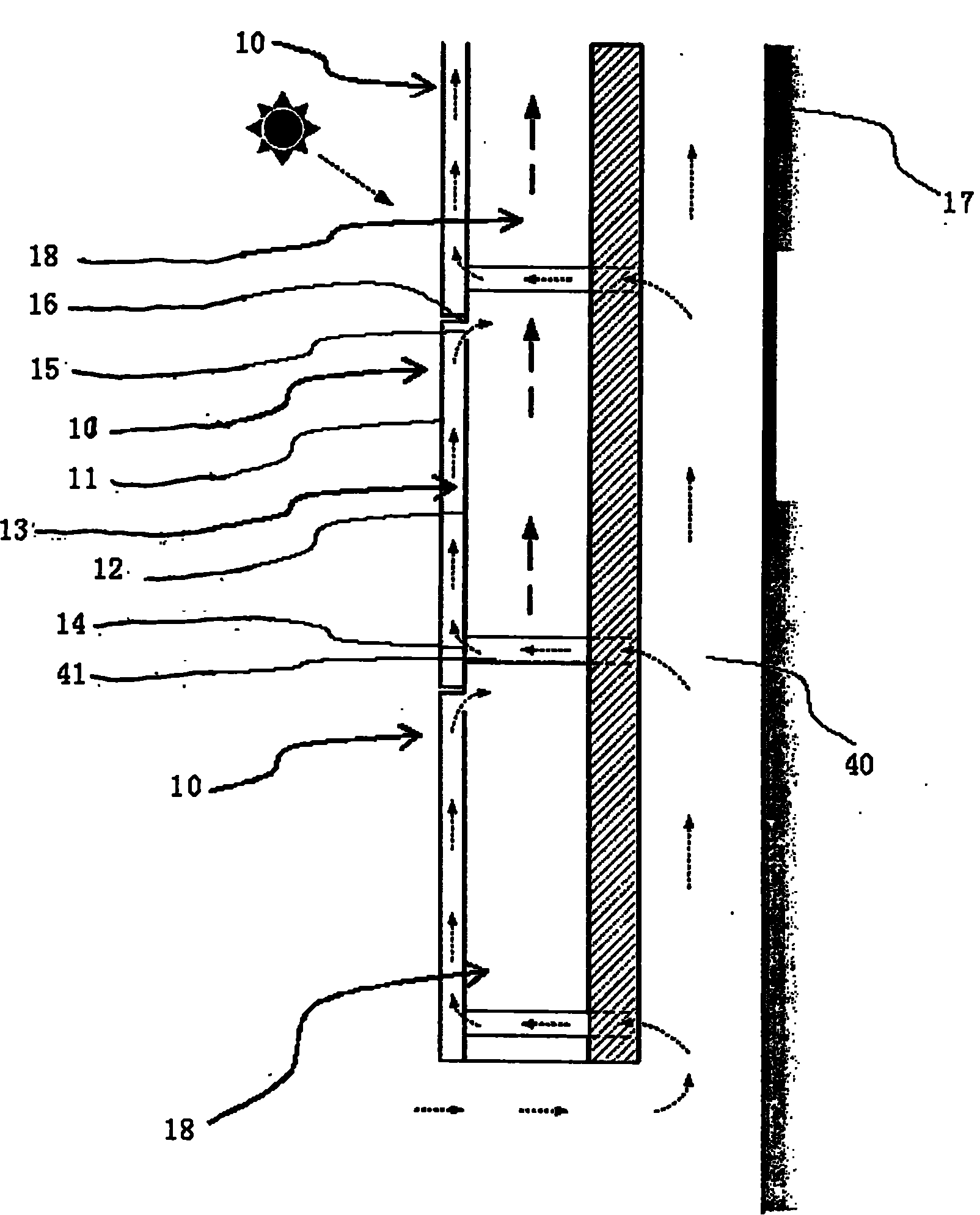

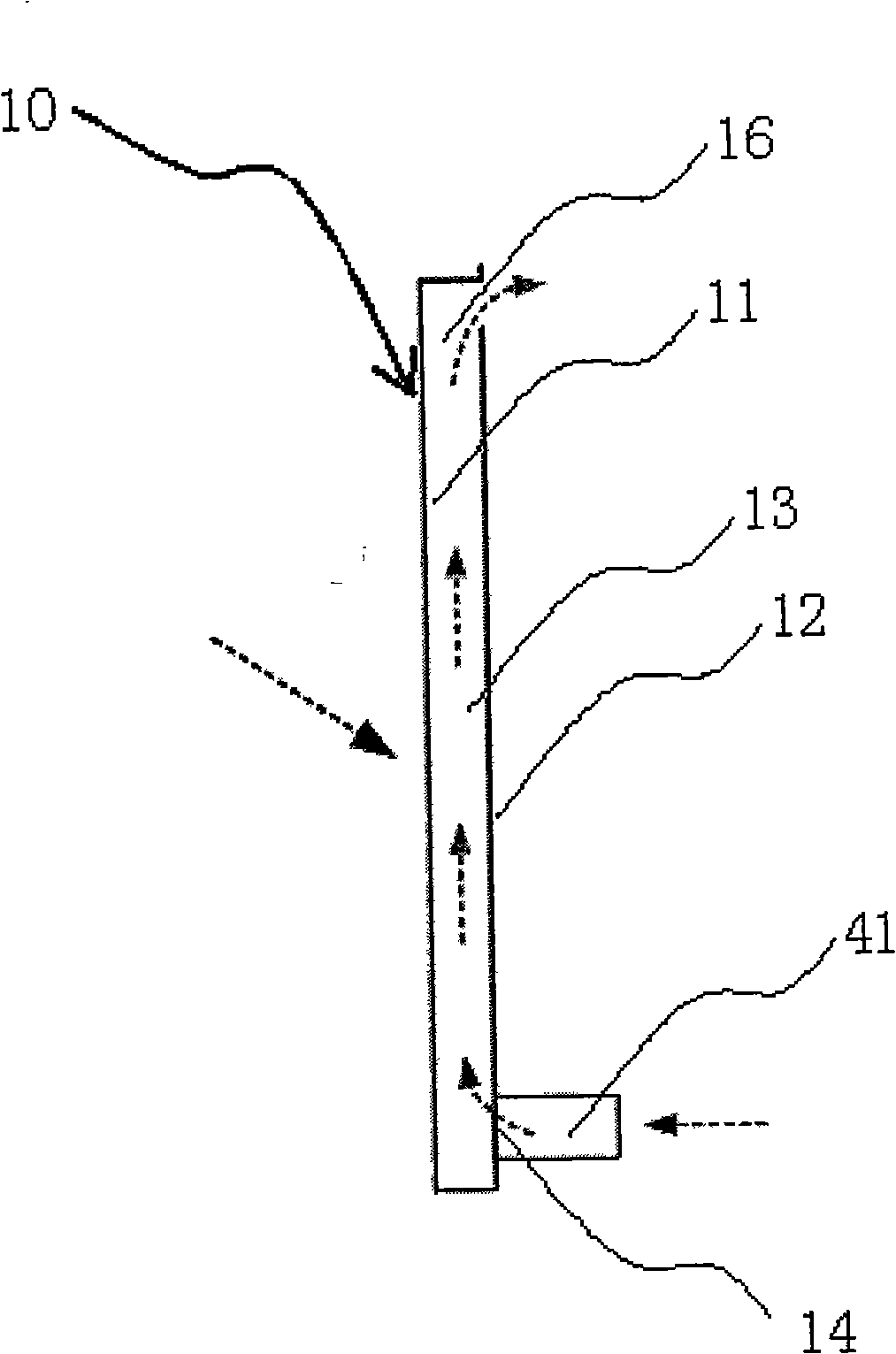

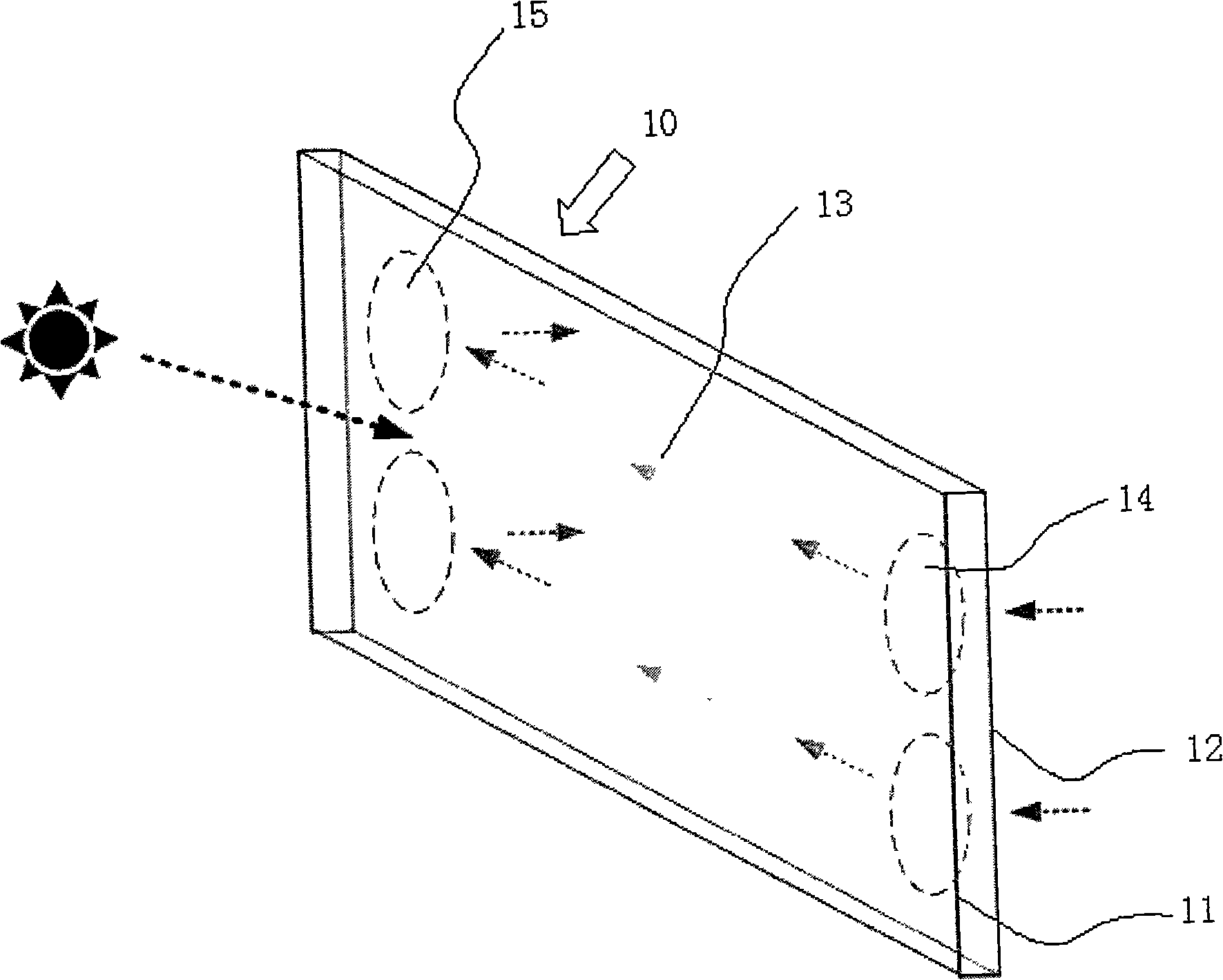

Air type solar energy heat-collecting ventilation system

InactiveCN101059279ASolve the problem of suction blockageReduce the influence of wind etc.Solar heat devicesSolar thermal energy generationCold seasonGreenhouse

The present invention discloses an air-type solar heat-collecting ventilation system. An extremely thin venting layer is formed between the solar radiation lighted side plate and the shaded side plate, and the thickness of the extremely thin venting layer is less than 15 mm, the length is ranged from several centre meters to several meters and the section inner flow rate is less than 5m / s, one end of the venting layer is air inlet and another end is air blowing mouth, the plate bodies of the end mouth surface formed by facing solar lighted side and shaded side are fully arranged and installed on the solar radiation lighted surface as air-type heat-collecting materials, the air blowing out mouth faces the collecting venting layer formed by the solar radiation lighted side and shaded side of plate bodies, at the same time the continuous space of plate bodies used for venting and connected with said air inlet is formed. The invention can provide adequate indoor ventilation to prevent chemical pollution, condensation and moldy and insects, on the other hand, the use of solar energy to release the cold venting air temperature in cold seasons, it plays an active role of preventing global greenhouse phenomenon and the problem of inadequate energy.

Owner:EOM

Vertical smokeless steam boiler of Venturi tube effect

InactiveCN101074767AGuaranteed heat transfer efficiencySimple structureSolid fuel combustionSteam boilersCoalCombustion chamber

This invention relates to a venturi smoke-free vertical steam boiler, a thermal equipment, including shell, curved pipes and combustion devices, the outside bending pipes is placed in the box, between the introvert pipes form a hot gas cavity, beneath the cavity is the combustion chamber, beneath the combustion chamber is the grate, beneath the grate is the ash chamber, on the combustion chamber has stove door to coal, and on the ash chamber has a gray ash doors, ash chamber is equipped with a tuyere, on the top of combustion chamber has narrow high temperature gas export, above the export has a secondary combustion chamber, the cross section of the secondary combustion chamber is circular, the secondary combustion chamber has a secondary tuyere, on the top of the secondary combustion chamber has high temperature gas export, the high temperature gas export connect hot gas chamber. A rational structure, solve the problem of coal-smoke emission, carry out smokeless emission, high thermal efficiency, conservation of coal resources and the environment.

Owner:王树洲

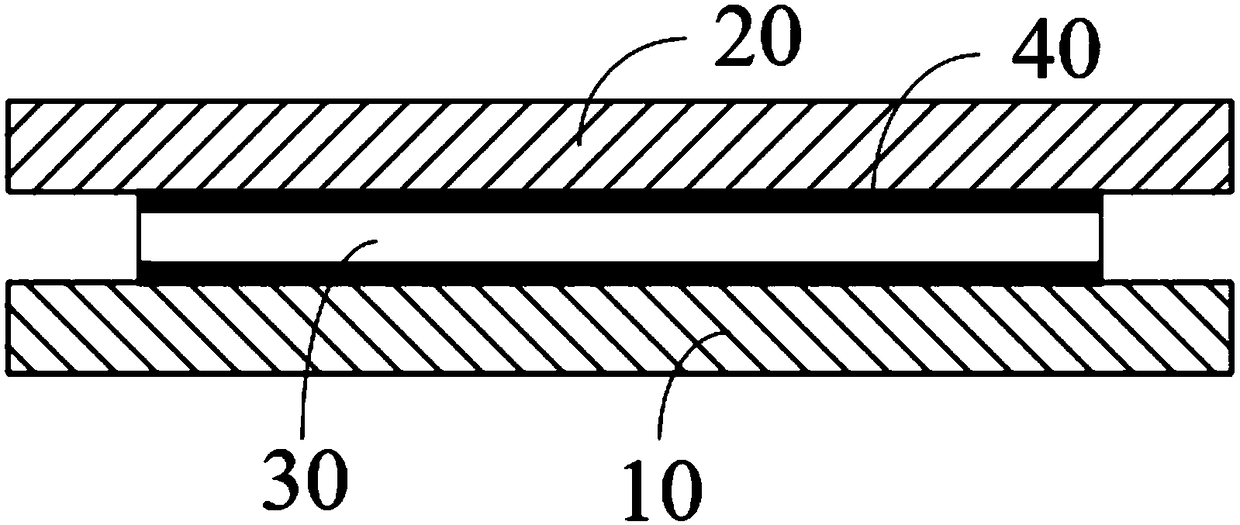

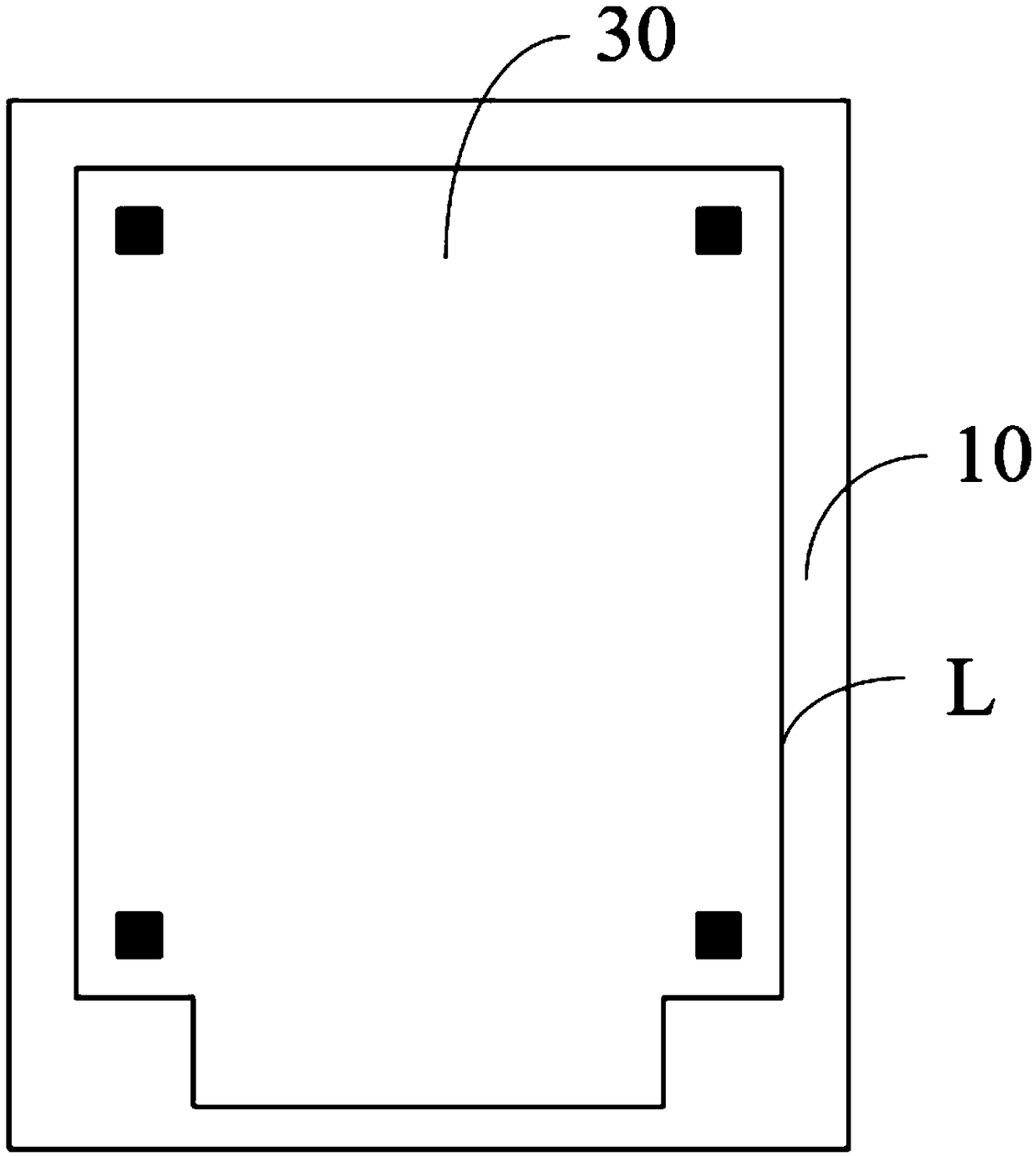

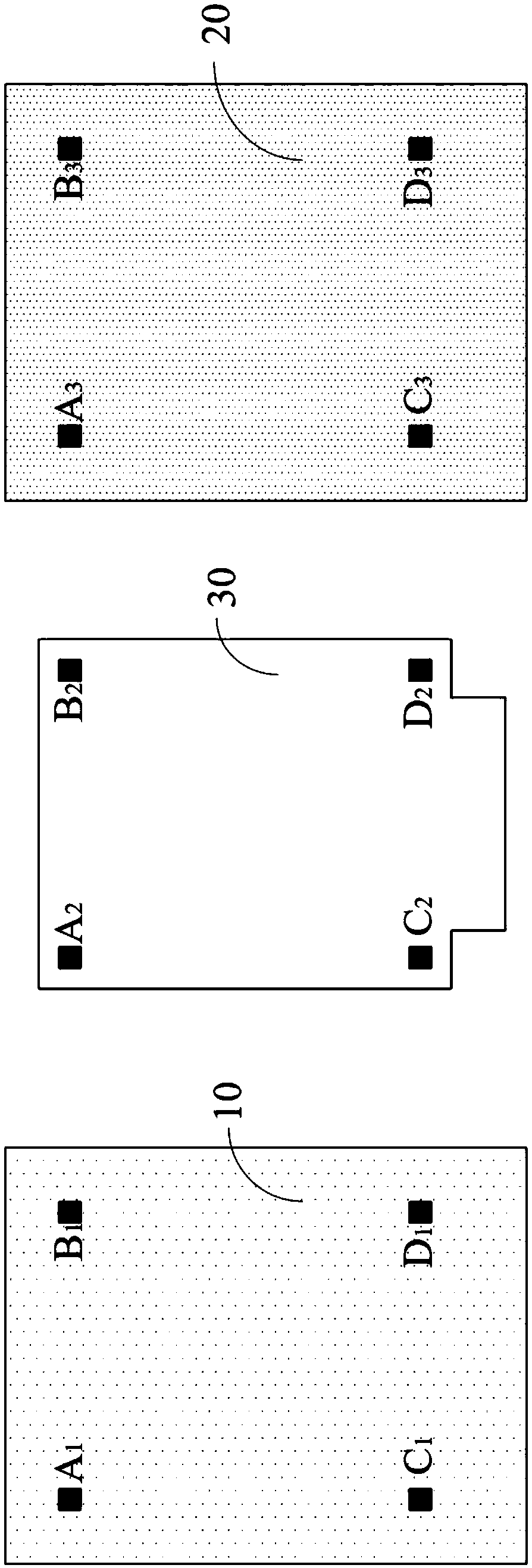

To-be-cute display module and manufacturing method thereof

ActiveCN109031745AEliminate dust accumulationShorten processing timeSolid-state devicesNon-linear opticsMachining processEngineering

The invention provides a to-be-cut display module and a manufacturing method thereof. The to-be-cut display module comprises a support layer, a display panel located on the support layer, and a backboard layer located between the support layer and the display panel; and a shape of a positive projection of the backboard layer on the display panel is same as the shape of a target display module. Thebackboard layer is arranged as the shape same as that of the target display module, so that a cutting machine processes the to-be-cut display module by taking an outer circle of the backboard layer as a cutting path; the ash deposit on the backboard layer is eliminated, and the processing time is reduced.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

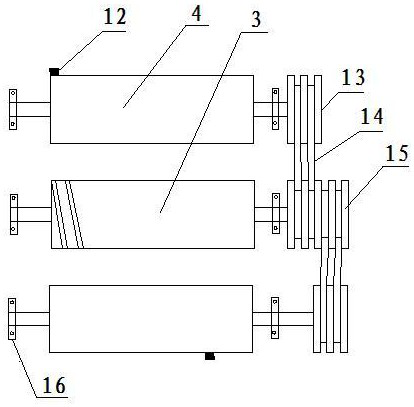

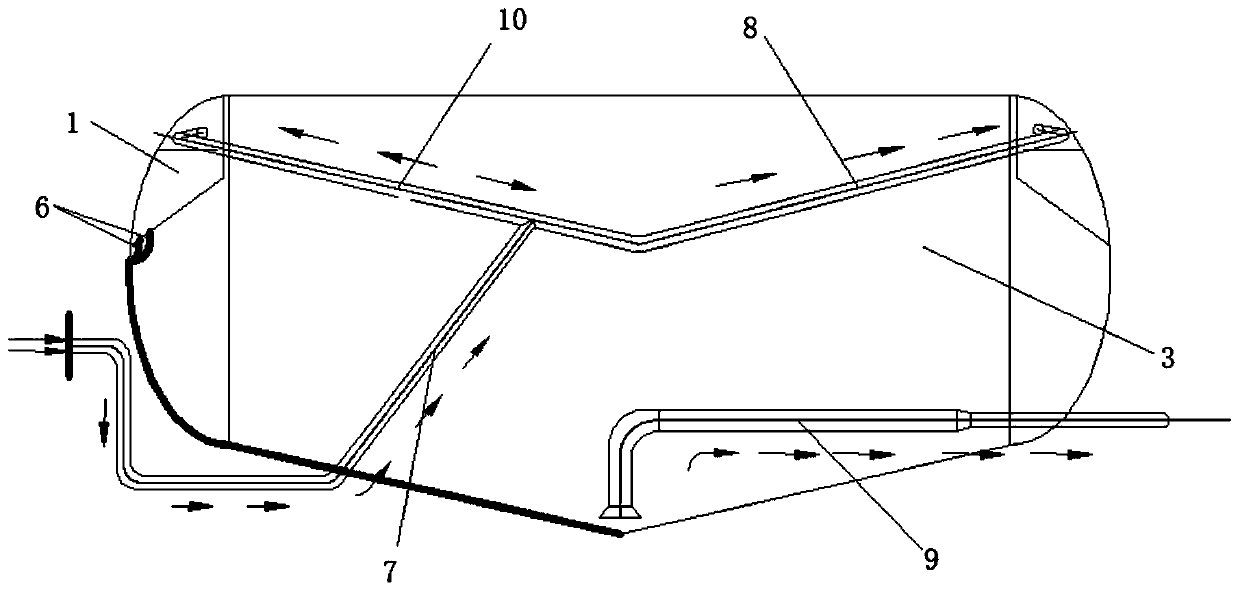

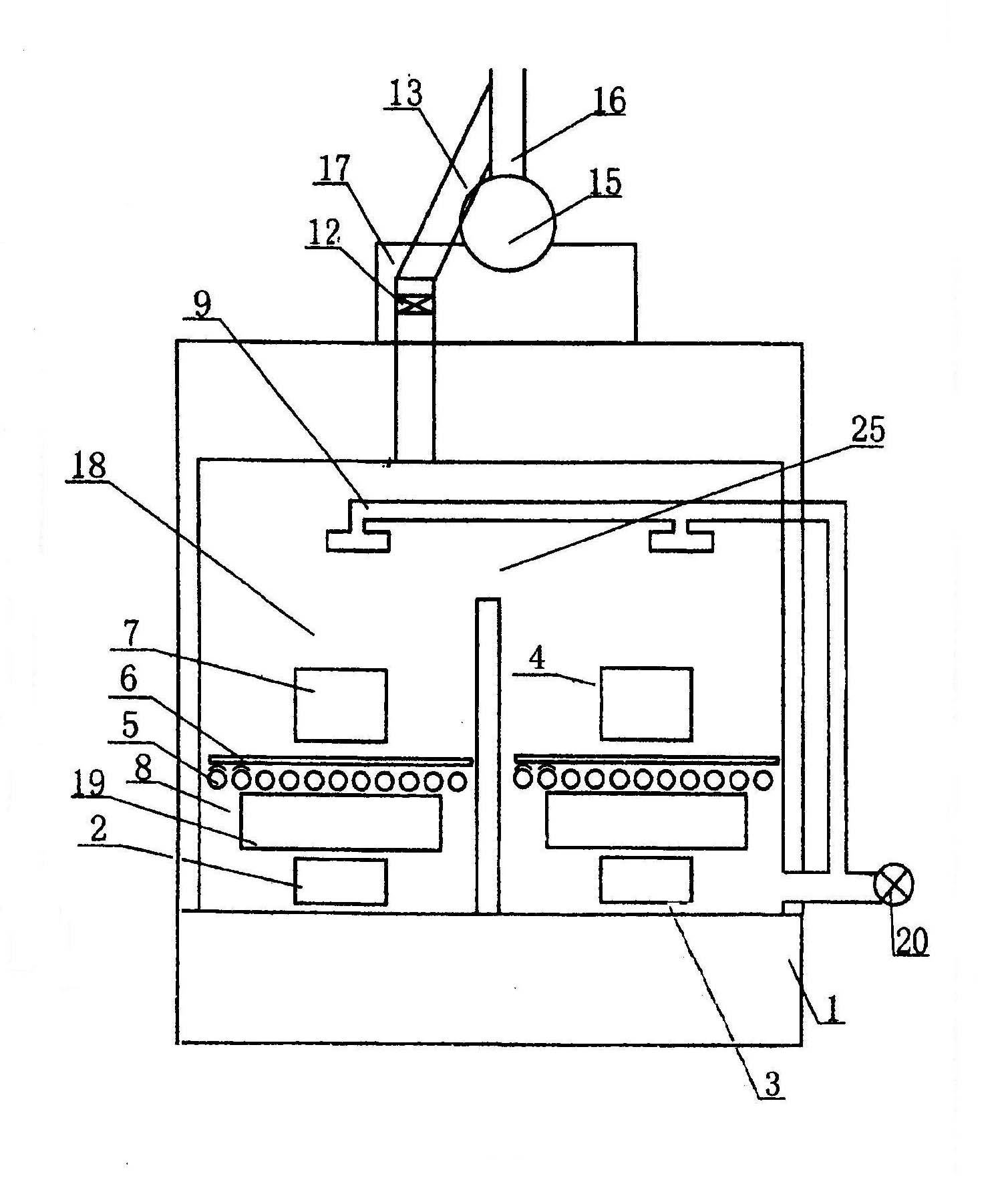

Integrated bunch type radiant boiler and preheating boiler mixed energy utilization device

InactiveCN103013578AImprove recycling ratesImprove energy efficiencyEnergy inputGranular/pulverulent flues gasificationHigh energySlag

The invention relates to an integrated bunch type radiant boiler and preheating boiler mixed energy utilization device. The energy utilization device comprises a gasifier body and a heat recovery device, wherein the gasifier body is arranged above the heat recovery device; the heat recovery device comprises a pressure shell, a synthesis gas inlet, a radiation heat exchange component, a desuperheater component, a slag basin, a heat convection component, and a synthesis gas outlet; the synthesis gas inlet is formed in the top of the pressure shell; the synthesis gas outlet is formed in the upper end of the side wall of the pressure shell; the radiation heat exchange component is longitudinally fixed in the middle of the pressure shell; the heat convection component is arranged between the radiant heat exchange component and the pressure shell; the desuperheater component is fixedly arranged below the heat convection component; the slag basin is positioned at the lower part inside the pressure shell; and a lower slag hole of the gasifier body is connected with the top of the heat recovery device through a flange. The energy utilization device can effectively absorb sensible head in the coarse synthesis gas to generate high-pressure steam or intermediate-pressure steam for power generation or preheating other working media, so as to greatly improve the whole source utilization ratio, and achieve high energy recovery utilization ratio. The whole size of the exhaust boiler can be effectively reduced; and manufacturing, transportation and installation are convenient.

Owner:中国东方电气集团有限公司

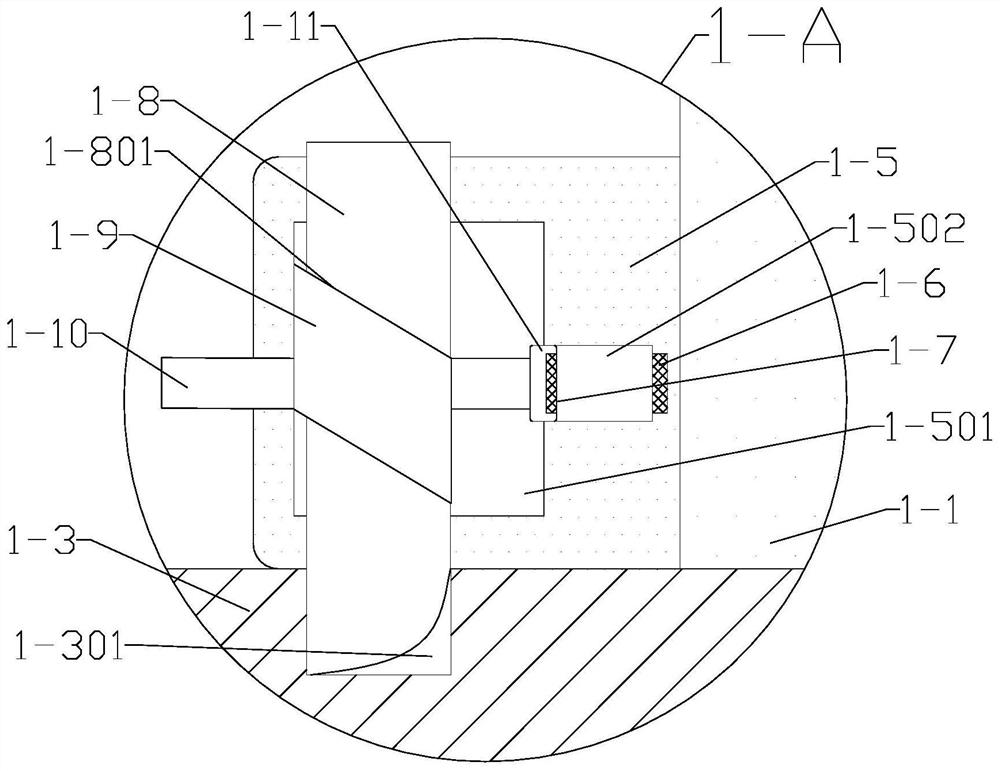

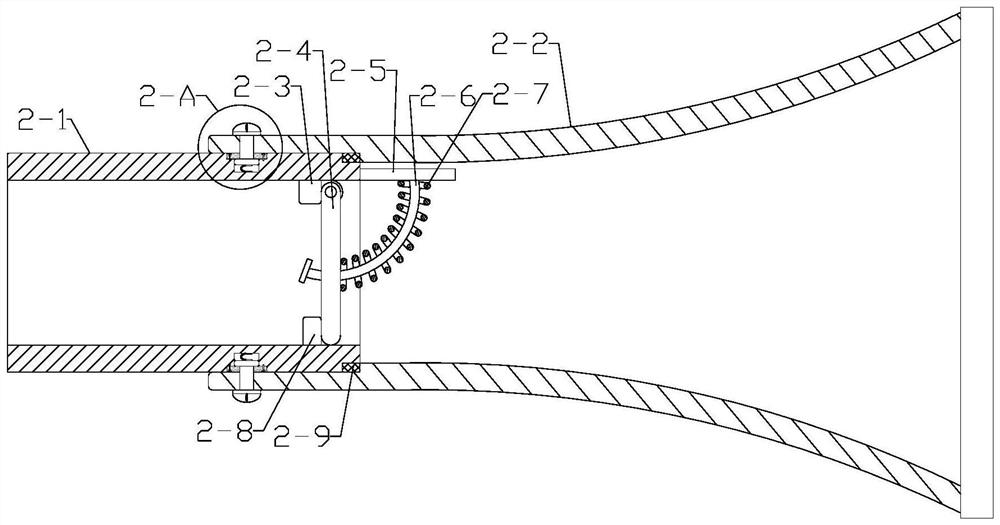

Ash-cleaning mechanical air cooler

The air blast for cooling high-temp. smoke and removing ash in the fields of metallurgical industry and power industry is characterized by that it mainly comprises radiating pipe, wall plate, intermediate partition board, fan ashpit ring beam, ashpit component and support platform, and the header is connected with ash-cleaning mechanism, and mounted on the radiating pipe, and said radiating pipe is horizontally mounted on the ashpit ring beam. Said invention is simple in structure, small in volume, light in weight, low in cost, high in cooling efficiency, and can completely remove ash and prolong its service life.

Owner:WUXI XUELANG ENVIRONMENTAL TECH CO LTD

Integral rotational radiation preheating mixing energy utilization device with flue gas chilling

ActiveCN103013577BIncrease profitEffective sensible heatEnergy inputCombined combustion mitigationHigh pressureConvection heat

The invention relates to an integral rotational radiation preheating mixing energy utilization device with flue gas chilling. The device comprises a gasification furnace body and a heat recovery unit, which are connected with each other through a flange; the heat recovery unit comprises a pressurized shell, a syngas inlet, a radiation heat exchange component, a flue gas chilling component, a convection heat transfer component, an attemperator component, a slag tank and a syngas outlet; the gasification furnace body is communicated with the heat recovery unit through the syngas inlet; syngas is subjected to radiation heat exchange and then chilling for temperature reduction, and then liquid slag falls into the slag tank for discharge; and the syngas reversely flows up, and is subjected to convection heat transfer for temperature reduction. The device integrates radiation heat exchange, flue gas chilling and convection heat transfer effectively, and can be used for an IGCC (Integrated Gasification Combined Cycle) power generation system, the sensible heat of crude syngas is absorbed to produce high-pressure steam or medium-pressure steam to generate power, the entire energy utilization rate is increased greatly, the energy recycling rate is high, the overall dimension of a waste-heat recovery boiler is reduced effectively, the manufacturing, transporting and installing are more convenient, and the problem of dust stratification on convection heat transfer surface can be eliminated.

Owner:DONGFANG ELECTRIC CORP LTD

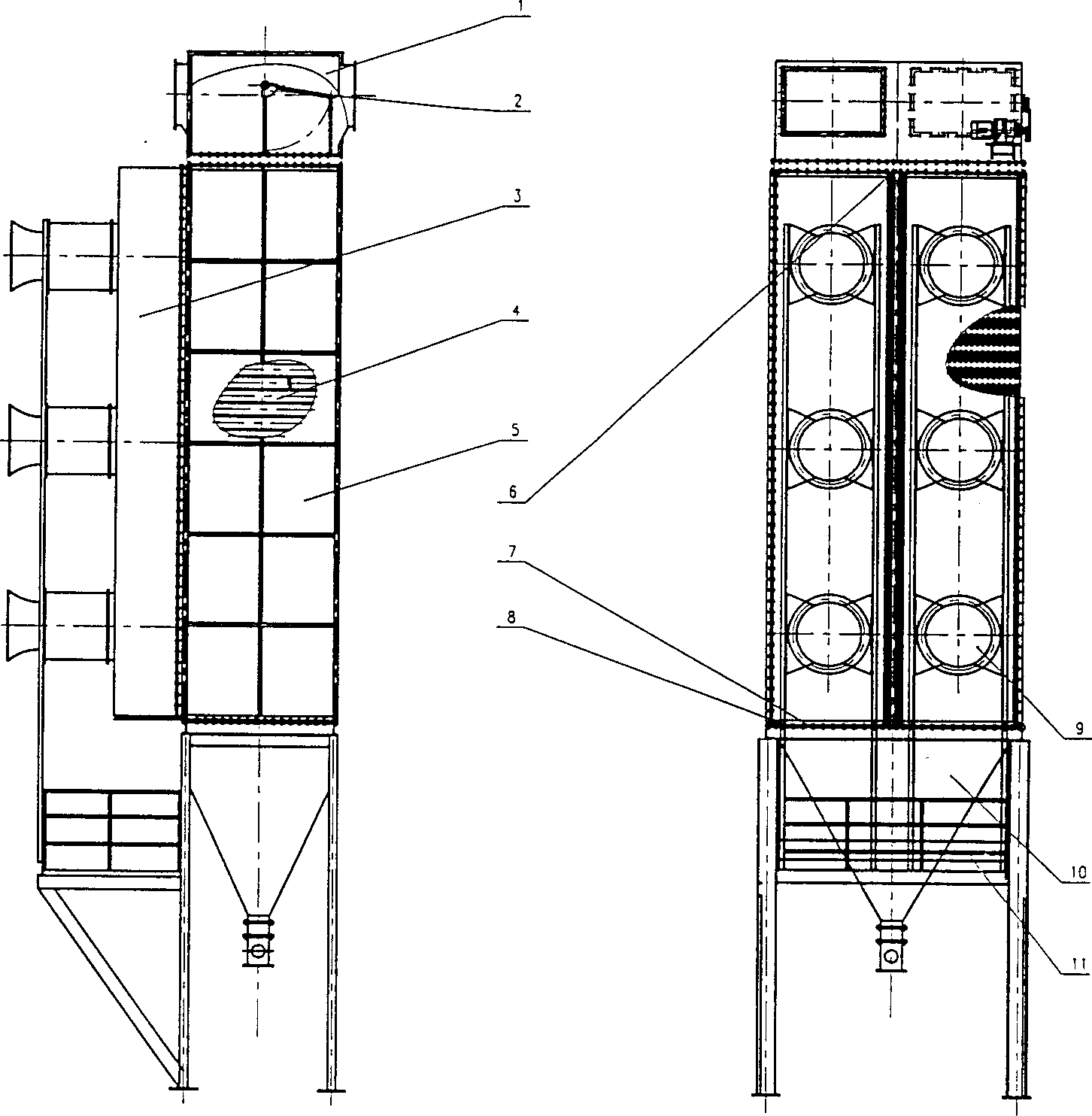

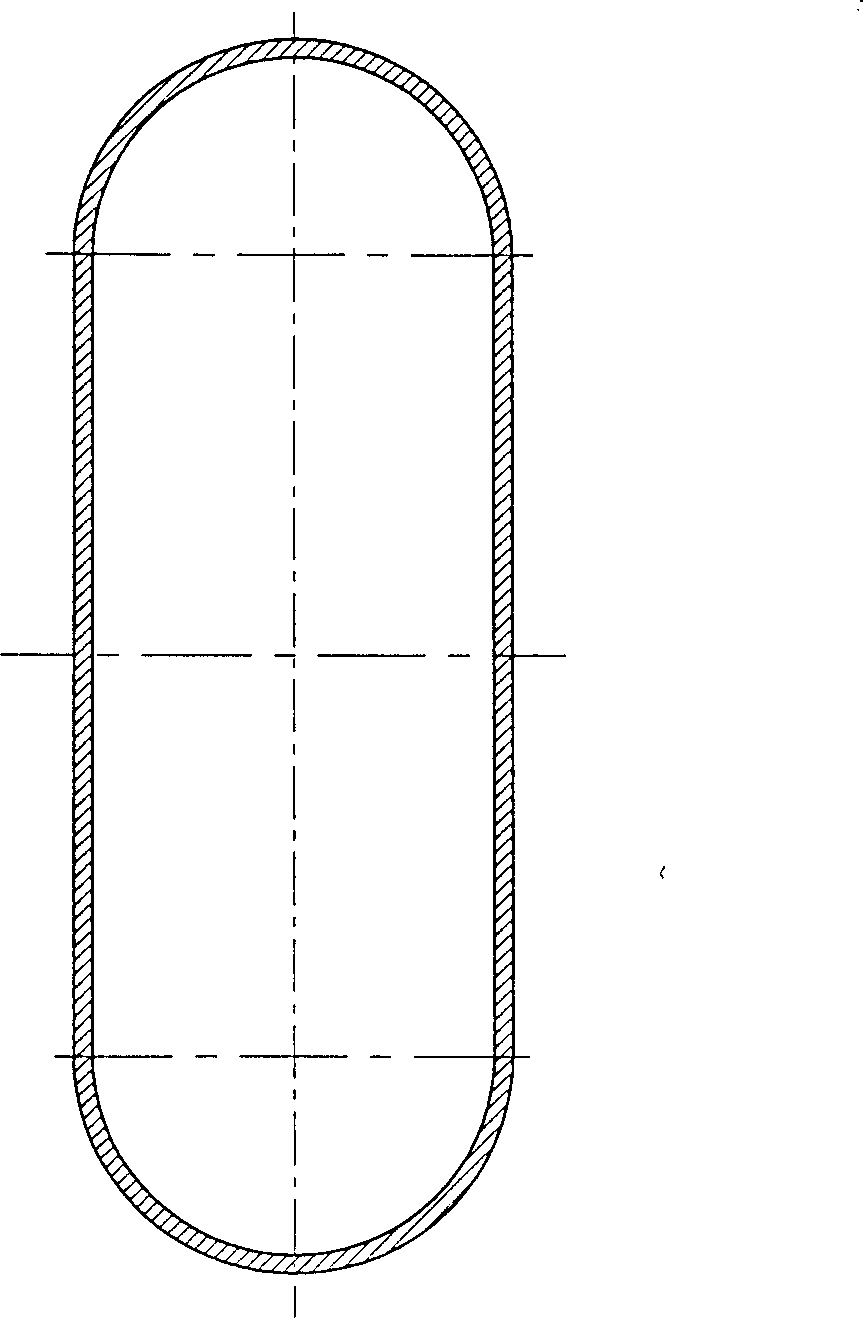

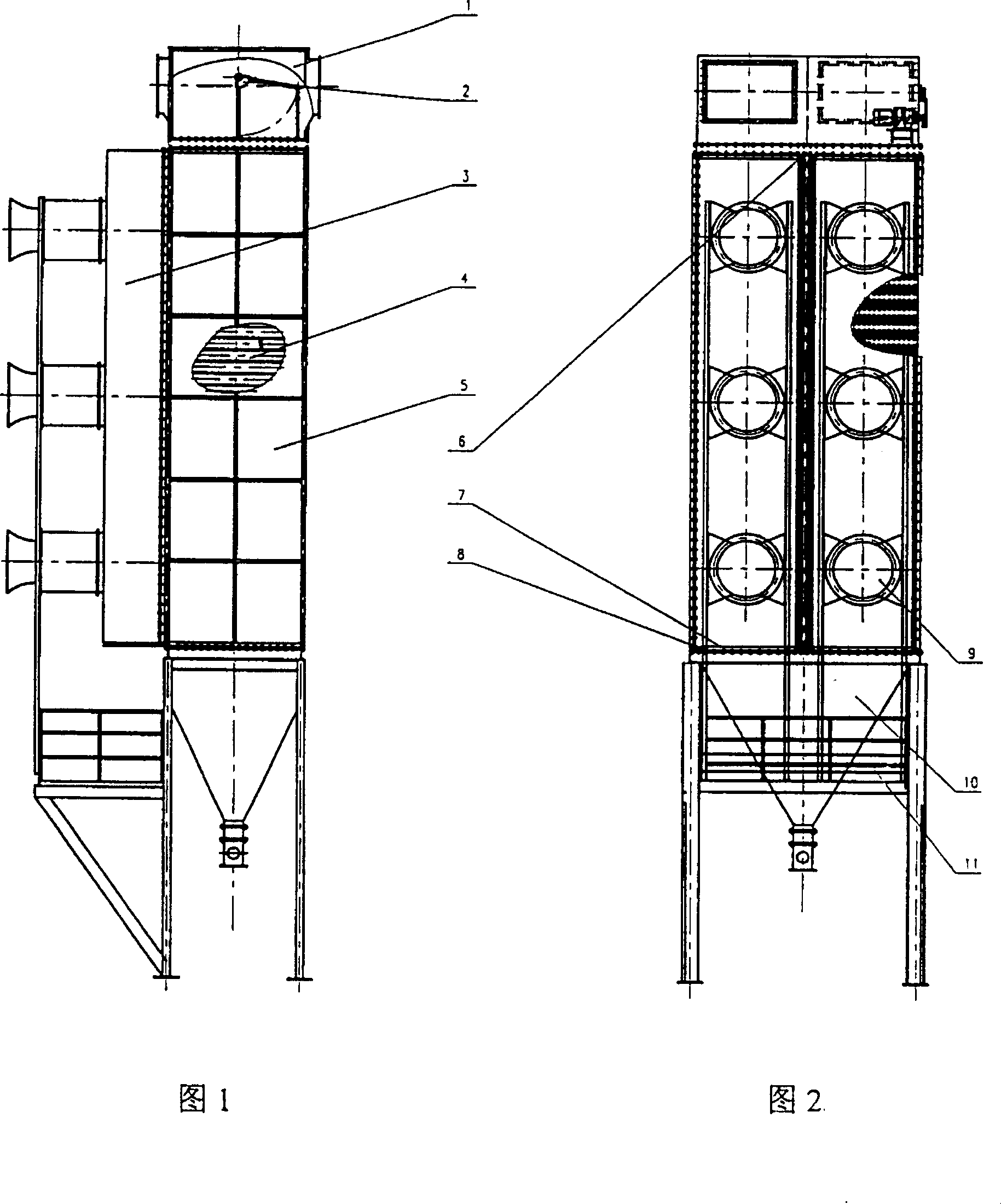

Air-blowing type dust removal device

PendingCN110882847ASuppress secondary dustImprove dust removal efficiencyExternal electric electrostatic seperatorElectrodes cleaningEngineeringAtmospheric sciences

The invention discloses an air-blowing type dust removal device which comprises a dust removal box body, wherein a flue gas inlet and a flue gas outlet are formed at the two ends of the dust removal box body respectively; a dust collection assembly which comprises an anode dust collection part and a cathode discharge part, wherein the anode dust collection part and the cathode discharge part are both fixed in the dust removal box body along a direction perpendicular to an airflow direction, and the anode dust collection part and the cathode discharge part are oppositely arranged at an insulation distance; an air injection assembly which is used for removing the dust on the anode dust collection part and the cathode discharge part, is fixed in the dust removal box body and is parallel to the anode dust collection part and the cathode discharge part; and a dust collection assembly which is arranged at the bottom of the dust removal box body and communicates with the inner cavity of the dust removal box body. The dust removal device is simple in structure, reasonable in design and high in safety, is easy to operate, is low in power consumption and high in dust removal efficiency in the dust removal process, effectively solves the problems that a traditional electric dust removal device is high in power consumption and low in dust removal efficiency, and has the good market application prospect.

Owner:张忠建

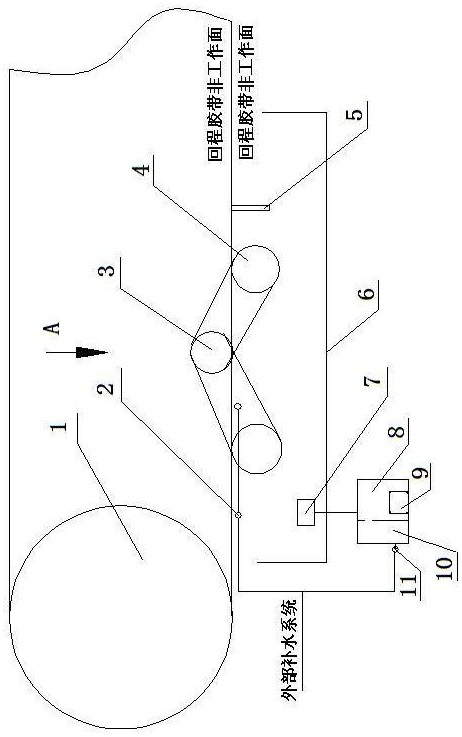

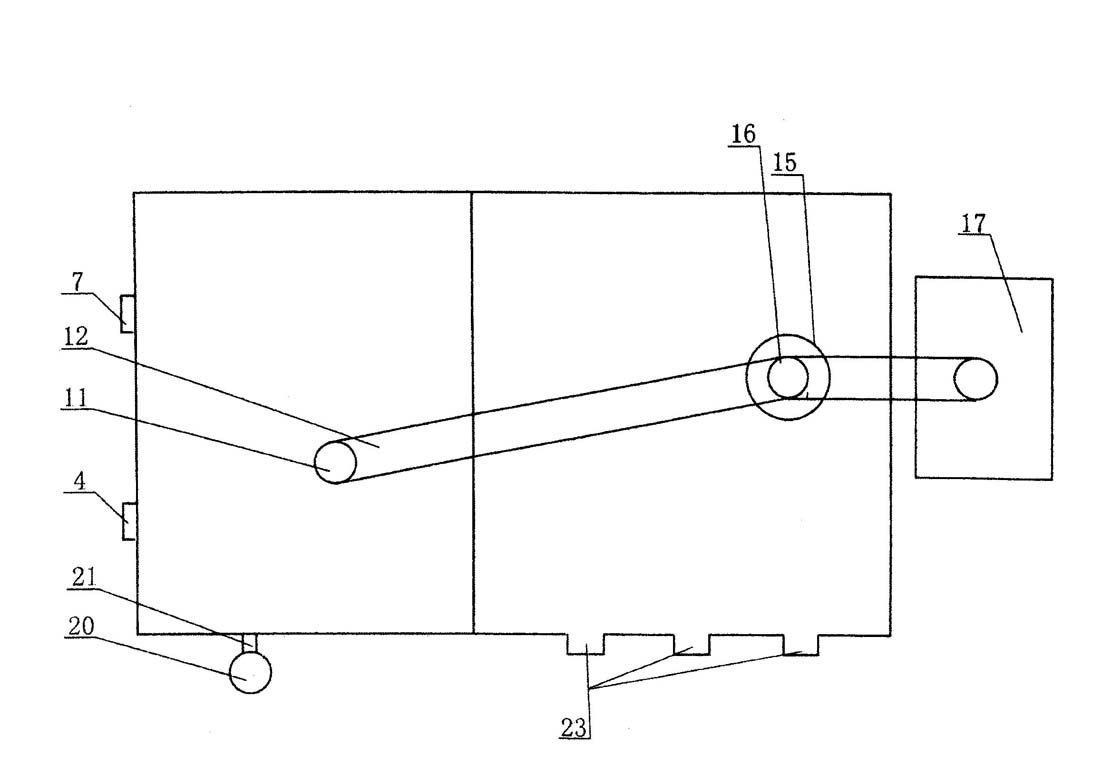

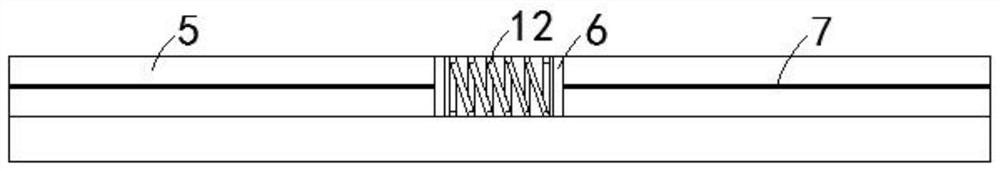

Belt conveyor rubber belt surface dust cleaning device and installation method

PendingCN113428610ARealize the purpose of saving waterEffective dust accumulationSludge treatmentConveyorsAdhesive beltBristle

The invention discloses a belt conveyor rubber belt surface dust cleaning device. A sweeper in the prior art is made of metal materials, damage to the surface of a rubber belt is large, peeling, sliding grooves and unevenness of the surface of the rubber belt are caused, and sweeping of dust on the surface of the rubber belt is not facilitated. The belt conveyor rubber belt surface dust cleaning device comprises a compression roller (3), the compression roller is mounted on a non-working surface of a return rubber belt, a transmission wheel II (15) is fixed at one end of the compression roller, the transmission wheel II is connected with transmission wheels I (13) of two rolling brush sweepers (4) through triangular transmission belts respectively, bristles (12) are mounted on the outer side surfaces of the rolling brush sweepers, a water collecting tank (6) is mounted below the rolling brush sweepers, an overflow port is mounted at the bottom of the water collecting tank, the overflow port is connected with a flow dividing box through a pipeline, the flow dividing box is divided into a water side box body (10) and a mud side box body (8) through a partition plate, the side face of the water side box body is connected with a clean water pump (11) through a pipeline, and the clean water pump is connected with a spraying head (2) through a pipeline. The belt conveyor rubber belt surface dust cleaning device is used for cleaning the dust on the surface of the rubber belt of the belt conveyor.

Owner:HUANENG YIMIN COAL POWER CO LTD

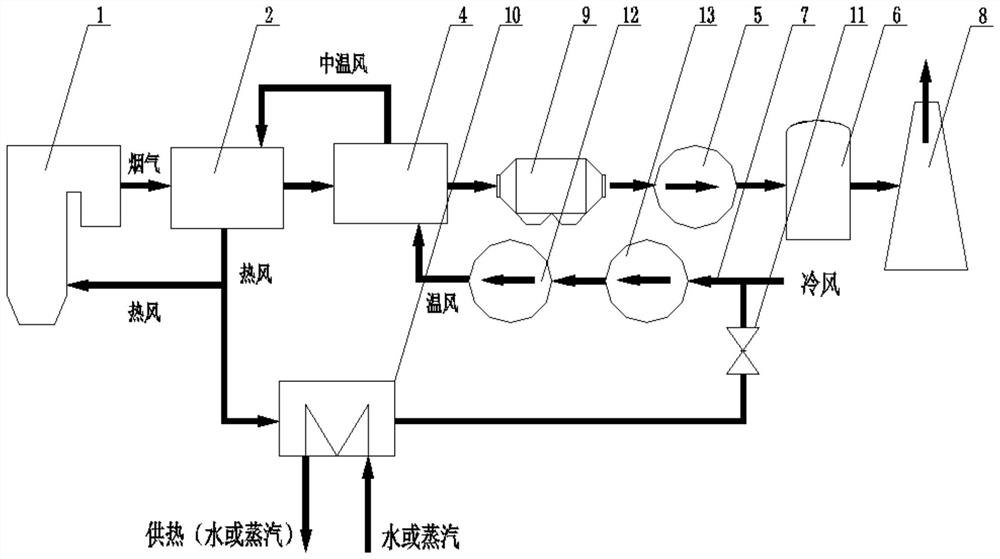

Power plant flue gas treatment system

PendingCN111895442AGuaranteed safe operationFlexible operationEmission preventionIndirect carbon-dioxide mitigationAir preheaterFlue gas

The invention provides a power plant flue gas treatment system. The power plant flue gas treatment system comprises a flue gas path which is mainly formed by connecting a boiler, a rotary air preheater, a flue gas air heater, an induced draft fan, a desulfurization tower and a chimney in sequence. The flue gas air heater adopts air as a cold medium, the air is introduced into the flue gas air heater and exchanges heat with flue gas flowing through the flue gas air heater, medium-temperature air obtained through heat exchange is introduced into the rotary air preheater and exchanges heat with flue gas flowing through the rotary air preheater, a first part of hot air obtained through heat exchange is introduced into the boiler to serve as a heat source, and a second part of hot air obtainedthrough heat exchange is cooled by heat exchange and then is recycled as part of the cold medium of the flue gas air heater. The power plant flue gas treatment system completely solves the problems oflow-temperature corrosion and ammonium bisulfate blockage of the rotary air preheater, can ensure the long-term safe and economical operation of the air preheater and reduce the maintenance and operation cost, and has high controllability and operation flexibility.

Owner:CHONGQING SHANGSHUN HEAT TRANSFER EQUIP

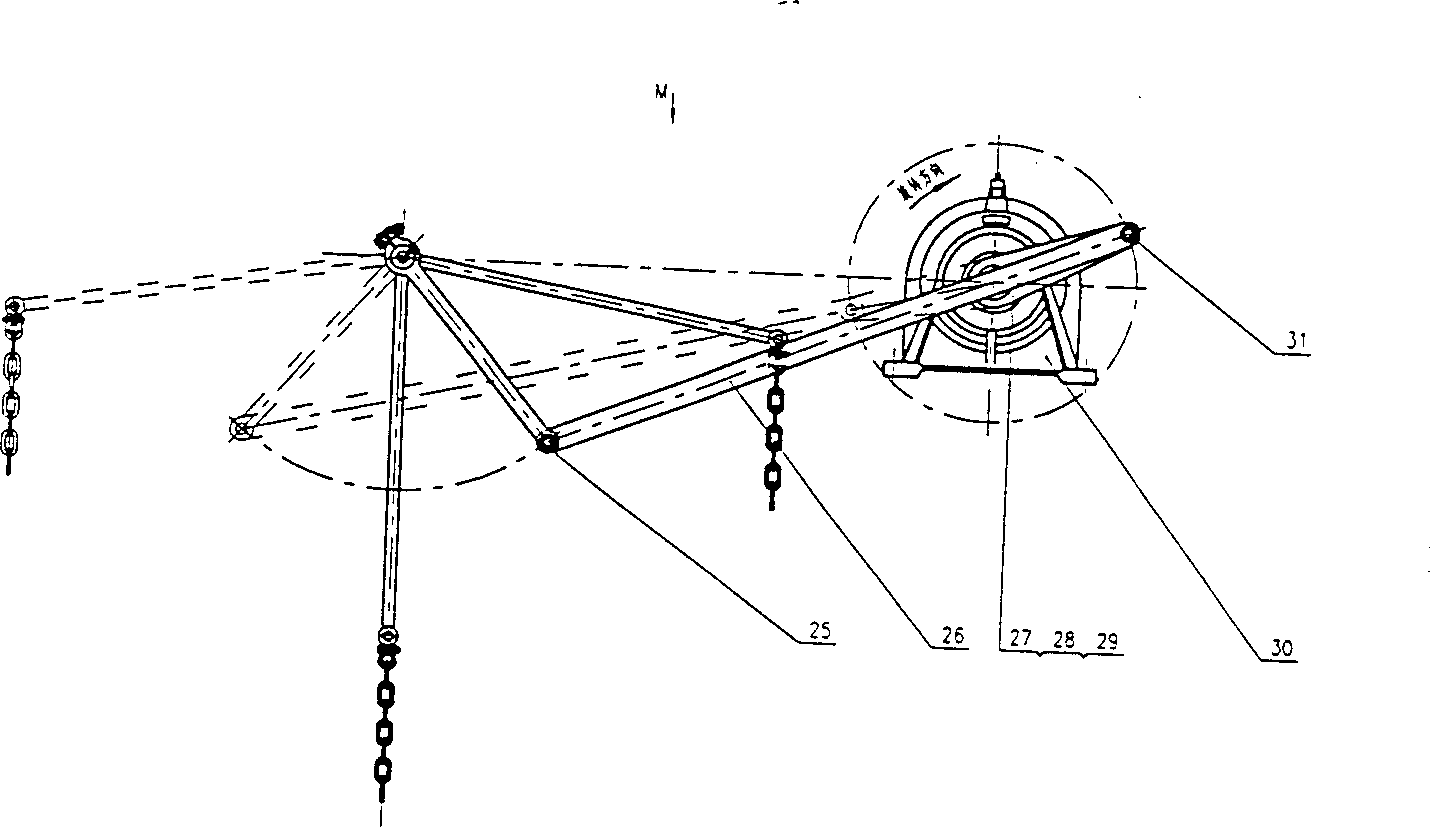

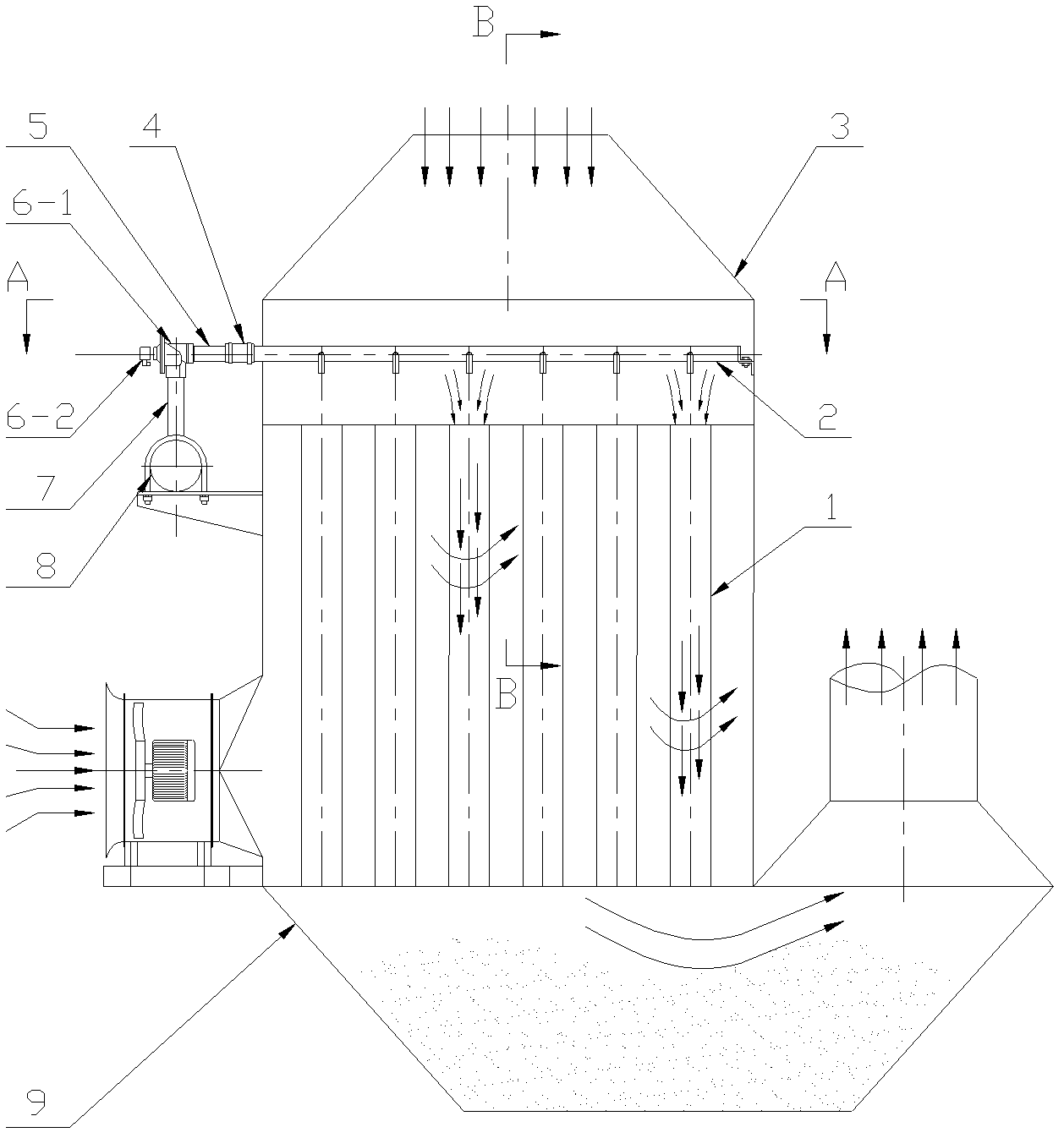

Tube bundle type cooler soot deposit cleaning device

The invention discloses a tube bundle type cooler soot deposit cleaning device which comprises a cooler machine body, wherein a plurality of rows of cooling tubes are arranged in the cooler machine body; a jetting tube is fixed above a space between the two rows of cooling tubes; each jetting tube is provided with a nozzle which is corresponding to the position of the tube mouth on the top of the corresponding cooling tube one by one; and one end of the jetting tube extends out of the cooler machine body and is communicated with an air supply system. The tube bundle type cooler soot deposit cleaning device has the advantages of simple structure, small energy consumption and low cost, is convenient to install and use and is convenient to operate and maintain, and instant expansion generated when air is compressed is used for impacting the soot deposit, raise the dust and take away the dust so as to prevent generation of scales.

Owner:合肥中亚环保科技有限公司

Air type solar energy heat-collecting ventilation system

InactiveCN101059279BImprove contact efficiencyIncreased heat collection/heat exchange efficiencySolar heat devicesSolar thermal energy generationCold seasonGreenhouse

The present invention discloses an air-type solar heat-collecting ventilation system. An extremely thin venting layer is formed between the solar radiation lighted side plate and the shaded side plate, and the thickness of the extremely thin venting layer is less than 15 mm, the length is ranged from several centre meters to several meters and the section inner flow rate is less than 5m / s, one end of the venting layer is air inlet and another end is air blowing mouth, the plate bodies of the end mouth surface formed by facing solar lighted side and shaded side are fully arranged and installedon the solar radiation lighted surface as air-type heat-collecting materials, the air blowing out mouth faces the collecting venting layer formed by the solar radiation lighted side and shaded side of plate bodies, at the same time the continuous space of plate bodies used for venting and connected with said air inlet is formed. The invention can provide adequate indoor ventilation to prevent chemical pollution, condensation and moldy and insects, on the other hand, the use of solar energy to release the cold venting air temperature in cold seasons, it plays an active role of preventing global greenhouse phenomenon and the problem of inadequate energy.

Owner:EOM

Anti-coking method and apparatus based on air-staged low-nitrogen combustion reconstruction

InactiveCN105202533APrevent dynamic field disturbanceAvoid disorderCombustion apparatusLow nitrogenEconomic benefits

The invention discloses an anti-coking method and apparatus based on air-staged low-nitrogen combustion reconstruction. The apparatus capable of injecting a plurality of high-air speed low-air quantity jet flows is arranged between a top secondary air nozzle and an over fire air nozzle of a corner-fired boiler. The anti-coking method and apparatus can overcome or greatly alleviate the coking problem of corner areas of the corner-fired boiler and improve economical efficiency and security of the boiler in operation; thus, the anti-coking method and apparatus bring good economic benefits to a thermal power generating unit and has wide popularization significance.

Owner:ELECTRIC POWER SCI RES INST OF GUIZHOU POWER GRID CO LTD +1

Improved air chamber and powder tank truck using the same

ActiveCN111483387ASpread evenlyFlow fastTank vehiclesItem transportation vehiclesThermodynamicsTank truck

The invention discloses an improved air chamber and a powder tank truck using the same. A gas inlet for introducing gas is formed in the air chamber; a gas outlet for discharging gas is also formed inthe air chamber. The air chamber is characterized in that a flow limiting plate is arranged in the air chamber, the air chamber is divided into an air inlet cavity with an air inlet and an air outletcavity with an air outlet by the flow limiting plate, and a gap for allowing an airflow to pass through and rectifying and accelerating the airflow exists on the flow limiting plate and / or between the flow limiting plate and the wall of the air chamber. The air chamber of the powder tank truck is moved upwards, and the ventilation proportion of the cloth bag is changed; an intelligent ash discharging system is additionally arranged, and the ash accumulation problem of three large ash accumulation prone parts of a traditional powder tank truck is solved.

Owner:HEFEI UNIV OF TECH

Multi-hearth full-anti-burning coal gasification boiler

InactiveCN101915413APromote environmental protectionIncrease burnback areaWater heatersSteam boilersCombustion chamberFlue gas

The invention discloses a multi-hearth full-anti-burning coal gasification boiler, belonging to the technical field of boilers and solving the problems of substandard flue gas, inconvenient operation and potential safety hazard existing in a traditional coal gasification boiler. The multi-hearth full-anti-burning coal gasification boiler comprises a plurality of anti-burning gas generating chambers which are respectively provided with coal-adding furnace doors, the upper parts of the anti-burning gas generating chambers are communicated through anti-burning communication holes, the lower part of each coal-adding furnace door is respectively provided with an anti-burning grate and an ash-poking hole, a combustion chamber, primary high-pressure air vents and a water sealing pool are arranged below the ash-poking hole, the combustion chamber is provided with a fire outlet communicated with a heat-absorbing area, a slag outlet is arranged below the fire outlet, secondary high-pressure blast is arranged above the anti-burning gas generating chambers, the heat-absorbing area is internally provided with a plurality of heat-absorbing water pipes, and flue gas outlets are arranged above the heat-absorbing area. The invention increases the anti-burning area, enables flue gas to be further environment-friendly, is convenient to operate, improves the flow velocity of the flue gas and lessens the potential safety hazard.

Owner:SHANXI XINJUXING BOILER

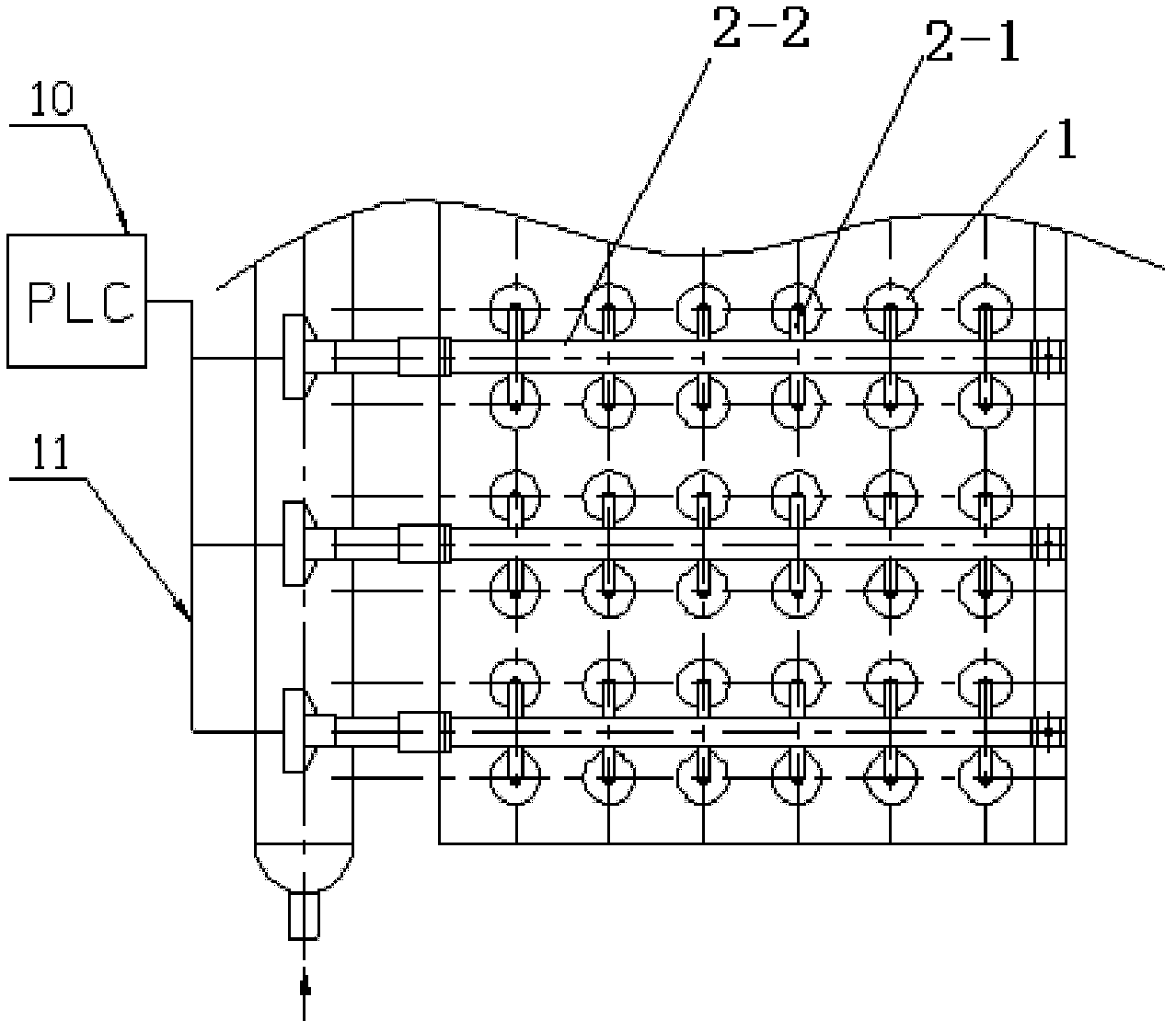

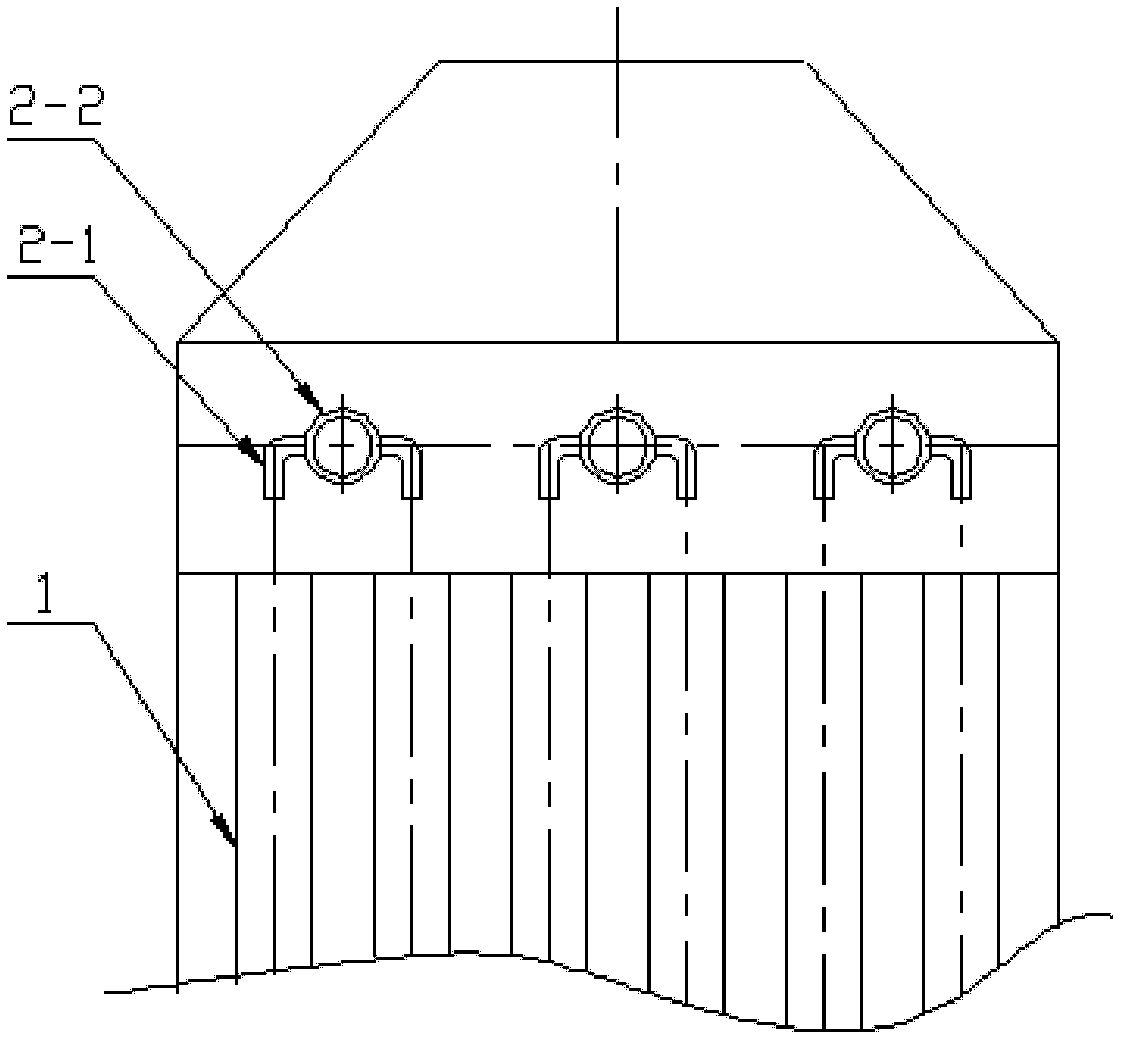

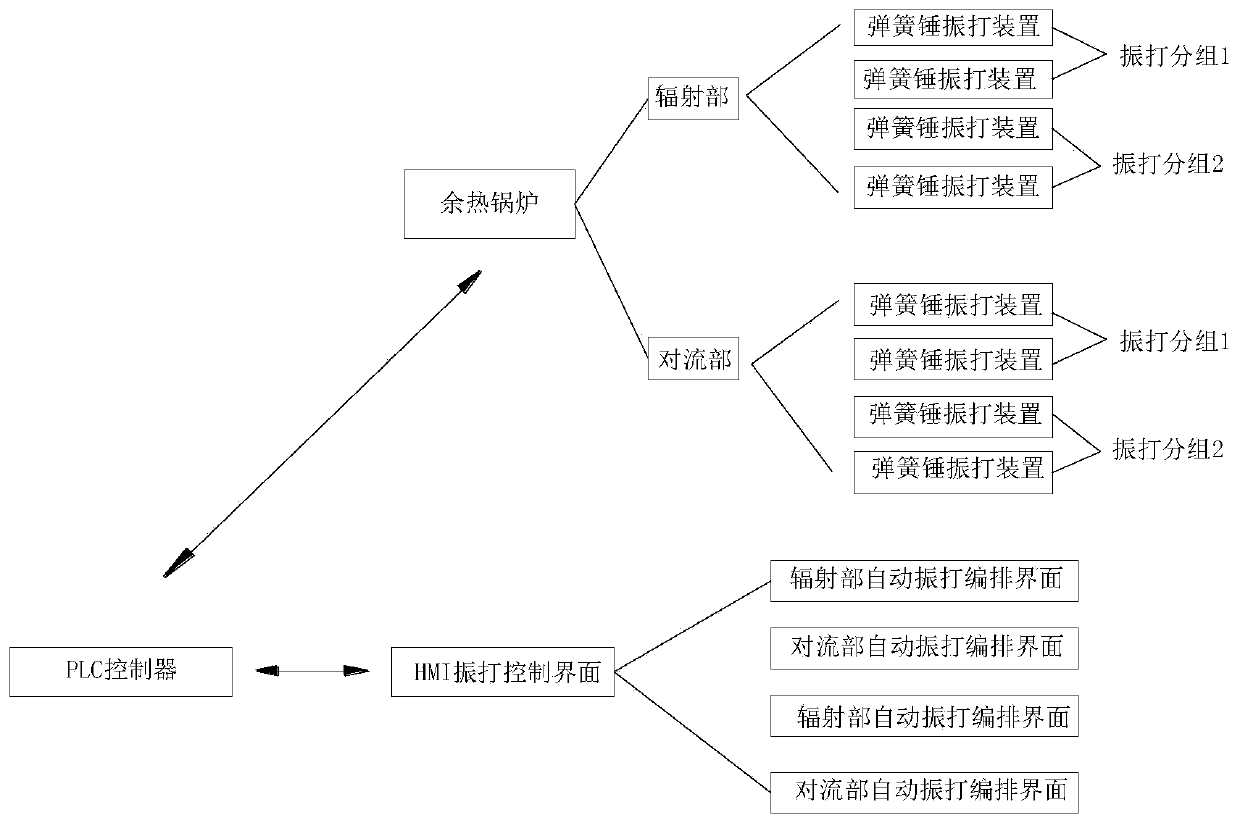

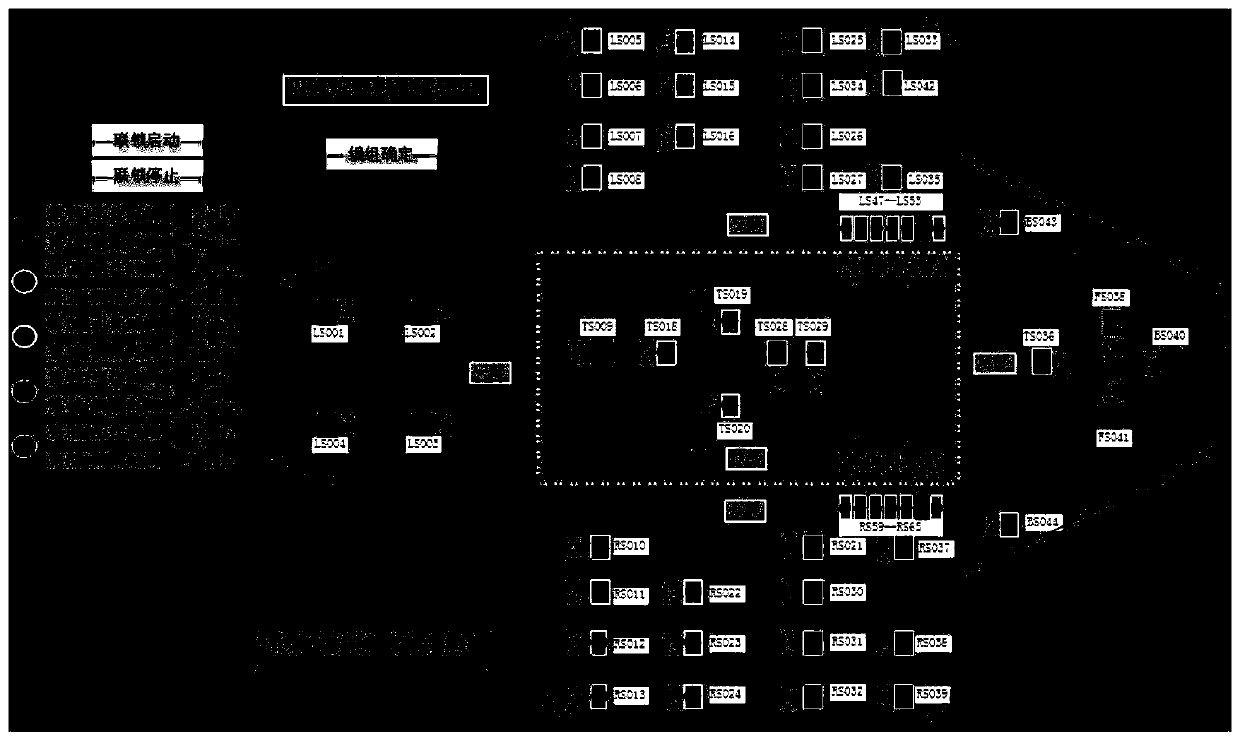

Waste heat boiler vibration control system and method

PendingCN110597175AEliminate dust accumulationImprove cleanlinessProgramme control in sequence/logic controllersHuman–machine interfaceVibration control

The invention discloses a waste heat boiler vibration control system and method. The waste heat boiler vibration control system includes a waste heat boiler which is provided with a plurality of spring hammer vibration devices, an HMI (Human Machine Interface) vibration control device configured to display an HMI vibration control interface which comprises an automatic vibration arrangement interface, and a PLC (Programmable Logic Controller) communicably connected to the HMI vibration control device; wherein the spring hammer vibration devices are divided into a plurality of vibration groups,and vibration time and interval time of the vibration groups are independent and adjustable; and the PLC is configured to store serial number of each spring hammer vibration device, receive control instructions, grouping instructions for the vibration groups and setting instructions for the vibration time and interval time of each vibration group transmitted by the HMI vibration control device, and control each vibration group to perform vibration in sequence according to the instructions. According to the waste heat boiler vibration control system and method, technologists can perform real-time grouping and adjustment for a boiler vibration device based on different production periods and conditions and ash deposition condition of the boiler, thus the effects of enhancing vibration effect, clearing ash deposition of the boiler and ensuring smooth operation of copper pyrometallurgical smelting production are achieved.

Owner:紫金铜业有限公司

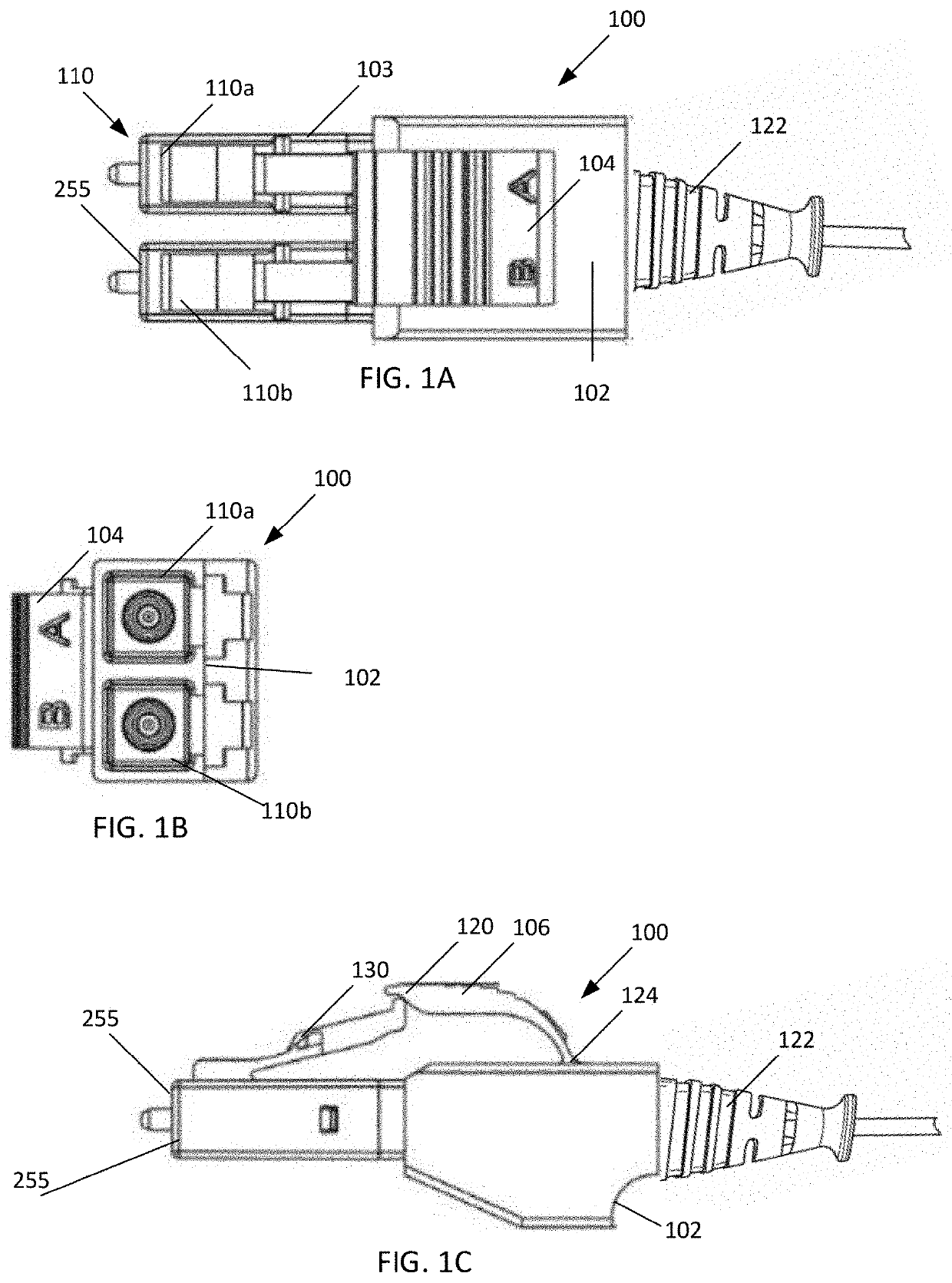

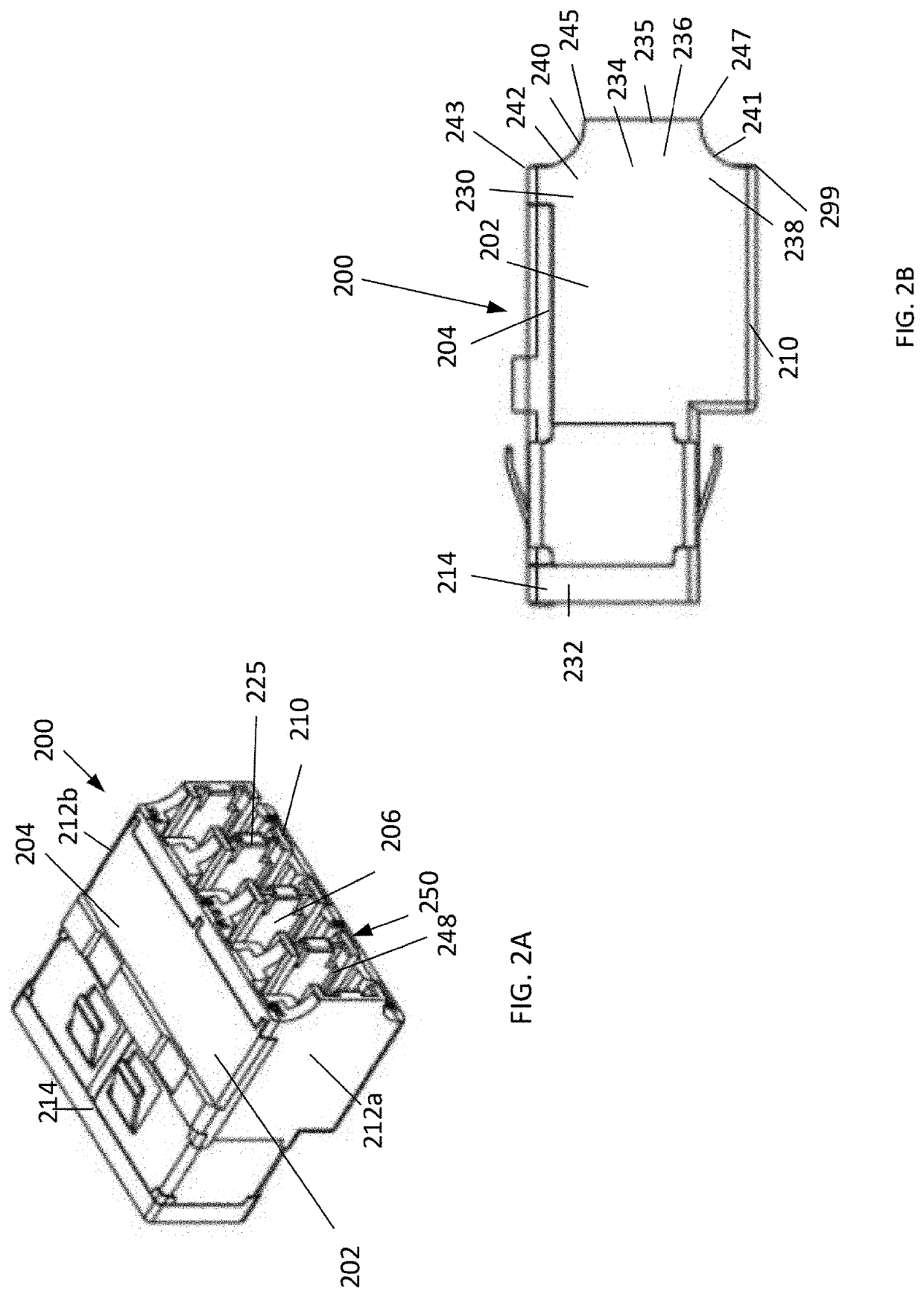

Optical Fiber Adapter with Shutter Assembly

ActiveUS20220221653A1Eliminate dust accumulationObstruct light beamMechanical apparatusPlanar/plate-like light guidesShutterLight beam

A shutter assembly for a dual polarity fiber optic adapter is provided. The shutter assembly disposed in the dual polarity fiber optic adapter may eliminate dust accumulation and obstruct light beams emission, thus preventing eyes from a user from exposure to the light beams. Furthermore, an extending tab formed in the dual polarity fiber optic adapter may also prevent misplacement of fiber optic connector during installation.

Owner:GOOGLE LLC

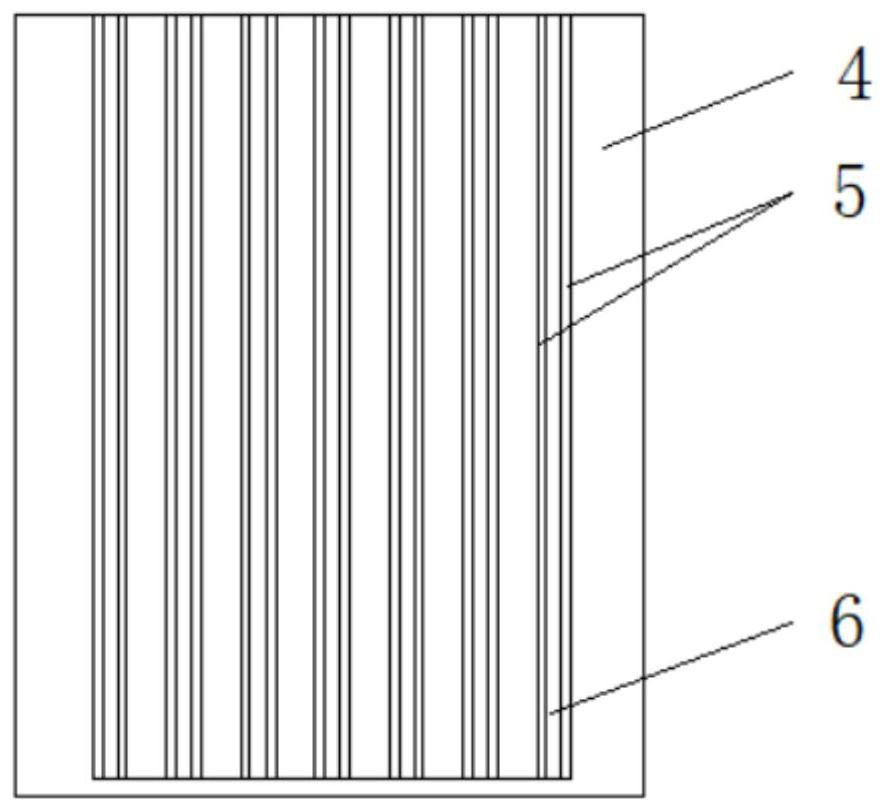

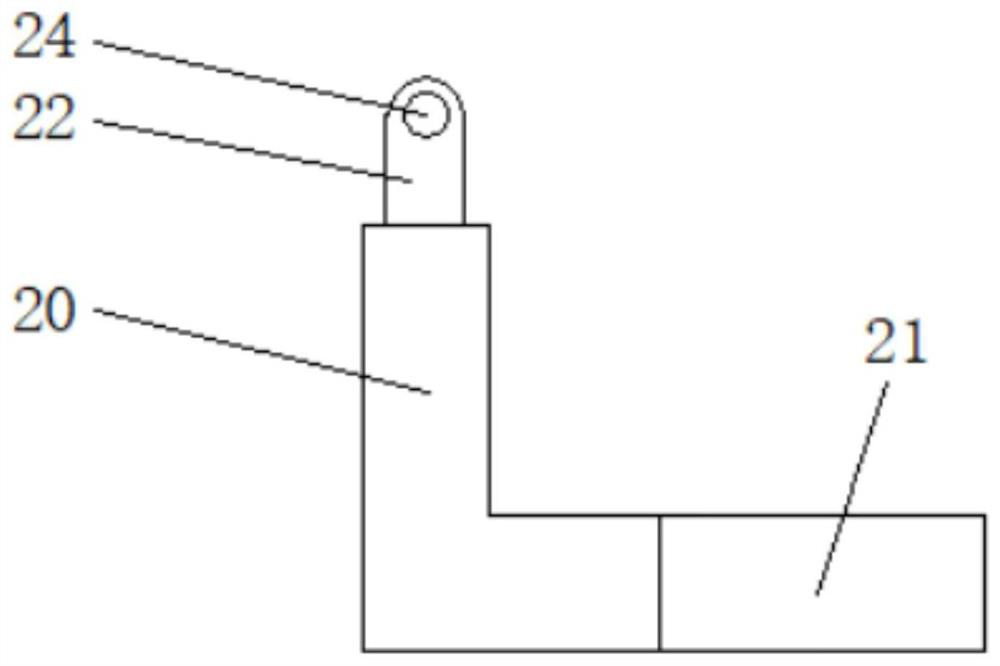

Control cabinet with efficient heat dissipation

PendingCN114710942ADoes not affect sealing effectEliminate dust accumulationModifications by conduction heat transferWater storageEngineering

The invention discloses an efficient heat dissipation control cabinet which comprises a box body (1) with one side provided with an opening, a step frame (2) is fixedly installed on the opening side of the bottom of the box body (1), a water storage pool (a) is arranged between the step frame (2) and the interior of the box body (1), a control cabinet body (3) is arranged in the box body (1), and the control cabinet body (3) is fixedly installed on the step frame (2). The control cabinet (3) can be in clearance interaction fit with the inner wall of the box body (1) and the step frame (2), a copper plate (4) is arranged on the back face of the control cabinet (3), a plurality of heat dissipation fins (5) are arranged on the back face of the copper plate (4), the lower ends of the heat dissipation fins (5) extend into the water storage pool (a), and a water absorption cotton strip (6) is clamped and fixed between every two adjacent heat dissipation fins (5). According to the invention, heat emitted by various components installed on the copper plate in the working process can be taken away through the cooling fins and the copper plate, the sealing effect of the control cabinet is not affected, and the phenomenon of dust accumulation is completely eradicated.

Owner:苏州中锦科技有限公司

A new energy source: self-cleaning solar panels

ActiveCN110336532BEasy to cleanRealize one-way cleaningPhotovoltaicsPhotovoltaic energy generationExternal energyLight energy

The invention belongs to the technical field of new energy equipment, and in particular relates to a new energy self-cleaning solar panel, including a solar panel, a brush plate is slidably connected to the upper side wall of the solar panel, and the left and right ends of the brush plate are fixedly connected with Sliding mechanism, the other end of the sliding mechanism is fixedly connected with a wing plate, the lower side of the solar panel is fixedly connected with a dust storage tank, and there are two dust scraping boards slidingly connected in the dust storage tank, and the opposite side walls of the two dust scraping boards Both are fixedly connected with connecting ropes, the other end of each connecting rope is fixedly connected with each sliding mechanism, a reset mechanism is arranged between the two scraping boards, and the four corners of the solar panels are fixedly connected with limiting blocks. The invention can make full use of the wind energy through the set wing plate, so that the brush plate slides up and down under the indirect drive of the wind, so as to remove dust from the surface of the solar panel and improve the absorption of light energy by the solar panel, and this process utilizes Clean and renewable wind energy, no need for external energy, clean and environmentally friendly.

Owner:中宏京(天津)智能科技有限公司

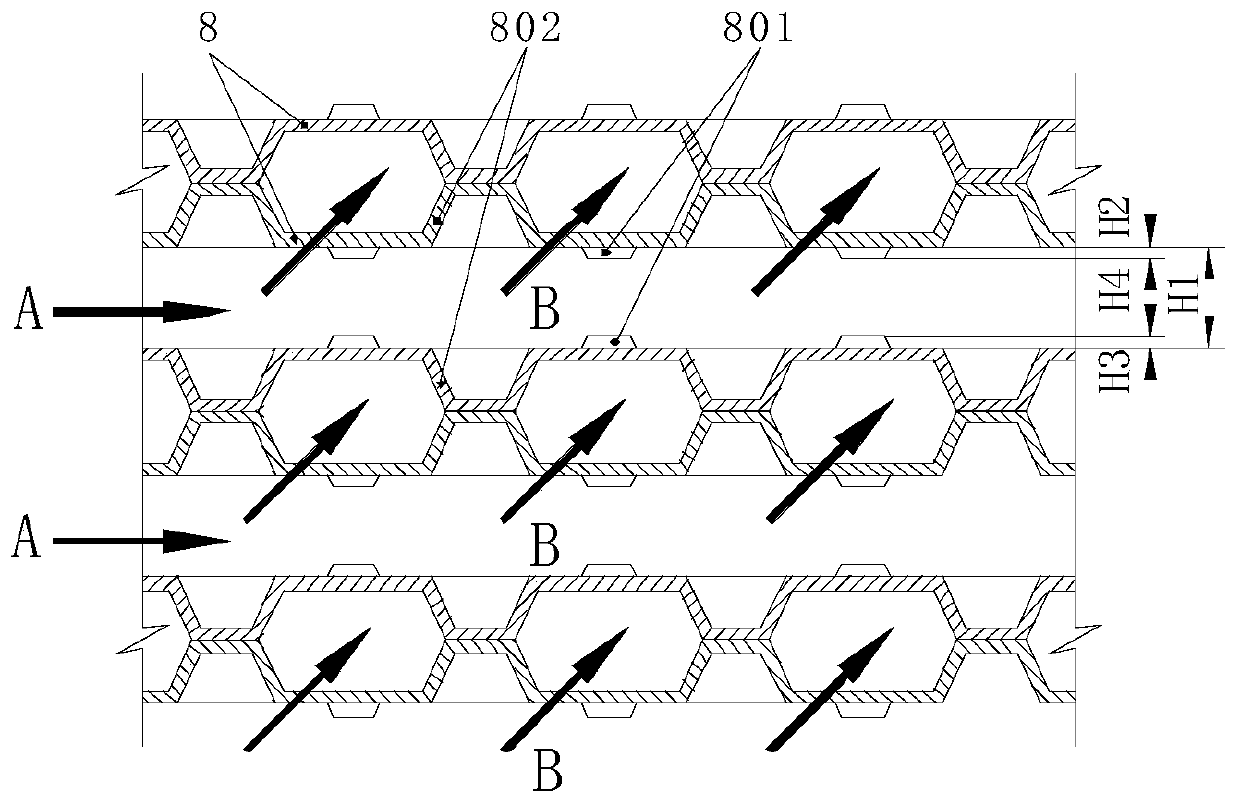

Built-in distributed full three-dimensional continuous micro-flow high-energy sound wave high-efficiency and energy-saving cleaning system

ActiveCN111780145BEliminate dust accumulationClear scaleSolid removalCleaning processes and apparatusResonant cavityFlue gas

The invention discloses a built-in distributed full-stereo continuous micro-flow high-energy sound wave high-efficiency and energy-saving dust cleaning system, which includes a resonator-type sonic cleaner, a pulse-resonance composite sonic cleaner, a pulse-type sonic cleaner and a compressed gas pipeline. Distributed full stereo wave ash cleaning unit composed of distributed full stereo wave ash cleaning unit; distributed full stereo wave ash cleaning unit is installed at intervals on the compressed gas pipeline; The air port, the air inlet of the pulse resonant cavity composite acoustic soot cleaner and the air inlet of the pulse type sonic soot cleaner are in fluid communication with the compressed gas pipeline respectively; the compressed gas pipeline is laid along the flow direction of the flue gas in the flue. Pulse-type sonic cleaning, resonant-cavity sonic-cleaning, and pulse-resonant-cavity composite sonic-cleaning work together to perform sonic soot cleaning, which can remove ash, scaling and coking on the inner wall of the flue.

Owner:北京中电永昌科技有限公司

Ash-cleaning mechanical air cooler

InactiveCN1126937CSimple structureCompact structureRotary device cleaningFlue gasNuclear engineering

The invention relates to a dust-cleaning mechanical air cooler, which is mainly used for cooling high-temperature flue gas in smelting and electric power industries, and belongs to the technical field of cooling equipment. It mainly includes heat dissipation pipes, wall panels, middle partitions, fans, ash hopper ring beams, ash hopper parts, and support platforms. superior. The invention has the advantages of simple structure, small volume, light weight, and low manufacturing cost; high-temperature flue gas goes out of the pipe, and cooling air goes inside the pipe, which facilitates dust removal, reduces wind resistance loss, and improves cooling efficiency; Ash, prolonging the service life.

Owner:WUXI XUELANG ENVIRONMENTAL TECH CO LTD

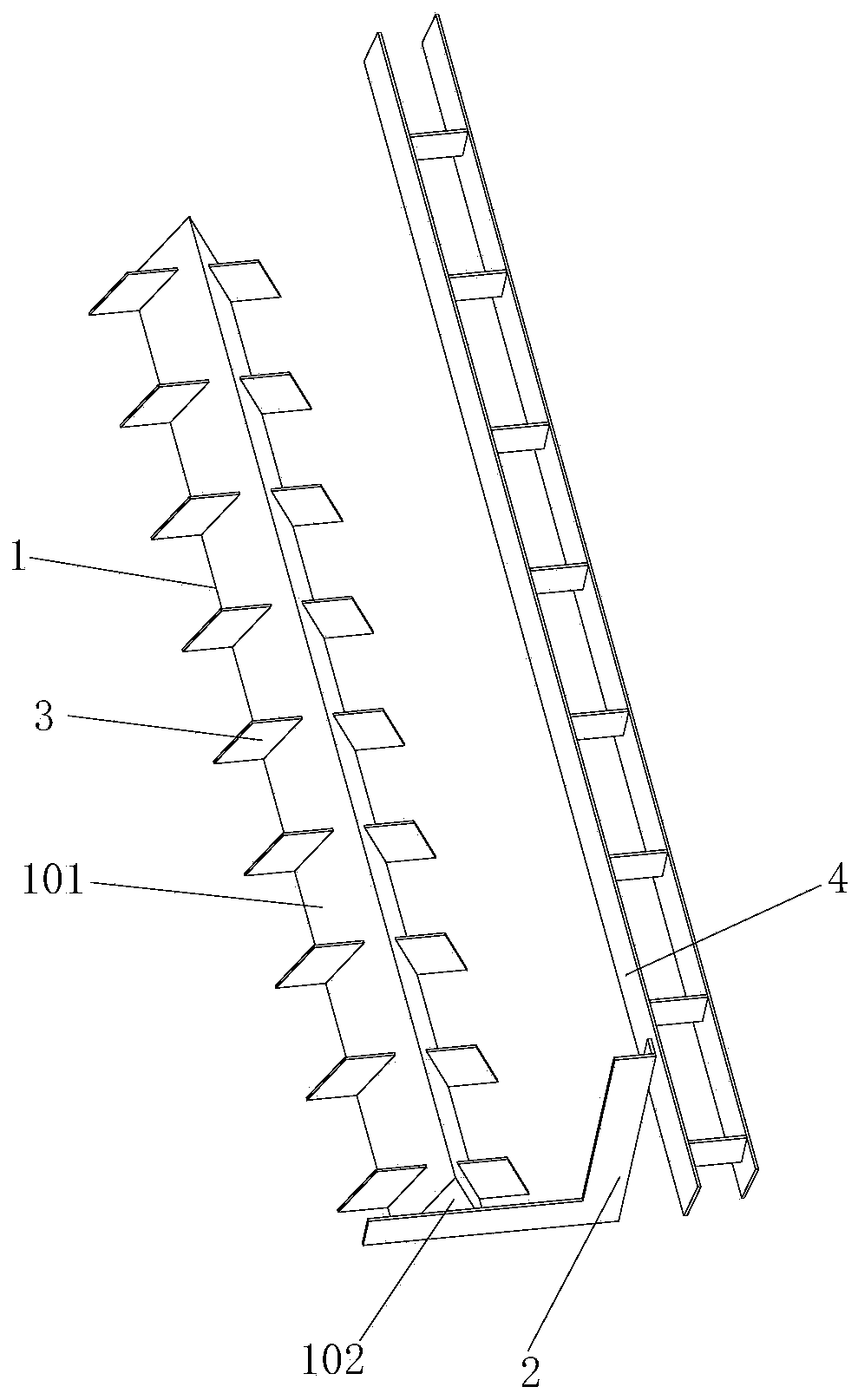

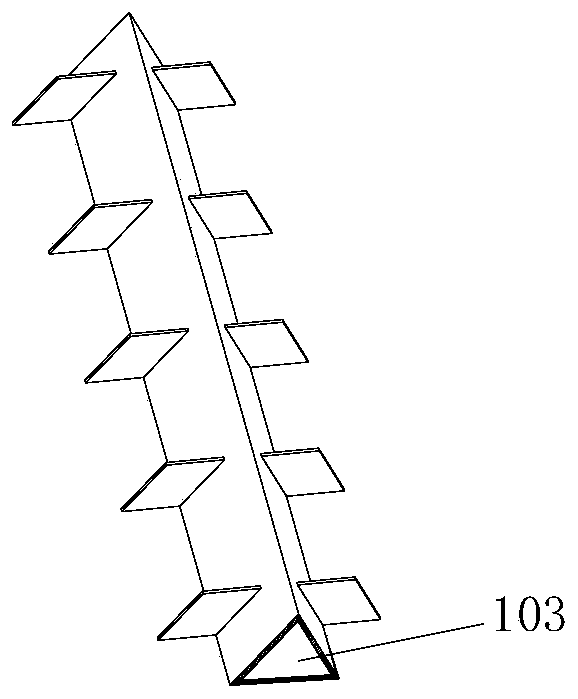

Dustproof device for electrostatic precipitator

PendingCN110124867AAvoid deformationInhibit sheddingElectrodes cleaningElectricityManufacturing cost reduction

The invention discloses a dustproof device for an electrostatic precipitator. The dustproof device comprises a cleaning long triangular body and a cleaning angle iron, wherein the cleaning long triangular body is formed by welding three rectangular plates and two triangular plates, and is provided therein with a cavity; the cleaning angle iron is connected with at least one triangular plate, and is also connected with a rapping striking rod on the lower edge of an anode plate in the electrostatic precipitator. The cavity in the cleaning long triangular body is designed to reduce the weight ofthe cleaning long triangular body and reduce the manufacturing cost. The dustproof device can prevent the dust with poor fluidity from accumulating in the electrostatic precipitator by the cleaning long triangular body, and avoids a dust accumulation phenomenon, so that the cathode plate and the anode plate in the electrostatic precipitator cannot be subjected to a short circuit due to the accumulation of dust. The dustproof device can completely solve the dust accumulation caused by the deterioration of the dust fluidity inside the electrostatic precipitator when the flue-gas temperature at the inlet of the electrostatic precipitator is lowered from 110 degrees centigrade to 90+ / -2 degrees centigrade, so that the dust cannot accumulate at the lower part of the cathode plate in the electrostatic.

Owner:HUADIAN LAIZHOU POWER GENERATION

Improved fluidized bed and powder tank truck using improved fluidized bed

ActiveCN111348342AEliminate dust accumulationAvoid accumulationTank vehiclesLarge containersFluidized bedTank truck

The invention discloses an improved fluidized bed and a powder tank truck using the improved fluidized bed. High-pressure gas is introduced into the end part of the fluidized bed, the improved fluidized bed is characterized in that the fluidized bed comprises at least two flow dividing strips or at least one protruding point structure, wherein breathable materials are laid on the at least two flowdividing strips or the at least one protruding point structure, and the at least two flow dividing strips or the at least one protruding point structure are / is matched with the breathable materials to form a fluid channel. The improved fluidized bed is used, and an intelligent ash discharging system is additionally arranged on the powder tank trunk, so that the ash deposition problem of three parts, where ash is easily deposited, of a traditional powder tank trunk is solved.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com