Dustproof device for electrostatic precipitator

A technology for electrostatic precipitator and anti-fouling, which is applied in electrostatic separation, electrode cleaning and other directions, can solve the problems of poor dust mobility and fouling in electrostatic precipitators, and achieve no risk of falling off, avoid falling off, and avoid fouling. effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

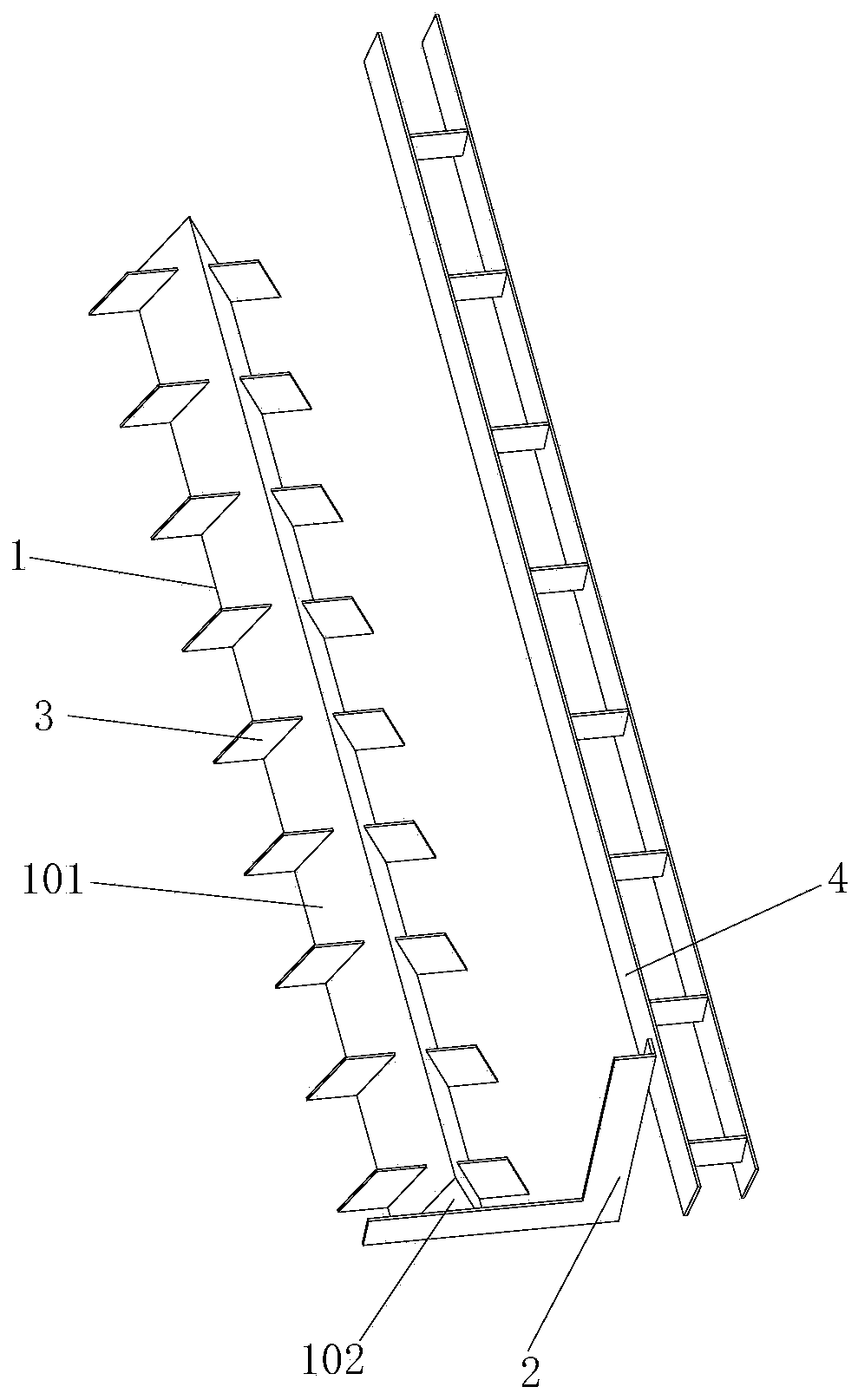

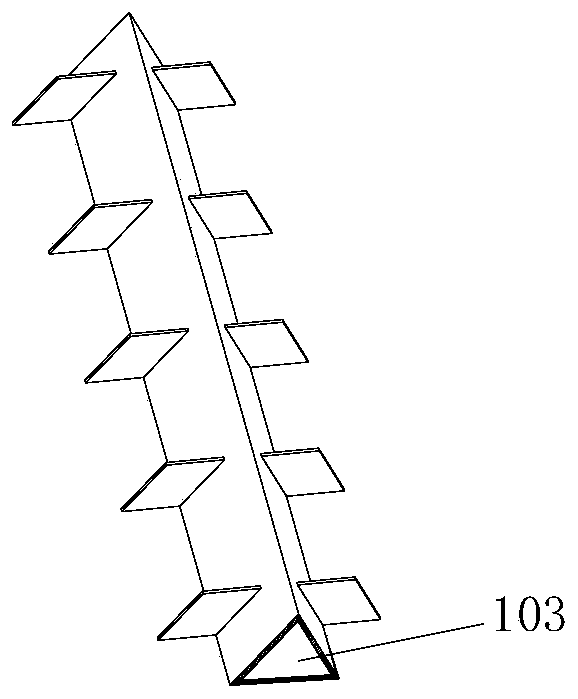

[0020] Embodiment 1 of the present invention: an anti-dusting device used on an electrostatic precipitator, comprising a long triangle body 1 for cleaning dust and an angle iron 2 for cleaning dust, and the long triangle body 1 for cleaning dust consists of three rectangular plates 101 and Two triangular plates 102 are welded, and a cavity 103 is arranged in the long triangle body 1 for cleaning dust, and the angle iron 2 for cleaning dust is connected with at least one triangle plate 102, and the angle iron 2 for cleaning dust is also connected with the inside of the electrostatic precipitator The rapping impact rod 4 on the lower edge of the anode plate is connected. Cavity 103 is established in the ash-clearing triangular body 1 in order to reduce the weight of the ash-clearing triangular body 1 self, and reduce manufacturing cost. When rapping the impact rod 4 to perform the rapping action, the dust-cleaning triangle 1 can be driven by the dust-clearing angle iron 2, there...

Embodiment 2

[0021] Embodiment 2 of the present invention: an anti-dusting device used on an electrostatic precipitator, comprising a long triangle body 1 for cleaning dust and an angle iron 2 for cleaning dust, and the long triangle body 1 for cleaning dust is composed of three rectangular plates 101 and Two triangular plates 102 are welded, and a cavity 103 is arranged in the long triangle body 1 for cleaning dust, and the angle iron 2 for cleaning dust is connected with at least one triangle plate 102, and the angle iron 2 for cleaning dust is also connected with the inside of the electrostatic precipitator The rapping impact rod 4 on the lower edge of the anode plate is connected. Cavity 103 is established in the ash-clearing triangular body 1 in order to reduce the weight of the ash-clearing triangular body 1 self, and reduce manufacturing cost. When rapping the impact rod 4 to perform the rapping action, the dust-cleaning triangle 1 can be driven by the dust-clearing angle iron 2, th...

Embodiment 3

[0022] Embodiment 3 of the present invention: an anti-dusting device used on an electrostatic precipitator, comprising a long triangle body 1 for cleaning dust and an angle iron 2 for cleaning dust, and the long triangle body 1 for cleaning dust is composed of three rectangular plates 101 and Two triangular plates 102 are welded, and a cavity 103 is arranged in the long triangle body 1 of the dust removal. The two triangular plates 102 are connected with a dust removal angle iron 2, and each dust removal angle iron 2 is connected with the electrostatic precipitator The rapping and striking rod 4 on the lower edge of the anode plate in the device is connected. The cavity 103 is provided in the ash-cleaning triangular body 1 in order to reduce the weight of the ash-cleaning triangular body 1 itself and reduce the manufacturing cost. The rectangular plates 101 on both sides of the long triangle body 1 for cleaning dust are provided with a plurality of ribs 3 arranged at equal int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com