Soot blowing system and method for pi-shaped boiler furnace arch

A technology of soot blowing system and deflection angle, which is applied to the soot blowing system and soot blowing field of π-type boiler deflection angle, to achieve the effects of reducing wear, reasonable structure and avoiding tube explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

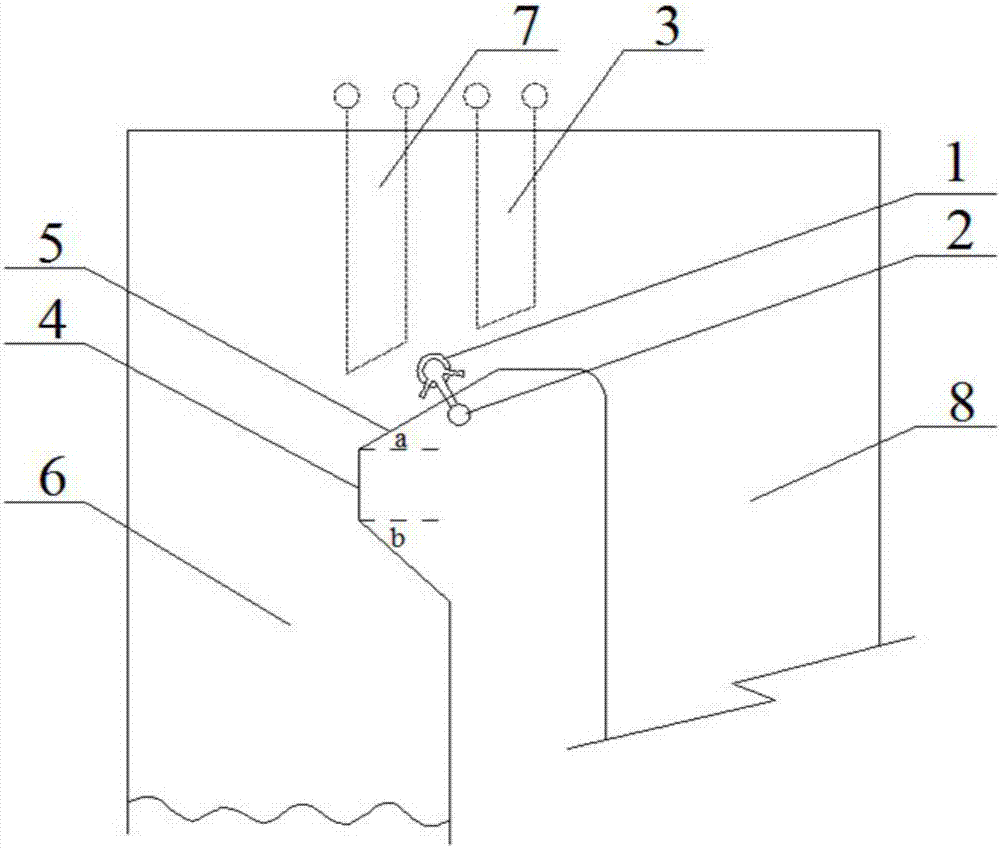

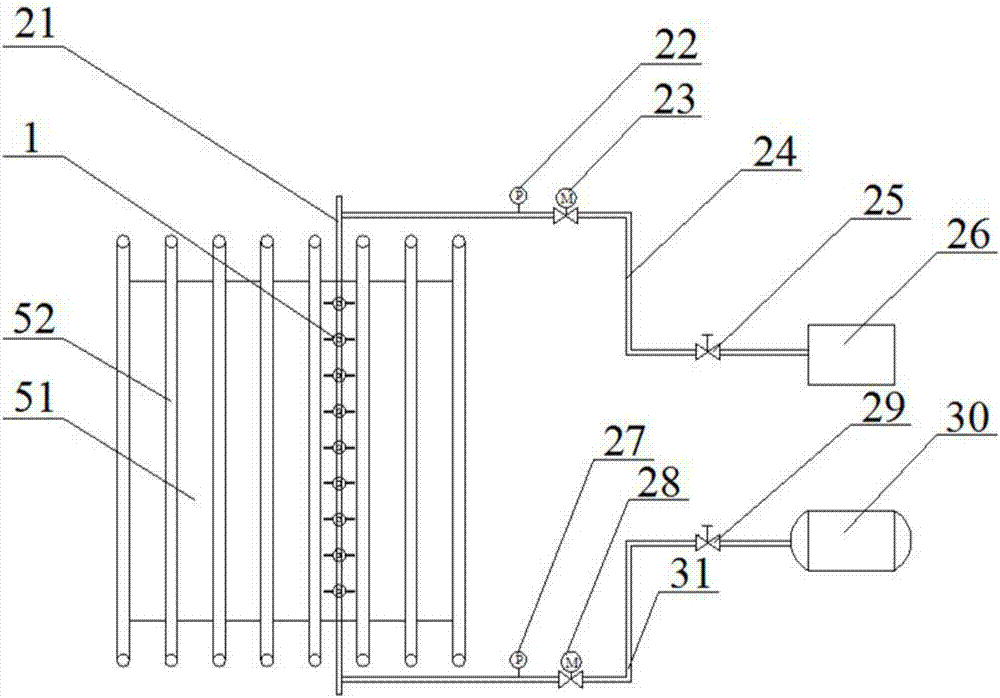

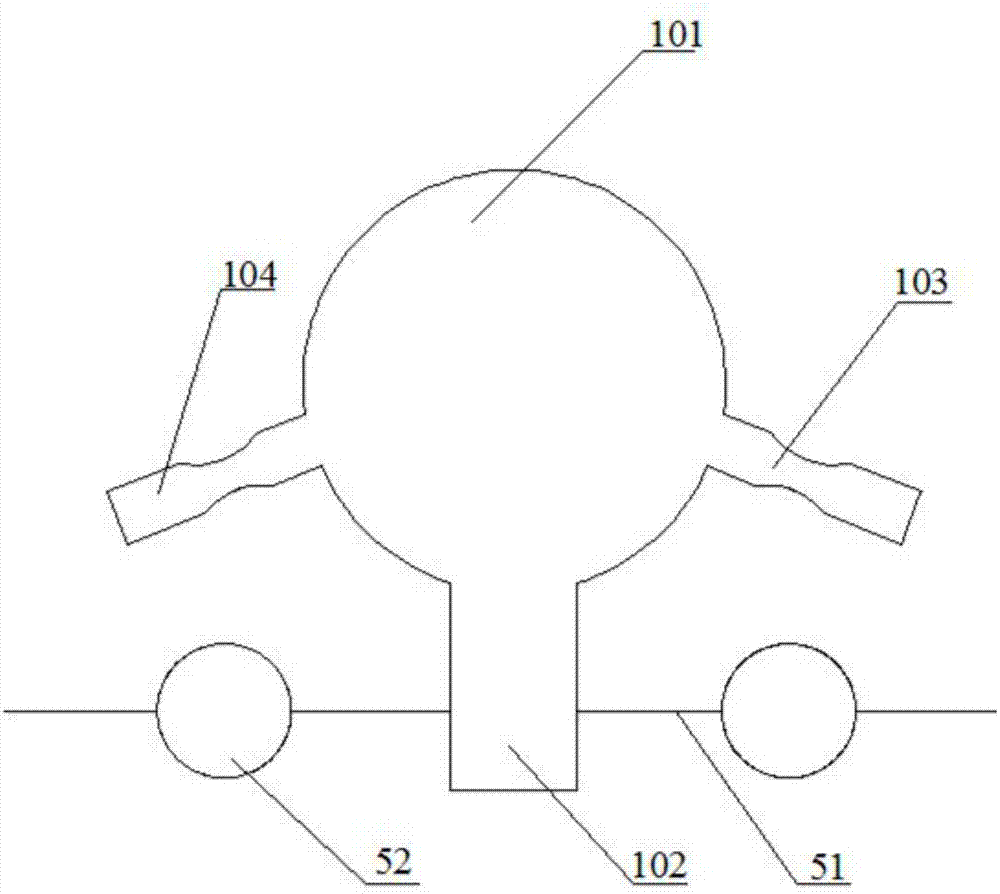

[0043] Example: see figure 1 , image 3 , the hood-type sootblower 1 of the present invention passes through the upper slope 5 of the refraction angle 4, is connected with the soot blowing medium delivery pipeline 2, and is arranged on the upper slope of the refraction angle between the high-temperature superheater 7 and the high-temperature reheater 3 superior. The upper slope 5 of the refraction angle includes a diaphragm 51 and a heat exchange tube 52. The hood type soot blower 1 is installed on the diaphragm 51 of the upper slope 5 of the refraction angle, and its structure includes a spherical hood 101, a first soot blowing nozzle 104 , the second soot blowing nozzle 103 and the inlet 102 for the purge medium. The first soot blowing nozzle 104 and the second soot blowing nozzle 103 of the present invention are obliquely downward, and the angle between the upper slope 5 of the flame angle 4 is controlled at 20° to 40°. The first soot blowing nozzle 104 The shape of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com