Integral rotational radiation preheating mixing energy utilization device with flue gas chilling

A hybrid, radiation heat exchange technology, applied in the manufacture of combustible gas, granular/powdered fuel gasification, energy input, etc. The effect of high energy recovery rate, improved energy utilization rate, convenient transportation and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

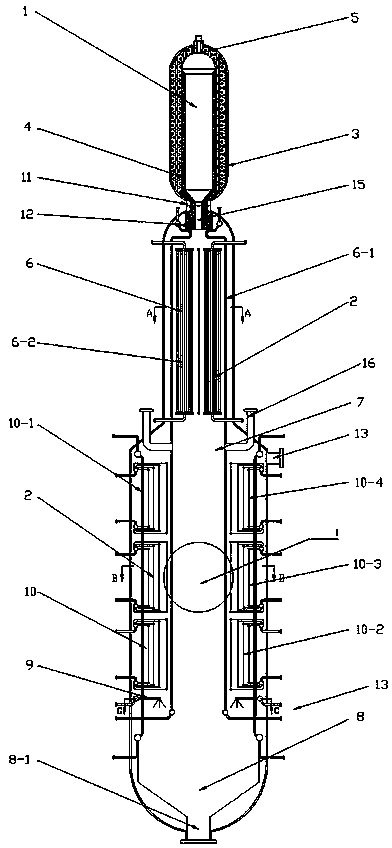

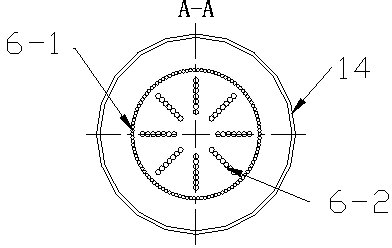

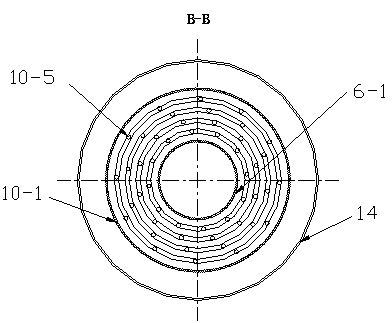

[0037] Such as Figure 1-5 As shown, the integrated rotary radiation preheating hybrid energy utilization device with flue gas quenching according to the present invention includes a gasification furnace body 1 and a heat recovery device 2, and the gasification furnace body 1 is arranged on the heat recovery device 2 Above; the gasification furnace body 1 includes the pressure shell 3 of the gasification furnace, the refractory lining or water wall 4 of the gasification furnace, the nozzle passage 5, the refractory lining of the gasification furnace arranged in the pressure shell of the gasification furnace or The water-cooled wall and the top of the gasification furnace body are provided with a nozzle channel 5 .

[0038] The gasifier is an entrained-bed gasifier, including single-nozzle and multi-nozzle gasifiers, coal slurry and pulverized coal gasifiers, water-cooled wall and refractory-lined gasifiers, and other gasifiers in various forms.

[0039] The heat recovery devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com