Soot blowing method for high-temperature reheater of coal-fired boiler

A coal-fired boiler and reheater technology, applied in the field of soot blowing, can solve the problems of difficulty in guaranteeing accuracy, affecting the soot blowing effect, etc., and achieve the effect of good soot blowing effect and accurate and reliable soot deposition degree coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

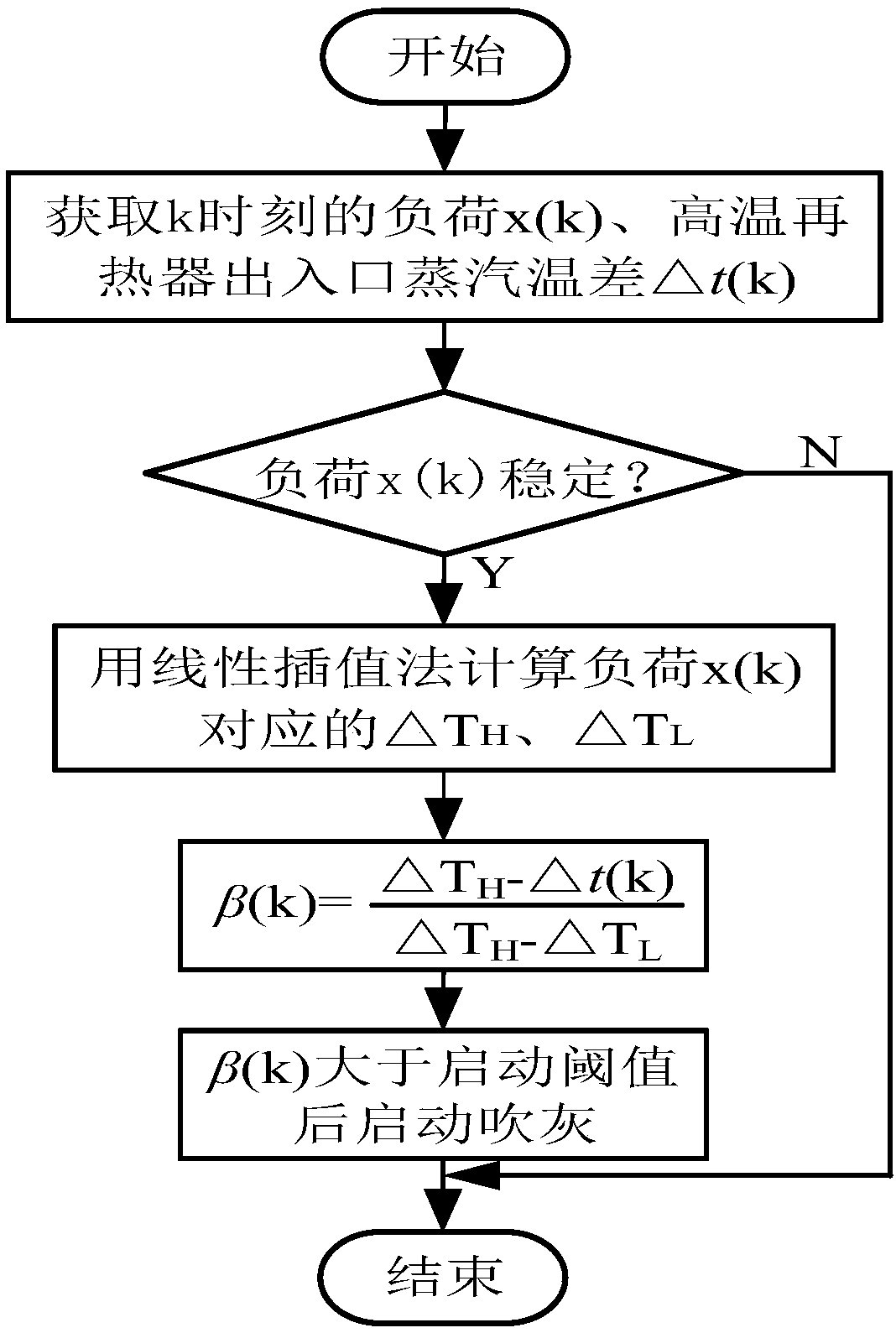

Method used

Image

Examples

Embodiment

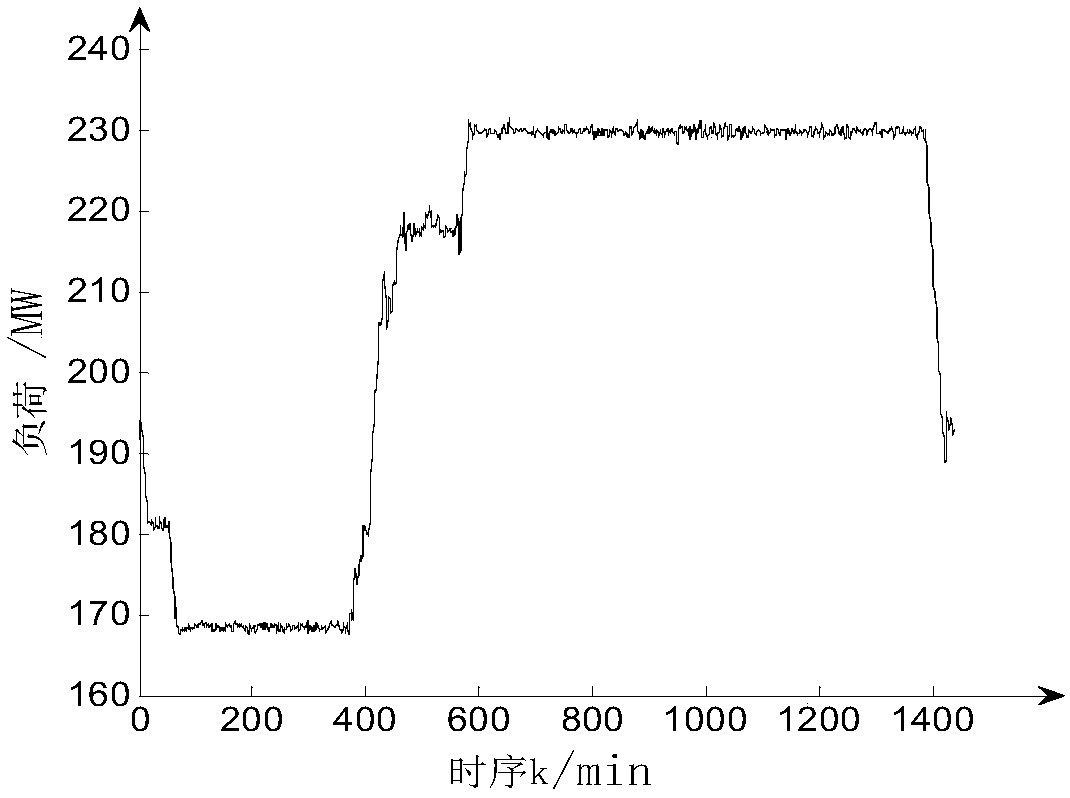

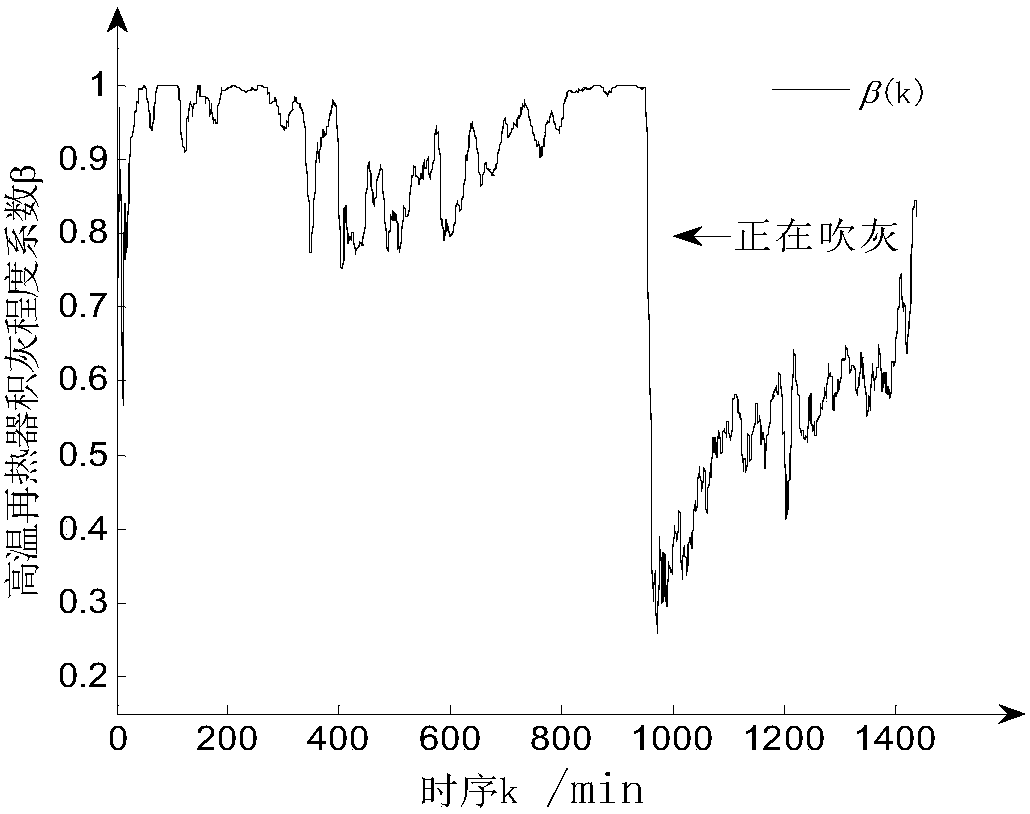

[0028] Through the combination of thermodynamic mechanism analysis and production data mining, it is determined that under steady-state conditions, the smaller the steam temperature difference between the inlet and outlet of the high-temperature reheater, the higher the degree of ash deposition in the high-temperature reheater. The larger the steam temperature difference between the inlet and outlet of the high temperature reheater, the higher the cleanliness of the high temperature reheater. The specific thermodynamic mechanism analysis and production data mining process are as follows:

[0029] A(1): From the perspective of boiler combustion, use correlation and regression analysis methods to quantify the relationship between load and boiler combustion parameters such as boiler coal feed rate, boiler feed water flow rate, total furnace air volume and reheat steam pressure, etc., and determine The unary linear relationship between the load and the above-mentioned other quanti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com