Online hydraulic ash removal system of waste incineration waste heat boiler

A waste heat boiler and waste incineration technology, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of poor cleaning efficiency and insufficient cleaning, and achieve the effect of fast purging speed, short time and high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

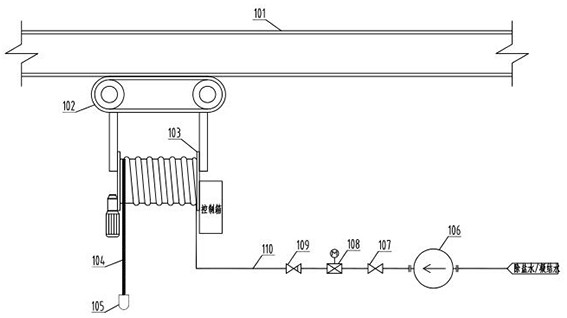

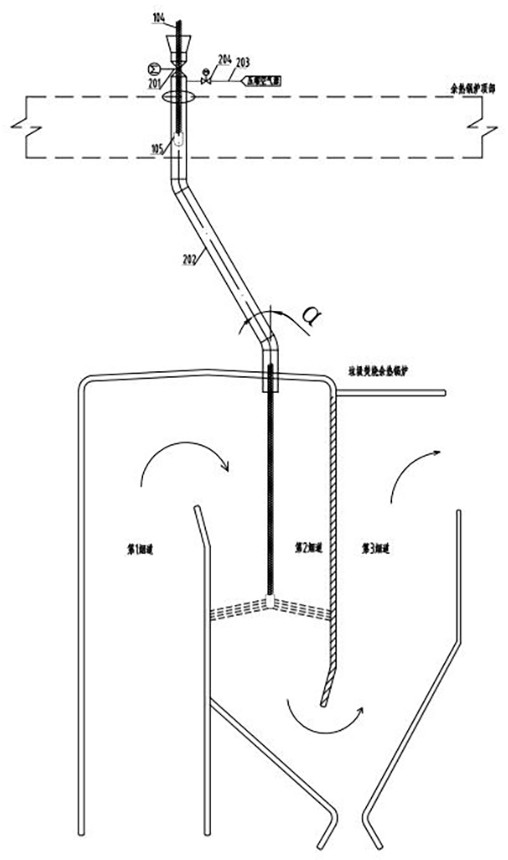

[0033] A waste incineration waste heat boiler online hydraulic ash cleaning system, such as figure 1 and figure 2 As shown, it includes cleaning parts and several prefabricated pipes 202 arranged in an array. The cleaning parts are connected with a first driving part for driving them to move laterally, and the moving path of the cleaning parts passes directly above each prefabricated pipe 202 .

[0034] Such as figure 1 As shown, the first driving part includes an installation guide rail 101 and a traveling mechanism 102 moving along the installation guide rail 101 , and the cleaning part is connected under the traveling mechanism 102 . In this embodiment, the installation guide rail 101 includes a crossbeam and a bottom plate welded to the bottom of the crossbeam. The traveling mechanism 102 includes four traveling wheels abutting on the bottom plate, and two traveling wheels are symmetrically arranged on both sides of the crossbeam. The traveling mechanism 102 can It is a...

Embodiment 2

[0045] The structure of this embodiment is roughly the same as that of Embodiment 1, the difference is that:

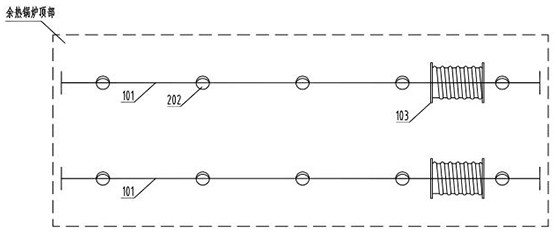

[0046] This embodiment adopts the U-shaped layout method, such as Figure 4 As shown, there are two rows of prefabricated pipes 202 connected to the top of the waste heat boiler, and a U-shaped steel structure track (installation guide rail 101) is installed on the top of the waste heat boiler, and a hydraulic ash cleaning device (cleaning part) is connected to ensure a hydraulic ash cleaning The stroke of the device on the U-shaped steel structure track can cover all the pre-opened round holes and prefabricated pipes 202 on the top of the waste heat waste heat boiler, so as to meet the ash cleaning requirements of the second and third flues in turn.

[0047] Compared with Embodiment 2, Embodiment 1 needs to configure one more hydraulic dust removal device, and the cost will increase. However, two hydraulic dust removal devices can work at the same time, and the work ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com