Intelligent soot blowing method and system based on image three-dimensional reconstruction

A three-dimensional reconstruction and image technology, applied in combustion methods, lighting and heating equipment, removal of solid residues, etc., can solve the problems of large blindness, large loss, inability to accurately monitor the accumulation of ash and slag, and solve excessive soot blowing. and underblowing, reducing sootblowing power consumption, and optimizing the effect of sootblowing duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

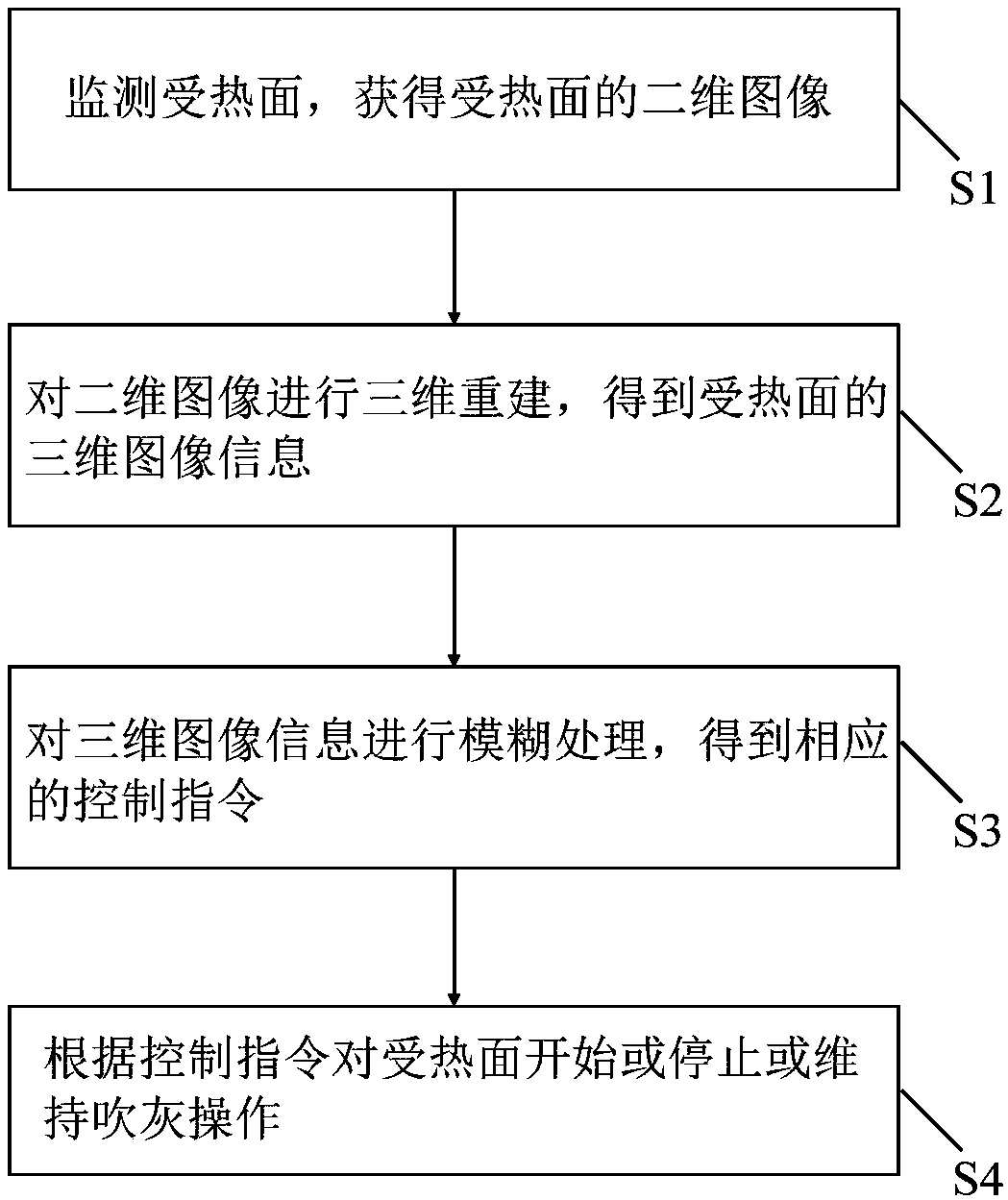

[0059] see figure 1 , the present invention provides a kind of intelligent soot blowing method based on image three-dimensional reconstruction, it comprises the following steps:

[0060] Step S1: monitoring the heating surface to obtain a two-dimensional image of the heating surface;

[0061] Step S2: performing three-dimensional reconstruction on the two-dimensional image to obtain three-dimensional image information of the heating surface;

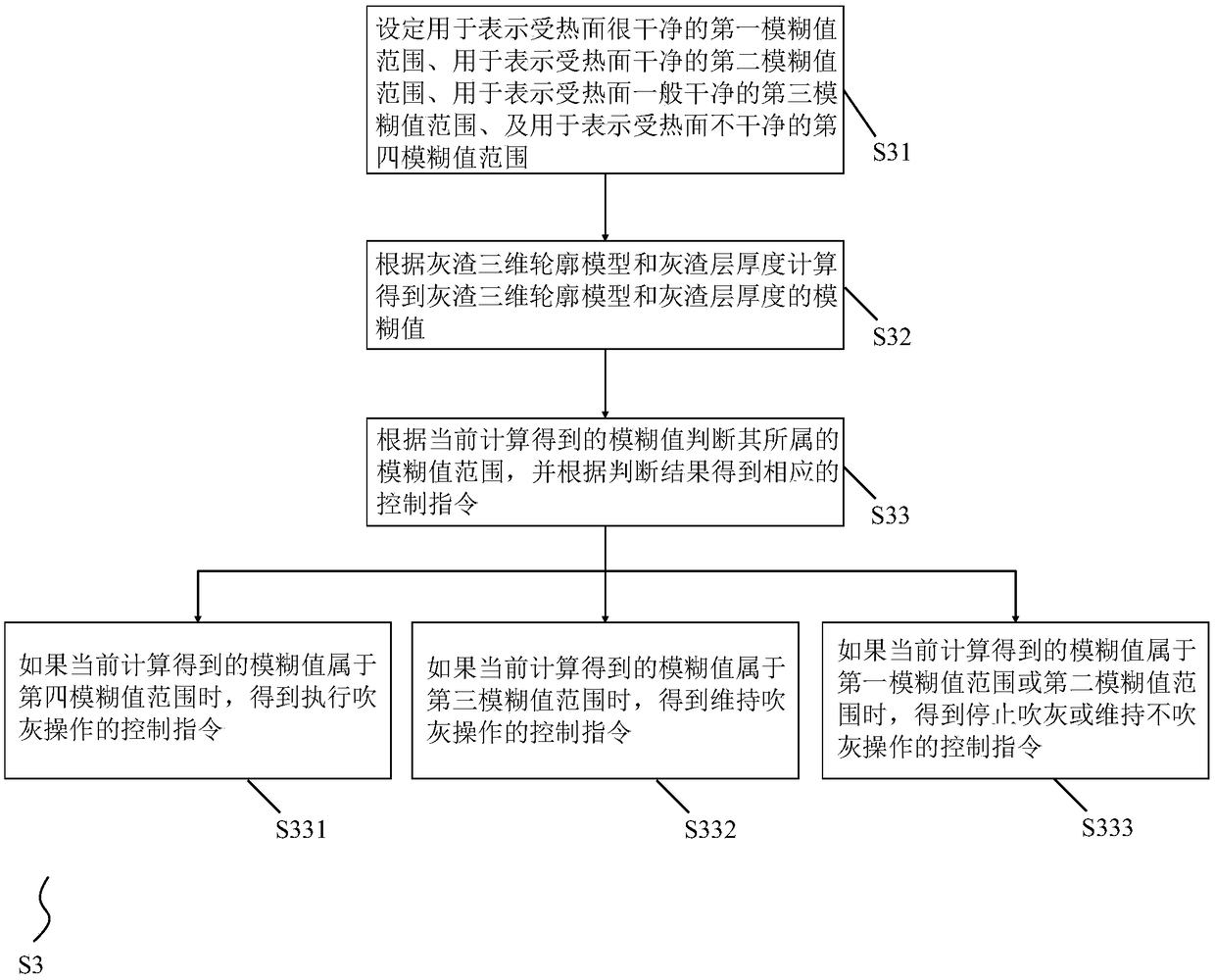

[0062] Step S3: performing fuzzy processing on the three-dimensional image information to obtain corresponding control instructions;

[0063] Step S4: Start or stop or maintain the soot blowing operation on the heating surface according to the control instruction.

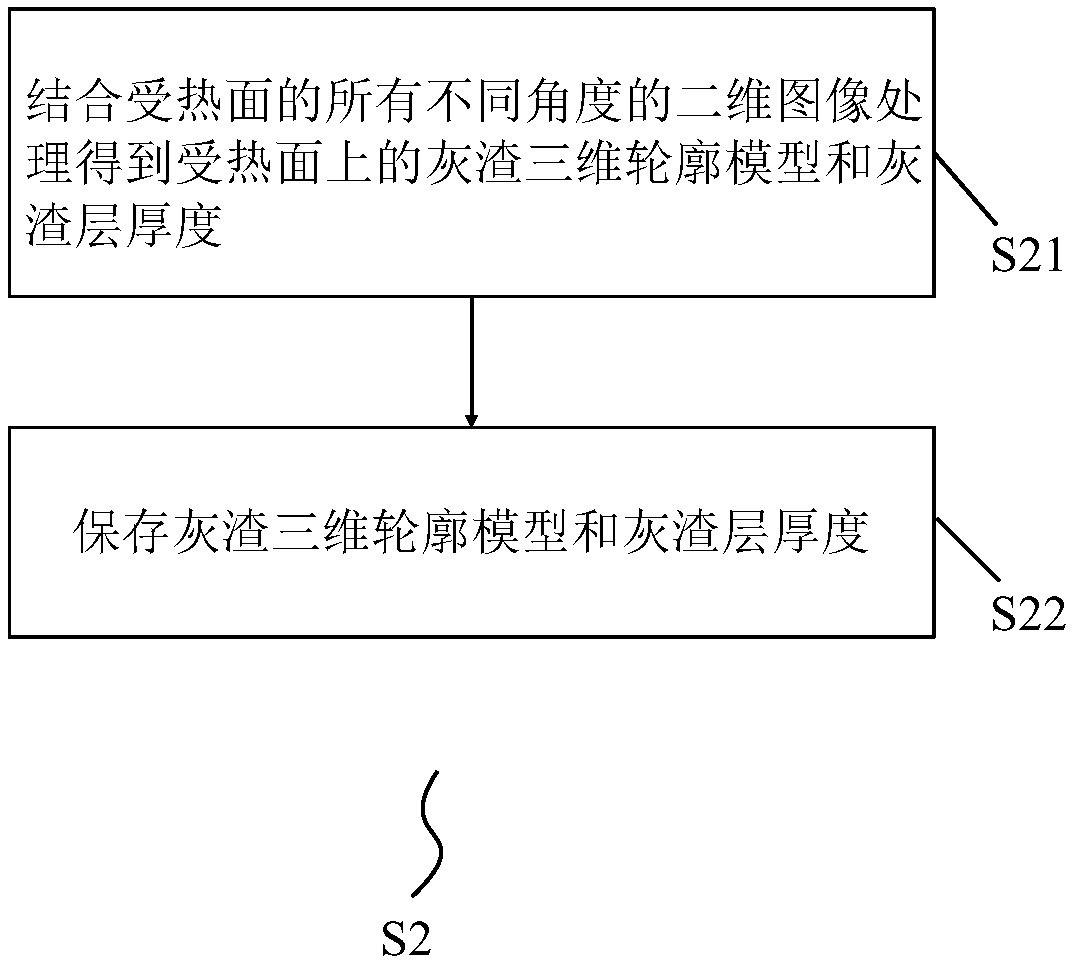

[0064] see figure 2 , specifically, the step S2 specifically includes the following steps:

[0065] Step S21: Combining the two-dimensional image processing of all different angles of the heating surface to obtain the three-dimensional contour model of the ash on the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com