Steam soot blower of novel multifunctional blowing tube

A soot blowing tube, multi-functional technology, applied in the direction of combustion product treatment, combustion method, solid residue removal, etc., can solve the problems of easy dead angle, poor soot blowing effect, poor soot blowing fullness, etc. Injection efficiency, improvement of soot blowing effect, effect of increasing soot blowing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

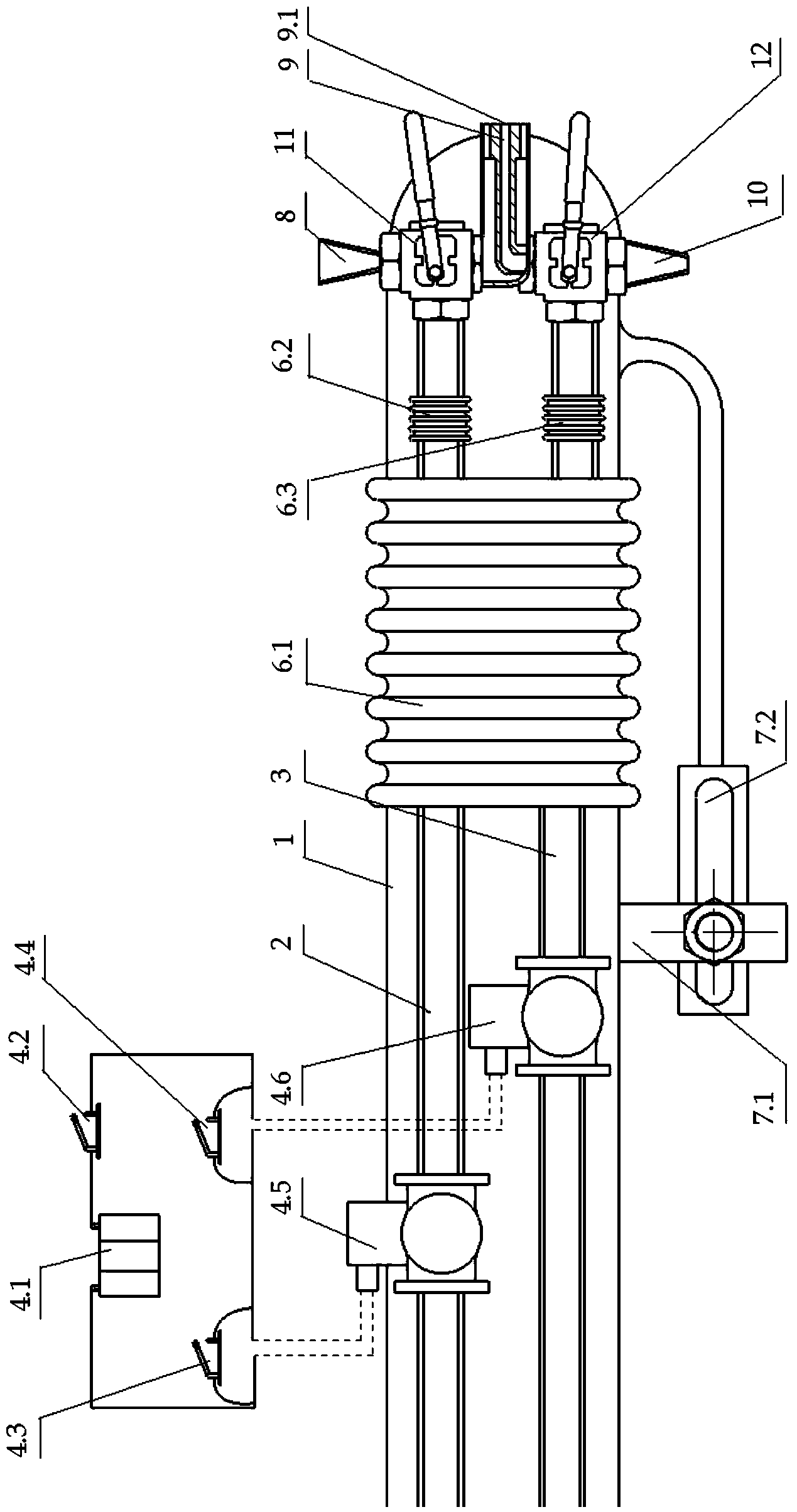

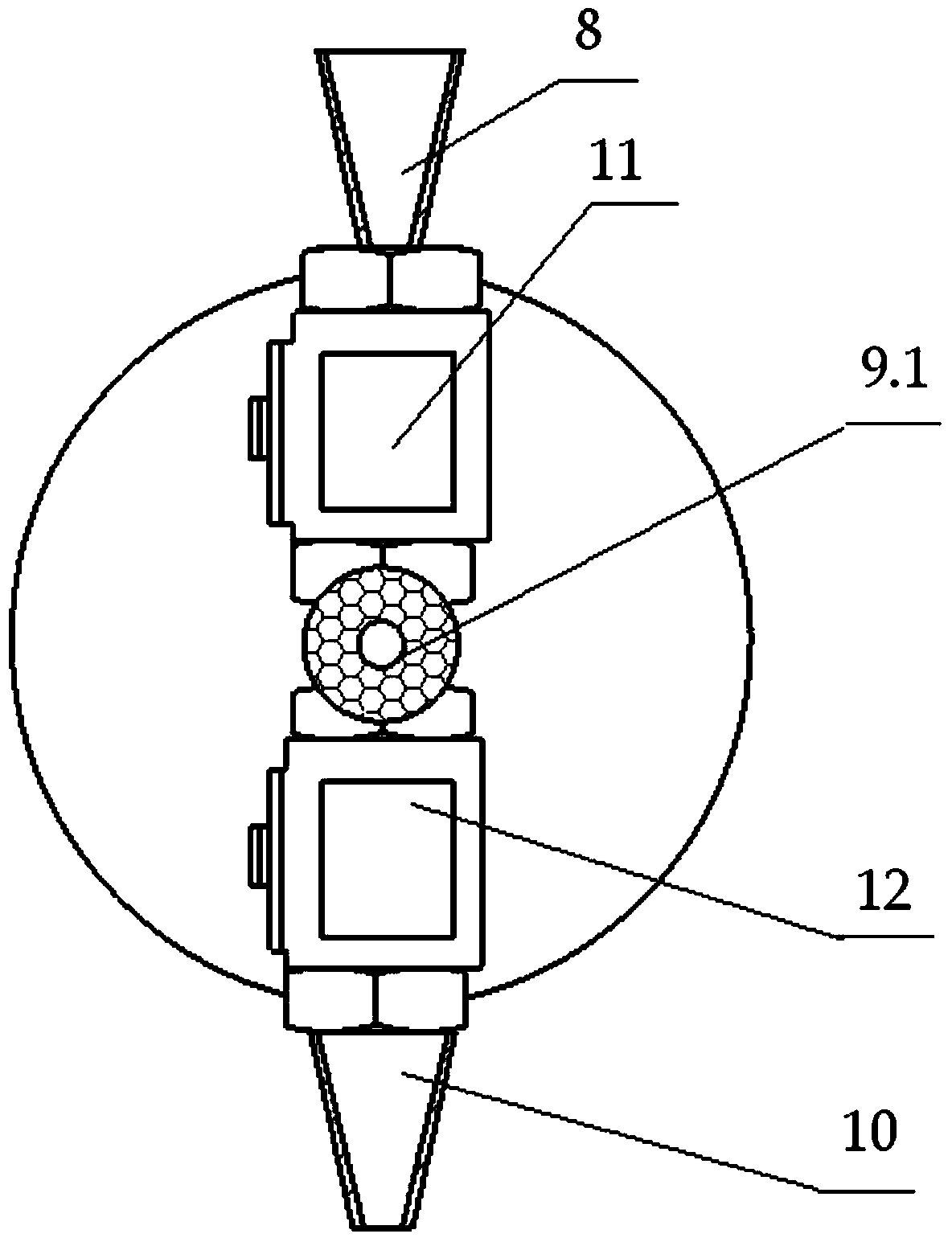

[0026] The present invention provides a steam soot blower of a novel multifunctional soot blowing tube, comprising:

[0027] The soot blowing pipe 1 is wrapped with two parallel conveying pipes: the steam conveying pipe 2 and the high-temperature water conveying pipe 3, the steam conveying pipe is used for conveying steam, and the high-temperature water conveying pipe is used for conveying high-temperature water,

[0028] The fluid switch control unit 4 includes a power supply 4.1, a steam switch solenoid valve 4.5, a high temperature water switch solenoid valve 4.6, a switch 1 (4.2), a switch 2 (4.3) and a switch 3 (4.4). On the pipe, the high-temperature water switch solenoid valve is installed on the high-temperature water delivery pipe, and the power supply, switch 1, swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com