Ash injector fo gas pulsing weak-explosion wave

A gas and pulse technology, applied in the direction of combustion method, removal of solid residue, treatment of combustion products, etc., can solve problems such as insufficient soot blowing energy intensity, poor equipment reliability, and limited range of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

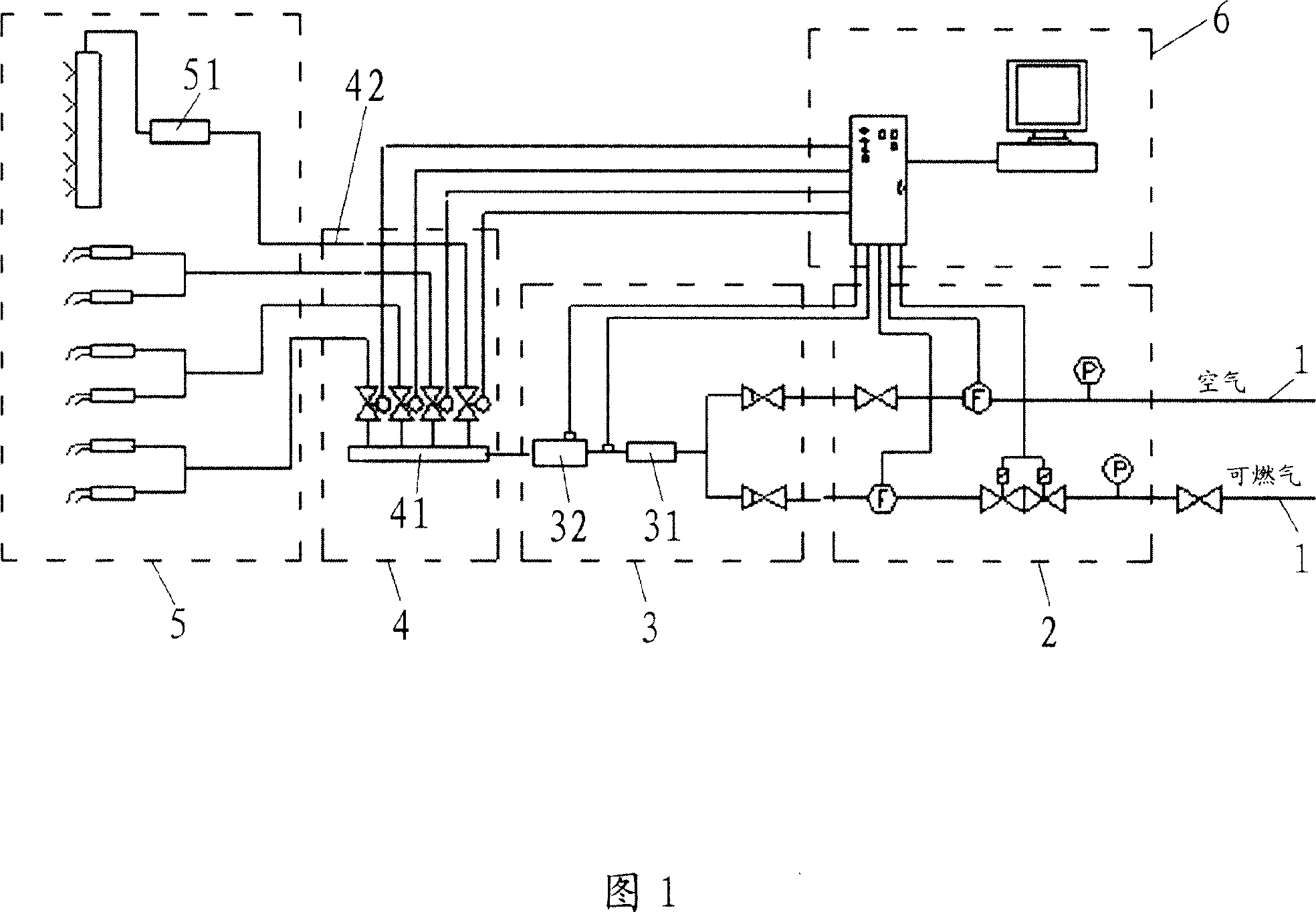

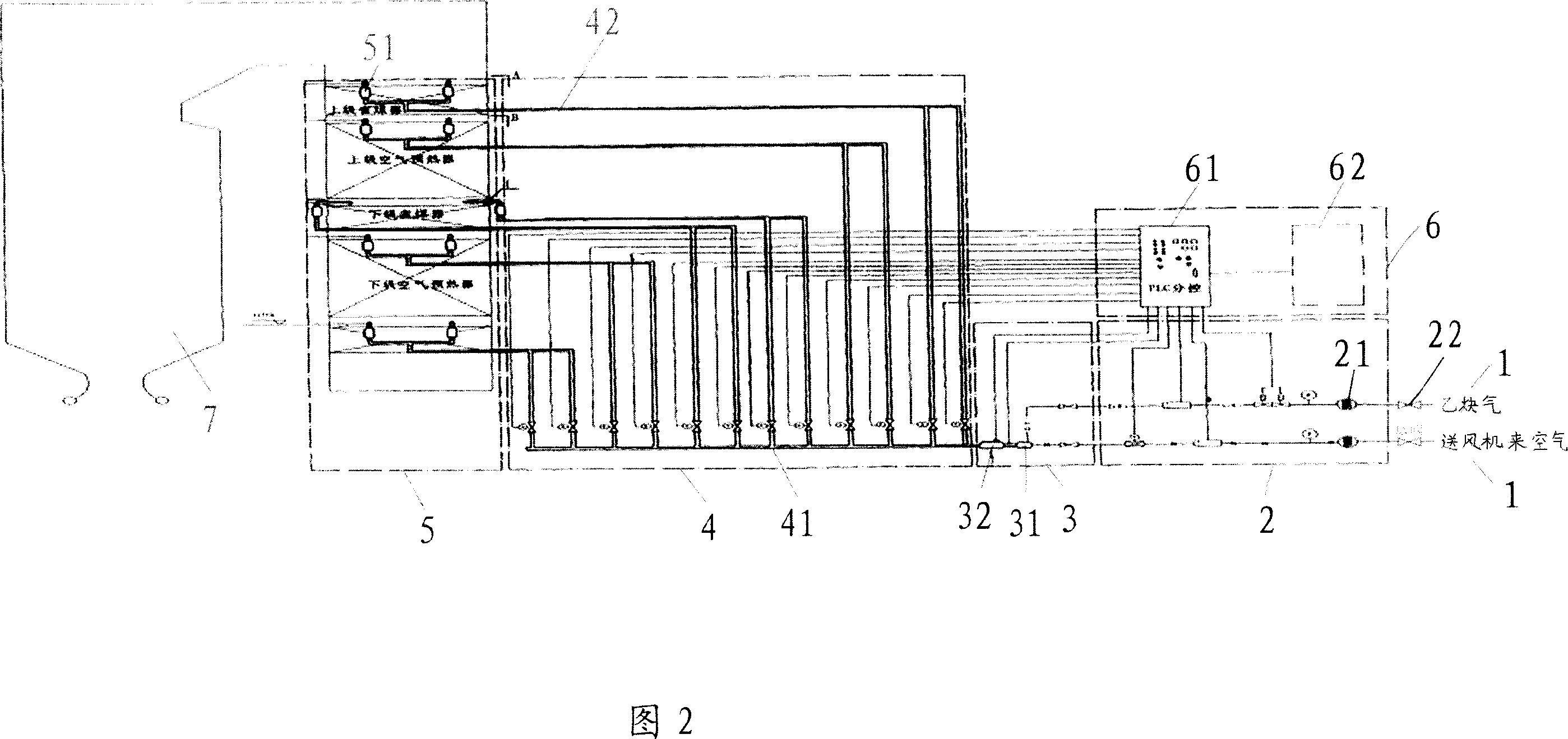

[0022] Fig. 1 and Fig. 2 are respectively the principle diagram and system diagram of the embodiment of the weak blast wave dust cleaner according to the present invention.

[0023] As can be seen from Figures 1 and 2, the weak explosive wave sootblower of this embodiment consists of a gas source 1, a flow measurement unit 2, a mixed ignition unit 3, a soot blowing distribution unit 4, a soot blowing power unit 5 and a soot blowing control unit 6 constitute. Among them, the gas source is composed of air and acetylene gas, and the ratio of air and acetylene gas is controlled by the flow measurement unit 2. In the flow measurement unit 2, the air and acetylene gas pass through the respective ball valve 22 and filter 21 respectively, and pass through the control unit The PLC sub-control in 6 controls the gas flow. Subsequently, air and acetylene gas with an appropriate ratio enter the mixed ignition unit 3, and enter the mixed ignition tank through the check valve respectively, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com