Hydrogen-oxygen heat exploding pulse sootblower

A technology of soot blower and pulse generator, applied in the fields of thermal explosion pulse sootblower and hydrogen-oxygen thermal explosion pulse sootblower, can solve problems such as fuel consumption, achieve improved safety, high explosion intensity, and avoid safety problems and the effect of reliability issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

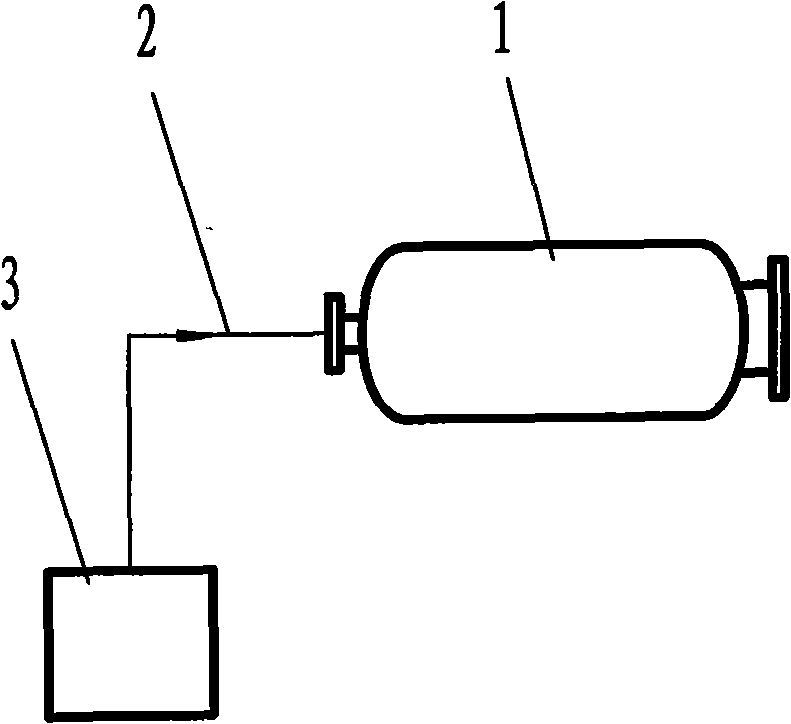

Embodiment 1

[0020] As shown in Figure 1, the thermal explosion pulse sootblower of this embodiment mainly includes a pulse generator 1, a mixed gas pipeline 2, an electrolyzed water-oxygen generator 3; the outlet of the electrolyzed water-hydrogen generator 3 and the pulse generator The inlets of 1 are connected through the mixed gas pipeline 2; the output of the electrolyzed water hydrogen-oxygen generator 3 is hydrogen-oxygen mixed gas.

[0021] When carrying out soot blowing operation, first energize the electrolytic water hydrogen-oxygen generator 3 to generate hydrogen-oxygen mixed gas, which is sent to the pulse generator 1 through the mixed gas pipe 2, and the hydrogen-oxygen mixed gas filled in the pulse generator 1 meets the requirements , the hydrogen-oxygen mixture in the pulse generator 1 can be detonated.

Embodiment 2

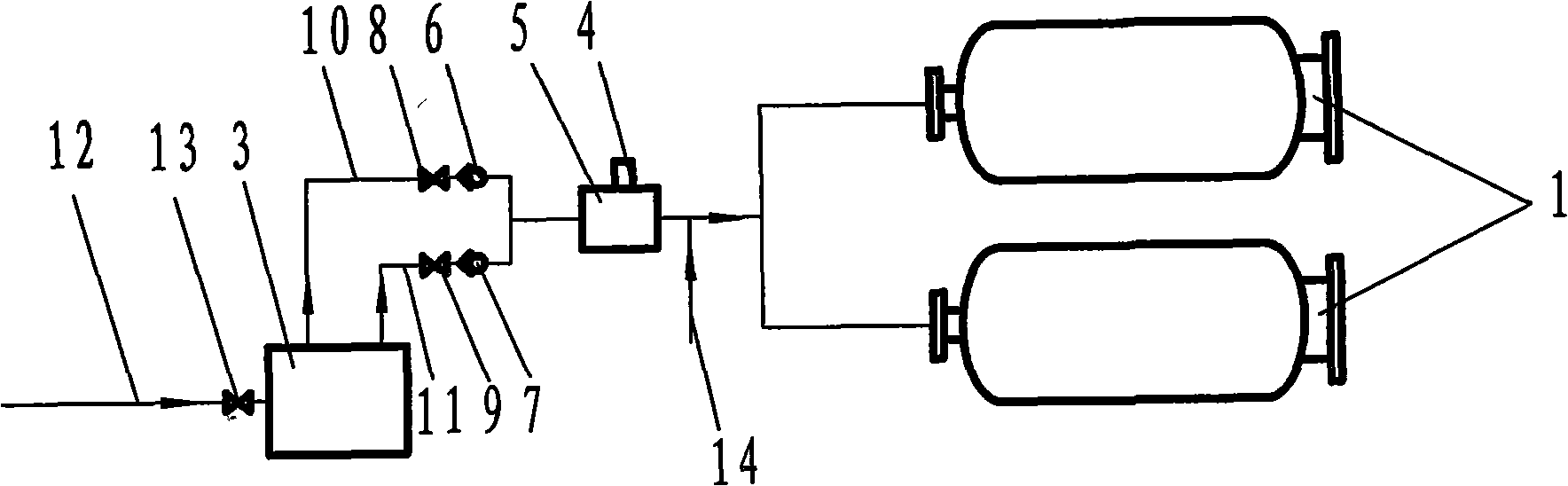

[0023] As shown in accompanying drawing 2, the thermal explosion pulse soot blower of the present embodiment mainly includes a pulse generator 1, a mixed gas pipeline 2, an oxygen pipeline 10, a hydrogen pipeline 11, and an electrolyzed water hydrogen-oxygen generator 3; The oxygen generator 3 is connected with the pulse generator 1 through the oxygen pipeline 10, the hydrogen pipeline 11 and the mixed gas pipeline 2. A replenishment valve 13 is connected in series; an oxygen switch valve 8 and a check valve 6 are connected in series on the oxygen pipeline 10 along the gas flow direction, and a hydrogen switch valve 9 and a check valve are connected in series on the hydrogen pipeline 11 along the gas flow direction. Valve 7; a mixer 5 is connected in series on the hydrogen-oxygen mixture pipeline 2, and another purge gas pipeline 14 is connected to the hydrogen-oxygen mixture pipeline, and the ignition head 4 is installed on the mixer 5.

Embodiment 3

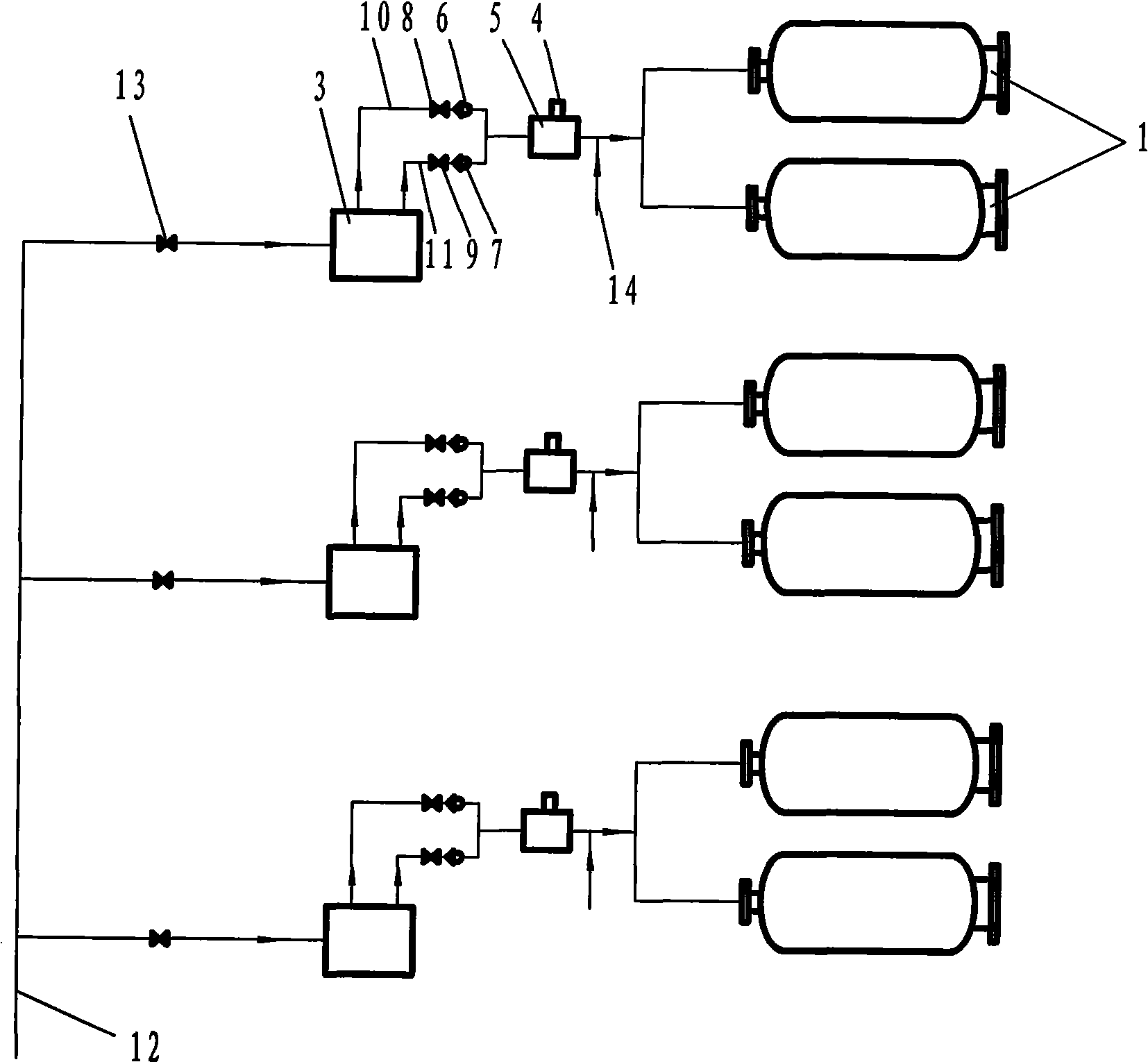

[0025] As shown in FIG. 3 , the thermal explosion pulse soot blower of this embodiment mainly includes three soot blowing units as described in embodiment 2, and these three soot blowing units are connected in parallel on the water supply pipe 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com