Coal-fired boiler shaft flue with sonic soot blowers

A technology for a sonic sootblower and a coal-fired boiler, which is applied in the field of coal-fired boilers, can solve the problems of large maintenance workload, large workload and cost, and will be stuck, and achieves low input efficiency and large maintenance workload. , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

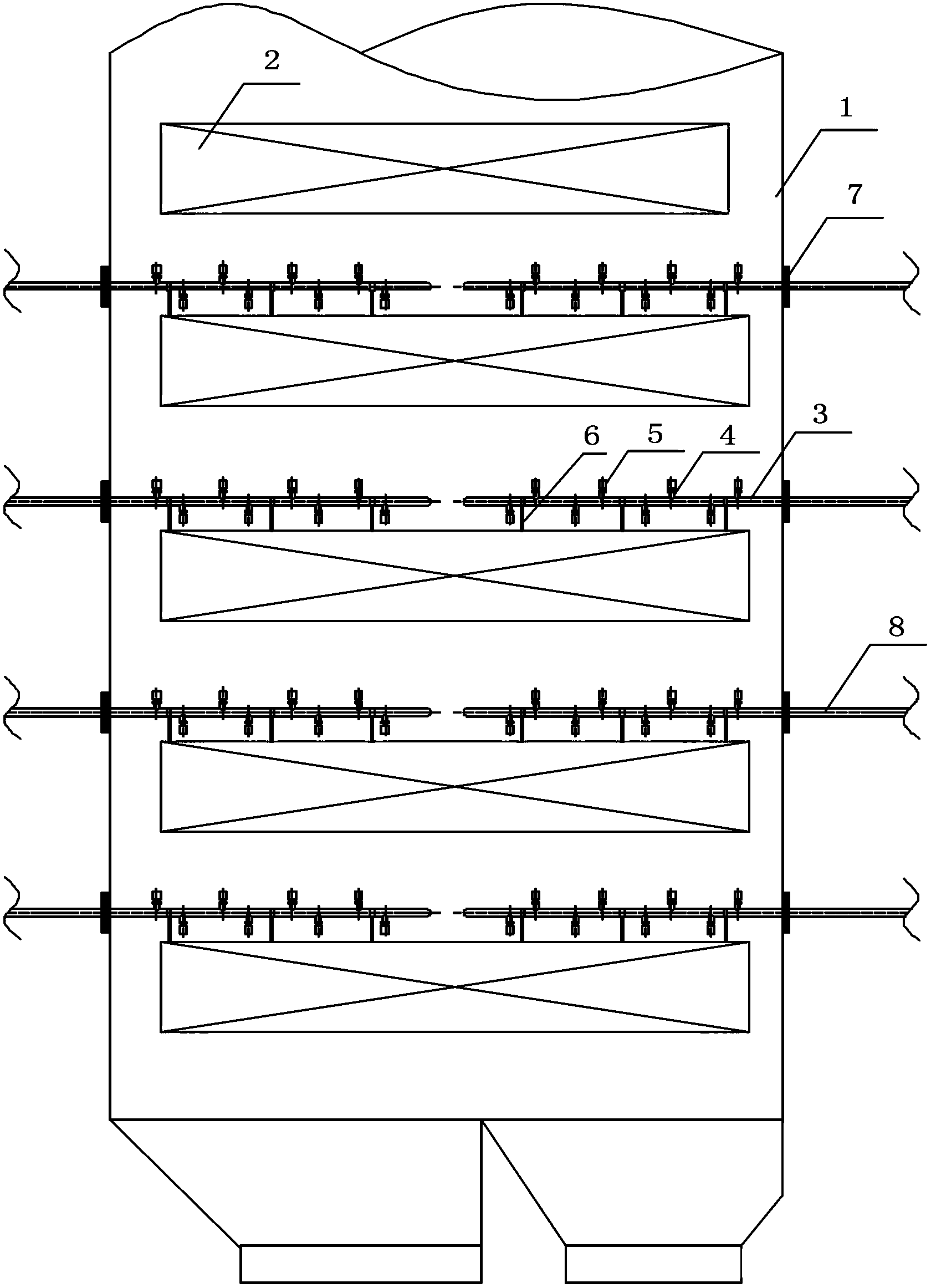

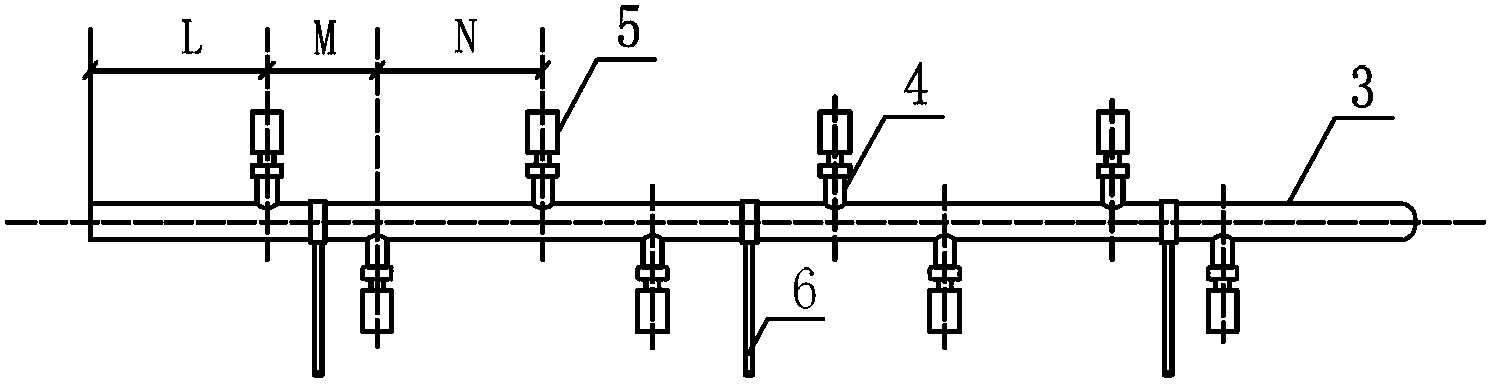

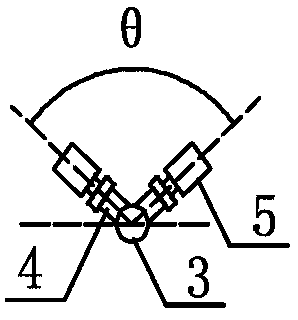

[0018] The shaft flue of the coal-fired boiler with the sonic soot blower proposed by the present invention has a structure such as figure 1 As shown, it includes a heat exchanger 2 , multiple pairs of main pipes 3 and multiple sonic soot blowers 5 . Multiple pairs of main tubes 3 are evenly distributed along the cross section of the boiler, one end of each pair of main tubes is opposite to each other and is in the center of the boiler, the other end of each pair of main tubes protrudes from the boiler wall, and the end of the main tube protrudes from the boiler wall The part is connected with the steam supply main pipe 8 outside the boiler by welding. The heat exchanger 2 and multiple pairs of main pipes 3 are installed in the shaft flue 1 at intervals, and the main pipes 3 are relatively fixed to the heat exchanger 2 through the main pipe support 6 . A plurality of sonic sootblowers 5 are installed on the main pipe 3 through the base pipe 4 .

[0019] The sonic soot blower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com