Patents

Literature

52results about How to "Solve the leaky seal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

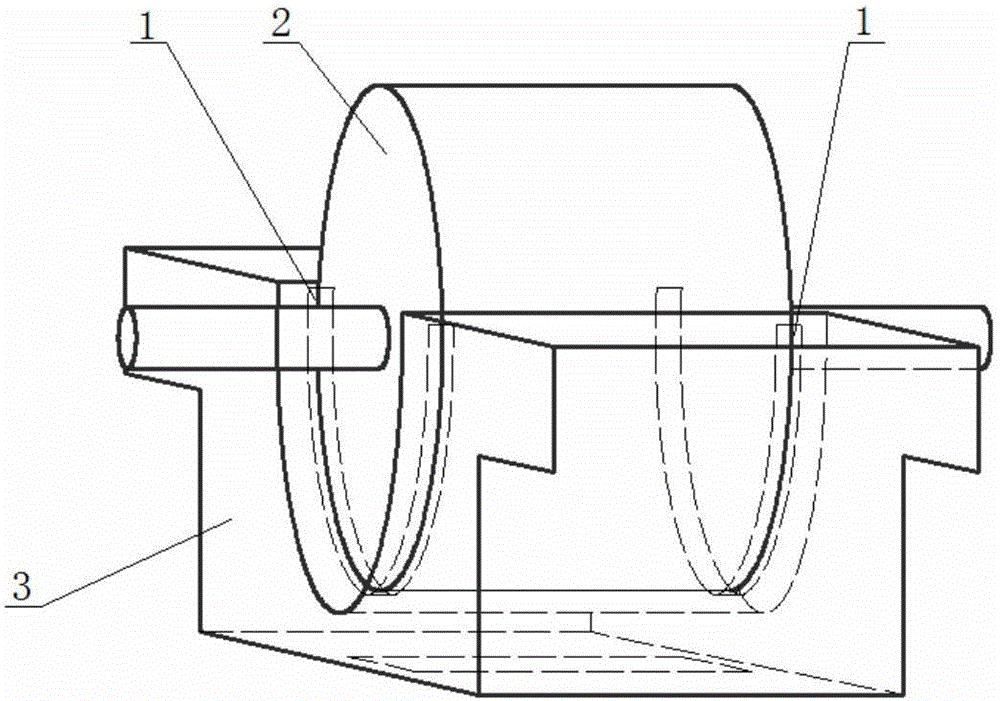

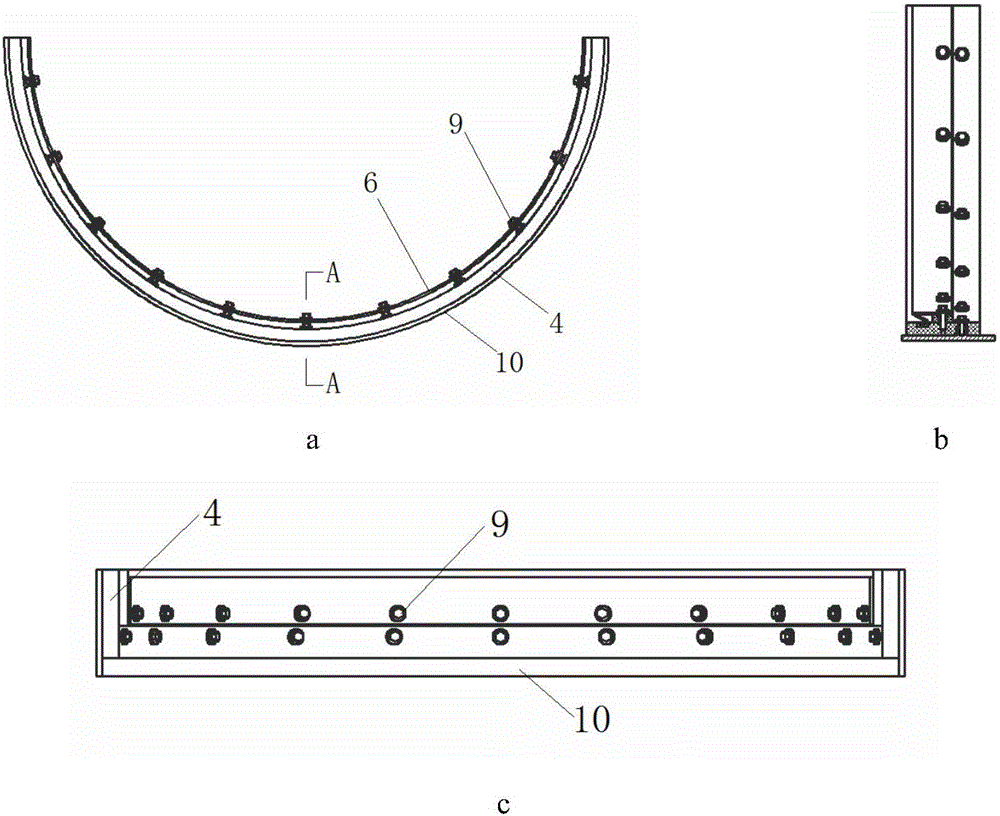

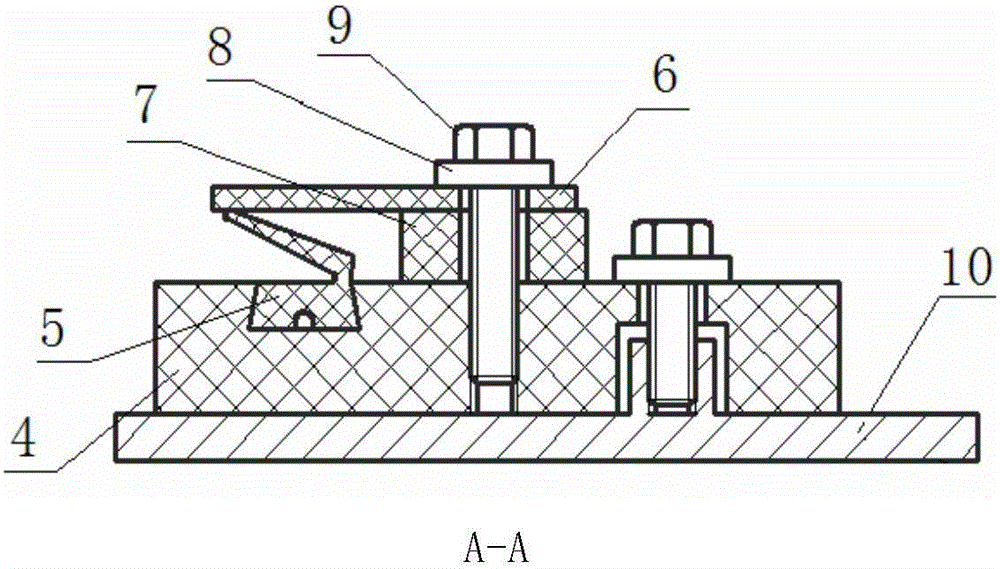

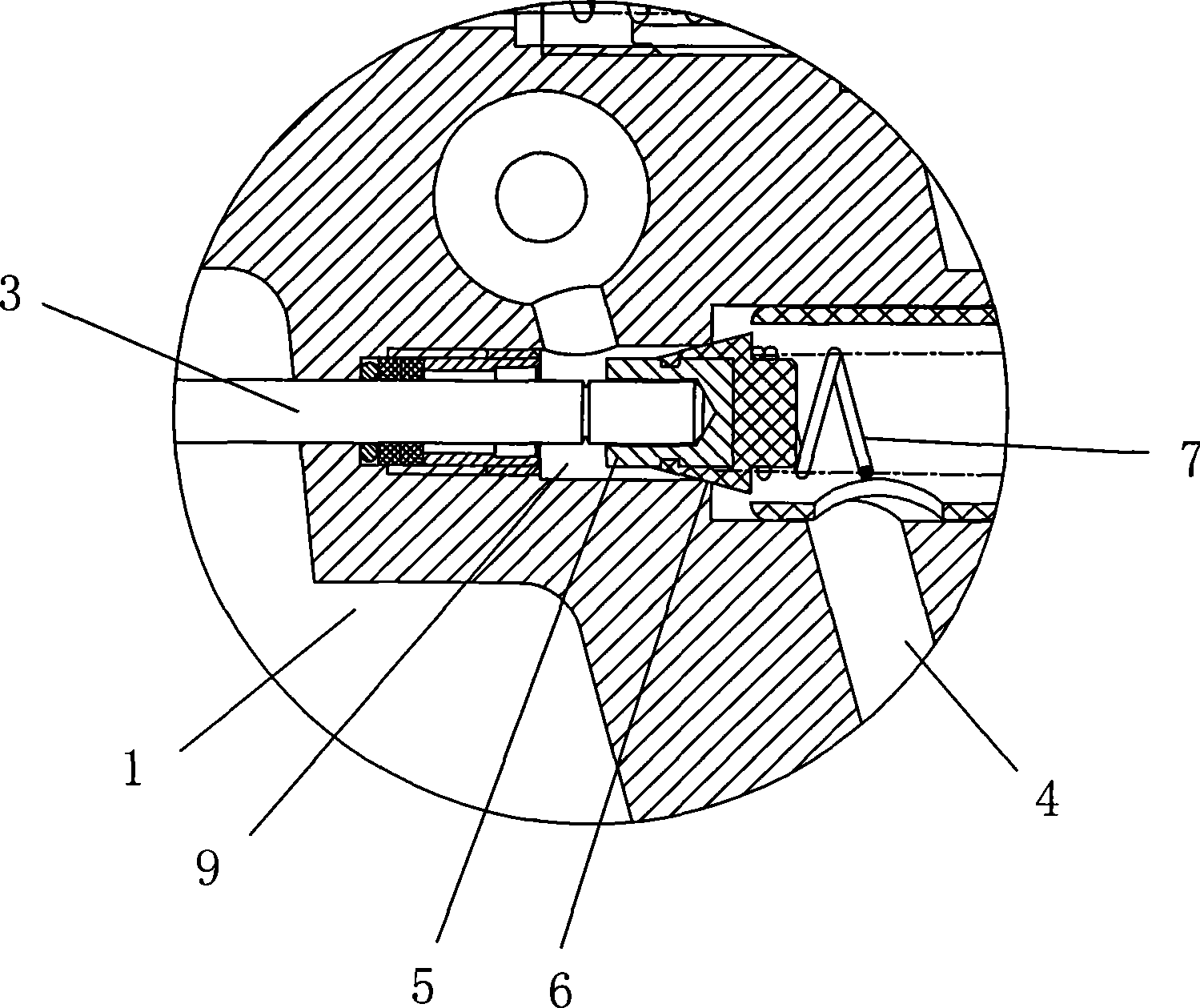

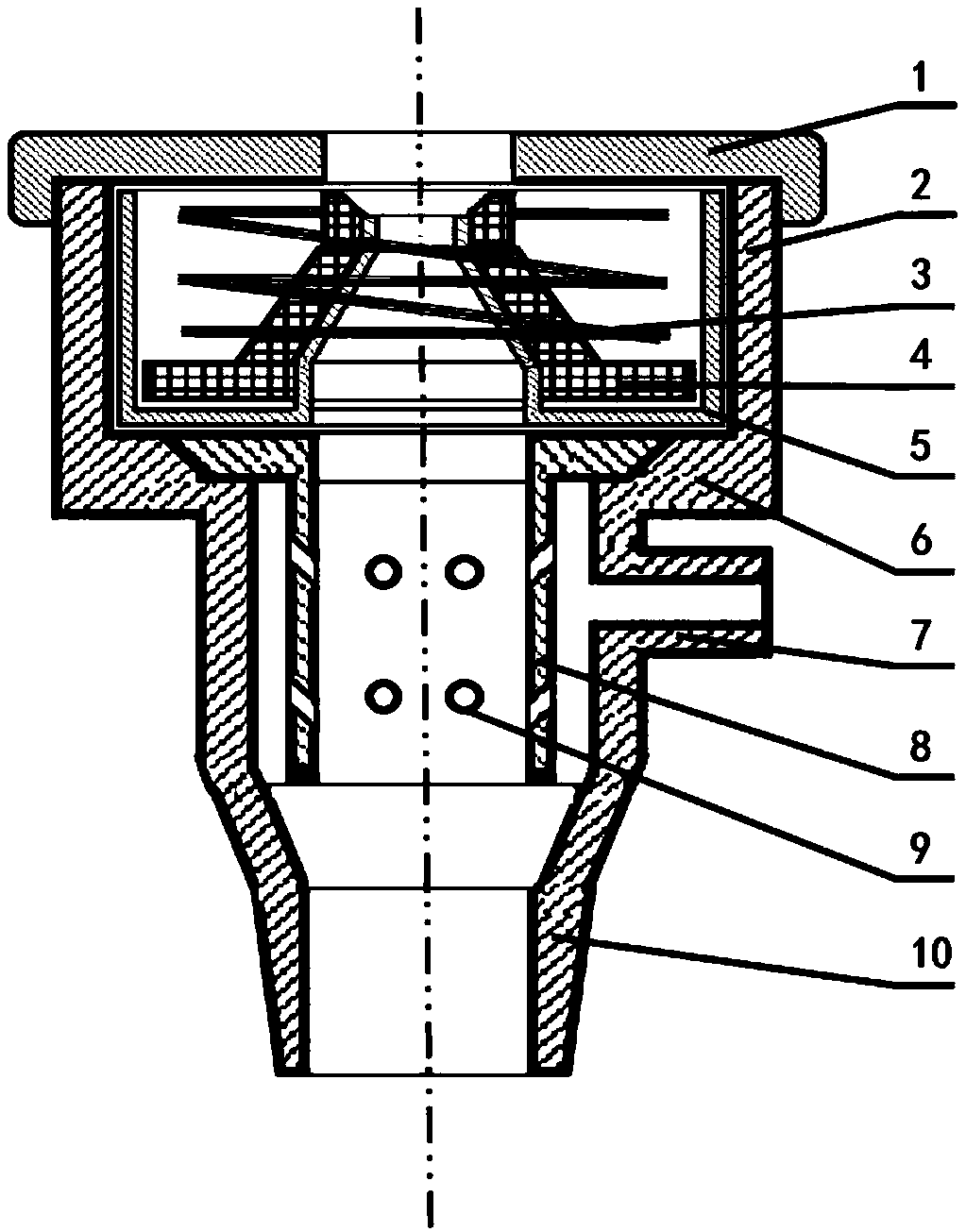

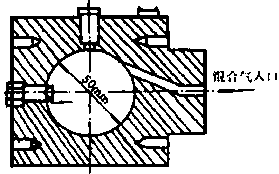

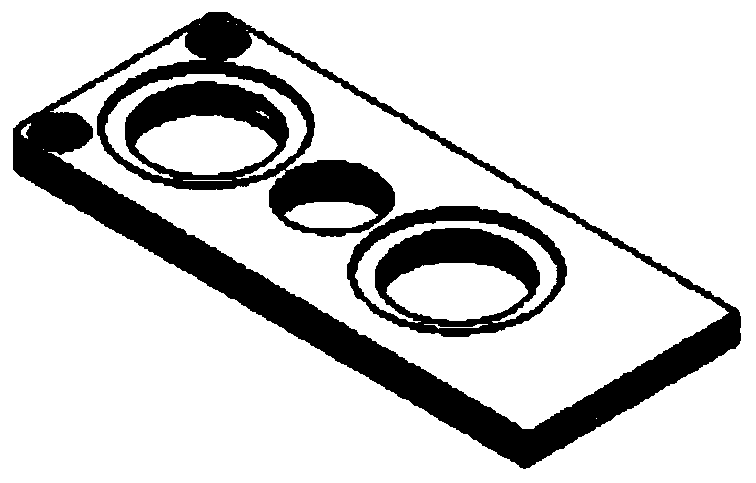

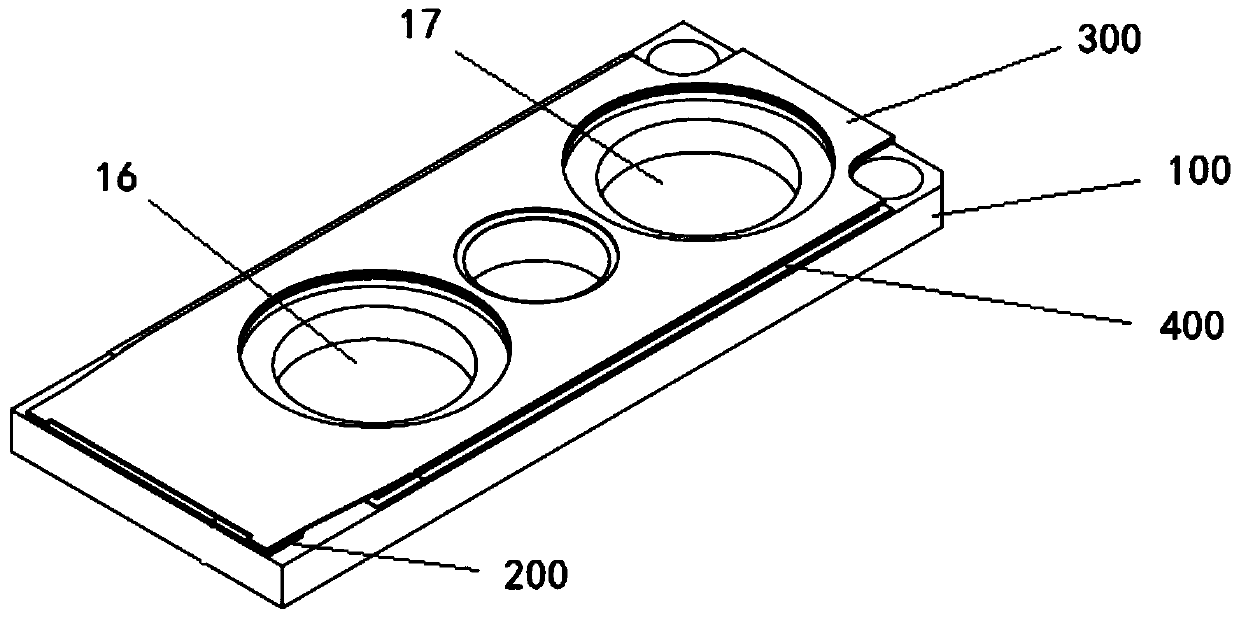

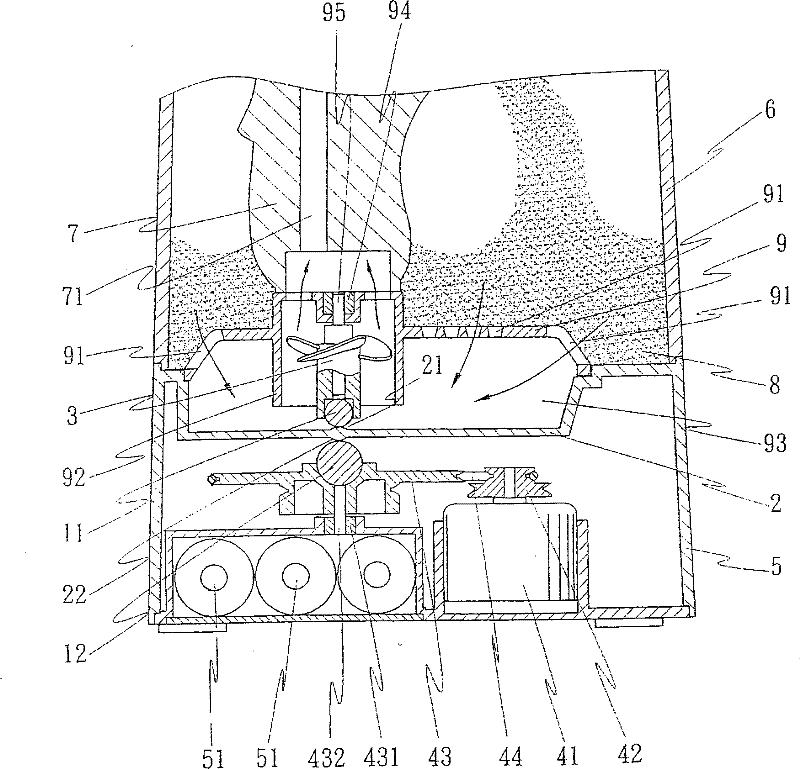

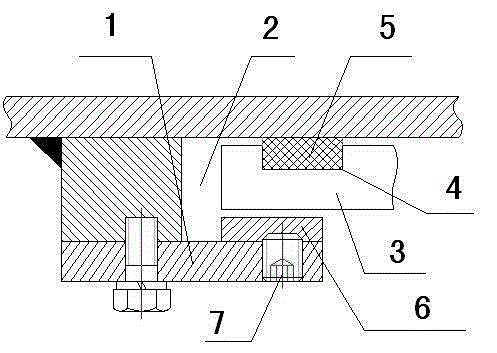

Sealing device for anode groove and cathode roller of crude foil engine

InactiveCN106400061ASolve the leaky sealSolve side leakageSealing devicesElectroforming processesShock coolingEngineering

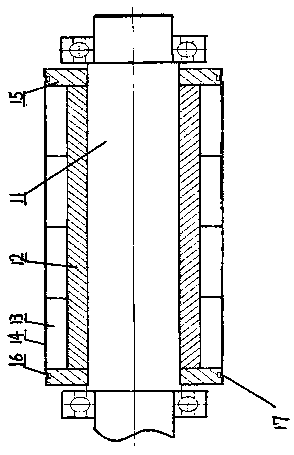

A sealing device for an anode groove and a cathode roller of a crude foil engine is characterized in that a semi-arc-shaped lip sealing strip baseplate is fixed on the inner surface of a lining plate, a sealing plate base plate is fixed on the upper surface of the lip sealing strip baseplate, a lip sealing strip is located on one side of the upper surface of the lip sealing strip baseplate, the lower end of the lip sealing strip is embedded into a dovetail groove in the upper surface of the lip sealing strip baseplate to be fixed, a sealing plate is fixed on the upper surface of the sealing plate base plate, and one side edge of the sealing plate covers the upper surface of the lip sealing strip. The adopted polytetrafluoroethylene sealing plate is resistant to shock cooling and shock heating and chemical corrosion, has high lubricating non-sticky performance and favorable electric insulativity and ageing resistance, is combined with the lip sealing strip to make up for the shortcoming of high frictional resistance of an EPDM lip sealing strip, and replaces the EPDM lip sealing strip to be in contact with the cathode roller, so that the sealing is tight and reliable, the problem of side leakage of a PVC end plate is solved, and normal running of the cathode roller is guaranteed.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

Chemical wastewater reaction tank wastewater sampling device

InactiveCN112229677AStir wellSolve the problem of inconvenient moving upWithdrawing sample devicesWater storageProcess engineering

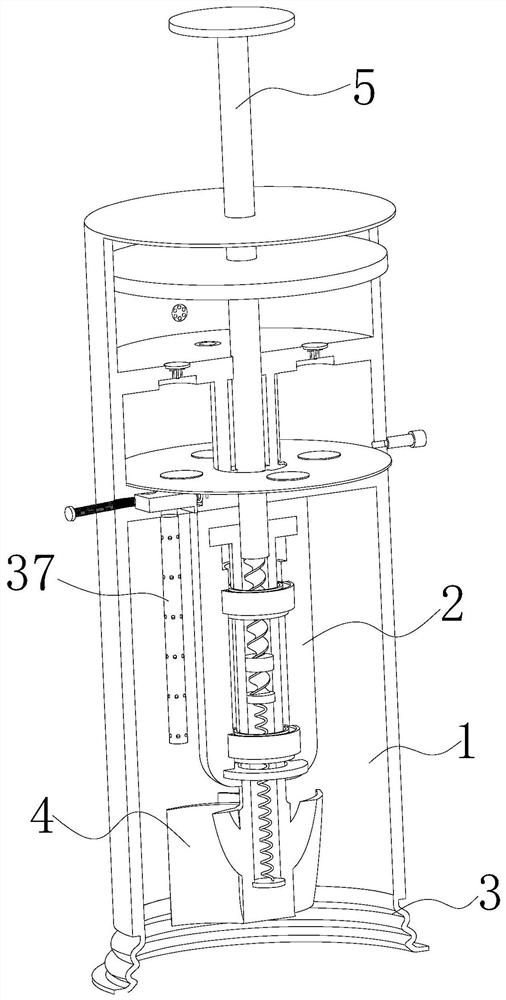

The invention provides a chemical wastewater reaction tank wastewater sampling device, and relates to the field of chemical wastewater treatment. The chemical wastewater reaction tank wastewater sampling device comprises a sampling barrel, a sleeve is fixedly mounted in the sampling barrel, a telescopic sealing gasket is fixedly mounted at the bottom end of the sampling barrel, a rotating mechanism is rotatably connected into the sleeve, and a pressing mechanism is rotatably connected into the rotating mechanism, penetrates through the sampling barrel and extends to the position above the sampling barrel; and the sampling barrel is divided into a stirring cavity, a water storage cavity and an exhaust cavity, and the stirring cavity is located at the bottommost part. According to the chemical wastewater reaction tank wastewater sampling device, by arranging the center rod and the spiral steel bar, wastewater in the stirring cavity can be stirred through vertical movement of the center rod, air in the water storage cavity is pumped out through the piston sleeve to form negative pressure, and after the threaded shaft is rotated, the stirred wastewater can be automatically stored in the water storage cavity, so that the problems that in the prior art, a reaction tank is large in area, stirring is not easy, and stratified sampling operation is inconvenient are solved.

Owner:田庆丰

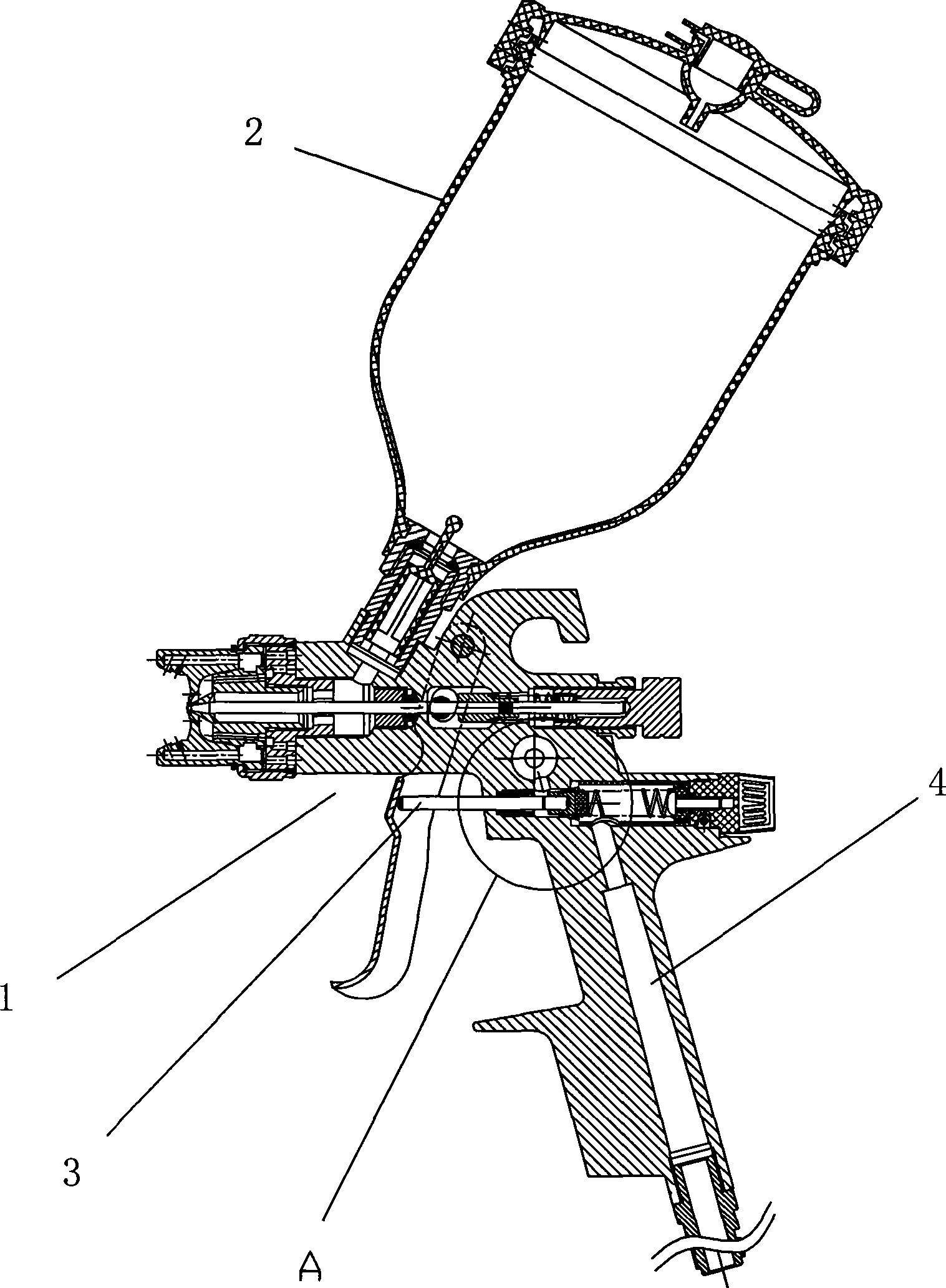

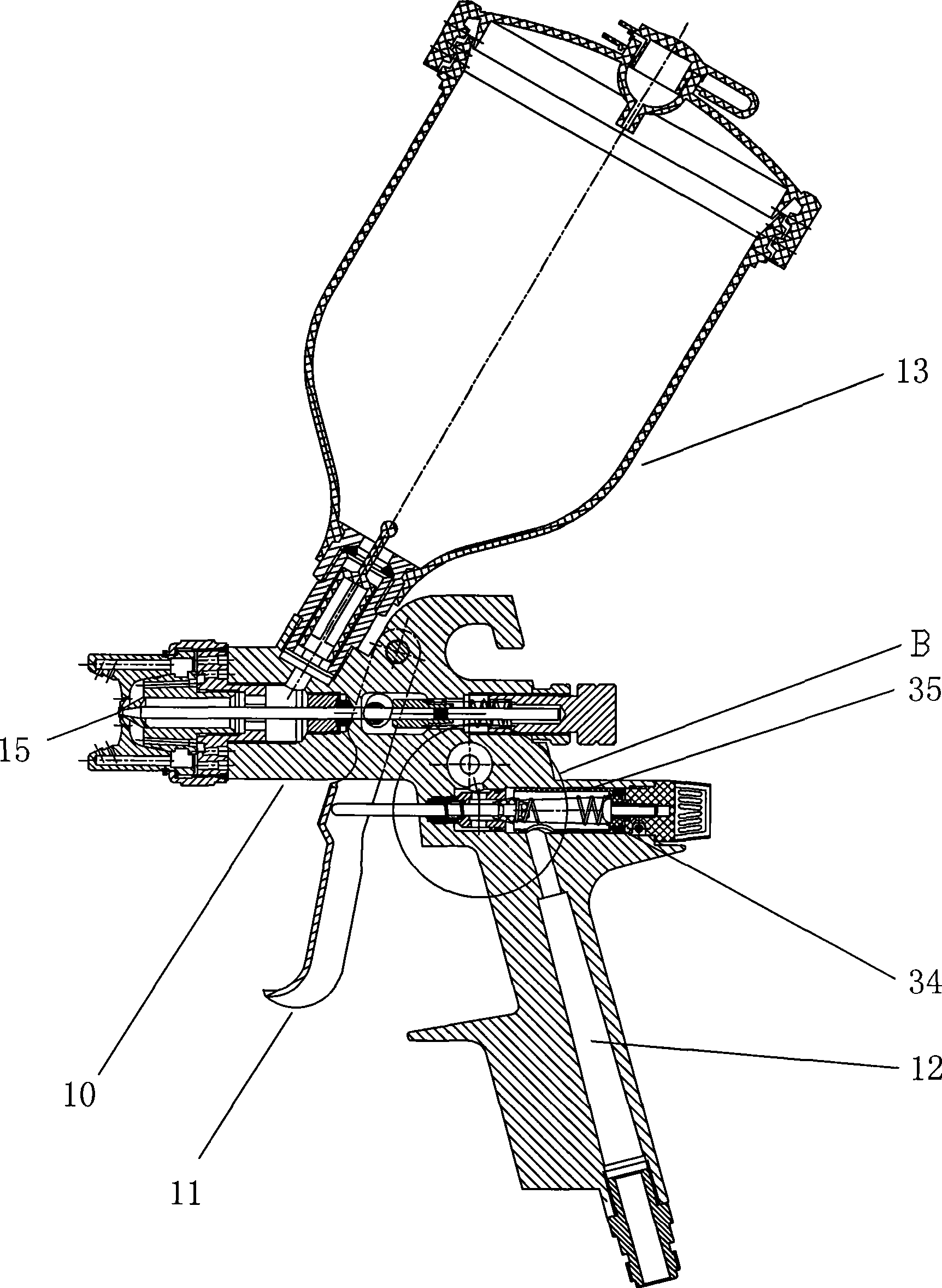

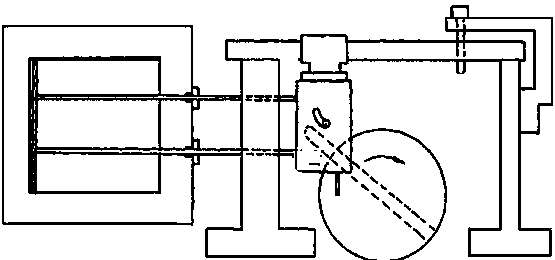

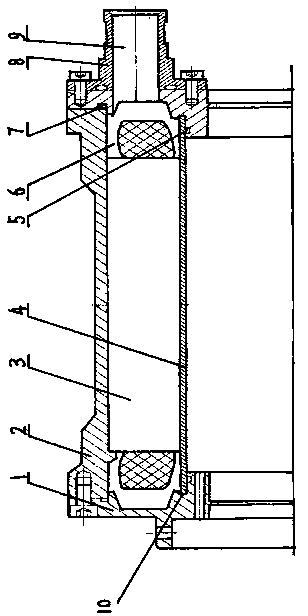

Air-intake control device of paint spray gun

InactiveCN101543808ASolve the leaky sealImprove impact resistanceSpraying apparatusLacquerEngineering

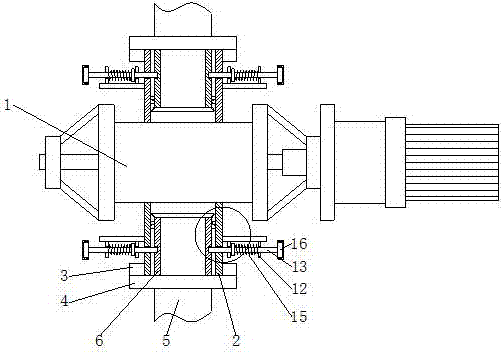

An air-intake control device of paint spray gun belongs to the technology field of paint spray gun, which includes the valve chamber setup in the middle of air-draft manifold assembly of the gun, the valve core setup at the valve spindle and offsetting spring. In the valve chamber there is a running-liner with the clack seat at one side, the valve spindle is setup in the through hole of the running-liner, the radial burn-out pipe connected with spraying lacquer out spout of the paint spray gun is setup at the through hole in the middle of the running-liner, one side of the valve spindle sticks out of the gun body after sealed by the sealed ring while at the other side of the valve spindle there is the valve core with offsetting spring outside combining with clack seat to open and close the induction trunk, at the other side of the offsetting spring there is a sealing cushion. This invention accounts for the problem of the valve chamber wall easy to leaking, the hermeticity of the products is good, the sealing member is not liable to attaint for the valve core and sealing member employ the corrosion resistant materials, and the life time of the product is long.

Owner:ZHEJIANG REFINE WUFU AIR TOOLS

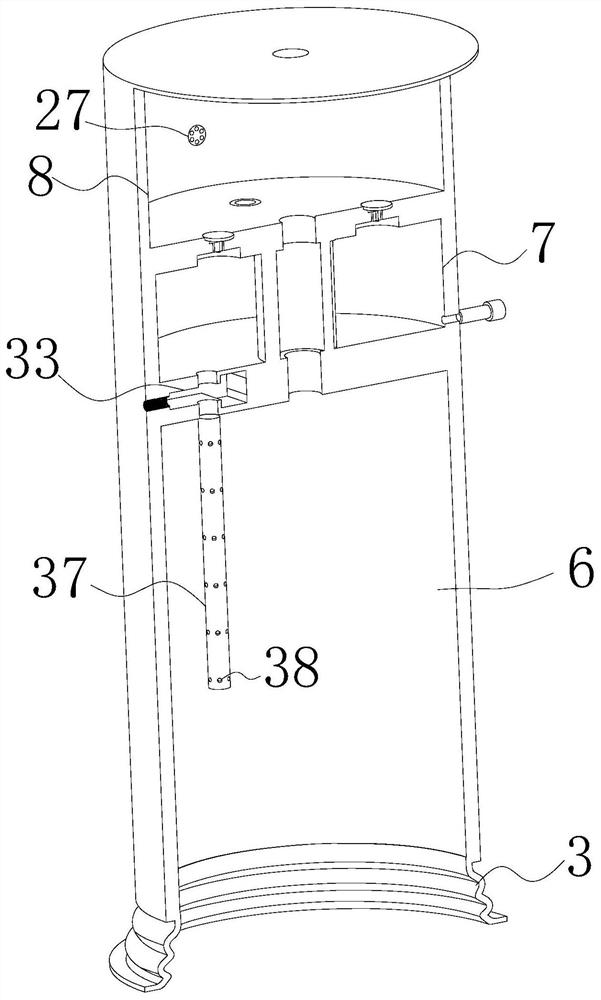

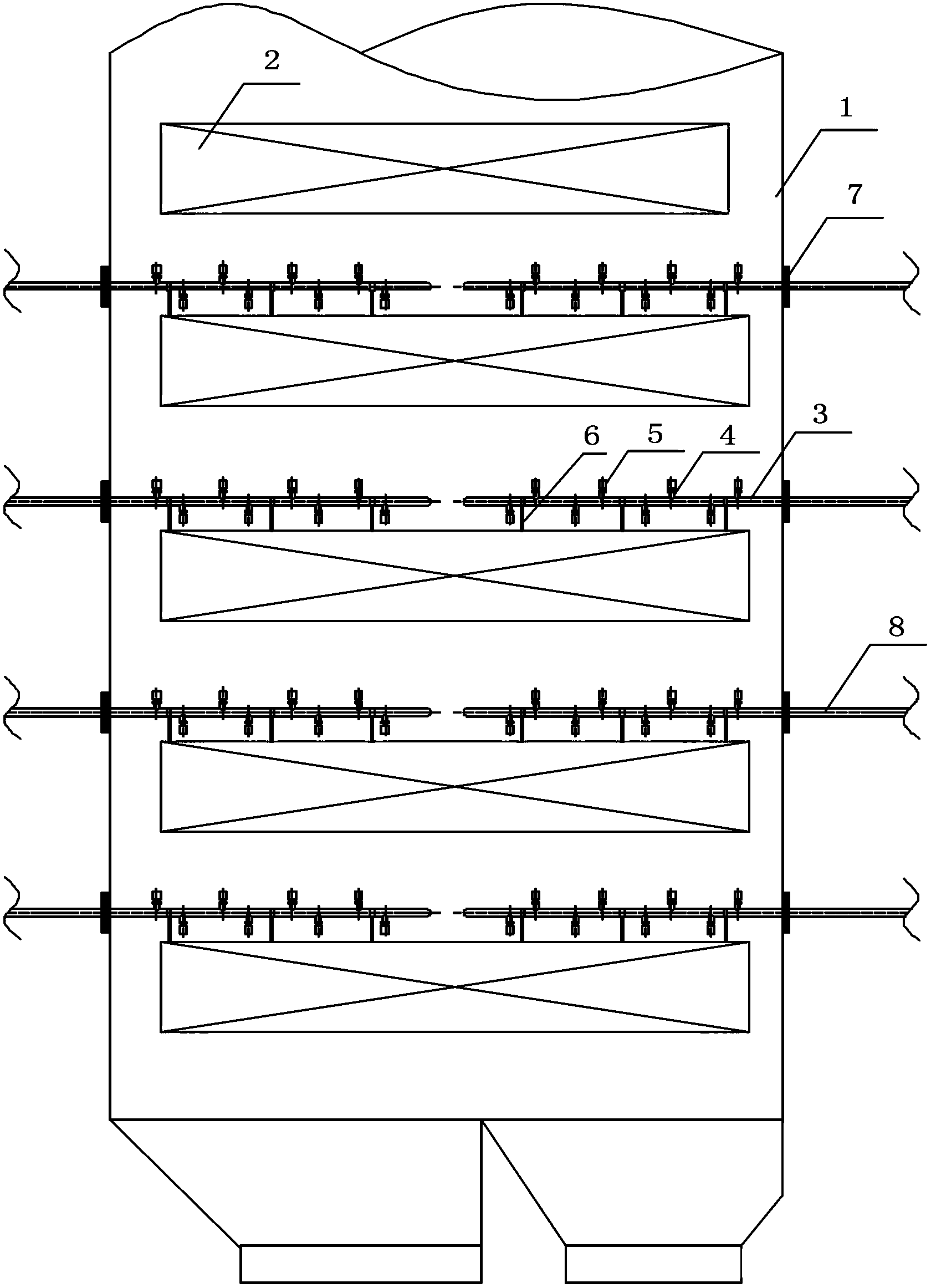

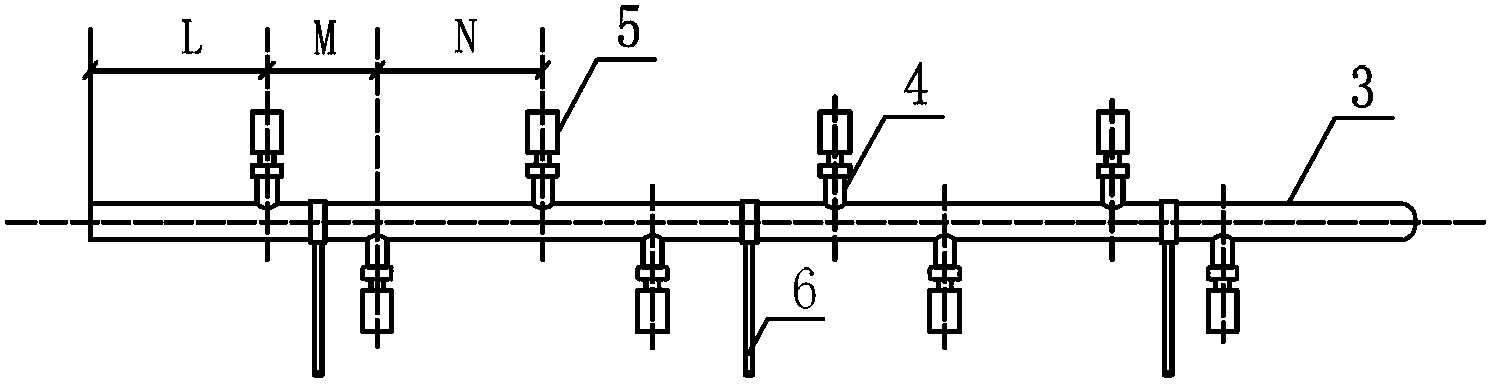

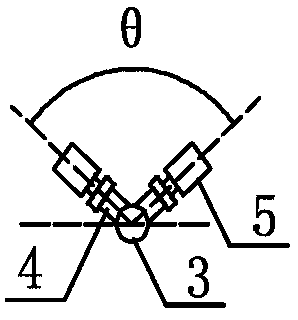

Coal-fired boiler shaft flue with sonic soot blowers

The invention relates to a coal-fired boiler shaft flue with sonic soot blowers and belongs to the technical field of coal-fired boilers. The coal-fired boiler shaft flue with the sonic soot blowers comprises heat exchangers, a plurality of pairs of primary pipes and the sonic soot blowers, wherein the pairs of primary pipes are evenly distributed along the cross section of a boiler, one end portions of each pair of primary pipes are opposite to each other and located in the center of the boiler, the other end portions of each pair of primary pipes extend out of the wall of the boiler respectively, and the end portions, extending out of the wall of the boiler, of the primary pipes are connected with steam supplying primary pipes outside the boiler in a welding mode. The heat exchangers and the pairs of primary pipes are installed in the shaft flue in a mutually spaced mode, and the primary pipes are fixed opposite to the heat exchangers through primary pipe supports. The sonic soot blowers are installed on the primary pipes through base pipes. The coal-fired boiler shaft flue has the advantages of being efficient, safe and energy-saving, promotes safety of the boiler, and can be free from daily tedious maintenance work. The sonic soot blowers are arranged in the boiler, and are free of rotating components and reliable in sealing.

Owner:张晨

One-way valve

Owner:CHANGZHOU XINJIANGNAN ENERGY EQUIP

Polarization-regulating energy-saving vertical sealing device

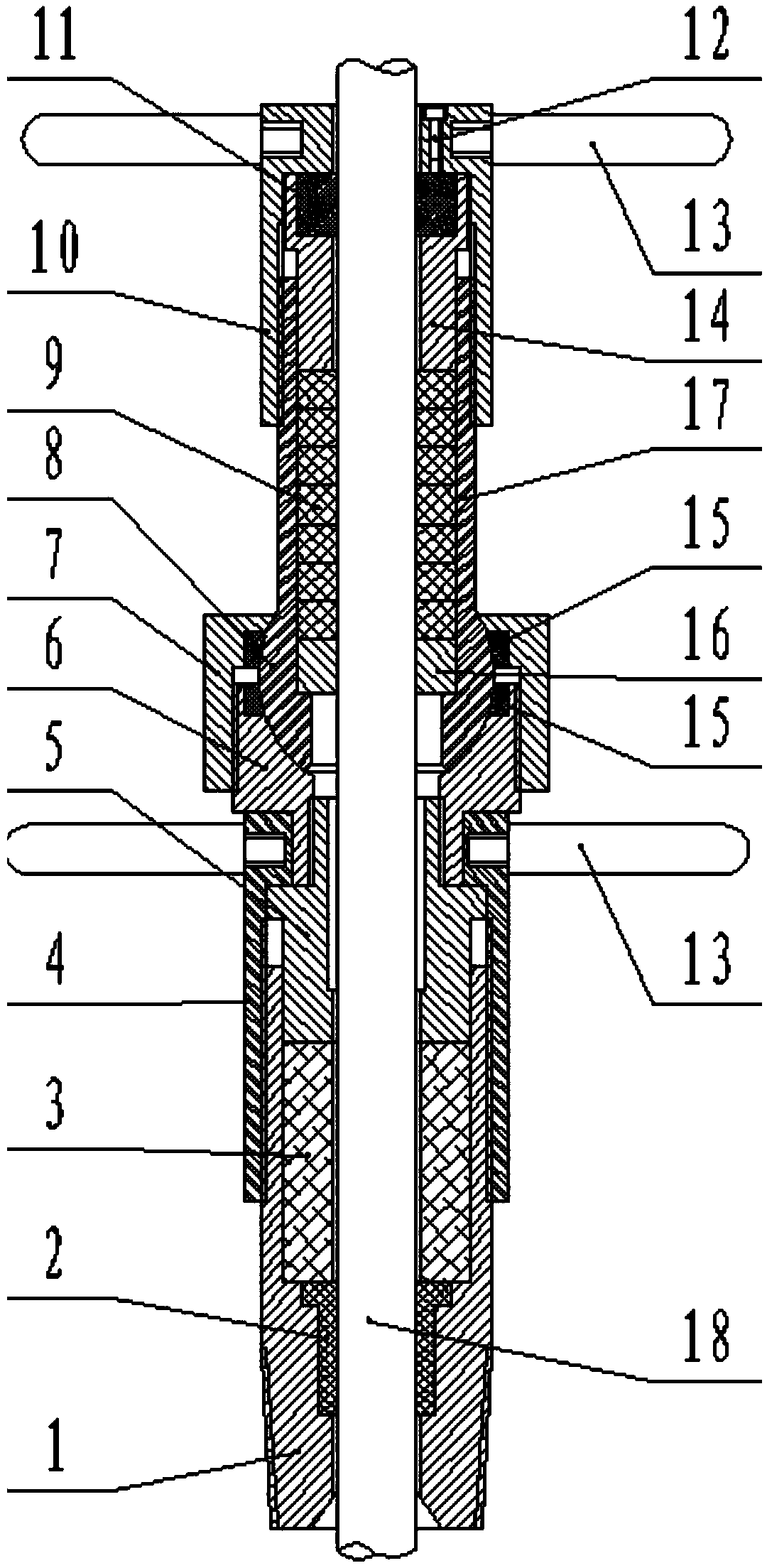

InactiveCN108868685ASolve the leaky sealEasy to operateDrilling rodsPositive displacement pump componentsEngineeringOil production

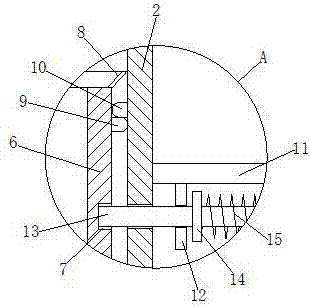

The invention belongs to the technical field of oil production equipment and particularly relates to a polarization-regulating energy-saving vertical sealing device. The device comprises a polished rod sealing device and a sealing device, a sucker rod is worn in the middle of the polished rod sealing device and the sealing device; the polished rod sealing device comprises an adjusting sleeve, a packing gland, a packing root, a supporting ring and a packing case, and the inner side of the upper end of the packing gland is provided with an inner stopper. The inner stopper is provided with a feltfor storing lubricating grease. The adjusting sleeve is provided with an oil hole sealing device corresponding to the felt. The sealing device comprises a driving sleeve, a press sleeve, a rubber sleeve and a lower joint. The partial energy-saving vertical sealing device subverts the radial sealing pattern of an existing sealing device, and adopts a vertical sealing pattern, which completely solves the problem that the wellhead sealing is not tight due to uneven force of the sucker rod in the existing sealing device, and the operation is also simpler.

Owner:DAQING RUNXIN PETROCHEM TECH

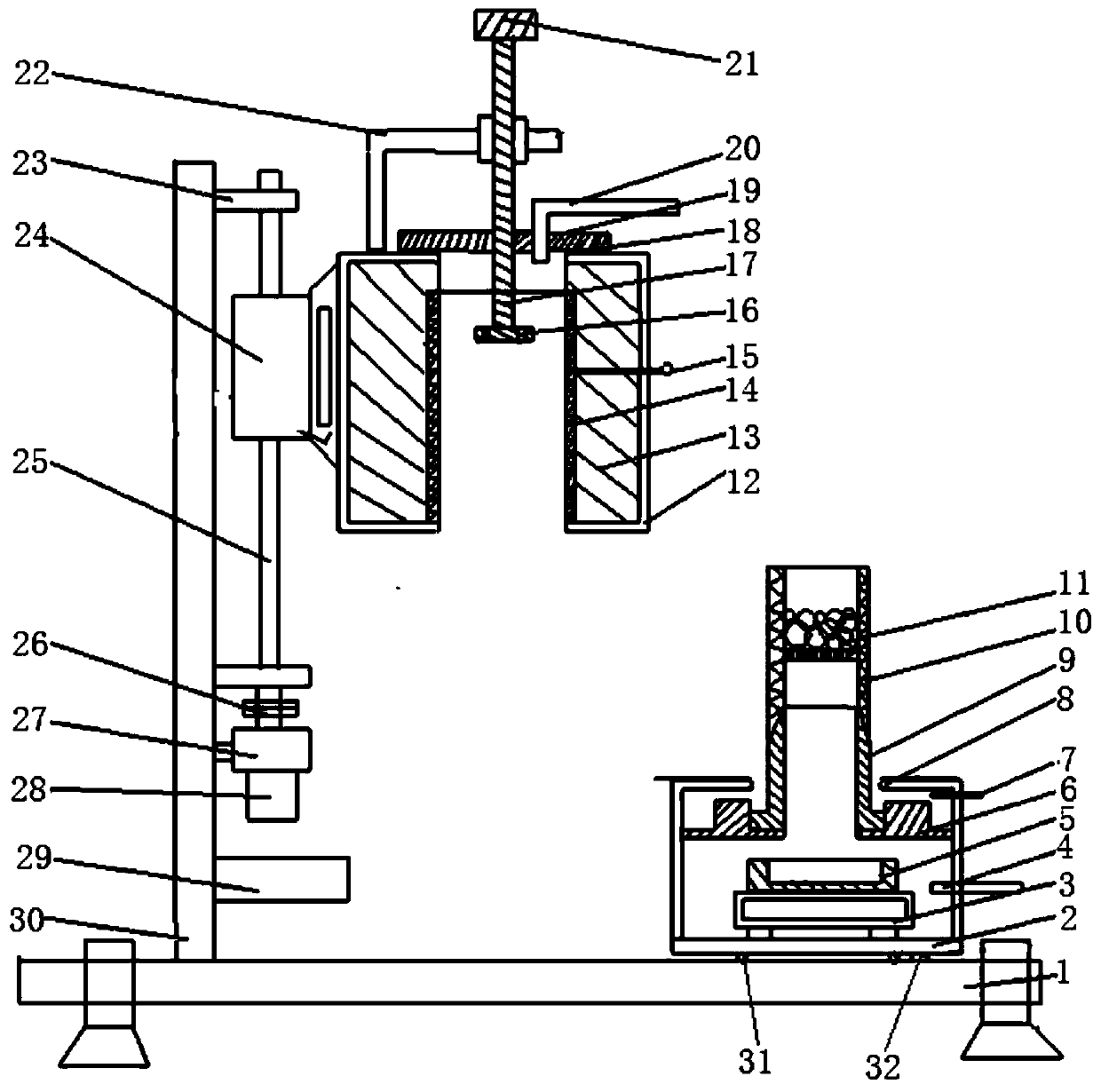

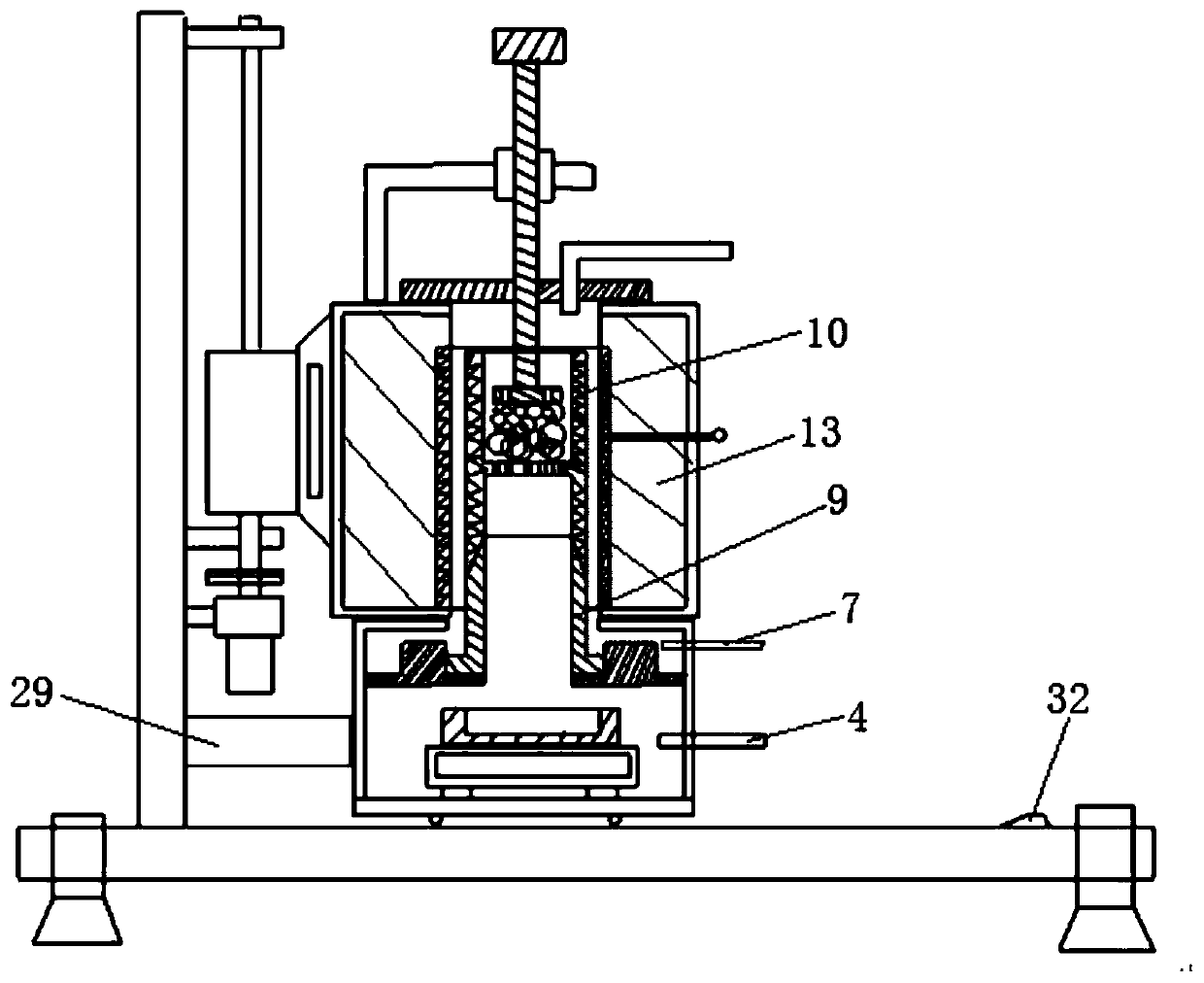

Iron ore high-temperature performance measuring device

PendingCN111380897ASafety inspectionConvenient inspectionMaterial thermal analysisThermodynamicsCrucible

The invention discloses an iron ore high-temperature performance measuring device, and the device comprises a frame mechanism, a lifting mechanism, a heating furnace mechanism, a chassis mechanism, agas distribution mechanism and a loading mechanism; the frame mechanism comprises a horizontal base and a vertical supporting frame installed at one end of the horizontal base; the lifting mechanism is arranged on the vertical supporting frame and can ascend and descend along the vertical supporting frame, and the heating furnace mechanism is fixedly connected with the lifting mechanism. A crucible is arranged on the chassis mechanism, and the chassis mechanism is arranged on the horizontal base and can move to the position below the heating furnace mechanism along the horizontal base; an airinlet pipe of the air distribution mechanism is communicated with an inner cavity of the chassis mechanism, and the loading mechanism extends into the heating furnace mechanism from the upper part toapply pressure to a sample in the crucible. The determination device can be used for taking and placing the crucible more safely, quickly and conveniently, so the detection of the high-temperature performance of the iron ore is safer, lower in consumption, quicker and more accurate.

Owner:BENGANG STEEL PLATES

Righting sucker rod wellhead cleaning device for workover operation and operating method thereof

PendingCN109296323ASolve pollutionPrevent overflowDrilling rodsCleaning apparatusPollutionSucker rod

The invention discloses a righting sucker rod wellhead cleaning device for workover operation and an operating method thereof. The righting sucker rod wellhead cleaning device comprises a main body; agland is arranged at the upper end of the main body, and the lower end of the main body is connected with a tubing coupling through a lower joint; a clamping table is arranged in the main body and separates the main body into an upper sealing cavity and a lower cleaning cavity; an oil scraping sleeve is arranged in the sealing cavity, and a liquid inlet is formed in one side of the exterior of the cleaning cavity; and a sucker rod sequentially passes through the lower joint, the cleaning cavity, the oil scraping sleeve and the gland and then penetrates out. The overall design is adopted, theheight of the device is decreased, wellhead operation is convenient, during closed cleaning, in the sucker rod pulling process of the workover operation, through the sucker rod wellhead cleaning device, sucker rod pulling operation and cleaning operation are carried out synchronously, and the problem of environment pollution caused by sucker rod pulling operation and sucker rod ground cleaning iseffectively solved.

Owner:PETROCHINA CO LTD

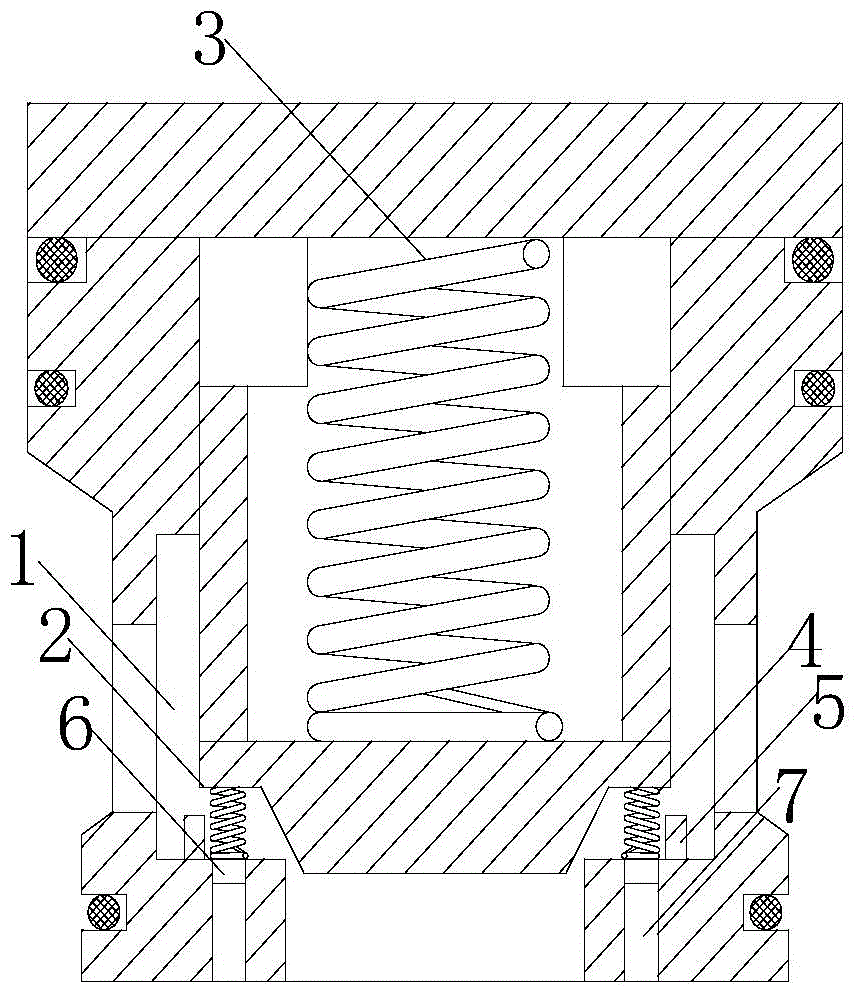

Check valve

The invention relates to a check valve. The check valve comprises a valve body and a valve element installed in the valve body, wherein a supporting spring is arranged on the bottom face of the valve element. The check valve is characterized in that first elastic parts are arranged on the inner wall face of an inlet of the valve body, and baffles are arranged on the portion, where the first elastic parts are opposite to the inlet, of the inner wall face of the valve body. According to the check valve, because the first elastic parts are arranged on the inner wall face of the inlet of the valve body, and the baffles are arranged on the portion, where the first elastic parts are opposite to the inlet, of the inner wall face of the valve body, the upward tension of the valve element is increased, and the problem that the check valve cannot be sealed tightly in the locking process is solved.

Owner:ZHEJIANG XINCHANG SANRUI HORNSEY STAMPING IND

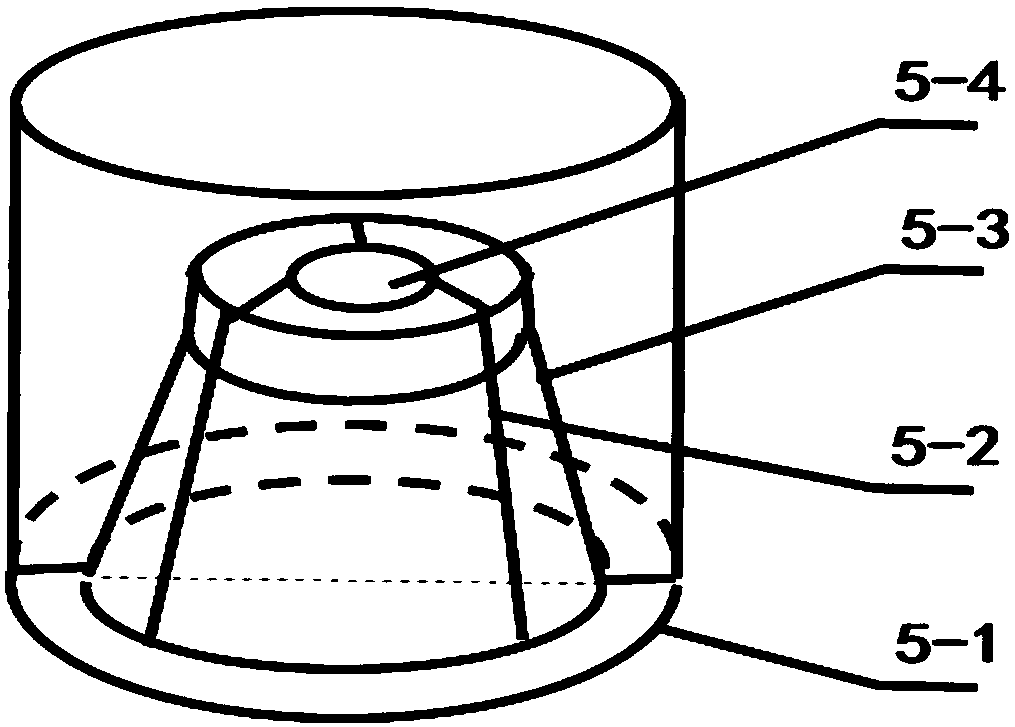

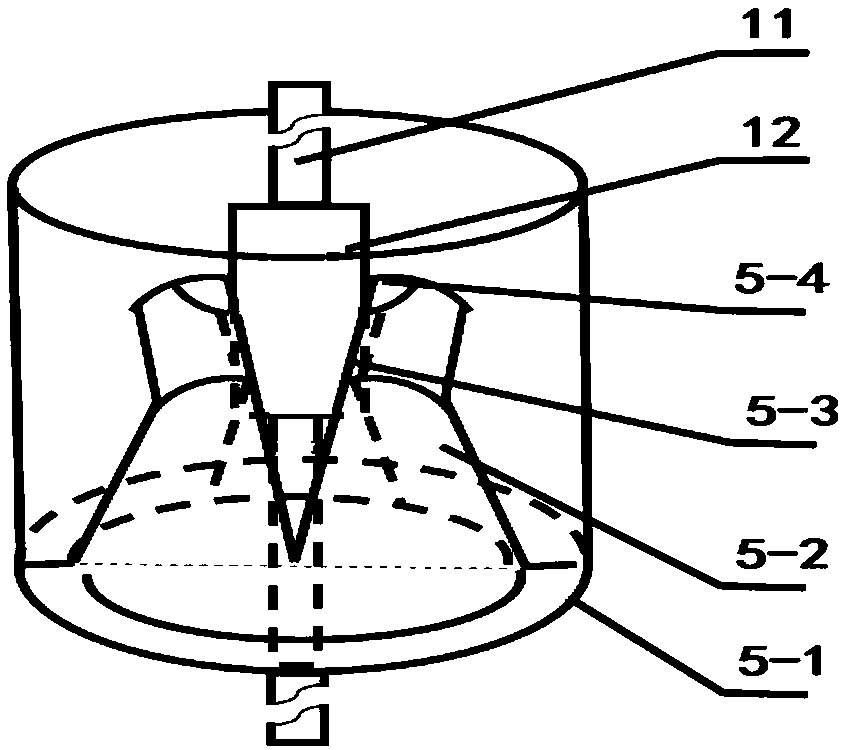

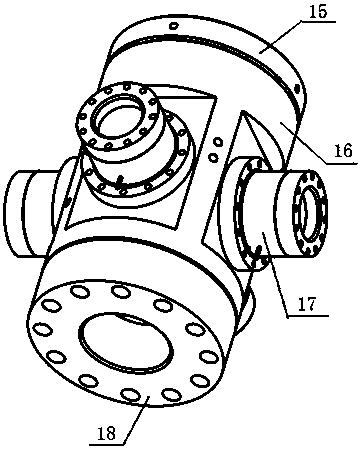

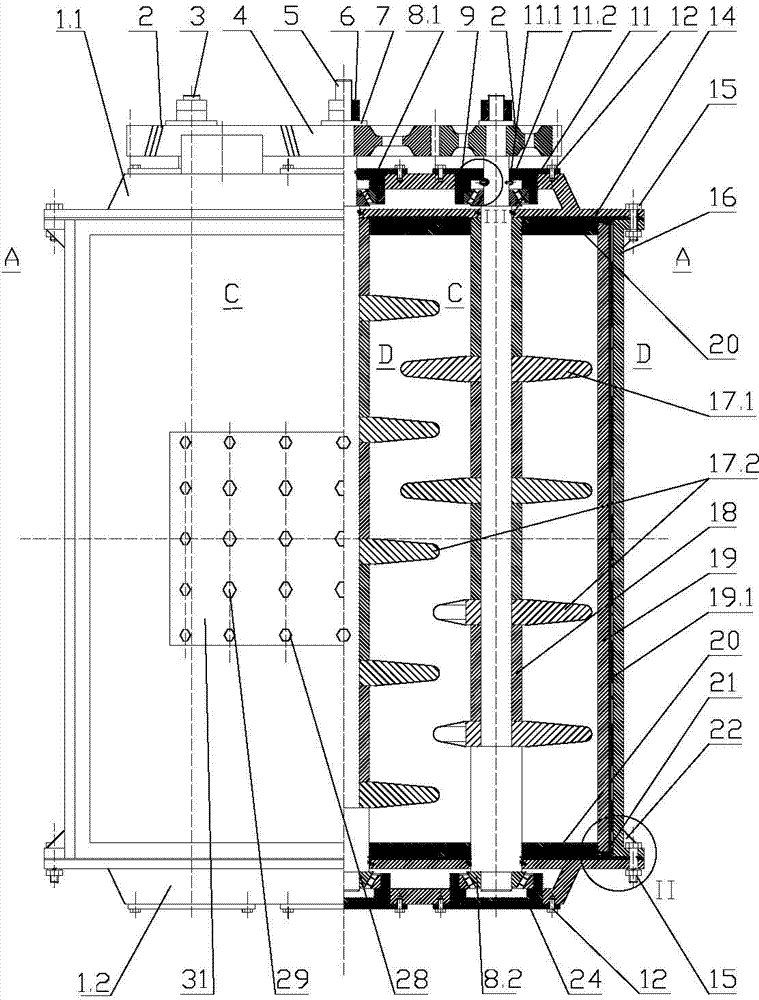

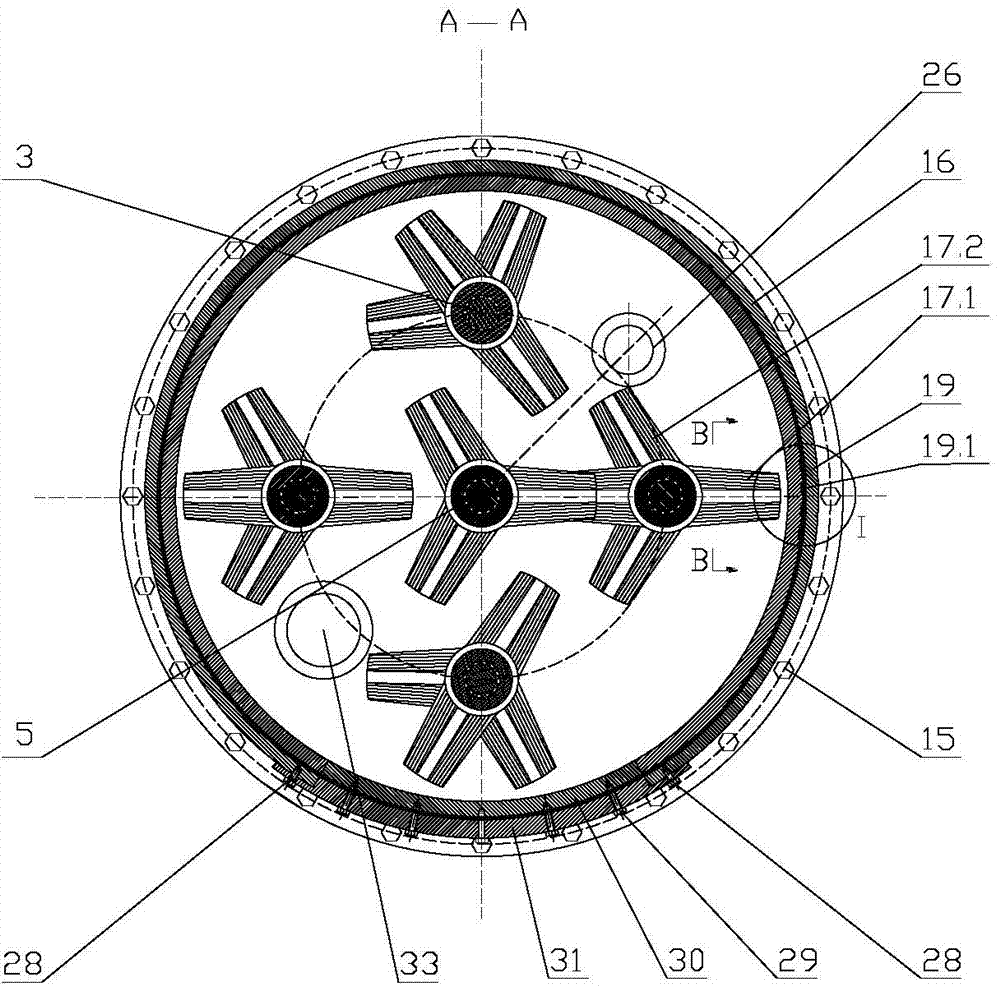

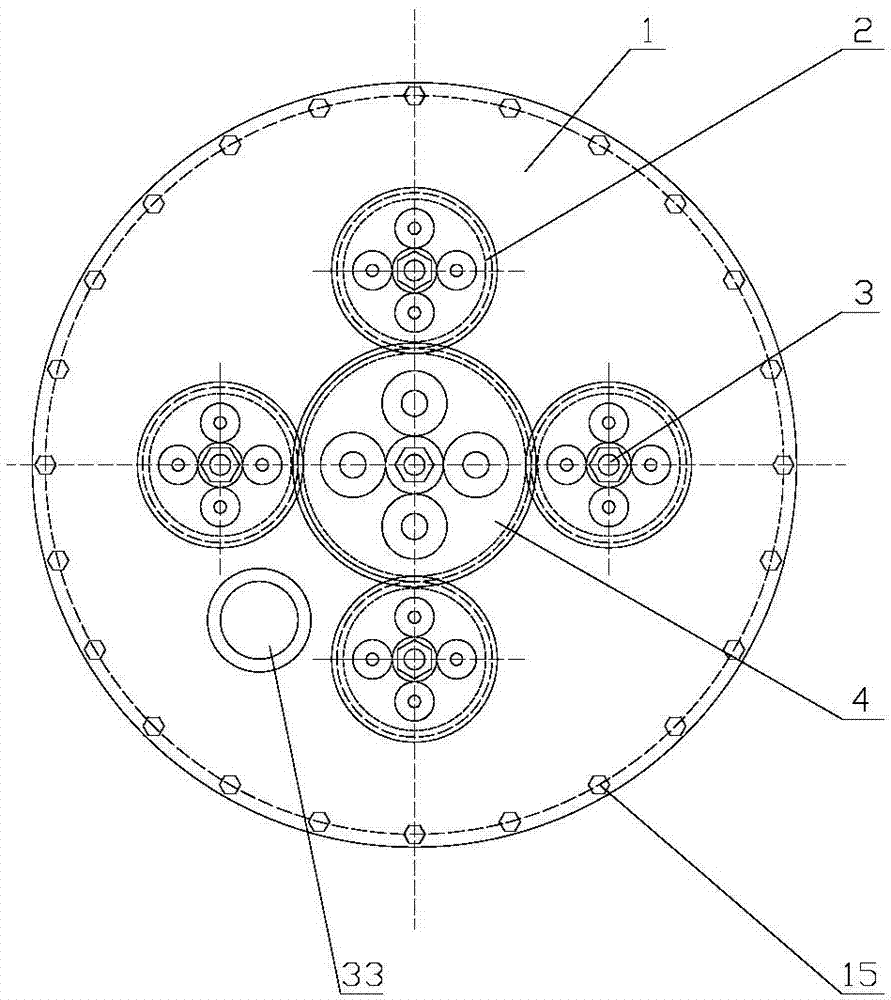

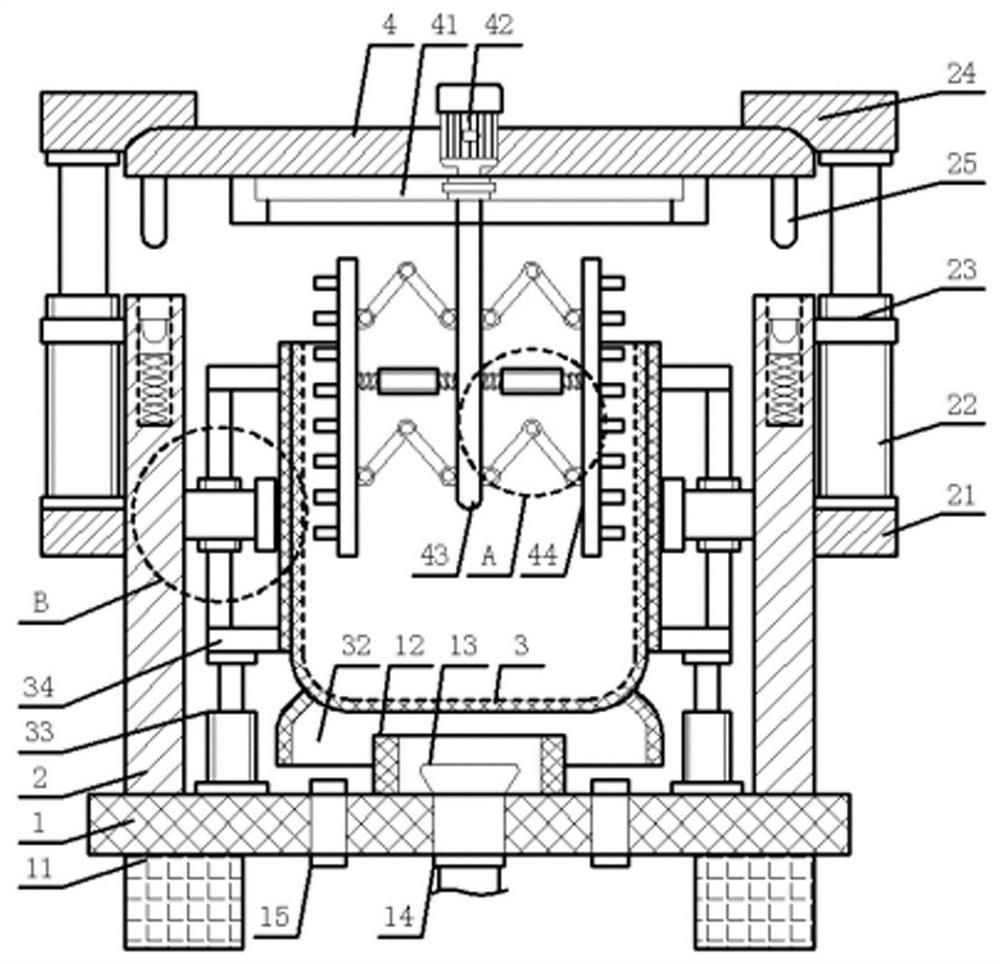

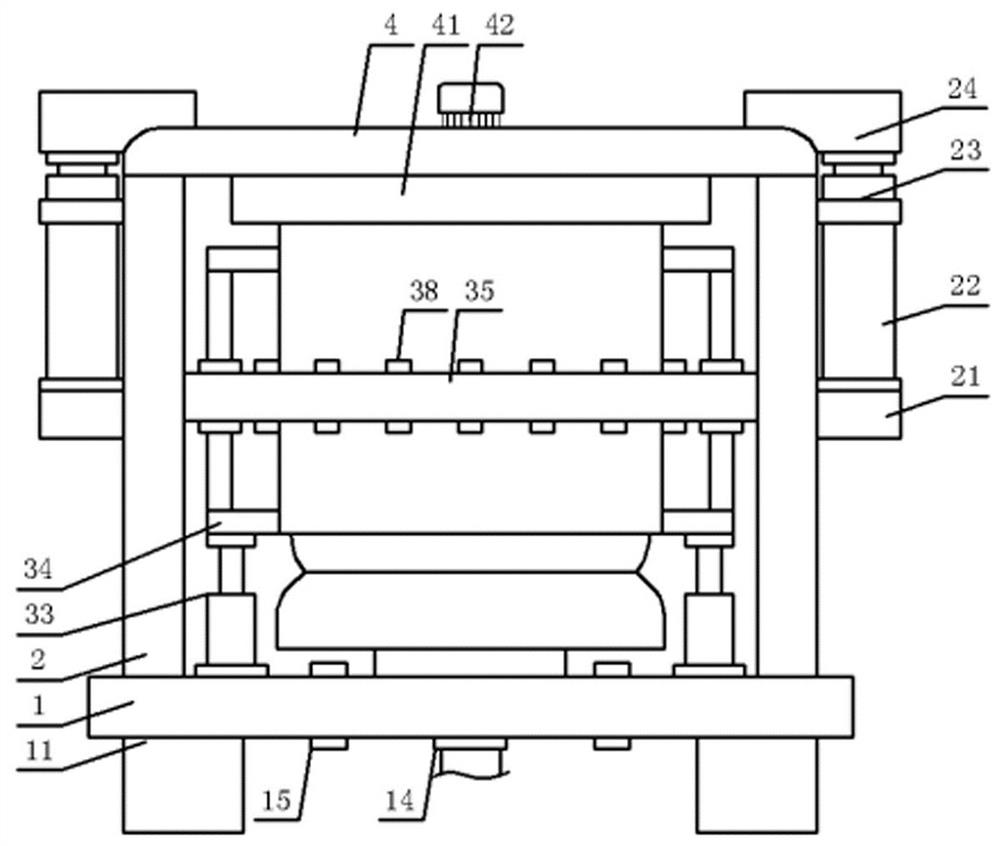

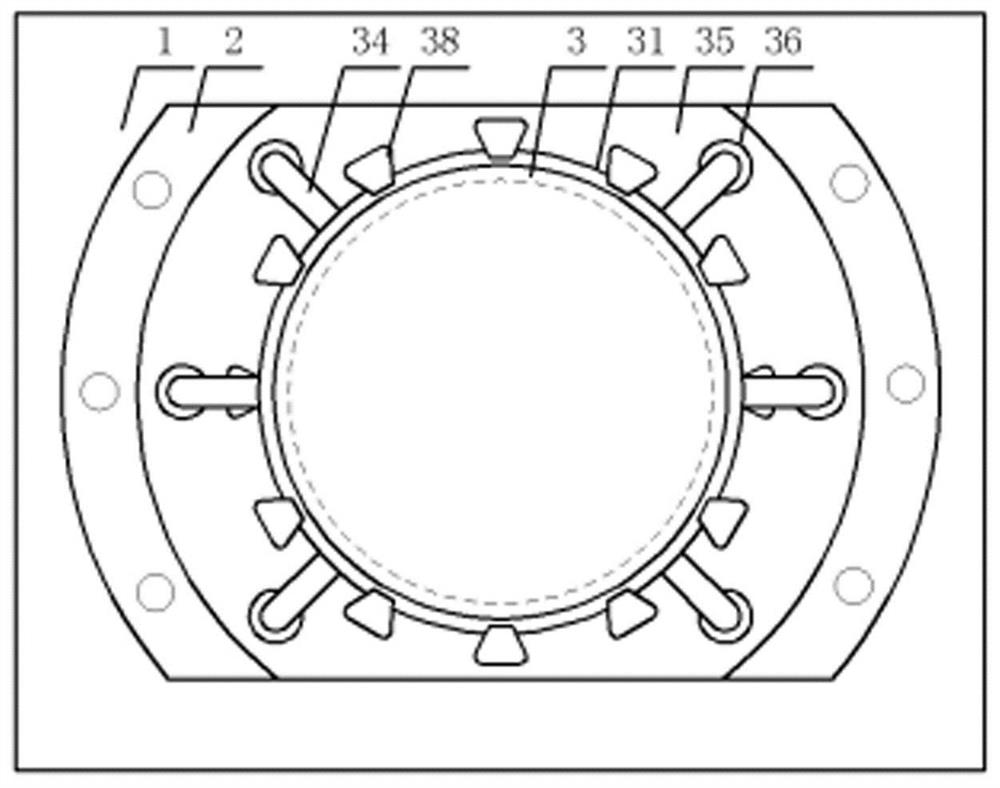

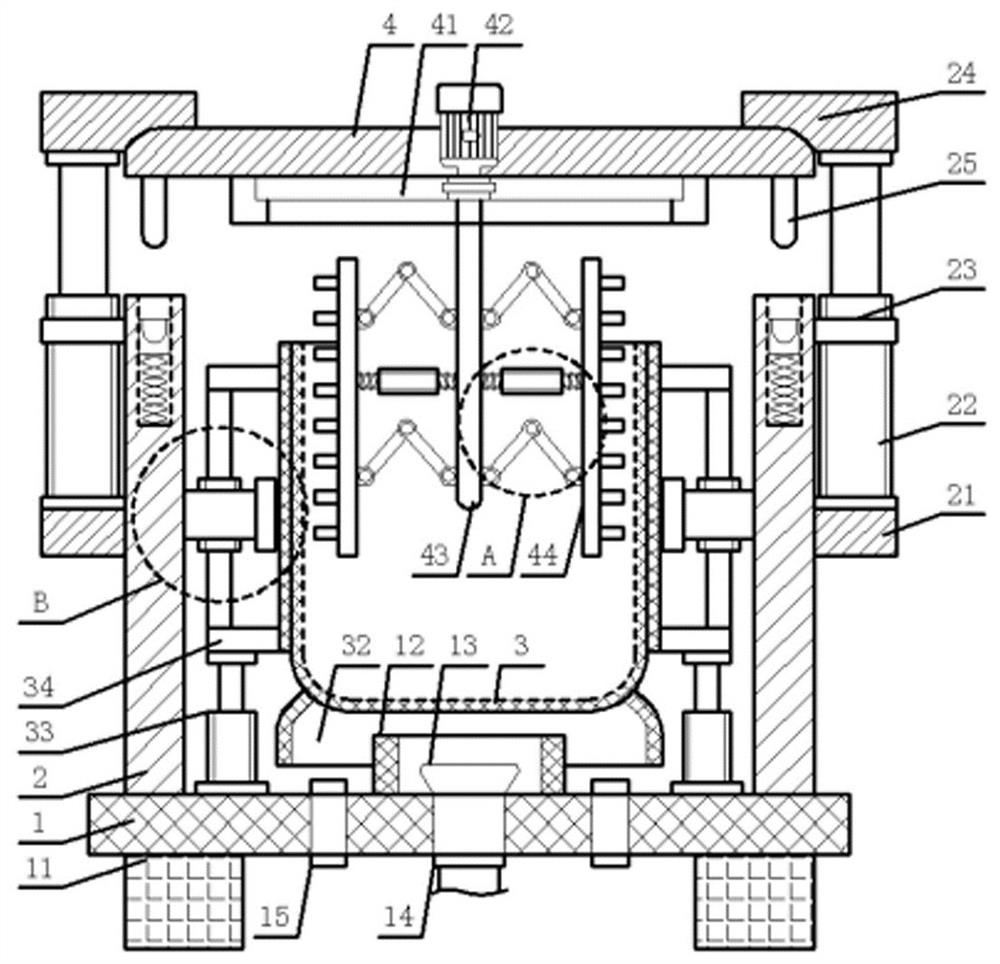

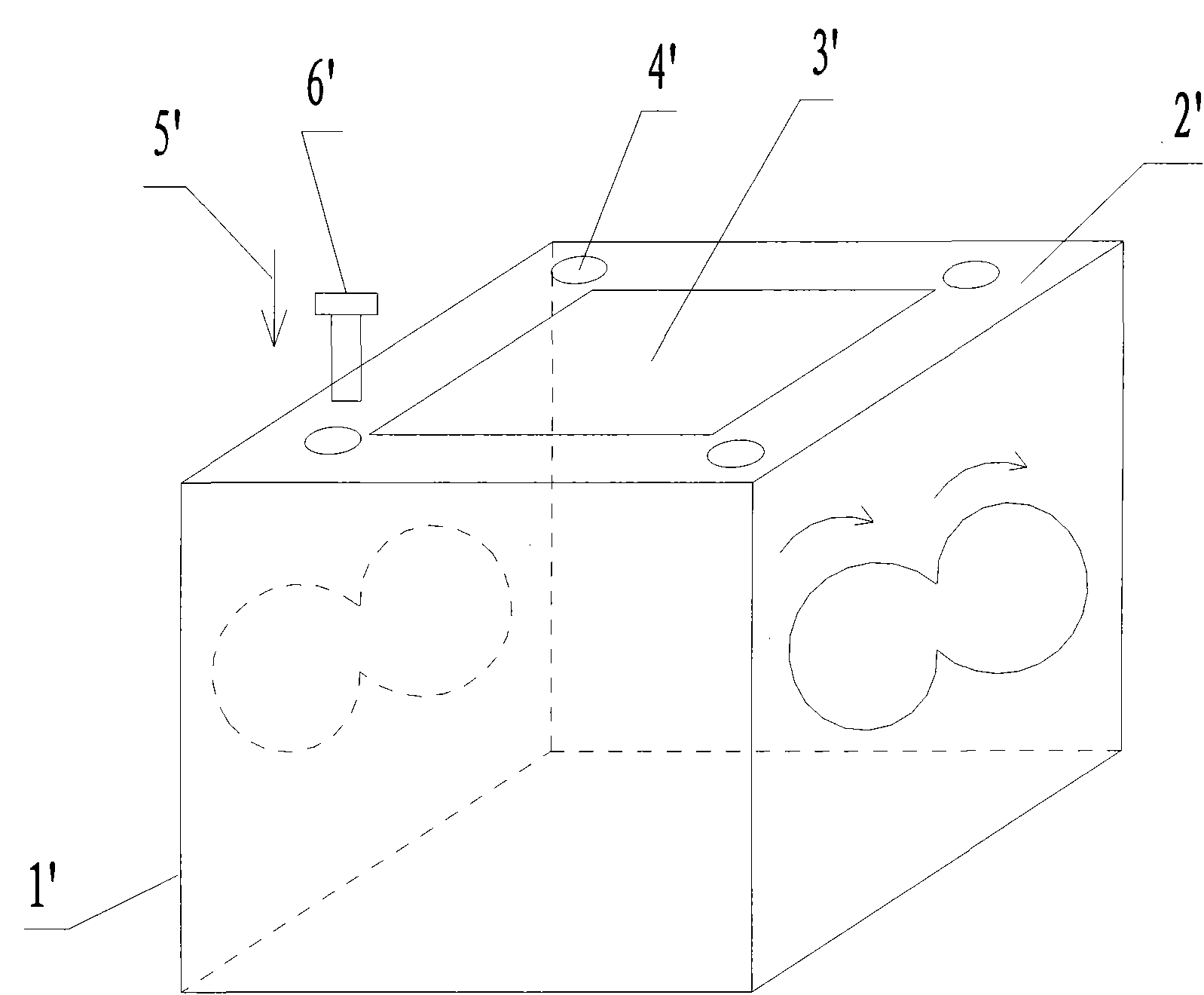

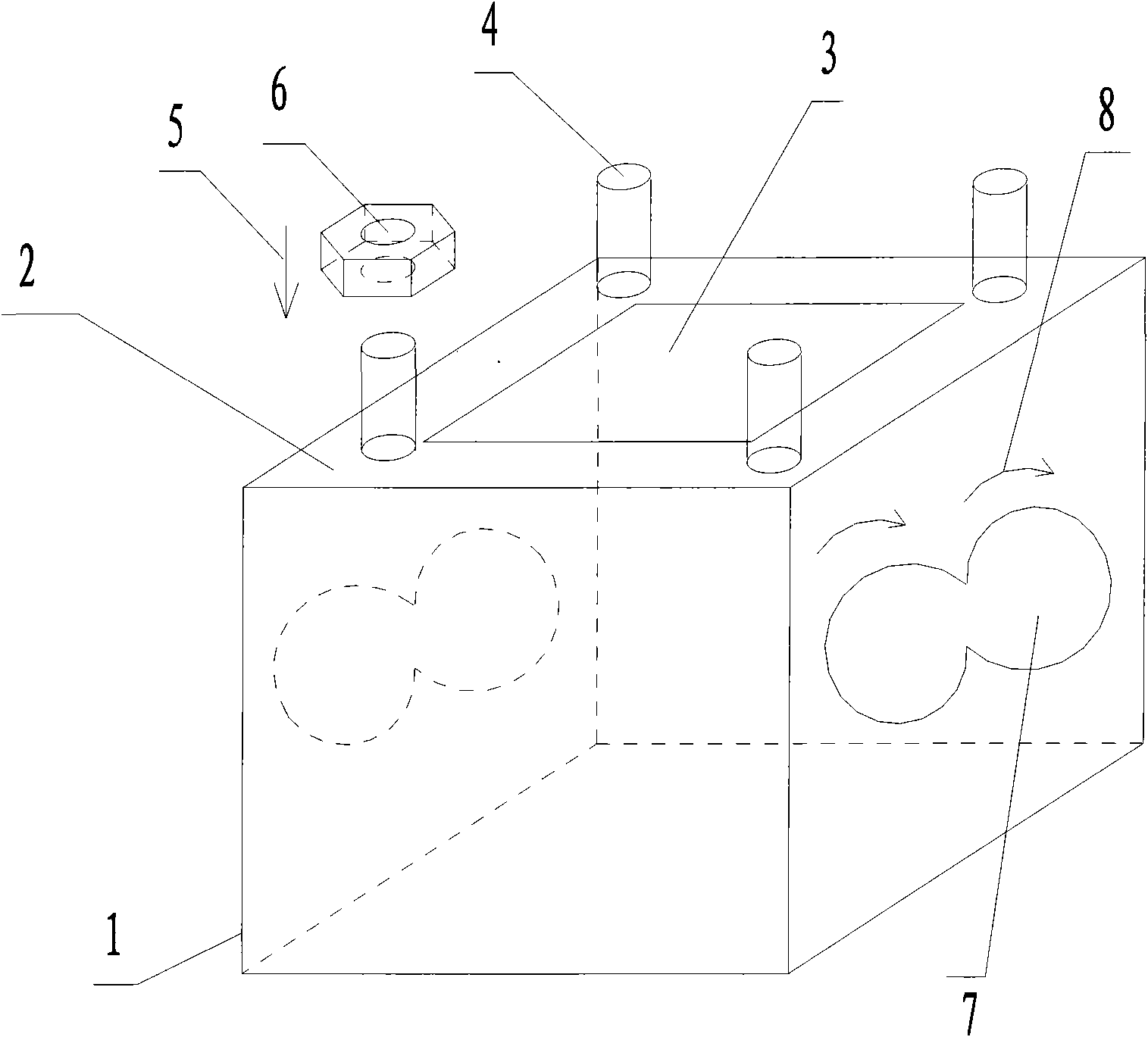

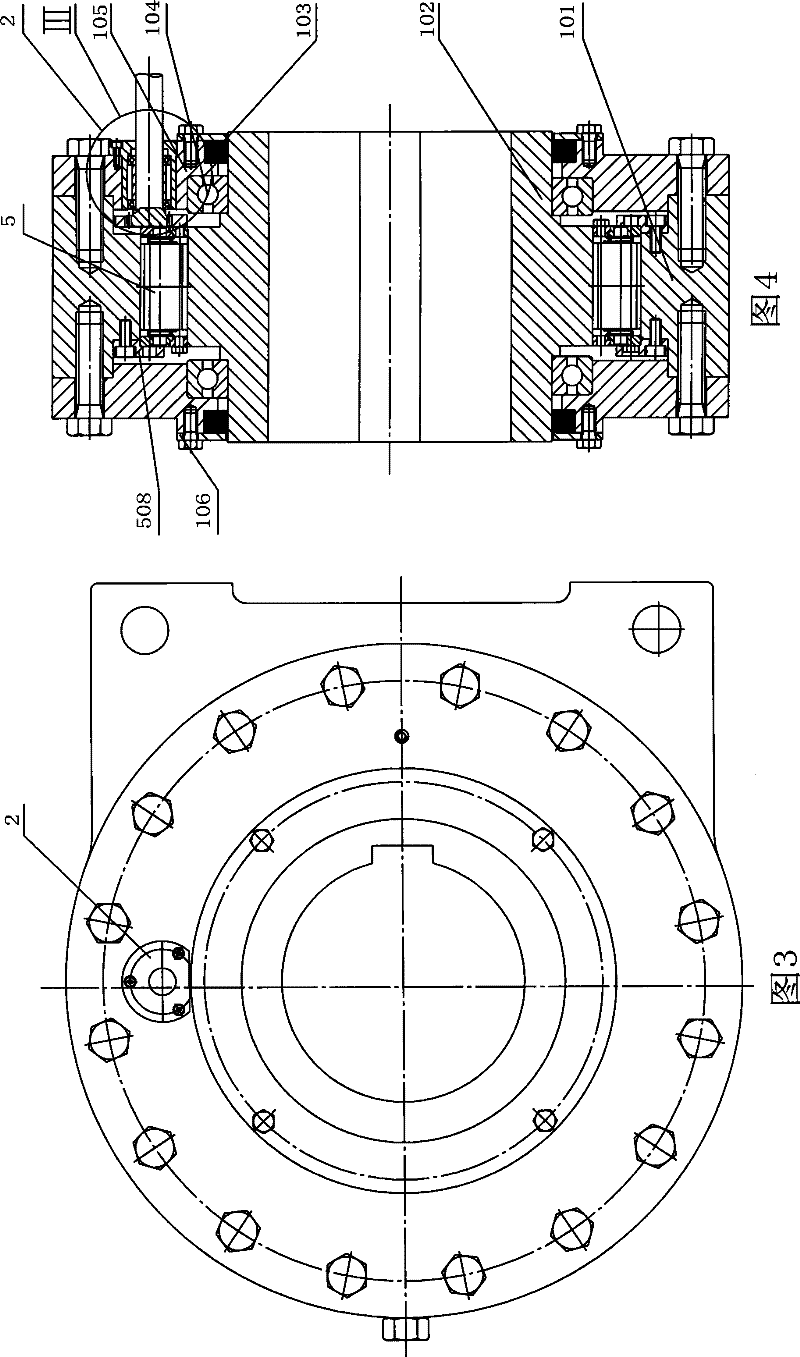

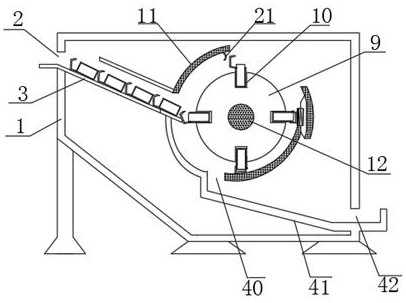

Constant volume combustion bomb device capable of turbulence movement simulation, and control system for constant volume combustion bomb device

PendingCN109238725ASolve the leaky sealQuick responseInternal-combustion engine testingAirflowBomb device

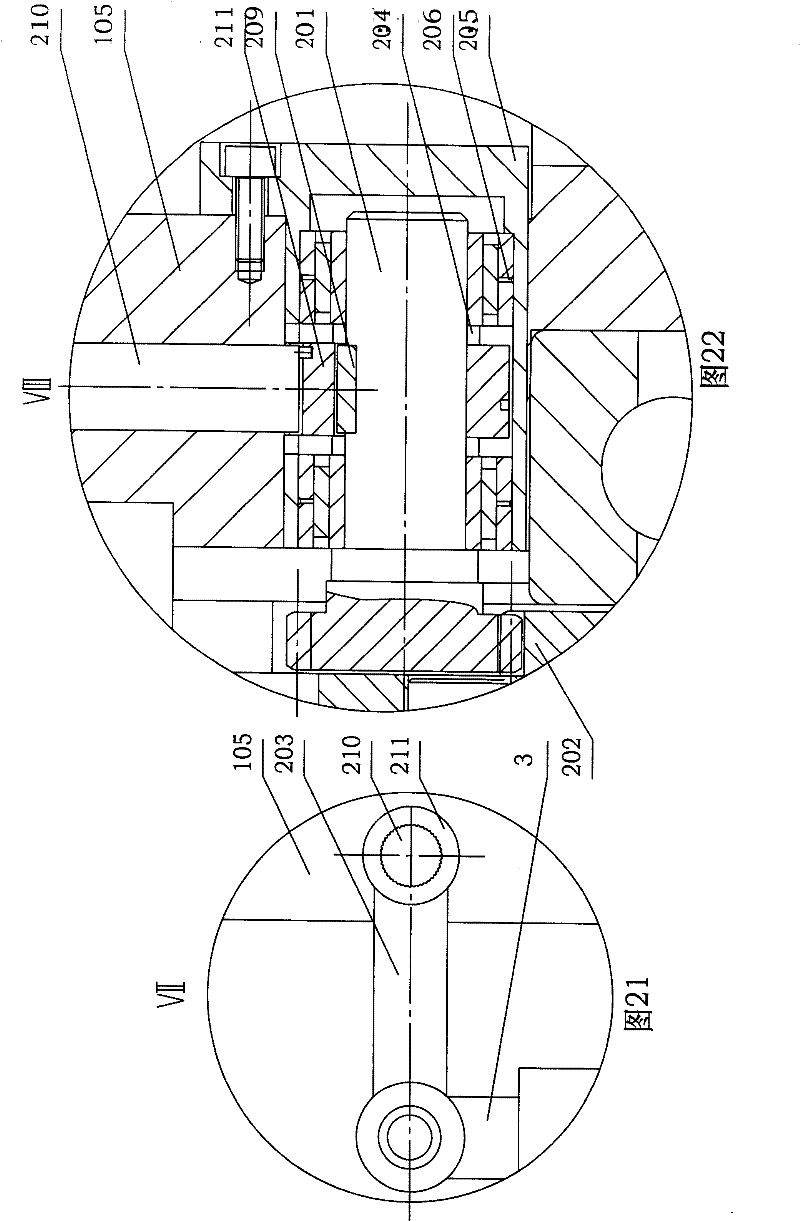

The invention discloses a constant volume combustion bomb device capable of turbulence movement simulation, and a control system for the constant volume combustion bomb device. The device comprises acylindrical hollow bomb body, wherein the two ends of the bomb body are sealed through a front flange, a rear flange, and a spark plug mounting seat; observation windows are distributed on the side wall of the bomb body; a pneumatic driving device and a porous plate are assembled in the bomb body; the spark plug mounting seat is fixed on the front flange; the pneumatic driving device is fixed on the rear flange; and the porous plate is arranged on the pneumatic driving device and carries out translational movements along the inner wall of the bomb body. The device and the system disclosed by the invention have the advantages that the pneumatic driving device mounted in a constant volume combustion bomb is used as a power source to drive the porous plate to move, so that turbulences can beproduced due to throttling effects after gas flows pass through the porous plate; the problem of high difficulty in sealing is radically avoided through the device, and better isotropic turbulences can be generated in the constant volume combustion bomb; and the device achieves a high response speed and is easy to implement.

Owner:SHAOYANG UNIV

Plug for sealing signal line of instrument probe

ActiveCN109309369ASolve the leaky sealCompletely sealedElectrical apparatusEngineeringElectronic component

The invention relates to a plug for sealing a signal line of an instrument probe, and belongs to the technical field of petroleum storage and transportation. The plug includes a plug seat having a through cavity and a plug gland attached to one end of the plug seat for sealing the through cavity, the plug gland comprising a gland body and a sealing gasket between the plug seat and the gland. A wire bolt is disposed on the sealing gasket, one terminal of the wire bolt is located in the through cavity, and the other terminal of the wire bolt is located outside of the gland body. The plug provided by the embodiment of the invention solves the problem of poor sealing effect caused by a signal line of an instrument probe directly passing through a sealing pad, and the lubricating oil can be completely sealed to ensure that the oil and gas are not leaked; waste of lubricating oil is avoided, the safety hazard of erosion of electronic components by lubricating oil and lubricant leakage is eliminated.

Owner:PETROCHINA CO LTD

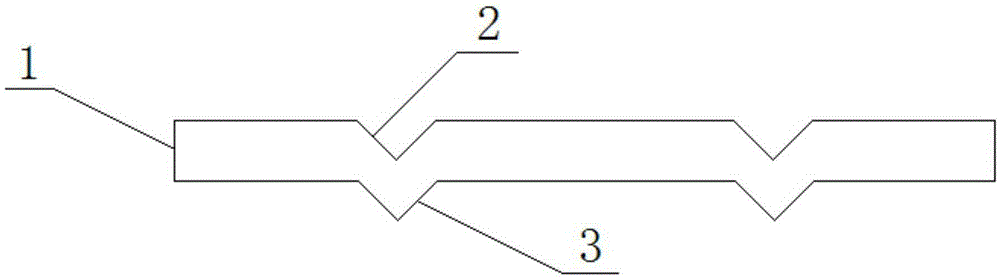

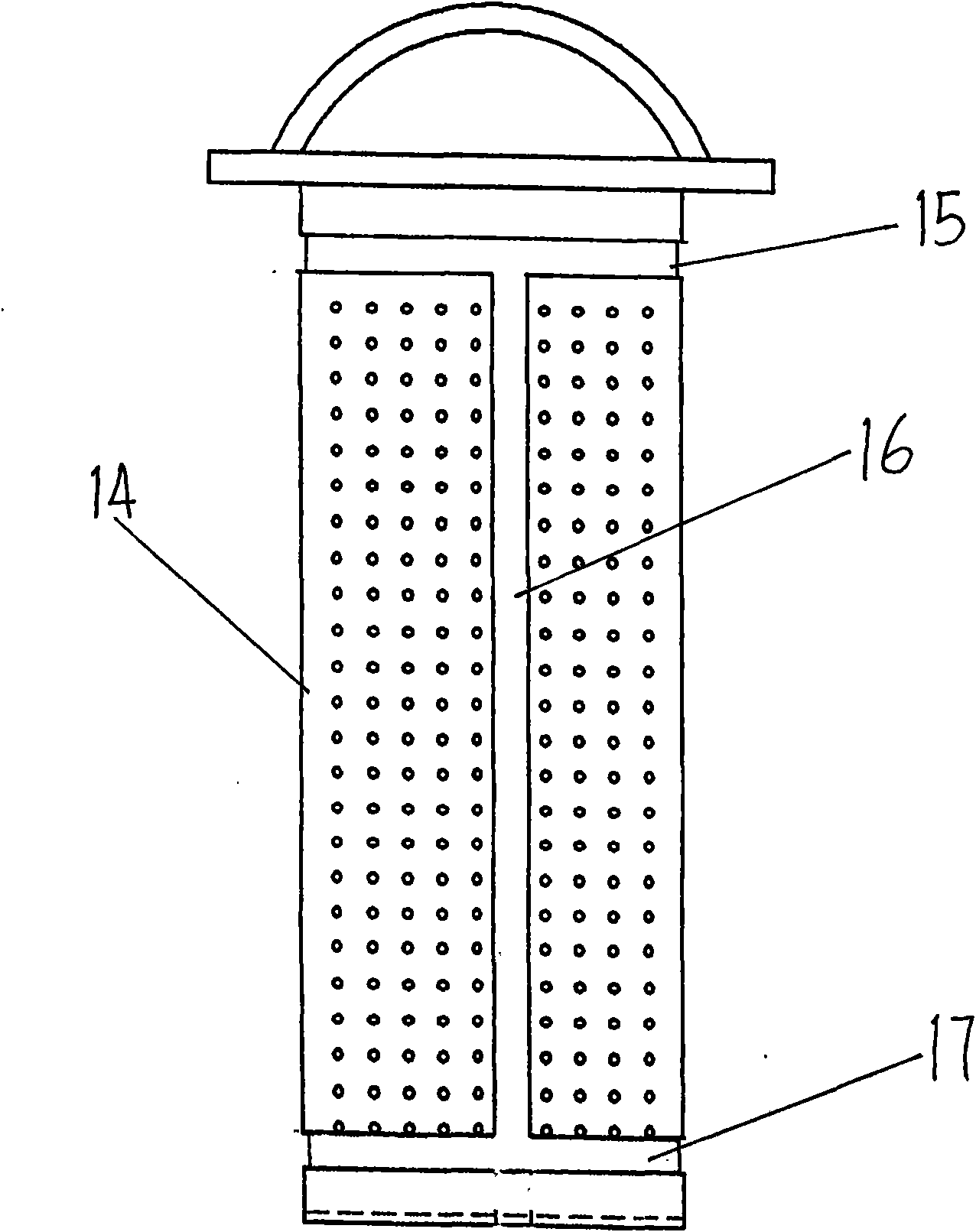

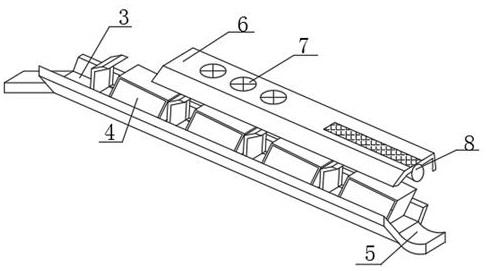

Sealing strip structure for sealing

InactiveCN105270139ASolve the leaky sealSolve the problem of air leakageAir-treating devicesVehicle heating/cooling devicesElectrical and Electronics engineeringCoating

The invention discloses a sealing strip structure for sealing. The sealing strip is a long strip, and two end surfaces in the length direction of the sealing strip are glue coating surfaces (1); a plurality of V-shaped notches (2) are sequentially formed in one lateral side of the sealing strip; a plurality of V-shaped bulges (3) are arranged on the other side which is opposite to the side with the V-shaped notches (2); the positions of the notches (2) and the positions of the bulges (3) are in one-to-one correspondence. According to the sealing strip structure for sealing, through the manner that the notches are formed in one side, and the bulges are arranged on the other side, the sealing strip can be prevented from wrinkling at corners, and the problem that a ventilation door cannot be tightly sealed in an air conditioner structure is solved; therefore, the air leakage of the ventilation door is avoided; besides, the cost for using frame-type sponge design is reduced.

Owner:BONAIRE AUTOMOTIVE ELECTRICAL SYST

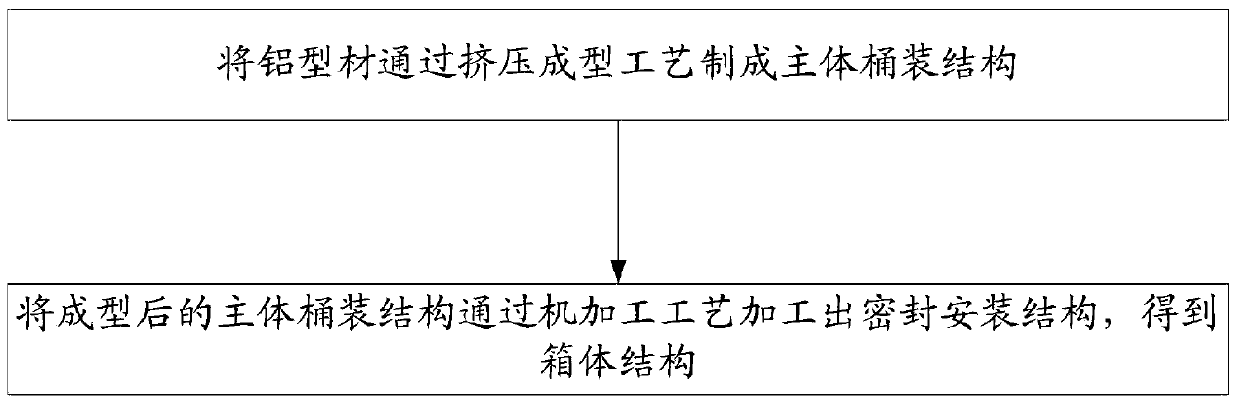

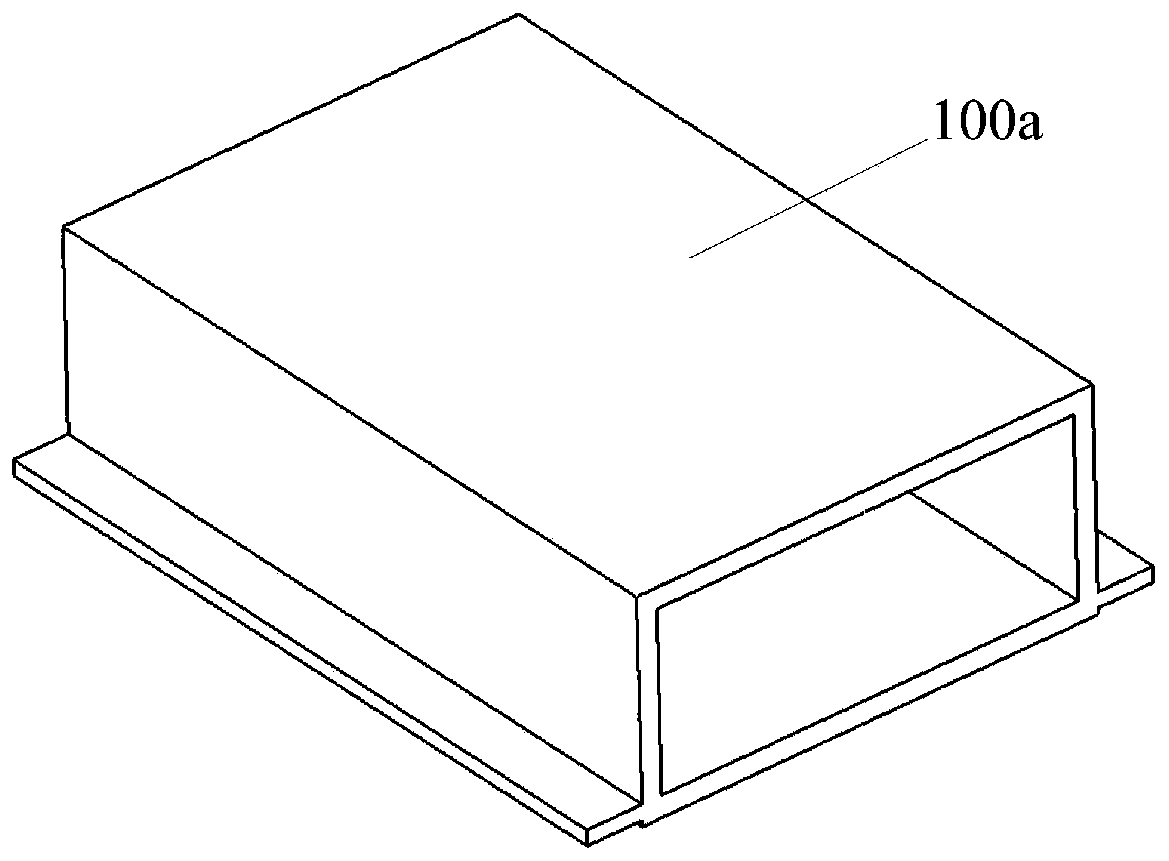

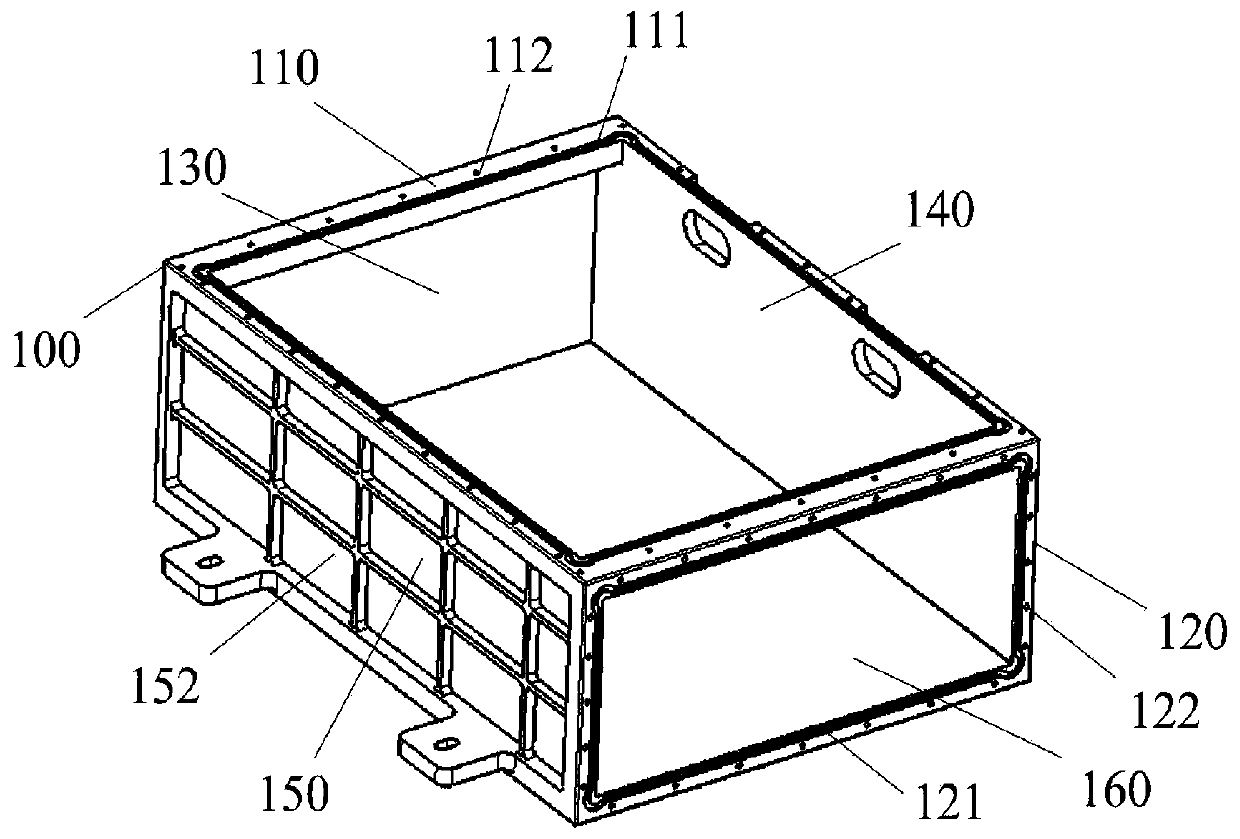

Fuel cell system, box body structure thereof and manufacturing method of box body structure

PendingCN111509281AAchieve airtight installationGuaranteed waterproof performanceFinal product manufactureFuel cellsFuel cellsMachining process

The invention discloses a fuel cell system, a box body structure thereof and a manufacturing method of the box body structure, and the manufacturing method of the box body structure comprises the following steps: manufacturing an aluminum profile into a main body barrel structure through an extrusion molding process; and machining the formed main body barrel structure into a sealed mounting structure through a machining process to obtain a box body. In the scheme, the main body barrel structure is manufactured through an extrusion molding process; the assembly of six planes of the box body structure can be effectively avoided, the assembly surface is reduced, the problem of the untight sealing of the box body is solved based on the sealed mounting structure of the box body, and the sealinginstallation of a fuel cell in the box body is realized, so that the waterproof effect of the fuel cell in the box body is ensured.

Owner:风氢扬氢能科技(上海)有限公司

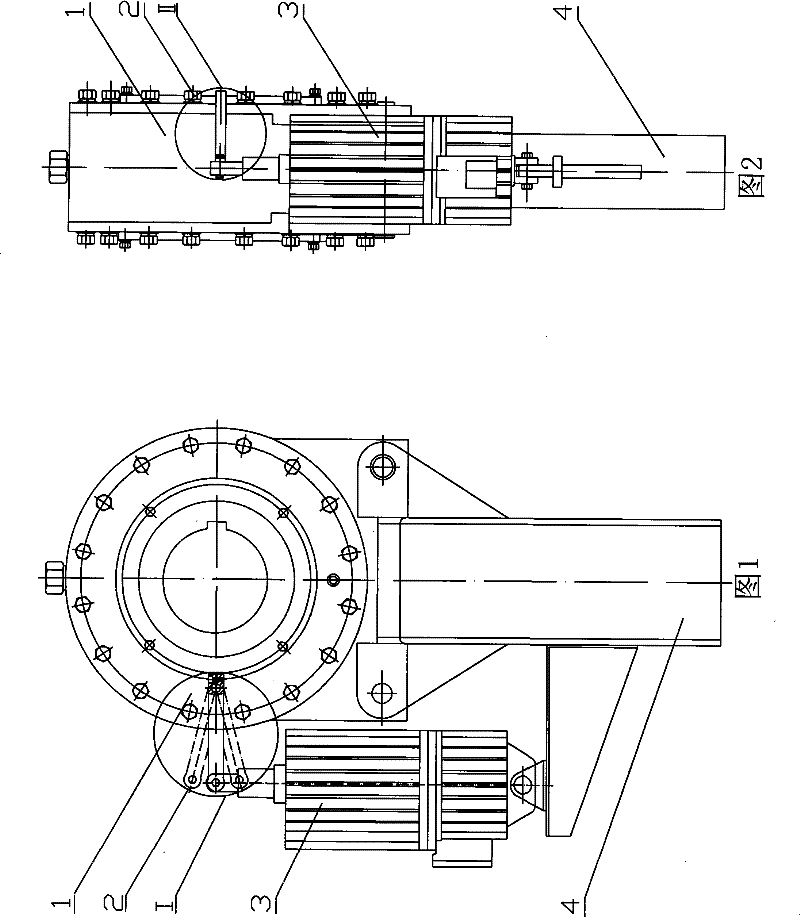

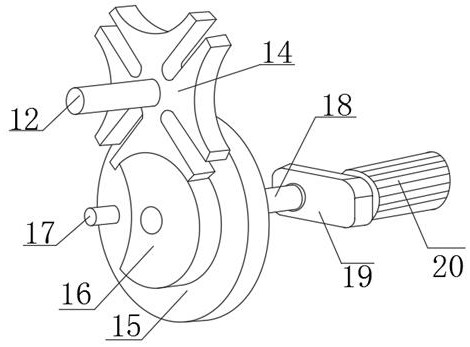

Damping rotary seal multi-rotary-hammer crusher

InactiveCN104759318AReduce energy consumptionImprove work efficiencyGrain treatmentsSet screwDrive shaft

The invention provides a damping rotary seal multi-rotary-hammer crusher. The crusher comprises upper and lower bearing housings, driving and driven transmission shafts, driving and driven gears, a bearing block ventilation cover and a bearing block stuffy cover and is characterized in that a crusher barrel is cylindrical; the bearing housings are installed at the upper and lower parts of the crusher barrel respectively; the upper and lower bearing housings are respectively connected with the bearing block ventilation cover and the bearing block stuffy cover; upper and lower tapered roller bearings are installed in the upper and lower bearing housings; the driving and driven transmission shafts penetrate through the bearing block ventilation cover; the middle parts of the driving and driven transmission shafts are arranged in the crusher barrel; the bottoms of the driving and driven transmission shafts are connected with the bearing block stuffy cover; sanding hammers are installed on the transmission shafts respectively and are connected with the transmission shafts by splines; a wearproof liner is installed in the crusher barrel; a wearproof liner damping sleeve is inlaid in the outer wall of the wearproof liner; a rotary seal ring is fixed together with the driving and driven transmission shafts via rotary seal ring set screws. The crusher has the characteristics of improvement of the work efficiency, reduction of the energy consumption, damping and noise reduction.

Owner:马宏

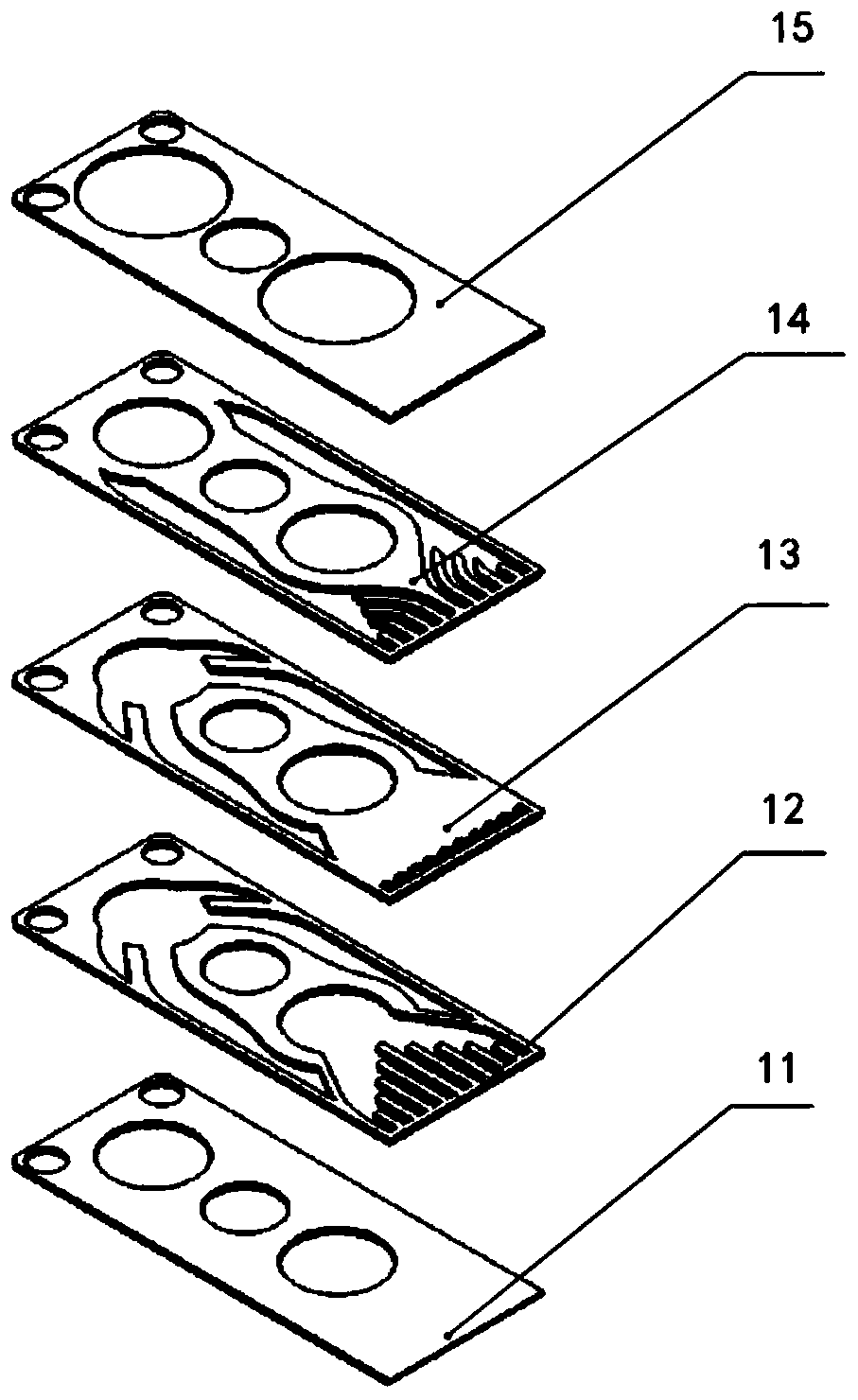

Semiconductor laser, semiconductor laser refrigeration structure and manufacturing method thereof

InactiveCN111082310AAchieve a tight sealSolve the leaky sealLaser detailsSemiconductor lasersLaser arrayHeat sink

The invention discloses a semiconductor laser, a semiconductor laser refrigeration structure and a manufacturing method of the semiconductor laser refrigeration structure. The semiconductor laser refrigeration structure comprises a lower cover piece, a water return piece, a water diversion piece, a micro-channel cooling fin and an upper cover piece which are sequentially arranged from bottom to top, wherein the upper cover piece comprises an insulating layer, a first step metal layer and a second step metal layer; the first step metal layer is arranged on the insulating layer; the second stepmetal layer is arranged on the insulating layer; the lower cover piece, the water return piece, the water diversion piece, the micro-channel cooling fin, the insulating layer and the second step metallayer are respectively provided with coaxial cooling water channels, and the peripheries of the cooling water channels are sealed by welding; the length of the upper cover piece is less than that ofthe micro-channel cooling fin, and the thickness of the second step metal layer is greater than that of the first step metal layer. According to the semiconductor laser adopting the semiconductor laser refrigeration structure, each semiconductor laser can be connected in a sealed welding mode to form a semiconductor laser array, and strict sealing among all the semiconductor lasers is achieved.

Owner:SUZHOU EVERBRIGHT PHOTONICS CO LTD

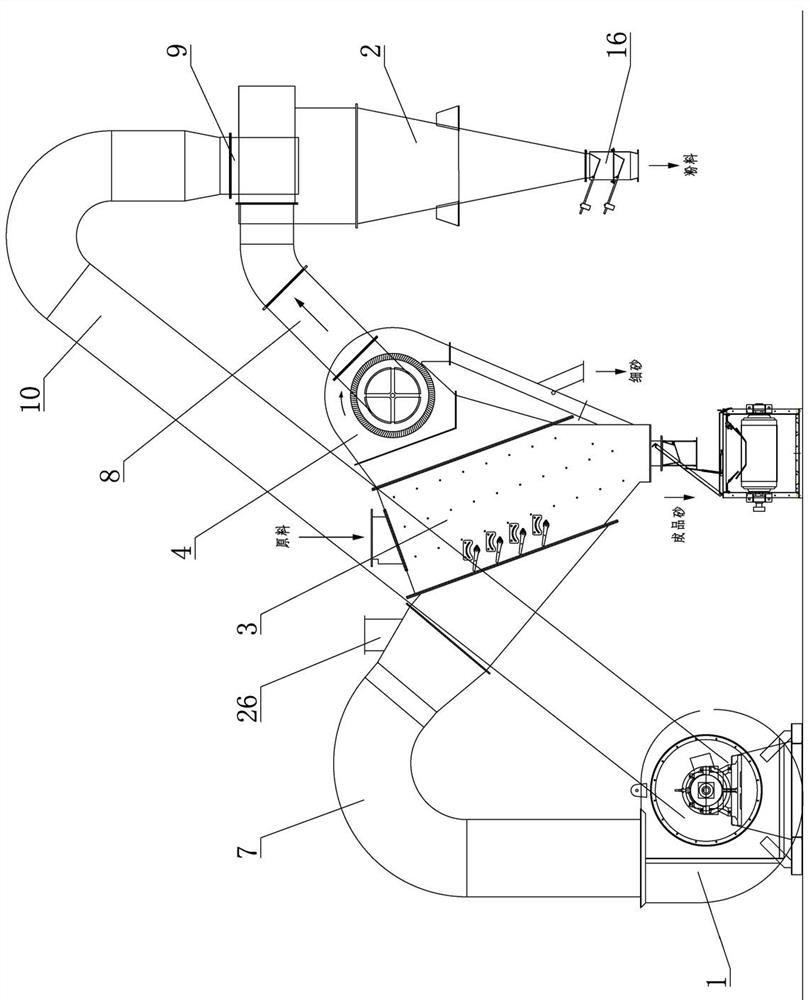

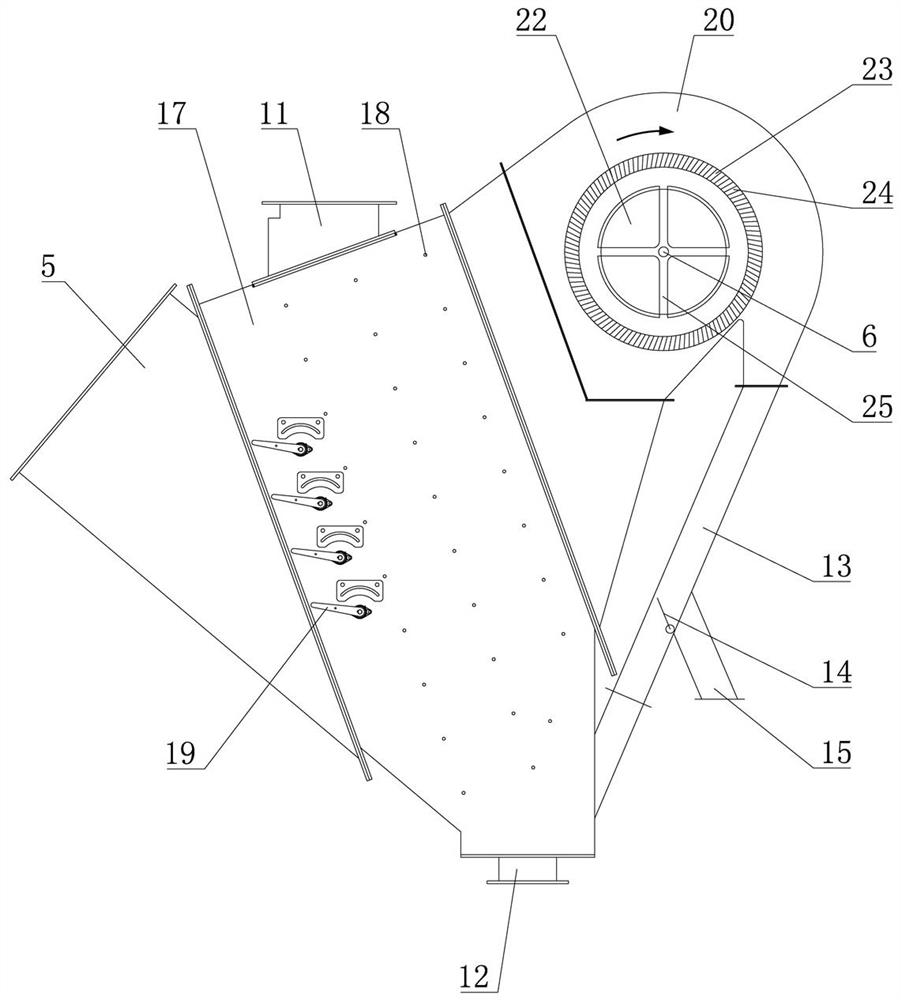

Gravel grading system

PendingCN111940294ALow powerRealize closed loopGas current separationVortex flow apparatusStructural engineeringProcess engineering

The invention discloses a gravel grading system comprising a powder selecting device, a centrifugal fan and a winnowing chamber. The powder selecting device comprises a static powder selecting deviceand a dynamic powder selecting device, an air inlet and an air outlet are formed in the static powder selecting device and the dynamic powder selecting device correspondingly, the centrifugal fan is connected with the air inlet through a first pipeline, and the winnowing chamber is connected with the air outlet through a second pipeline; an air return opening is further formed in the upper end ofthe winnowing chamber and connected with the centrifugal fan or the first pipeline through a third pipeline; and a feeding opening and a first discharging opening are formed in the upper end and the lower end of the static powder selecting device correspondingly, a second discharging opening is further formed in a conveying channel, and a third discharging opening is formed in the winnowing chamber. The air outlet of the device is connected with the air inlet of the fan, so that the closed cycle of a powder selecting system is realized, pollution to the environment can be reduced, meanwhile the power of the fan can be reduced, the effects of saving energy and reducing consumption are achieved, and the winnowing effect is improved; and a dynamic powder selecting machine can adjust the content of powder in a finished sand product to meet the requirement of controlling the component content of machine-made sand.

Owner:HENAN ZHONGYU DINGLI INTELLIGENT EQUIP CO LTD

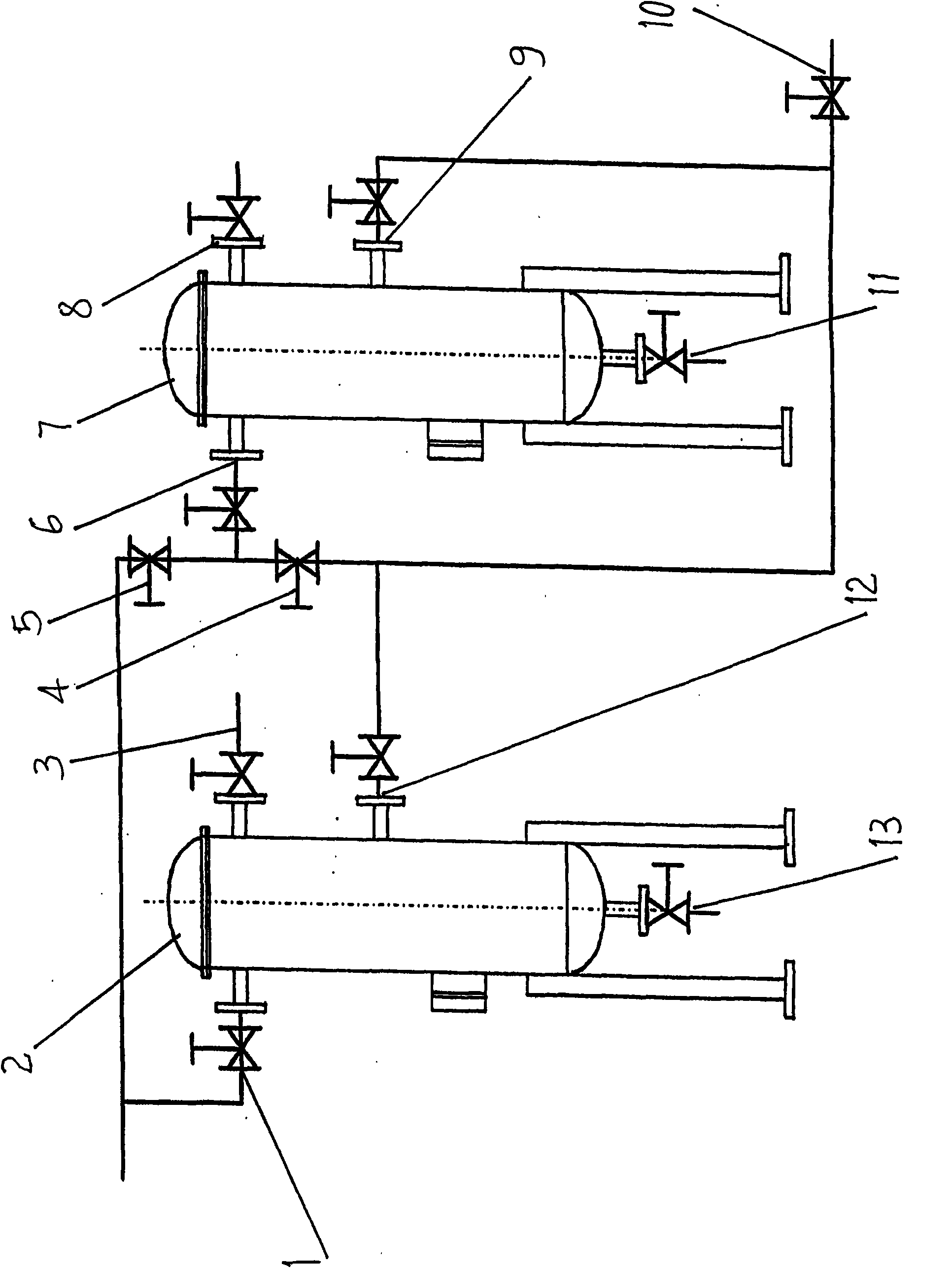

Technology for removing and leaching impurity in mixed liquor in production of lutein factice

ActiveCN101590088AReduce flow rateReduce stagnationHydroxy compound active ingredientsAerosol deliveryDifferential pressureInlet valve

The invention discloses a technology for removing and leaching impurities in mixed liquor in the production of lutein factice, which relates to a technology part and an equipment part. The leaching technology comprises the following steps: an olefin pump is adopted to generate power, and two leaching tanks are used for circularly soaking and extracting; differential pressure is 1.5MPa-2MPa when liquor is poured; an evaporating tank No. 1 is adjusted to 50 DEG C-55 DEG C, and the evaporating time is not more than 10 minutes; and the opening degree between a liquor inlet valve and a liquor outlet valve of each filter is adjusted in such a way that the opening degree of the liquor inlet valve is smaller than that of the liquor outlet valve. The filter screen density of each of the three filters is A1 of 200 meshes, A2 of 350 meshes and A3 of 400 meshes; and the two adjacent filters are connected in a mixing way of parallel connection and series connection, two annular grooves are respectively processed in the position with not less than 5 cm of distance from the upper bottom and the lower bottom of a filter element, and a strip connecting groove is processed between the two annular grooves so as to form a filter screen mounting groove communicated by the three grooves. The impurity content of a lutein factice product is reduced to below 1 percent by technical measures of a technology aspect and an equipment aspect.

Owner:QUJING BOHAO BIOTECH

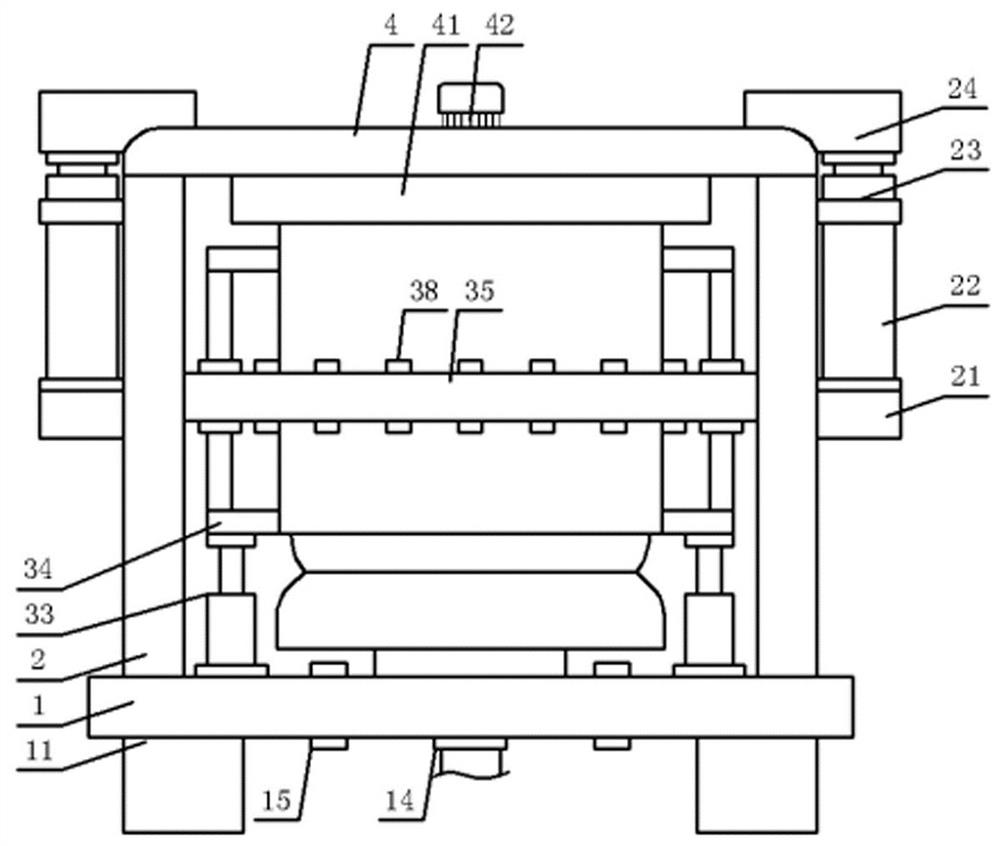

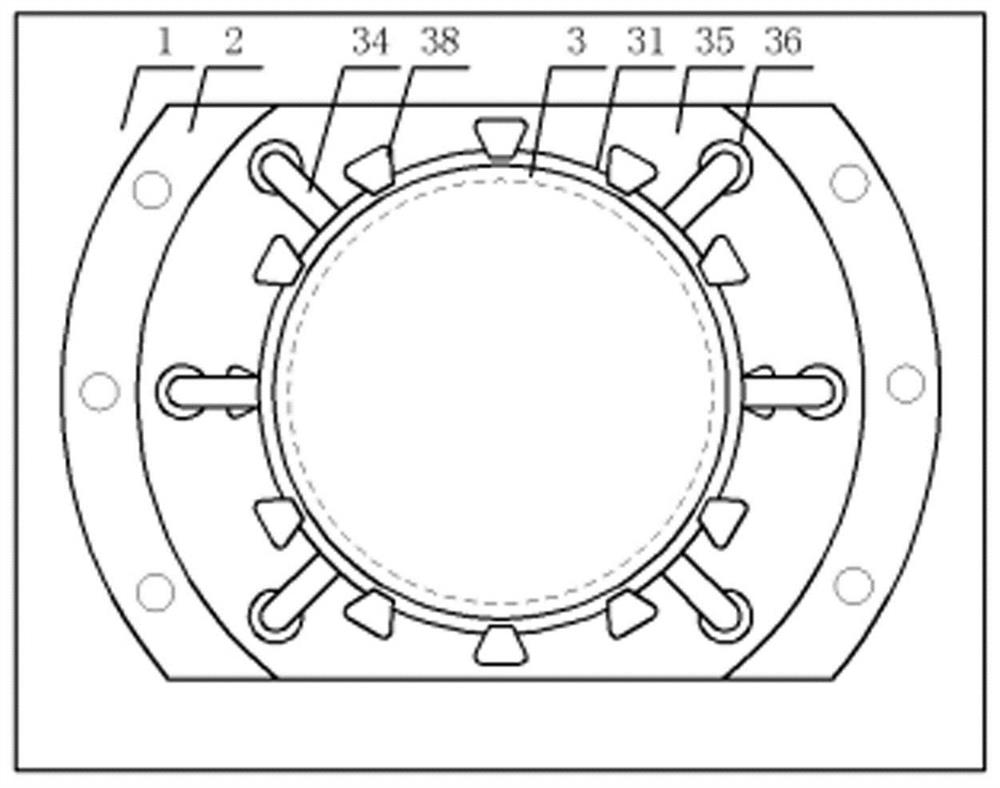

Blank machining equipment for graphite thermal field and machining method thereof

ActiveCN111906917ASolve the problem of inconvenient installation and liftingAvoid uneven mixingCeramic shaping plantsCrucibleElectric machinery

The invention discloses blank machining equipment for a graphite thermal field. The equipment comprises a bottom plate, arc-shaped vertical plates, sliding mechanisms, lifting mechanisms and a stirring mechanism, the two ends of the top face of the bottom plate are provided with a pair of arc-shaped vertical plates, a supporting plate is arranged between the two arc-shaped vertical plates, a crucible barrel is installed in a circular through hole, and the outer side face of the crucible barrel is sleeved with a heat preservation barrel. The two sides of the outer wall of the heat preservationcylinder are in sliding connection with the supporting plate through the multiple pairs of sliding mechanisms. The two ends of a circular cover plate are movably connected with the corresponding arc-shaped vertical plates through a pair of lifting mechanisms. The end part of a motor shaft of a motor and the stirring mechanism synchronously rotate. The invention further discloses a machining methodof the blank machining equipment for the graphite thermal field. The problems that a crucible is inconvenient to install and lift, a graphite material is non-uniformly stirred, and an opening of thecrucible is not tightly sealed are solved, through cooperative use of all mechanisms, the operation steps are simplified, the labor burden of workers is relieved, and the processing and production efficiency of the graphite material is improved.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

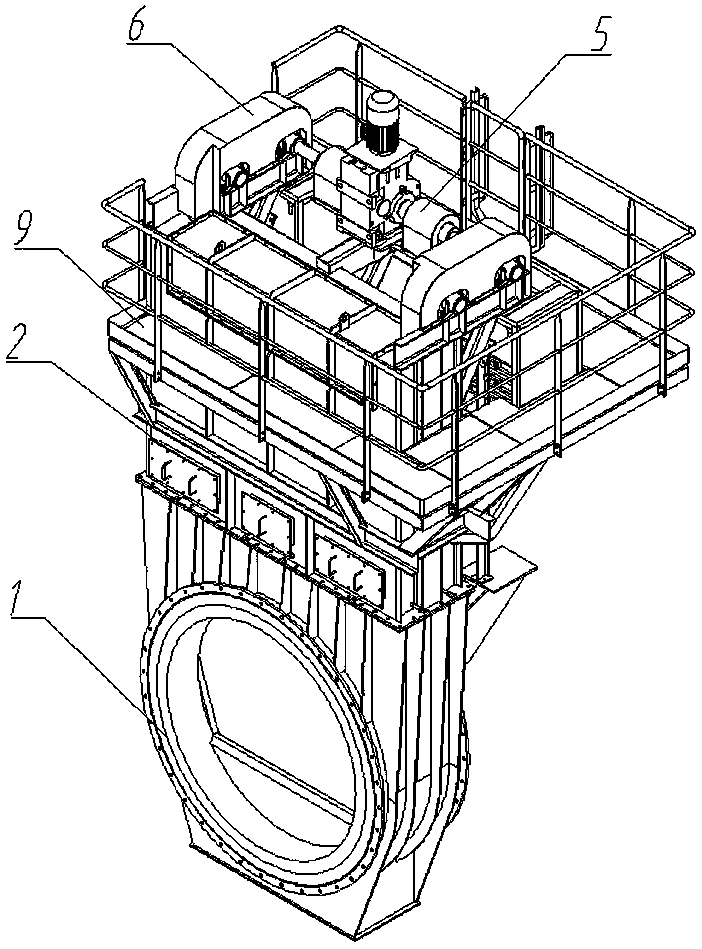

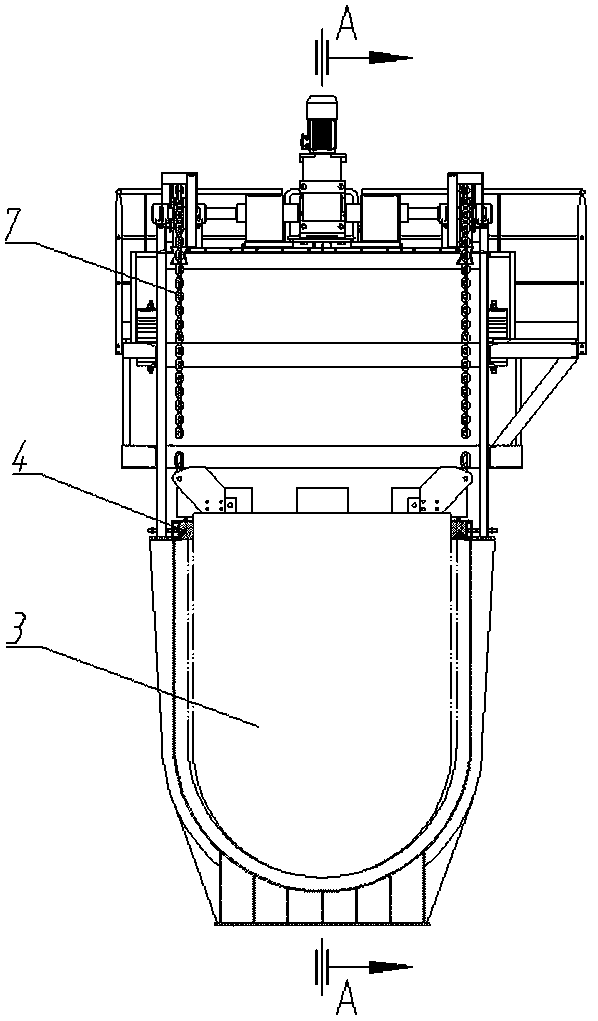

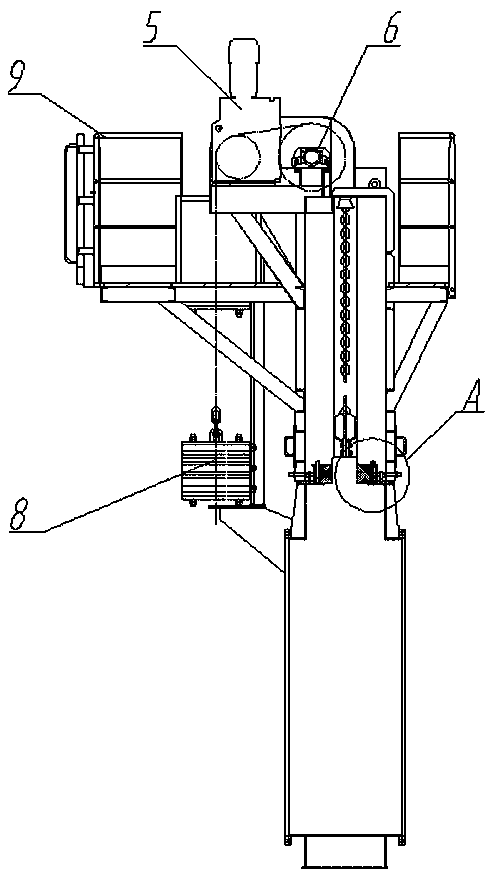

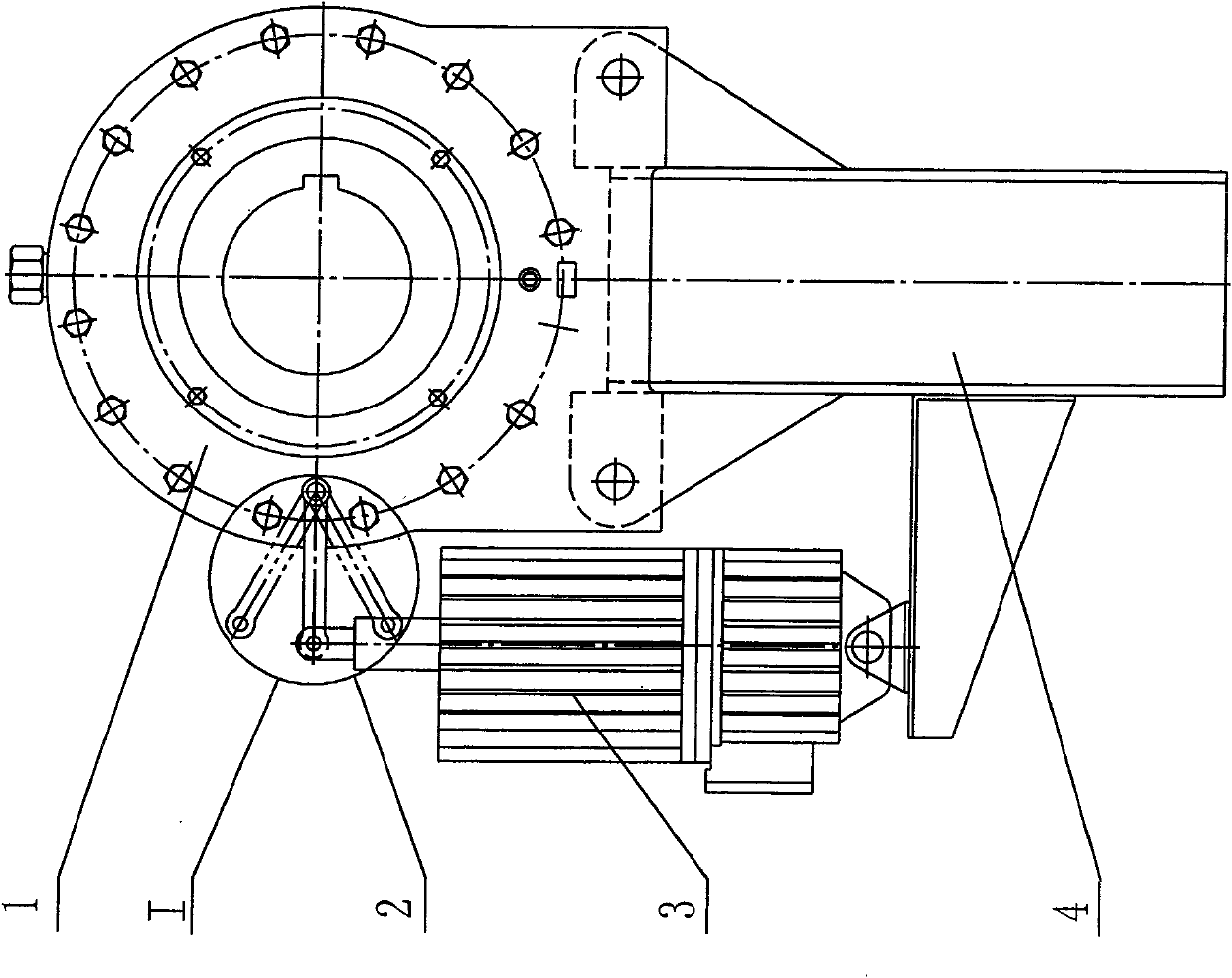

Electric gate valve

ActiveCN106195301BImprove sealingSolve the leaky sealOperating means/releasing devices for valvesSlide valveFiberDrive wheel

The invention relates to a pipe gate valve, in particular to an electric gate valve used in a high-temperature environment. The electric gate valve comprises a valve plate, a lower valve body, an upper valve body, a platform, a driving device, driven wheel devices, counterweight devices and a sealing device, wherein the sealing device is mounted on the upper part of the lower valve body and comprises ceramic fibers, a pressing plate, a pressing rod, a push plate, a push rod and locking nuts; the ceramic fibers are mounted on the upper part of the lower valve body; the pressing plate is mounted on the upper parts of the ceramic fibers through the pressing rod and the locking nuts and is used for adjusting the sealing effect of the ceramic fibers in the radial direction; and the push plate is mounted on the other sides of the ceramic fibers relative to the lower valve body through the push rod and the locking nuts, and is used for adjusting the sealing effect of the ceramic fibers in the axial direction. The sealing effect of the ceramic fibers can be adjusted in the radial direction and the axial direction by the sealing device, the problem of untight seal caused by change of sizes of the ceramic fibers is solved, and the sealing effect is good.

Owner:CBMI CONSTR

Fork type controlled non-contact wedge backstop

InactiveCN100593085CImprove load sharingEasy to assembleControl devices for conveyorsBrake typesEngineeringTorsion spring

Owner:吕泽英

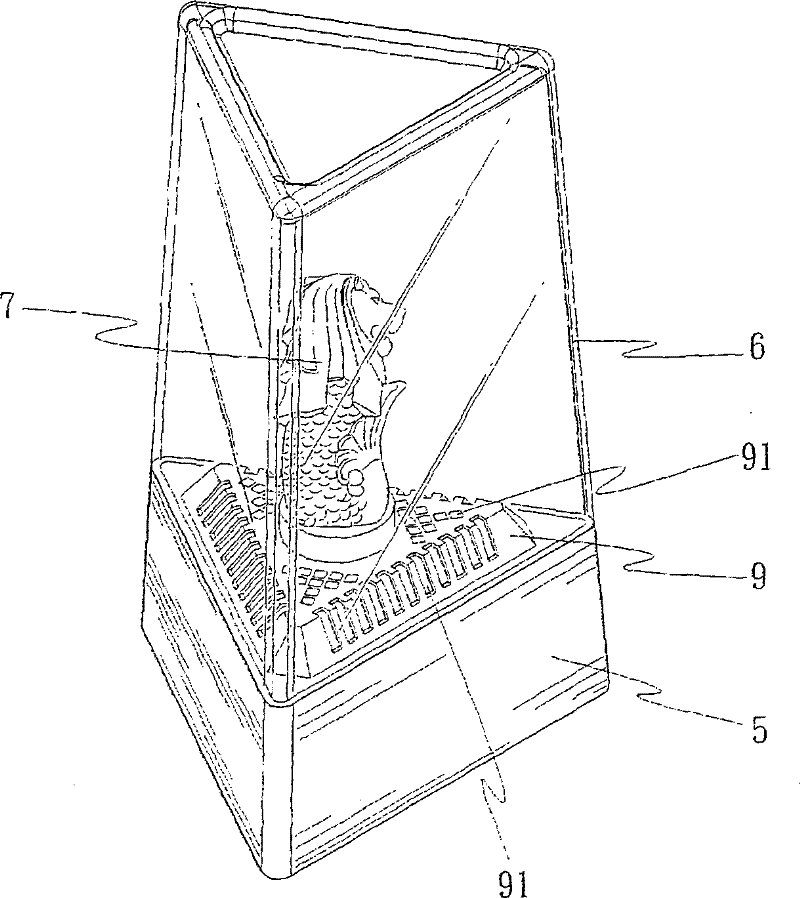

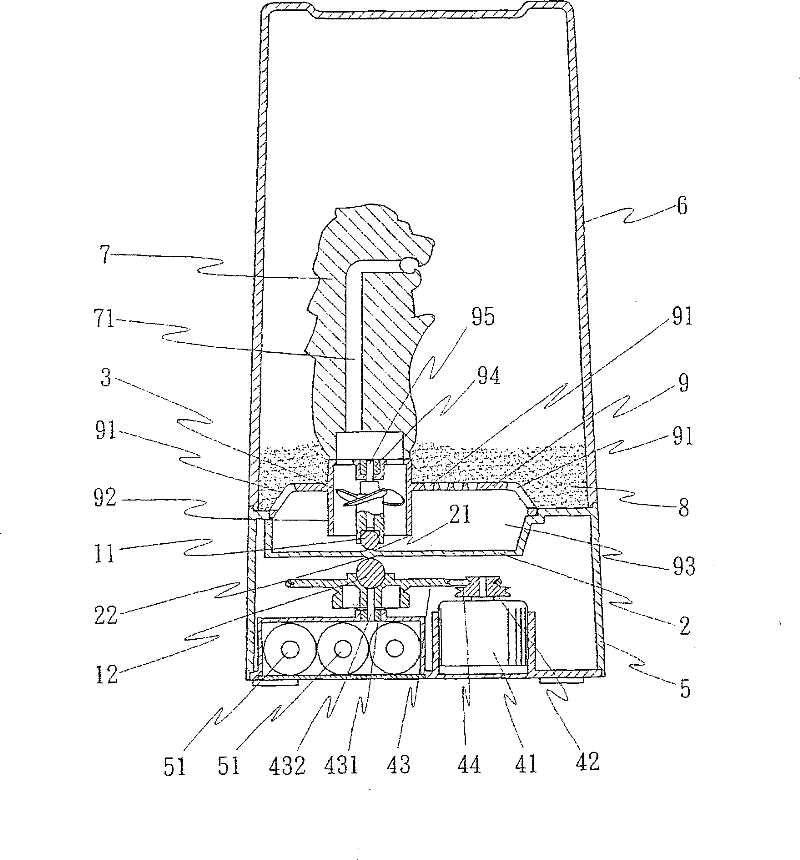

Magnetic Rotary Device

InactiveCN101280646BAchieve free spinsSolve the leaky sealToysGearing controlRotational freedomActive component

The invention discloses a magnetic suction type rotating device, which comprises one or more sets of magnetic blocks, a partition of a non-magnetic material, a rotating object and a power source, one or more sets of magnetic blocks, The upper and lower magnetic blocks are respectively arranged on the upper and lower sides of the partition, the upper magnetic block is a passive component, the lower magnetic block is an active component, and the upper magnetic block is combined with the rotating object; the lower magnetic block is driven by a power source. The invention utilizes the interaction of the N and S polarities of the magnetic blocks on both sides to drive the rotation. The magnetic block on one side can be controlled and driven by a power source, and the magnetic block on the other side can be attached to a rotating object. Therefore, Through the control of the power source, the rotating object can rotate freely. It can be applied to a closed ornamental cover, and the rotating object is driven by means of space to drive the quicksand to stir, creating a special visual viewing effect of the jet scene. The passive component and the active component do not need to be in direct contact, which solves the problem of poor sealing in the prior art.

Owner:余双仑

Blank processing equipment and processing method for graphite heat field

ActiveCN111906917BSolve the problem of inconvenient installation and liftingAvoid uneven mixingCeramic shaping plantsCrucibleElectric machinery

The invention discloses blank processing equipment for graphite heat field, which comprises a bottom plate, an arc-shaped vertical plate, a sliding mechanism, a lifting mechanism, and a stirring mechanism. There is a support plate in the middle of the shaped vertical plate, a crucible tube is installed in the circular through hole, an insulation tube is set on the outer surface of the crucible tube, and the two sides of the outer wall of the insulation tube are slidingly connected with the support plate through multiple pairs of sliding mechanisms; The two ends of the cover plate are movably connected to the corresponding arc-shaped vertical plate through a pair of lifting mechanisms; the motor shaft end of the motor rotates synchronously with the stirring mechanism. The invention also discloses a processing method for the blank processing equipment used in the graphite thermal field; The invention solves the problems of inconvenient installation and lifting of the crucible, uneven stirring of graphite materials, and poor sealing of the crucible opening. Through the cooperative use of various mechanisms, the operation steps are simplified, the labor burden of workers is reduced, and the efficiency of graphite material processing and production is improved.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

Gas leak-proof vacuum port screw cylinder

The invention provides a gas leak-proof vacuum port screw cylinder which comprises a vacuum port screw cylinder body, a vacuum port and a plurality of lead screws, wherein, corresponding through-holes are respectively formed on two opposite sides of the vacuum port screw cylinder body, and double screws can pass through the through-holes; the vacuum port is formed at the top of the vacuum port screw cylinder body, and a vacuum gland can be installed through the vacuum port; and the lead screws are arranged at the top of the vacuum port screw cylinder body and positioned around the vacuum port. No screw hole is formed on the gas leak-proof vacuum port screw cylinder, and the lead screws are arranged on the upper surface at the top of the vacuum port screw cylinder in a protruding manner, so that air leakage is caused because the screw hole is jammed by material and then a screw cannot be screwed in can be avoided consequentially, and the problem that the vacuum port is poorly sealed can be solved.

Owner:SHANGHAI KINGFA SCI & TECH

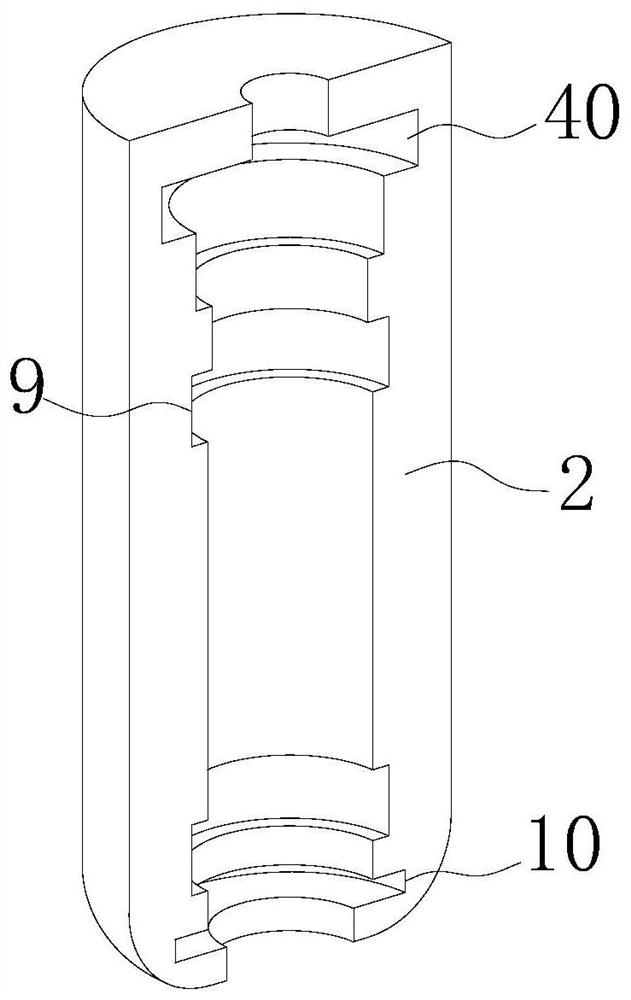

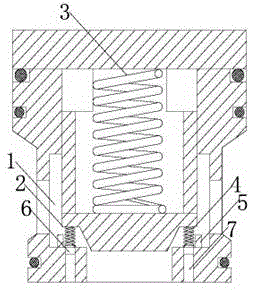

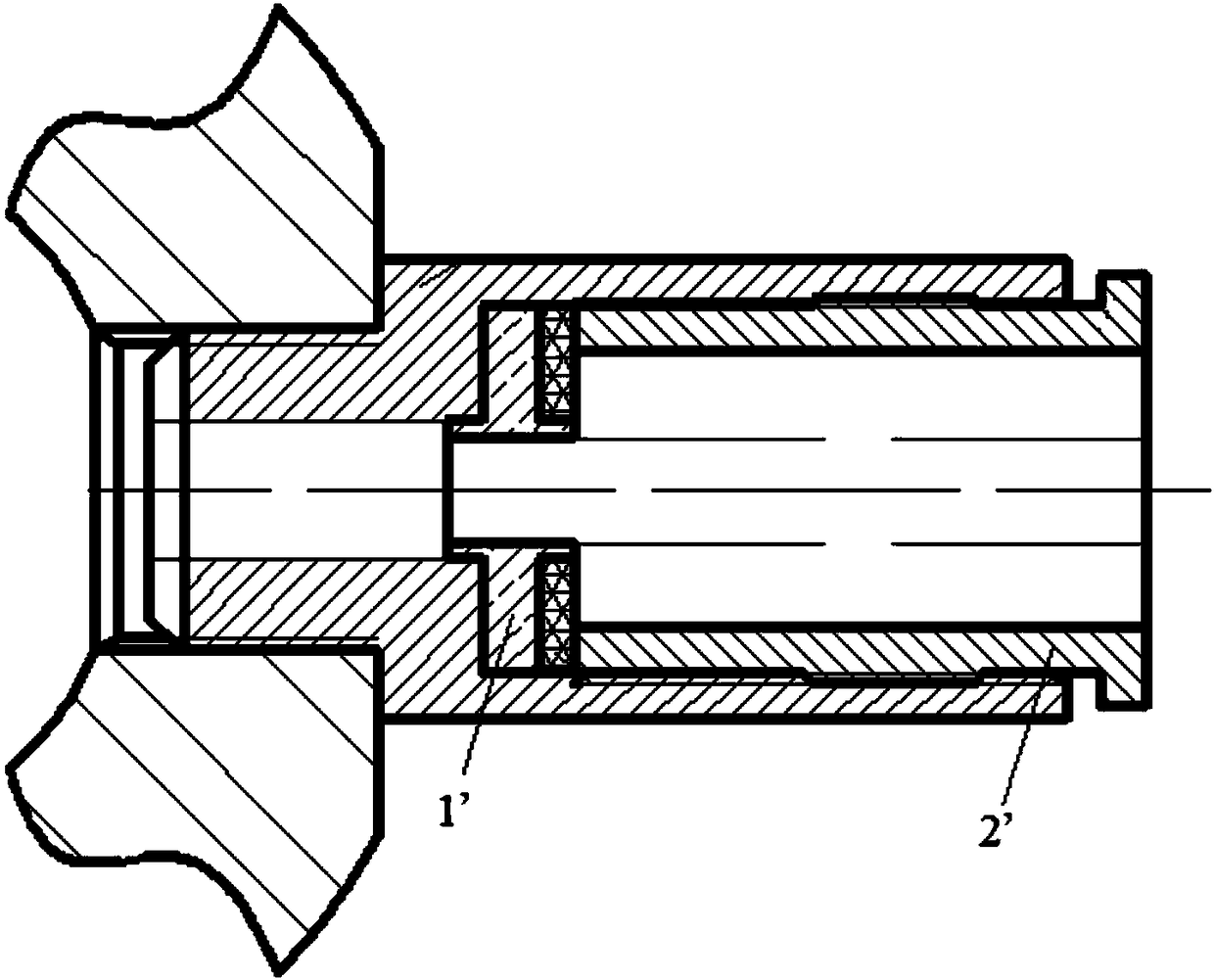

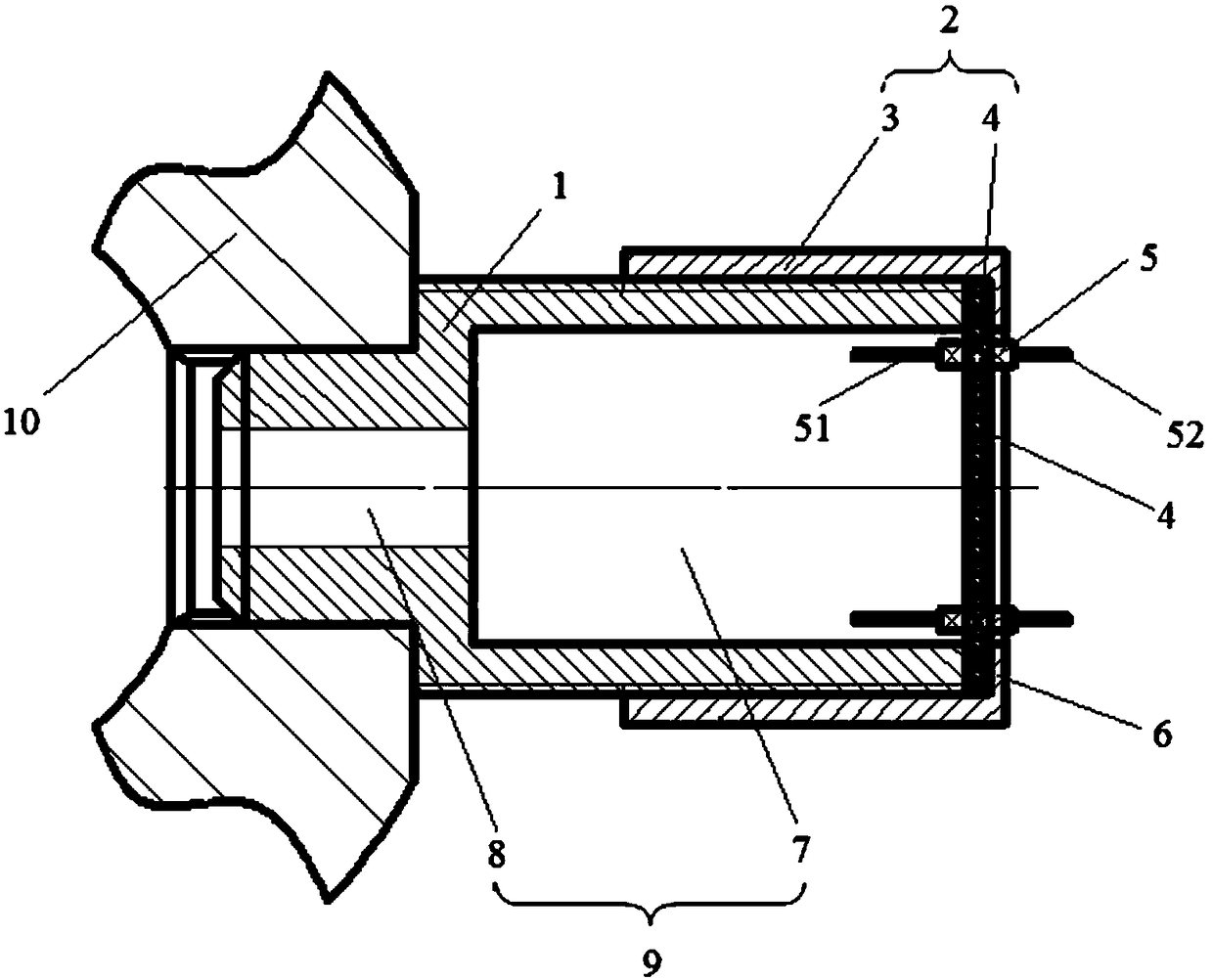

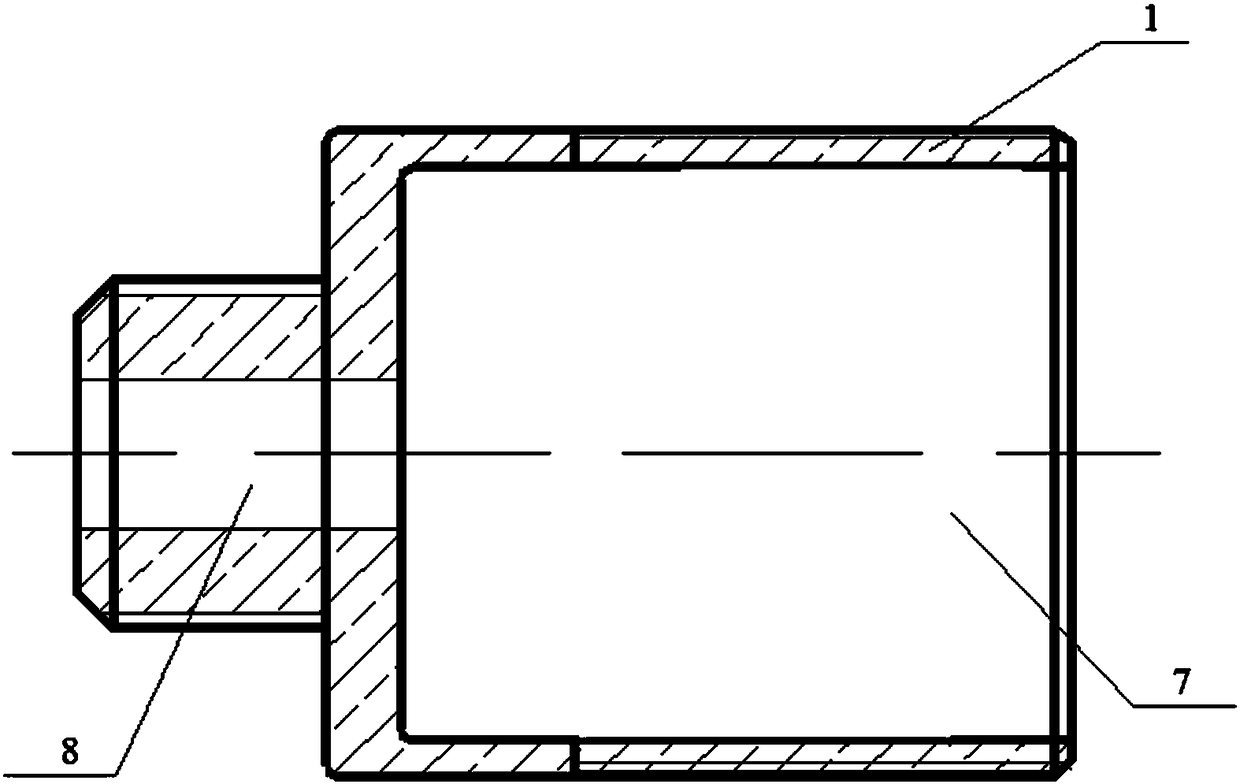

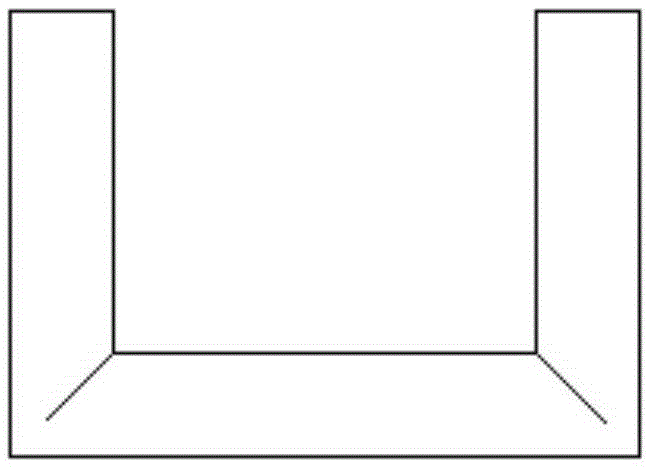

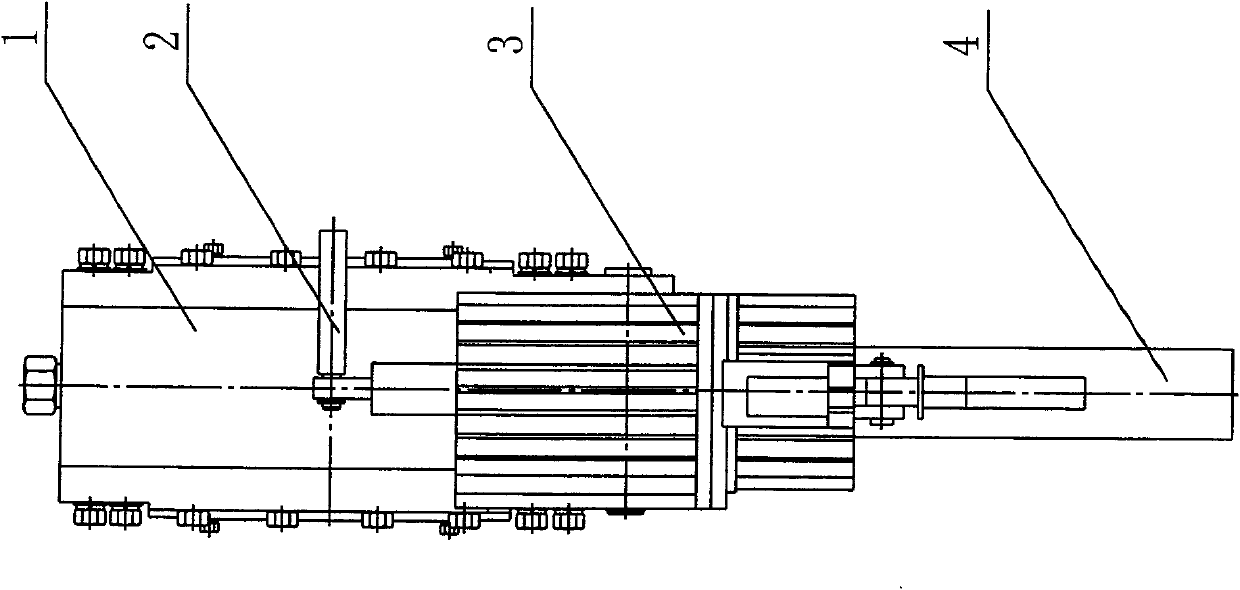

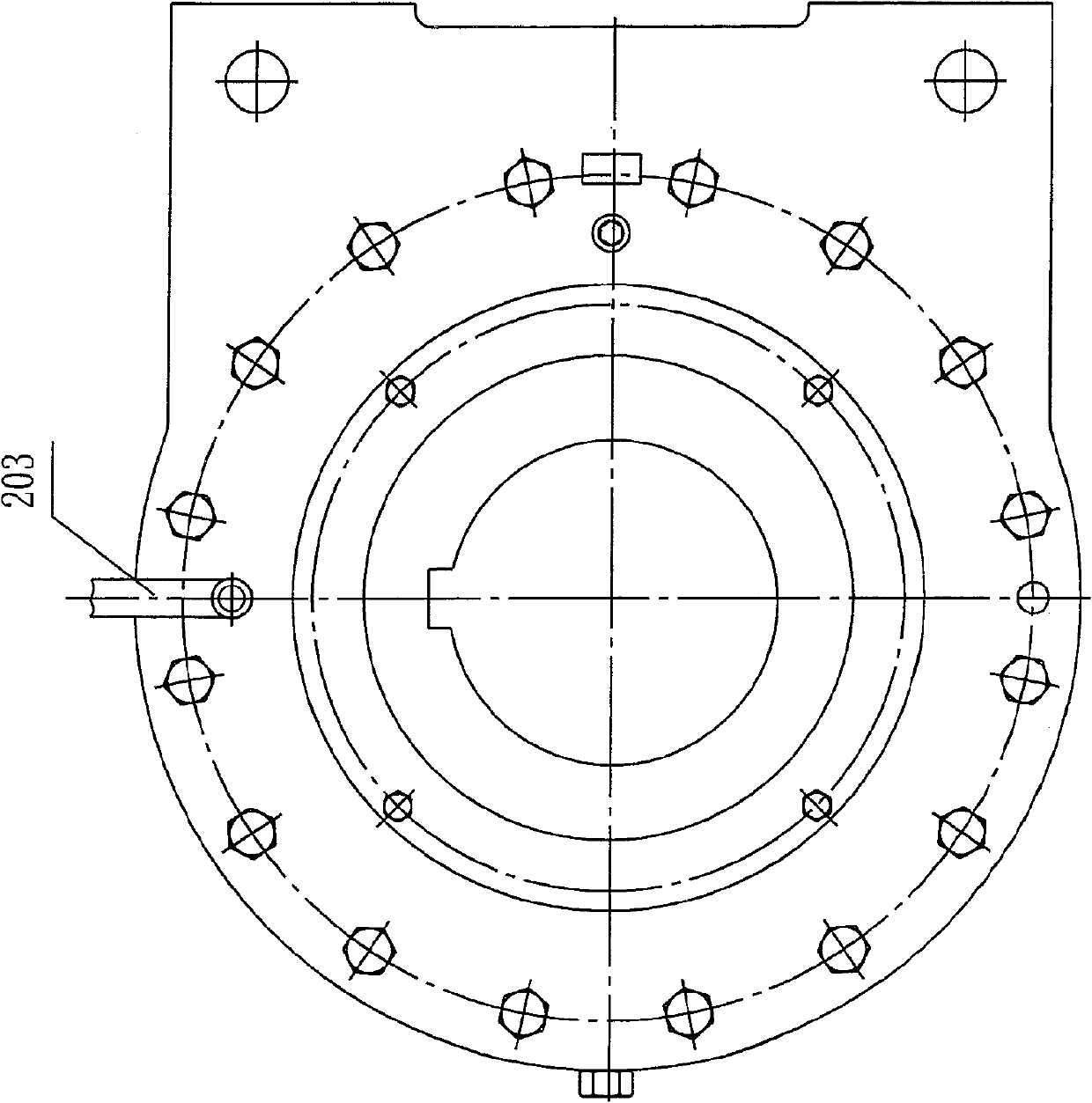

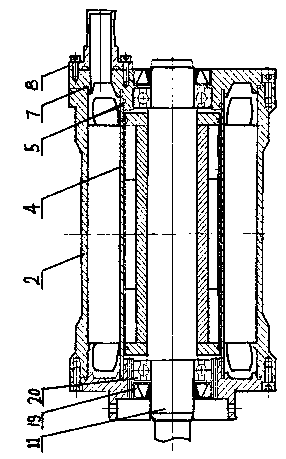

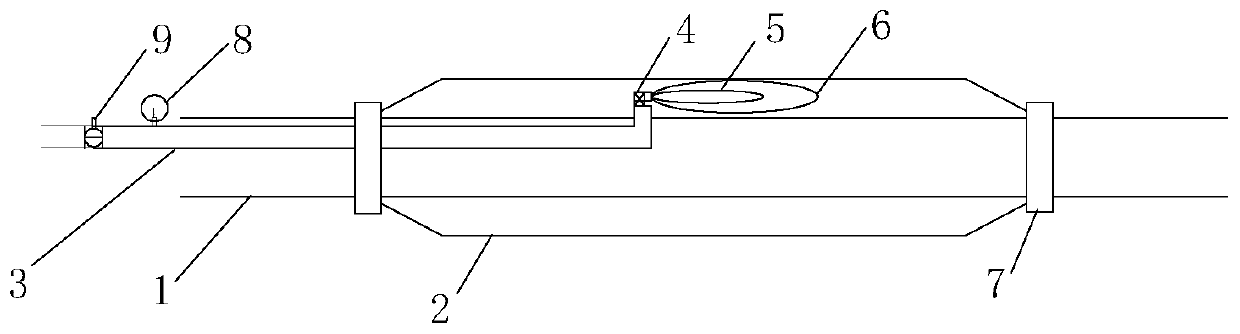

A compression-resistant structure of a deep-water propulsion motor

ActiveCN109067068ASolve the leaky sealImprove stress resistanceSupports/enclosures/casingsEngineeringInjection pump

The invention discloses a compression-resistant structure of a deep-water propulsion motor, which solves the problem that the seal structure of the existing deep-water motor is not scientific and reasonable and cannot meet the working requirements of the deep-water motor. The compression-resistant structure comprises a motor end cover (1) fixedly connected to the left and right end faces of the frame (2), A shielding cylinder (4) is arranged in the inner cavity of the stator (3), An annular groove (10) is provided on the inner surfaces of both motor end caps (1) on the outer side of the motorshaft, the left end of the shield cylinder (4) is fitted into an annular groove on the inner side of the left end cover, The right end of the shielding cylinder is embedded in an annular groove on theinner side of the right end cover, and the two motor end covers, the frame (2) and the shielding cylinder form a closed space (6). A tubing adapter (8) is arranged on the right end cover of the motor, an oil injection hole in the tubing adapter is communicated with the closed space (6), and a pressure-adjustable oil injection pump is connected to the tubing adapter. The compression resistance ofthe motor frame is further strengthened.

Owner:CSIC ELECTRICAL MACHINERY SCI & TECH

Discharging machine with good sealing effect

InactiveCN107381061AGood sealing effectImprove practicalityBulk conveyorsCantileverPulp and paper industry

The invention discloses a shut-off fan with good sealing effect, which comprises a shut-off fan body, the top and bottom of the shut-off fan body are connected with first pipes, and the surface of the first pipe is fixedly connected to an end far away from the shut-off fan body. There is a first fixing ring, the side of the first fixing ring away from the main body of the fan is fixedly connected with the second fixing ring, the side of the second fixing ring away from the first fixing ring is connected with a connecting pipe, and the first fixing ring is connected with a connecting pipe. The side of the two fixing rings away from the connecting pipe is communicated with a second pipe. The present invention achieves a good sealing effect by arranging the second pipe, the card slot, the circular baffle plate, the second sealing gasket, the first sealing gasket, the cantilever beam, the collar, the moving column, the limit ring, the spring and the handle to cooperate with each other. The advantages of the utility model solve the problem that the existing fan is not tightly sealed, so that when the fan is in use, it is not easy to leak air and run out of materials, which improves the practicability of the fan and is suitable for popularization and use.

Owner:泰州瑞沣环保科技有限公司

Engagement type controlled non-contact wedge backstop

InactiveCN101169167BImprove stress conditionsReduced additional radial forceControl devices for conveyorsBrake typesStress conditionsEngineering

The invention relates to a engagement-type controllable non-contact wedge block inverted device, which comprises a non-return member, a controller, a rotation-preventing arm and a wedge block assembly, wherein, the non-return member and the controller are arranged on the rotation-preventing arm; the inner ring of the non-return member is provided with a bearing and a seal ring, and the outer ringis provided with a front end cap and a rear end cap; cover plates are arranged on the end caps; the wedge block assembly is arranged in a rail formed between the inner ring and the outer ring; a plurality of wedge blocks are arranged between two yoke plates of the wedge block assembly; two ends of the wedge block are provided with torsion springs; the two yoke plates and two shift rings are integrated movably via ring openings which correspond mutually; two fixed stopping rings of the wedge block assembly are provided with holes corresponding to a stopping pin and a yoke plate positioning pinand are assembled together by mutual embedment; engaging elements are arranged in the end caps of the non-return member. The engagement force between gears and a gear chain is adopted to overcome inverted moments, the additional radial force produced during the force transmission can be significantly reduced, thereby improving the stress conditions of the wedge blocks, distributing loads evenly, facilitating the inverted device to run stably and reliably, and prolonging the service life of the inverted device.

Owner:吕泽英

A kind of hole sealing device for coal mine

The invention discloses a hole packer for a coal mine. The hole packer comprises a water injection pipe, a pressure bearing pipe and two steel hoops, wherein the water injection pipe is arranged in an inner cavity of an extraction pipe and penetrates through the pipe wall to form an opening; the pressure bearing pipe wraps the extraction pipe and covers the opening; and the two steel hoops are located on the two sides of the opening and fix the pressure bearing pipe to the extraction pipe in a sealing mode. The pressure bearing pipe at least comprises one rubber layer and one woven cloth layer. When rubber substances inside the pressure bearing pipe deform along with deformation of a drill hole in later period of extraction, the pressure bearing pipe can always keep in tight fit with the wall face of the drill hole, and long-term sealing of the drill hole is achieved. Meanwhile, a coagulation capsule does not need to be installed inside the pressure bearing pipe, namely high-pressure water is adopted for supporting the pressure bearing pipe, and good sealing of the drill hole is kept always. The hole packer for the coal mine is simple and reliable to operate and good in blocking effect, the labor intensity of operators is greatly relieved, and the problem that when solid hole sealing materials like polyurethane are adopted, sealing is not tight due to deformation of the drill hole after extraction is conducted for a period is solved.

Owner:南京铸安能源科技有限公司

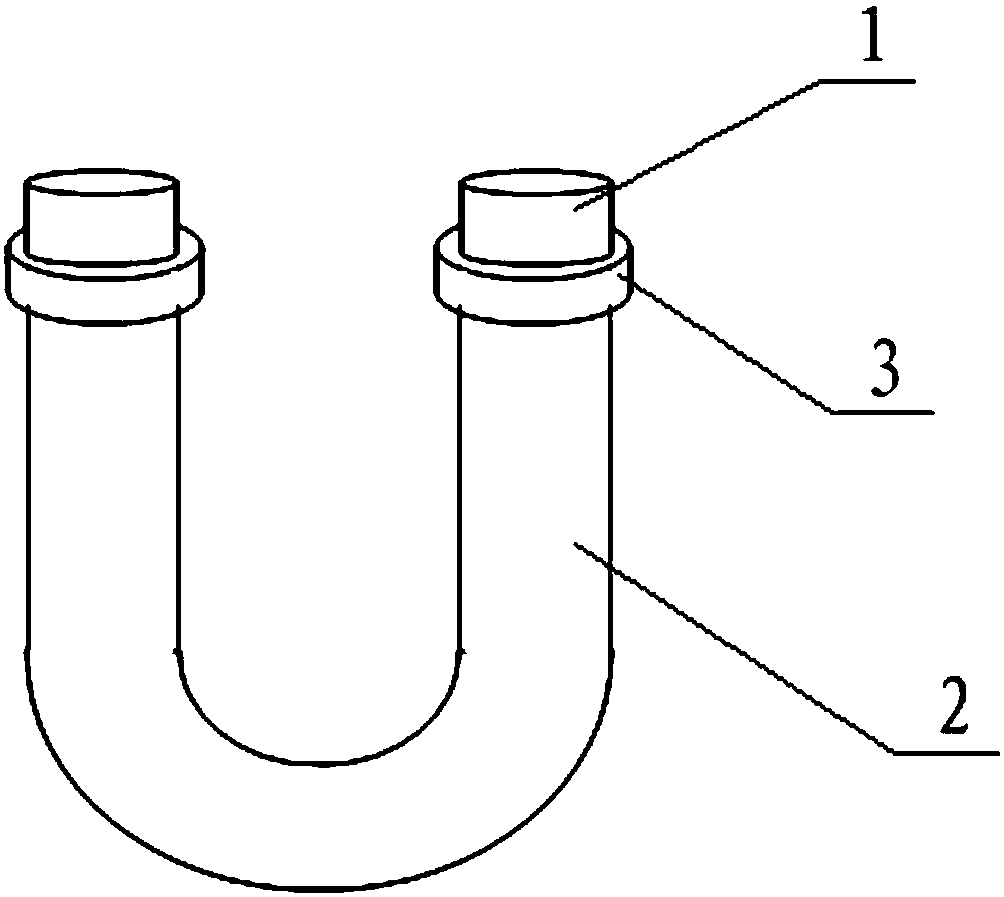

U tube

InactiveCN108072290ASimple structureIngenious designEvaporators/condensersTubular elementsEngineeringDual layer

Owner:TIANJIN LONGTAI HEATING & COOLING EQUIP MFG

Tail compensation type dynamic and static seal structure of bucket elevator

The invention discloses a tail compensation type dynamic and static seal structure of a bucket elevator. The tail compensation type dynamic and static seal structure comprises a shell and a cavity defined by the shell. A seal sliding plate is arranged in the cavity; a milling groove is formed in the inner side of the seal sliding plate and is internally provided with asbestos packing; and a fastening plate is arranged on the outer side of the seal sliding plate. The tail compensation type dynamic and static seal structure is simple and good in seal effect, and the use efficiency of the elevator is improved.

Owner:丁琦亮

Aluminum-foil paper folding repairing machine

InactiveCN111994383AImprove packaging qualitySolve the leaky sealPackaging cigarettePackage sterilisationStructural engineeringAluminum foil

The invention discloses an aluminum-foil paper folding repairing machine. The aluminum-foil paper folding repairing machine comprises a shell, wherein a feeding hole is formed in the upper half part of one side face of the shell; a feeding track is obliquely and downwardly mounted at the feeding hole; a plurality of groups of cigarette cases are placed on the feeding track; an upper baffle is fixedly arranged in the shell and located above the feeding track; three groups of ash removal fans acting on the cigarette cases are mounted in the upper baffle at equal intervals; and an ultraviolet sterilization lamp is mounted at the bottom of the upper baffle and located on one sides of the ash removal fans. According to the aluminum-foil paper folding repairing machine, a seal is added to a cigarette case aluminum foil through a repairing mechanism, so that the problem of untight sealing is solved, and the cigarette packaging quality is improved. In addition, the repairing mechanism adopts amechanical and automatic design, and the combination of the ash removal fans and the ultraviolet sterilization lamp is designed for carrying out ash removal and sterilization on the outer side and the inner part of a cigarette case waiting for feeding in a sealed environment, so that the aluminum-foil paper folding repairing machine is suitable for different working conditions, and brings a better use prospect.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com