Gas leak-proof vacuum port screw cylinder

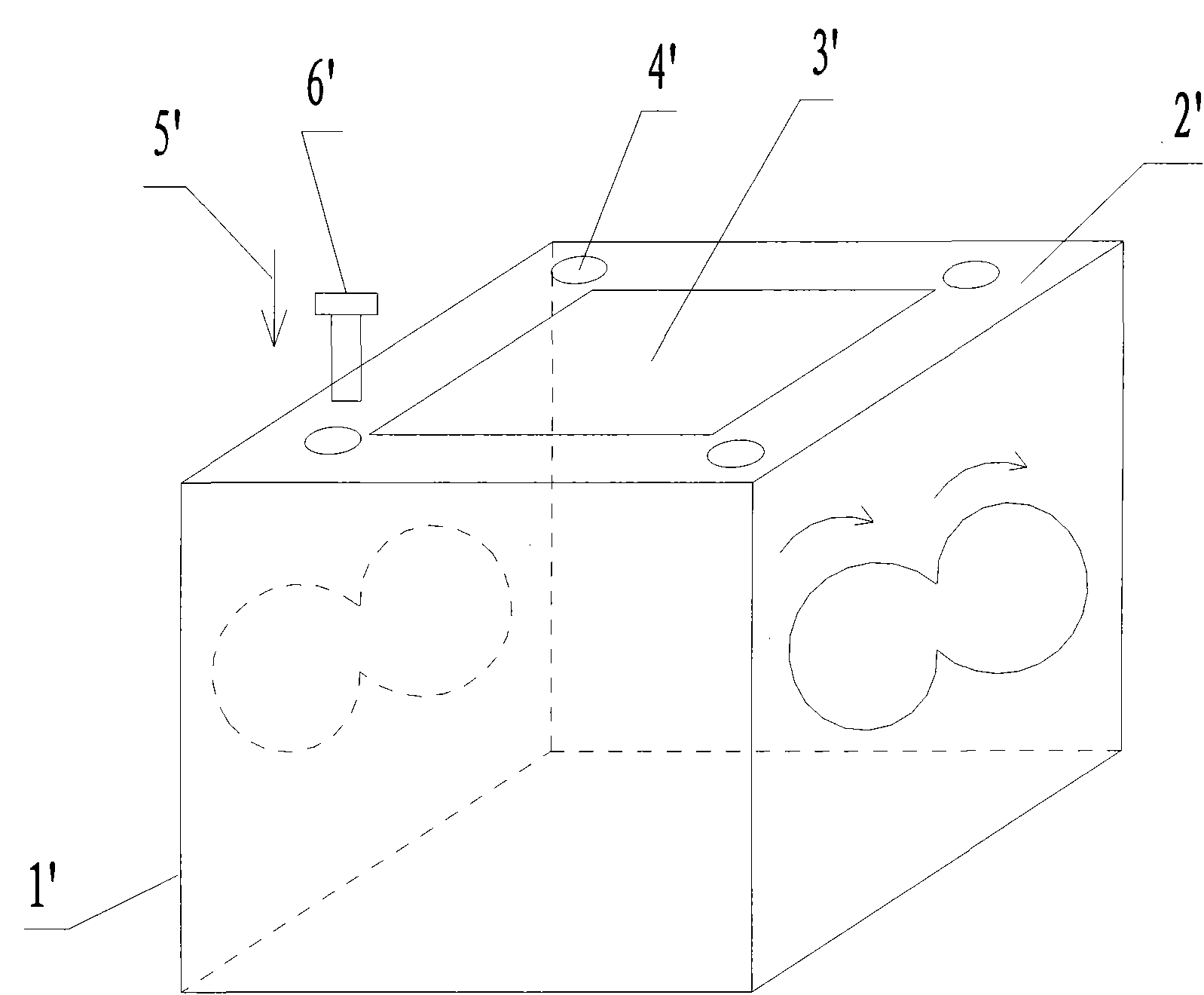

A vacuum port and anti-leakage technology, which is applied in the field of air-leakage-proof vacuum port screw barrels, can solve problems such as poor vacuum sealing, blocked screw holes, and screw 6' that cannot be screwed in and sealed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

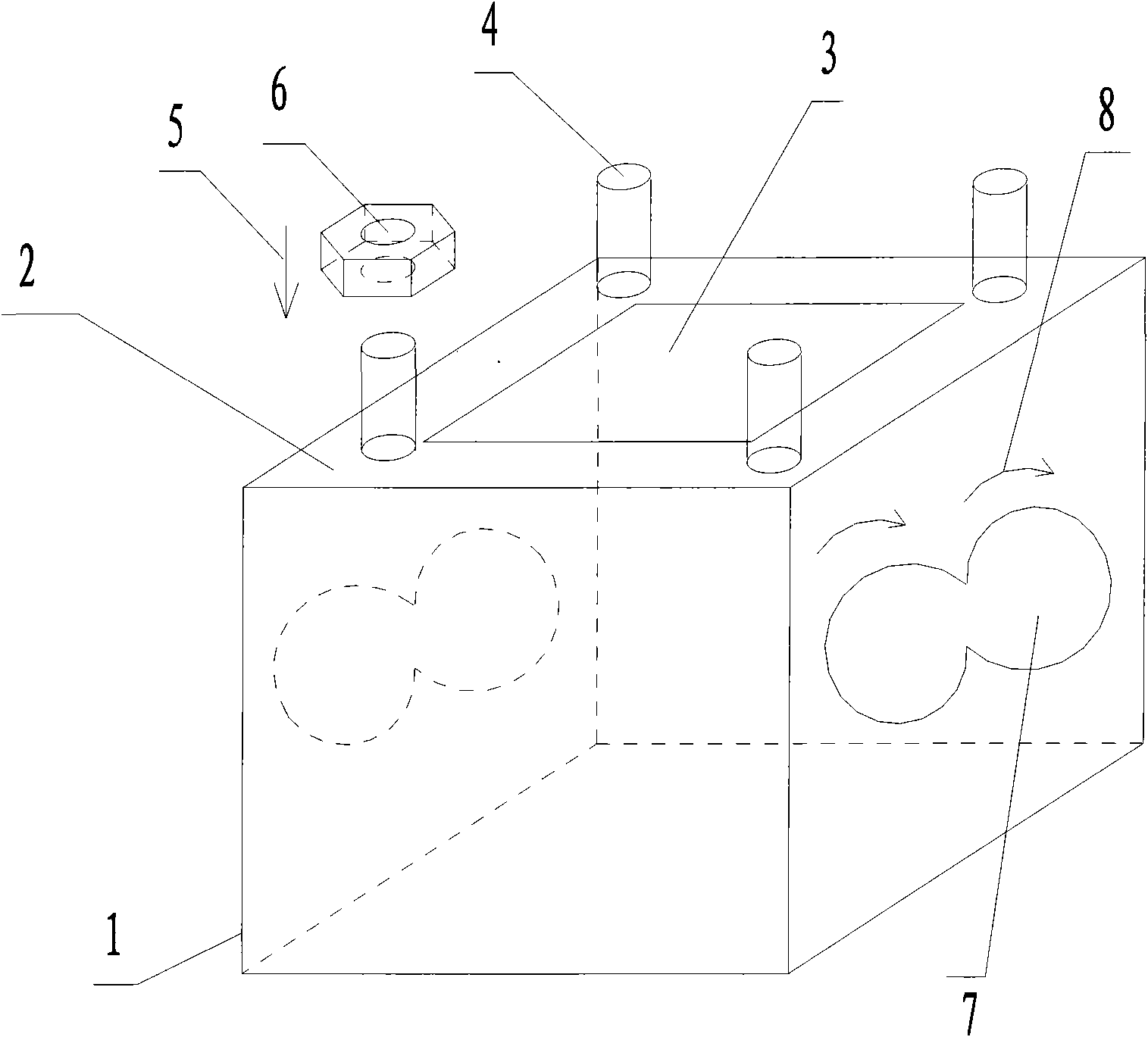

[0015] The following is attached figure 2 Embodiments of the present invention will be further described.

[0016] Such as figure 2 As shown, the invention provides a kind of anti-leakage vacuum port screw barrel, which comprises:

[0017] The vacuum port screw barrel body 1, the vacuum port screw barrel body 1 is a hollow barrel body, and the opposite sides of the screw barrel body 1 are respectively provided with corresponding through holes 7 for the twin-screw to pass through. The material in the body 1 rotates and moves in the direction shown by the arrow 8 through the twin-screw extruder, and is extruded for use;

[0018] On the top 2 of the vacuum port barrel body 1, a rectangular vacuum port 3 for installing a vacuum gland is provided, and at the four corners next to the rectangular vacuum port 3, four vacuum port barrels are provided. The screw rod 4, the bottom of the screw rod 4 is arranged on the upper surface of the top 2 of the vacuum port screw barrel body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com