Tail compensation type dynamic and static seal structure of bucket elevator

A bucket elevator and sealing structure technology, which is applied to the sealing of engines, conveyors, mechanical equipment, etc., can solve the problems of large damage to the site environment, poor sealing, and easy material leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

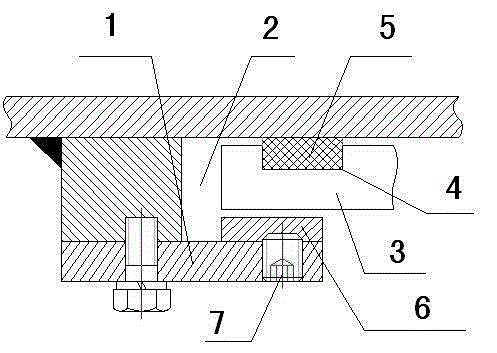

[0011] As shown in the figure, a bucket elevator tail compensation dynamic and static sealing structure of the present invention includes a casing 1 and a cavity 2 surrounded by the casing, a sealing slide 3 is arranged in the cavity 2, and the sealing The inner side of the sliding plate 3 is provided with a milling groove 4 , and an asbestos filler 5 is arranged in the milling groove 4 , and a fastening plate 6 is arranged on the outer side of the sealing sliding plate 3 .

[0012] The fastening plate 6 is provided with threaded holes, and the housing 1 is provided with screws 7 matched with the threaded holes.

[0013] An open cavity 2 is formed by assembly and welding of plates and section steel. The sealing slide plate 3 can realize relative movement in the cavity 2, and the soft seal with the shell is realized by filling the milling groove 4 with asbestos filler 5. . Due to the relative movement between the sealing slide plate 3 and the shell 1, the asbestos filler 5 wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com