Sealing device for anode groove and cathode roller of crude foil engine

A technology of sealing device and cathode roll, which is applied in the field of electrolytic copper foil, and can solve problems such as poor sealing and electrolyte leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

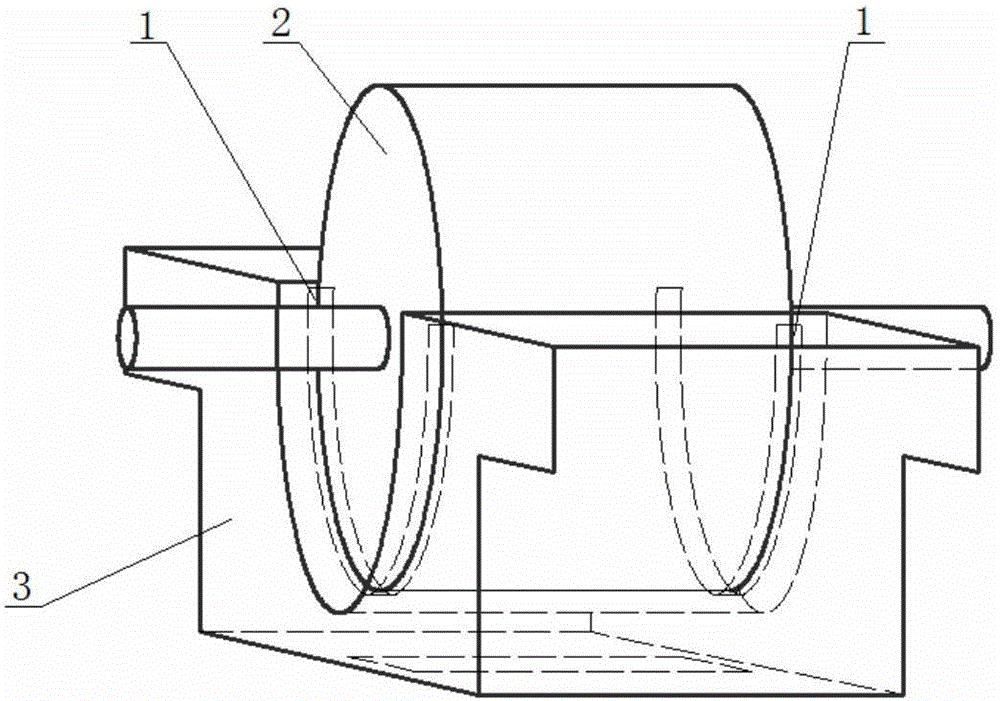

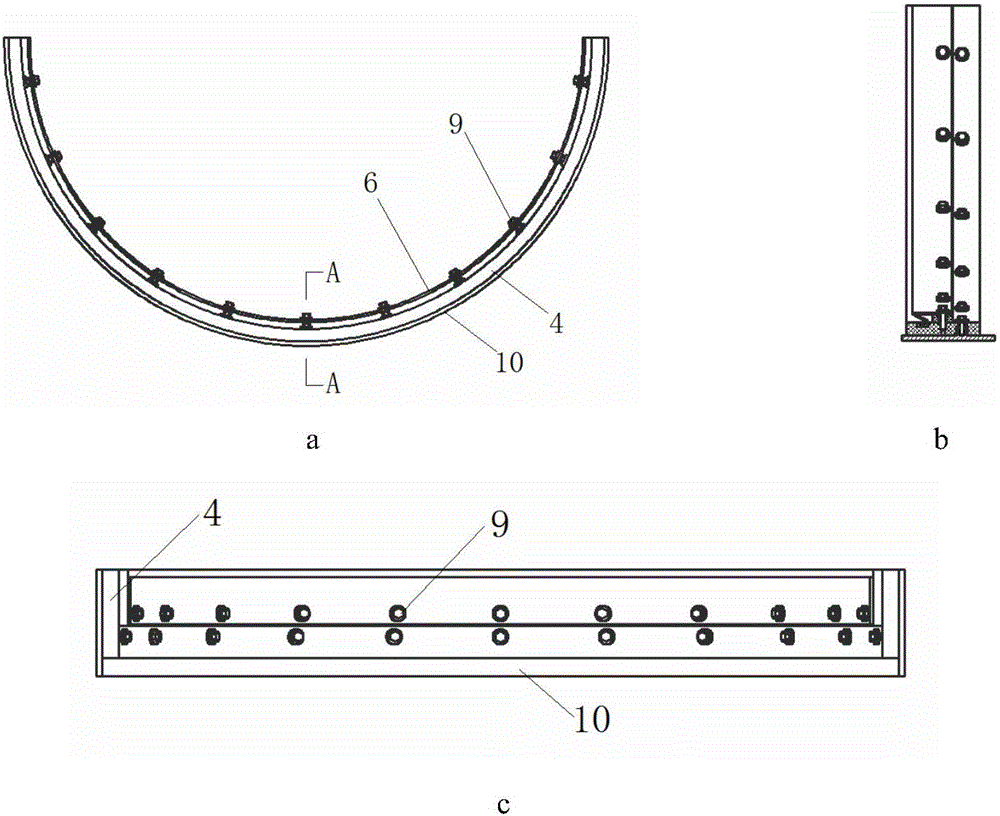

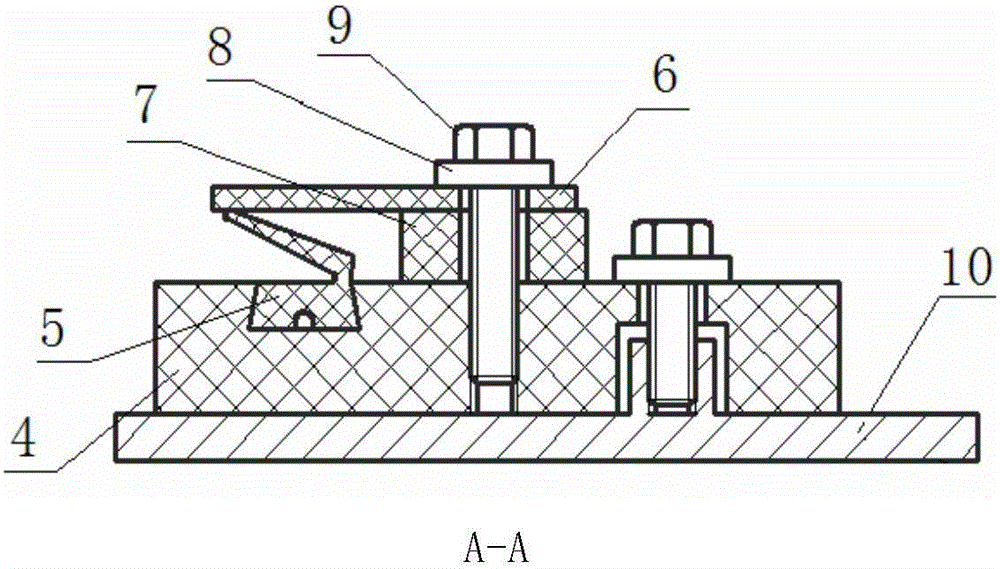

[0020] This embodiment is a sealing device for the anode groove and the cathode roll of a foil machine, including a lip seal bottom plate 4, a lip seal 5, a seal plate 6, a seal plate backing plate 7, a flat washer 8, bolts 9 and lining plate 10.

[0021] Wherein: the liner 10 is in the shape of a semicircle. The bottom plate 4 of the lip seal is also in the shape of a semicircle, and is fixed on the inner surface of the liner 10 by bolts 9 and titanium flat washers 8 . The sealing plate backing plate 7 is fixed on the upper surface of the bottom plate 4 of the lip sealing strip, and is located in the middle of the bottom plate in the width direction of the sealing strip. The lip sealing strip 5 is located on the side of the upper surface of the lip sealing strip bottom plate 4 , and the lower end of the lip sealing strip is embedded in the dovetail groove on the upper surface of the lip sealing strip bottom plate 4 to be fixed. The sealing plate 6 is located on the upper su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com