Iron ore high-temperature performance measuring device

A technology for high-temperature performance and measuring devices, applied in measuring devices, material thermal analysis, instruments, etc., can solve problems such as cumbersome operation, unsafety, and lack of micro positive pressure nitrogen protection system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

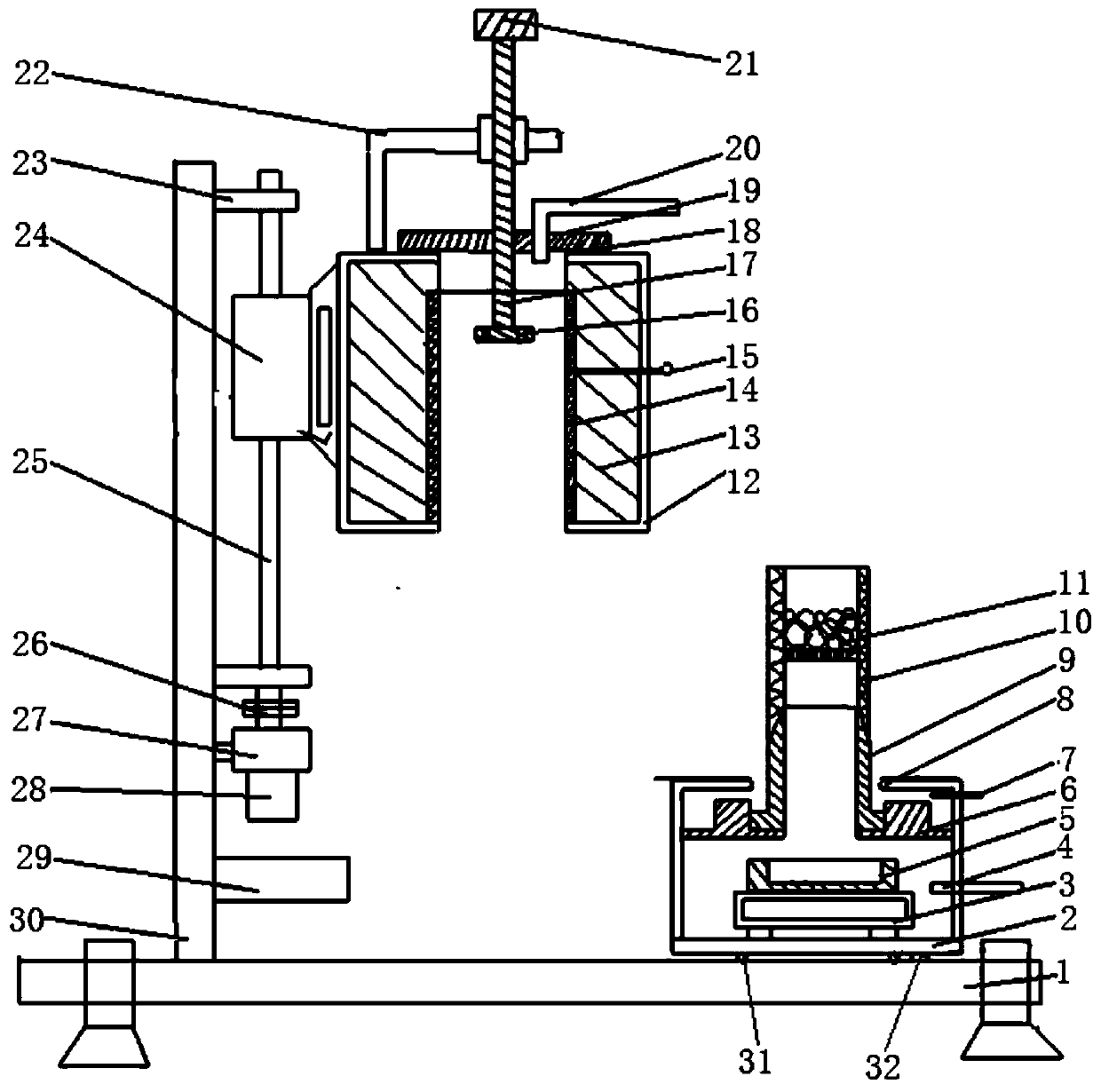

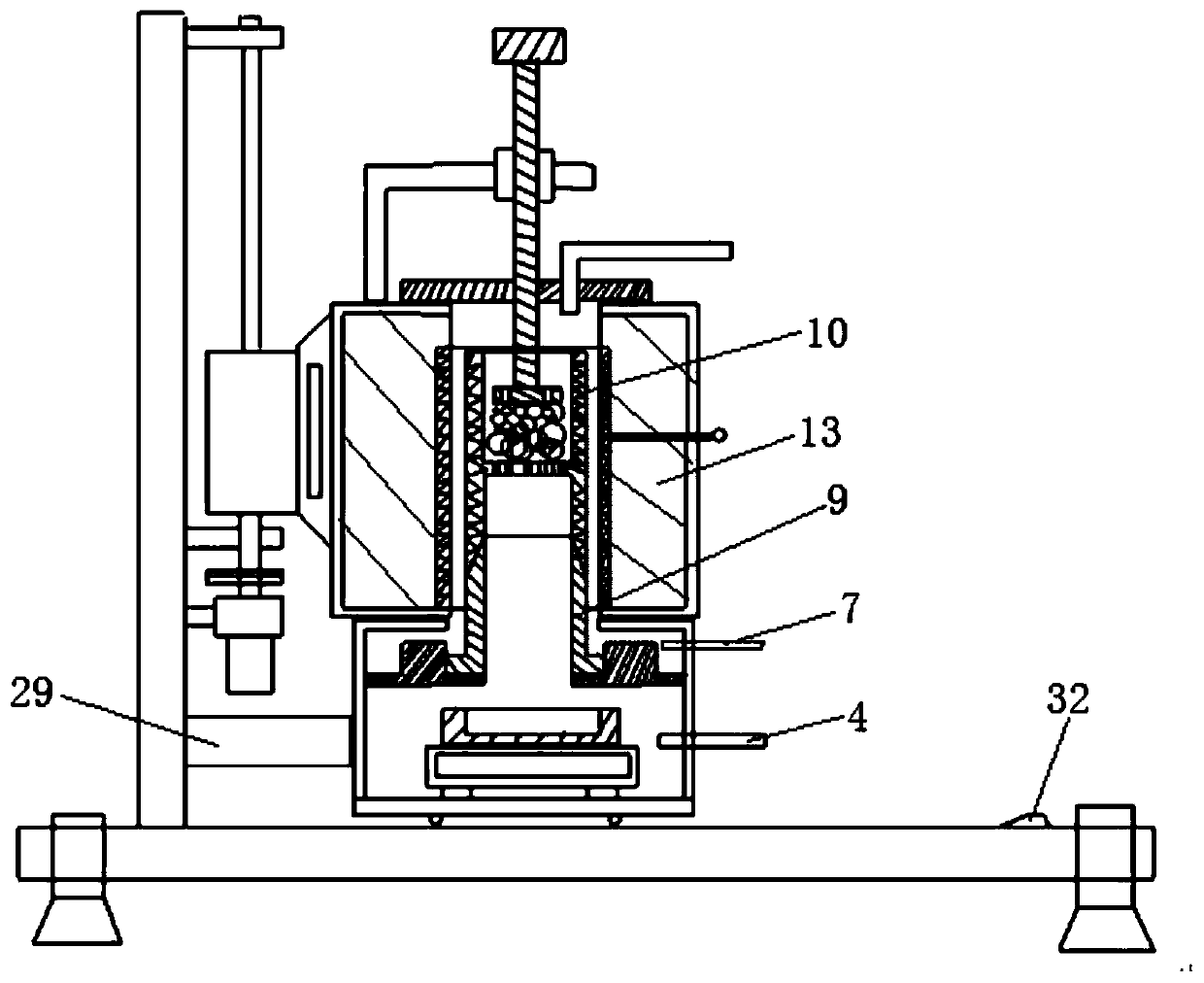

[0022] like figure 1 and 2 As shown, an iron ore high-temperature performance measuring device of the present invention includes: a frame mechanism, a lifting mechanism, a heating furnace mechanism, a chassis mechanism, a gas distribution mechanism and a load mechanism. The frame mechanism includes a horizontal base 1 and a vertical support frame 30 installed at one end of the horizontal base 1. The lifting mechanism is arranged on the vertical support frame 30 and can move up and down along the vertical support frame. The heating furnace The mechanism is fixedly connected with the lifting mechanism; the chassis mechanism is provided with a crucible 10, and the chassis mechanism is arranged on the horizontal base 1 and can be moved to the bottom of the heating furnace mechanism along the horizontal base 1; the air inlet pipe of the gas distribution mechanism and the inner cavity of the chassis mechanism In communication with each other, the load mechanism extends into the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com