Air-intake control device of paint spray gun

A technology of a control device and a paint spray gun, which is applied in the field of paint spray guns, and can solve problems such as gasket corrosion damage, poor impact resistance of the valve core, and affecting the normal use of the gun body 1, and achieve good impact resistance, anti-corrosion performance, and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

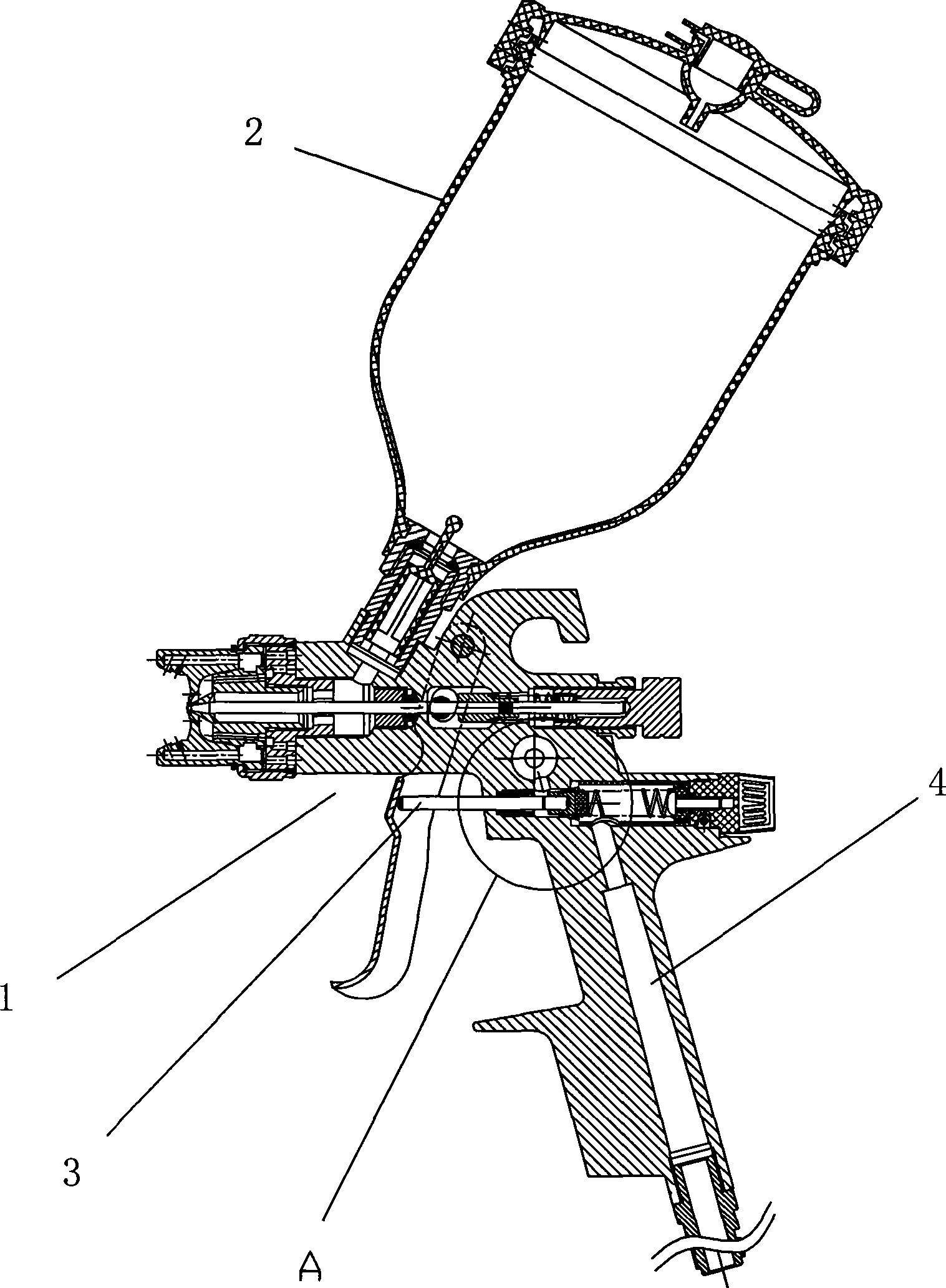

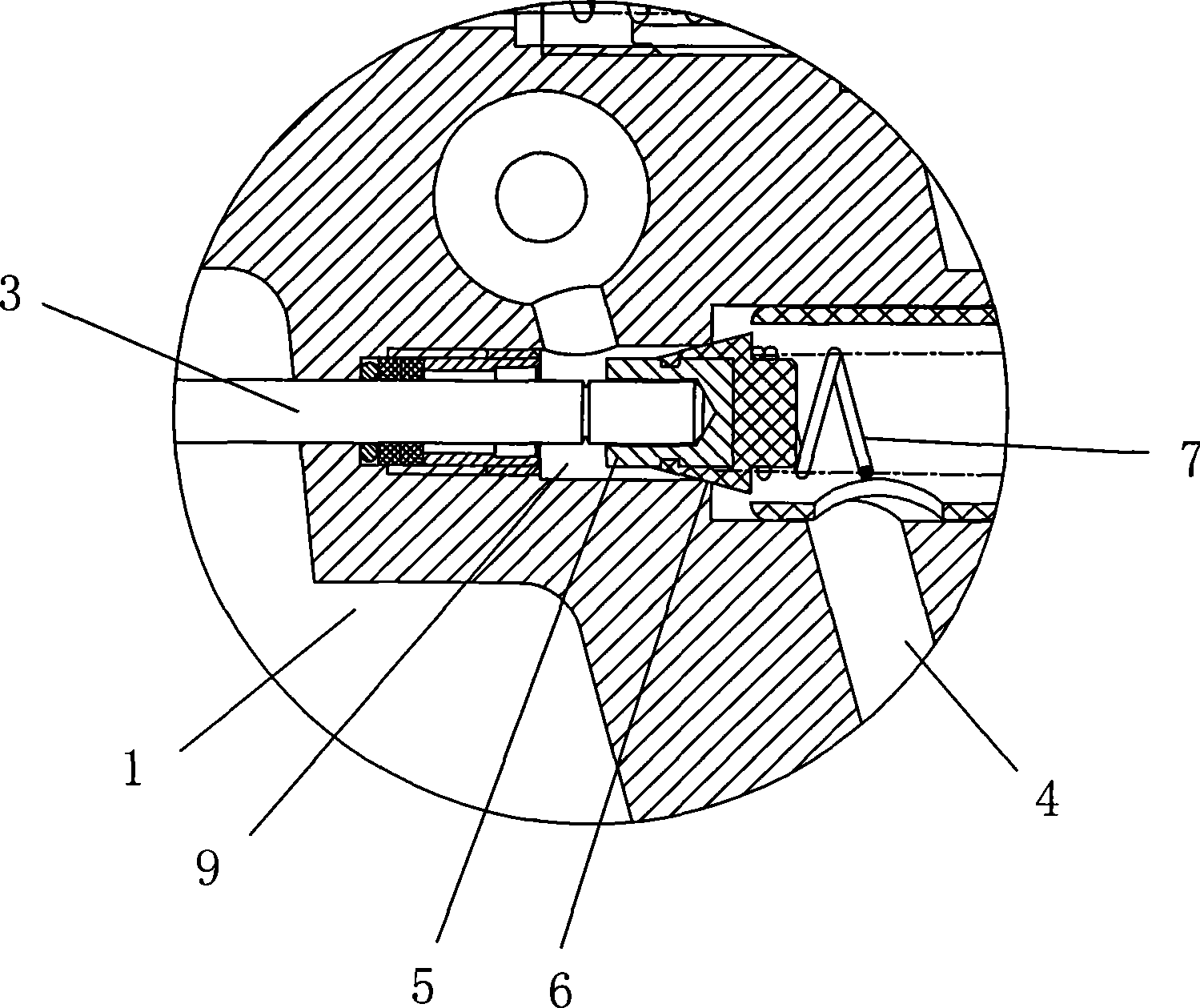

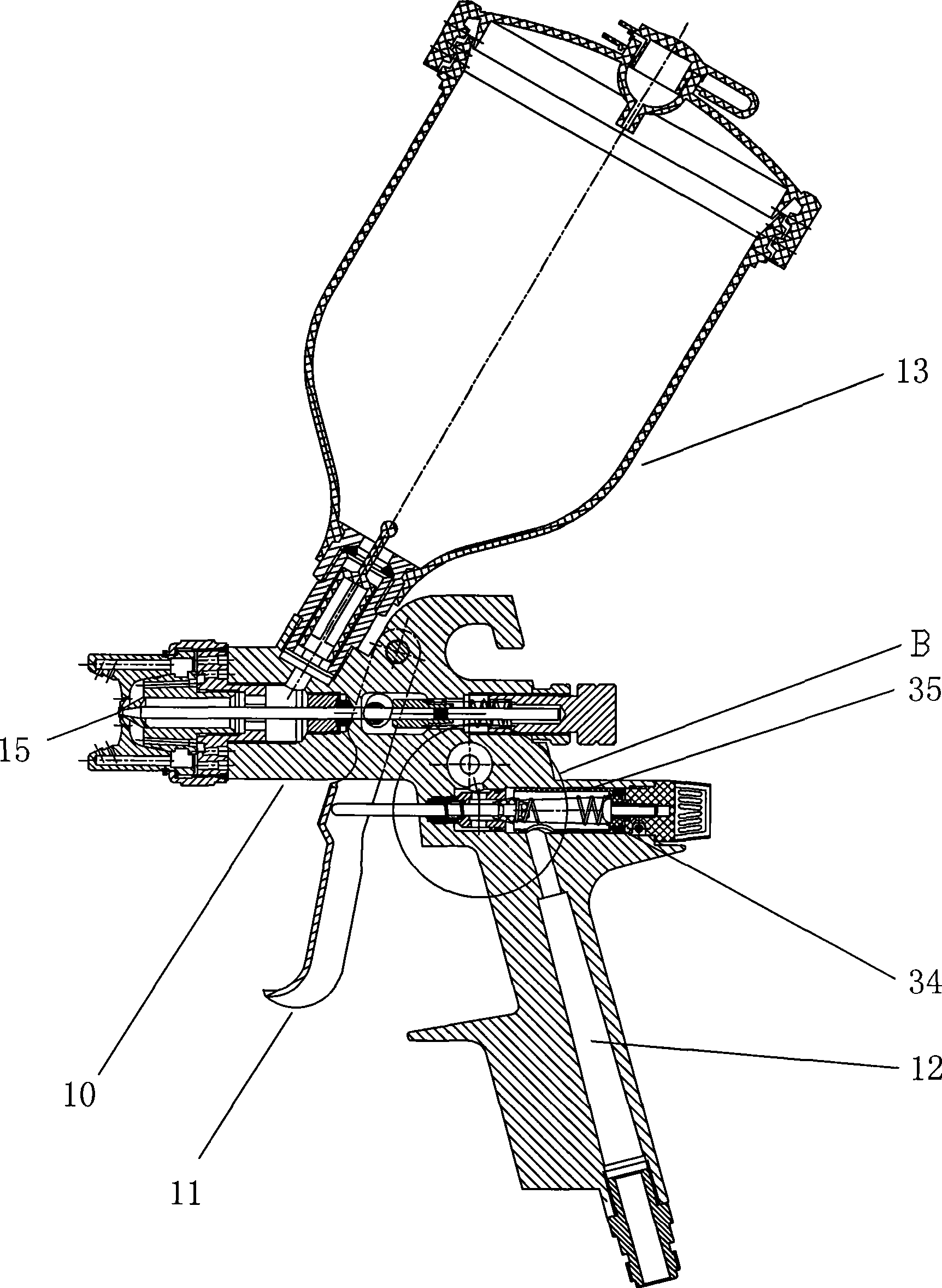

[0018] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see image 3 —4:

[0019] The air intake control device of the paint spray gun includes a gun body 10, a vent pipe 12 arranged on the gun body 10, a valve chamber 14 arranged in the middle of the vent pipe 12, a valve core 50 arranged on the valve stem 20 and a return spring 33. A liner 40 with a valve seat 404 on one side is provided in the valve chamber 14, and a sealing ring 32 is provided between the outer wall of the liner 40 on the side with the valve seat 404 and the gun body 10. On the liner 40, along the valve stem 20 is provided with a through hole in the center of the axial direction, the inner diameter D1 of the through hole 401 in the middle of the liner 40 is larger than the outer diameter D2 of the valve stem 20, and the through hole 401 in the middle of the liner 40 is provided with a radial connection with the spray gun. The vent ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com