Electric gate valve

A technology of electric gate and valve body, applied in the direction of sliding valves, valve details, valve devices, etc., can solve the problems that affect the stability of production line conditions and product quality, poor sealing effect, and tight sealing, etc., to achieve uniform force , Good sealing effect, avoiding the effect of valve stuck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with embodiments, and the purpose is only to better understand the content of the present invention. Therefore, the examples cited do not limit the protection scope of the present invention.

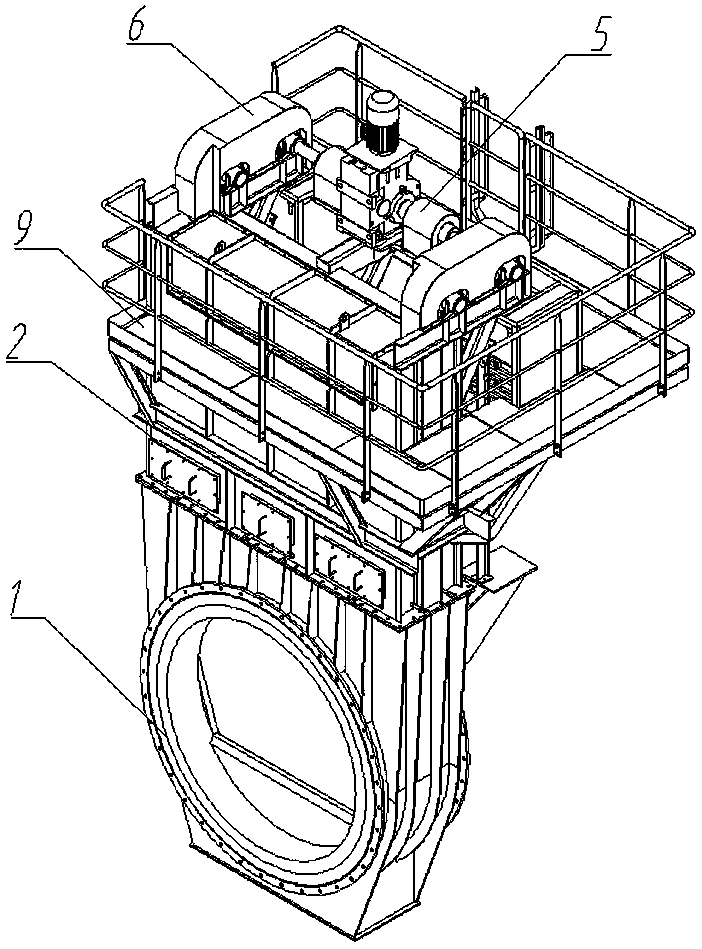

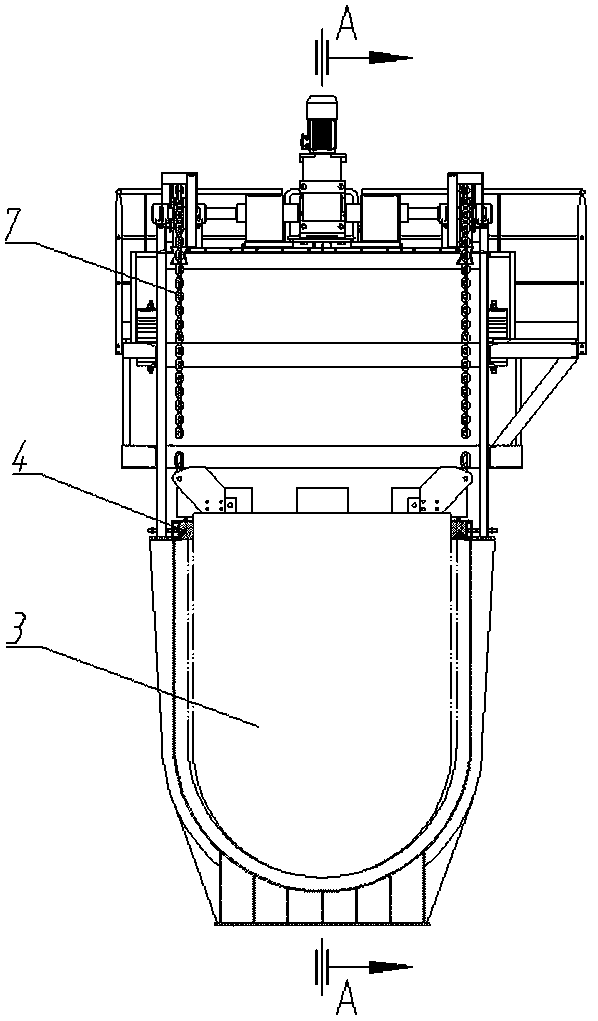

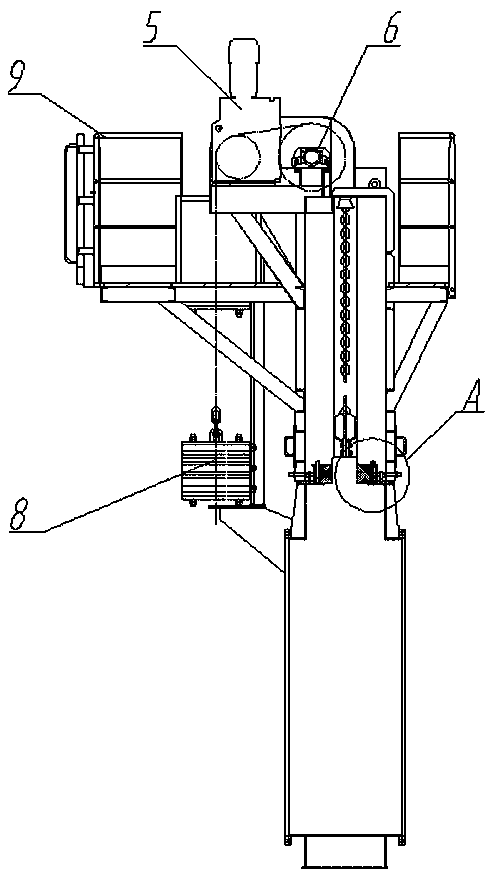

[0017] See figure 1 , figure 2 , image 3 , Figure 4 , The valve plate 3 is installed in the lower valve body 1, and the opening and closing of the valve is controlled by the up and down movement in the lower valve body 1. The lower valve body 1 and the upper valve body 2 are connected by bolts to form a valve body, and the upper valve body 2 is installed with The platform 9, the driving device 5 and the driven wheel device 6 are installed on the platform 9. The driving device 5 is composed of double motors. Two sets of the driven wheel device 6 are arranged symmetrically on both sides of the driving device 5. The valve plate 3 is respectively connected by a chain 7 It is connected to the two sets of driven wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com