One-way valve

A one-way valve and one-way valve technology, applied in the direction of control valve, valve device, functional valve type, etc., can solve the problems of the valve core of the valve port being stuck, increasing the cost, and failing to achieve a sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

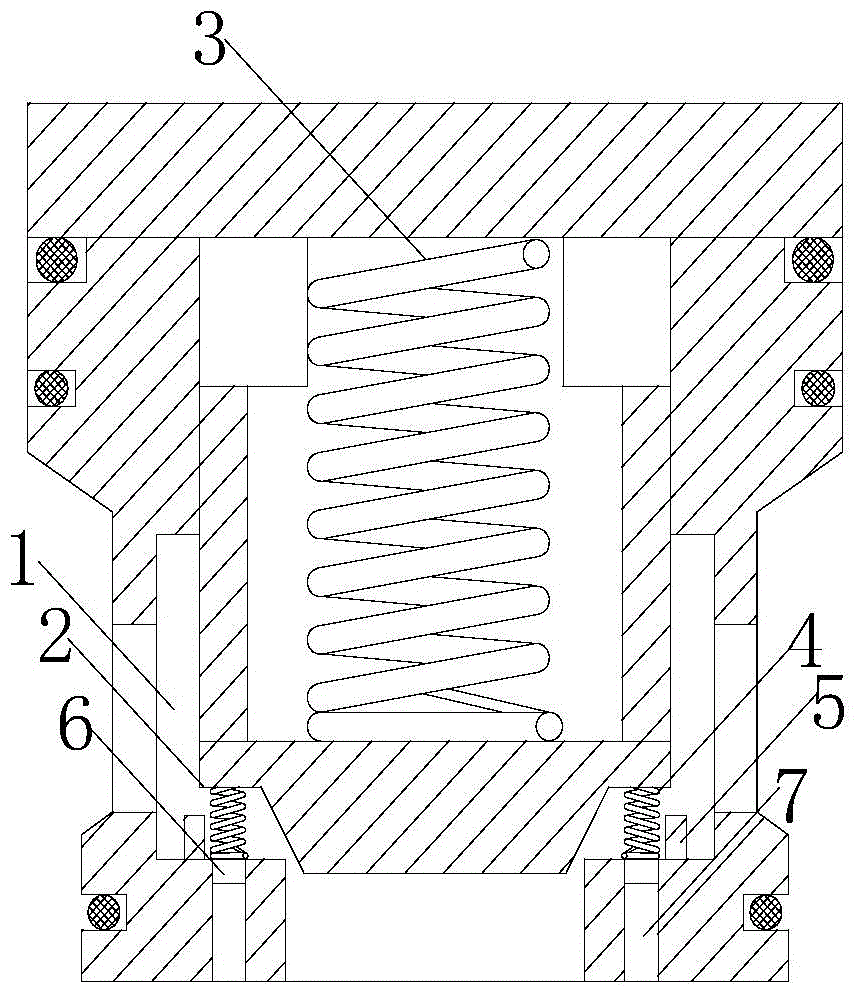

[0014] See figure 1 As shown, the one-way valve includes a valve body 1 and a valve core 2 installed in the valve body. The bottom surface of the valve core is provided with a support spring 3, and the inner wall of the valve body inlet is provided with a first elastic Piece 4; The first elastic piece is provided with a baffle 5 on the inner wall of the valve body on the side opposite to the inlet. Since the elastic part is also designed on the top surface of the spool, the upward pulling force of the spool is increased, and the problem that the check valve is not tightly sealed and the spool is stuck causing the medium to flow back during the locking process is solved.

[0015] A support rod 6 is provided at the connection between the first elastic member and the inner wall surface, and the top end of the support rod is located in the small hole 7 on the inner wall surface of the entrance. The support rod is used to fix the elastic member to prevent the elastic member from bend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com