Patents

Literature

38results about How to "Sealed well" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

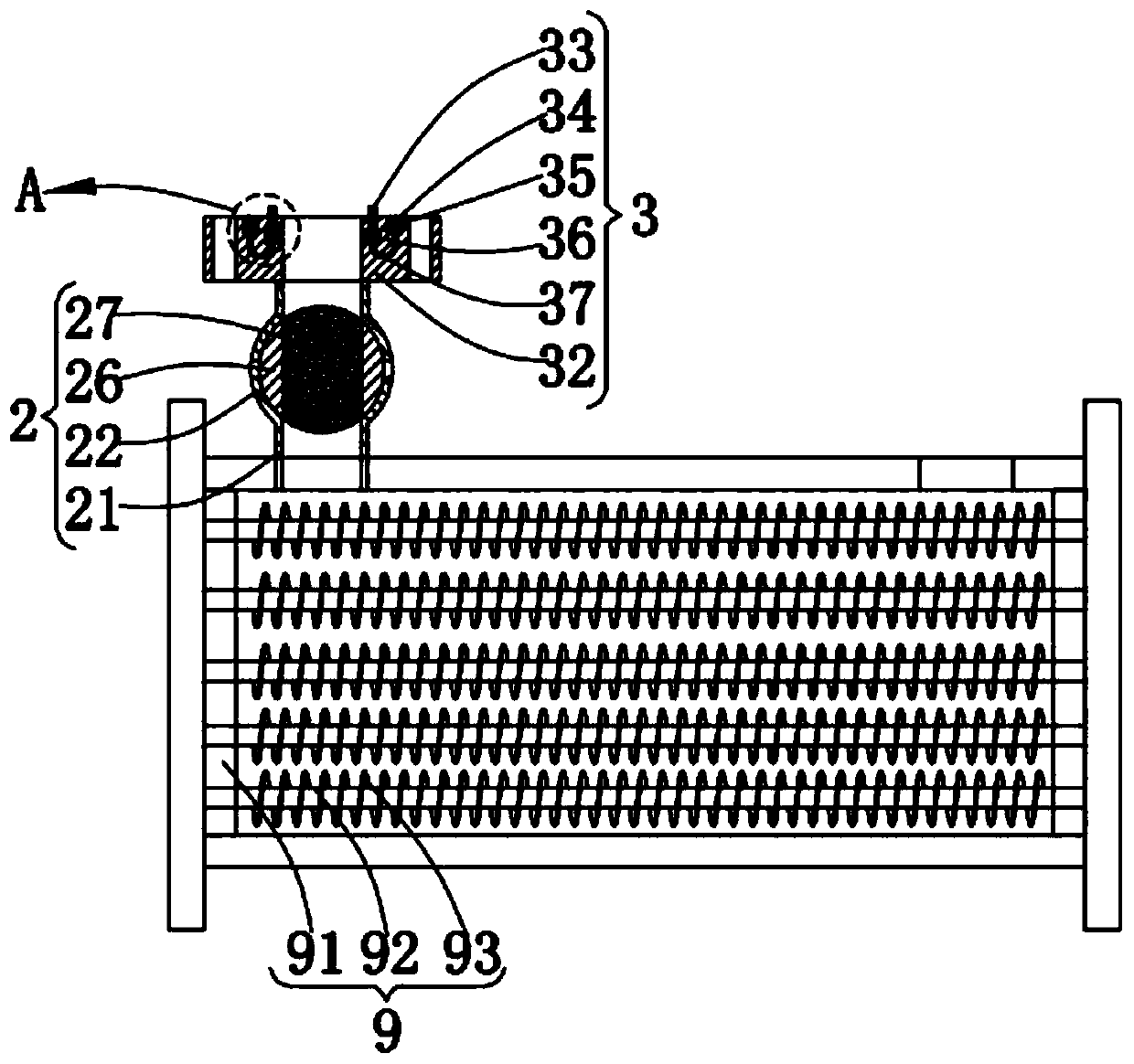

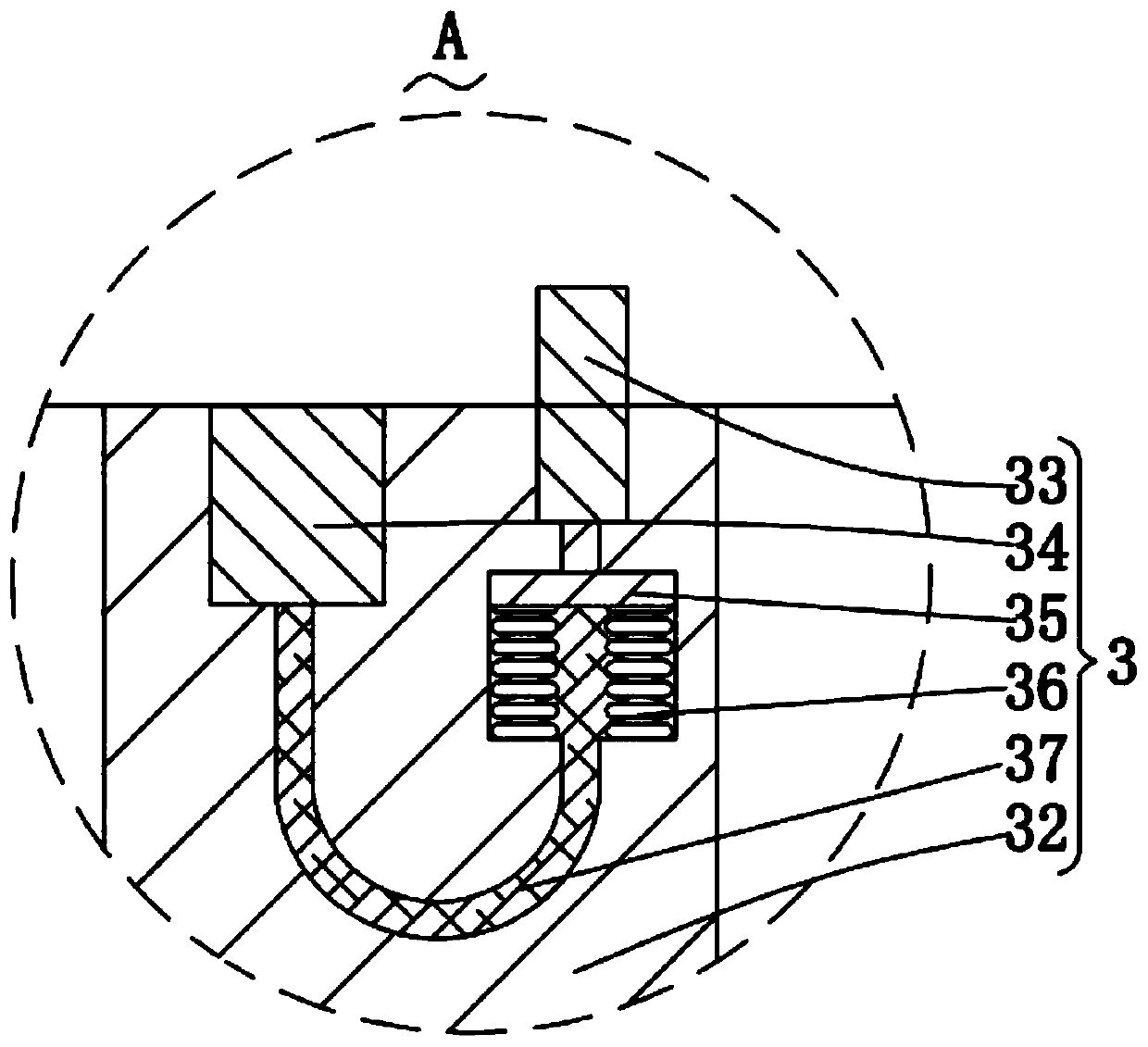

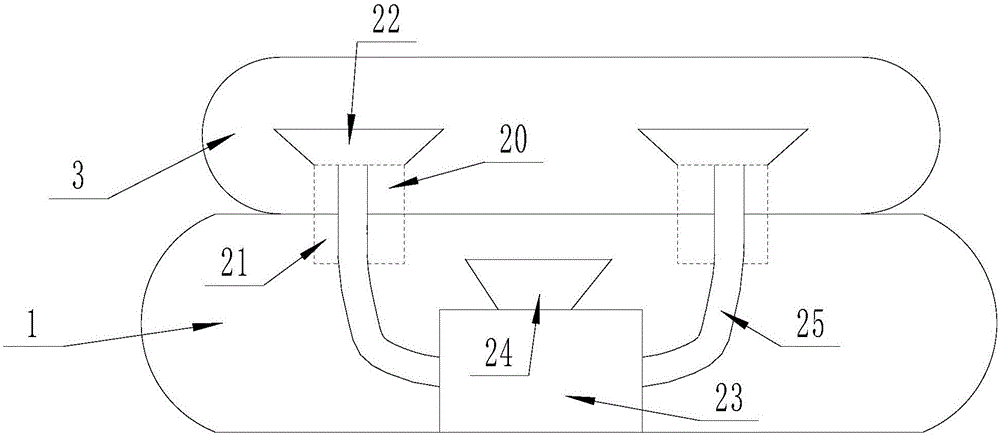

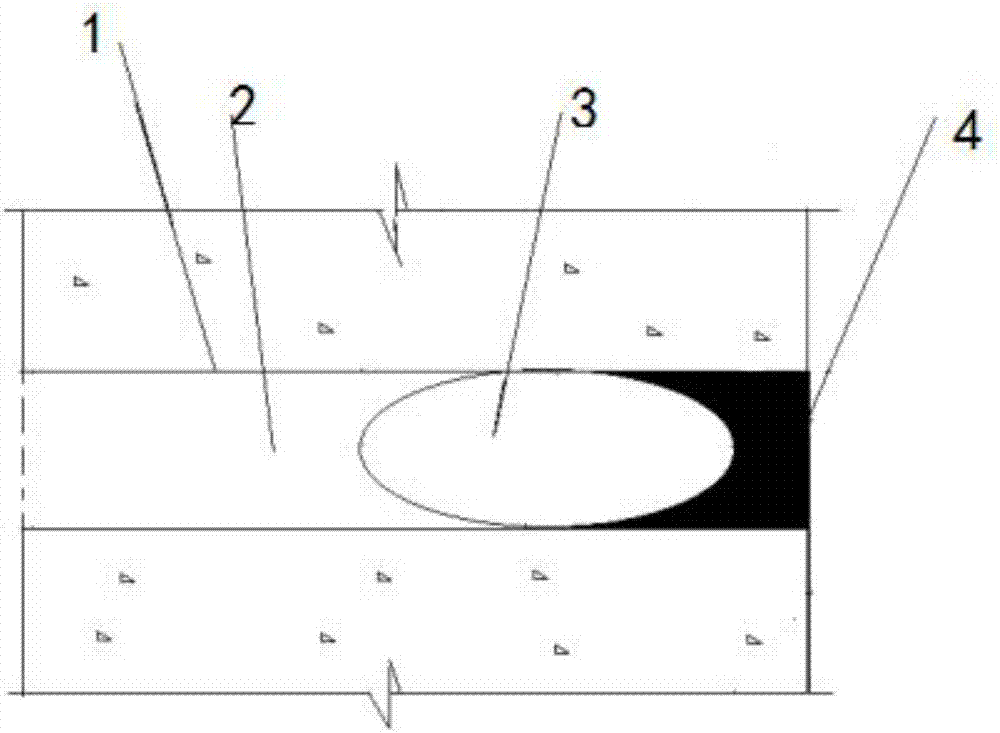

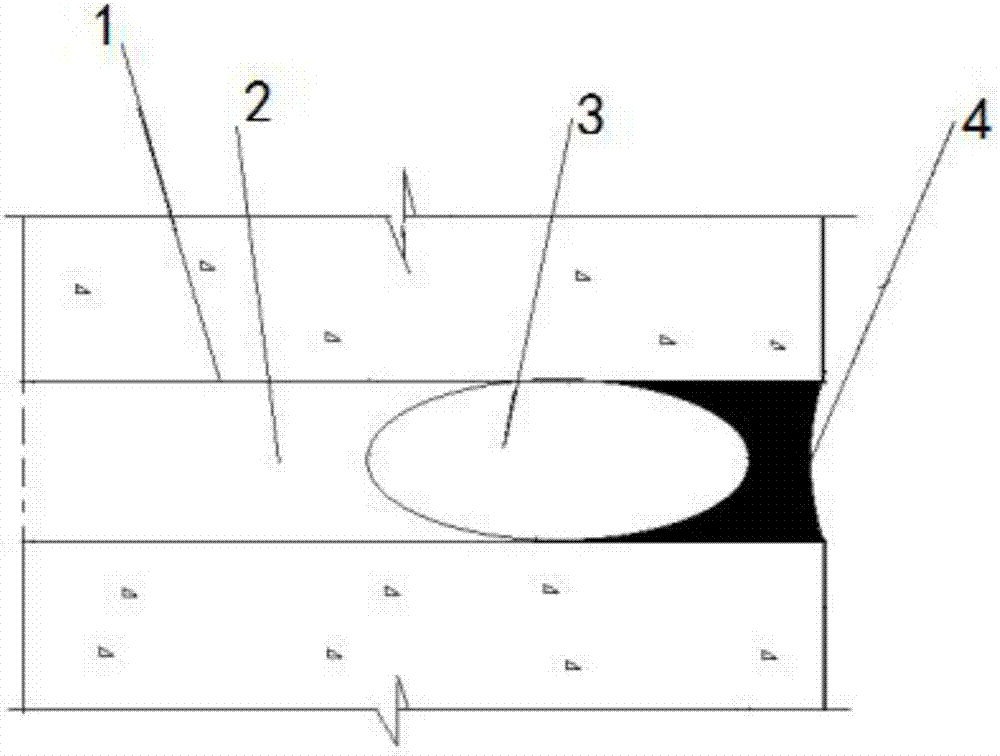

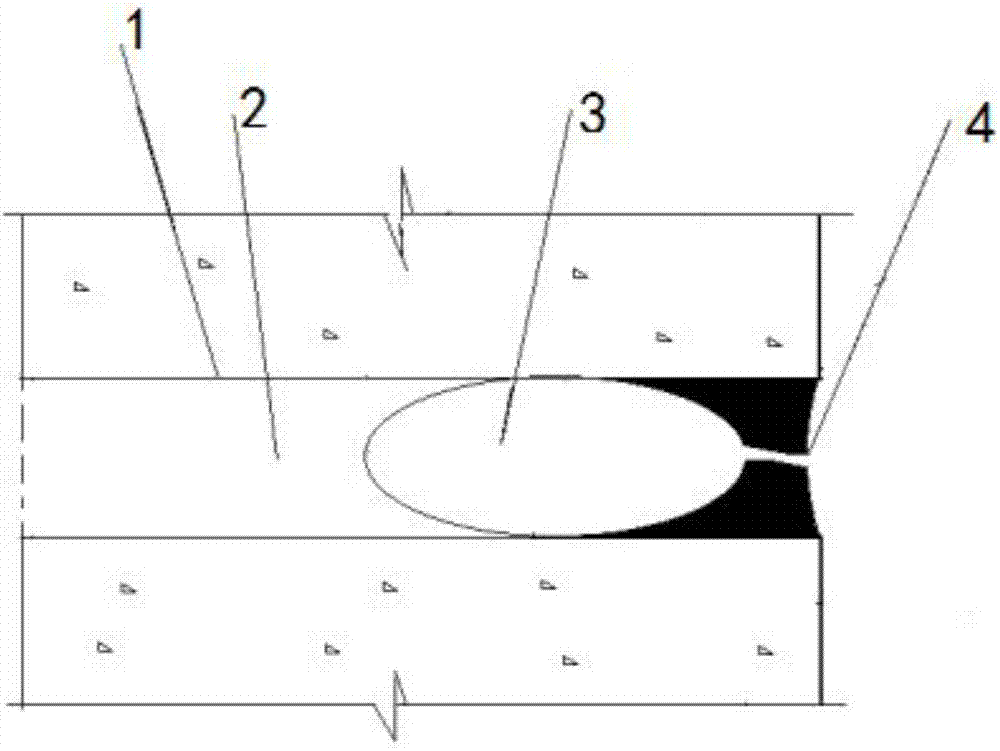

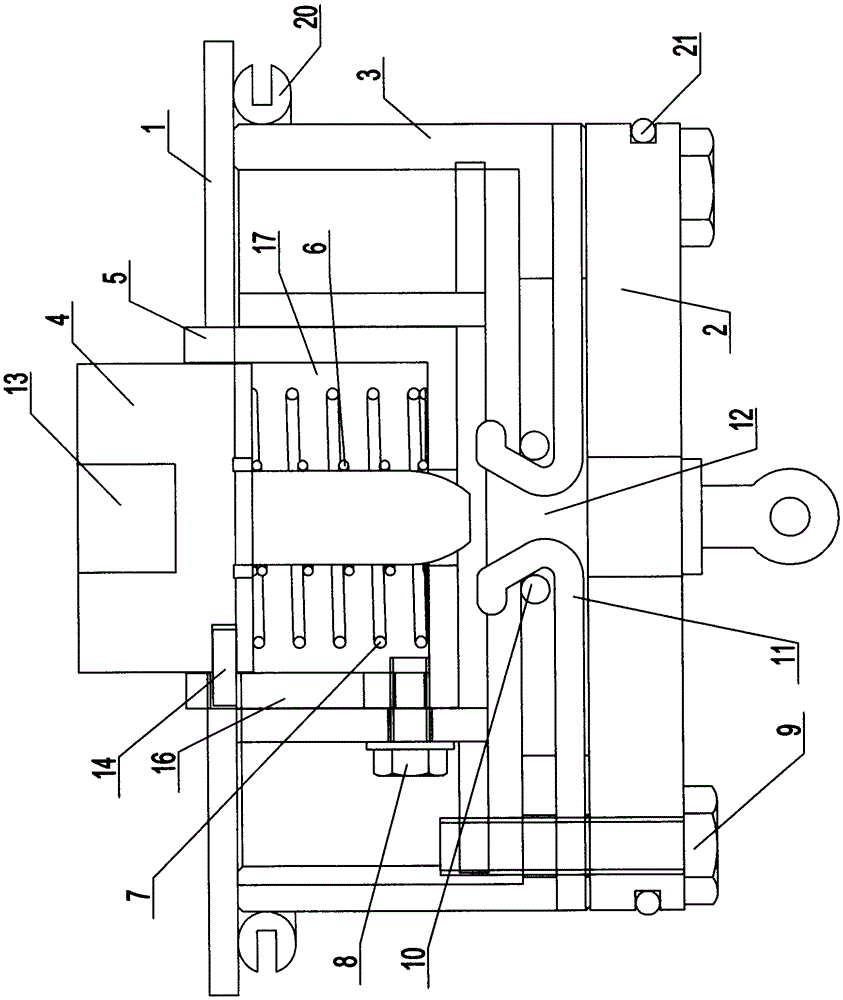

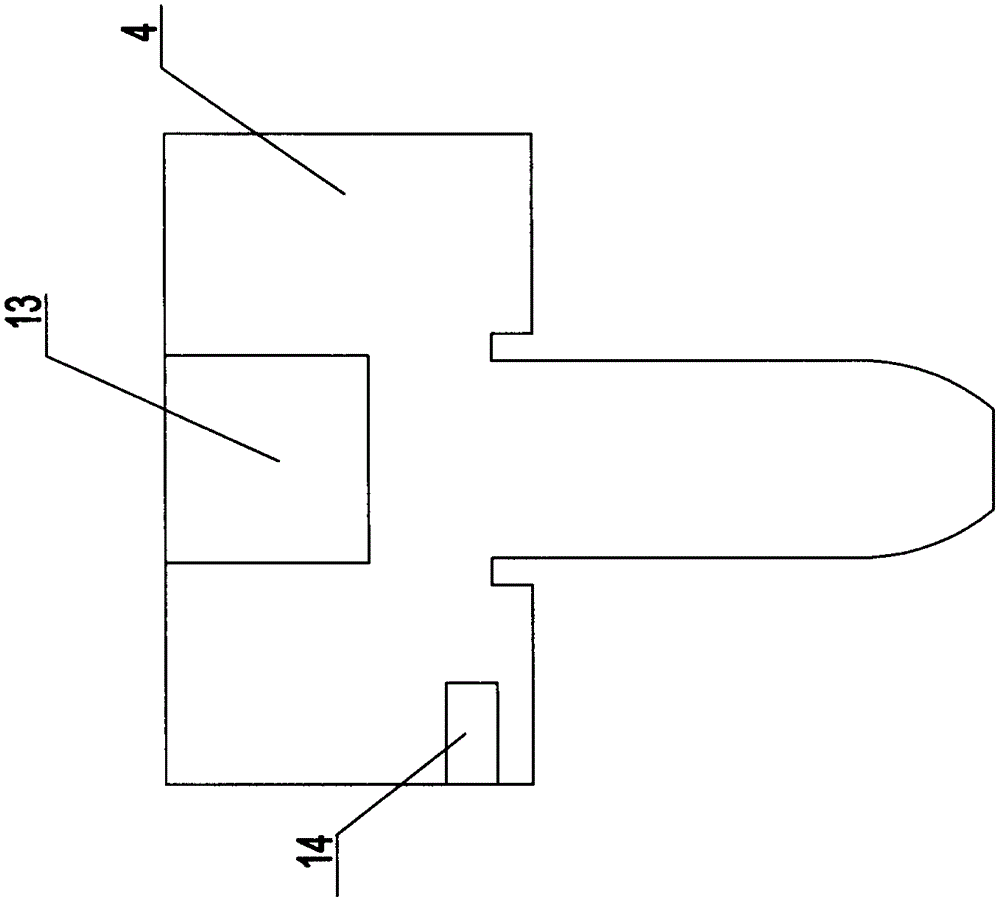

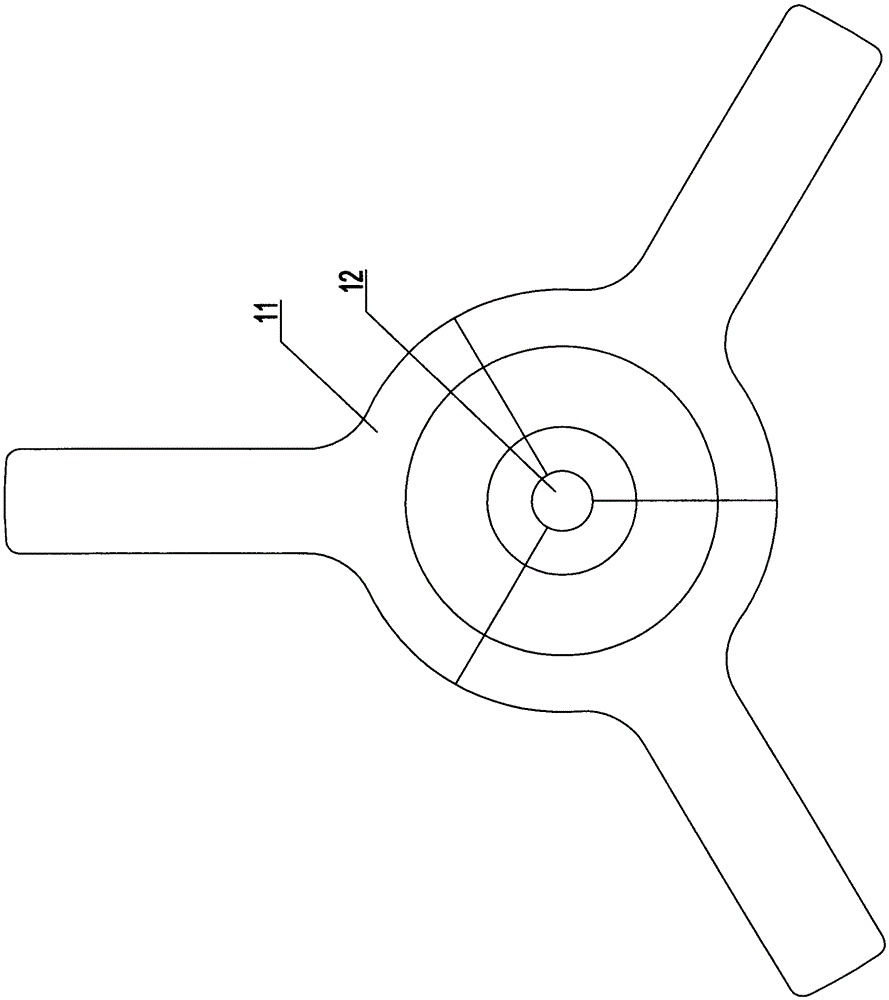

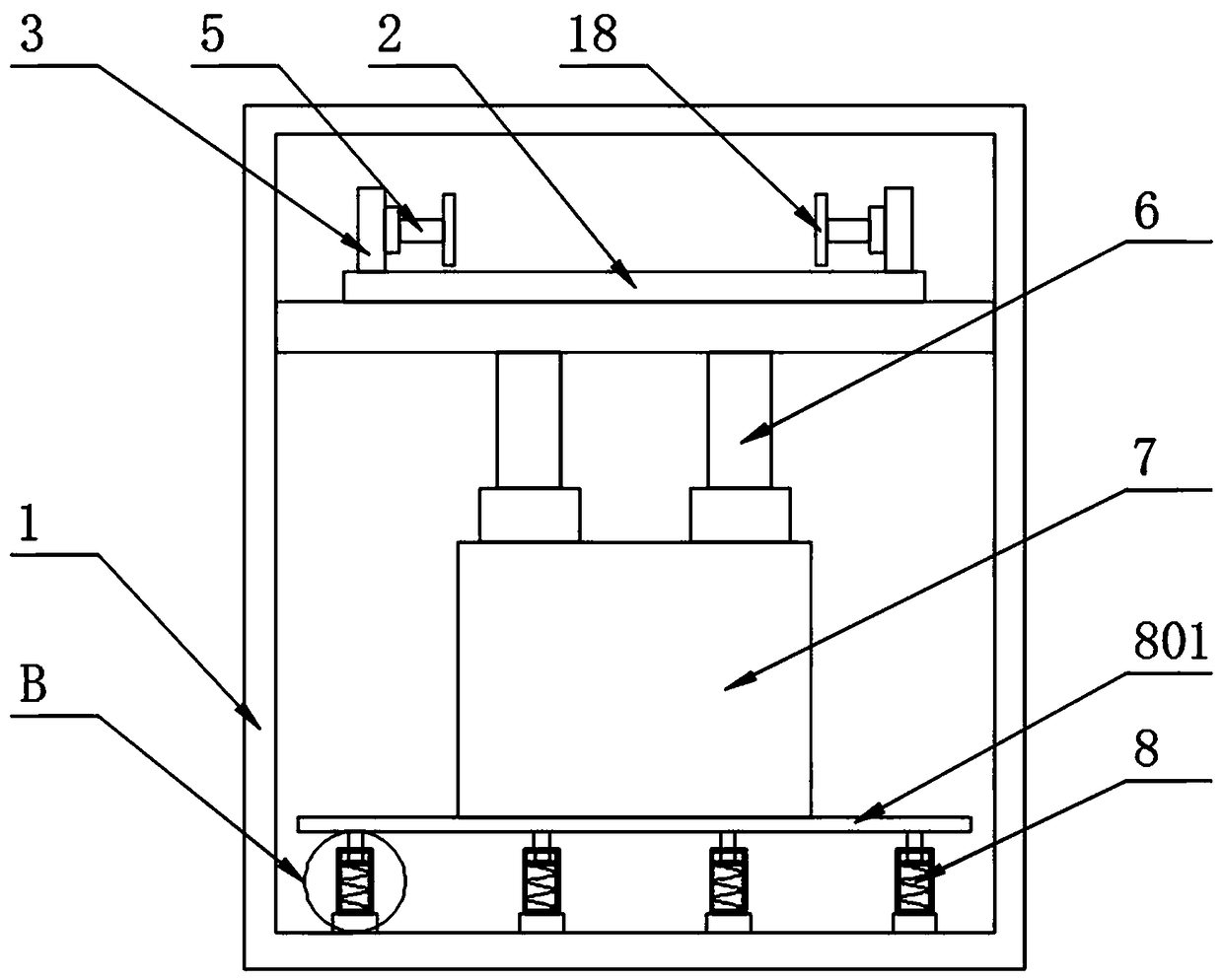

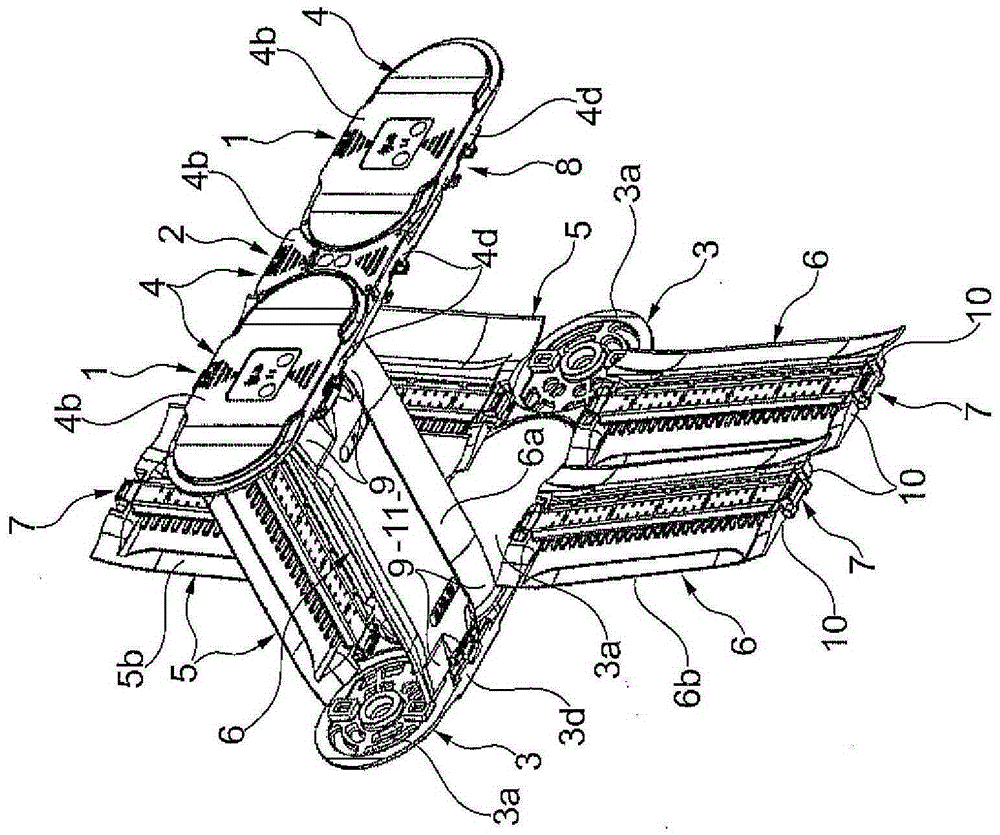

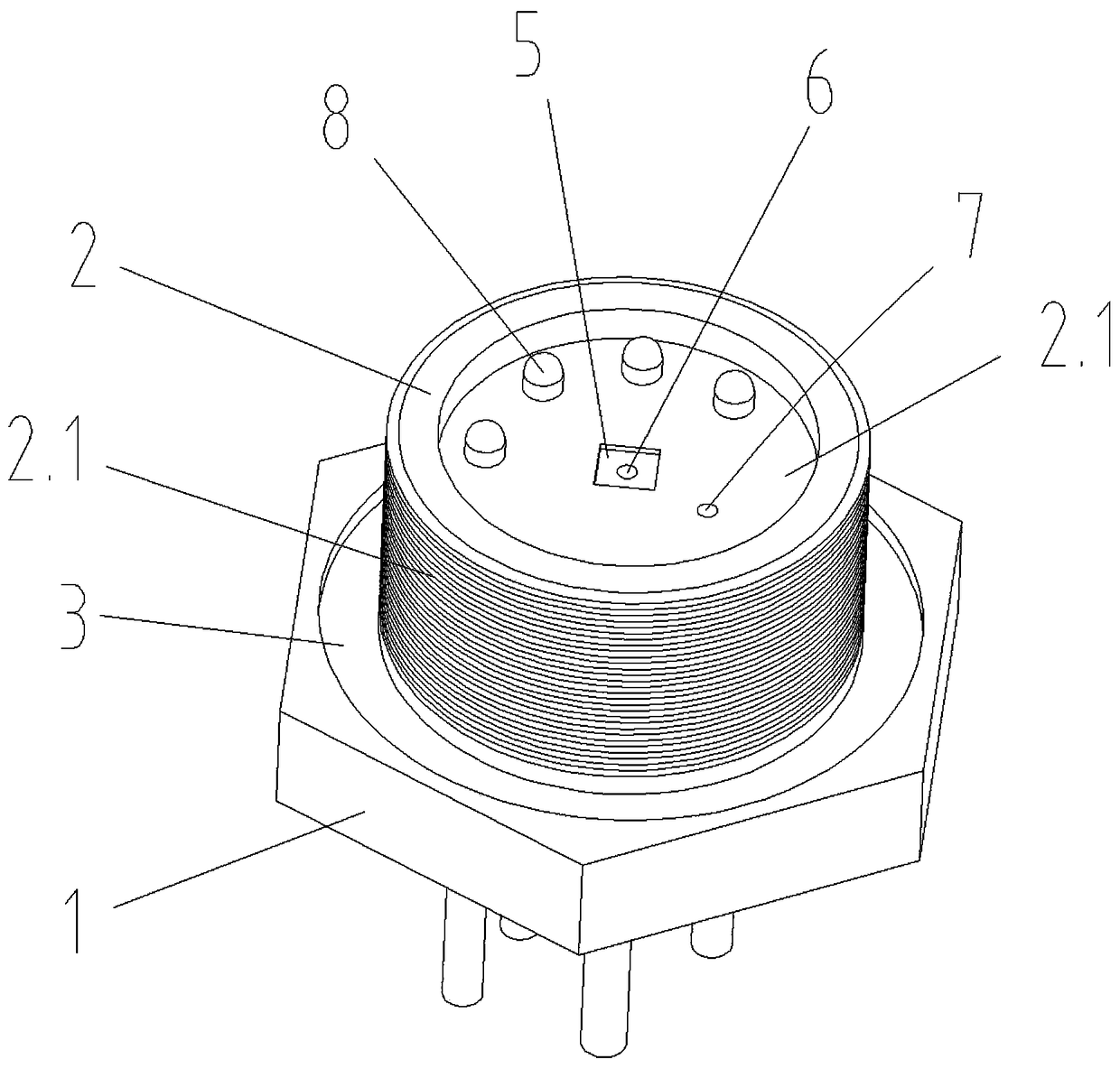

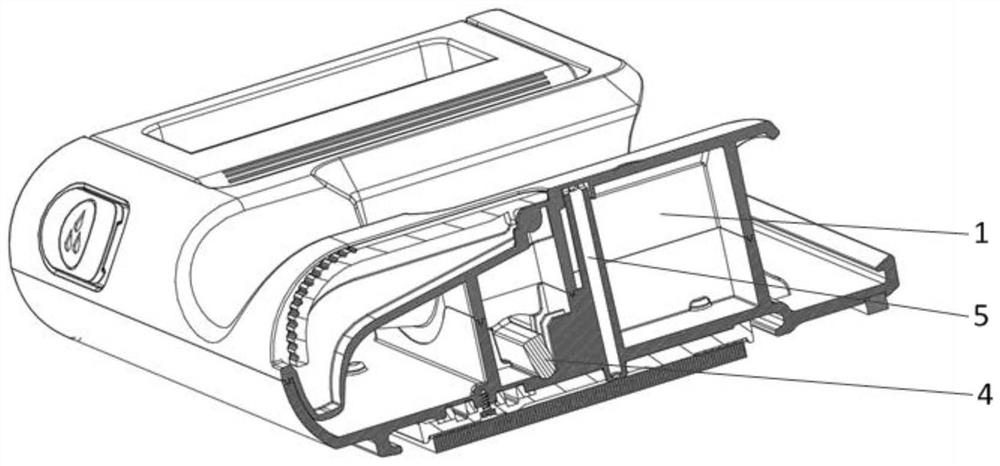

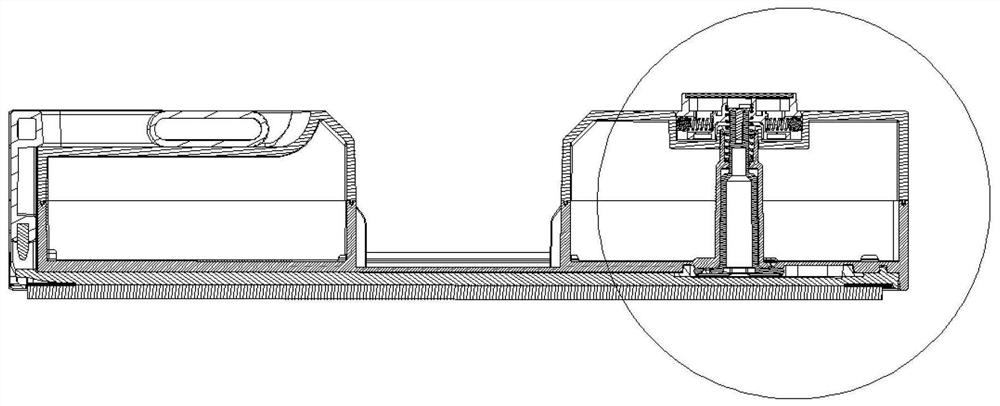

Magnetic sealing guide rail system and powder laying system suitable for powder sintering equipment

PendingCN106956431ASealed wellCompact structureAdditive manufacturing with solidsApplying layer meansMagnetEngineering

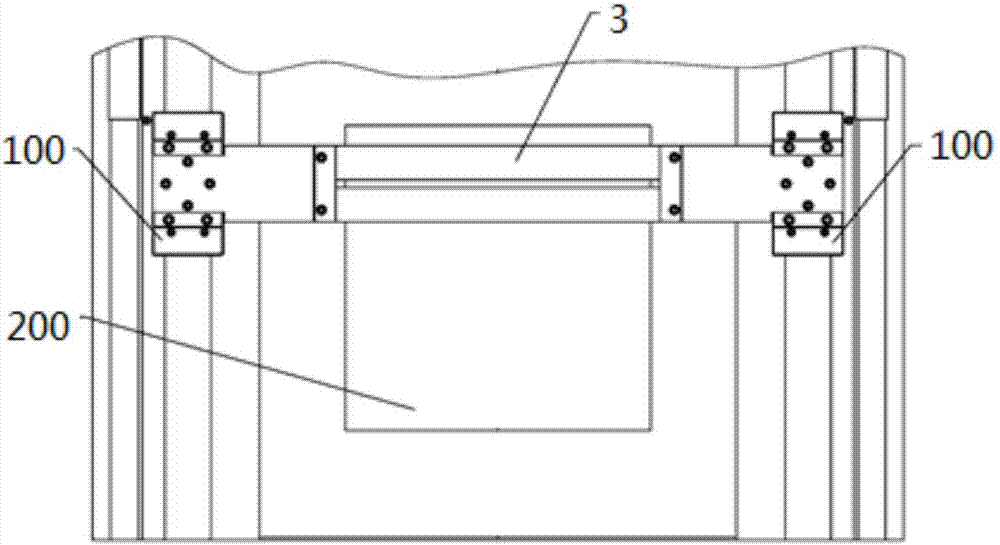

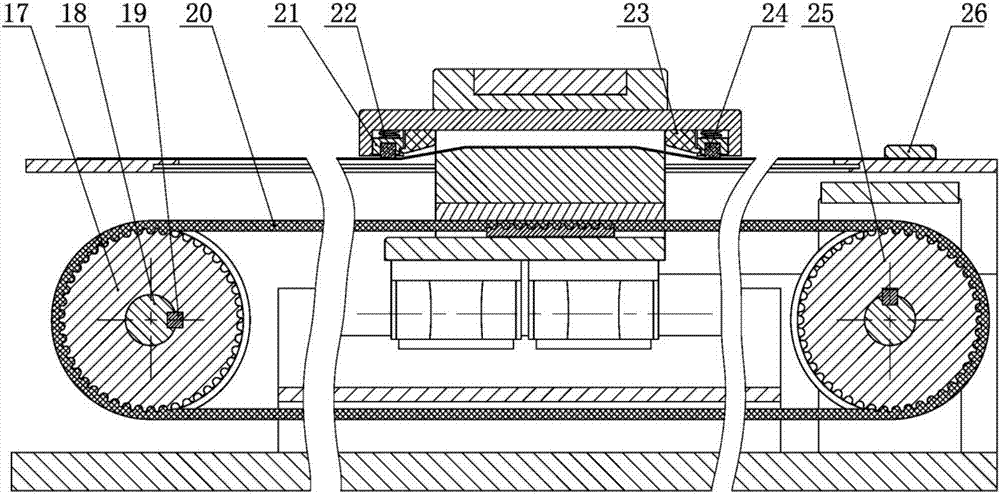

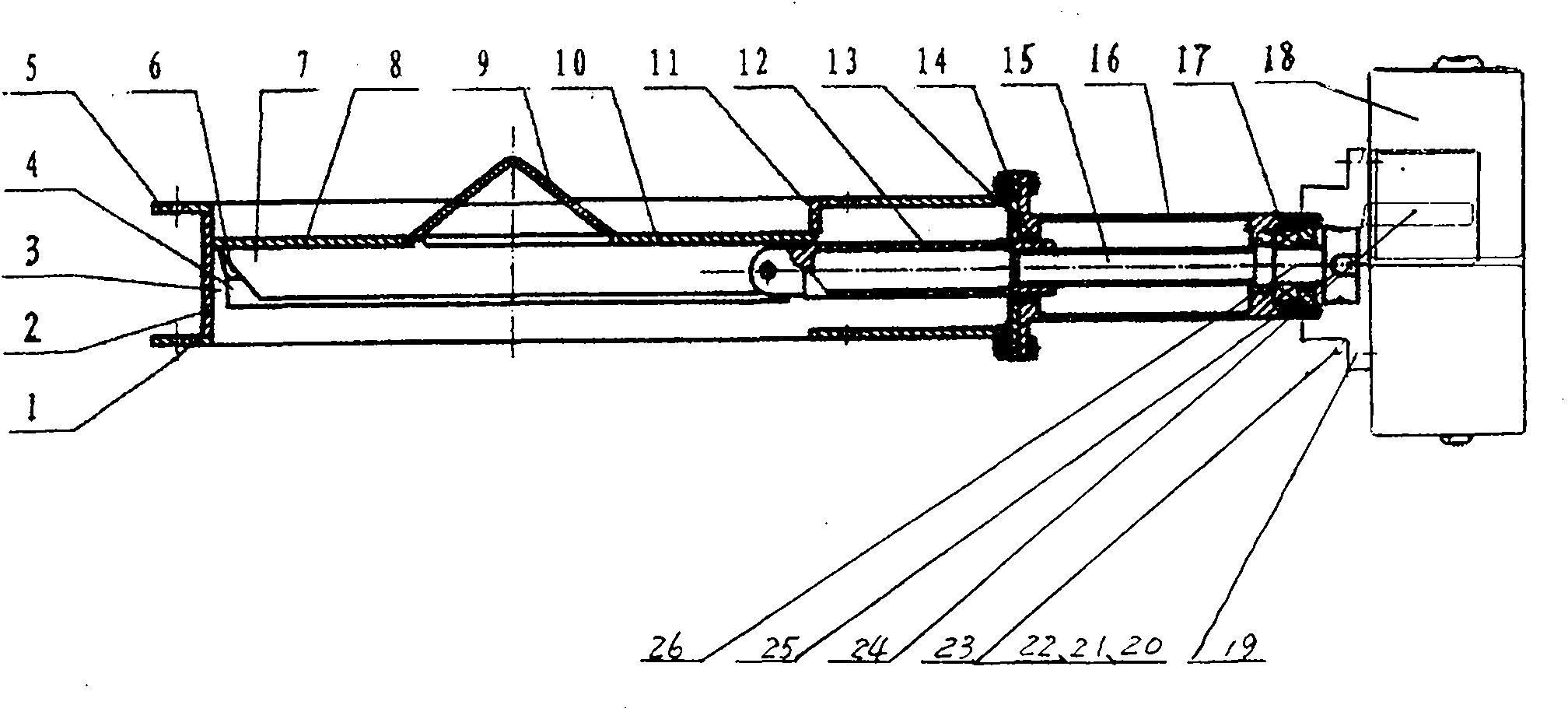

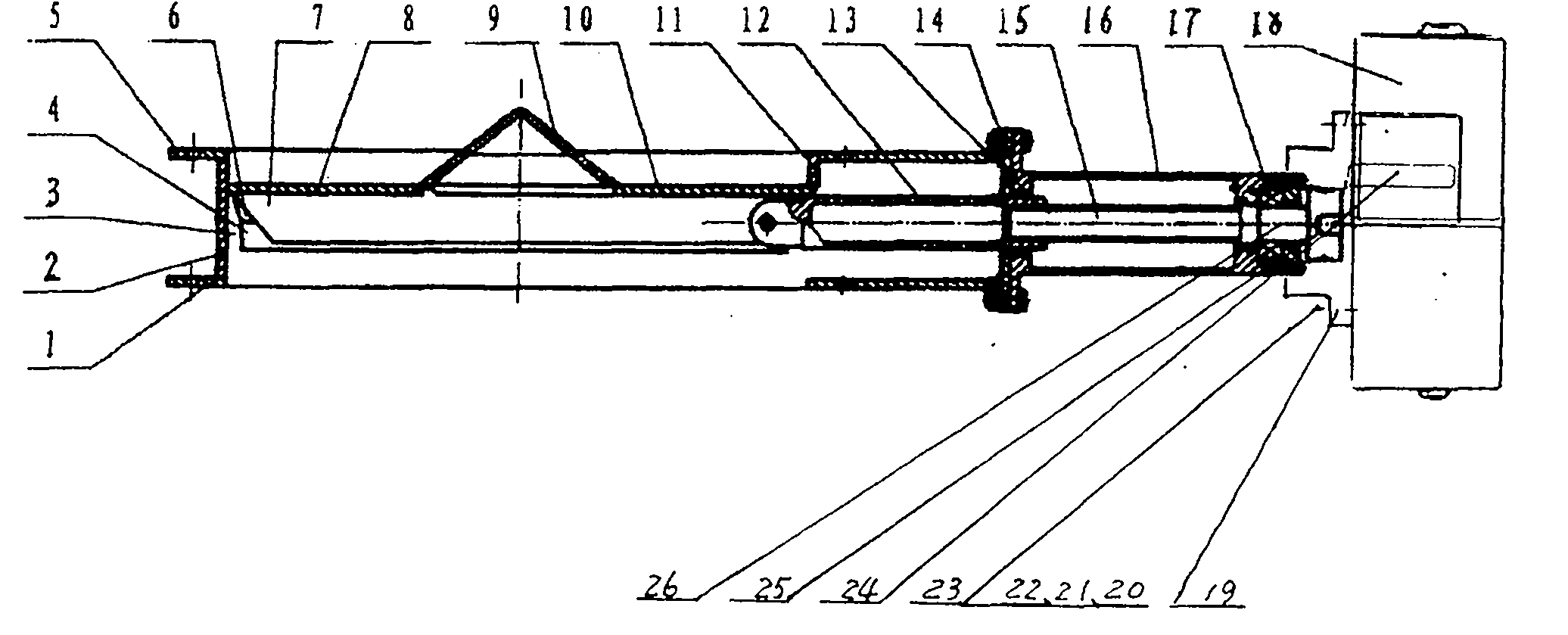

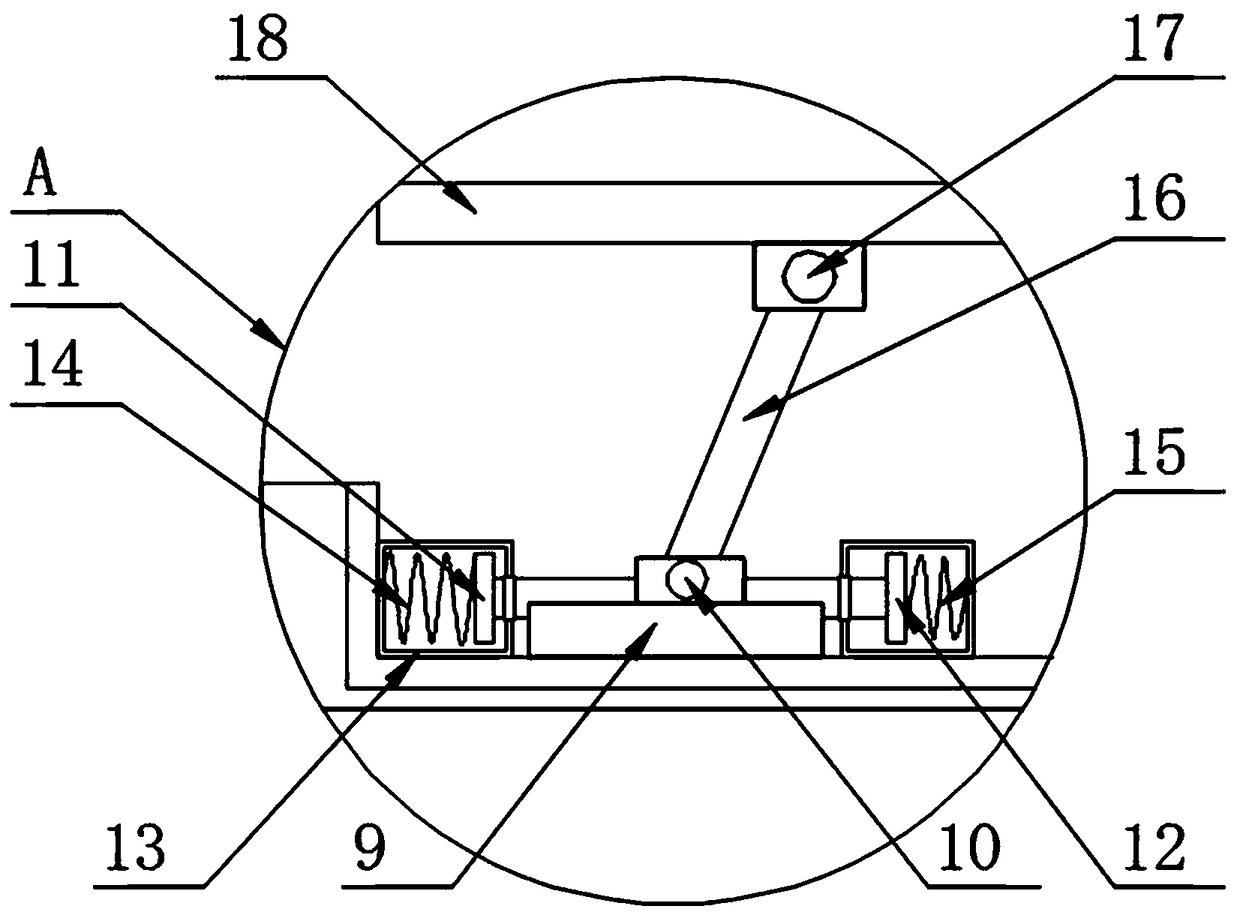

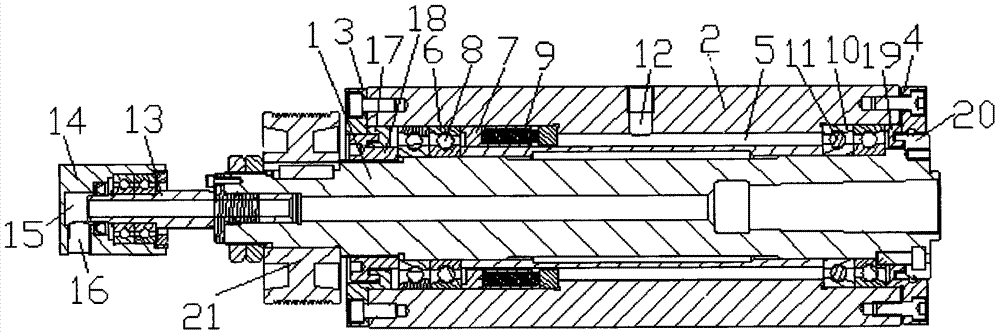

The invention discloses a magnetic sealing guide rail system and a powder laying system suitable for powder sintering equipment. The magnetic sealing guide rail system comprises a rail, a lateral protection plate, an inner protection plate, a cover plate located above the rail, a T-shaped guide bridge, a guide rail cover, a sliding assembly and a transmission assembly, wherein the lateral protection plate and the inner protection plate are located on the two sides of the rail. The middle of the cover plate is provided with a slot body, the two sides of the slot body are provided with permanent magnets, a cavity is formed among the lateral protection plate, the inner protection plate, the cover plate, the guide bridge and an iron magnetic component, and the transmission assembly, the sliding assembly and the rail are located in the cavity; and the transmission assembly is connected with the sliding assembly, drives the sliding assembly to move back and forth along the rail in the cavity and drives the inclined face of the guide bridge to pry the iron magnetic component up and move back and forth along the slot body. According to the magnetic sealing guide rail system and the powder laying system suitable for the powder sintering equipment, through the structure of the guide rail system in combination with the absorption function of the permanent magnets on iron materials, quite good sealing performance is achieved, and the magnetic sealing guide rail system and the powder laying system are compact and stable in structure, simple and reliable and low in cost.

Owner:WUHAN POLYTECHNIC

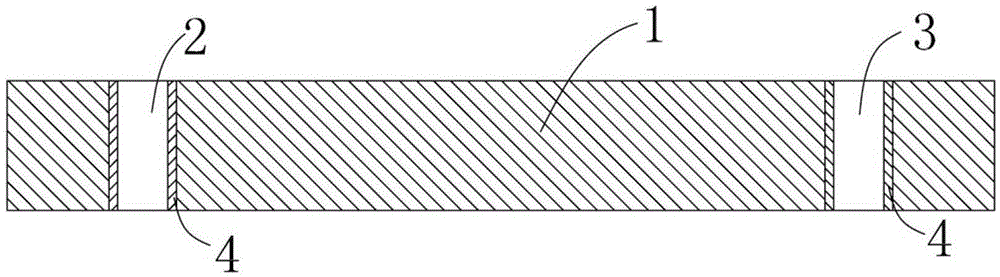

Sealing braided base material for foodstuff processing machinery and method for preparing same

The invention discloses a sealing braided base material for foodstuff processing machinery. The base material comprises a core layer and a skin layer; the core layer employs continuous nylon fiber bundles; the skin layer employs nylon fiber yarn having a S-twist structure with the twist being 80-100; the skin layer is clockwise wound around the outer surface of the core layer; and the core layer is provided with a silane coupling agent and an antistatic agent. The invention also discloses a method for preparing the sealing braided base material for foodstuff processing machinery. The method comprises following steps: preparing a compound molding agent by the use of the silane coupling agent and the antistatic agent with the ratio being 1:1; soaking the continuous nylon fiber bundles in the compound molding agent for 3-5 minutes; preparing the nylon fiber yarn by the use of nylon fibers based on the S-twist structure with the twist being 80-100; and clockwise winding the nylon fiber yarn around the outer surface of the continuous nylon fiber bundles after the continuous nylon fiber bundles are soaked in the compound molding agent. According to the invention, a problem that nylon fibers are difficult to mold as the nylon fibers are high in elasticity is solved, and the sealing braided base material is ageing resistant, and is high in sealing performance and antibacterial performance.

Owner:DONGTAI HUAYANG GLASS FIBER

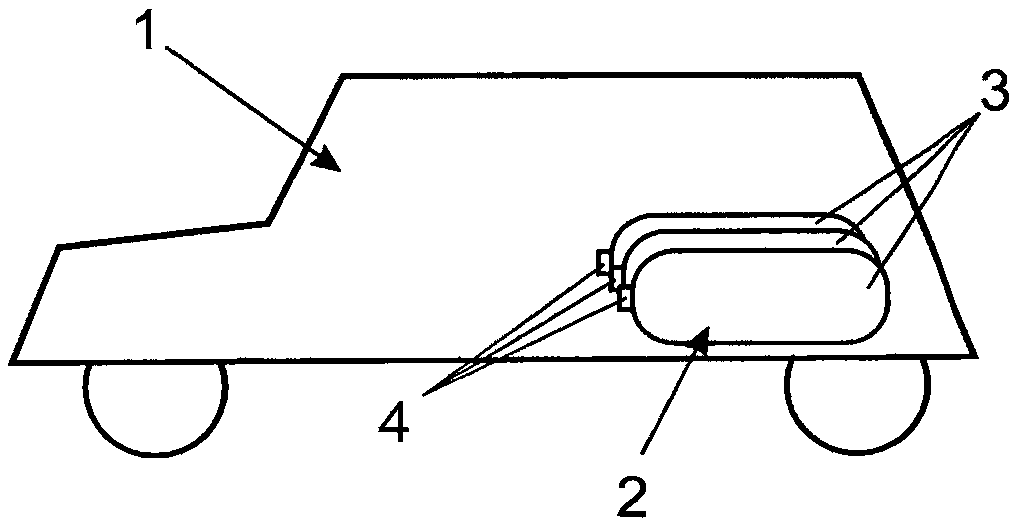

Vehicle-mounted dry powder fire extinguishing device

The invention discloses a vehicle-mounted dry powder fire extinguishing device. The vehicle-mounted dry powder fire extinguishing device comprises a bracket, and a fire extinguishing cylinder arranged on the bracket, wherein the fire extinguishing cylinder comprises a cylinder body; a gas generator is arranged at one end of the cylinder body, and a nozzle is arranged at the other end of the cylinder body; a dry powder fire extinguishing agent is filled in the cylinder body between the nozzle and the gas generator; an aluminum film for blocking the nozzle is arranged at the outer side of the nozzle; an atomizing ring is arranged at the outer side of the aluminum film; and a blocking ring in threaded connection with the cylinder body is arranged at the outer side of the atomizing ring. The vehicle-mounted dry powder fire extinguishing device has the beneficial effects of reasonable structure design, capability of preferable sealing, difficult leakage under the condition of frequent vibration, vibration resistance, high-temperature resistance, good fire extinguishing effect and capability of adapting to vehicle environments.

Owner:SHANDONG GUOTAI TECH

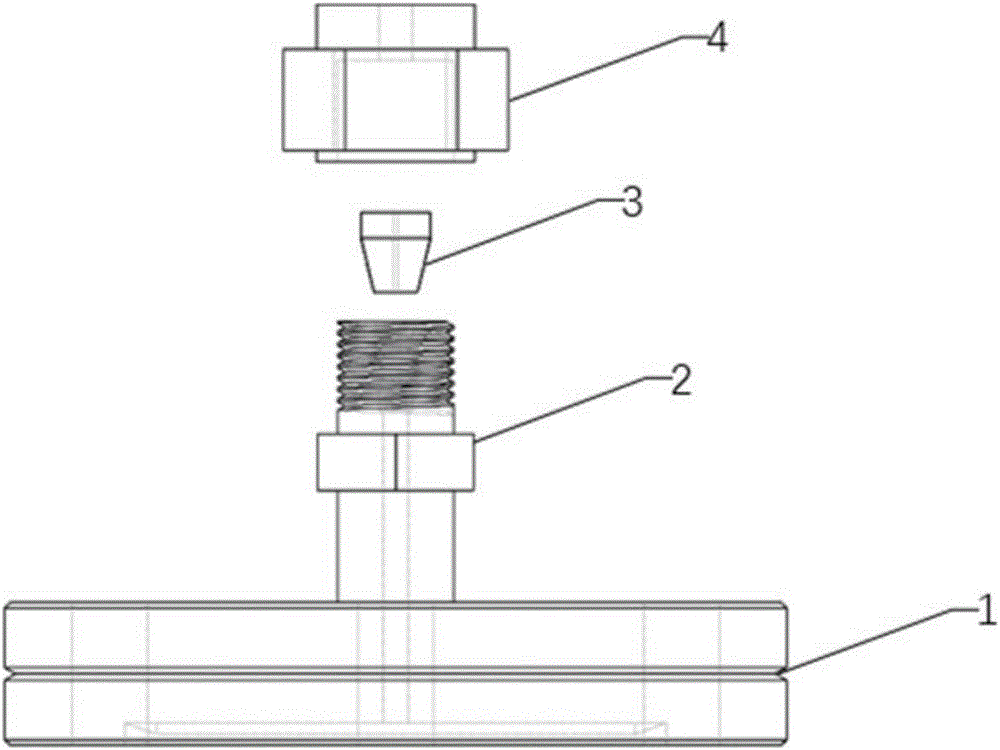

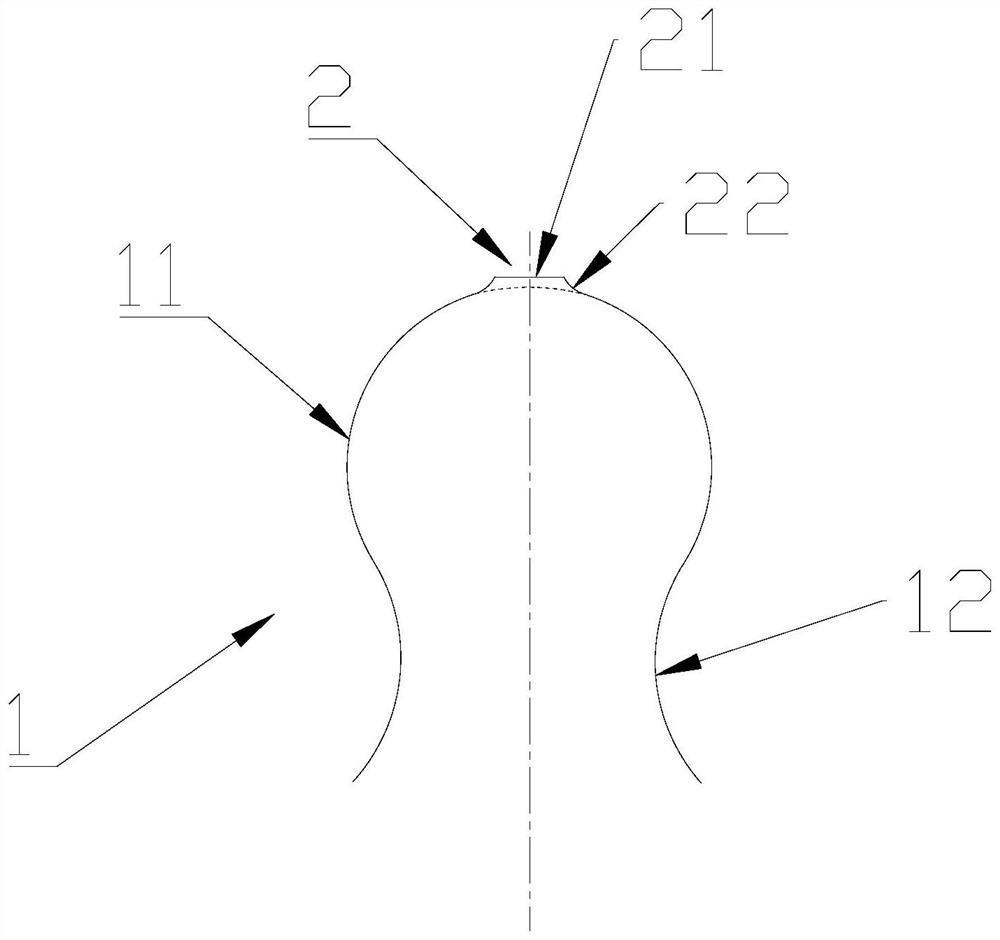

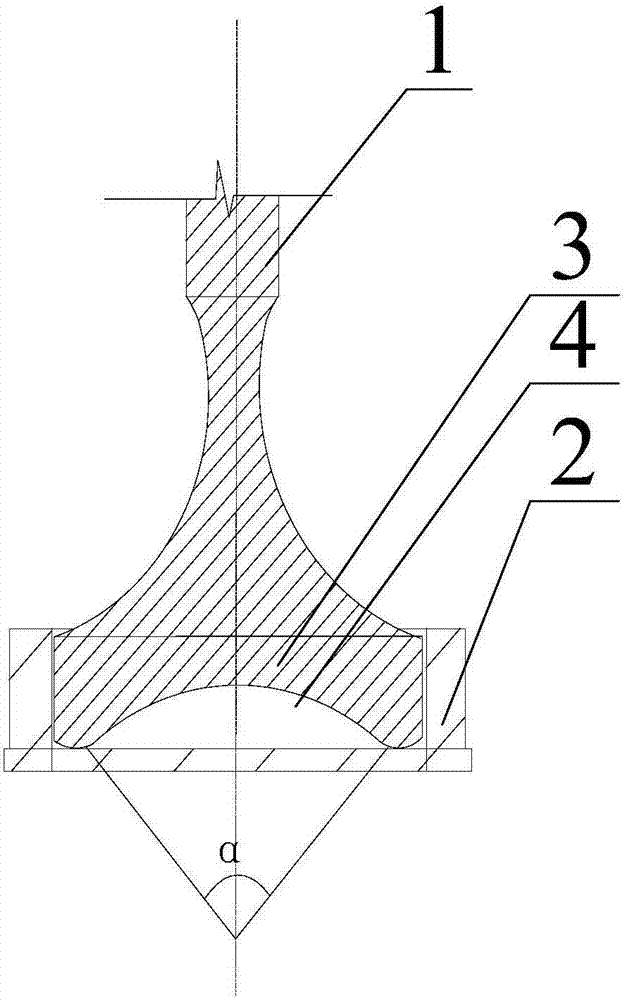

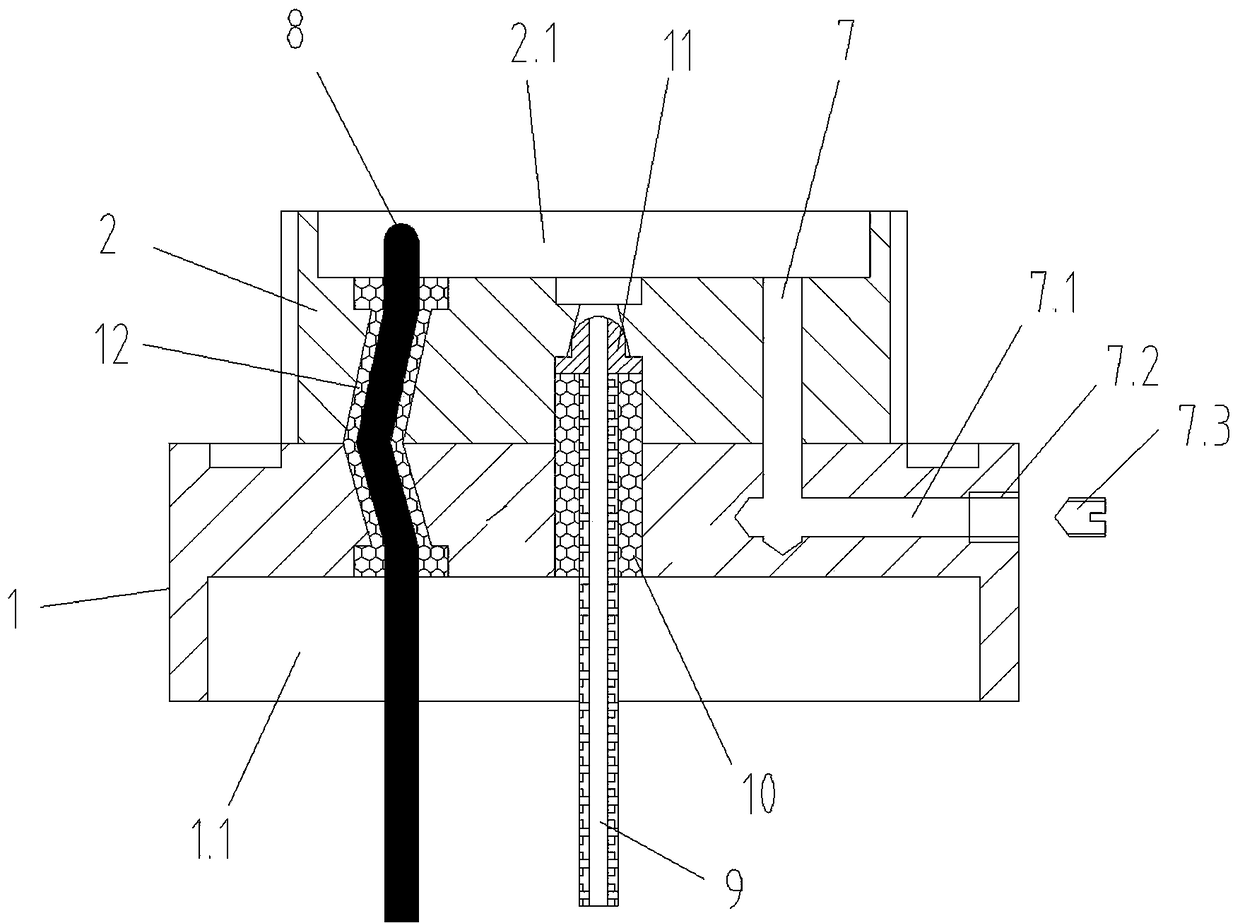

Vacuum bare fiber introducing device

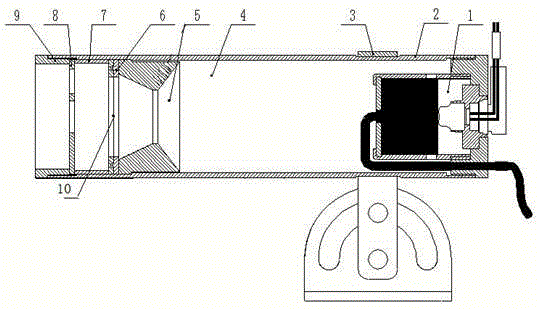

The invention relates to a bare optical fiber vacuum introduction device, comprising: a ferrule is fixed on a flange, and a first through hole is arranged at the place where the ferrule is fixed; the end of the ferrule far away from the flange is provided with a screw thread, and the end of the ferrule is provided with a thread The second through hole, the second through hole of the tube is connected with the first through hole of the flange; the sealing ferrule is elastic, with a vertical through hole, and the lower part shrinks gradually from top to bottom, and is a rotating body; the ferrule The tube nut fits with the thread of the tube, and the inside is a through hole; the upper part of the second through hole of the tube gradually opens from bottom to top, and cooperates with the sealing ferrule, the first through hole of the flange, the tube The centerlines of the second through hole, the vertical through hole of the seal ferrule, and the through hole of the tube nut coincide when assembled. The invention does not need optical fiber connectors and vacuum sealants, has low cost, simple structure, convenient installation and disassembly, is suitable for different types of bare optical fibers, ensures lossless transmission of optical fiber signals and maintains ultra-high vacuum inside the vacuum chamber.

Owner:EAST CHINA UNIV OF SCI & TECH

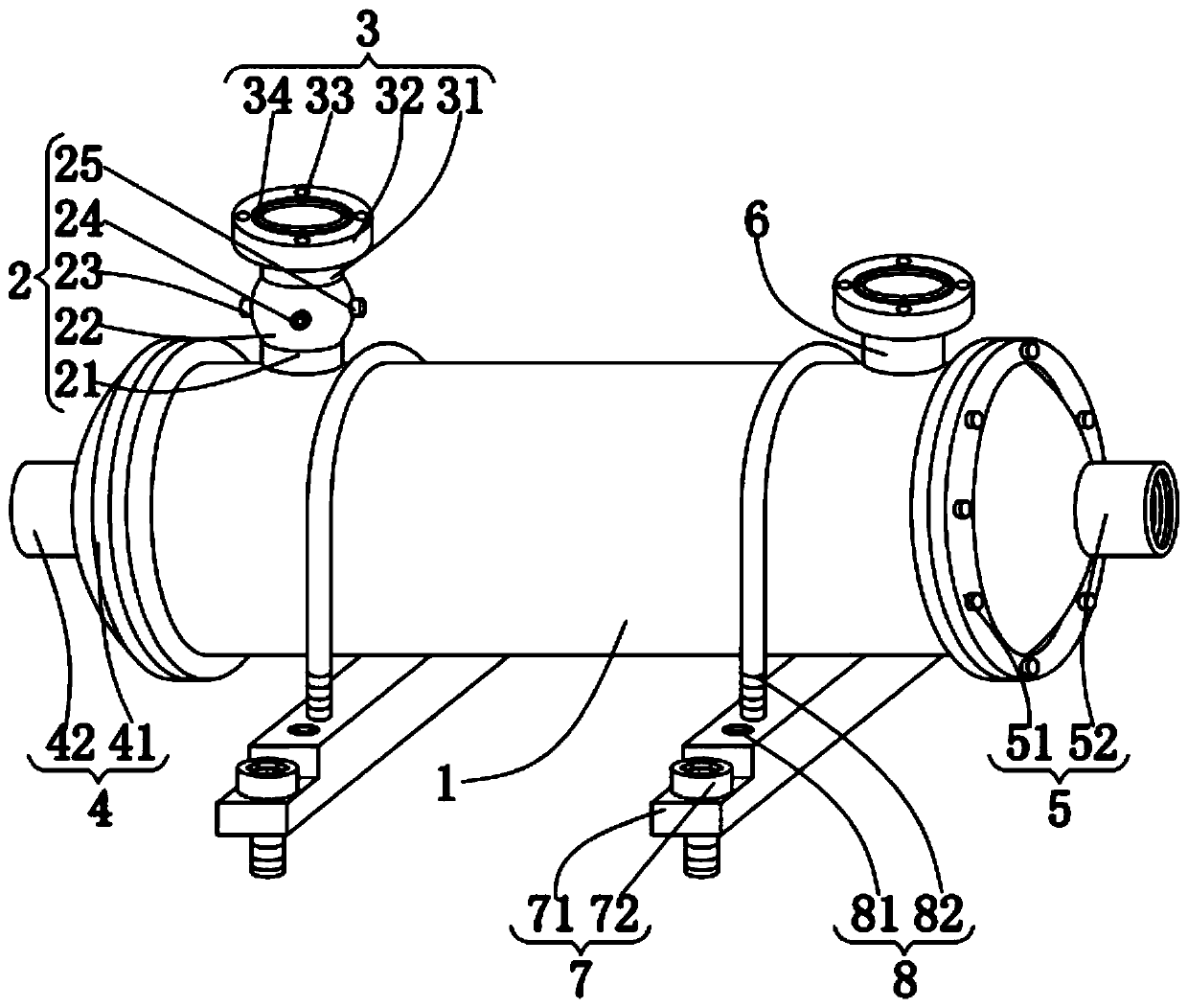

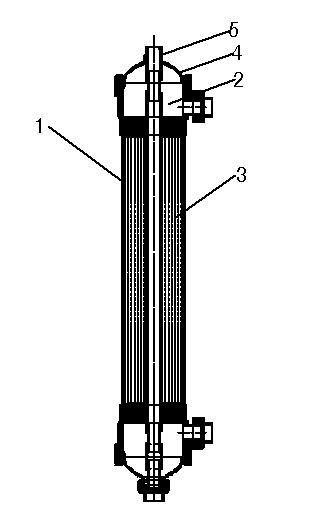

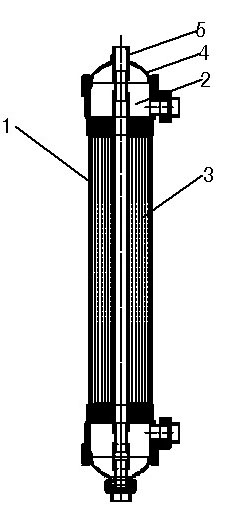

Tube type heat exchanger for chemical production

ActiveCN109696069ASealed wellAvoid pollutionCorrosion preventionHeat exhanger sealing arrangementEngineeringHeat exchanger

The invention relates to the technical field of heat exchangers, in particular to a tube type heat exchanger for chemical production. The tube type heat exchanger comprises a tube body, a filtering structure, a sealing structure, a water inlet structure, a water outlet structure, a discharge pipe, a locking structure, and a heat exchanging structure. The filtering structure is fixed to one end ofthe tube body. The heat exchanging structure is arranged in the tube body. A medium entering the heat exchanging structure passes through the filtering structure. Through cooperation of the filteringstructure and the heat exchanging structure, the medium entering the heat exchanging structure can be fully filtered, and impurities are prevented from entering the heat exchanging structure and influencing working efficiency and the service life of the heat exchanging structure. The sealing structure is fixed to the end, back on to the tube body, of the filtering structure. The sealing structureis connected with an external pipeline. Through cooperation of the sealing structure and the external pipeline, the connecting position between the sealing structure and the external pipeline ca be better sealed, and pollution caused by chemical leakage can be effectively prevented.

Owner:内蒙古宏远天呈科技发展有限公司

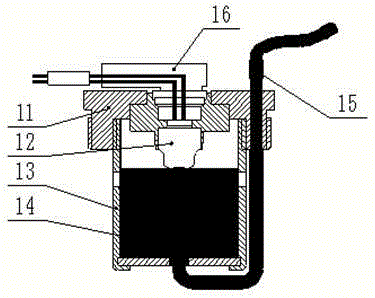

Internal heating medical device

ActiveCN106214456ASimple structureSealed wellBathing devicesEngineeringElectrical and Electronics engineering

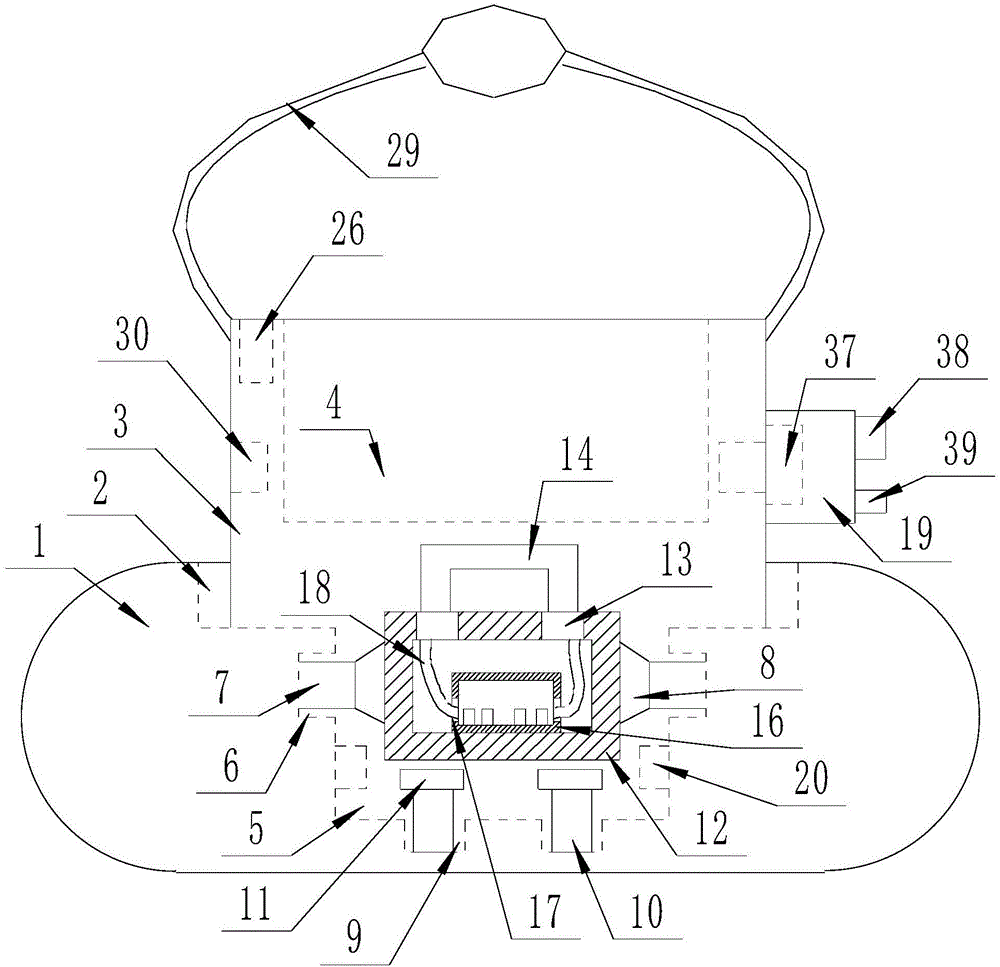

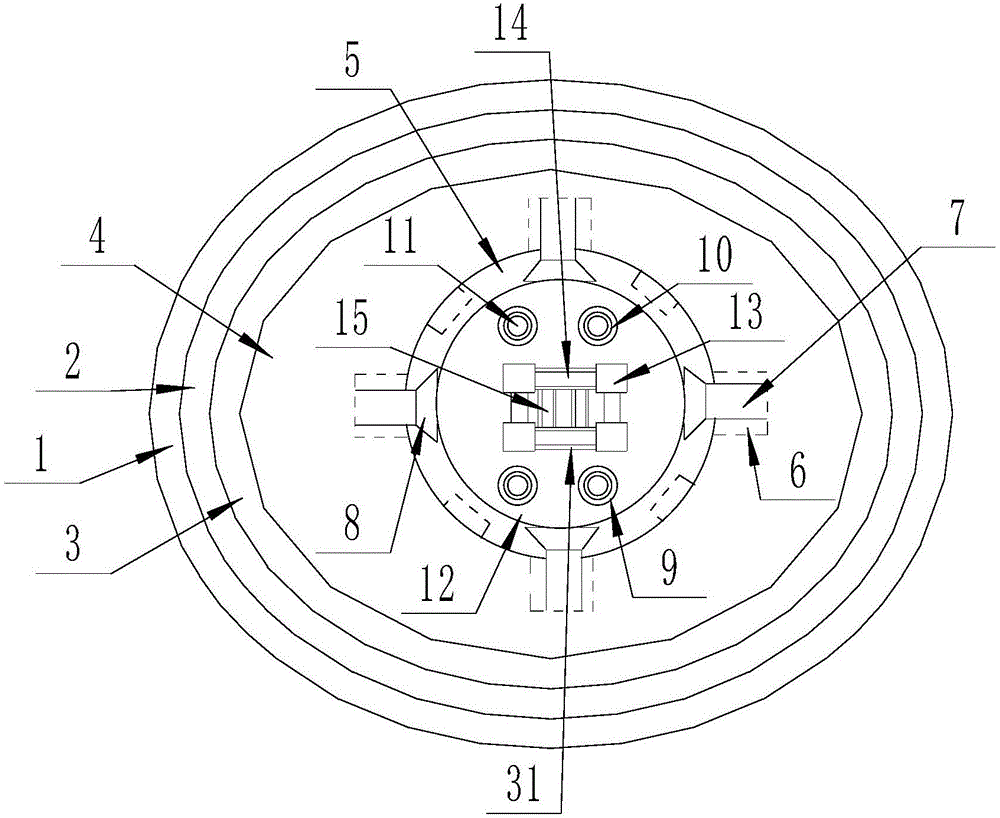

The invention discloses an internal heating medical device. The internal heating medical device includes an oval base; the internal part of the oval base is of a hollow structure; a generation mechanism is arranged in the oval base; a first oval groove is formed in the upper surface of the oval base; an oval casing is embedded in the first oval groove; an oval opening is formed in the upper surface of the oval casing; a heating mechanism is arranged on the internal lower surface of the oval casing; a bearing mechanism is arranged in the oval casing and is positioned over the heating mechanism; a moving mechanism is arranged on the lower surface of the oval base; a sealing mechanism is arranged at the upper end of a lateral surface of the oval base; a controller is arranged on a lateral surface of the oval casing; and the controller is electrically connected to the heating mechanism, the generation mechanism and the sealing mechanism. The beneficial effects of the invention are that the internal heating medical device is simple in structure and is high in practicability.

Owner:SHANGYU SNAKE HOT RUNNER

Waterproof structure and construction method thereof

ActiveCN107268809AReduce tensile stressEliminate tensile stress concentrationBuilding repairsBuilding insulationsElastomerStructural engineering

The invention discloses a waterproof structure. The waterproof structure comprises positioning foam bars, a plurality of elastic body waterproof layers and isolating bars. The positioning foam bars are used for being placed on the inner side of a joint, the elastic body waterproof layers are adhered to the outer sides of the positioning foam bars, and the isolating bars are arranged between the elastic body waterproof layers correspondingly. The waterproof structure is composed of the multiple elastic body waterproof layers, has an over long waterproof function and is good in durability. Through the structure that a plurality of elastic bodies (sealants and coating films) and the multiple isolating bars are spaced, the thicknesses of the elastic bodies (the sealants and thick coatings) are decreased, so that the tensile stress of each elastic body is reduced, stress concentration is effectively eliminated, and the durability of the sealants is improved accordingly. According to the construction method of the waterproof structure, accurate positioning of the elastic bodies and the foam bars can be achieved, elastic layers and the positioning bars can be better combined in a sealed mode, and the overall performance of the waterproof structure is improved.

Owner:TIANJIN SENJUKE SEAL COATING MATERIALS CO LTD

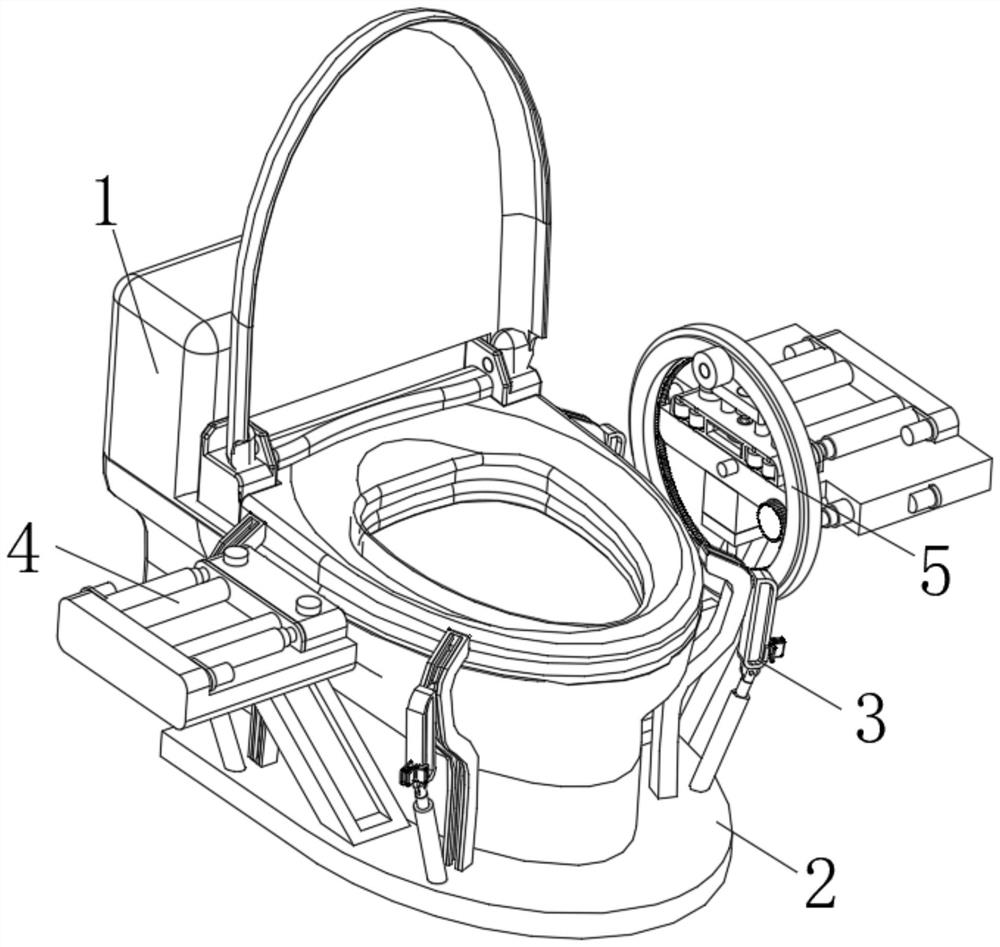

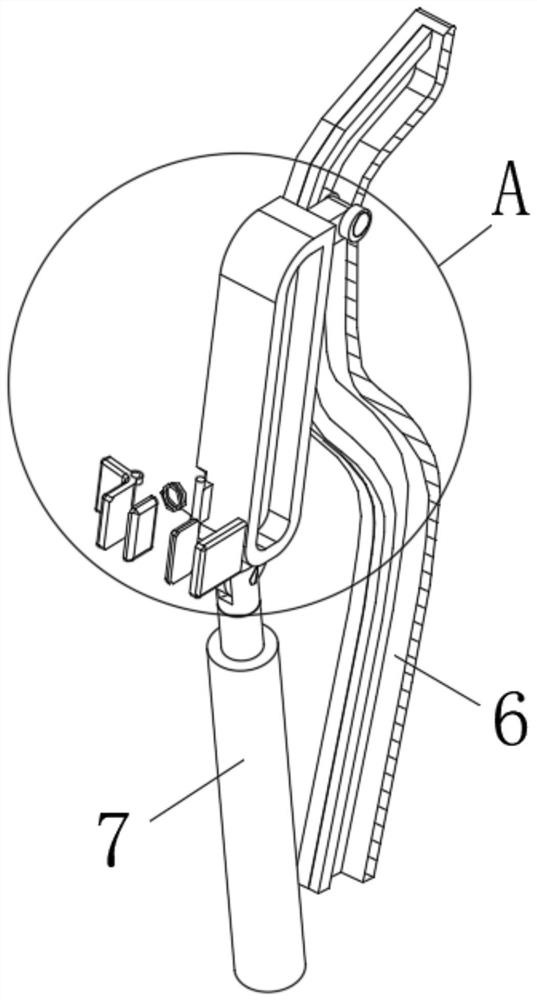

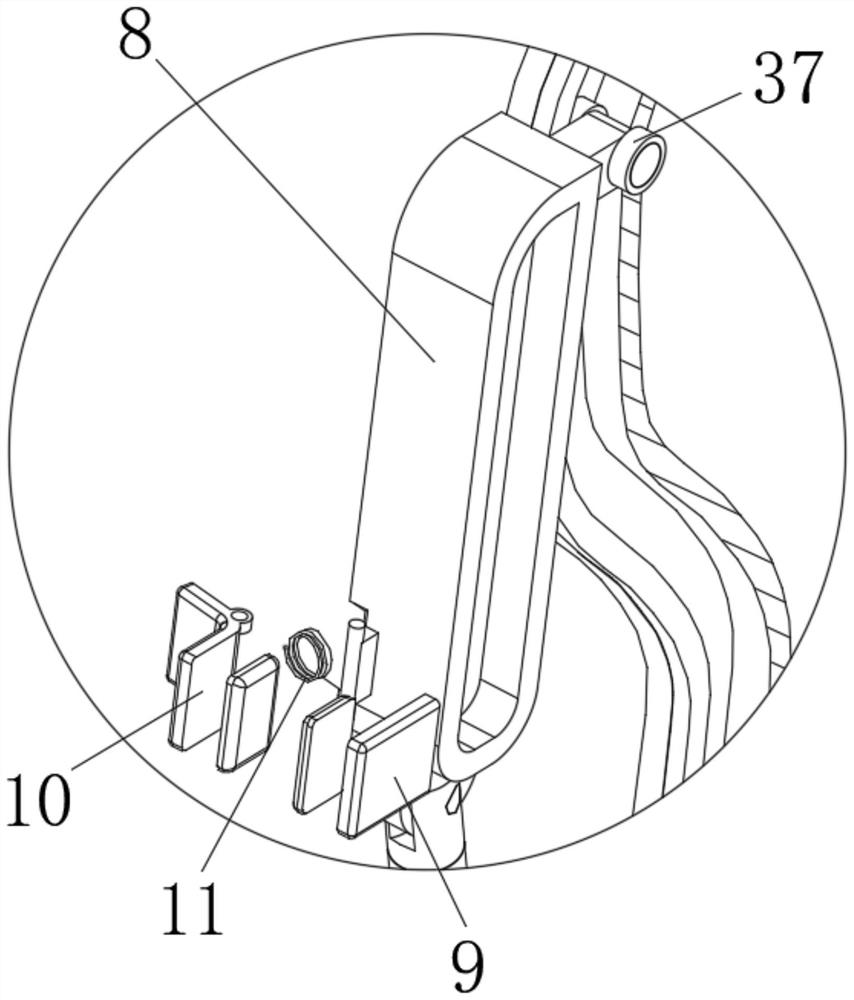

Flushing-free packaging device for excreta of infectious patient

PendingCN112603187ASealed wellAvoid pollutionBathroom coversStructural engineeringMechanical engineering

The invention discloses a flushing-free packing device for excreta of an infectious patient. The device comprises a closestool, a mounting seat is connected to the closestool, a plurality of sets of gathering devices are arranged and are all mounted on the mounting seat, and the gathering devices are arranged on the mounting seat and are used to gather a bag opening after a converging device converges a packaging bag, and a sealing device is connected with the gathering devices. The converging device, the gathering devices, the sealing device and the like are arranged on the periphery of the closestool, when the flushing-free packing device is used, due to the fact that the packing bag is arranged on the closestool and are pulled by the converging device, the patient does not make contact with other positions and can only make contact with the interior of the packaging bag, after use, the bag opening is folded through the folding device, then gathered through the gathering devices and finally folded and sealed through the sealing device, better sealing can be achieved, the device is prevented from being polluted, flushing-free packaging can be achieved, and the risk of cross infection is greatly reduced.

Owner:XUZHOU COLLEGE OF INDAL TECH

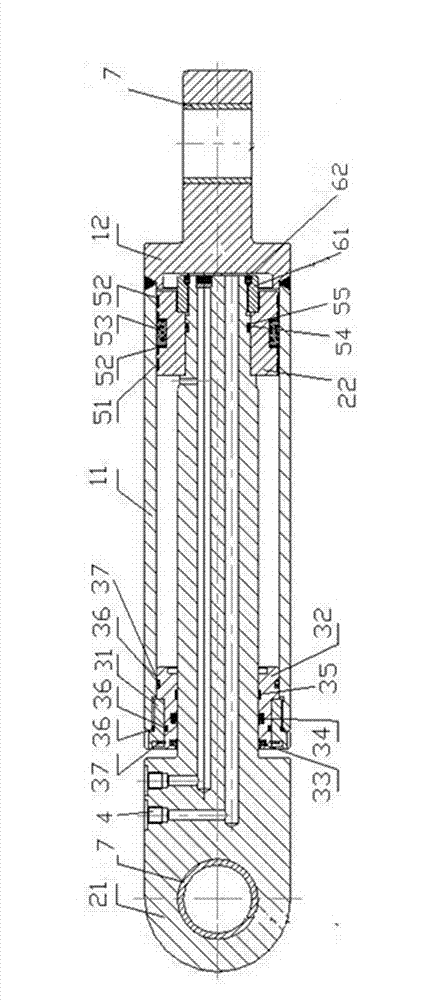

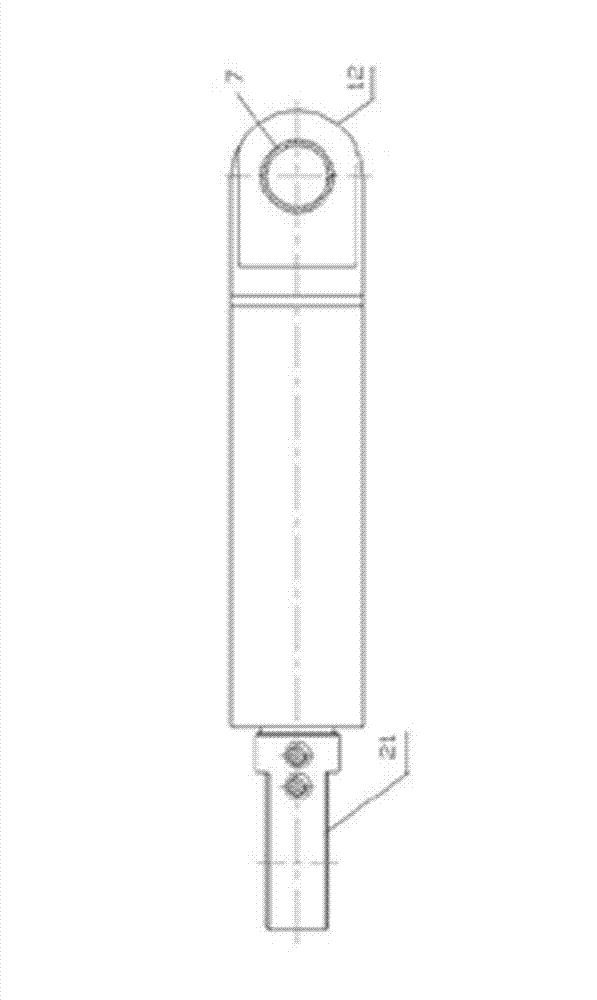

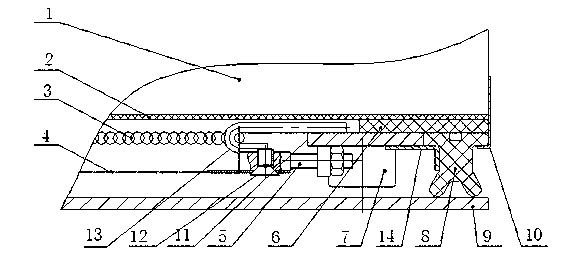

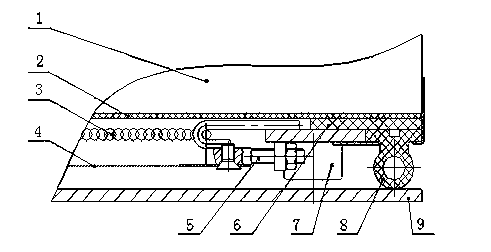

Hydraulic oil cylinder device capable of being easily disassembled and assembled

InactiveCN102777445AEasy to install and removeSealed wellFluid-pressure actuatorsEngineeringMechanical engineering

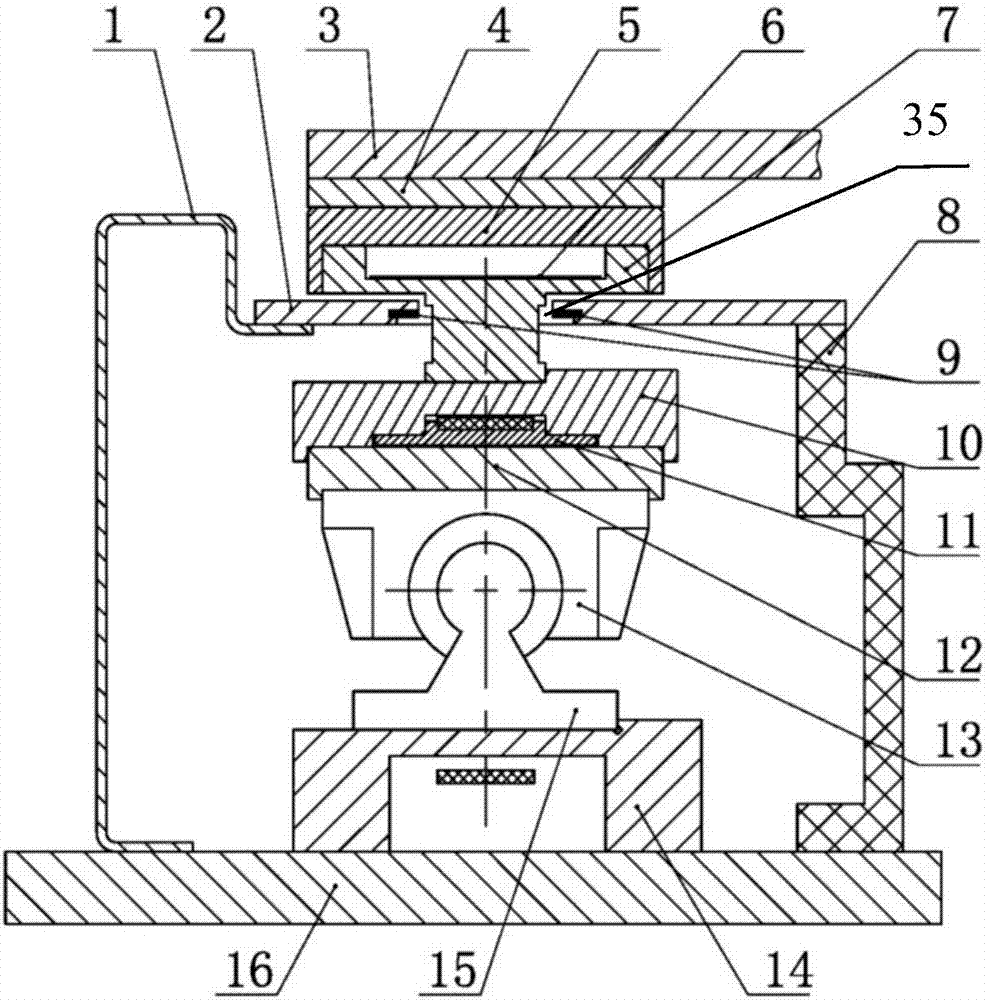

The invention discloses a hydraulic oil cylinder device capable of being easily disassembled and assembled, which comprises a shell assembly and a piston rod assembly. The shell assembly comprises a cylinder barrel and a cylinder body which is integrally connected with the cylinder barrel. One end of the piston rod assembly is arranged in the cylinder barrel and the other end of the piston rod assembly is arranged outside the cylinder barrel. The oil cylinder device additionally comprises a sealing assembly. The sealing assembly is arranged at one end of the cylinder barrel. The piston rod assembly comprises a piston rod and a piston. The piston is arranged in the cylinder barrel. One end of the piston rod is connected with the piston and the other end of the piston rod stretches out of the cylinder barrel. The hydraulic oil cylinder device has the advantages that the structure is reasonable, the sealing performance is good, a threaded sleeve and a guide sleeve can be separately installed and so the hydraulic oil cylinder device is simpler and more labor-saving to disassemble and assemble.

Owner:SHANGHAI CHUANGLI GRP

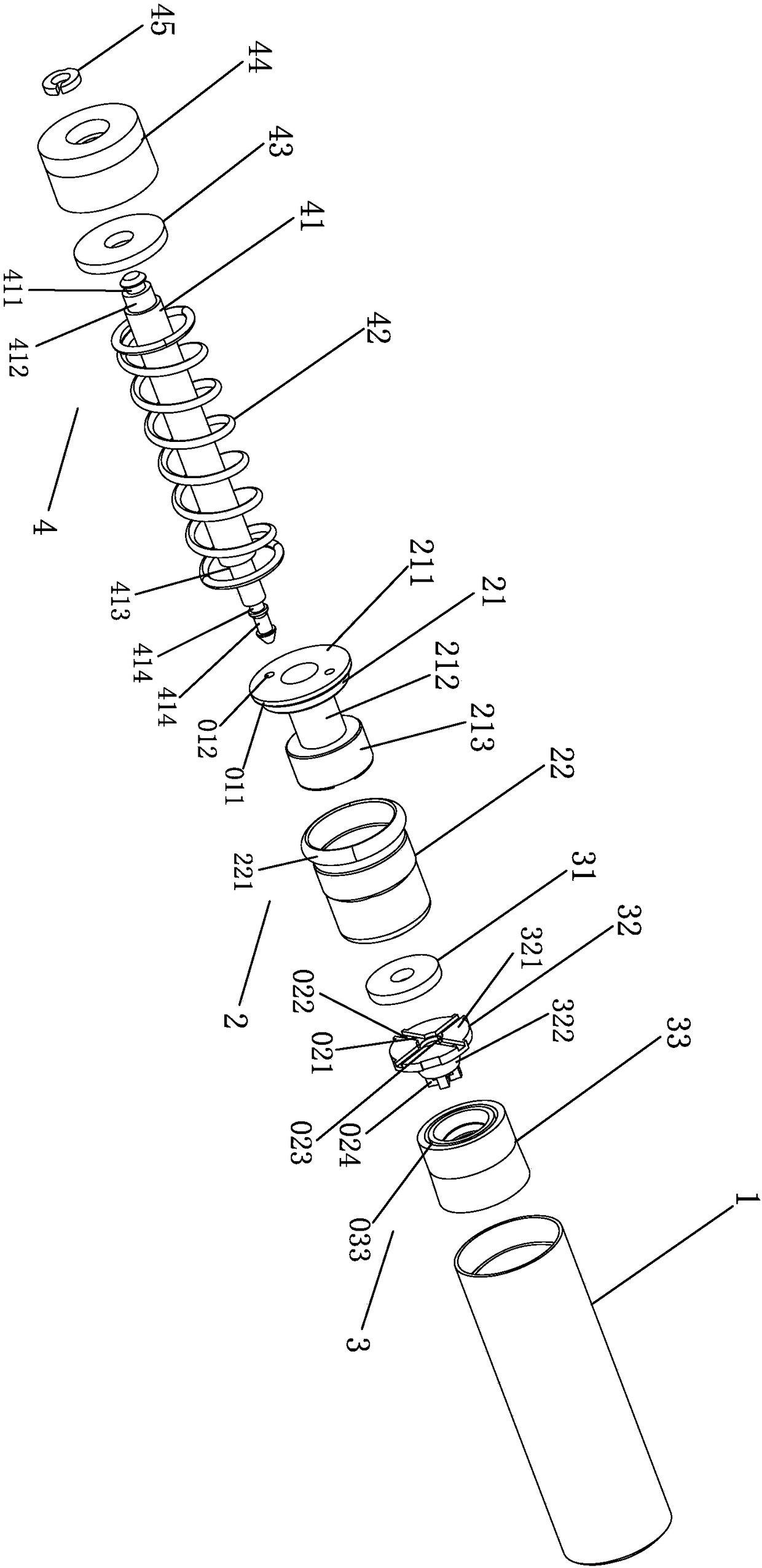

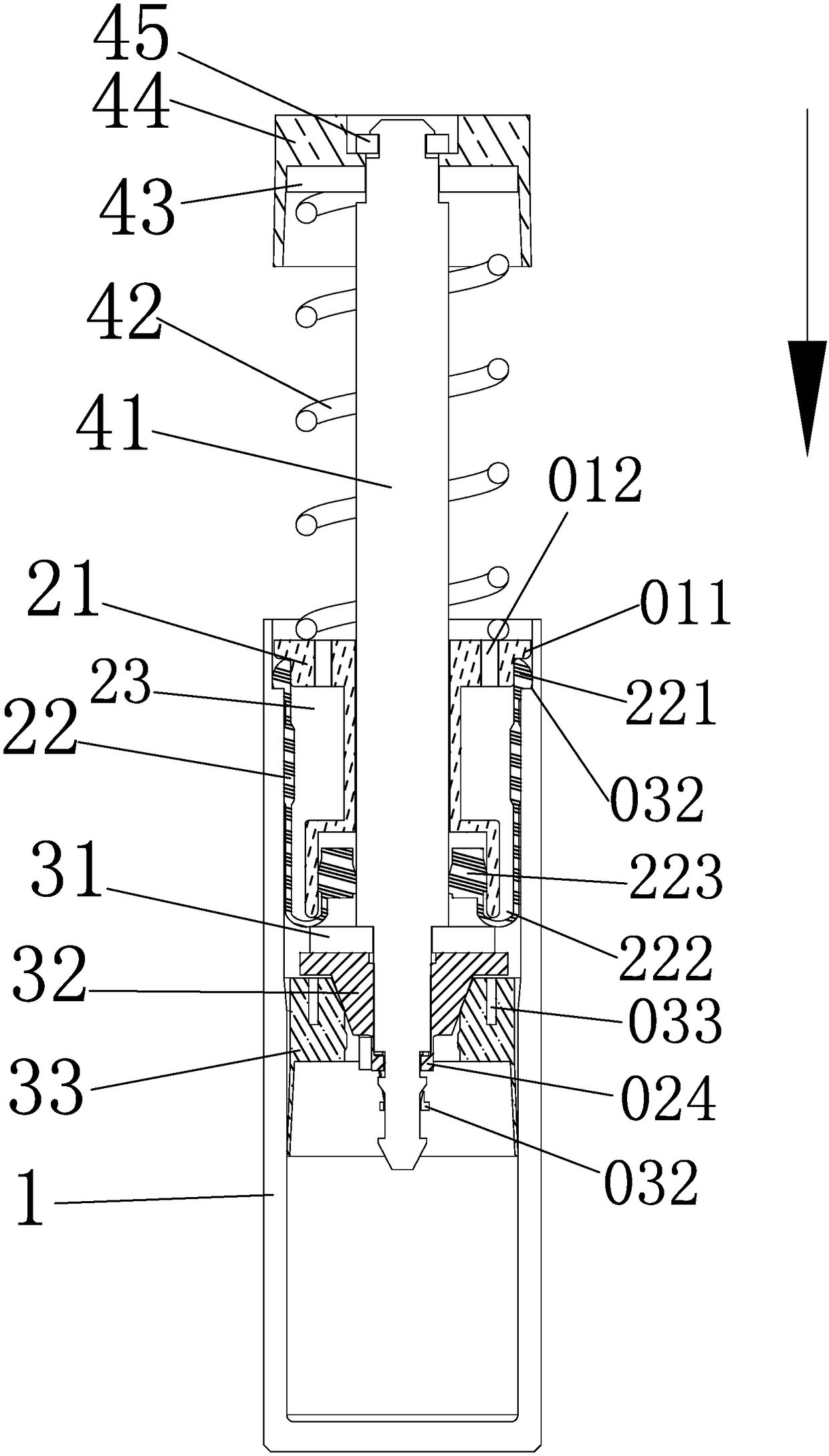

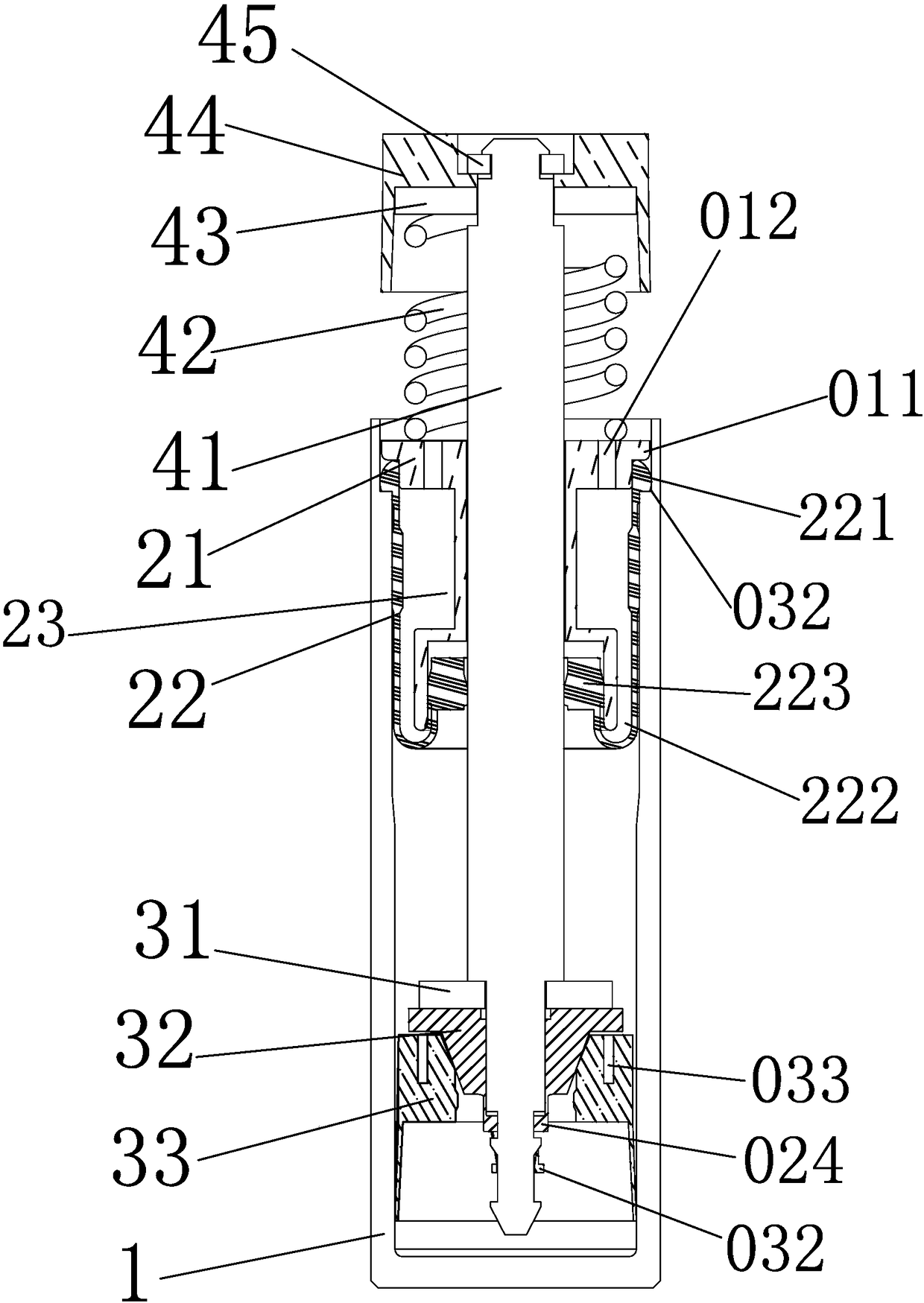

Damper with good sealing performance

The invention provides a damper with good sealing performance. By means of the flange riveting arrangement of the opening end of a shell, an end cover and a sealing ring are riveted tightly in the shell, damping oil is completely sealed in the shell, a ring baffle on the lower portion of a sealing sleeve blocks damping oil adhering to the outer wall of a piston core shaft, the damping oil is prevented from being taken out of the shell by the piston core shaft, gas enters a gas temporary storage space in the sealing sleeve from a vent hole in the upper end face of the end cover, the barometricpressure is increased to the sealing sleeve, the sealing sleeve achieves better sealing, and the damping oil cannot leak outwards.

Owner:HUBEI HONGSHENGCHANG ELECTRONICS CO LTD

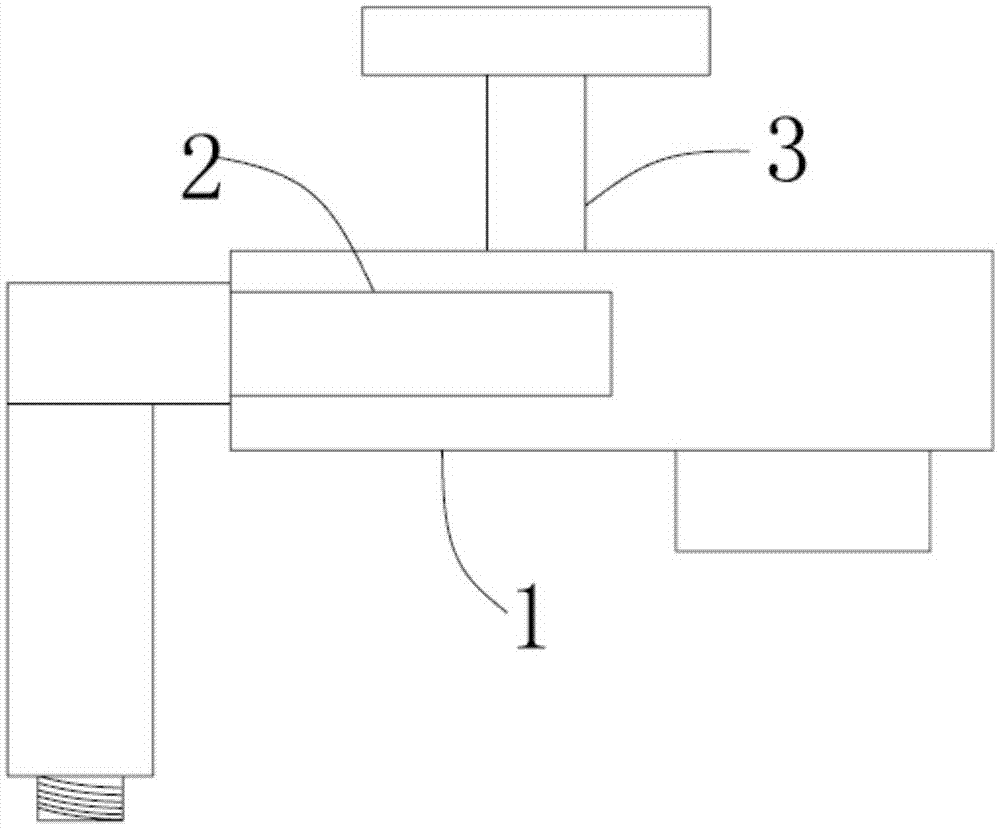

Motor-driven grating type spiral gate valve

InactiveCN102417112AQuick and easy to open and closeSealed wellOperating means/releasing devices for valvesBulk conveyorsElectricityMotor drive

The invention discloses a motor-driven grating type spiral gate valve, and relates to a motor-driven grating type spiral gate valve capable of controlling the conveying of powder. The grating gate valve consists of a motor drive head device, an electric control device, a gate valve body, a gate plate and a transmission device, wherein the motor drive head device is in mechanical connection with a connecting rack through a bolt, a plain washer, an elastic washer and a nut; a motor drive head core shaft sleeve is in mechanical connection with a motor drive head core shaft; and the motor drive head device is electrically connected with the electric control device. When the gate valve is opened and closed, the travel of the gate plate is only one third of gate plate travel of the conventional spiral gate valve, the gate valve slides in the gate valve body, and a screw sleeve which is connected with the gate plate in the transmission device slides under the action of a sealing ring, so that the powder in the gate valve body cannot be leaked to the outside and cannot enter a barrel of the transmission device to influence the normal operation of a screw rod, the screw sleeve and a bearing. The gate valve has a simple structure and low cost and is convenient to mount; and the gate valve can be operated within a long distance in the electric control process, so that the fitness of workers is protected.

Owner:SHANGHAI HAIXING VALVE FACTORY

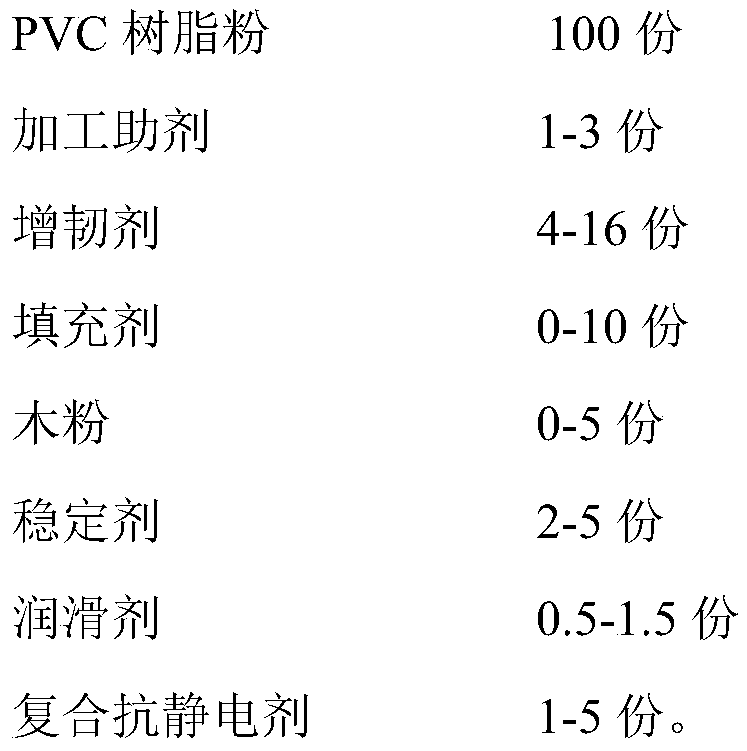

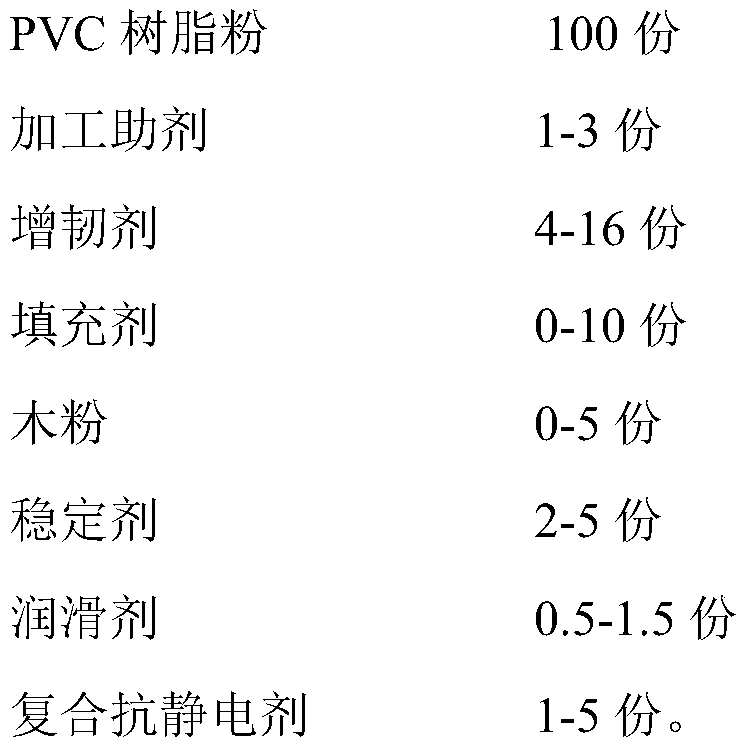

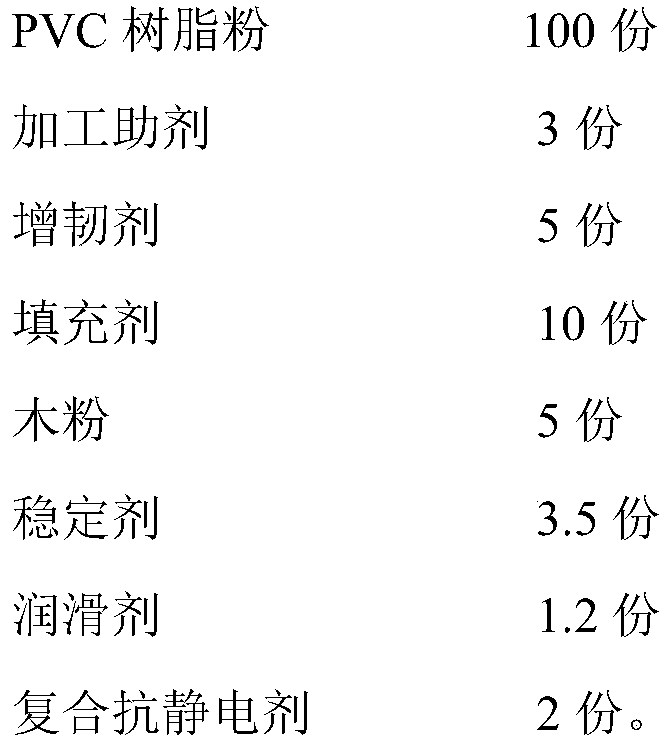

High-strength polyvinyl chloride folding-resistant plate and preparation method thereof

The invention belongs to the technical field of PVC plastic plates, and particularly relates to a high-strength polyvinyl chloride folding-resistant plate and a preparation method thereof, wherein theraw materials comprise PVC resin powder, a processing aid, a toughening agent, a filler, wood powder, a stabilizer, a lubricant and a composite antistatic agent. According to the invention, in orderto modify a polyvinyl chloride material, a toughening agent is added according to a production formula, so that the longitudinal and transverse folding resistance and the bending performance of a plate can be greatly improved while the tensile strength and other mechanical properties of the plate are improved, and the plate can be bent and be not broken after being slotted in the longitudinal andtransverse directions during use based on the changes, and nails and glues are reduced or not used; the product has few joints and good sealing performance and is attractive; and the preparation method is simple and easy to implement and easy to implement.

Owner:SHANDONG BODO PLASTICS CO LTD

Oil tank cover structure

InactiveCN105526031ASealed wellEasy to switchMachines/enginesLiquid fuel feedersKeyholeLocking plate

The invention discloses an oil tank cover structure with a good sealing effect. The oil tank cover structure comprises a lock framework and a lock plate. A lock sleeve is arranged between the lock framework and the lock plate. A lock cylinder and a lock cylinder sleeve are arranged in the middle of the lock framework. Lock cylinder springs and lock cylinder outer balance springs are arranged on the outer side of the part, at the lower end inside the lock cylinder sleeve, of the lock cylinder. The lock framework is connected with the lock cylinder sleeve through a first fixing bolt. The lock framework, the lock sleeve and the lock plate are connected through a second fixing bolt. A locking clamping device is movably arranged between the lock plate and the lower end of the lock framework and sleeved with locking clamping springs. The locking clamping device is formed by matching three locking clamps. Lock holes matched with the lower end of the lock cylinder are formed between the three locking clamps. A keyhole is formed in the upper end of the lock cylinder. A lock pin hole is formed in the upper end of the lock cylinder. A lock pin is arranged in the lock pin hole. The lock cylinder sleeve is provided with an L-shaped lock pin locating groove matched with the lock pin.

Owner:江苏弘昕油箱有限公司

Pipe connecting structure

InactiveCN104948855APlay a sealing effectPerformance impactSleeve/socket jointsMachining vibrationsElectrical and Electronics engineering

The invention discloses a pipe connecting structure. The pipe connecting structure is characterized by comprising a sealing connecting piece and pipes connected to the two ends, the two sides of the sealing connecting piece are connecting pipes, the middle of the sealing connecting piece is a sealing edge, the sealing connecting piece is hollow, the connecting pipes are connected to the pipes at the two ends, grooves are formed in the inner surfaces of positions, connected with the connecting pipes, of the pipes, sealing protruding blocks with the corresponding size are arranged at the positions, corresponding to the grooves of the pipes, of the outer surfaces of the connecting pipes, connecting edges are arranged on the outer edges of the connecting ends of the pipes, the connecting edges adapt to the sealing edge, corresponding fixing holes are formed in the connecting edges and the sealing edge, rubber layers are arranged on the outer surfaces of the sealing protruding blocks, rubber layers are arranged on the outer surfaces of the connecting pipes, the sealing edge protrudes out of the connecting edges, the protruding parts of the sealing edge extend horizontally towards the two sides, and the extending length of each side is equal to the thickness of the corresponding connecting edge. The pipe connecting structure can achieve the sealing effect effectively, and the performance of the pipe joint cannot be influenced by machine vibration.

Owner:吴春兰

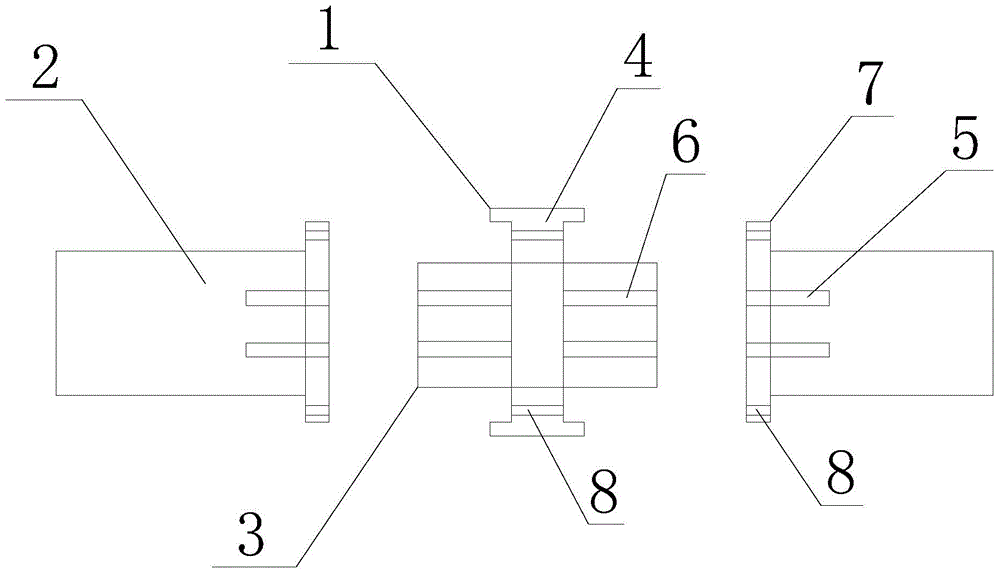

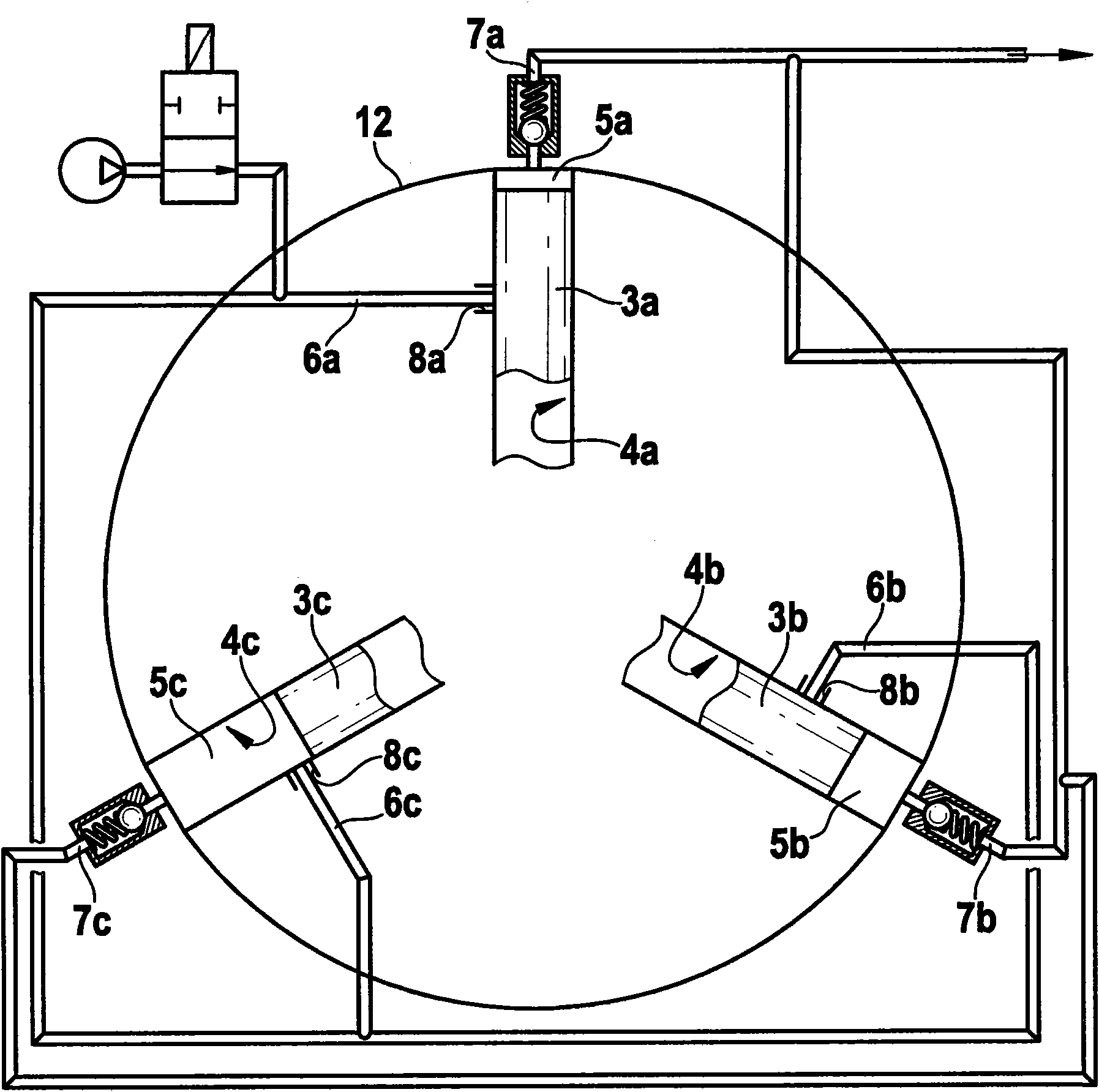

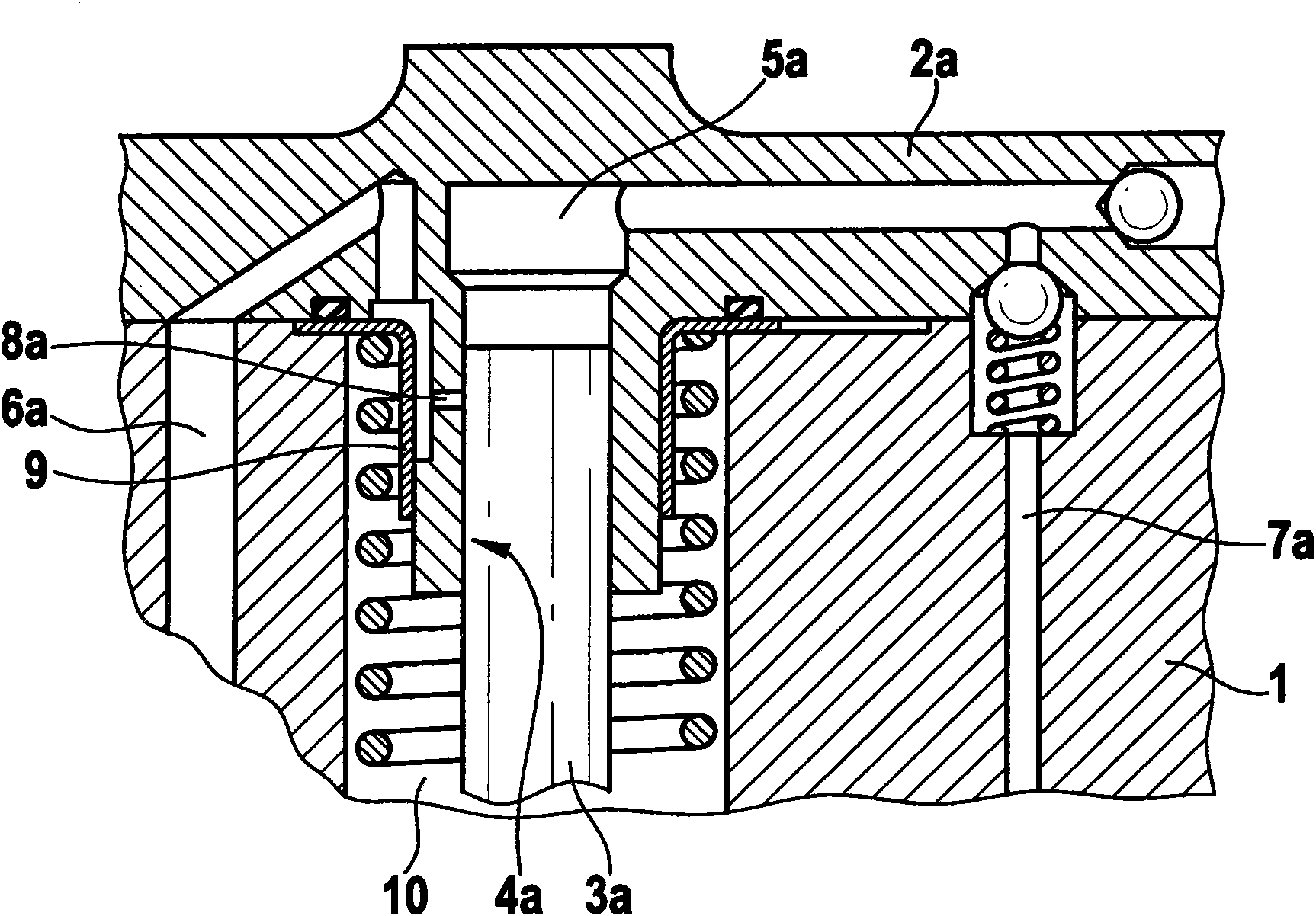

High-pressure fuel pump

InactiveCN101849099AReduce high pressure leaksSealed wellFuel injecting pumpsPositive-displacement liquid enginesLow stressHigh pressure

The present invention relates to a high-pressure fuel pump for operating an internal combustion engine, comprising a pump housing (1) and at least two pump cylinder heads (2a-2c), in each of which a pump piston (3a-3c) is guided in a piston guide (4a-4c), wherein one pressure chamber (5a-5c) each is disposed above said pump pistons (3a-3c), each of which is connected to one low-pressure inlet (6a-6c) and one high-pressure connection (7a-7c), and the pump pistons (3a-3c) are in contact with a mutual pump camshaft, whereby a translational movement of the pump pistons (3a-3c) can be created, and fuel can therefore be suctioned in the respective pressure chamber (5a-5c), can be compressed to high pressure and conveyed to the respective high-pressure connection (7a-7c), wherein the at least two pump cylinder heads (2a-2c) are further disposed at an equidistant angle to each other on the same circumferential line (12) about the pump camshaft, and fuel can be supplied to the pressure chambers (5a-5c) via one inlet bore (8a-8c) in the piston guide (4a-4c) by means of the low-pressure inlet (6a-6c).

Owner:ROBERT BOSCH GMBH

Faucet with water purifying function

The invention provides a water faucet with water purification function, comprising a main body, a temperature control device and a valve core, the main body is formed with a water inlet and a water outlet; the water outlet end of the main body is fixedly connected with the temperature control device; The valve core is fixedly connected with the temperature control device, and the temperature control device is provided with a water outlet; the water outlet of the temperature control device is isolated from the fixed water outlet pipe of the shower; the main body outlet pipe is connected to the water outlet of the spray gun shower ; The main body is fixed with the connecting body; the cover is clamped on the top of the main body; the sealing ring for sealing is arranged on the top of the connecting body. The invention has the advantages of simple structure, good sealing, more energy saving and good water purification effect.

Owner:宁波南池环保科技有限公司

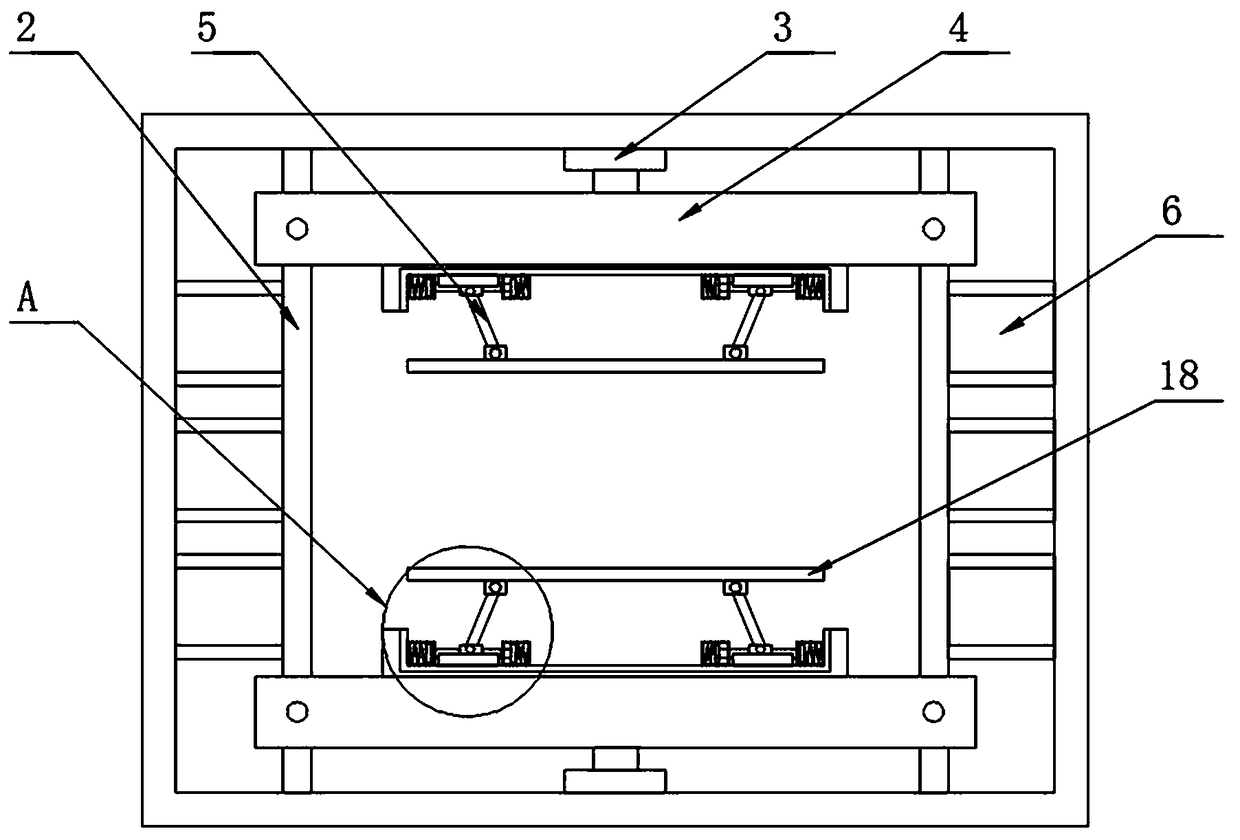

Efficient vacuum package machine

InactiveCN108482765ASealed wellPrevent uneven sealingWrapper twisting/gatheringPackaging under vacuum/special atmosphereEngineeringVacuum packing

The invention discloses an efficient vacuum package machine. The efficient vacuum package machine comprises a vacuum chamber, wherein a movable sliding rail is arranged in the vacuum chamber, hydraulic rods are arranged on one side of the movable sliding rail, a movable plate is arranged on one side of each hydraulic rod, a clamping deice is arranged on one side of each movable plate, air suctionports are arranged at the bottom of the movable sliding rail, and a vacuum pump is arranged at the bottoms of the air suction ports. By arranging the clamping devices, when the efficient vacuum package machine is used, a packaging bag is put between sealing cutters, then the vacuum pump is opened, a vacuum chamber is vacuated by the vacuum pump into vacuum, the hydraulic rods are opened and push the movable plates to move, the movable plates move the sealing cutters on one sides of the movable plates, so the sealing cutters seal the packaging bag, in the process, tension springs on one sides of sliding blocks push second pushing rods, meanwhile first springs push first pushing rods, the first pushing rods push the sliding blocks, and the sliding blocks are pulled towards one sides of the centers of the sealing cutters. According to the efficient vacuum package machine, the sealing cutters can be pushed and can better clamp and fix the packaging bag while sealing the packaging bag.

Owner:DIMENSION TECH

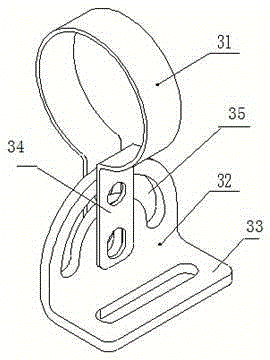

Bearing convenient to mount

InactiveCN107504078ASimple structureSealed wellBearing unit rigid supportEngineeringMechanical engineering

Owner:XINCHANG COUNTY XRKOBO MASCH CO LTD

Fan impeller and fan

ActiveCN111828316AConsistent widthSealed wellRotary piston pumpsRotary piston liquid enginesImpellerEngineering

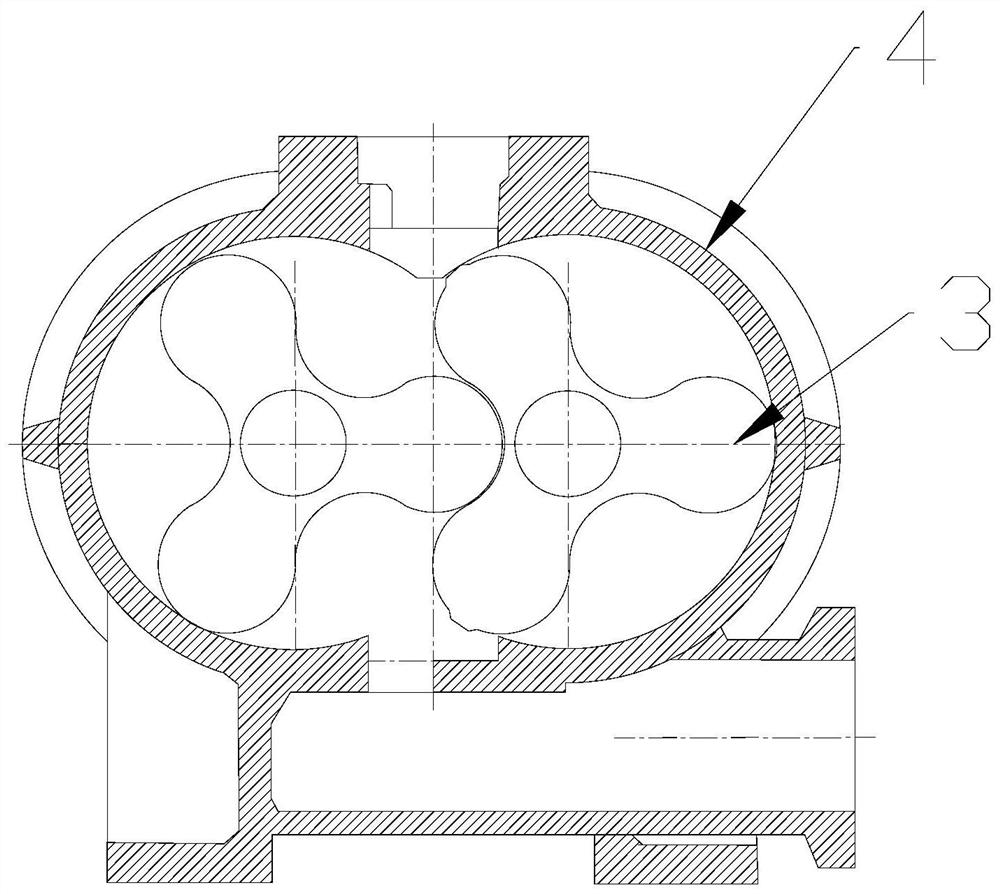

The invention discloses a fan impeller. The fan impeller comprises a plurality of blade teeth, wherein each blade tooth is provided with a blade peak part; the outer surface of each blade peak part isan arc surface; a wide rib protruding out of each blade peak part is arranged at the top end of each blade tooth; the distance from the top end of each wide rib to the center of the impeller is equalto the radius of the impeller; and each wide rib enables the blade top to have a large machinable area, can allow / adapt to a large error rate of a numerical control lathe, and facilitates the subsequent reprocessing process, so that the impeller with the distance from the top end to the center of the impeller being equal to the radius of the impeller can be obtained through accurate processing,and the problem of deviation from theoretical design to the product forming process is solved. The invention further provides a fan. The fan comprises a casing and the impeller arranged in the casingand matched with the casing, wherein the impeller is the fan impeller. The fan is convenient to process and manufacture, the impeller and the casing are well sealed, the leakage rate is low, the fan noise is low, the operation is stable, the stability and the wear resistance are high, and the service life is long.

Owner:山东章晃机械工业有限公司

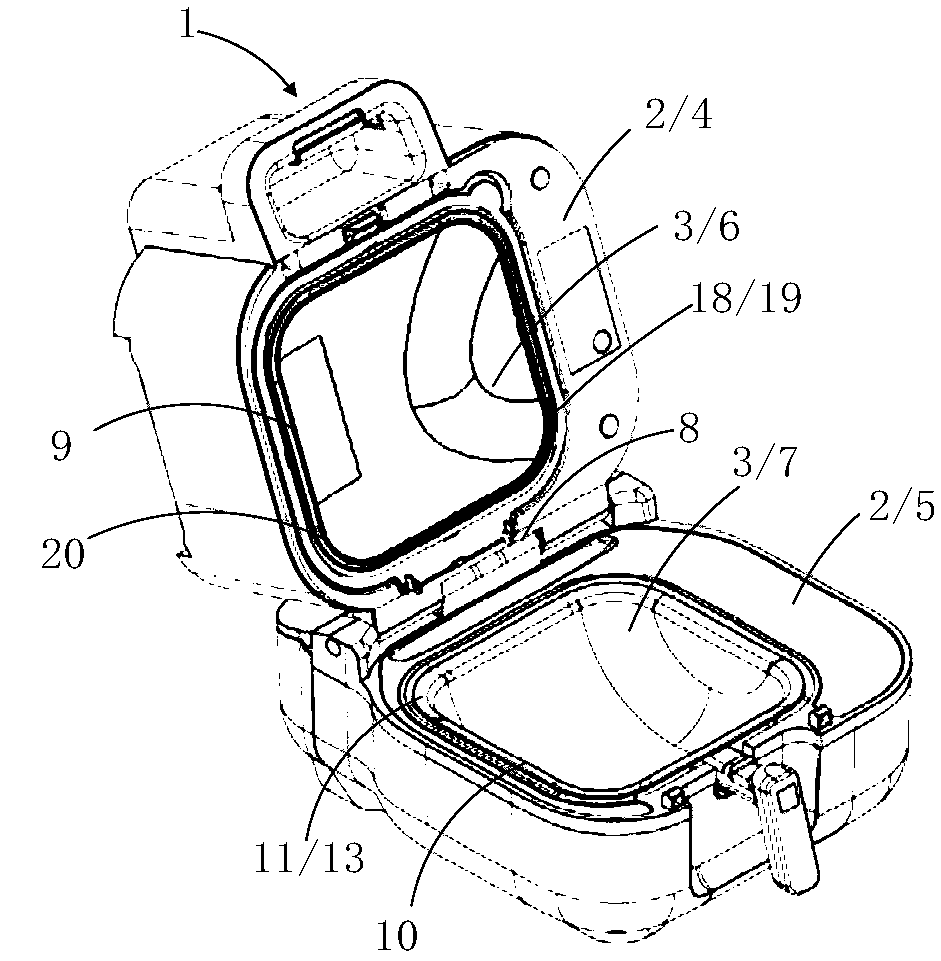

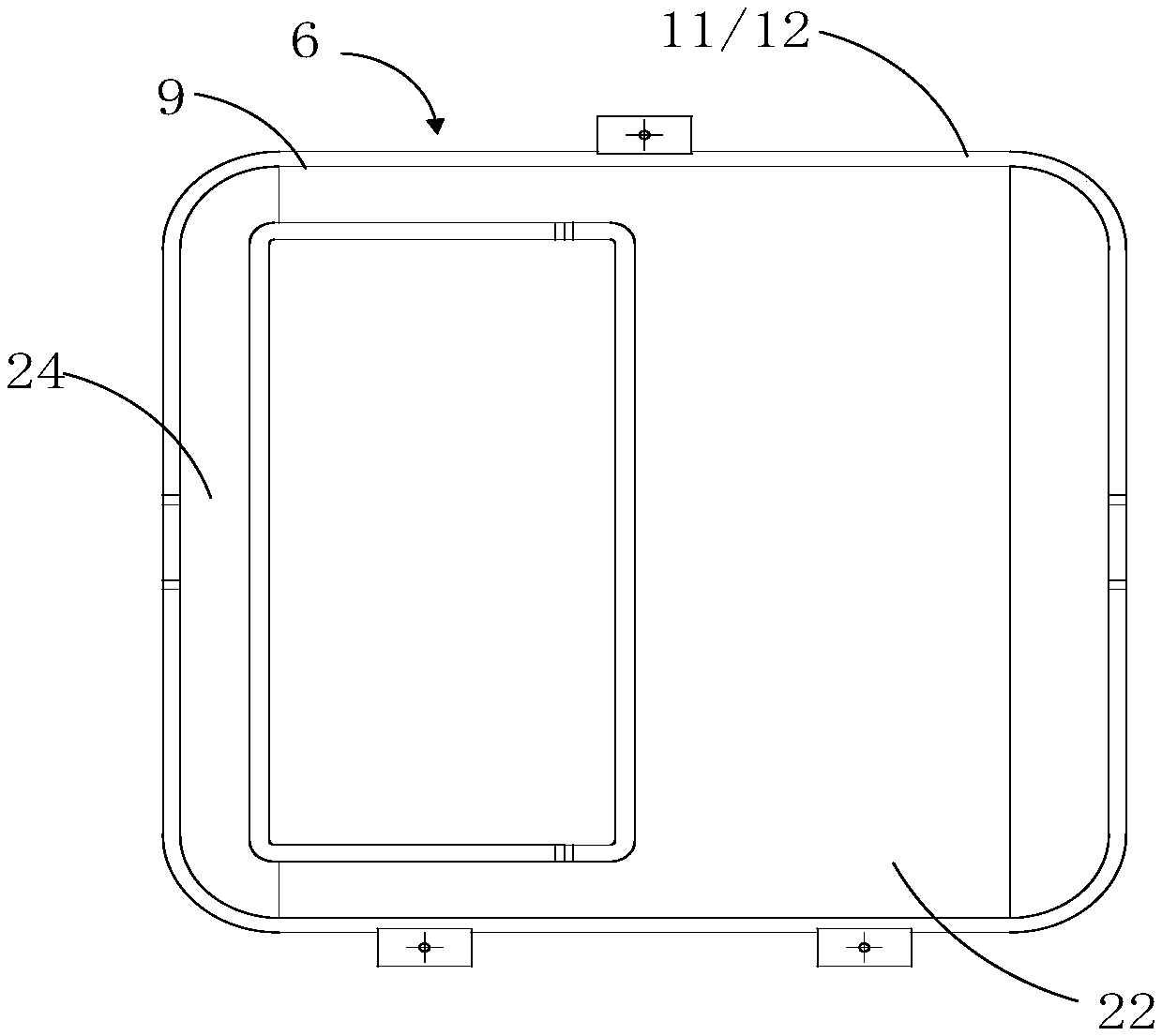

Seal structure of leather vacuum drying machine

InactiveCN103290146ASealed wellImprove sealingSkins/hides/leather/fur manufacturing apparatusLeather dryingRubber matEngineering

The invention relates to a seal structure of a leather vacuum drying machine. The seal structure of the leather vacuum drying machine comprises a cover cap framework and a working table board, wherein the cover cap framework is positioned above the working table board; the cover cap framework is internally provided with a three-dimensional net, a thin net, a buffer gasket, a pressing board and a seal rubber mat; the bottom of the cover cap framework is provided with a seal rubber board; the pressing board penetrates through the seal rubber board through a thread and is fixed on the cover cap framework, and is fixedly connected with the three-dimensional net; the thin net is arranged below the three-dimensional net, and is fixed on a tensioning screw; the buffer gasket is fixed at the bottom of the pressing board; the bottom of the seal rubber mat is provided with a seal ring; the seal ring is fixedly connected with the seal rubber mat through a baffle plate. The seal structure of the leather vacuum drying machine provided by the invention has the advantages that when a cap of the cover cap framework is covered, a seal ring tightly clings between the cover cap framework and the working table board through the pressure effect of the cover cap framework so as to form favorable seal.

Owner:NANTONG SIRUI ENG

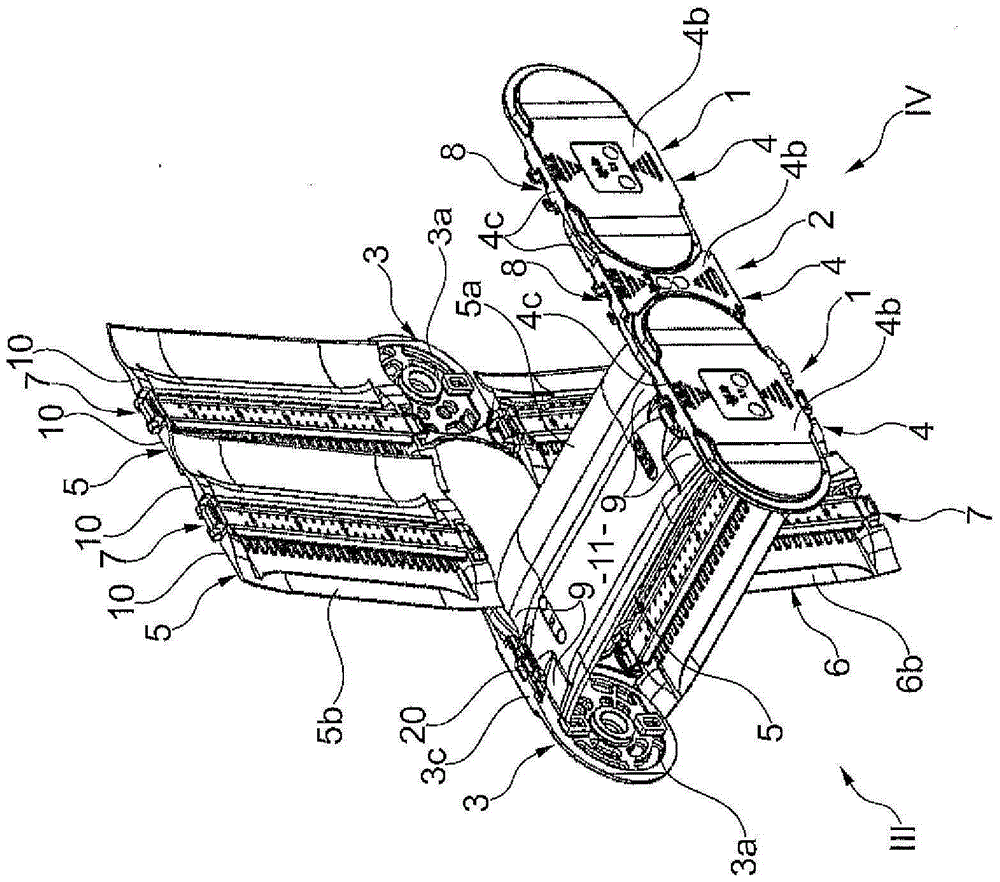

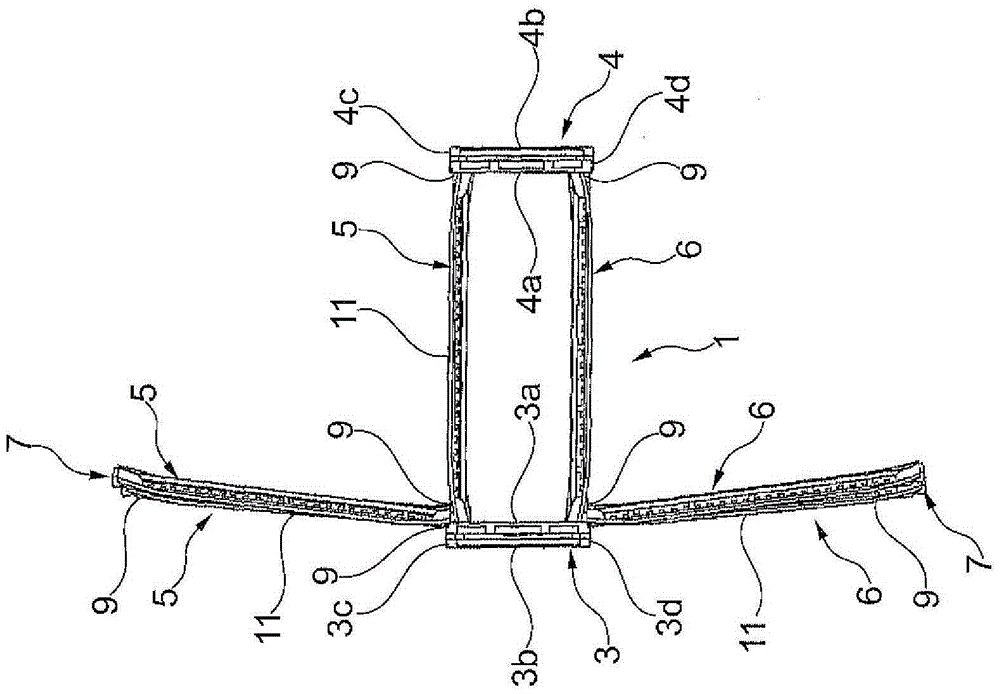

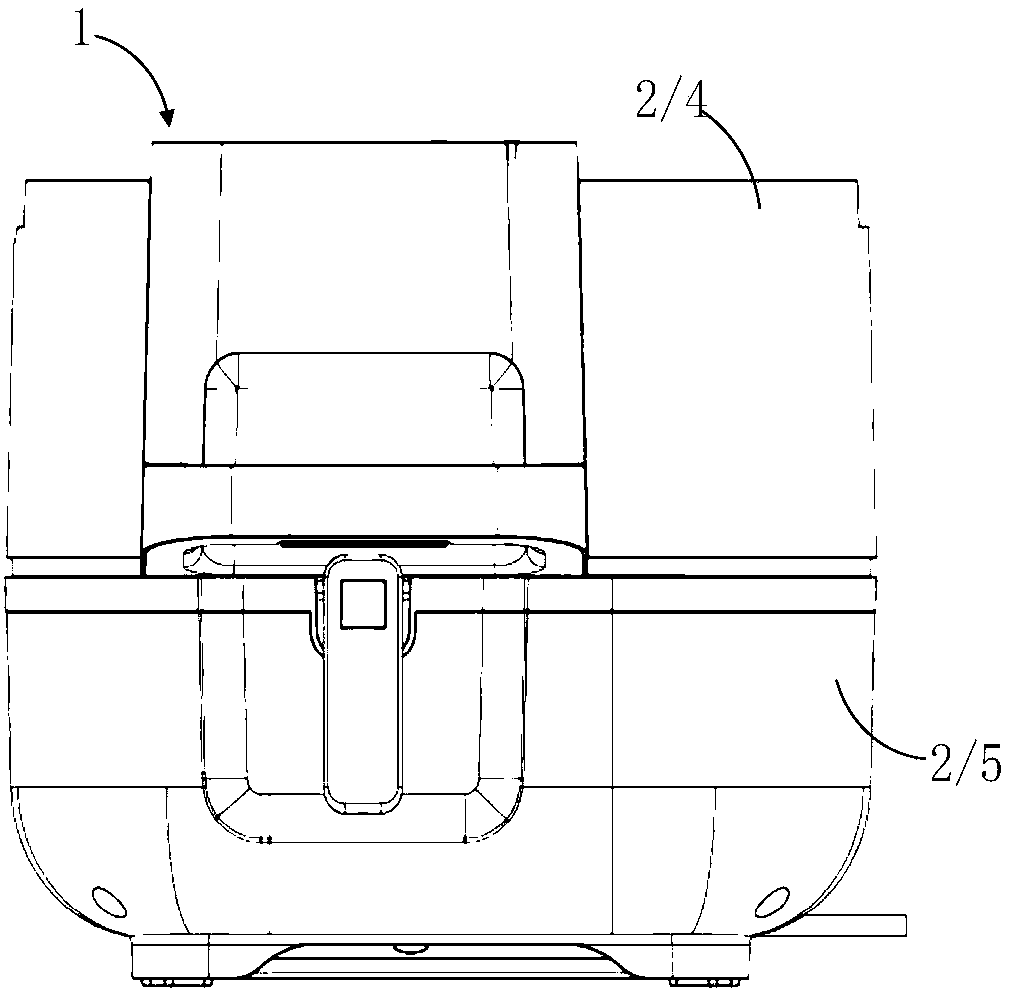

Energy guiding chain

ActiveCN105229336ASealed wellEasy to insert or replaceHauling chainsHoisting chainsBearing surfaceEngineering

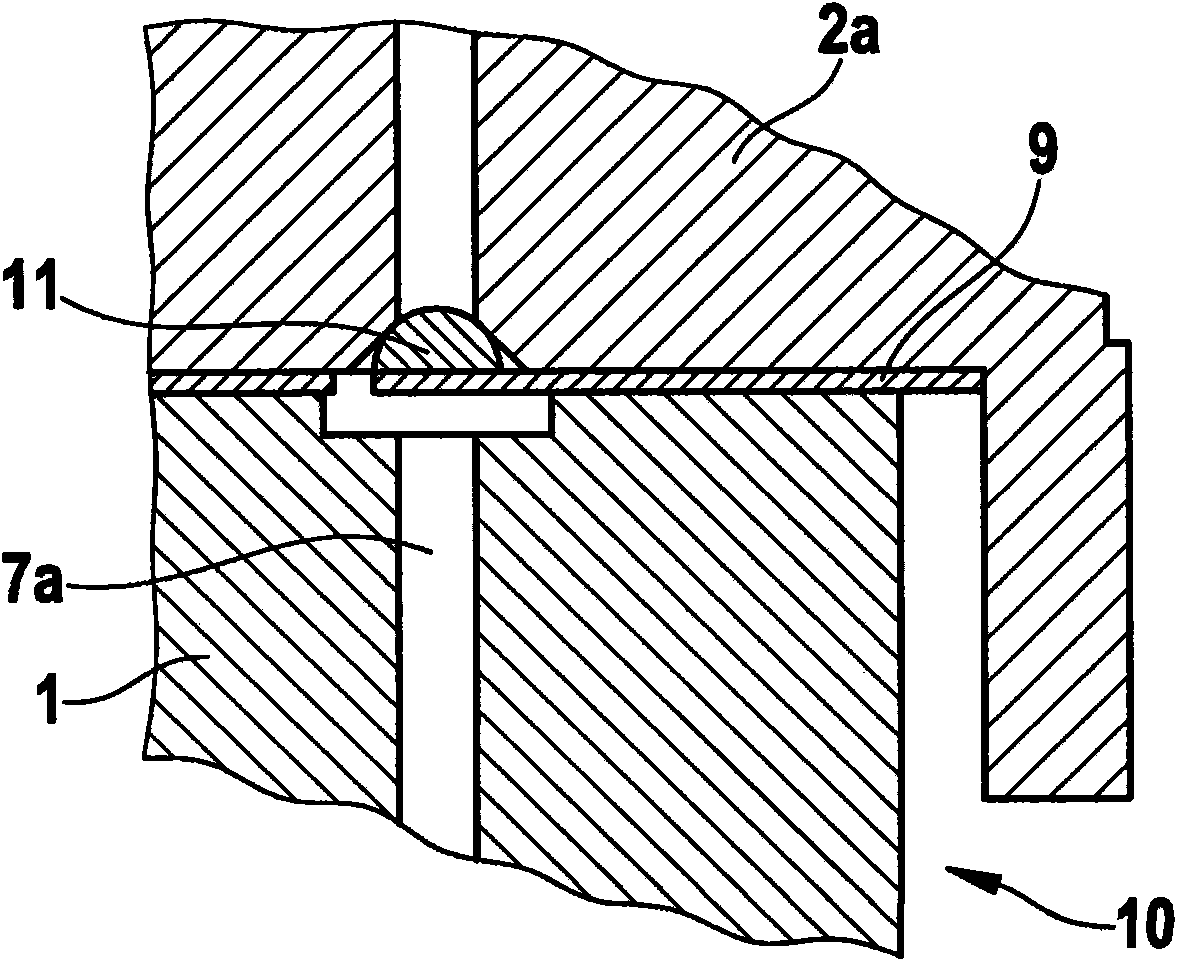

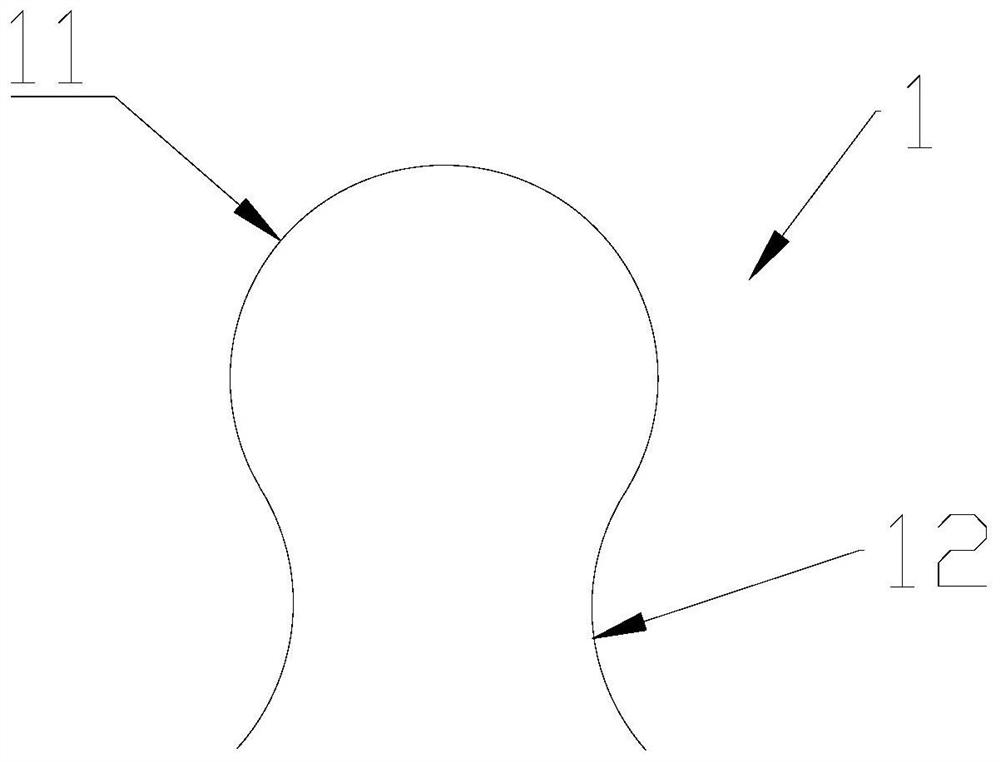

The invention relates to an energy guiding chain, the chain links thereof (1, 2) having two side plates (3, 4) each which are joined together by transverse rods (5, 6). Said transverse rods comprise on at least one of the ends thereof, a bearing area (7), and when seen in the longitudinal direction of the side plates (3, 4), has a contact area (9) which is outside of the bearing area. In order to prevent the accumulation of foreign bodies, the side (11) of the contact area of the transverse rods pointing from the inside of the chain to the outside is convexly curved inwards or is linearly inclined to the bearing surface (10) thereof and forms an angle, with the inner side (3a, 4a) of the respective side plate, which is less than 90 DEG C such that said bearing surface (10), when pivoting the traverse rod until a fully open position is reached, moves inwards along the inner side of the side plate to the inside of the chain.

Owner:IGUS

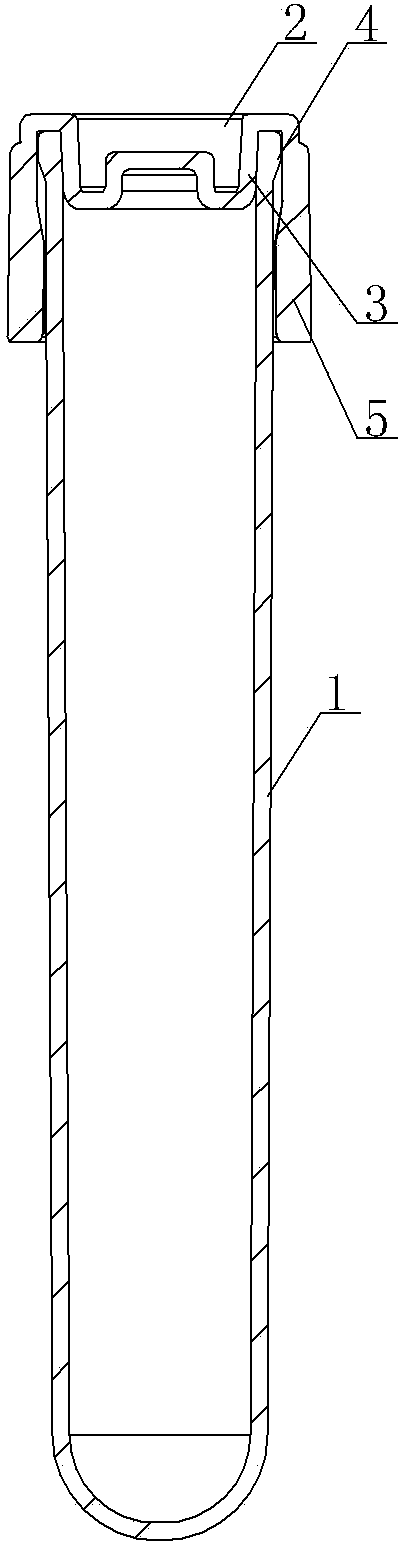

Cell culture tube structure

InactiveCN103642686ASealed wellImprove sealingBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringCultured Cell Line

The invention provides a cell culture tube structure, which is characterized in that a lid and a pipe body are sealed, no liquid overflows from a test tube even under a shaking state, so that subsequent tests can be smoothly carried out. The structure comprises a pipe body and a lid, a downward protruded sealing ring is provided on the upper inner wall of the lid, the outer ring surface of the sealing ring clings to the inner ring surface of the upper end part of the pipe body, an outwards expanding positioning projection is provided at the upper end part of the pipe body, a reversing structure with outwards expanding opening from down to top is arranged on the inner wall of a circular ring guide sleeve of the lid, the upper part of the reversing structure is a guiding ring surface structure, the sealing ring is the structure with the outwards expanding opening from down to top, the guiding ring surface structure clings to the outer ring surface of the positioning projection, and the upper end surface of the pipe body clings to an internal locating surface of the lid.

Owner:WUXI NEST BIOTECHNOLOGY CO LTD

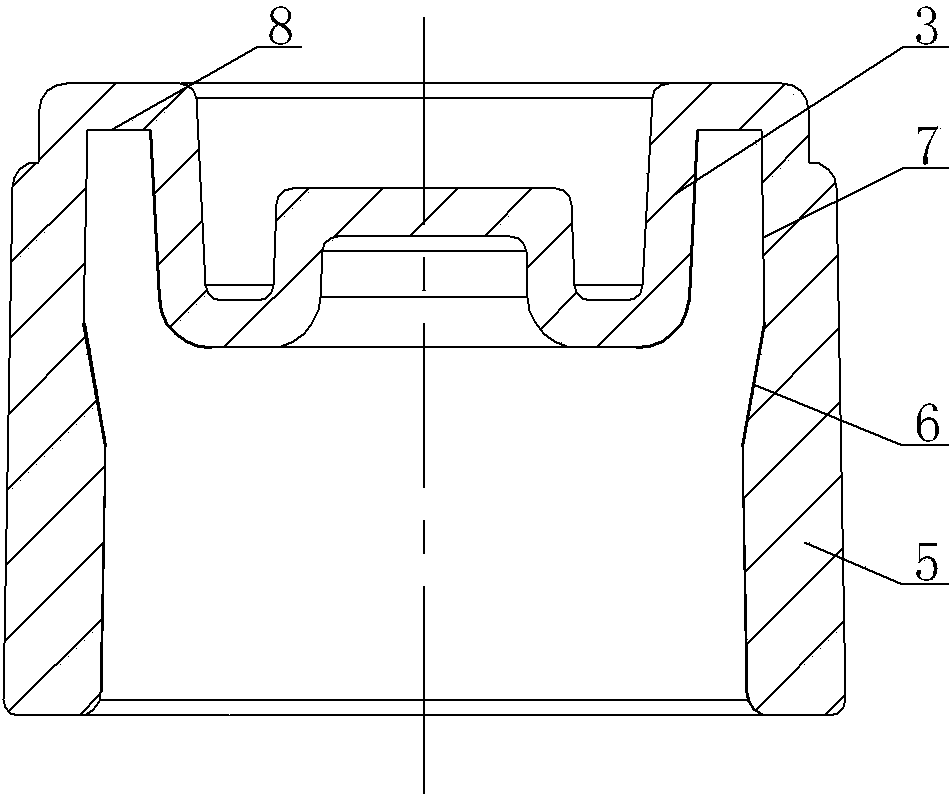

Valve rod sealing member with buffer function

The invention discloses a valve stem seal with a buffer function, which comprises a valve stem and a valve seat. The end of the valve stem in contact with the valve seat is a valve cover, and the valve seat is a rectangular groove. The contact end between the cover and the bottom of the valve seat is a smooth curved surface, and there is an arc-shaped groove on the side of the valve cover facing the valve seat, the center line of the arc-shaped groove and the center line of the valve stem Located on the same straight line, and the angle of the central angle corresponding to the arc surface of the arc groove is α, 75°≤α≤105°. The invention solves the problems of severe wear between the existing valve stem and the valve seat, which causes the valve to sink due to poor sealing, and the problems that the service life of the valve stem and the valve seat is short.

Owner:SICHUAN SENJIE GAS EQUIP CO LTD

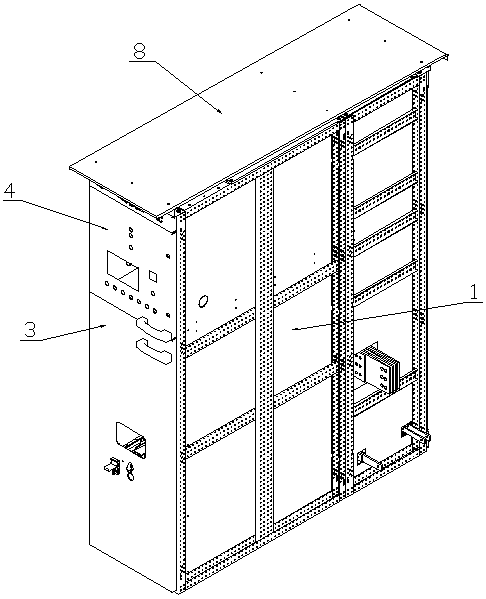

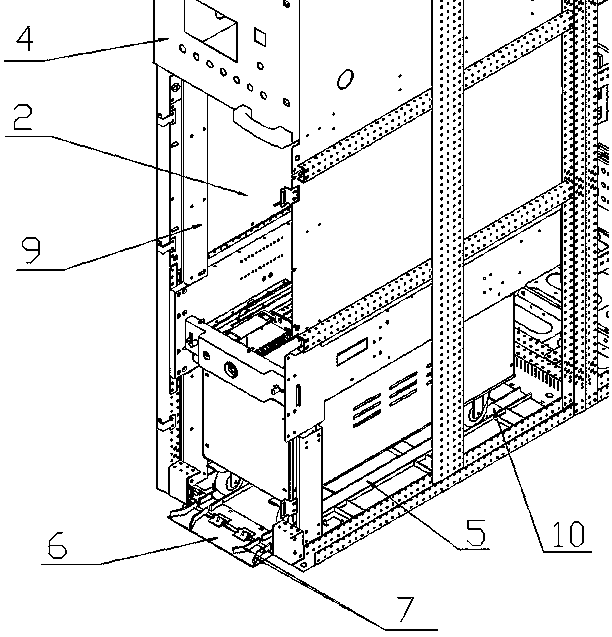

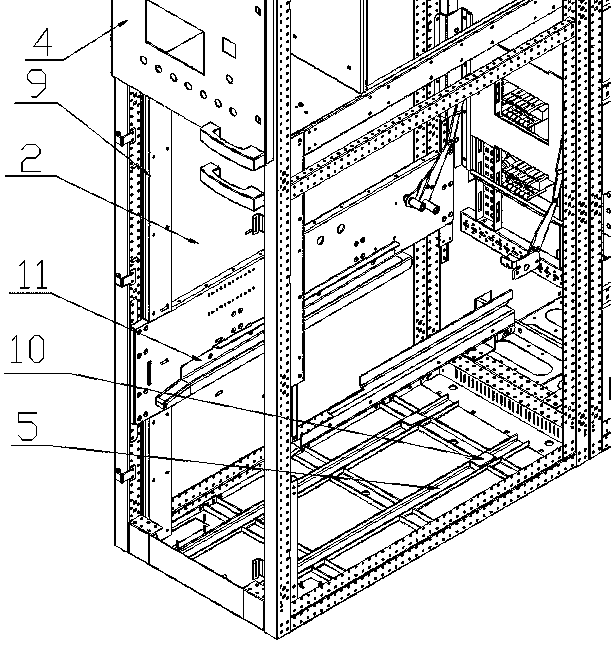

Intelligent direct current circuit breaker cabinet convenient in placing direct current circuit breaker handcart

InactiveCN109412064AEasy accessSealed wellSwitchgear with withdrawable carriageEngineeringControl line

The invention aims to provide an intelligent direct current circuit breaker cabinet convenient in placing a direct current circuit breaker handcart. A current circuit breaker handcart chamber is usedfor placing the current circuit breaker handcart, a guide rail is arranged to carry out feeding on the handcart, an approach rail guides fed materials, the handcart enters the circuit breaker handcartchamber, the approach rail can be collected to be convenient in sealing a cabinet body, and a metal sealing wiring channel performs a shielding function and also can prevent a cabinet arcing fault from damaging a control line. The cabinet body and an instrument room are independently provided with an insulation plate to avoid a situation that the cabinet body is electrified to generate dangers, the insulating installation screw of the cabinet body effectively avoids the influence of free metal ions on the cabinet body when the circuit breaker has faults to spray arc light, a water guiding plate on the top of the cabinet body conveniently enables water to flow to the ground behind the cabinet body when water drips in the outside, the safety of the cabinet body is protected, the whole cabinet is favorably matched with the direct current circuit breaker handcart, the handcart conveniently enters and leaves, and the cabinet body is good in sealing, is high in safety and convenient in operation.

Owner:ANHUI ZHONGDIAN XINGFA & XINLONG TECH CO LTD

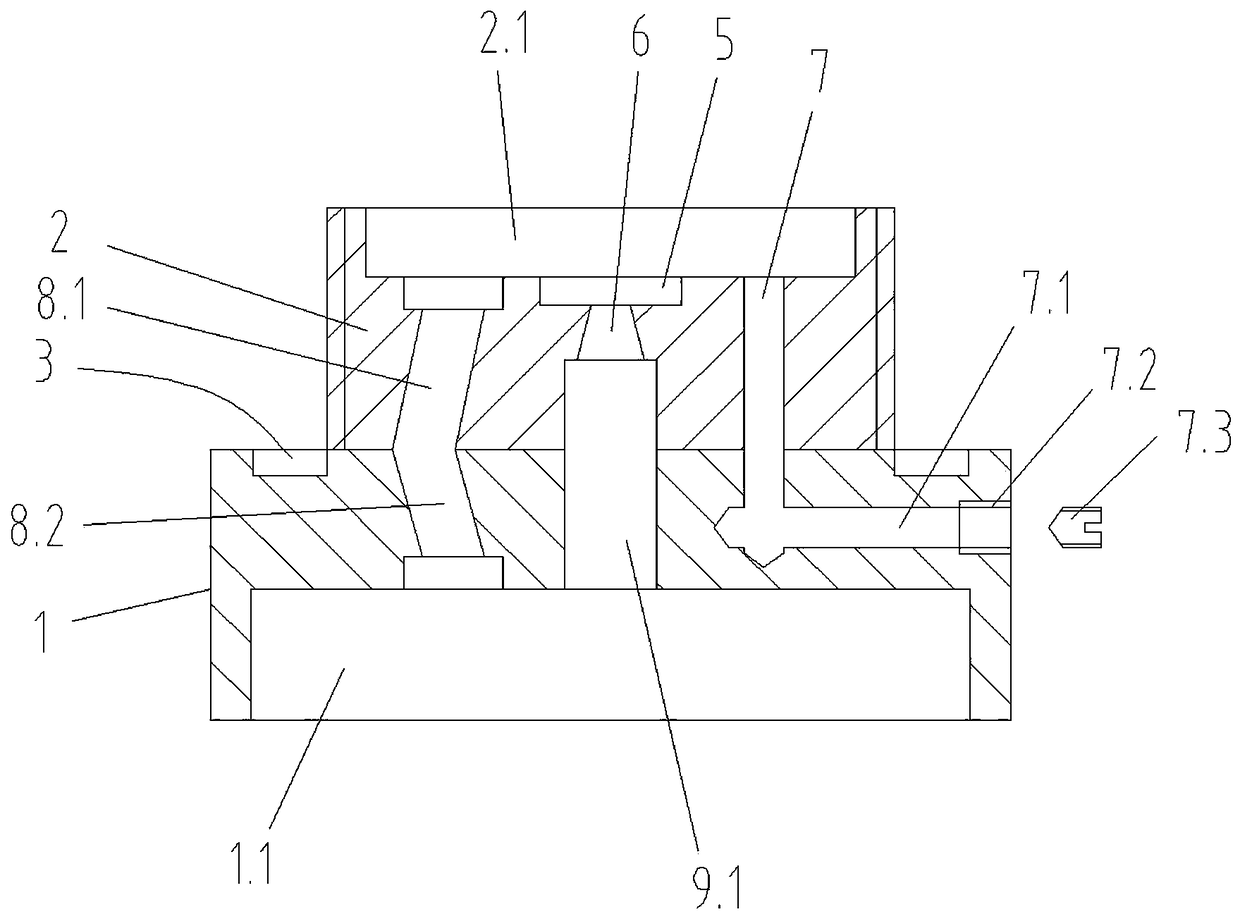

Pressure sensor base with good pressure resistance

InactiveCN108132121AHigh compressive strengthSealed wellFluid pressure measurementEngineeringPressure resistance

The invention discloses a pressure sensor base with good pressure resistance. The pressure sensor base is characterized by comprising a hexagonal plate, wherein a connecting column is fixedly connected with the center of the upper side of the hexagonal plate; an annular groove is formed in the upper side edge of the hexagonal plate; a sealing gasket is connected in match inside the annular groove;a first groove is formed in the center of the upper side of the column; and a vent hole, four first counterbores and an oil injection vertical hole are formed in the bottom of the first groove. The pressure sensor base has the advantages that an electrode channel is of a V-shaped structure, and when the pressure sensed by a pressure sensor exceeds working pressure, the direction of the pressure of an electrode can be changed inside an electrode channel, so that the pressure resistance of the pressure sensor base can be improved, an air inlet tube and the vent hole can be very well sealed, thevent hole is not blocked in the sintering process, and the finished product rate of the pressure sensor base can be increased.

Owner:BENGBU XINGCHUANG ELECTRONICS TECH CO LTD

Sealing part

The present invention provides a sealing element, which includes a main body, and a first through hole and a second through hole are respectively arranged in the main body; an iron ring is clamped and fixed in the first through hole and the second through hole. The invention has simple structure, good sealing and prolongs the service life of the machine.

Owner:慈溪埃弗龙密封件有限公司

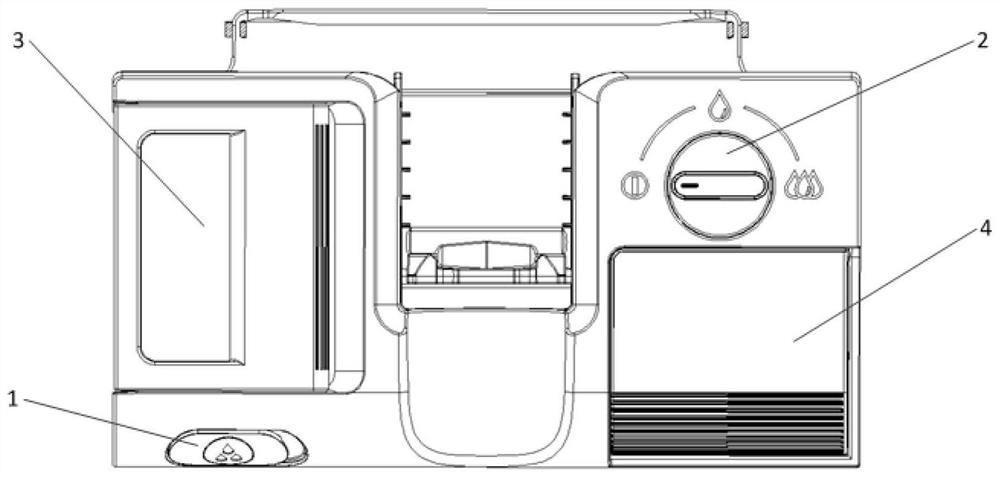

Limiting assembly for pot body of automatic cooker and automatic cooker

The invention discloses a limiting assembly for a pot body of an automatic cooker and an automatic cooker. The automatic cooker comprises a shell, the pot body and a sealing structure, wherein the shell comprises a first shell and a second shell, the pot body comprises a first pot body and a second pot body, the first pot body comprises a first pot hole, the second pot body comprises a second pothole, the first pot body is located in the first shell, the second shell is located in the second shell, the first pot hole corresponds to the second pot hole, the first pot hole and the second pot hole are connected through the limiting assembly, and the sealing structure is connected with the limiting assembly, so that the shifting of a contact part between the first pot hole and the second pothole can be prevented.

Owner:深圳英诺智慧科技有限公司

Water tank assembly

PendingCN112137532ASealed wellCorrect positionCarpet cleanersFloor cleanersWater tanksMechanical engineering

The invention discloses a water tank assembly which comprises a water tank, mop cloth arranged on the outer side of the bottom of the water tank, a water volume control assembly, a water passing channel formed in the bottom of the water tank, a water tank hole and a water outlet hole, the water volume control assembly comprises a knob and a water control disc, and the water control disc is controlled by the knob to be matched with the water tank hole. The amount of water entering the water passing channel from the water tank through the water tank hole is adjusted. The water volume adjusting process of the knob device is accurate and controllable, the waterproof sealing performance is good, and a user has good operation comfort.

Owner:BEIJING ROCKROBO TECH CO LTD

Upper sealing head structure of fiber ultrafiltration membrane

The invention belongs to the field of water treating equipment, and relates to a hollow ultrafiltration membrane component. The invention relates to a fiber ultrafiltration membrane upper sealing head structure comprising a pressing housing, a sealing head, a sealing head connection end and a fiber ultrafiltration membrane. A water inlet connected to an outer pipeline is arranged on the sealing head connection end. The water inlet is designed as a fast interface. The water inlet is directly adhered onto the outer pipeline by using an adhesive. With the upper sealing head structure, the sealing effect is better, and installation speed is faster.

Owner:SUZHOU DINGYU WATER TECH

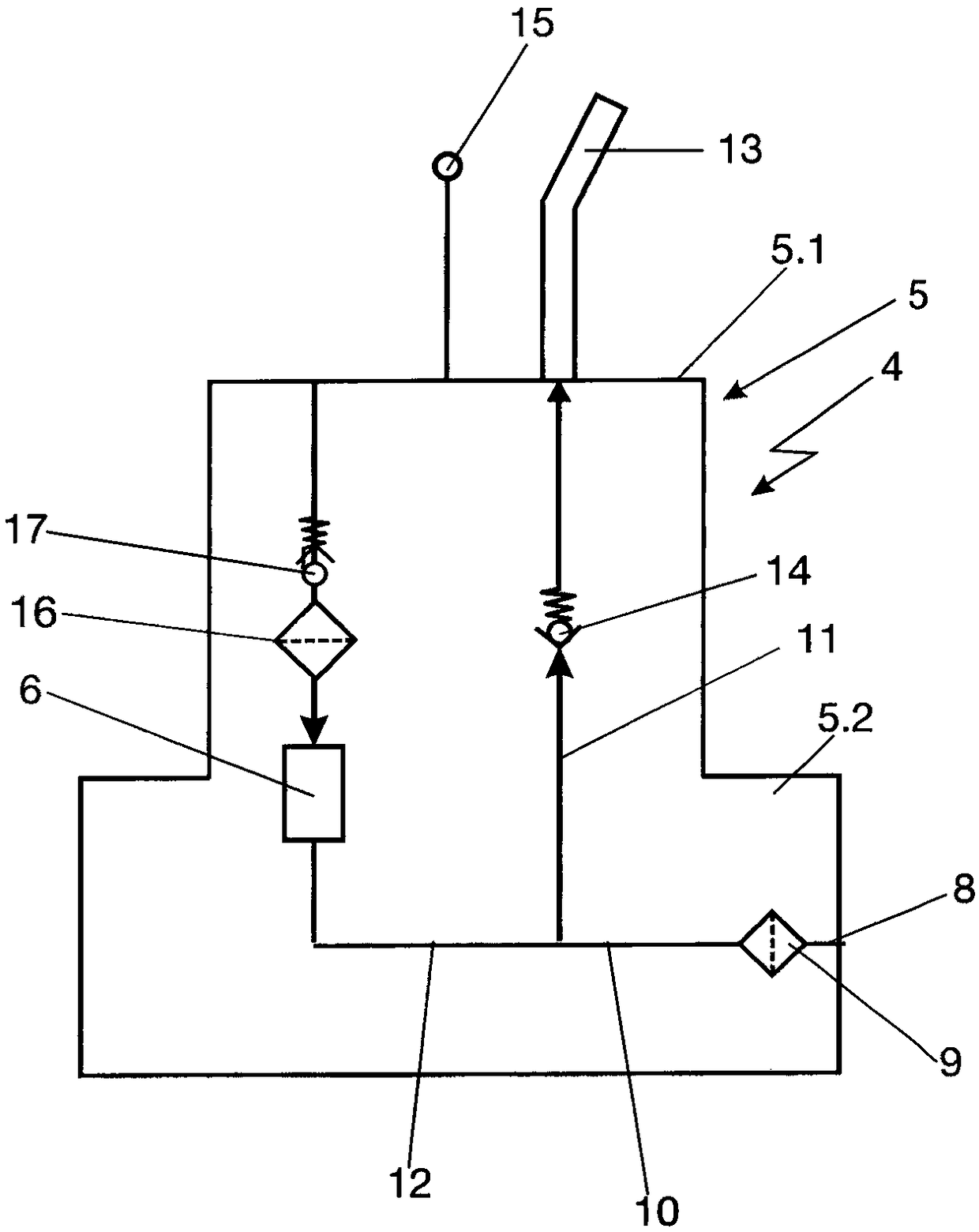

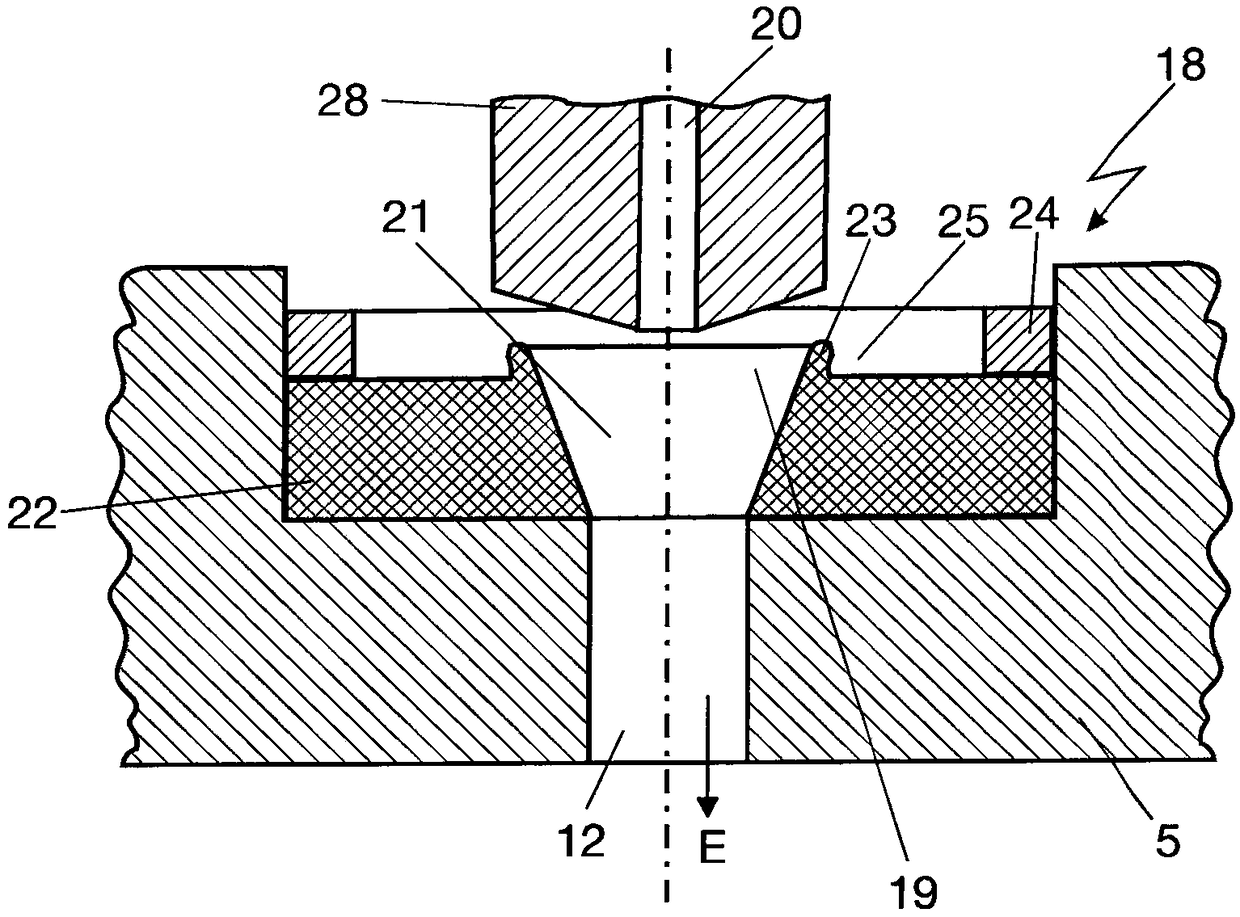

Tank valve

InactiveCN109416128AGood fitSealed wellVessel mounting detailsContainer filling methodsProduct gasCheck valve

The invention relates to a tank valve (4) for mounting on a pressurized-gas container (3), having a main body (5), having multiple functional subassemblies for the refilling of the pressurized-gas accumulator (3), for the removal of gas from the pressurized-gas accumulator (3) and for the implementation of safety and operating functions, wherein one of the functional subassemblies is formed as anextraction valve (6), and wherein at least one of the other functional subassemblies is formed as a check valve (14, 17). The tank valve according to the invention is characterized in that both the extraction valve (6) and the at least one check valve (14, 17) have in each case one valve seat carrier (22) with a valve seat (21) and one valve body (19), wherein that part of the valve seat carrier (22) which interacts with the valve body (19) has a sealing lip (23), which projects in an axial direction, as part of the valve seat (21).

Owner:DAIMLER AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com