Waterproof structure and construction method thereof

A waterproof structure and construction method technology, applied in the direction of building components, building structures, building maintenance, etc., can solve problems such as appearance problems, inability to operate, and inappropriateness, and achieve the effects of reducing tensile stress, reducing thickness, and eliminating stress concentration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

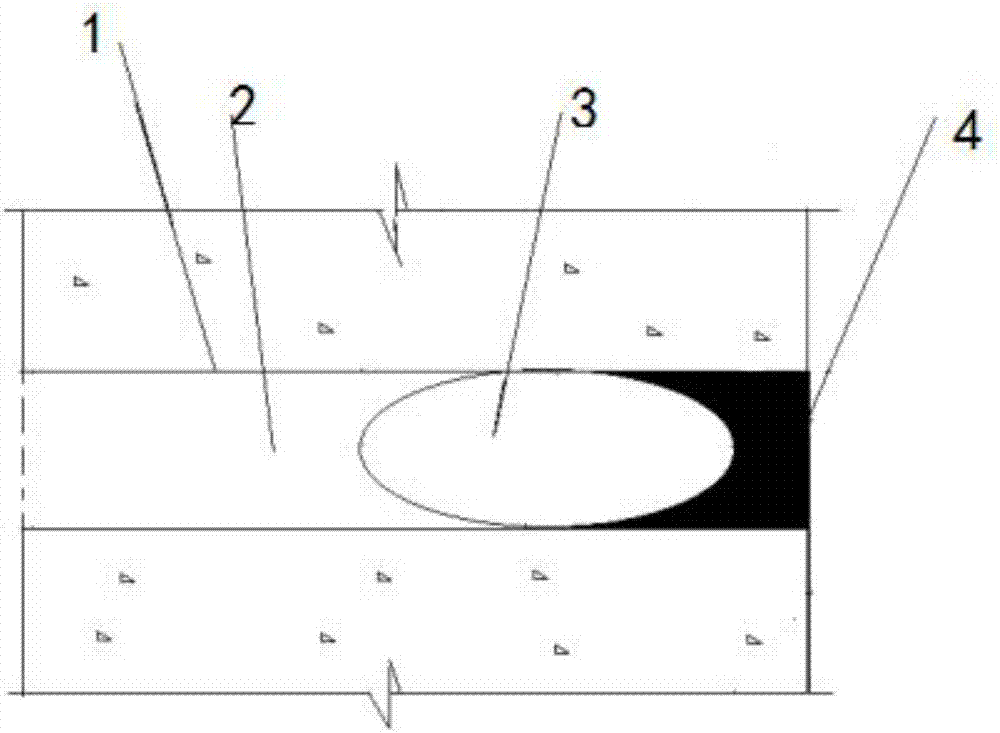

[0097] For the waterproofing of the exterior wall panels of prefabricated buildings, the joint width is 25mm, including the transverse seams and vertical seams of the exterior walls. The actual seam width is 22-27mm, the narrow part is 22mm, the wide part is 27mm, and most of them are about 25mm. In order to ensure the durability of the waterproof function, it is proposed to adopt three elastomer film waterproofing in the multi-channel waterproofing of the present invention.

[0098] A. Insert the positioning foam rod 3, the height of the positioning foam rod 3 is 28mm, and the width is 30mm. The inner part of the cross section of the positioning foam rod 3 is an arc surface, and the outer part is a plane with chamfering, and the length of the chamfering side is 4*4mm *mm; Use the positioning device to adjust the scale of the positioning plate 12 to 62mm, press the positioning foam rod 3 into the joint 2, push the positioning plate 12 against the outer edge of the joint, push ...

Embodiment 2

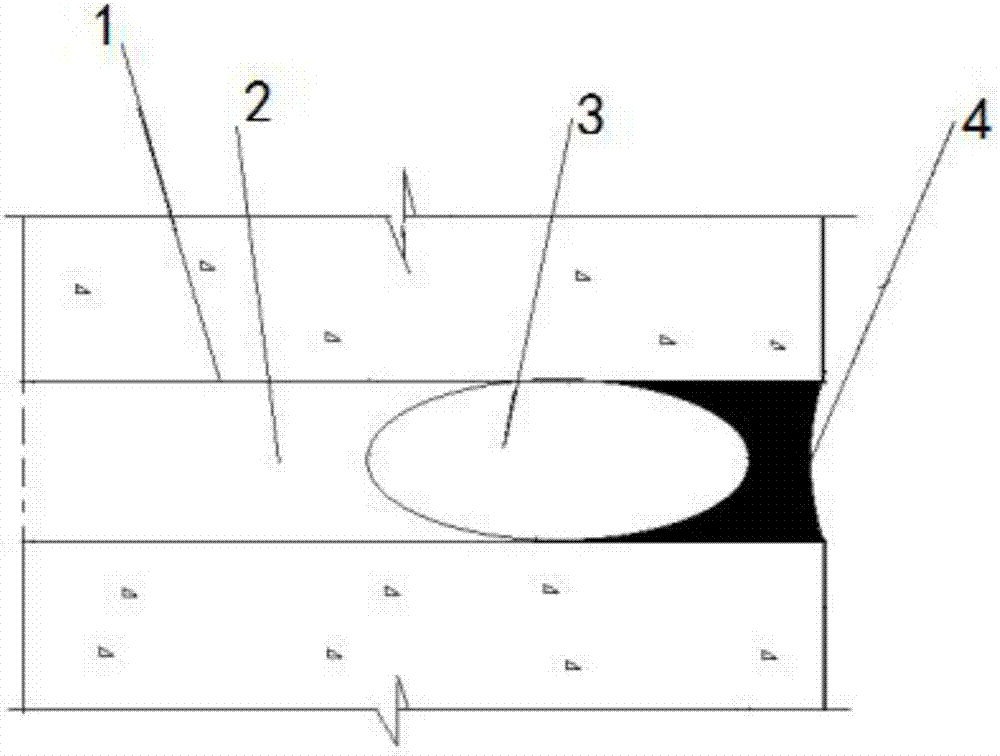

[0105] The inner seams of the pipe gallery are waterproof. The inner side is a rubber waterstop, and the joint width of the pipe gallery is 50mm, which is constructed from the inside of the pipe gallery to the joint.

[0106] A. Use a roller to coat the base treatment agent SJKR EXHT on the inner wall 1 of the joint of the pipe gallery, and dry for 4-18 hours;

[0107] B. Use the positioning foam rod 3 (height 53mm, width 50mm), use the positioning device, set the scale plate scale 186mm, push the positioning foam rod 3 to the seam opening 186mm away from the construction side, and set the seam around;

[0108] C. Cut the width of the scraper 19 under the nozzle to 45mm, the distance between the scraper and the nozzle outlet is 10mm, adjust the positioning scale of the nozzle to 177mm, extend into the seam 2, inject polyurethane sealant SJK1907, and push forward , along the corridor;

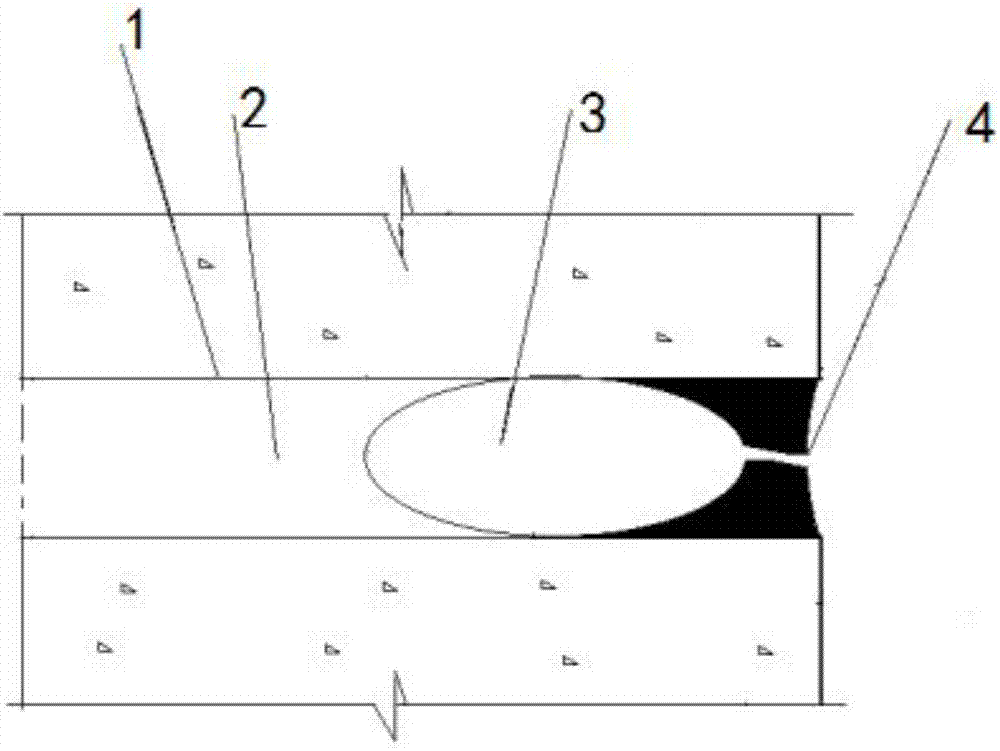

[0109] D. Adjust the spacer bar 7 (height 50mm, width 50mm) to 128mm using the positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com