Patents

Literature

620results about "Leather drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing process of semi-vegetable tanned wrinkled leather of cow leather

InactiveCN102080134AQuality assuranceReduce contentTanning treatmentPre-tanning chemical treatmentPulp and paper industryHexavalent chromium

The invention relates to a manufacturing process of the semi-vegetable tanned wrinkled leather of cow leather, which comprises the working procedures of initial tanning, deacidifying, vegetable tanning, filling and dry finishing. In the method provided by the invention, firstly tanning is carried out on raw hide by a small quantity of chromium tanning agent and then by a vegetable tanning agent, thereby under the premise of guaranteeing the quality of the leather, greatly reducing the content of chromium in tanning waste liquid, lightening the pollution of the chromium to the environment and effectively inhibiting the generation of hexavalent chromium through the vegetable tanning agent in the leather; and meanwhile, the granule surface of the leather is tightened through the working procedures of dry finishing and coating, and natural winkles are formed on the granule surface, thereby covering the injury of the granule surface of the leather and improving the additional value of the leather.

Owner:锦兴皮业科技有限公司

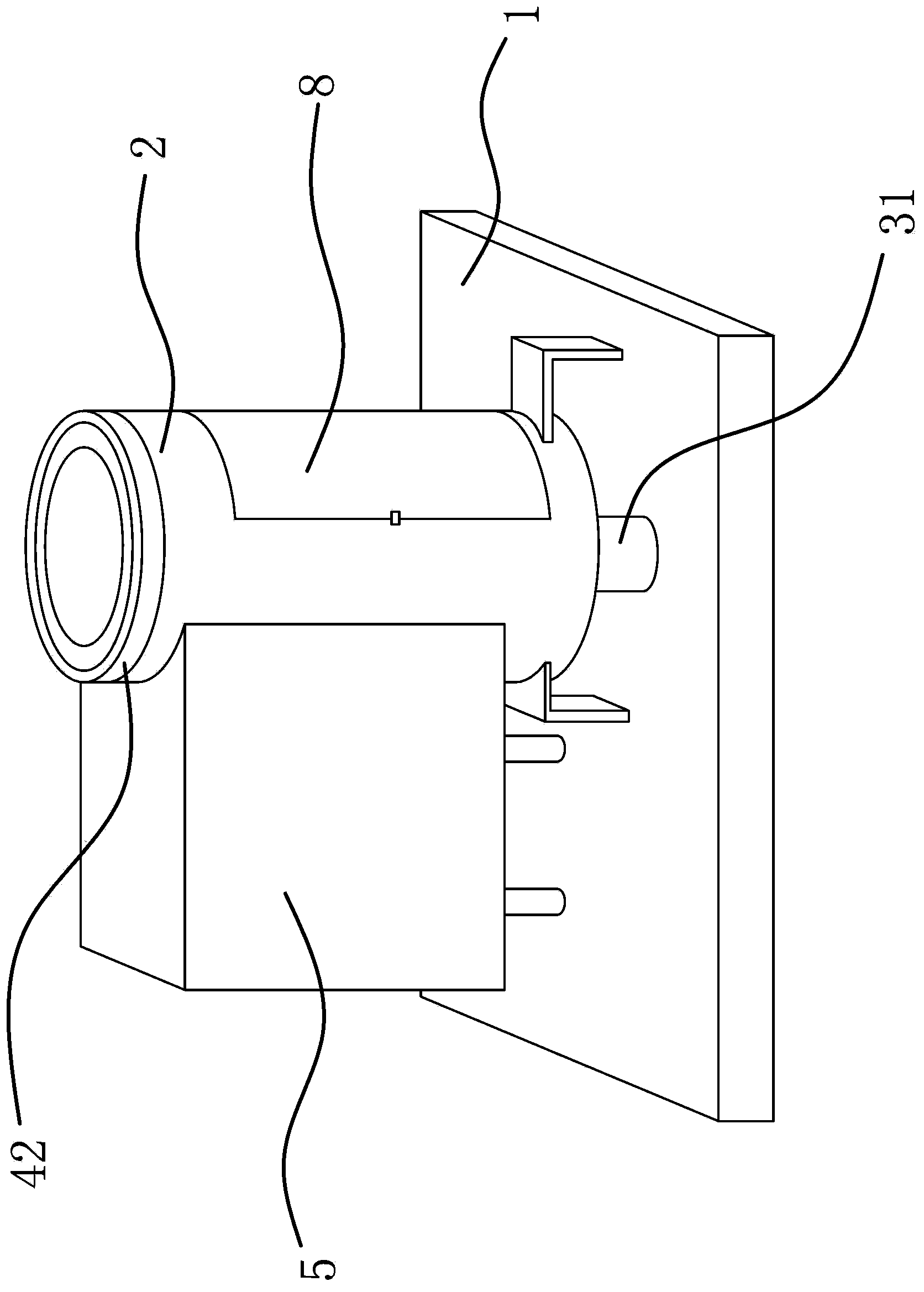

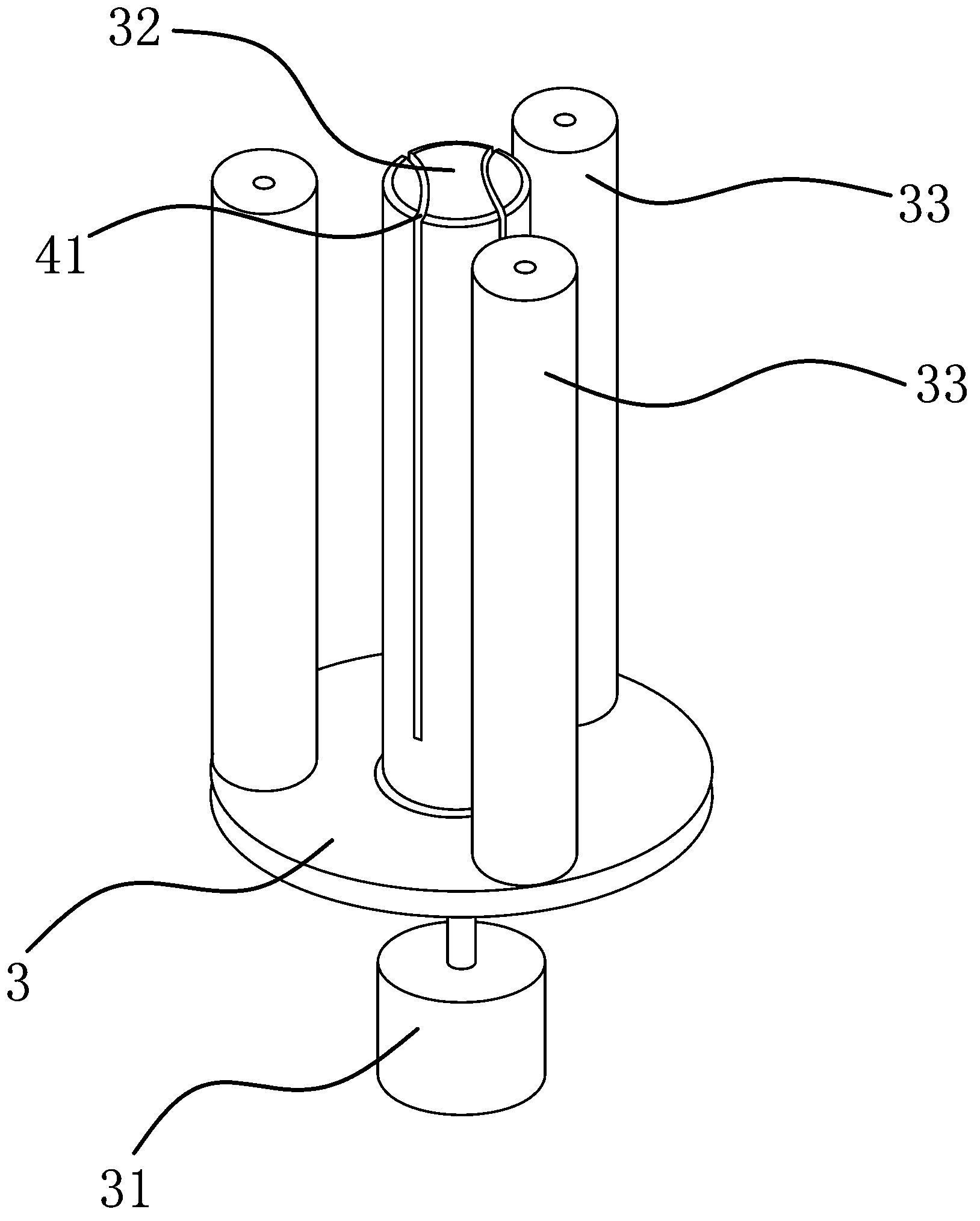

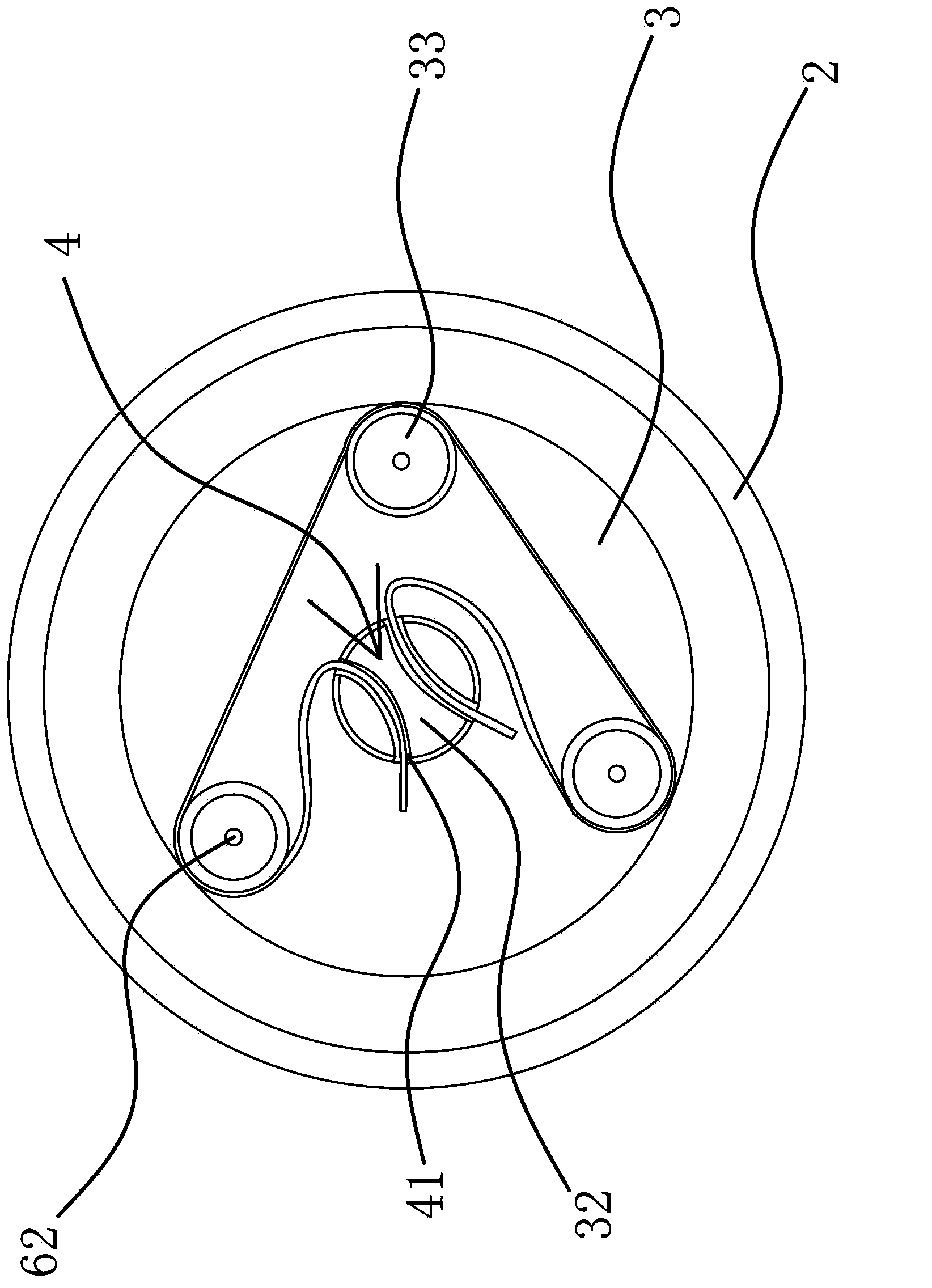

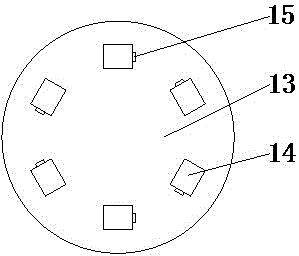

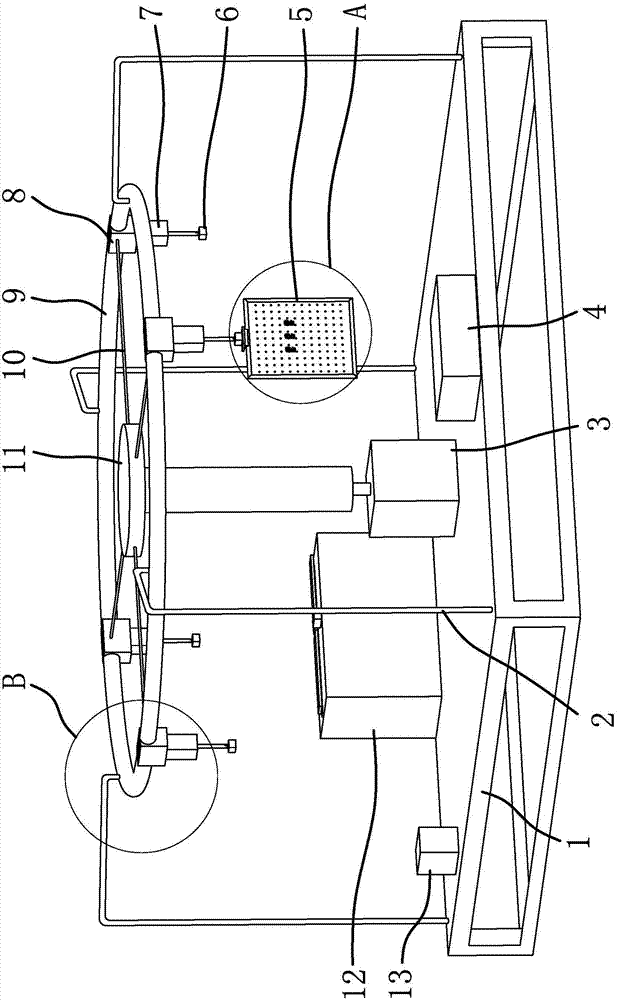

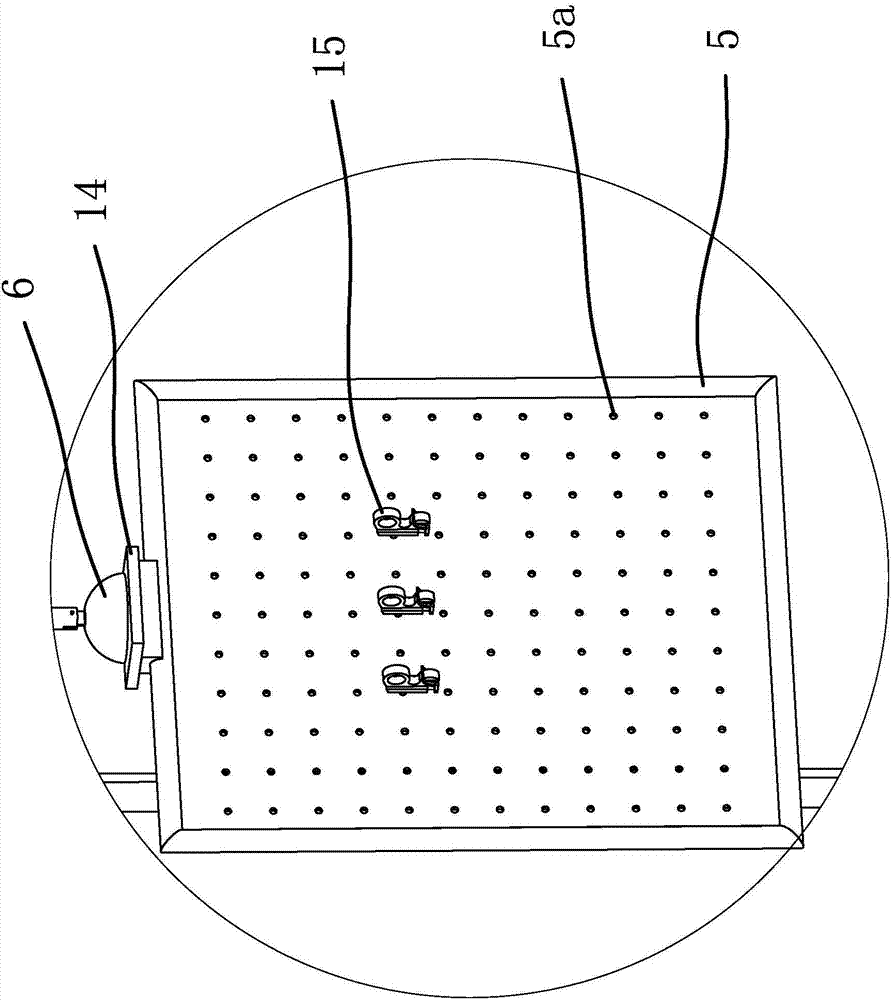

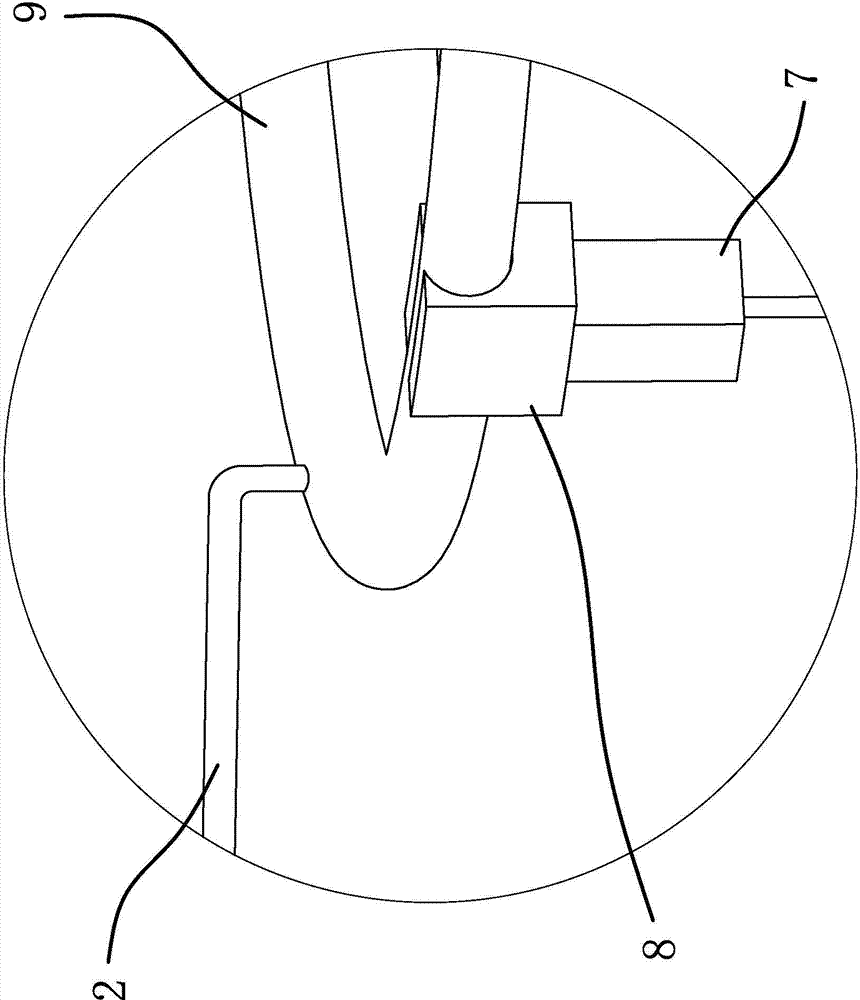

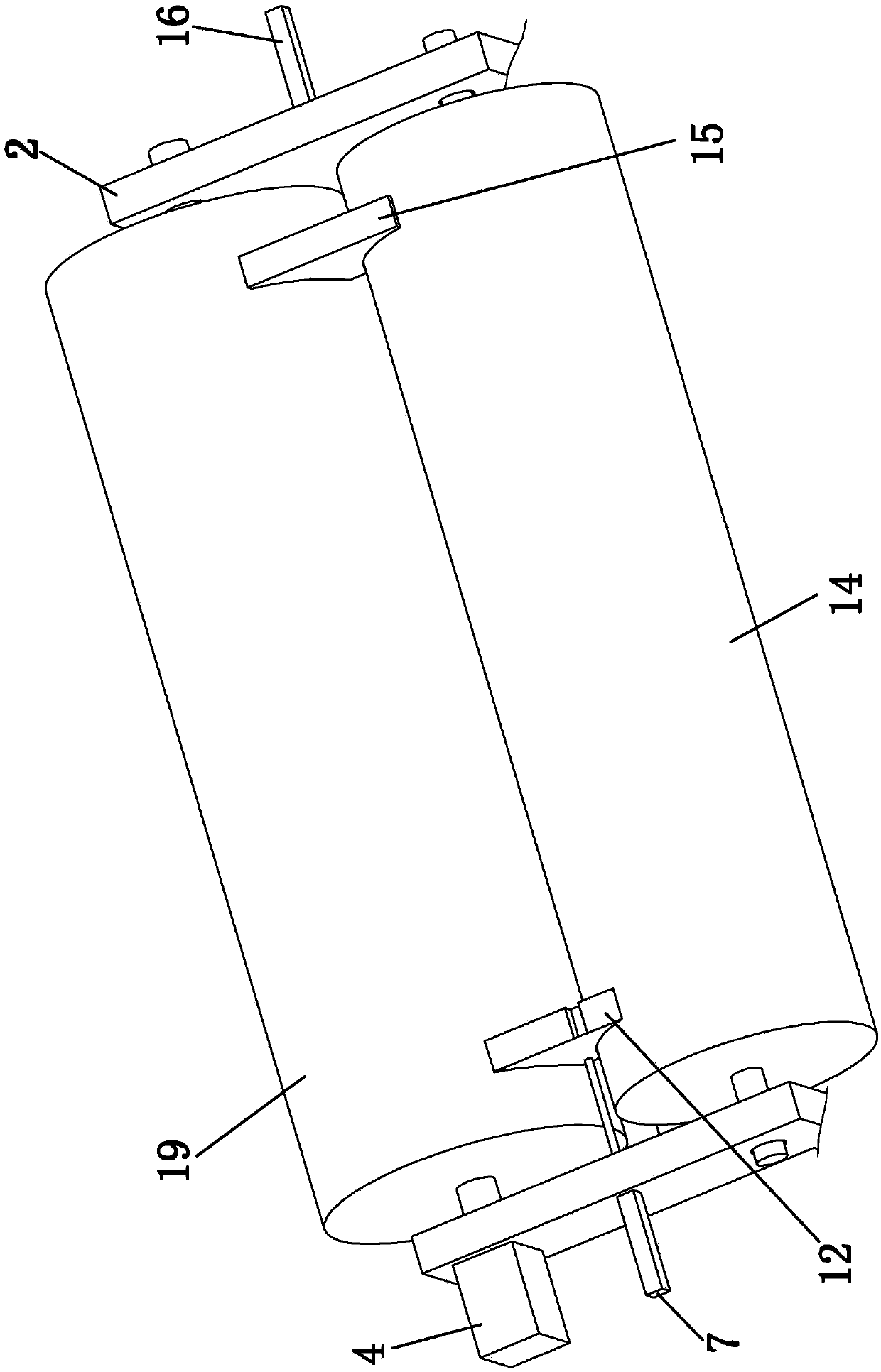

Leather drying machine

ActiveCN103451324AGuaranteed drying effectGuaranteed drying efficiencySkins/hides/leather/fur manufacturing apparatusLeather dryingEngineeringDrive motor

The invention provides a leather drying machine, which belongs to the technical field of leather production equipment and solves the technical problems of poor drying effect and the like of existing leather drying equipment. The leather drying machine comprises a base, wherein a drying drum with an opening at the upper end is fixedly arranged on the base; a driving motor is arranged at the bottom part of the drying drum; a rotating disc is connected onto an output shaft of the driving motor; a positioning shaft is arranged in the central position of the rotating disc and is provided with a clamping device which can fix two edges of leather on the positioning shaft; the rotating disc is also uniformly provided with three tensioning drums which abut against the leather and tension the leather; an air drum is arranged at the outer side of the drying drum, is internally provided with a fan and is communicated with the drying drum; the upper end of the drying drum is provided with a spongy water absorbing plate covering the opening; electric heating wires are arranged in the tensioning drum. The leather drying machine provided by the invention has the advantages of good drying effect and the like.

Owner:浙江富邦汽车内饰科技有限公司

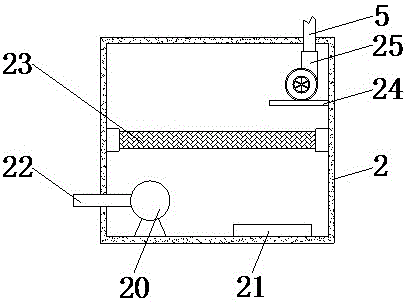

Leather drying device with high efficiency

InactiveCN106282431AImprove efficiencyDry fastDrying gas arrangementsDrying chambers/containersEngineeringDrying time

The invention discloses a leather drying device with high efficiency, relating to the technical field of leather processing equipment. The leather drying device with high efficiency comprises a base, a heating box and a drying box are installed at the top of the base in sequence from left to right, a controller and an air supply pipe are arranged at the top of the heating box in sequence from left to right, one end of the air supply pipe, close to the heating box, penetrates through the heating box and extends into the heating box, the other end of the air supply pipe, away from the heating box, penetrates through the drying box and extends into the drying box, and a ventilation plate is fixedly connected to one side of the inner wall of the drying box. The leather drying device with high efficiency adopts an exhaust fan, a blower, a fan and an air heater, wherein the air heater can heat air sucked into the heating box, and the blower and the fan can blow air to dry leather, so that the leather can be quickly dried, so that not only is the leather drying time reduced and also the working efficiency is also improved.

Owner:陈明

Method for manufacturing washable cow split leather

ActiveCN107502685AFully rehumidifiedImprove washing resistanceTanning treatmentPre-tanning chemical treatmentSofteningChemistry

The invention relates to a method for manufacturing washable cow split leather and belongs to the technical field of manufacture of leather. The method comprises the following steps: taking a cow split leather blank subjected to wringing and shaving, and sequentially performing re-wetting, primary washing, retanning, neutralizing, secondary washing, filling, dyeing, stuffing, acid solidification, thrice washing, fixing, quartic washing, drying, hanging and airing, vibratory softening, leather fluffing and milling. The washable cow split leather manufactured by the method has favorable washability, and is high in leather yield.

Owner:漳州香洲皮革有限公司

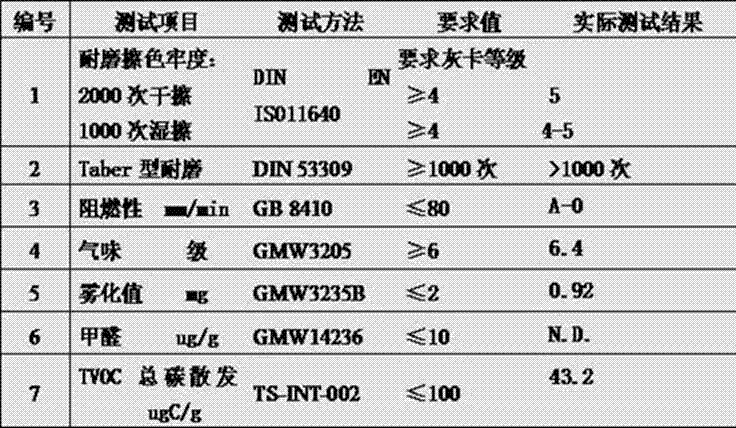

Production process of automobile interior decorative leather with ultralow total carbon emission

ActiveCN102732649ALeather tightGood wear and abrasion resistanceTanning treatmentPre-tanning chemical treatmentPulp and paper industryVolatile organic compound

The invention relates to a production process of automobile interior decorative leather with ultralow total carbon emission. The process comprises the steps of: cow leather fleshing, hair-saving, and unhairing, softening, tanning, retanning, dyeing, fat liquoring, drying, vibration staking, and finishing. The process of the invention controls the additive required in the steps so as to make the automobile interior decorative leather produced by the process has reduced total carbon emission and fogging value. Volatile organic compounds are under control, and the process is healthy and environment friendly.

Owner:HAINING SENDE LEATHER

Leather pulp shooting machine

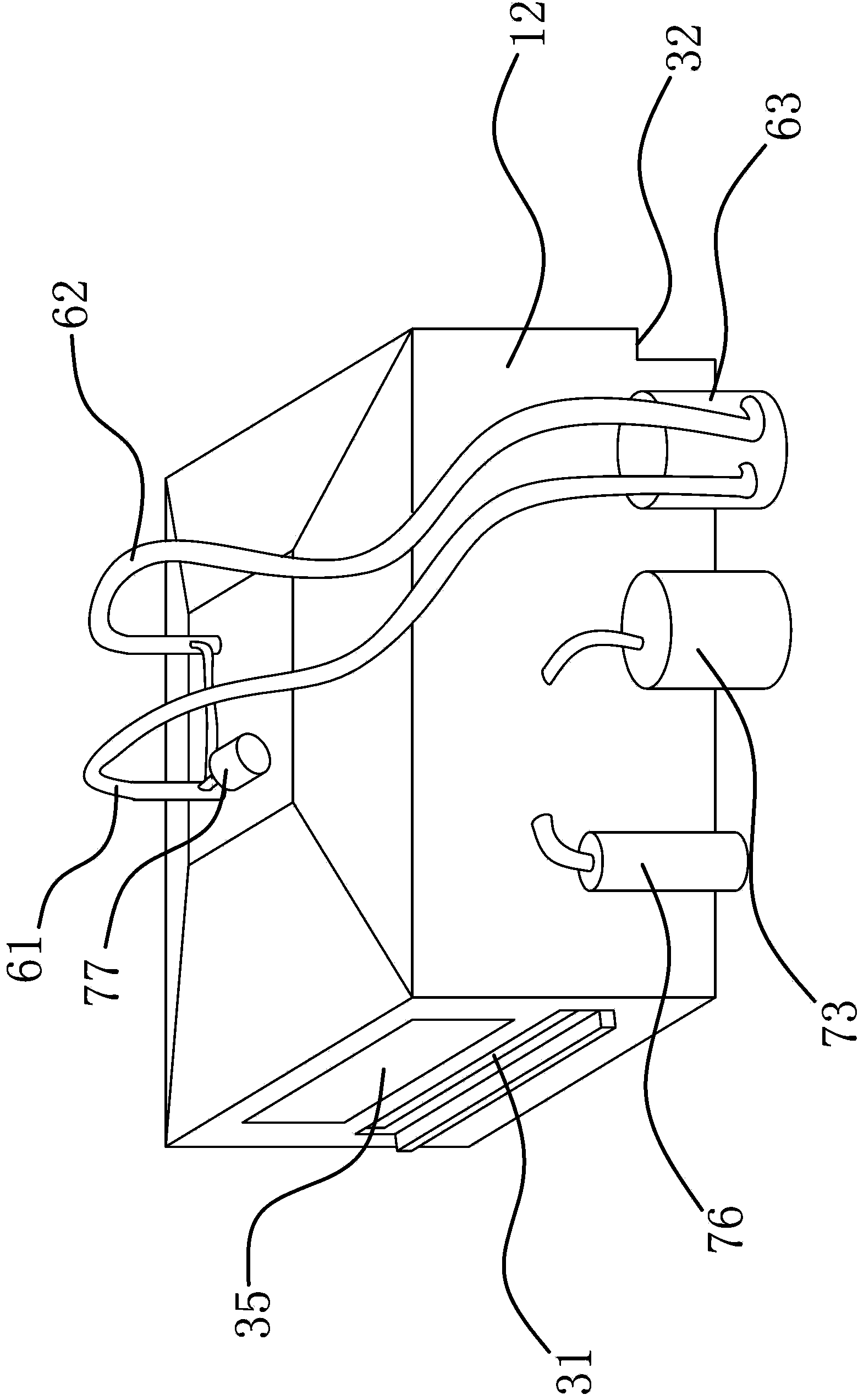

ActiveCN103397119AIncrease productivityWon't flow outLeather/skins/hides/pelt chemical treatment apparatusLeather surface finishingSlagPulp and paper industry

The invention provides a leather pulp shooting machine, belongs to the technical field of leather processing devices, and solves the technical problems, such as low production efficiency, pollution to the atmosphere and the like, of leather pulp shooting machines of the prior art. The leather pulp shooting machine comprises a bottom plate and a seal base sleeved on the bottom plate. A conveyor belt is arranged on the bottom plate. A material inlet is arranged at one end of the seal base. A material outlet is arranged at the other end of the seal base. A pulp shooting mechanism and a drying mechanism are arranged inside the seal base. A dust slag discharge pipe and a waste gas discharge pipe which are communicated with the interior of the seal base are arranged at the top of the seal base. A scrubbing cylinder is arranged on the outer wall of the seal base. The dust slag discharge pipe and the waste gas discharge pipe are both connected with the scrubbing cylinder. The leather pulp shooting machine is advantaged by high production efficiency, no pollution and the like.

Owner:江苏东方金狐狸服饰有限公司

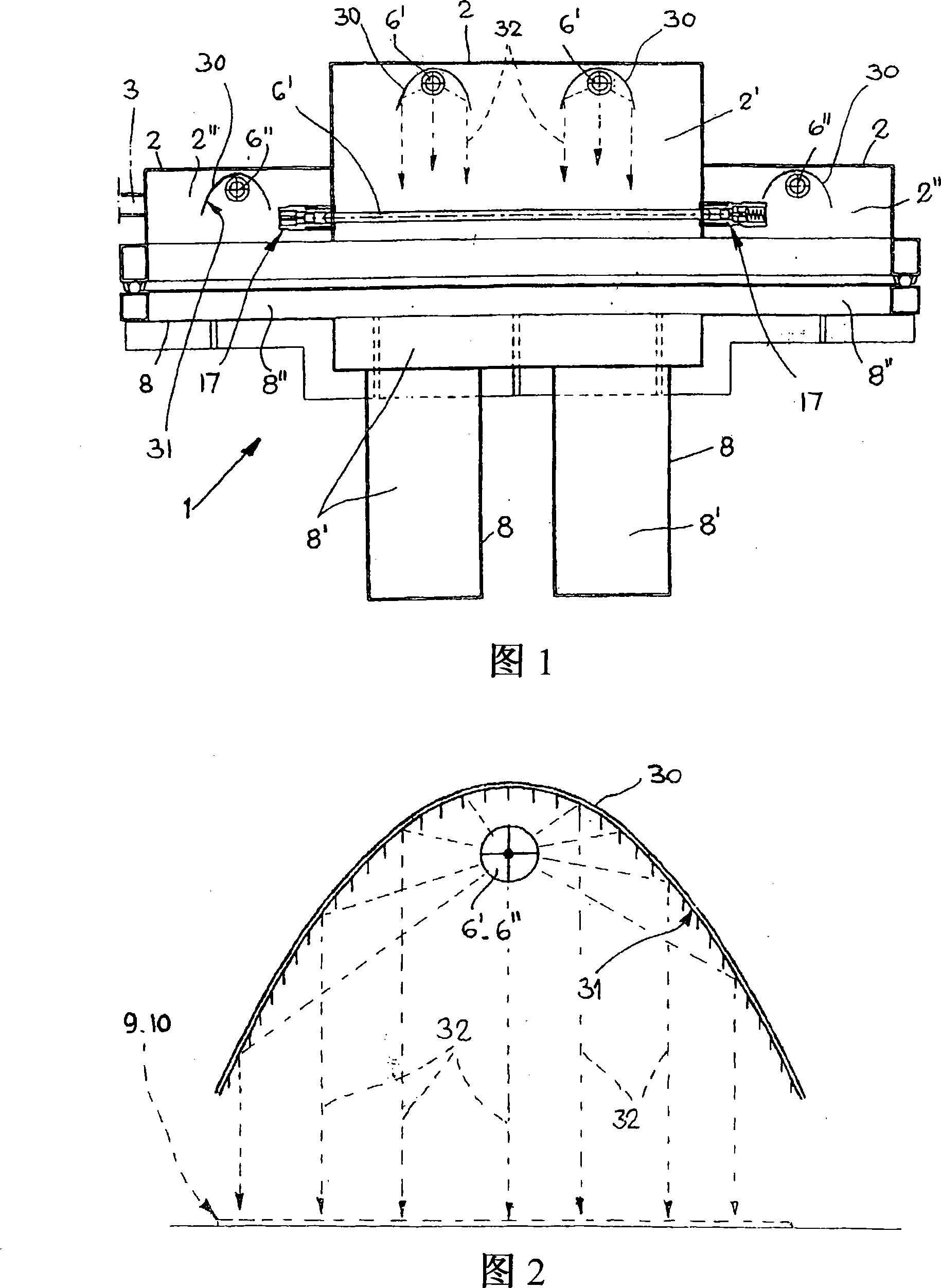

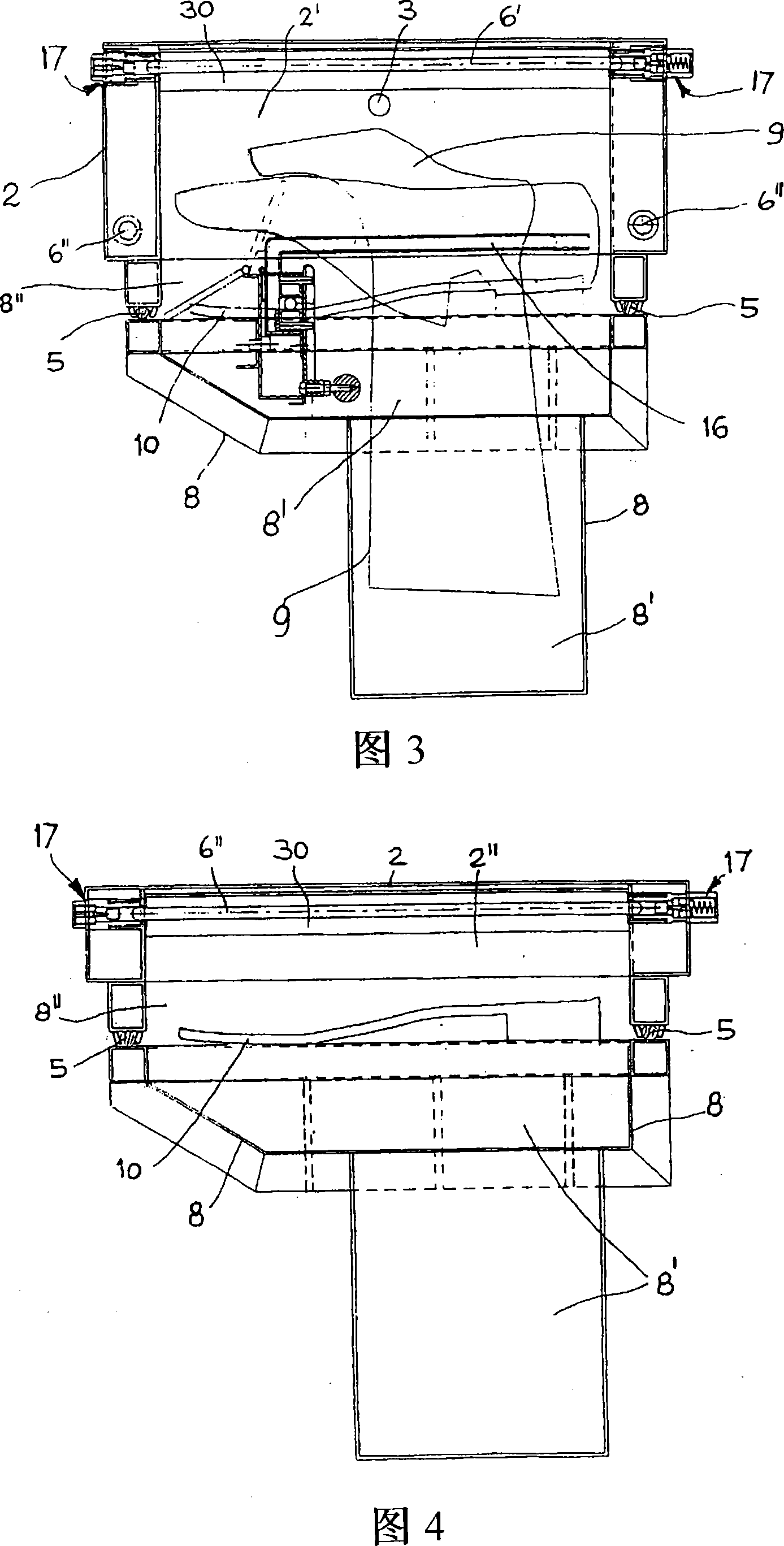

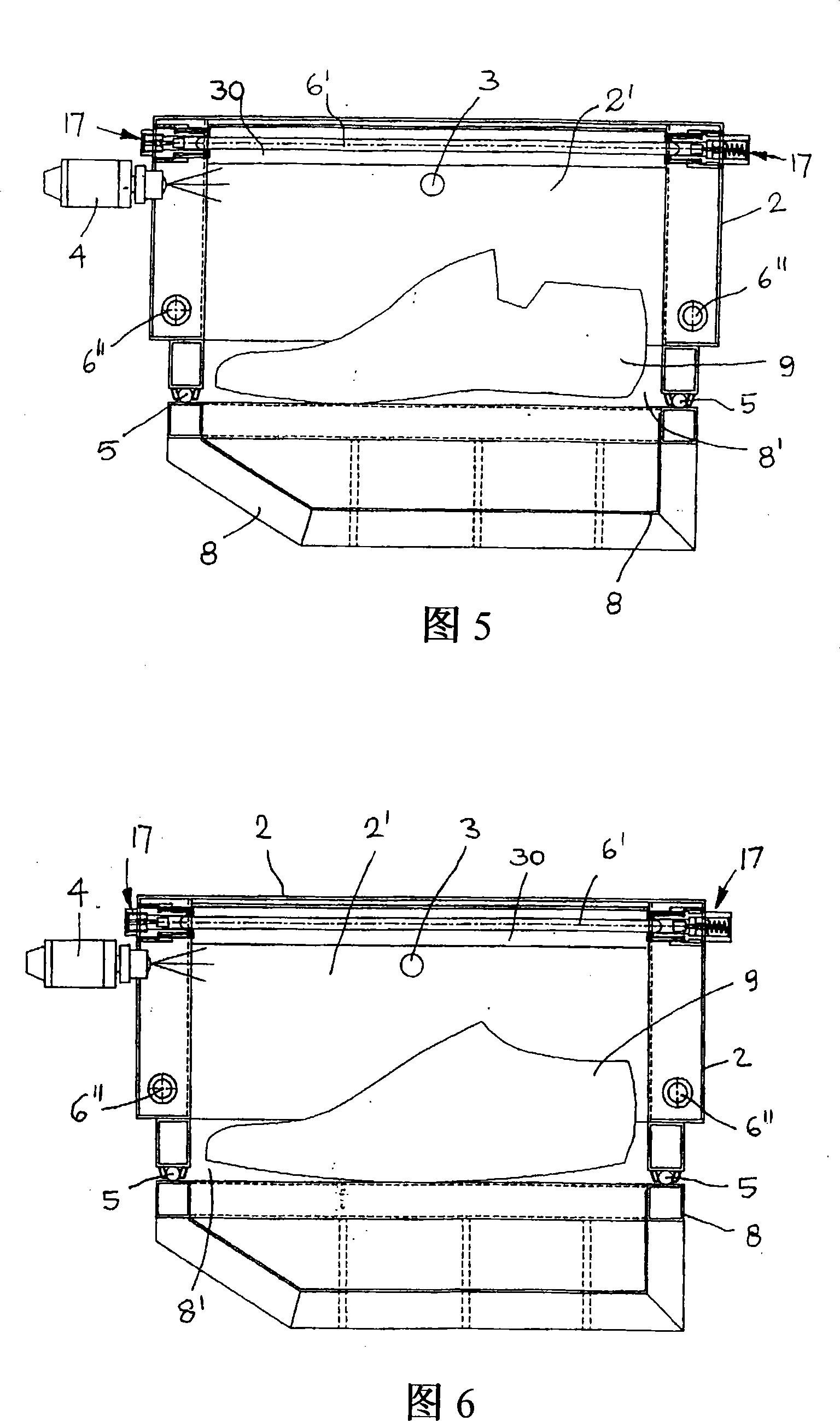

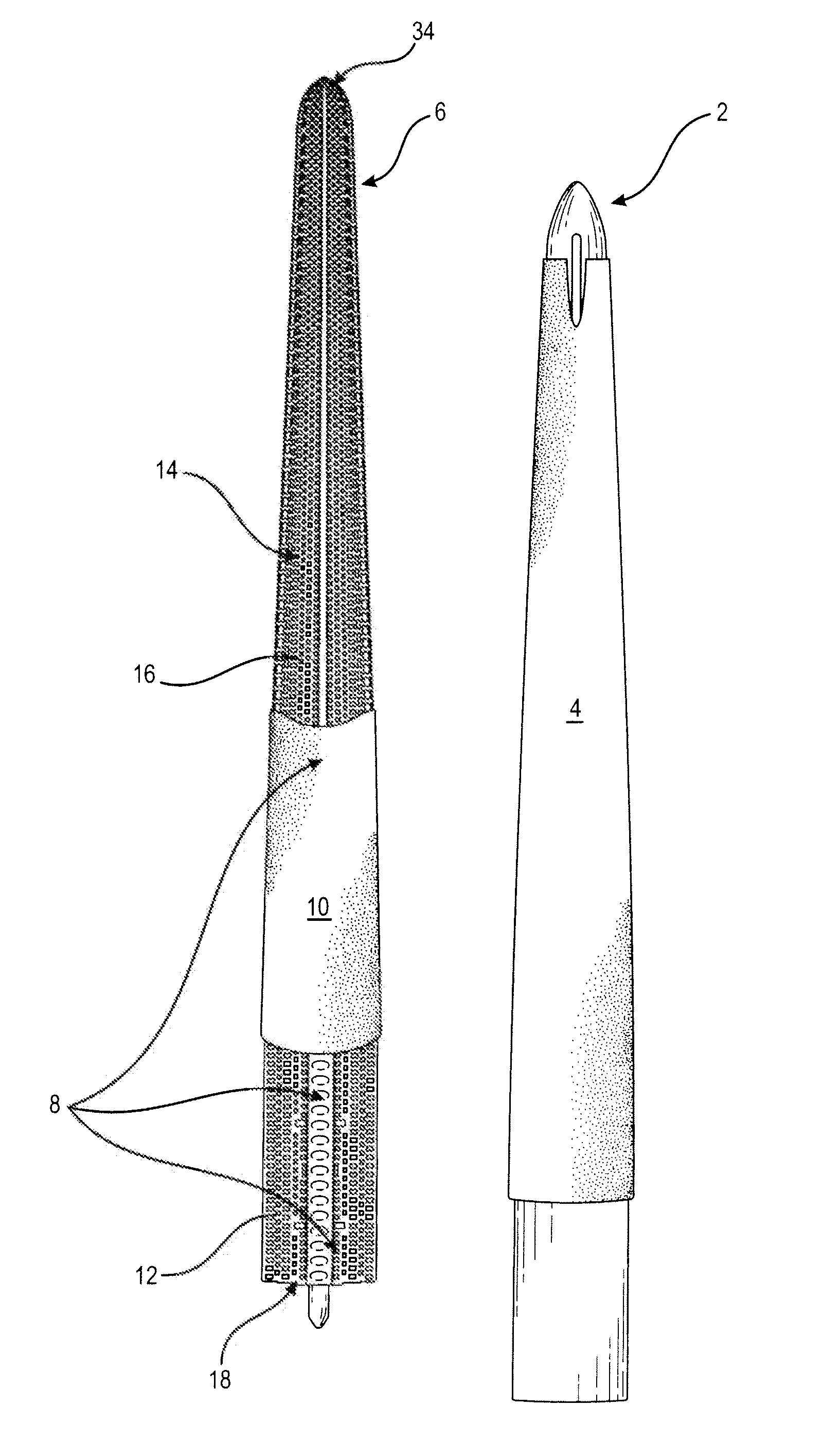

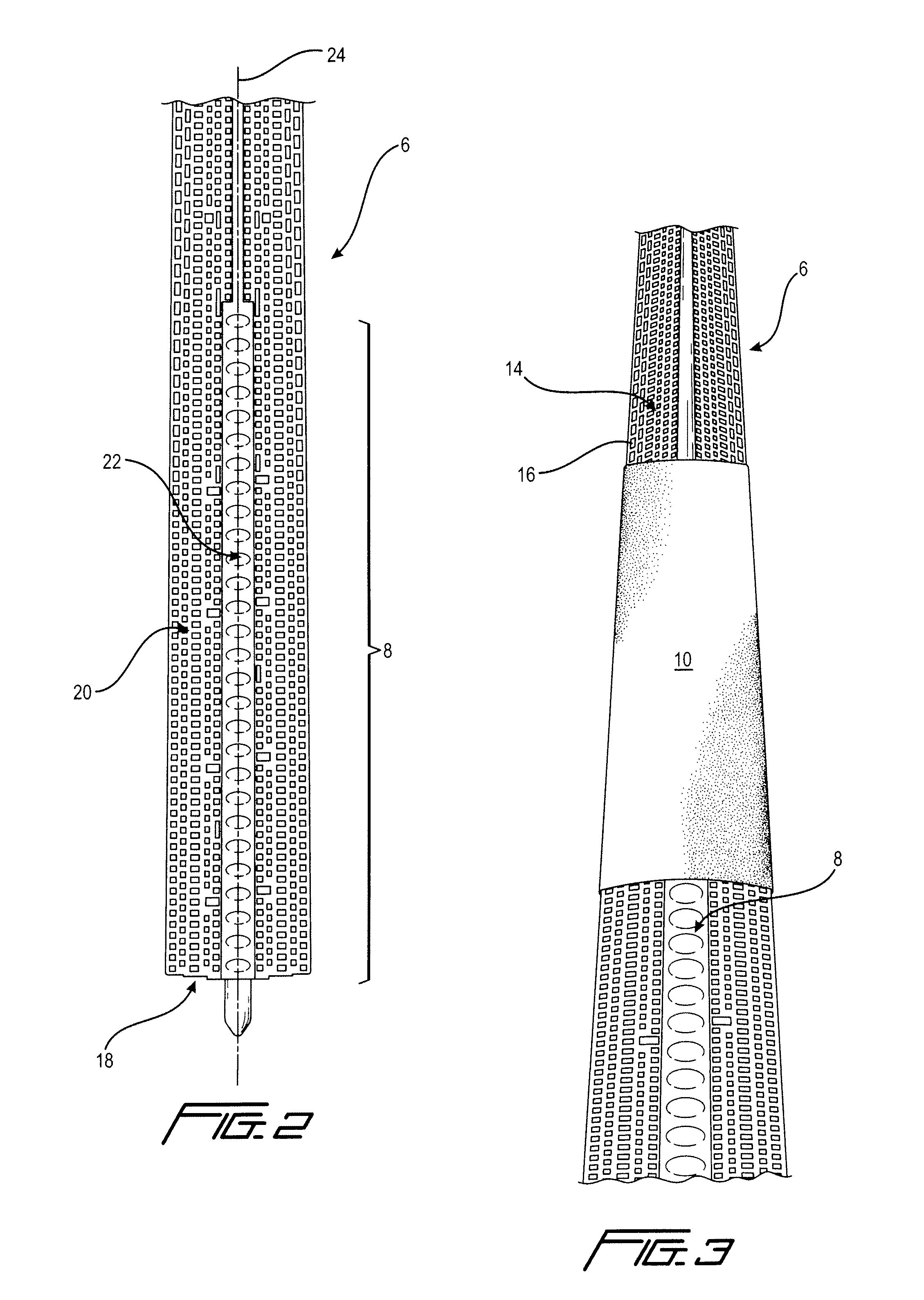

Method and system for drying out the leather side of a pelt stretched out and fixed in this position on a pelt board

ActiveUS7690228B2The process is fast and efficientWay fastFur dressingLeather stretching/tensioningBlack spotEngineering

A method, a system and a pelt board for the drying of the leather side of pelts from furred animals, in which the pelt board is a hollow distension element, the surface of which has an open structure. The leather side is dried by changing the air within the distension element. The distension element is lockable in a position in which it has a first circumference, and can also assume a position or be force controlled to a position in which it has a circumference which is smaller than the first, which results in a considerably easier removal of the pelt from the pelt board. A quicker, more uniform and more effective drying of the pelts is achieved, so that “black spots” on the leather side are avoided, and the pelt is fixed in its stretched position on the pelt board without the use of clips / staples.

Owner:MINKPAPIR

Making technology of natural dry milled leather

ActiveCN104988248ASimple processImprove flat finenessTanning treatmentPre-tanning chemical treatmentEngineeringColor processing

The invention relates to the technical field of making technologies of leather, and provides a making technology of natural dry milled leather. The making technology of the natural dry milled leather shortens the production time, improves the plumpness and uniformity of the pattern of the natural dry milled leather and enlarges the application range of leather sources through physical technologies. The making technology of the natural dry milled leather comprises the following steps: preparing wet blue leather, selecting, squeezing and spreading, weighing, returning the wet blue leather to a drum and immersing the wet blue leather in water, squeezing and spreading, carrying out vacuum treatment, drying, rinsing and neutralizing, carrying out closed washing, filling and dyeing, fatliquoring, carrying out color processing, washing by using water and discharging the obtained leather from the drum, carrying out stacking standing, squeezing and spreading, carrying out vacuum treatment, naturally hanging for airing, spraying water to regain moisture, standing, carrying out vibration softening, milling, and finishing.

Owner:XINGYE LEATHER TECH CO LTD

Waterproof chrome-free tanning leather manufacturing process

ActiveCN109628654AImprove waterproof performanceGood physical and chemical propertiesTanning treatmentPre-tanning chemical treatmentPollutionPolymer

The invention relates to the technical field of leather manufacturing process, and provides a waterproof chrome-free tanning leather manufacturing process. The manufacturing process comprises the steps that firstly, organic silicone modified polyurethane resin, an organic synthetic tanning agent and a polymetallic complex tanning agent are used for pickling-free and chrome-free combined tanning; then chrome-free retanning and chrome-free fixing are carried out by using the polymetallic complex tanning agent, and a waterproof polymer and a waterproof fatliquoring agent are used for filling andfatliquoring; the obtained chrome-free tanning leather has excellent waterproofing performance, and has both good physical and chemical properties and subsequent processing performance. During the process of implementation of the waterproof chrome-free tanning leather manufacturing process, by using cleaner production technologies such as ammonia-free deliming and softening co-bath, pickling-freeand chrome-free combined tanning and chrome-free retanning and chrome-free fixing, the prepared waterproof chrome-free leather is ecological and environmentally-friendly and excellent in waterproofingperformance, and pollution of heavy metal chromium is eliminated from a source; and the technical process is simple, the practicability is high, and the waterproof chrome-free tanning leather manufacturing process is suitable for industrial application.

Owner:XINGYE LEATHER TECH CO LTD

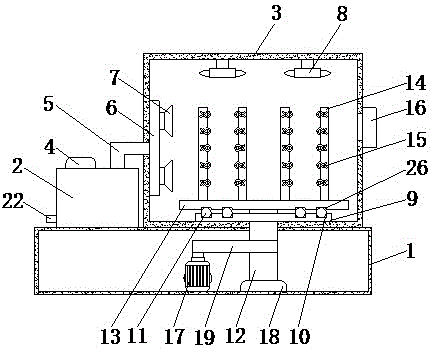

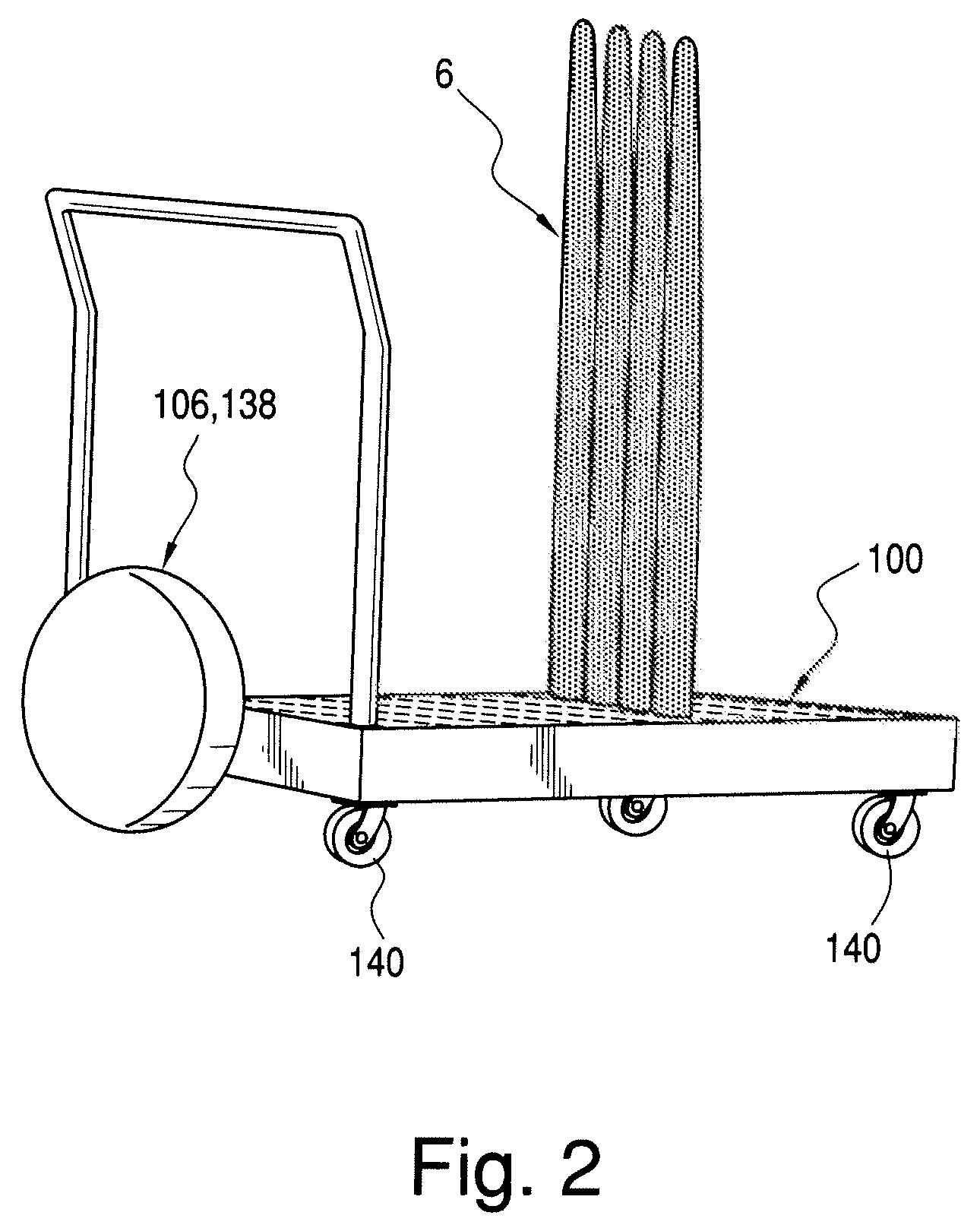

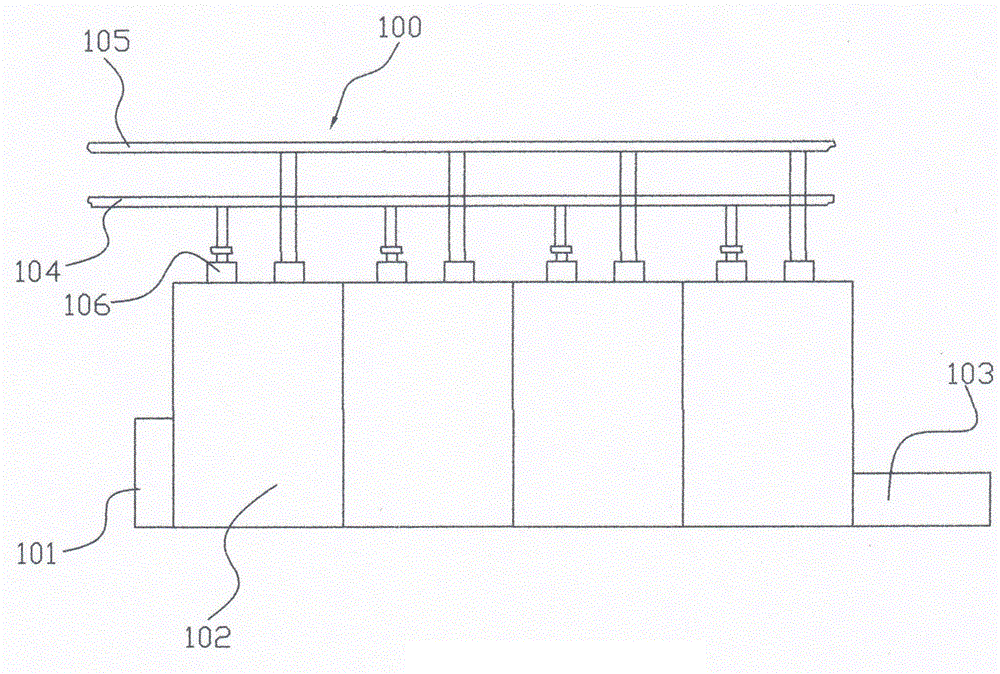

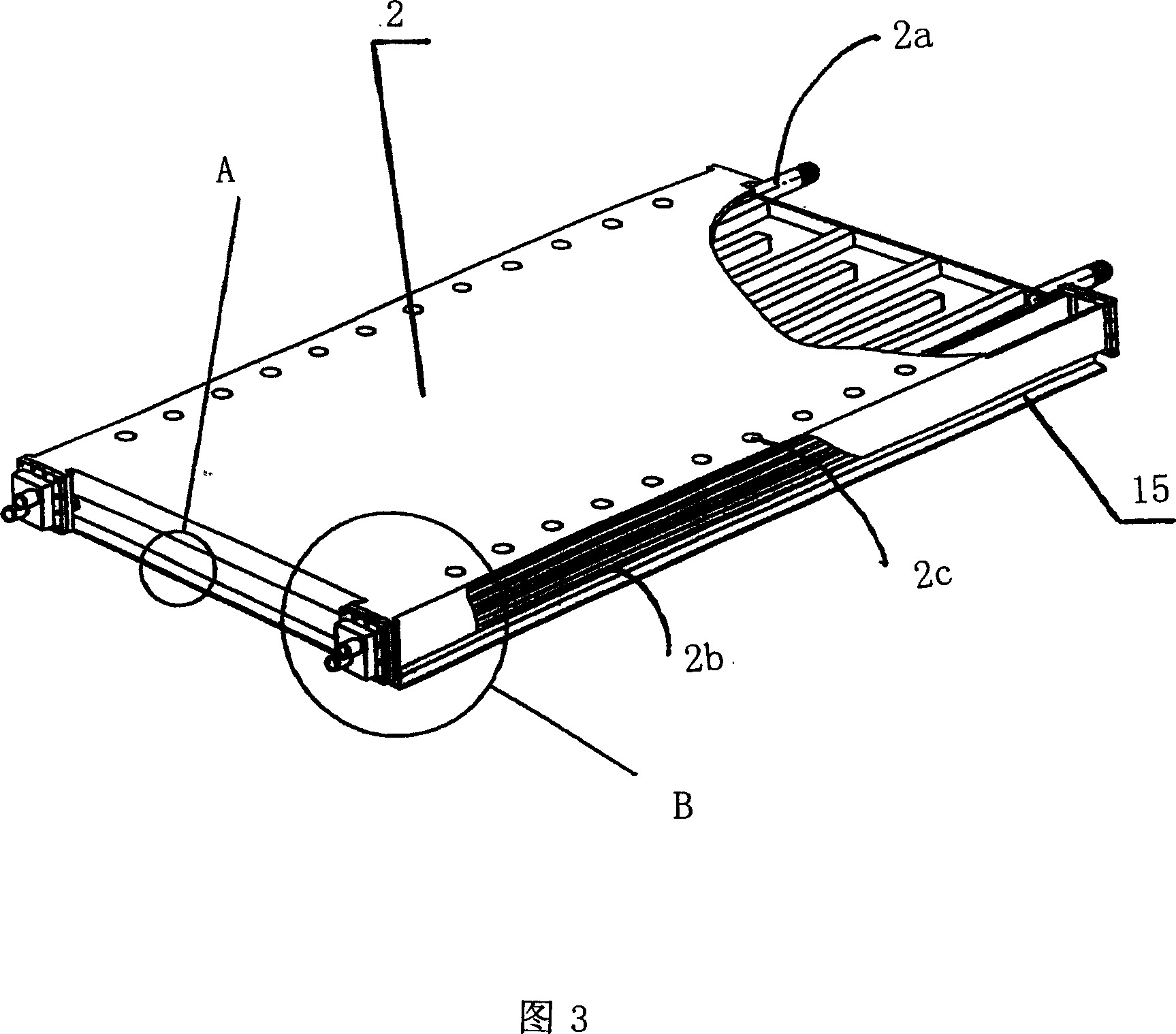

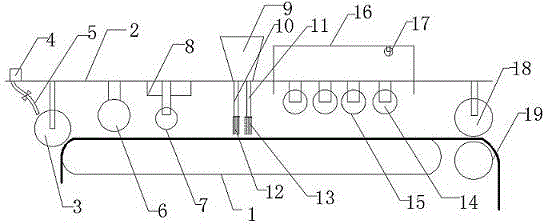

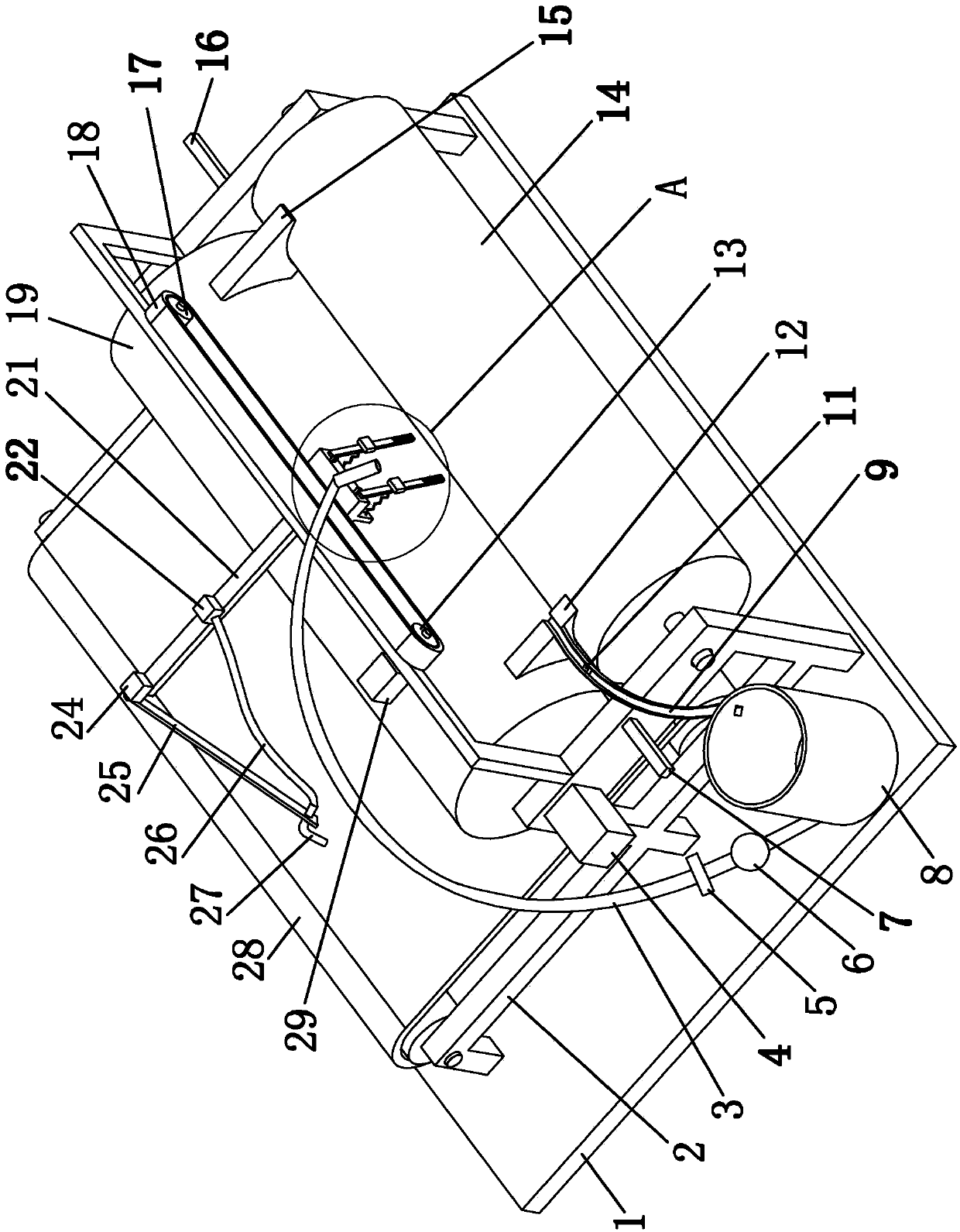

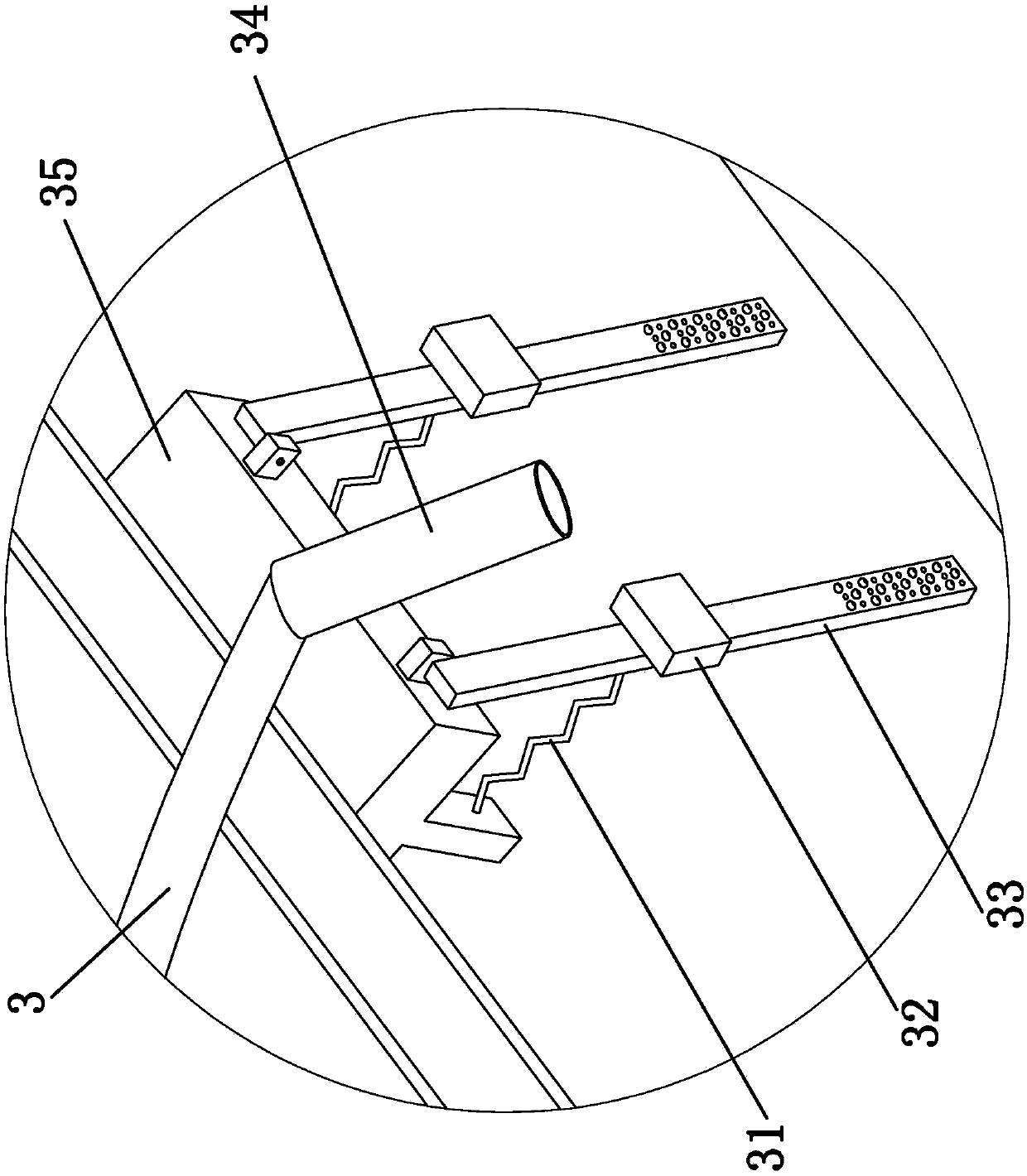

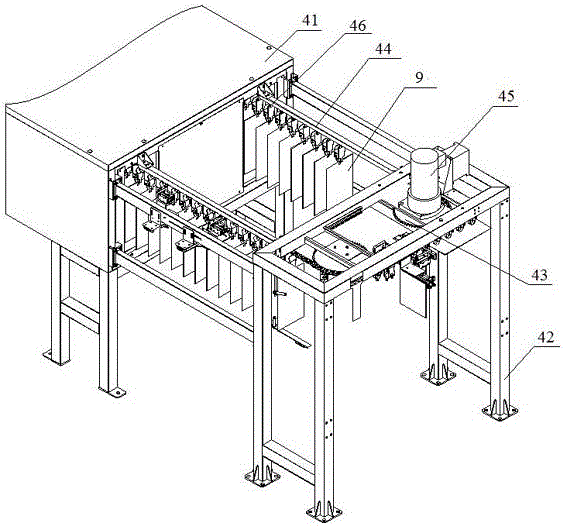

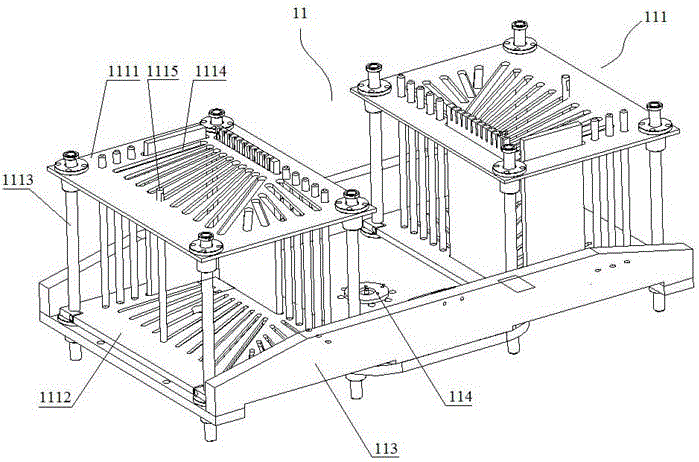

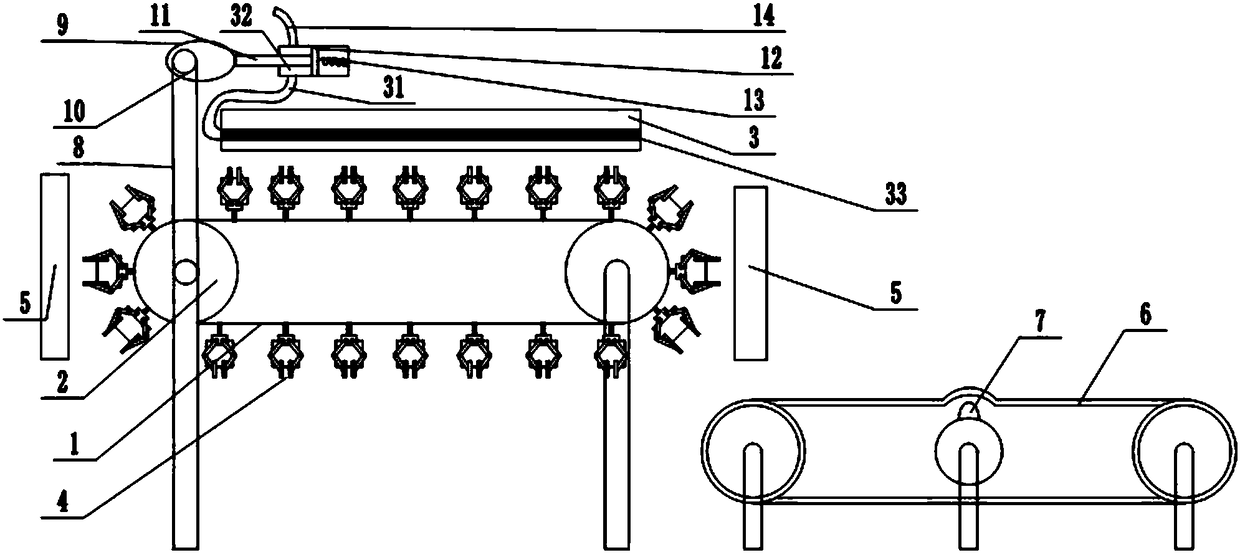

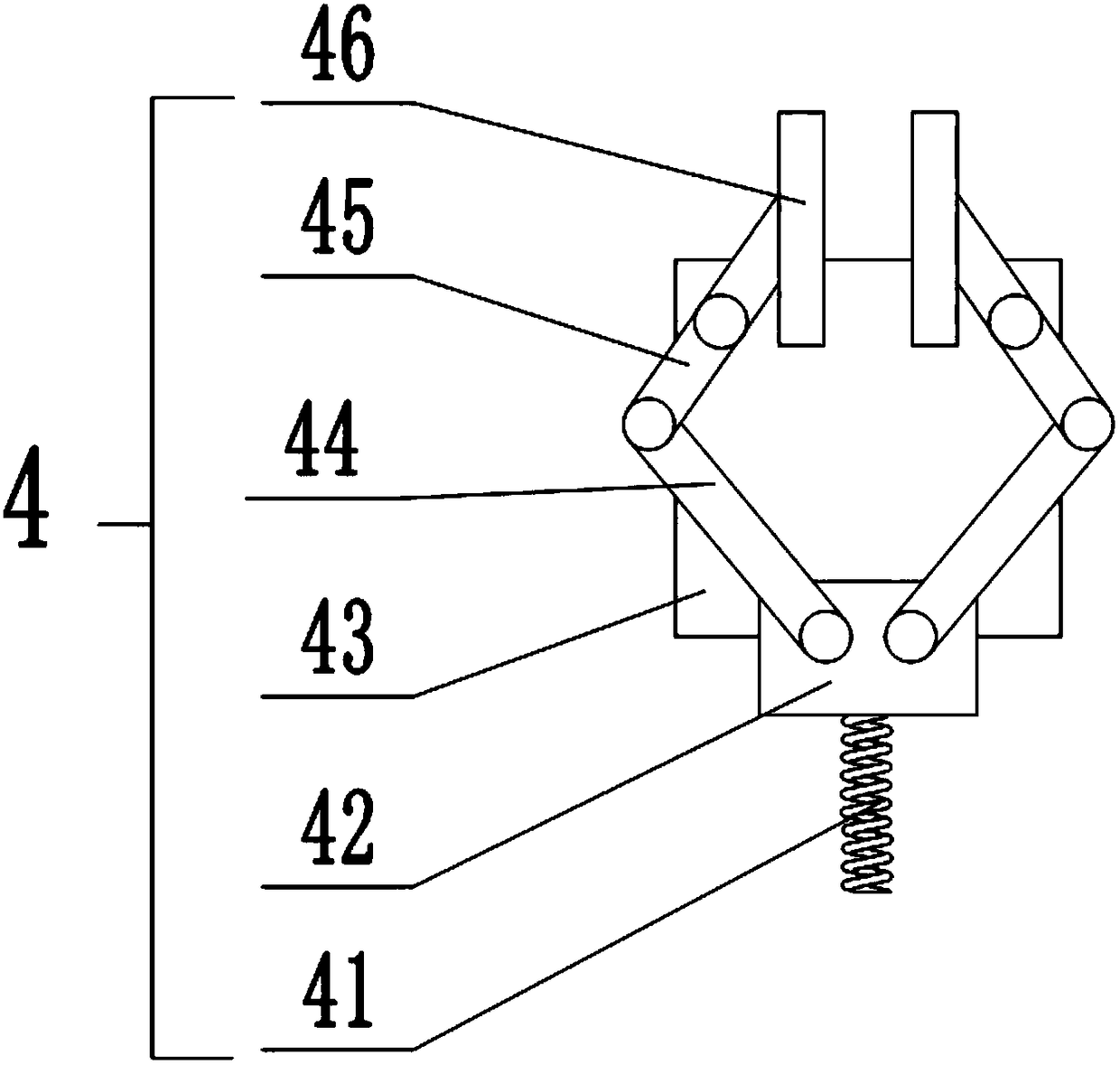

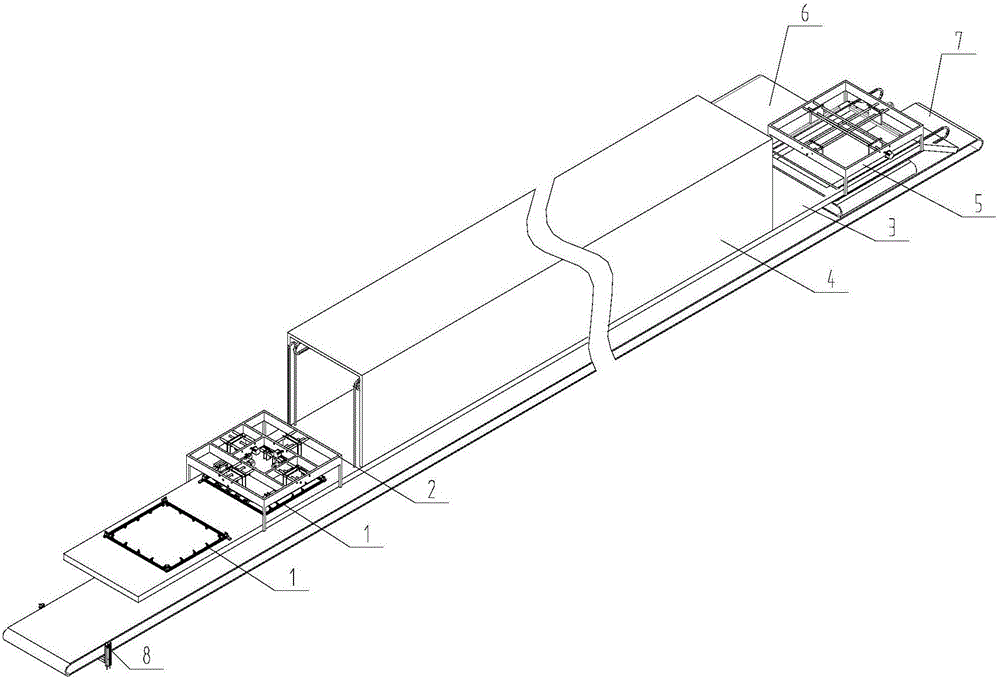

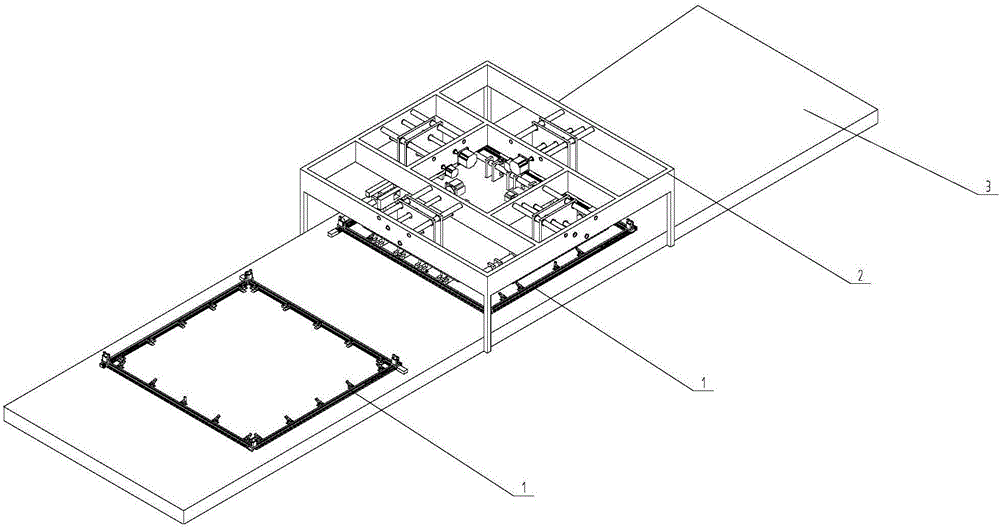

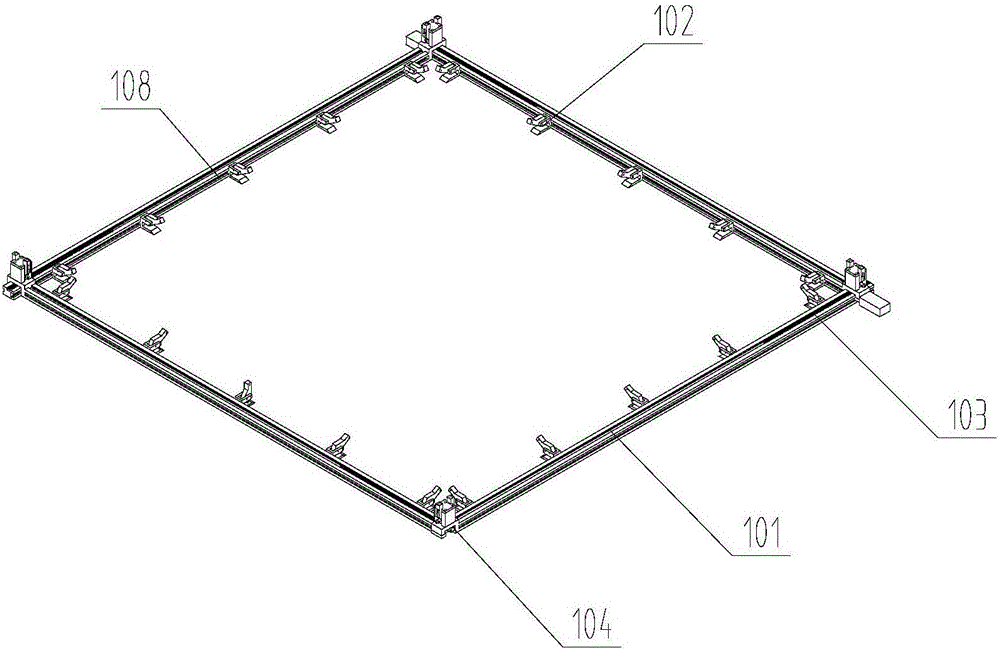

Automobile leather delivering and drying all-in-one (AIO) machine

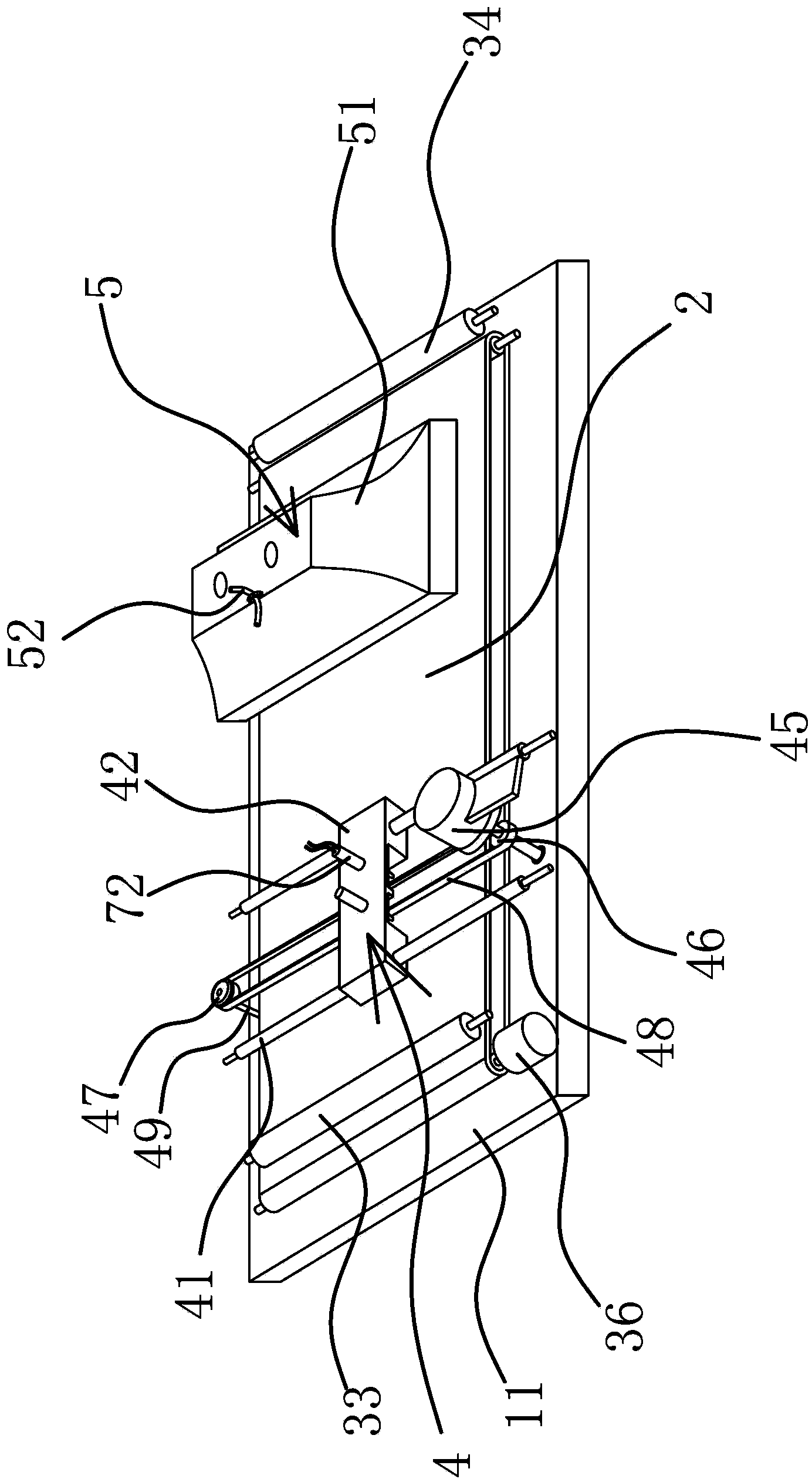

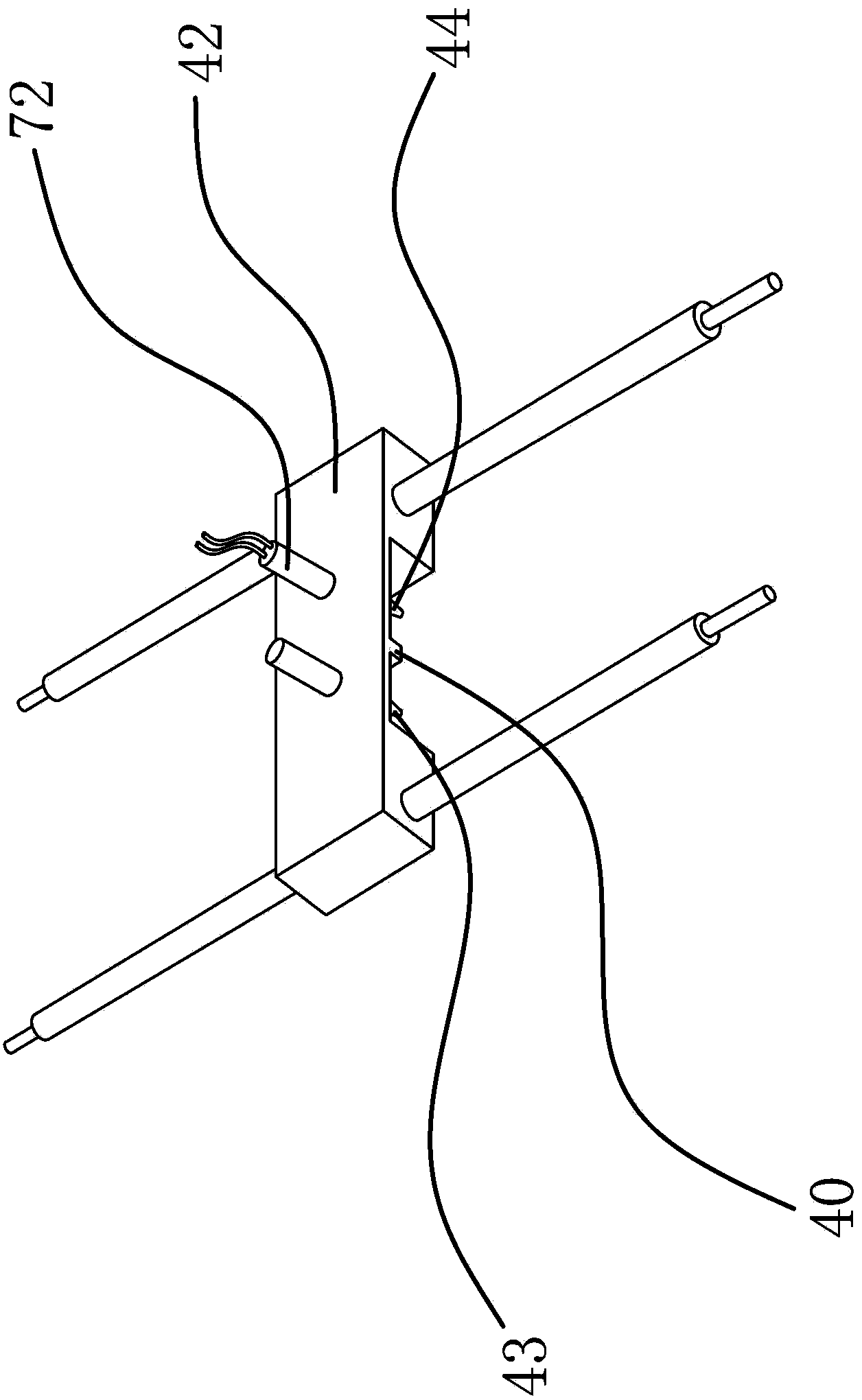

InactiveCN104774976ARealize deliveryRealize the drying operationSkins/hides/leather/fur manufacturing apparatusLeather dryingMechanical engineeringProcess engineering

The invention provides an automobile leather delivering and drying AIO machine, and belongs to the technical field of machinery. At present, automobile leather should be delivered to the baking oven of a conventional leather drying machine by people, the production cannot be carried out continuously, the production efficiency is low, and the provided AIO machine solves the problems mentioned above. The AIO machine comprises a delivering device and a drying device; the delivering device comprises a work bench and a plurality of positioning frames, an annular guide rail is arranged on the work bench, multiple clamping mechanisms for clamping the positioning frames are arranged under the annular guide rail, a power mechanism, which can drive the clamping mechanisms to move back and forth, is arranged in the annular guide rail, each positioning frame is provided with a positioning structure, which can be used to extend the automobile leather and position the automobile leather on the positioning frame; the drying device comprises a baking oven fixed on the work bench, the upper part of the baking oven is provided with a plurality of openings, from which the positioning frames can enter the baking oven, and the upper part of the baking oven is also provided with an closing structure, which can close the openings. The AIO machine has the advantages of high production efficiency, and low labor strength.

Owner:浙江富邦汽车内饰科技有限公司

Crocodile belly skin tanning processing method

ActiveCN104593527ASolve problems such as flat, thin, empty and looseAvoid separationTanning treatmentPre-tanning chemical treatmentBiologyChemistry

The invention relates to a crocodile belly skin tanning processing method. The problems that fats are difficult to remove, dermatome and oracle bone are difficult to soften, scales and shells are difficult to remove, bleaching and fading effects are not good, the finished leather is flat, thin, empty and loose, and the hang drying method is improper and the like are unsolved in the existing crocodile skin tanning technology. The crocodile belly skin tanning processing method comprises the steps of soaking, fleshing, oil film scraping, degreasing and pre-liming, oil film scraping, aldehyde pre-tanning, oil film scraping, liming, oil film scraping, scale brushing, deliming, oil film scraping, united bleaching, softening, oil film scraping, combined bleaching, degreasing, oracle bond softening and bleaching, pickling and softening, tanning, shaving, degreasing, neutralizing, re-tanning, fat-liquoring, leather fluffing, dry cleaning, dyeing, hang drying and coating. The processing technology of Nile crocodile belly raw material skin is provided, and the crocodile skin is soft and plump and elastic, keeps the complete crocodile skin patterns, not only can be processed into dark leather, but also can be processed into light leather and white leather. The leather can be used for processing luggage leather, shoe leather, belt and watch strap leather and the like, and has a very high market value.

Owner:蚌埠启邦科技信息咨询有限公司

Multifunctional leather goods processing workstation

InactiveCN101176577AImprove quality reliabilityAccurate graspShoemaking devicesLeather softeningInfraredAutomatic control

A multifunctional station for leather product treatment includes at least a cavity with inner part and at least an upper cover casing of a air exhaust port connected with a vacuum pump. The upper cover casing is predetermined to connect with at least a steam interface of peripheral steam generator. Each cavity is provided with at least a near infrared radiation type heating lamp, and a reflection plate with parabolic profile and with inner reflection surface treated through mirror, which is disposed around the middle luminous part of the heating lamp. Each upper cover casing is capable of combining temporarily with corresponding lower carrying tray for putting the treated leather products. No matter the multifunctional station for leather product treatment is set independently, or disposed along continuous production line, the operation of upper cover casing is capable of being programmed through an automatic control element, and performing treatment to the leather products, e.g. drying activation of agglutinant or softening, setting of leather products, etc.

Owner:蓝法兰可·安札尼 +1

Leather product automatic processing production line intelligent control system

InactiveCN105803123AAvoid jitterAvoid offsetDrying gas arrangementsDrying solid materialsProduction lineAutomatic processing

The invention discloses a leather product automatic processing production line intelligent control system. The system comprises an adjustment chamber for adjusting a drying temperature and humidity, a transmission chamber for moving the dried object, and an air inlet duct and an air return duct which are communicated with the adjustment chamber and the transmission chamber. A fan with a constant-temperature constant-humidity air-outlet groove is used so that air blowing to all parts of the object to be dried is even and all parts of the object to be dried get uniform air and thus drying quality is good.

Owner:刘新梅

Environmentally-friendly and high-grade sofa leather production process

ActiveCN109628653ARaise the pHReduce formaldehyde contentTanning treatmentPre-tanning chemical treatmentOrganic solventAcrylic resin

The invention relates to the technical field of leather manufacturing processes, and provides an environmentally-friendly and high-grade sofa leather production process. According to the environmentally-friendly and high-grade sofa leather production process, an organic pretanning agent F-90 is adopted to pretreat softened leather, main tanning is carried out on pre-tanned white wet leather by adopting an aldehyde tanning agent, a vegetable tanning agent, an aromatic synthetic tanning agent, an amino resin tanning agent and an acrylic resin tanning agent are adopted for retanning, cross-linking can be formed among the vegetable tanning agent, collagen and the aldehyde tanning agent, and a vegetable-aldehyde synergistic tanning effect is achieved, so that the water-washing resistance, organic solvent resistance and shrinkage temperature of obtained crust leather are improved; moreover, the environmentally-friendly and high-grade sofa leather production process is a technical skill integrating tanning, neutralization, retanning and dyeing, uniform patterns are easy to produce on the grain surface of obtained sofa leather, and the process is suitable for the mill operation; and the shrinkage temperature is higher than 85 DEG C, and physical and mechanical properties and sensory properties meet the standard of chrome-free tanning leather.

Owner:XINGYE LEATHER TECH CO LTD

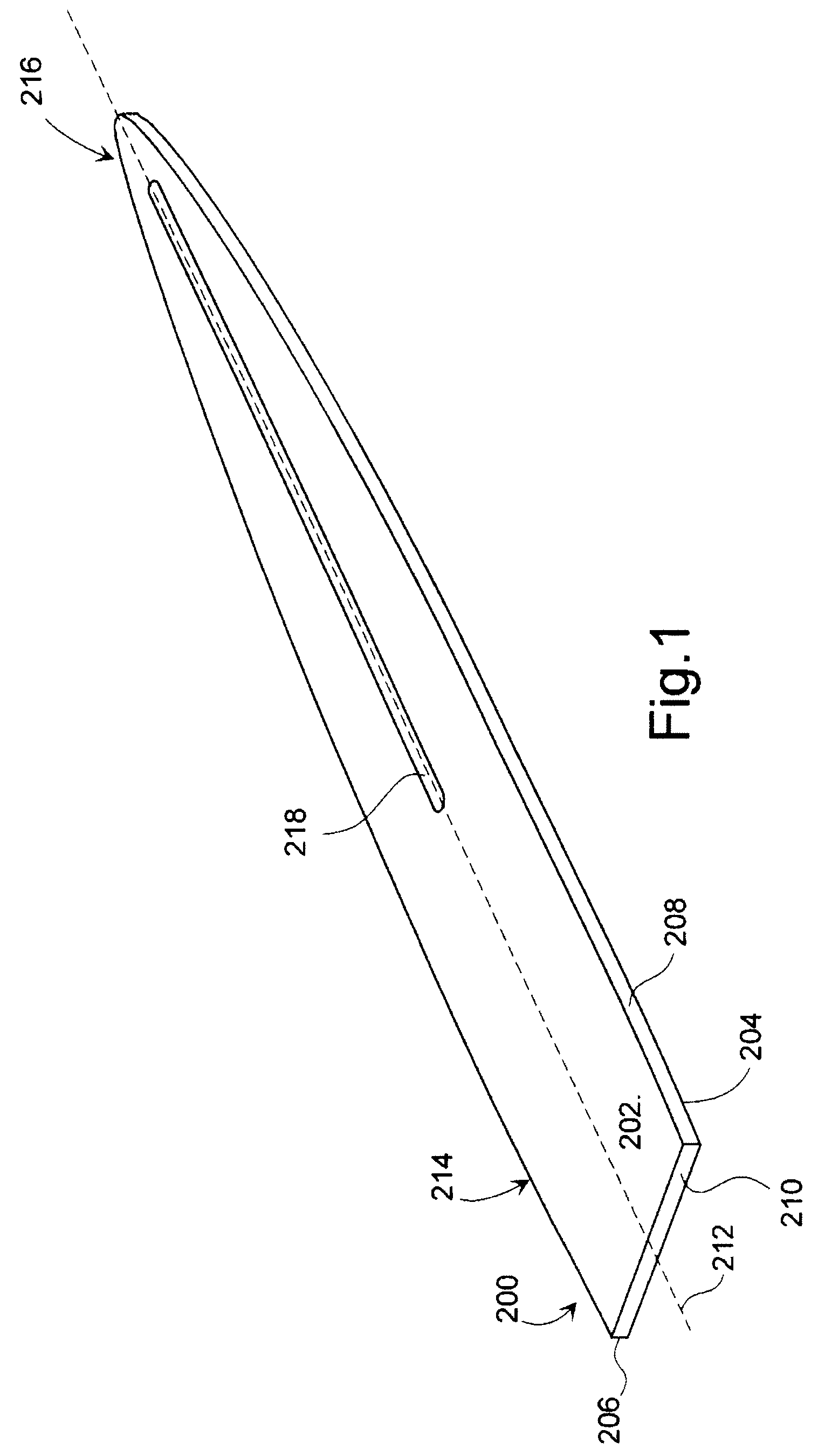

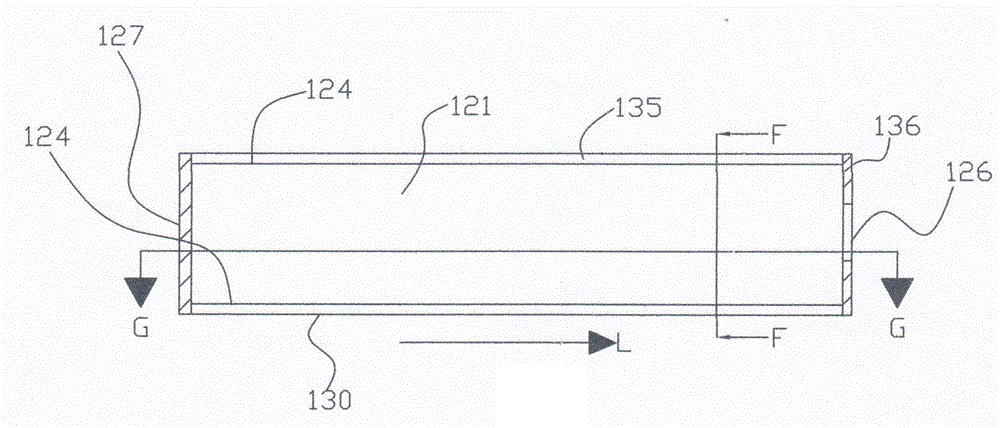

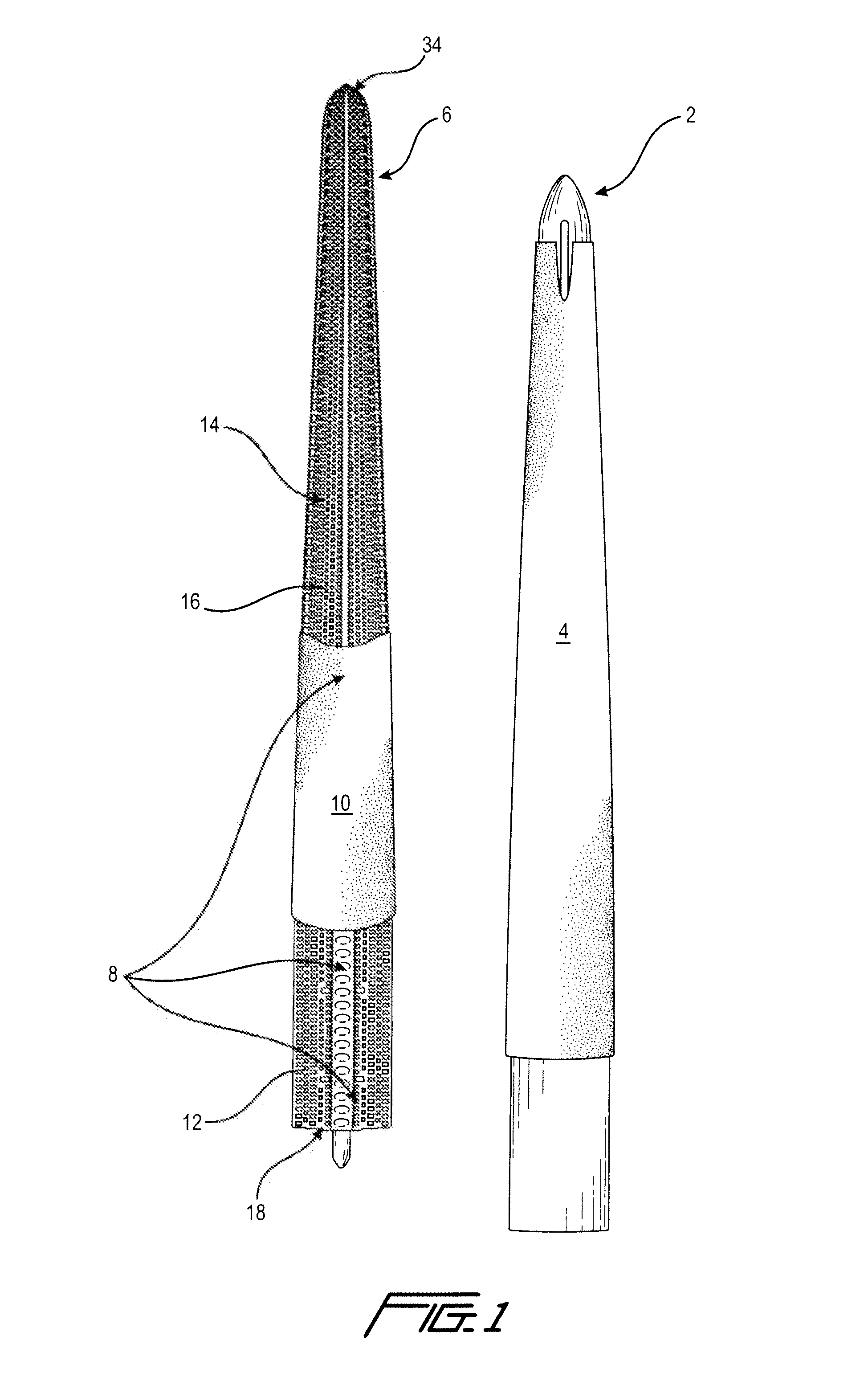

Pelt drying assembly comprised of a sleeve/bag of fat and moisture absorbing material and a pelt board

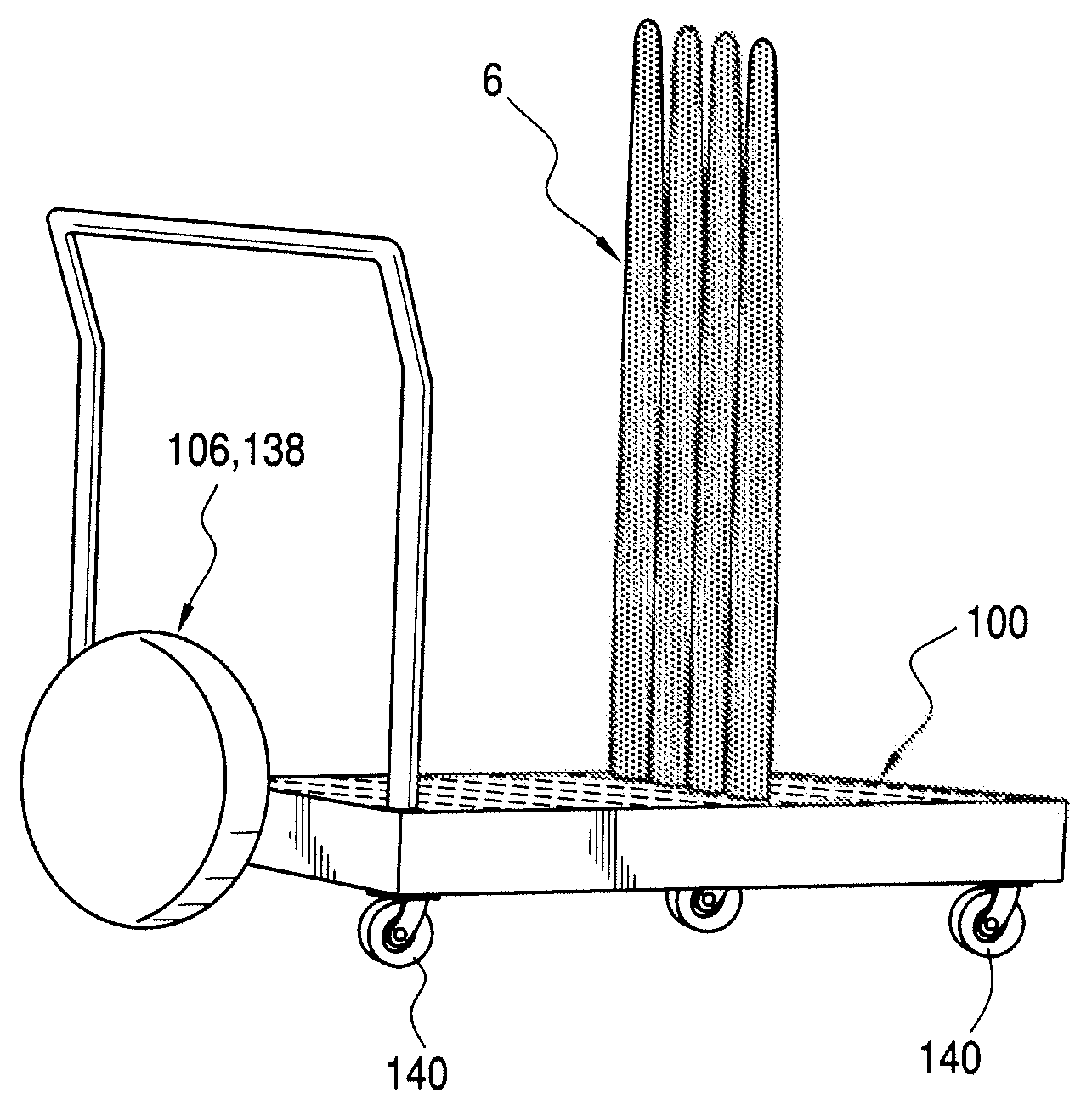

ActiveUS7578153B2Great frictional forceEasy to handleFur dressingLeather stretching/tensioningEngineeringMechanical engineering

A pelt drying assembly having a pelt board used in the drying of the leather side of a pelt which, in use, is applied to, stretched and secured on the distension element in the stretched position during drying, and a sleeve / bag made of fat and moisture absorbing material for covering the pelt secured in the stretched position by having been drawn over the fur side of the pelt so as to press the pelt against a holding area of the distension element. The sleeve / bag is tubular for drawing onto the pelt board from a pointed end thereof until it covers at least a part of the holding area on the distension element, and has a length equal to at least 1 / 3, preferably 1 / 2, of the length of the holding area of the distension element.

Owner:MINKPAPIR

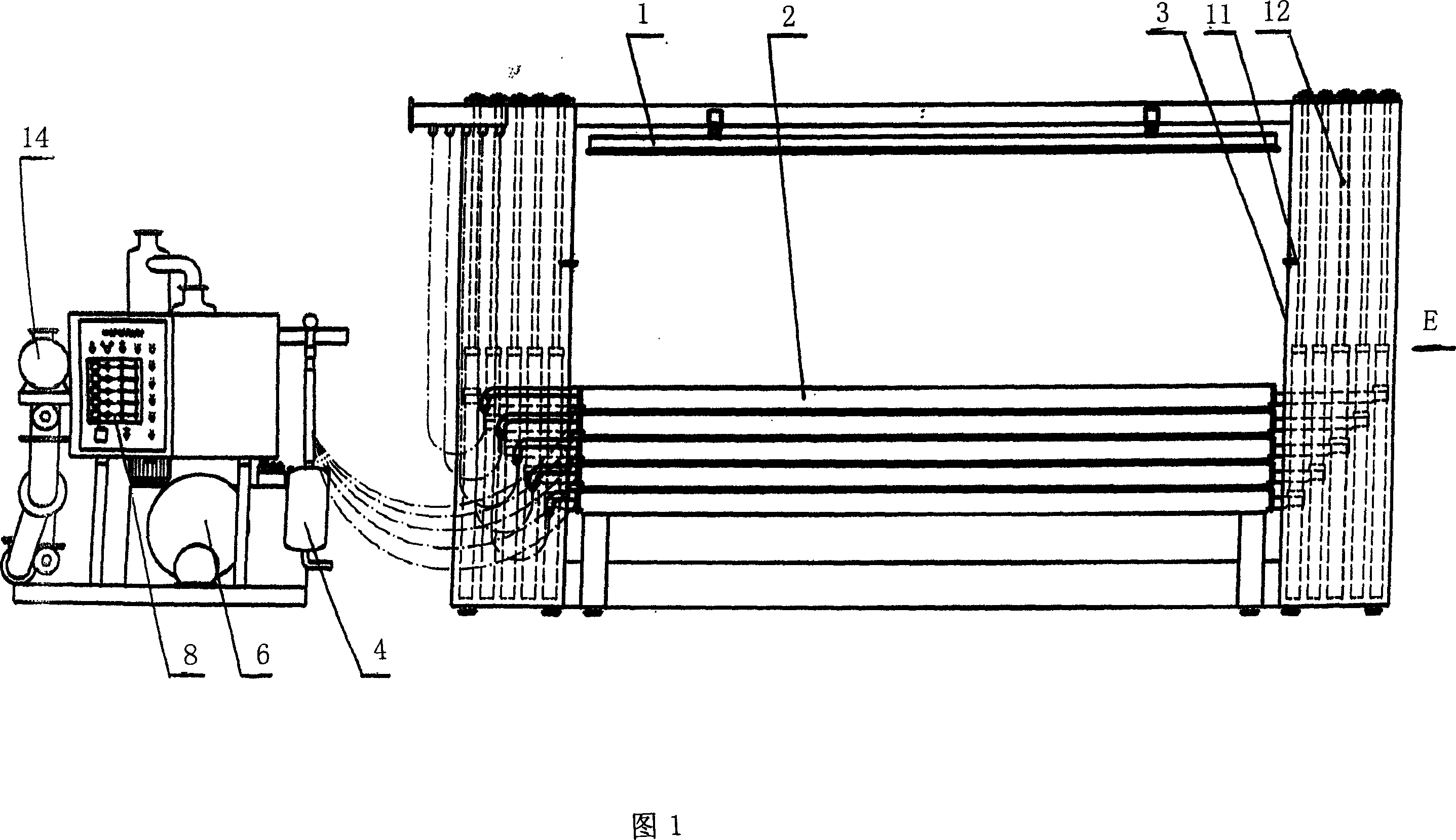

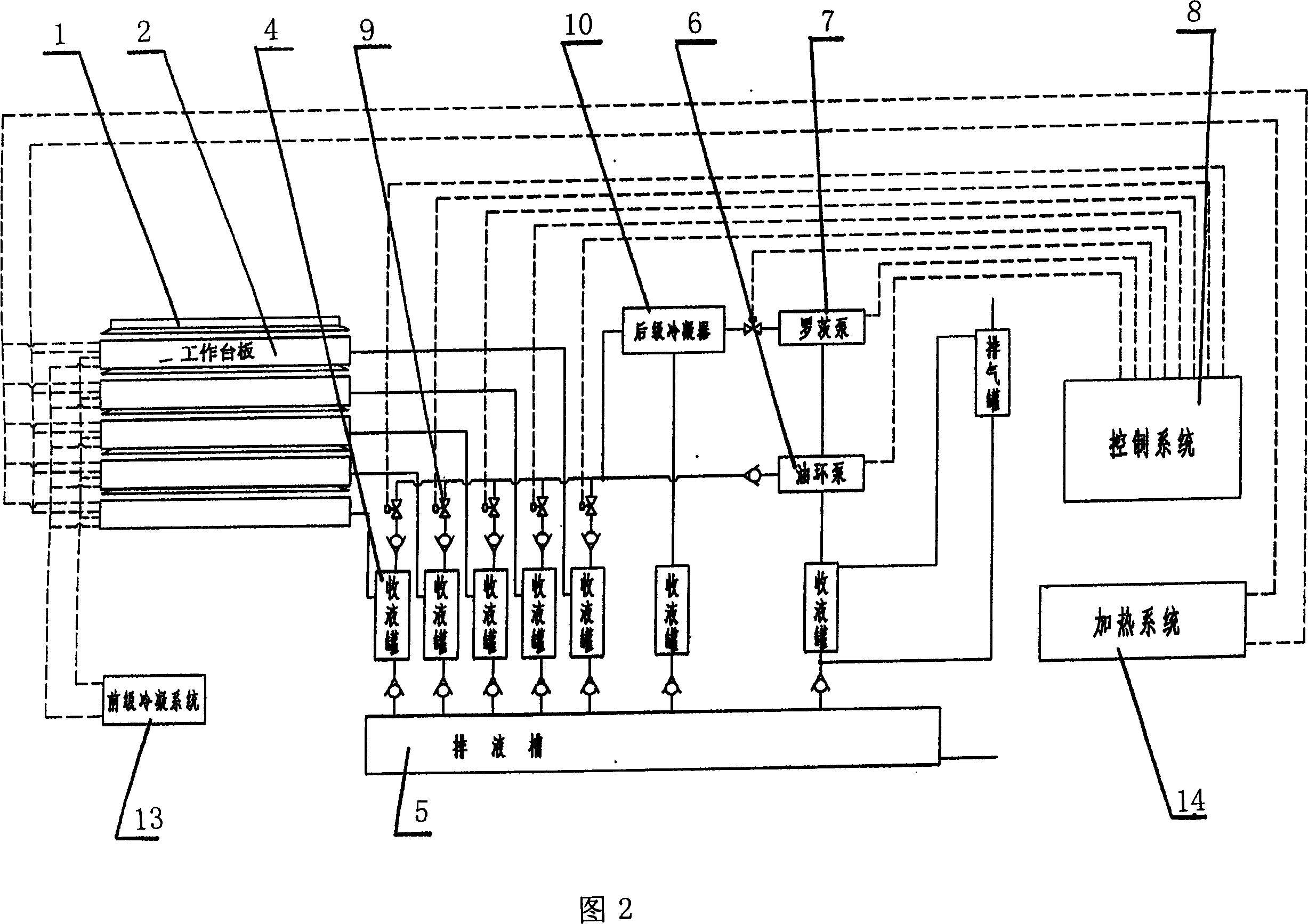

Low temperature vacuum drier

ActiveCN101046351AReduce the temperatureReduce compactionDrying solid materials without heatDrying machines with local agitationEngineeringVacuum pump

The low temperature vacuum drier for processing leather includes one cover on the machine frame, at least one layer of working board with heating element and vacuumizing ports and hoisted by means of oil cylinder onto the machine frame, one liquid collecting tank connected to the liquid draining grooves and connected to the vacuum pump, at least two safety devices on the uprights of the machine frame, one condensation system connected to the working board, one sealing cover below the working board, one cooling pipeline around the working board, and vacuum pump comprising oil circulating vacuum pump and Roots vacuum pump. The present invention has high vacuumizing capacity, lowered operation temperature, no damage on the leather tissue and raised quality of dried leather.

Owner:NANTONG SIRUI ENG

Processing technology of cowhide leather

InactiveCN107858458AGood removal effectNot perishableTanning treatmentPre-tanning chemical treatmentCross-linkRemoving hair

The invention discloses a processing technology of cowhide leather. The technology comprises the steps of: cleaning, degreasing, hair removal, alkali dipping, deashing, softening, acid dipping and tanning. According to the invention, the ester removal agent used in degreasing treatment can remove the residual ester well, is beneficial to intracutaneous penetration of tanning agent molecules and combination with collagen molecule active groups in a follow-up tanning process, formation of a cross-linked protein fiber three-dimensional network, and improvement of the stability and chemical resistance, and the prepared leather does not rot or deteriorate easily. Through the treatment of alkali dipping, deashing, softening and other steps, mesenchymal protein fiber in cortex can be dissolved, the softness of finished leather can be improved, and the handfeel is comfortable.

Owner:ANHUI DINGHENG LEATHER PROD

Method for processing sheepskin into fur or leather in multiple steps by using biological enzyme

ActiveCN103276117AReduce dosageLow costTanning treatmentPre-tanning chemical treatmentBiotechnologyBiochemical engineering

The invention discloses a method for performing multiple-step treatment on sheepskin by using biological enzymes, which is characterized in that industrial pancreatic enzymes, composite enzymes TA for acid pickling and softening and composite enzymes TB for acid pickling and softening are respectively used for performing softening treatment on sheepskin in an enzyme softening procedure and an acid pickling procedure; and the treated sheepskin is processed through the conventional process, thereby obtaining the very soft and lightweight sheepskin. Thus, the quality and added values of the sheepskin and products thereof are greatly improved.

Owner:SICHUAN UNIV +1

Leather fabric waxing device

InactiveCN104437957AGuaranteed to be straightEasy to apply waxPretreated surfacesLeather/skins/hides/pelt chemical treatment apparatusCold airEngineering

The invention relates to a leather fabric waxing device which comprises a conveying belt supported by a supporting frame to accommodate a leather fabric, wherein a clean sponge stick is arranged above one end of the conveying belt through an upper bracket, a water tank is arranged above the clean sponge stick, a downcomer with a valve is connected below the water tank and is connected above the downcomer, a blowpipe is arranged on one side of the clean sponge stick on the upper bracket, a rolling wheel of which an outer layer is a piece of dry cloth is hoisted on the upper bracket on one side of the blowpipe, a waxing box for accommodating wax liquid is arranged on the upper bracket, a pre-coating discharge pipe and a waxing pipe are respectively arranged below the waxing box, a hard brush is connected below the pre-coating discharge pipe, a soft brush is connected below the waxing pipe, a plurality of cold air pipes and a plurality of hot air pipes are also arranged on the upper bracket, and an upper rolling wheel and a lower rolling wheel are arranged at the other end of the conveying belt. The leather fabric waxing device has the benefits that the leather fabric is uniformly waxed, and the processing speed is high.

Owner:倪国权

Manufacturing method of bicolor wax-texture crack split leather

ActiveCN107236833AStrong two-color contrast effectImprove performanceLeather/skins/hides/pelt chemical treatment apparatusLeather softeningWaxCrazing

The invention relates to a manufacturing method of bicolor wax-texture crack split leather and belongs to the technical field of leather. The manufacturing method of the bicolor wax-texture crack split leather comprises the following steps that processed and dyed split leather is obtained, dried, ground, milled, sprayed for the first time, roll-finished, sprayed for the second time, vibration-softened, rolled with oil wax and milled in sequence, and thus the bicolor wax-texture crack split leather is obtained. According to the manufacturing method of the bicolor wax-texture crack split leather, the processed and dyed split leather is dried, ground, milled, sprayed for the first time, roll-finished, sprayed for the second time, vibration-softened, rolled with the oil wax and milled, and the technological conditions of the steps and the chemical therapy ratio are strictly controlled and optimized, so that the low-level split leather is manufactured into the high-level crack leather with the wax texture, and the crack leather further has the strong bicolor contrast effect.

Owner:漳州香洲皮革有限公司

Leather production process

InactiveCN104894299AIncreased durabilityLow costTanning treatmentPre-tanning chemical treatmentFiberEngineering

The invention discloses a leather production process, which comprises the steps of 1) lot grouping: classifying the raw hides of leathers similar in width size and thickness; 2) soaking in water: soaking the raw hides in water after the lot grouping step; 3) unhairing and degreasing: removing grease in hide cells and hairs on the surfaces of the raw hides; 4) liming: adding alkali to expand the hides to a certain thickness for facilitating the splitting operation; 5) deliming and pickling: removing redundant alkali in the raw hides during the liming step; 6) tanning: connecting collagen groups in hide fibers by means of trivalent chromic ions, and enhancing the tensile strength and the anti-tear intensity of the leather; 7) re-tanning: selecting a retanning agent of better in filling effect to retan the tanned leather; 8) dyeing; 9) fatliquoring; 10) drying; 11) staking; 12) finishing; 13) examining and warehousing finished products. The leather production process is simple in operation, and the produced leather is good in durability. Meanwhile, the cost of manufacturers is saved, and the requirements of customers can be met at the same time.

Owner:卢家雄

Crocodile skin clean leather-making processing method

ActiveCN104630394AReduce dosageAvoid creasesTanning treatmentPre-tanning chemical treatmentEnvironmental engineeringChloride

The invention relates to a crocodile skin clean leather-making processing method. In the existing leather-making process, the problems of chloride ion contamination, excessive sulfide in a waste liquid, high chromaticity of dyeing wastewater, difficulty in the thickness adjustment of the crocodile skin and the like are more serious. The crocodile skin clean leather-making processing method comprises the following steps of soaking the fresh crocodile skin in saline water, rolling salt, preserving, transporting, classifying, grouping and batching, bundling, weighing, pre-soaking, soaking, removing meat, degreasing, pre-liming, liming, brushing scale, deliming, carrying out primary combined bleaching, softening, carrying out secondary combined bleaching, softening oracle bone, pickling, softening, tanning, fluffing leather, degreasing, rinsing, neutralizing, re-tanning, dyeing, greasing, drying on a nail plate, scrubbing the leather and finishing. By the crocodile skin clean leather-making processing method, the usage amount of salt can be greatly decreased in the aspect of corrosion resistance of raw crocodile skin, the crocodile skin is convenient to transport, the content of S<2-> in the waste liquid and the chromaticity of the waste liquid are effectively decreased, the thickness of the leather can be precisely adjusted and the high-brightness leather can be obtained by virtue of finishing. The crocodile skin produced by the clean production process has clear pattern and the shrinkage temperature and physical and mechanical properties can reach the national standards.

Owner:蚌埠启邦科技信息咨询有限公司

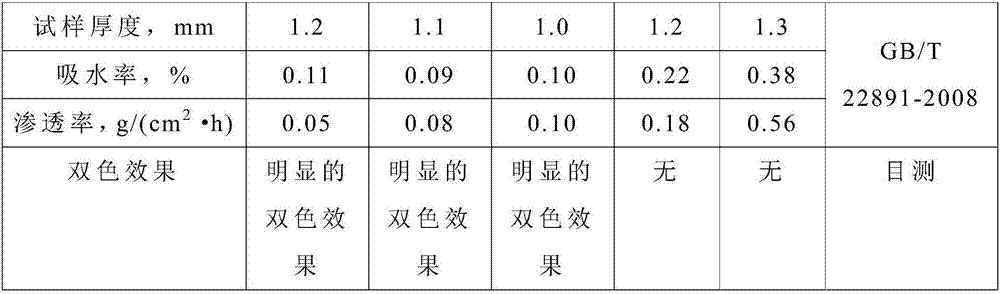

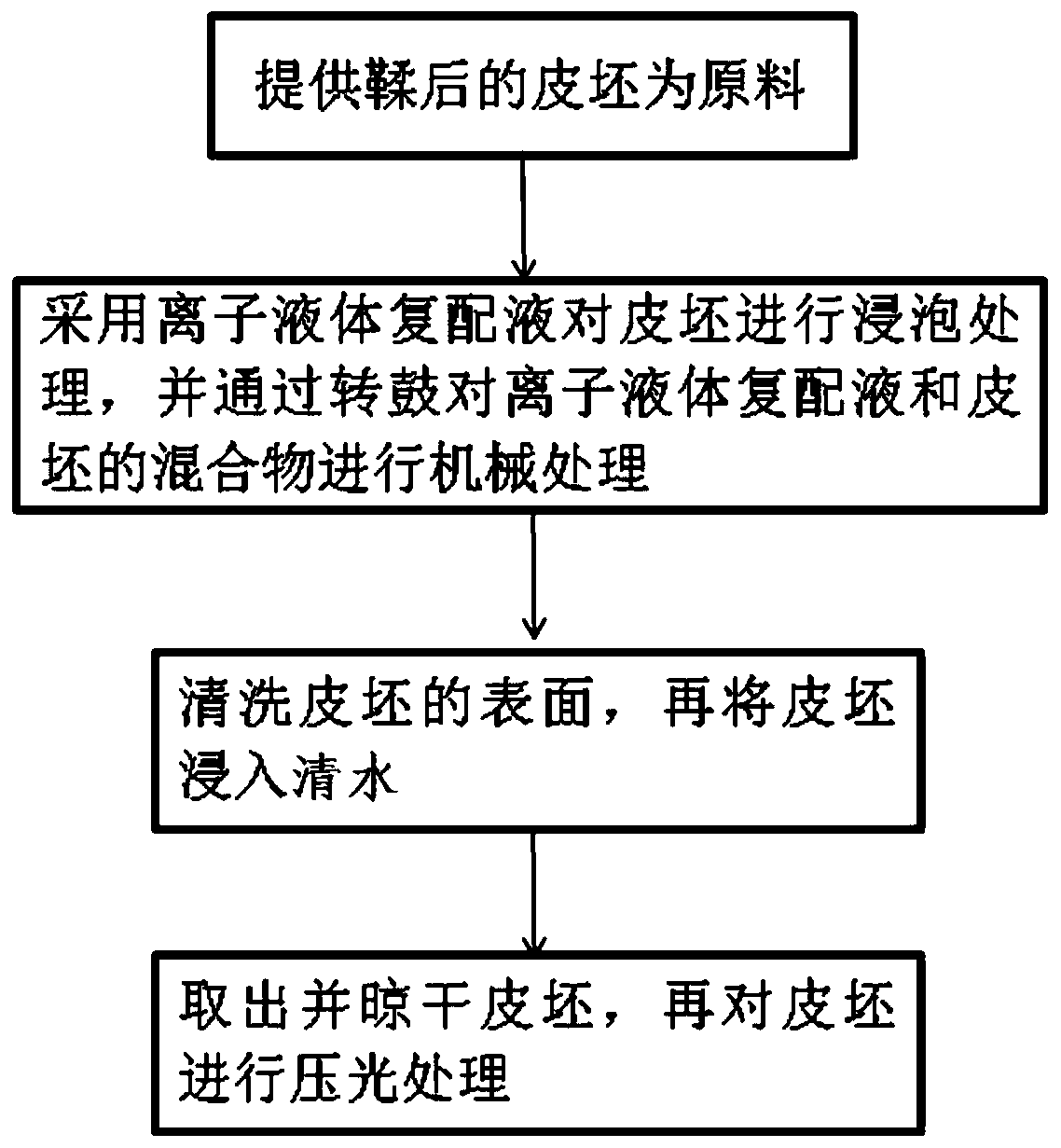

Transparent leather and preparation method thereof

ActiveCN110184398AIncrease shrinkage temperatureKeep natural propertiesLeather/skins/hides/pelt chemical treatment apparatusLeather surface mechanical treatmentIonic liquidRaw material

The invention relates to transparent leather, wherein transparency of the transparent leather is 46-74%, the shrinkage temperature is 90-110 DEG C, and the thickness is 0.4-1.4 mm. The invention further provides a preparation method of the transparent leather. The preparation method comprises the following steps: providing a tanned leather blank as a raw material; carrying out immersion treatmenton the leather blank by adopting an ionic liquid compound liquid, and carrying out mechanical treatment on the mixture of the ionic liquid compound liquid and the leather blank through a rotary drum;cleaning the surface of the leather blank, and then soaking the leather blank into clear water; and taking out the leather blank, airing the leather blank, and then carrying out calendering treatmenton the leather blank.

Owner:浙江通天星集团股份有限公司

Manufacturing method of sofa leather

ActiveCN107937632AAchieve preparationEasy to manufactureLeather softeningLeather surface mechanical treatmentKnurlingEngineering

The invention provides a manufacturing method of sofa leather, and solves the technical problems of more complicated steps, need of spending a lot of manufacturing time, complicated manufacturing andthe like in a traditional manufacturing method. The manufacturing method of the sofa leather comprises the following steps: (a) a leather blank is flatly paved on a passing water extruder to for waterextrusion to remove 78-96% of water in the leather blank; (b) the leather blank is dried through a drying device; (c) a repair agent is coated on the leather blank; (d) the leather blank is polishedthrough a leather polishing machine; (e) the leather blank is sized through a roller coating device; (f) paint is sprayed to the leather blank through a spraying device to obtain leather; (g) the leather is embossed or printed by two modes of knurling and plate pressing; (h) fall softening or pull softening is performed by a pull softening machine and a fall softening rotating drum; (i) the leather is ironed through high temperature to obtain finished sofa leather; and (j) the leather is measured, detected and warehoused. The manufacturing method of the sofa leather has the advantage of convenience to manufacture.

Owner:德州兴隆皮革制品有限公司

Suede leather production method

ActiveCN108165678AEnhance the feelImprove fullnessTanning treatmentPre-tanning chemical treatmentPhosphateTannin

The invention provides a suede leather production method. Suede leathers are obtained through performing water leaching, ash leaching, ash removal, acid leaching, tanning, uniform turning, retanning,neutralization, dyeing and degreasing and drying on leathers. The retanning process comprises the following steps: after 2% of acid-resistance acrylic acid and 0.5% of acid-resistance grease are usedfor treatment, pH is controlled as 3.0; and a chromium retanning agent is added for treatment. The neutralization process comprises the following steps: 150% of water, 2% of sodium formate and 2% of neutralization auxiliary are added; a rotating drum is rotated by 60 min; then, water washing is performed by 10 min; and the temperature is increased to 60 DEG C. The dyeing and greasing process comprises the following steps: 150% of water with a temperature of 40 DEG C, 1.5% of dicyandiamide tannin, 2% of amphoteric synthesized tannin, 4% of tannin extract and 2% of dye are added; the rotating drum is rotated by 50 min; 2% of sulfonated oil, 2% of phosphate and 5% of synthesized oil are added; the rotating drum is rotated by 50 min; 0.8% of formic acid is added; and the drum is stopped by 3 hours. The retanning, neutralization and greasing processes are improved to improve uniformity, hand feel, fullness, reading-writing effect and mercerization of the suede leathers.

Owner:NINGXIA JINHAI LEATHER IND

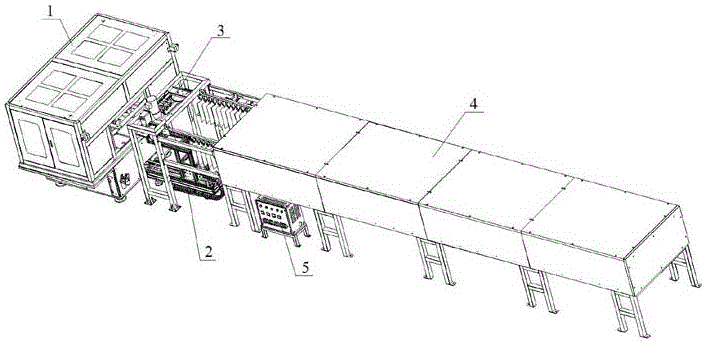

Automatic oil edge production line

ActiveCN105936949AImprove work efficiencyEasy to grabFur dressingSkins/hides/leather/fur manufacturing apparatusProduction lineRobot hand

The invention discloses an automatic oil edge production line which comprises a control mechanism, an oil edge machine, a material hanging mechanism and a drying mechanism. The oil edge machine, a material hanging mechanism and a drying mechanism are sequentially connected. A clamping mechanism and a discharging mechanism are arranged on the connecting portion between the drying mechanism and the material hanging mechanism. The oil edge machine comprises a feeding mechanism, a shaping mechanism, an oil edge mechanism and a rotary mechanical arm. The rotary mechanical arm is of a four-station structure arranged in a cross mode. The feeding mechanism, the shaping mechanism, the oil edge mechanism and a material receiving end of the material hanging mechanism are arranged under the four stations of the rotary mechanical arm in the rotating direction of the rotary mechanical arm respectively. The control mechanism is connected with the controlled end of the rotary mechanical arm, the controlled end of the feeding mechanism, the controlled end of the shaping mechanism, the controlled end of the oil edge mechanism, the controlled end of the material hanging mechanism, the controlled end of the clamping mechanism, the controlled end of the drying mechanism and the controlled end of the discharging mechanism. Under control of the control mechanism, all the mechanisms are coordinated to cooperate to work, the whole oil edge operation is finished automatically under the circumstance without manual interference, and the working efficiency is improved greatly.

Owner:张志军

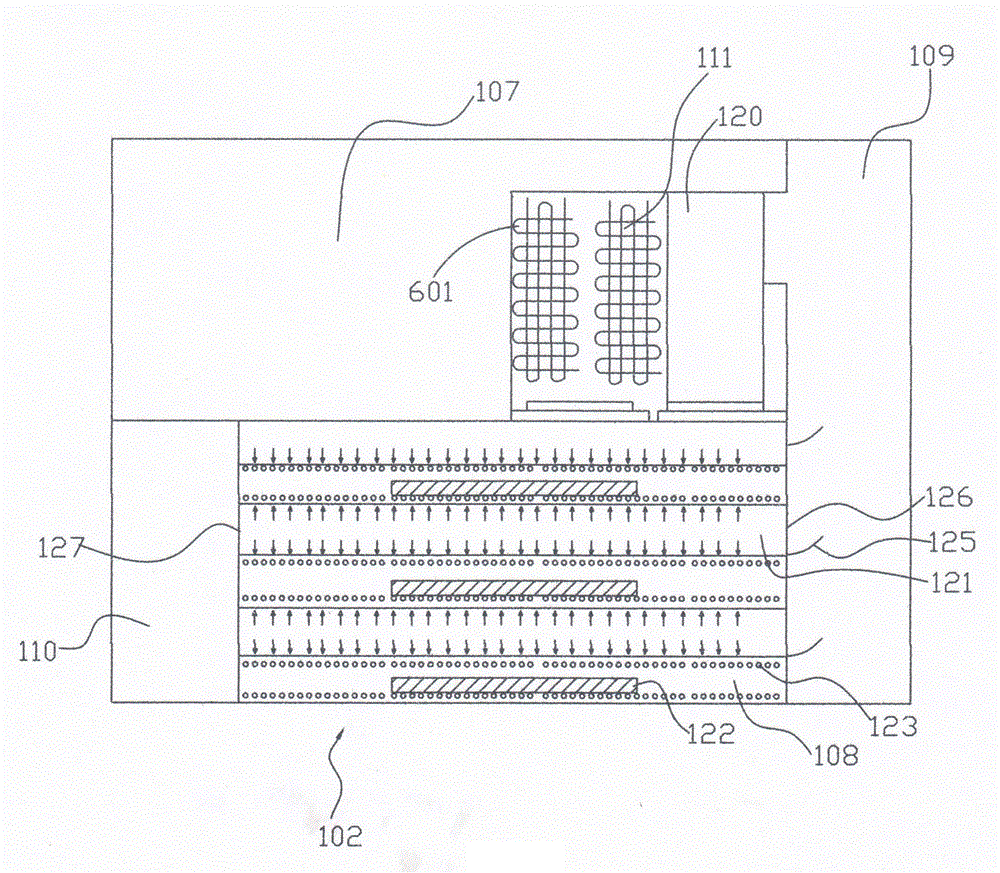

Automatic leather drying device

ActiveCN108611446AReduce manual operationsHigh degree of automationSkins/hides/leather/fur manufacturing apparatusLeather dryingMagnetic polesConveyor belt

The invention relates to the technical field of leather processing, in particular to an automatic leather drying device. The automatic leather drying device comprises a machine frame, a conveying beltand a pair of belt wheels used for driving the conveying belt, wherein a heating device is arranged on one side of the conveying belt, the heating device is arranged on the machine frame, and clamping mechanisms are uniformly arranged on the working surface of the conveying belt; each clamping mechanism comprises a first spring and a pushing block, the pushing blocks are magnetic blocks, one endsof the first springs are connected with the working surface of the conveying belt, the other ends of the first springs are connected with the pushing blocks, two first connecting rods are hinged to each pushing block, second connecting rods are hinged to the first connecting rods, and clamping plates are hinged to the tail ends of the second connecting rods; and the sides, close to the belt wheels, of the machine frame are provided with magnet blocks and the magnetic pole of the opposite ends between the magnetic blocks and the pushing blocks are the same; and a conveyor belt for collecting dried leather is arranged on one side of the conveying belt. According to the automatic leather drying device, the clamping mechanisms are arranged on the conveying belt, so that the conveying belt canbe used for conveying the leather, meanwhile, the clamping mechanisms can be used for fixing the leather, and then the leather cannot be blown off and blown away by a hot air blower.

Owner:宁波隆锐机械制造有限公司

Automatic fur expanding and drying device

ActiveCN106521042AIncrease productivityEasy to operateSkins/hides/leather/fur manufacturing apparatusLeather dryingEngineeringMechanical engineering

Owner:ZHEJIANG UNIV OF TECH

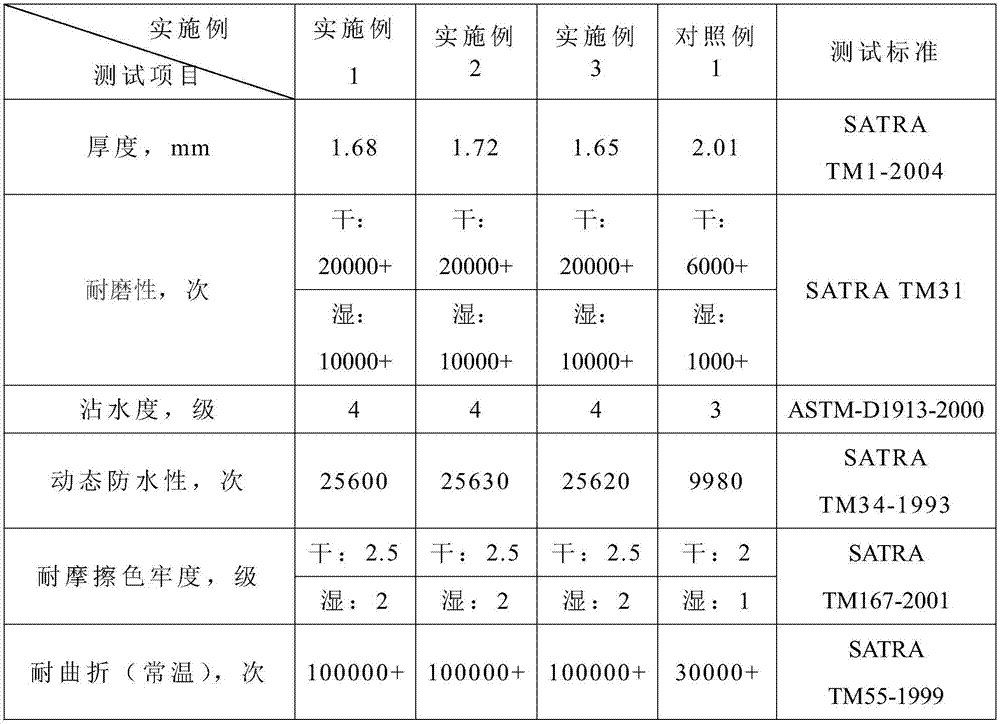

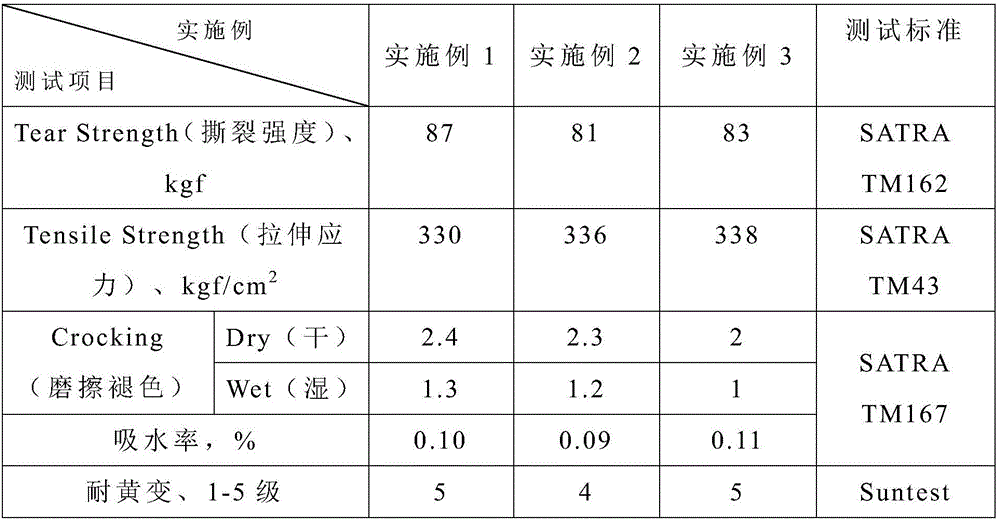

Production technique of xanthochromia-resisting and illumination-resisting two-layer leather

ActiveCN107523655AEnhanced yellowing resistance and light resistanceEasy to stretchTanning treatmentPre-tanning chemical treatmentSofteningXanthochromia

The invention relates to a production technique of xanthochromia-resisting and illumination-resisting two-layer leather, and belongs to the technical field of leather. The production technique of the xanthochromia-resisting and illumination-resisting two-layer leather includes steps of taking two-layered leathers, and orderly performing rewetting, retanning, alkali extraction, neutralizing, dyeing, fat liquoring, fixation, drying, softening, leather grinding, milling to obtain the xanthochromia-resisting and illumination-resisting two-layer leather. The xanthochromia-resisting and illumination-resisting two-layer leather has the advantages of being excellent in stretching performance, good in wear and fading resistance, good in waterproof property, and excellent in xanthochromia resistance and illumination resistance.

Owner:漳州香洲皮革有限公司

Akhal-teke horse posture specimen hide preparation method

InactiveCN103773910AElasticEasy to storeTanning treatmentPre-tanning chemical treatmentEngineeringProtective Agents

The invention discloses an Akhal-teke horse posture specimen hide preparation method. The Akhal-teke horse hide preparation method is divided into two stages, wherein the first stage is the wet finishing of the fresh hide of the Akhal-teke horse, including the processes of soaking at normal temperature, re-soaking at normal temperature, pickling, degreasing, softening, tanning and basification; the second stage is the dry finishing of the fresh hide, including repeated drum treatment for cleaning and drum treatment for bright fur to obtain a finished product. According to the method disclosed by the invention, the tanned Akhal-teke horse hide is light, thin, soft, elastic and easy to store and can be stored for a long time without using a protective agent; the prepared specimen does not deform easily and better reflects the form details of animals; the specimen fur is glossy, thus the prepared specimen is more realistic.

Owner:KUNMING INST OF ZOOLOGY CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com