Method for manufacturing washable cow split leather

A production method, the technology of cow split leather, which is applied in the directions of leather impregnation, leather drying, leather surface mechanical treatment, etc., can solve the problems of poor color fastness to washing and dimensional stability, failure to achieve washing resistance, and high cost. , to achieve the effect of ensuring color fastness to washing, excellent washing resistance, and improving combination fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

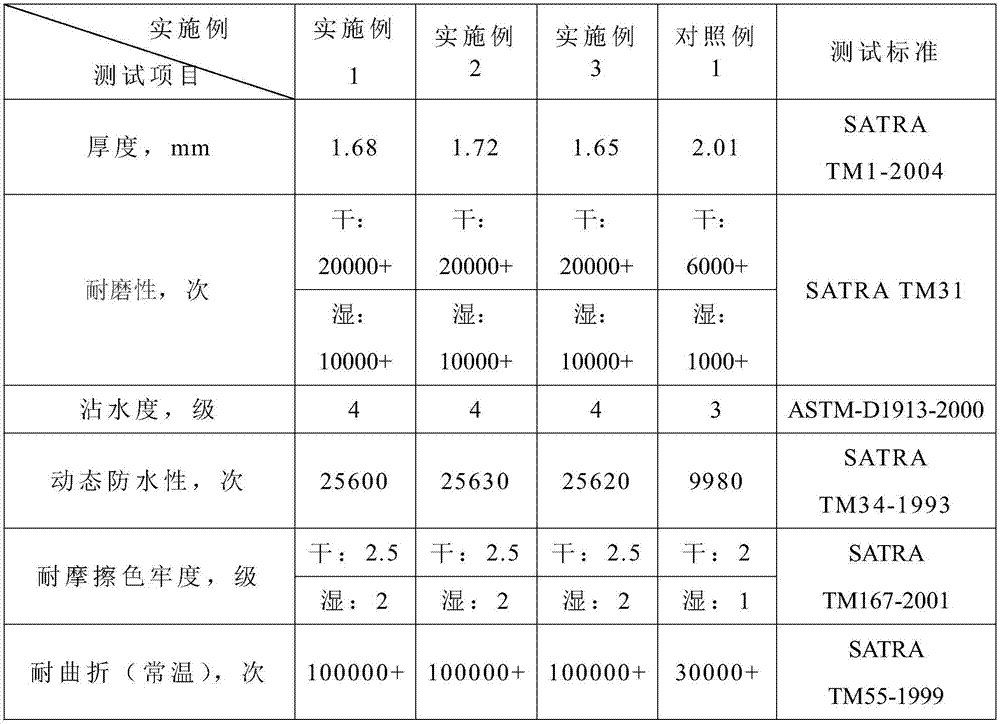

Examples

Embodiment 1

[0037] The method for making water-resistant cow split leather comprises the following steps: taking the cow split leather which has been processed, squeezed and evenly shaved, and then subjected to rewetting → primary washing → retanning → neutralization → secondary washing →filling→dyeing→fatliquoring→acid-fixing→washing three times→fixing→washing four times→drying→hanging to dry→vibrating and softening→rubbing leather→breaking soft, the specific steps are as follows:

[0038] Step 1, re-humidification: take the skin base that has been processed, squeezed and evenly shaved, and put it in a drum for re-humidification to obtain a re-wet leather material. The specific re-humidity is: calculated according to the mass percentage of the skin base Add 180% water, 0.5% PASTOSOL M2 degreaser, 0.3% moisture rehumidifier and 0.8% oxalic acid into the drum, adjust the pH to 3.8-4.0, and drain after running for 100 minutes, wherein the water temperature is 45°C;

[0039] Step 2, one-time w...

Embodiment 2

[0051] The method for making water-resistant cow split leather comprises the following steps: taking the cow split leather which has been processed, squeezed and evenly shaved, and then subjected to rewetting → primary washing → retanning → neutralization → secondary washing →filling→dyeing→fatliquoring→acid-fixing→washing three times→fixing→washing four times→drying→hanging to dry→vibrating and softening→rubbing leather→breaking soft, the specific steps are as follows:

[0052] Step 1, re-humidification: take the skin base that has been processed, squeezed and evenly shaved, and place it in a drum for re-wetting to obtain a re-wet leather material. The specific re-humidity is: calculated according to the mass percentage of the skin base, Add 150% water, 0.4% PASTOSOL M2 degreaser, 0.2% moisture rehumidifier and 0.7% oxalic acid into the drum, adjust the pH to 3.8-4.0, drain after running for 90 minutes, wherein the water temperature is 45°C;

[0053] Step 2, one-time washing:...

Embodiment 3

[0065] The method for making water-resistant cow split leather comprises the following steps: taking the cow split leather which has been processed, squeezed and evenly shaved, and then subjected to rewetting → primary washing → retanning → neutralization → secondary washing →filling→dyeing→fatliquoring→acid-fixing→washing three times→fixing→washing four times→drying→hanging to dry→vibrating and softening→rubbing leather→breaking soft, the specific steps are as follows:

[0066] Step 1, re-humidification: take the skin base that has been processed, squeezed and evenly shaved, and place it in a drum for re-wetting to obtain a re-wet leather material. The specific re-humidity is: calculated according to the mass percentage of the skin base, Add 200% water, 0.6% PASTOSOL M2 degreaser, 0.4% moisture rehumidifier and 0.9% oxalic acid into the drum, adjust the pH to 3.8-4.0, drain after running for 120 minutes, wherein the water temperature is 40°C;

[0067] Step 2, one-time washing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com