A kind of manufacturing method of environment-friendly twist-resistant soft upper leather

A production method and bending-resistant technology, applied in special leather manufacturing, leather impregnation, leather surface treatment, etc., can solve the problems of hard and brittle coating materials, poor water resistance, poor bending resistance, etc., to achieve increased compactness, uniformity, consistency, Avoid coarse grain and reduce the effect of poor parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below by way of a particular embodiment in order to further explain the present invention.

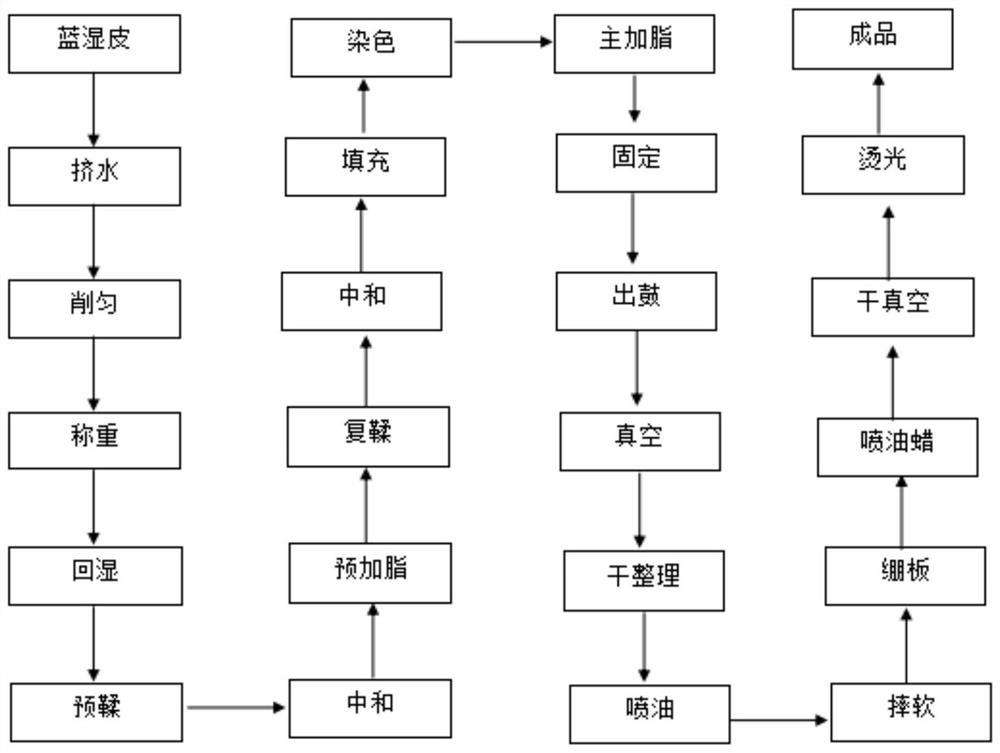

[0021] A method of fabricating a conventional step and an improvement process comprising a conventional step and an improvement process comprising a backup step, a neutralization process, and a filling dyeing step, and a conventional process is specifically employed in the industry. However, it will not be described in detail herein. The improvement process includes a moisturizing process, a retanning process, an additional finish step, and a dry finishing process. In the present invention, the fat-fat step comprises a pre-fat step and a main fatty process, and the pre-fat step, the retaining process and the main elevated finishing step are sequentially carried out. The specific process route of this embodiment is like figure 1 Indicated.

[0022] As a preferred embodiment, in the moistive step, the blue wet skin is scratched, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com