Automatic oil edge production line

A production line and oil edge technology, applied in the field of leather oil edge, can solve problems such as low efficiency, and achieve the effect of improving work efficiency, accurate feeding operation, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

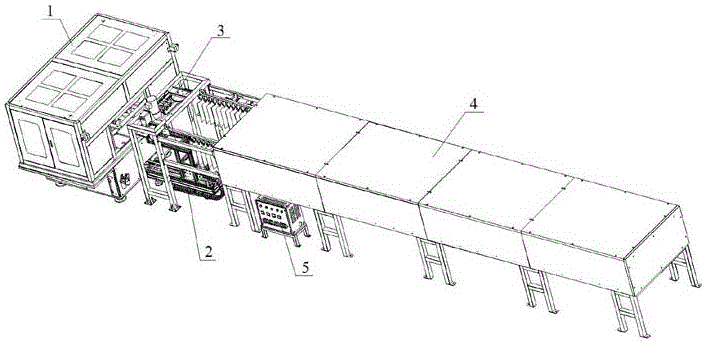

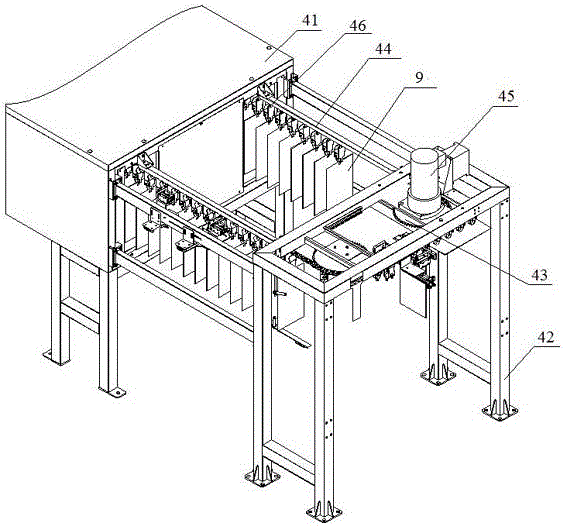

[0043] An automatic oil edge production line, its overall structure is as follows figure 1 As shown, it includes the control mechanism 5 and the oil edge machine 1, the material hanging mechanism 2 and the drying mechanism 4 arranged successively. The connection between the drying mechanism 4 and the material hanging mechanism 2 is also provided with a clamping mechanism 3 and a discharging mechanism. , the control mechanism is respectively connected with the oil edge machine 1, the material hanging mechanism 2, the clamping mechanism 3, the drying mechanism 4 and the controlled end of the unloading mechanism, and is used to control each mechanism to coordinate and complete the oil edge operation.

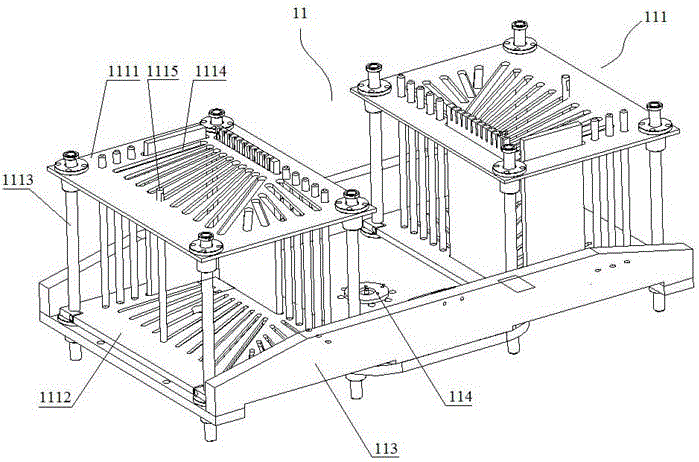

[0044] The oil edge machine 1 is used for oil edge operation on the blank, including a feeding mechanism 11 , a rotating manipulator 12 , a shaping mechanism 13 and an oil edge mechanism 14 . In the present invention, the rotary manipulator is a four-station structure arranged in a...

Embodiment 2

[0075] The difference between this embodiment and Embodiment 1 is that the structure of the oil transfer mechanism in the oil edge head is different. In this embodiment, the structure of the oil edge head 144 is as follows Figure 9 with Figure 10 shown.

[0076] The oil delivery mechanism includes an oil side motor 1447, a driving wheel 1443, a lower guide wheel 1448, a tensioner wheel 1444, an upper guide wheel 1445, a belt guide mechanism 1449 and an oil delivery belt 1446. Both the driving wheel 1443 and the lower guide wheel 1448 are arranged on one side wall of the oil storage box 1442, and are immersed in the oil of the oil storage box 1442; Guide wheel 1445 is fixedly arranged on the support top, and is positioned at the top of driving wheel 1443; The wheel 1444 and the lower guide wheel 1448 are located in the same vertical plane, and are surrounded by the oil transfer belt 1446 to form a quadrilateral structure; the belt guide mechanism 1449 is arranged at the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com