Patents

Literature

63results about "Fur dressing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and system for drying out the leather side of a pelt stretched out and fixed in this position on a pelt board

ActiveUS7690228B2The process is fast and efficientWay fastFur dressingLeather stretching/tensioningBlack spotEngineering

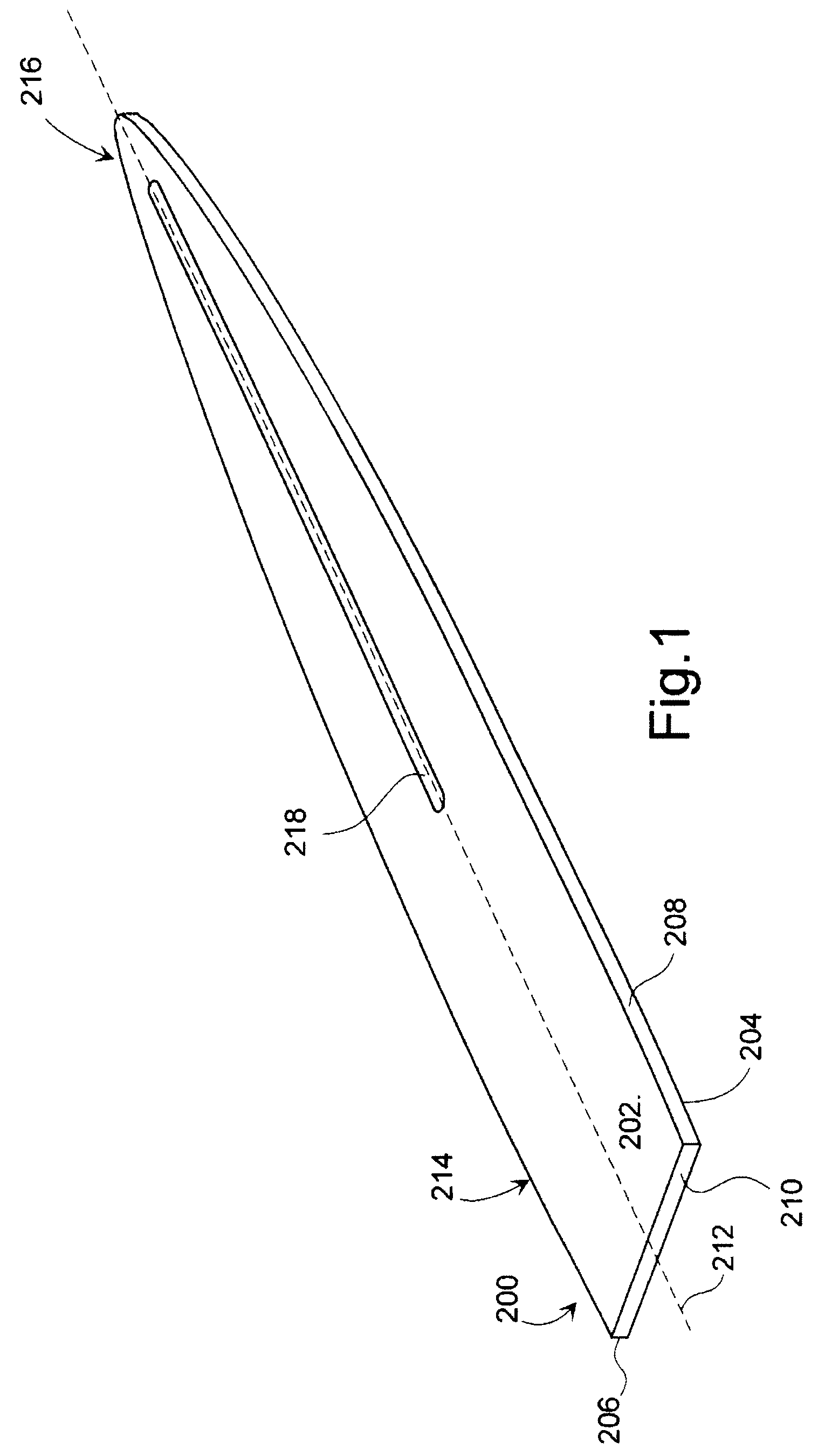

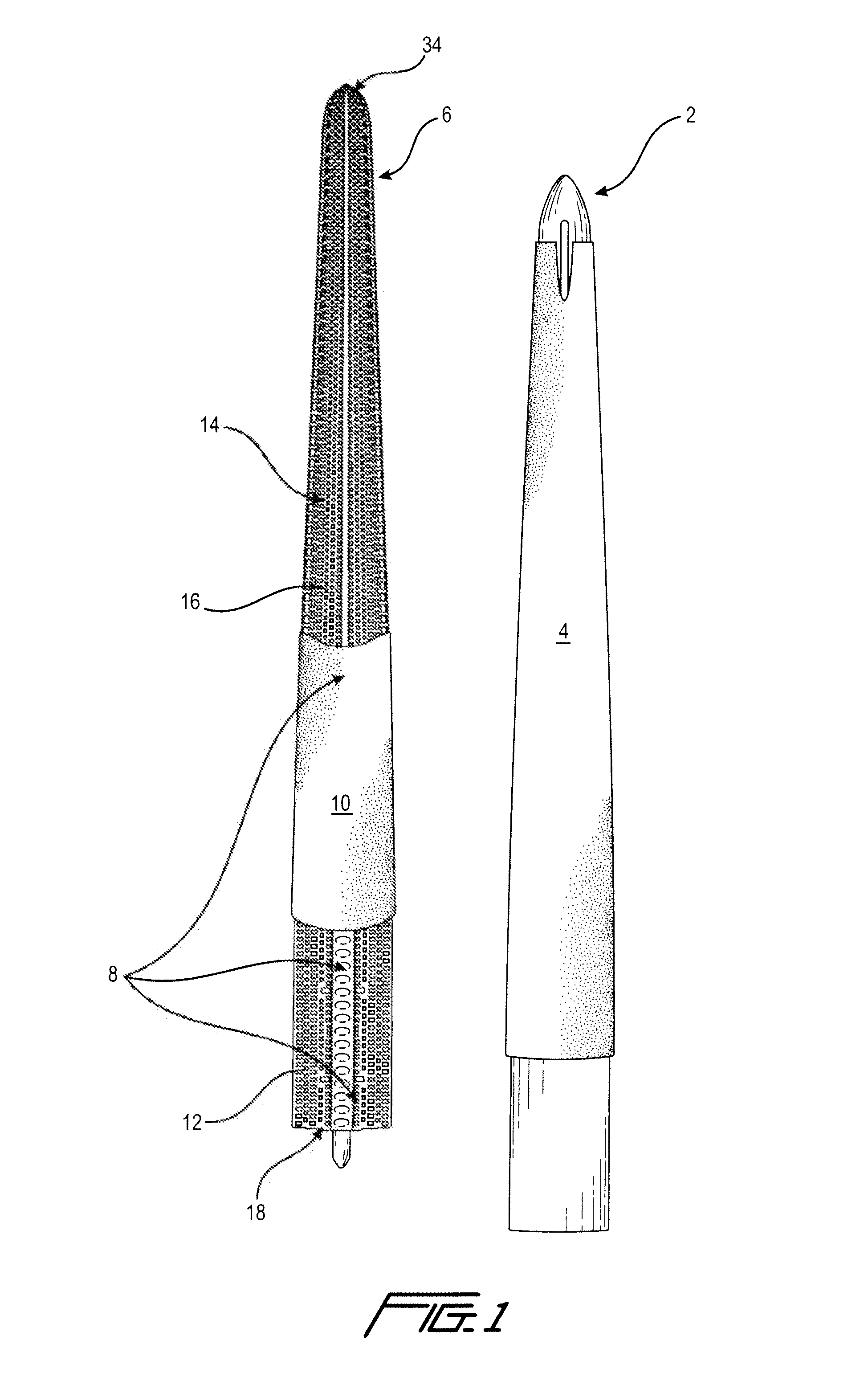

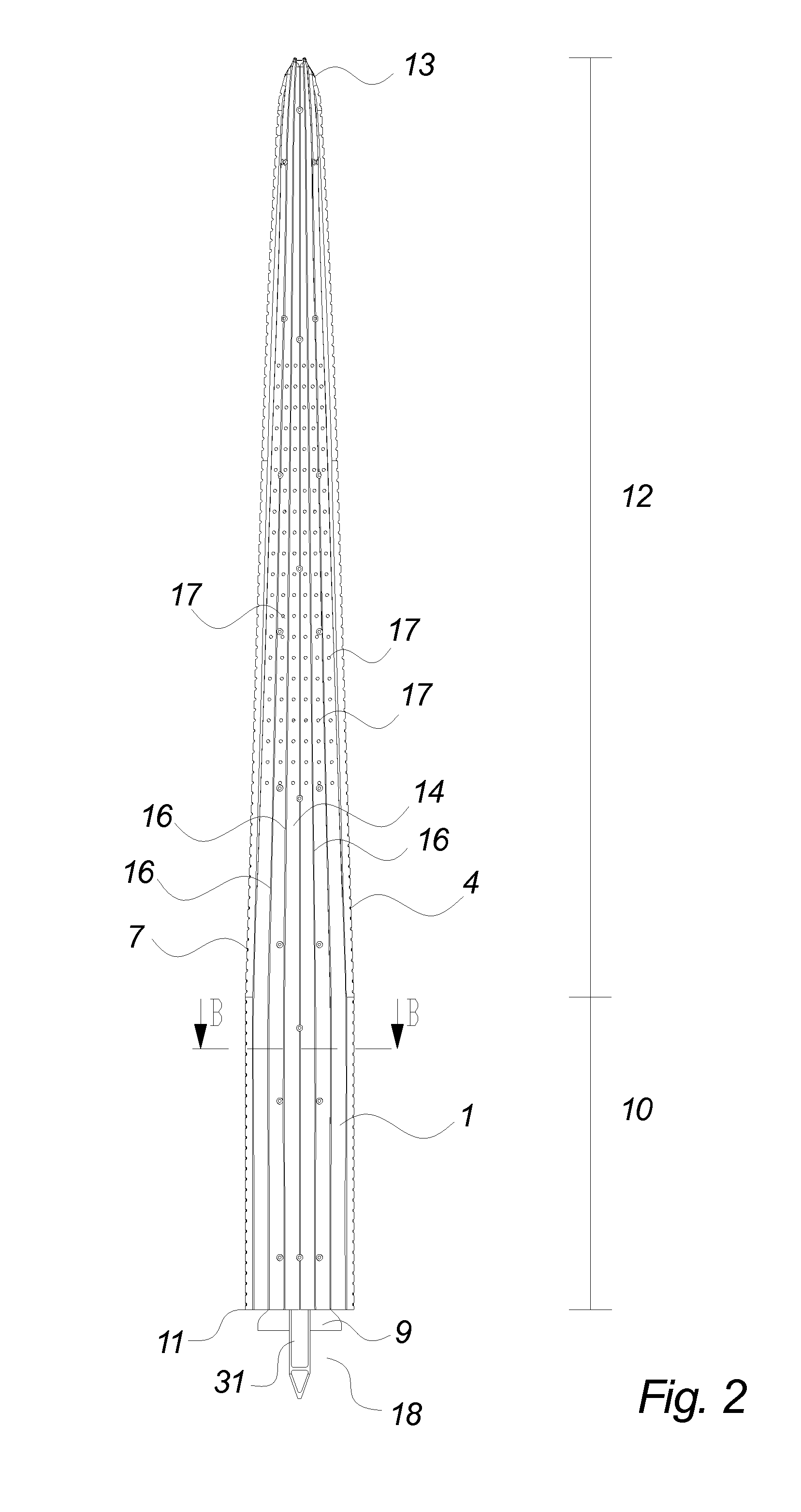

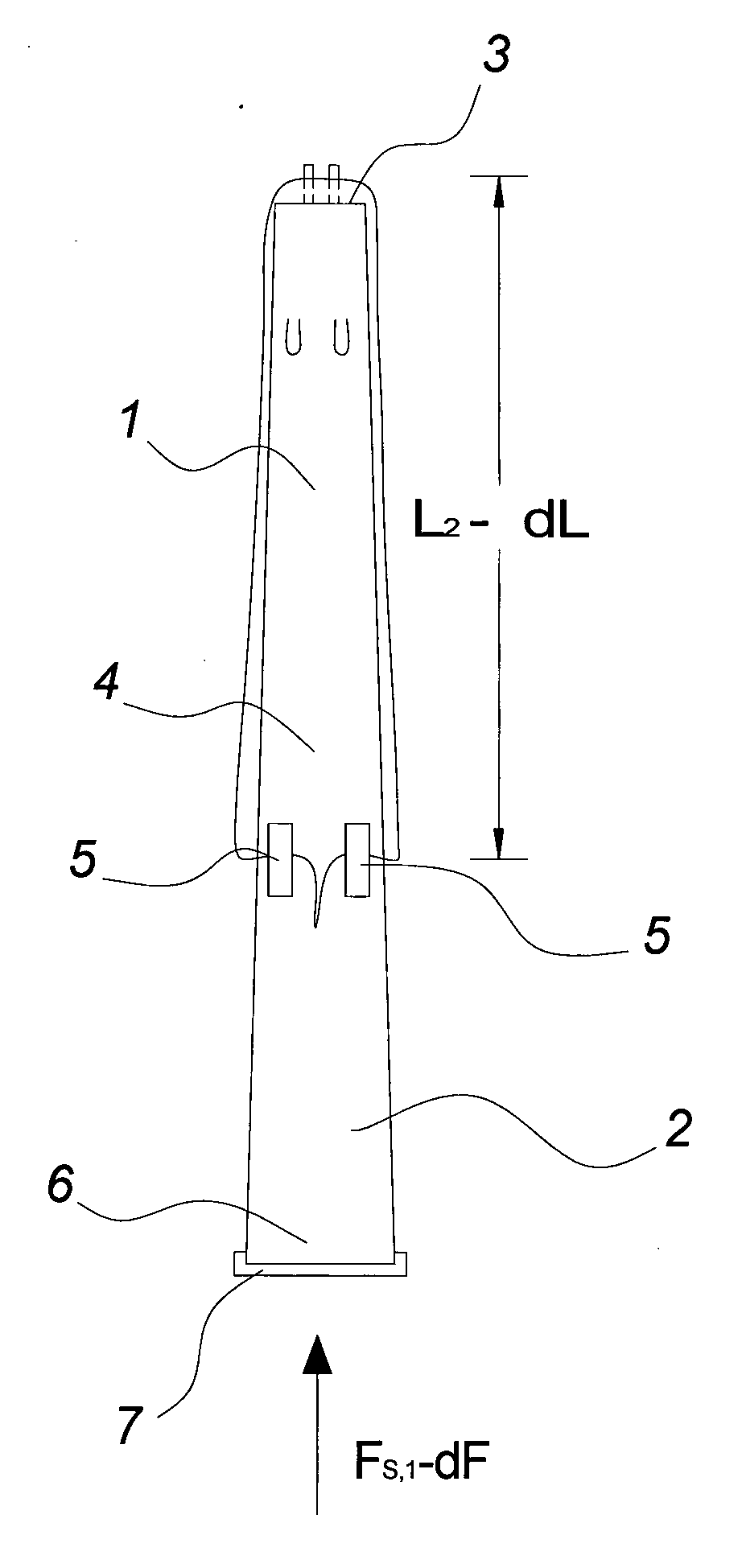

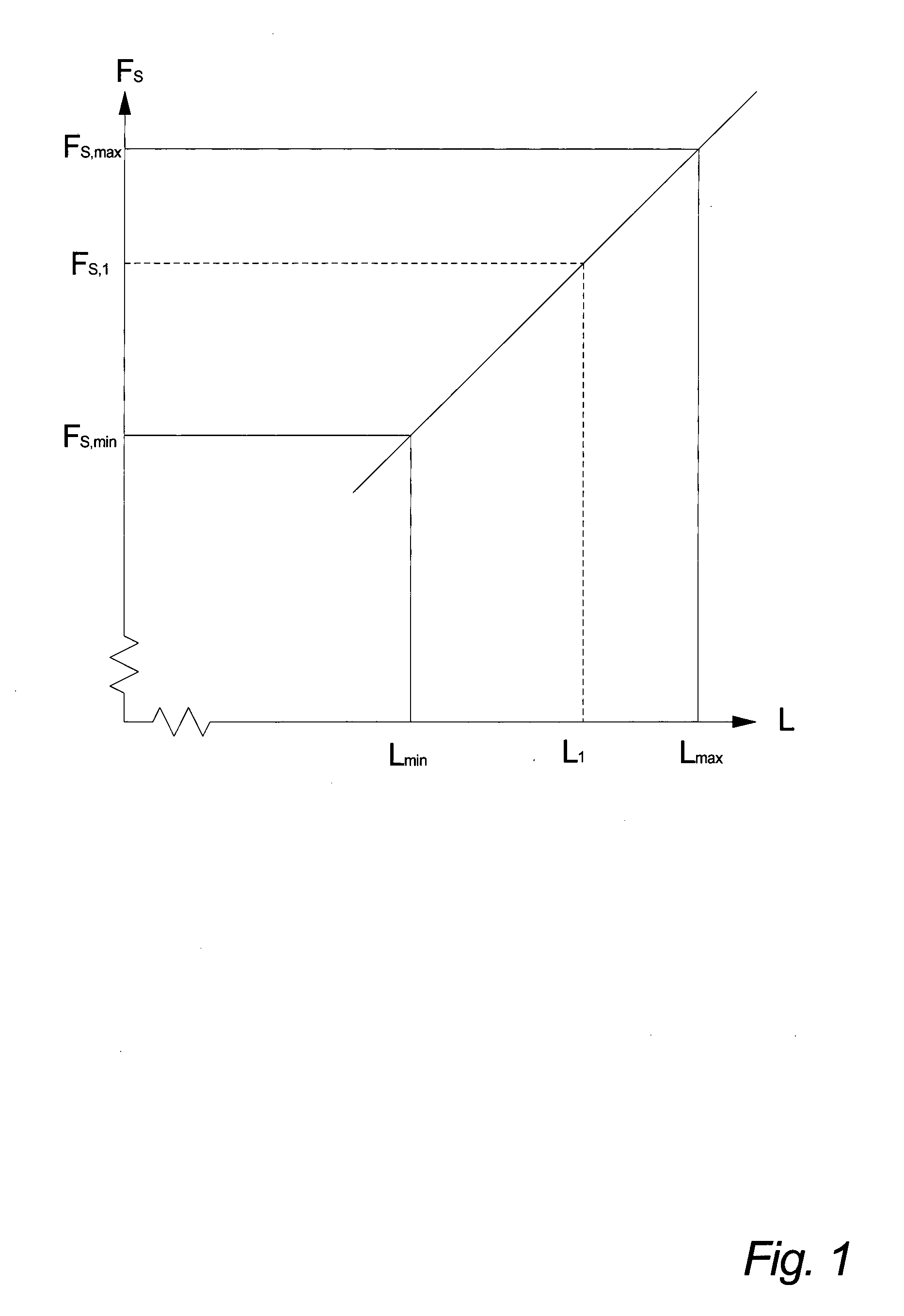

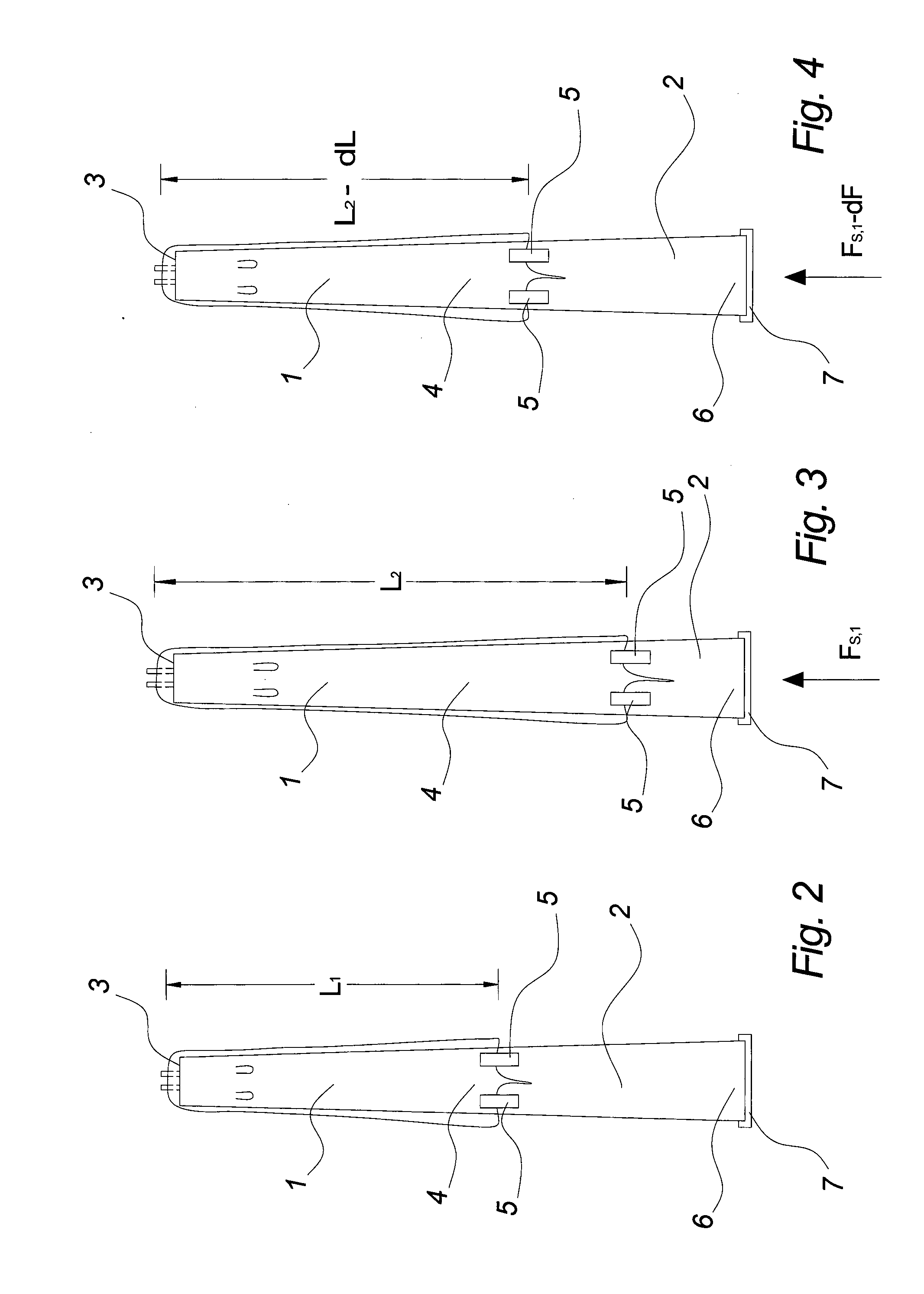

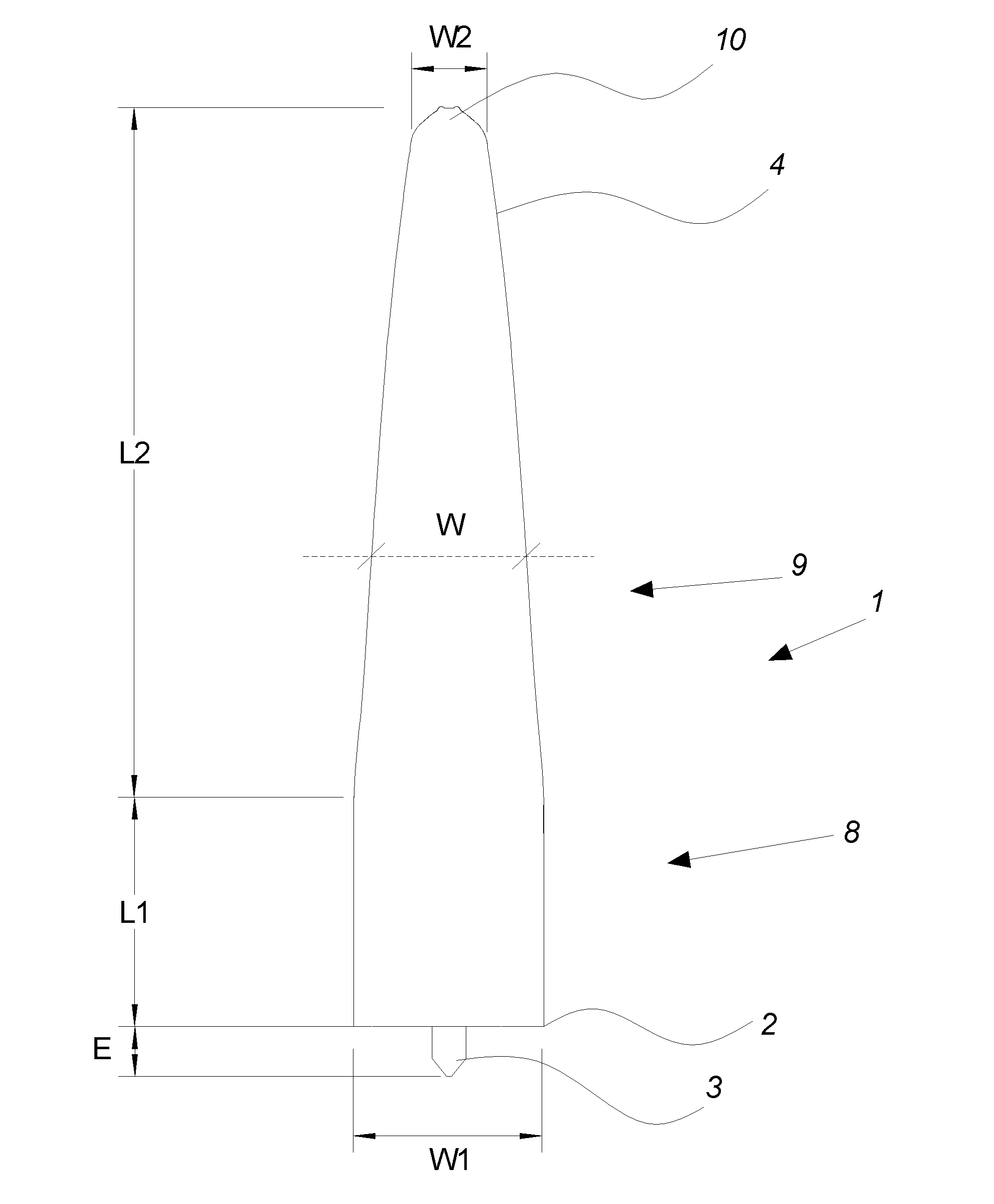

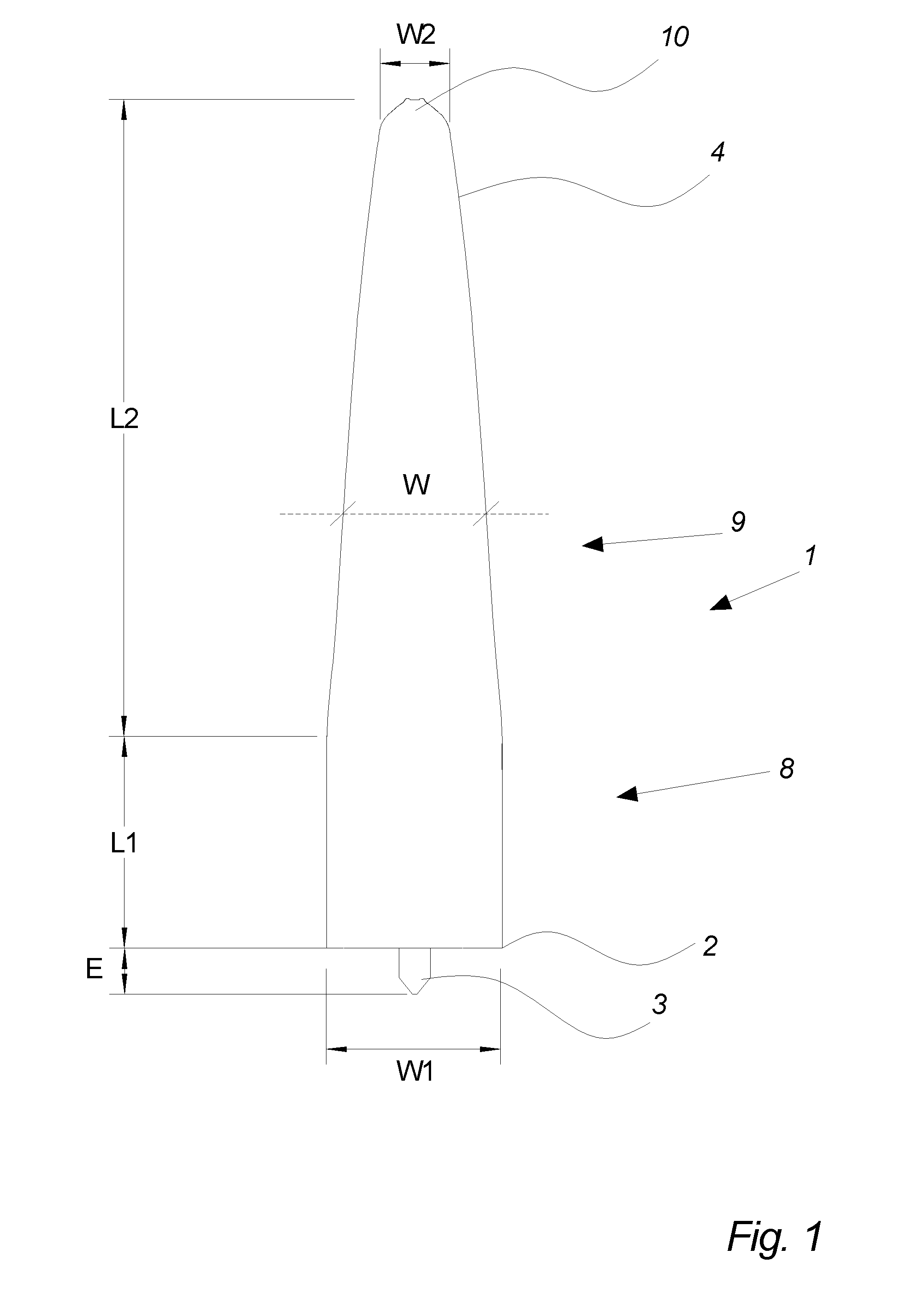

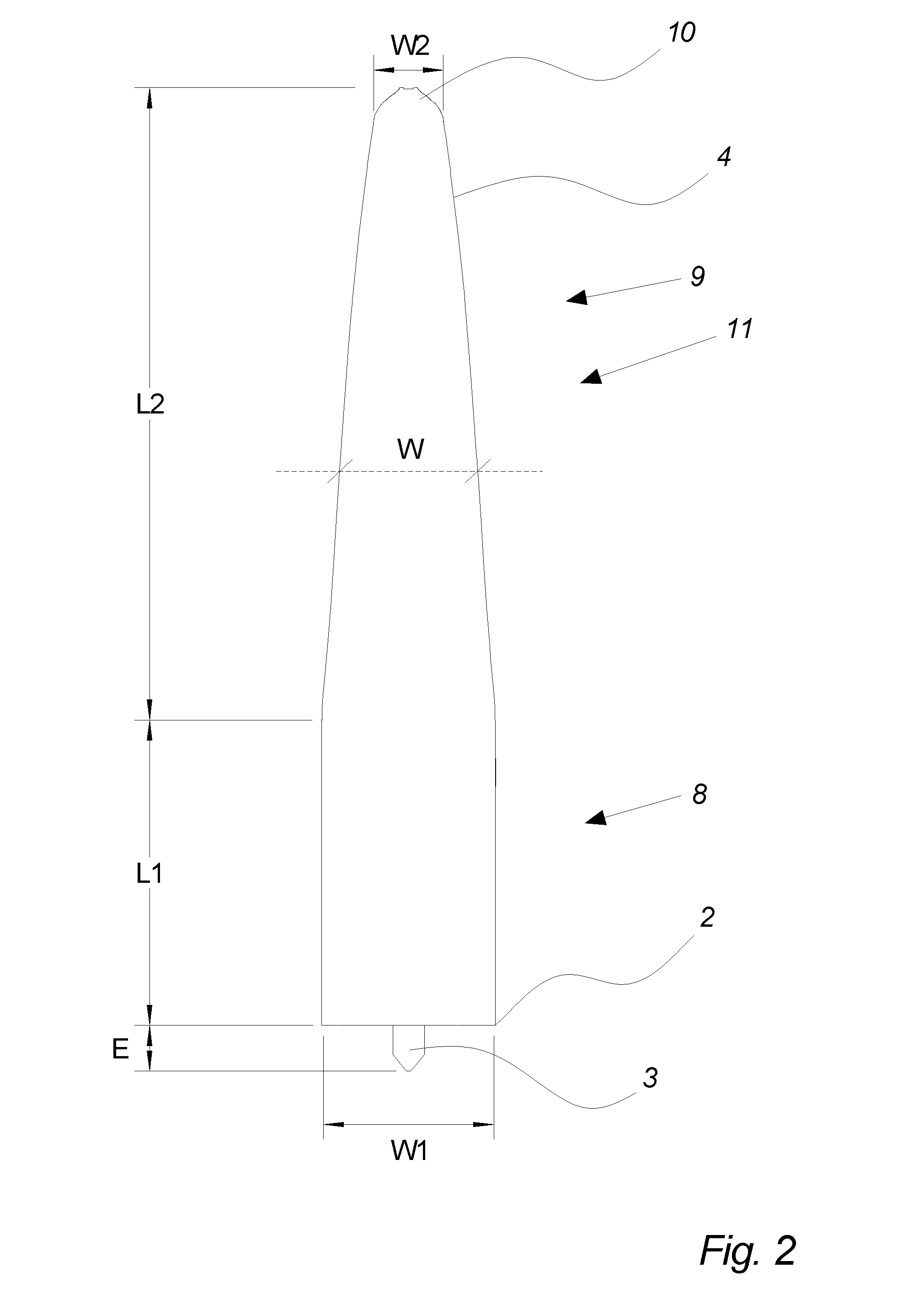

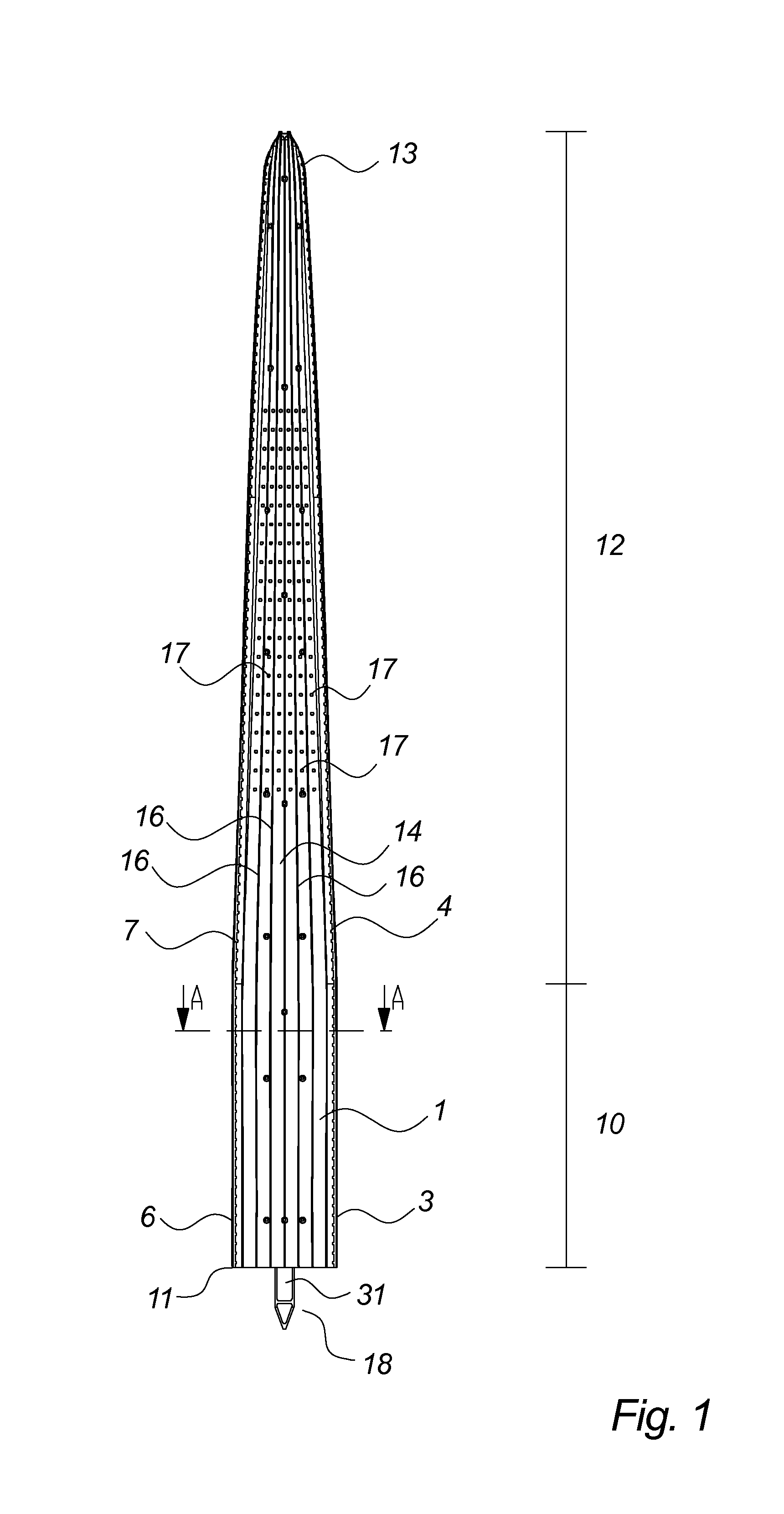

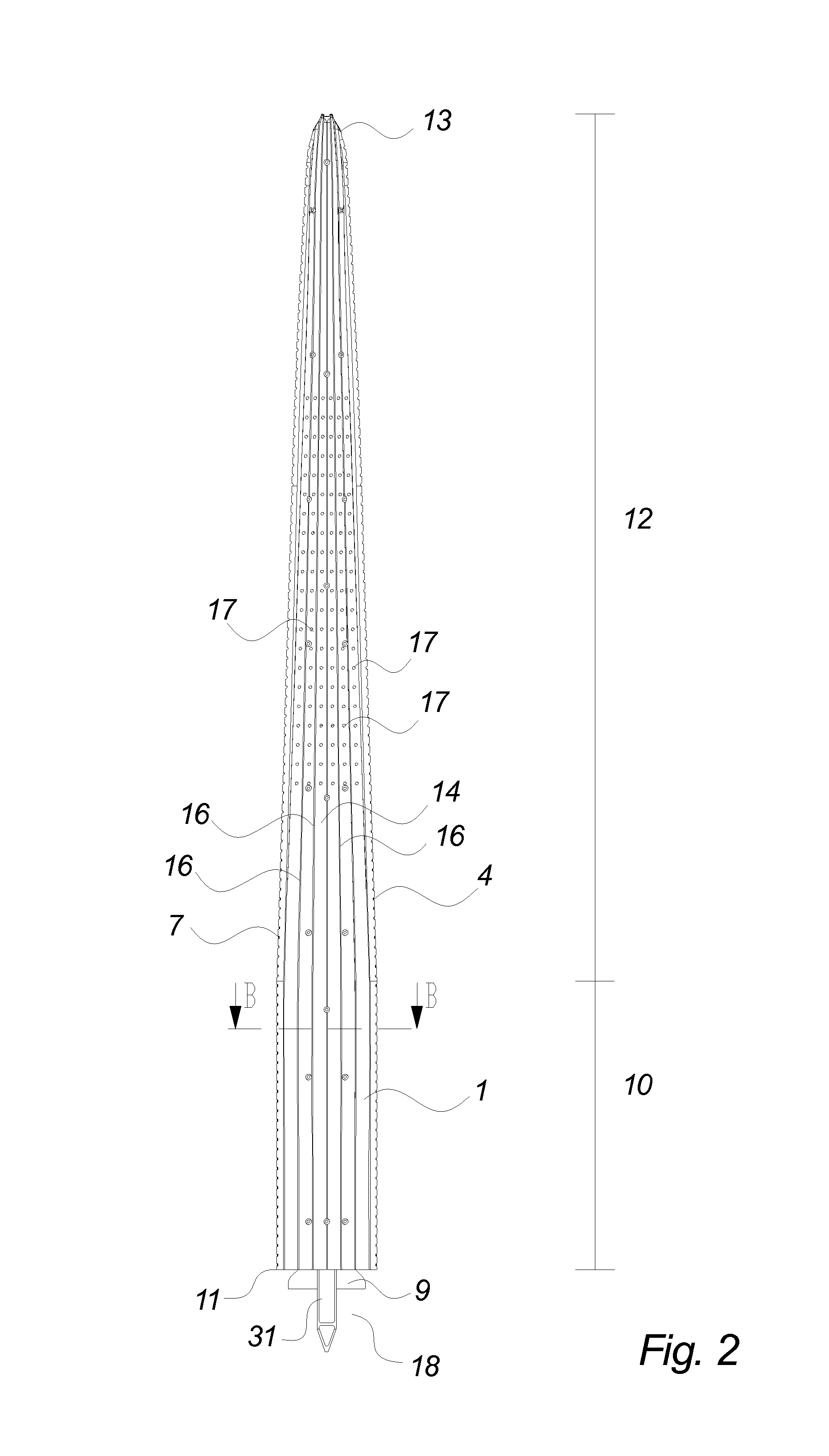

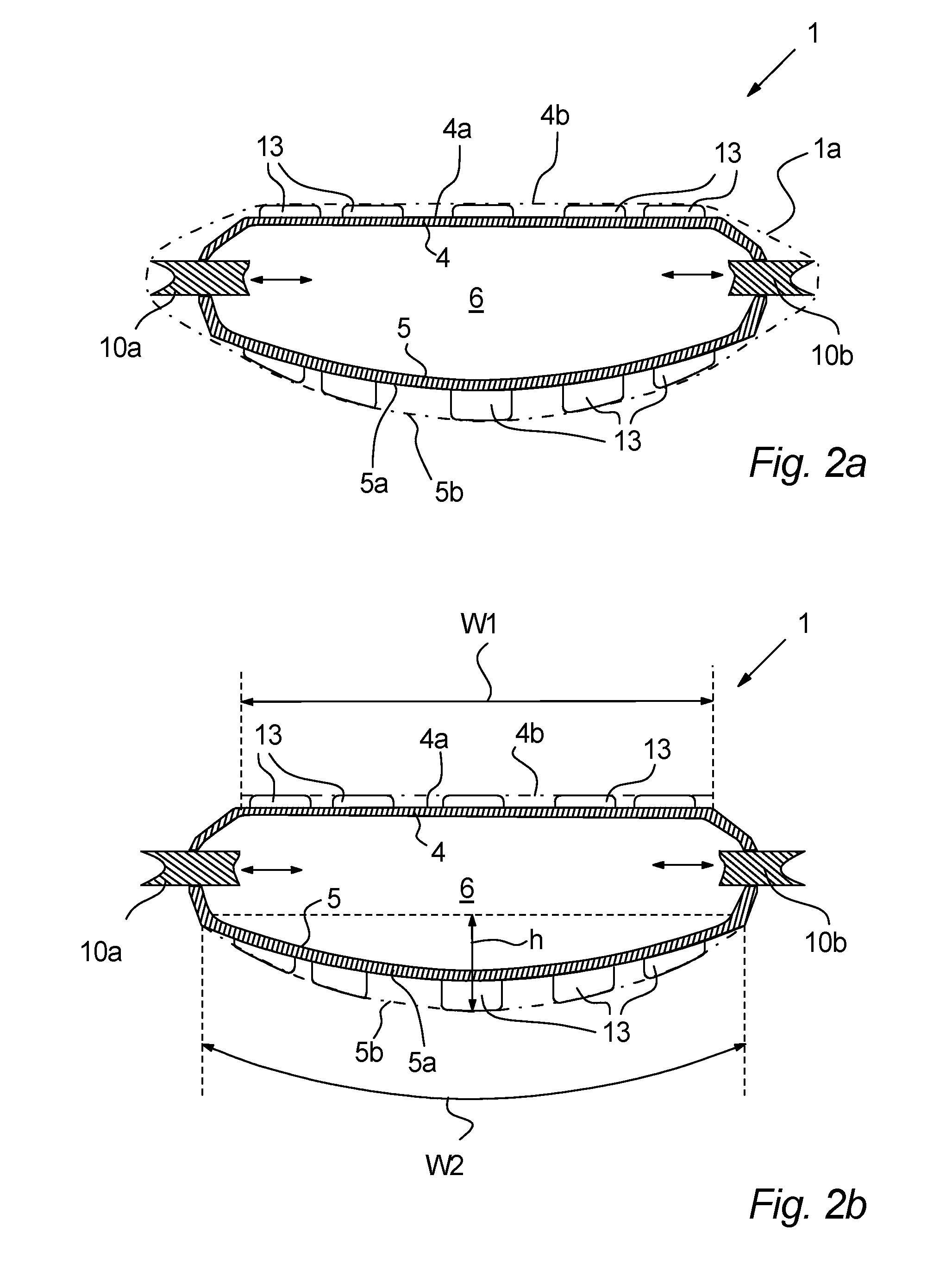

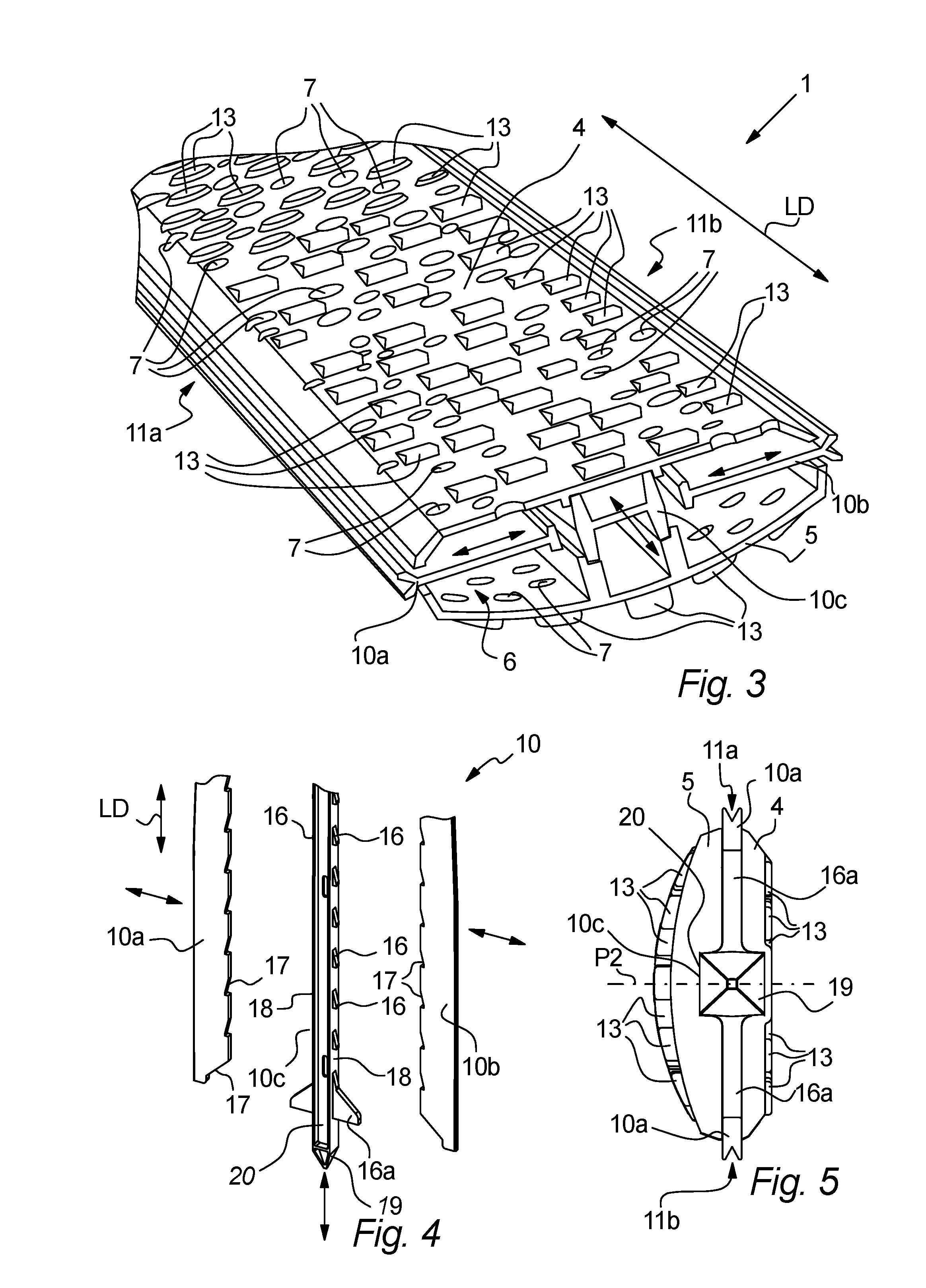

A method, a system and a pelt board for the drying of the leather side of pelts from furred animals, in which the pelt board is a hollow distension element, the surface of which has an open structure. The leather side is dried by changing the air within the distension element. The distension element is lockable in a position in which it has a first circumference, and can also assume a position or be force controlled to a position in which it has a circumference which is smaller than the first, which results in a considerably easier removal of the pelt from the pelt board. A quicker, more uniform and more effective drying of the pelts is achieved, so that “black spots” on the leather side are avoided, and the pelt is fixed in its stretched position on the pelt board without the use of clips / staples.

Owner:MINKPAPIR

Technology for imitating mink fur by using rabbit fur

The invention discloses a technology for imitating mink fur by using rabbit fur and is characterized in that the technology comprises the following steps that: 1) the rabbit fur is tanned by using a routine technique; 2) hairs are sheared, ironed and combed, and treatment such as shaving, carving and the like is conducted; 3) surface finish treatment is conducted; 4) surface waterproof treatment is conducted; 5) leather sheet strength treatment is conducted; 6) mordant dyeing is conducted; 7) coloring treatment is conducted; and 8) imitated mink fur is formed. By using low-level fur such as rabbit fur, beaver rabbit fur and the like, through routine process treatment such as hair shearing, hair ironing, hair combing and the like, then through special process treatment such as hair surface finish treatment, hair surface waterproof performance treatment, leather sheet strength treatment and the like and finally through process treatment such as dyeing, color spraying, printing, carving and the like, the processed rabbit fur and beaver rabbit fur can reach the effect of mink velvet, thereby realizing the effect of turning low-level fur into high-level fur.

Owner:HUASI HLDG CO LTD

Pelt drying assembly comprised of a sleeve/bag of fat and moisture absorbing material and a pelt board

ActiveUS7578153B2Great frictional forceEasy to handleFur dressingLeather stretching/tensioningEngineeringMechanical engineering

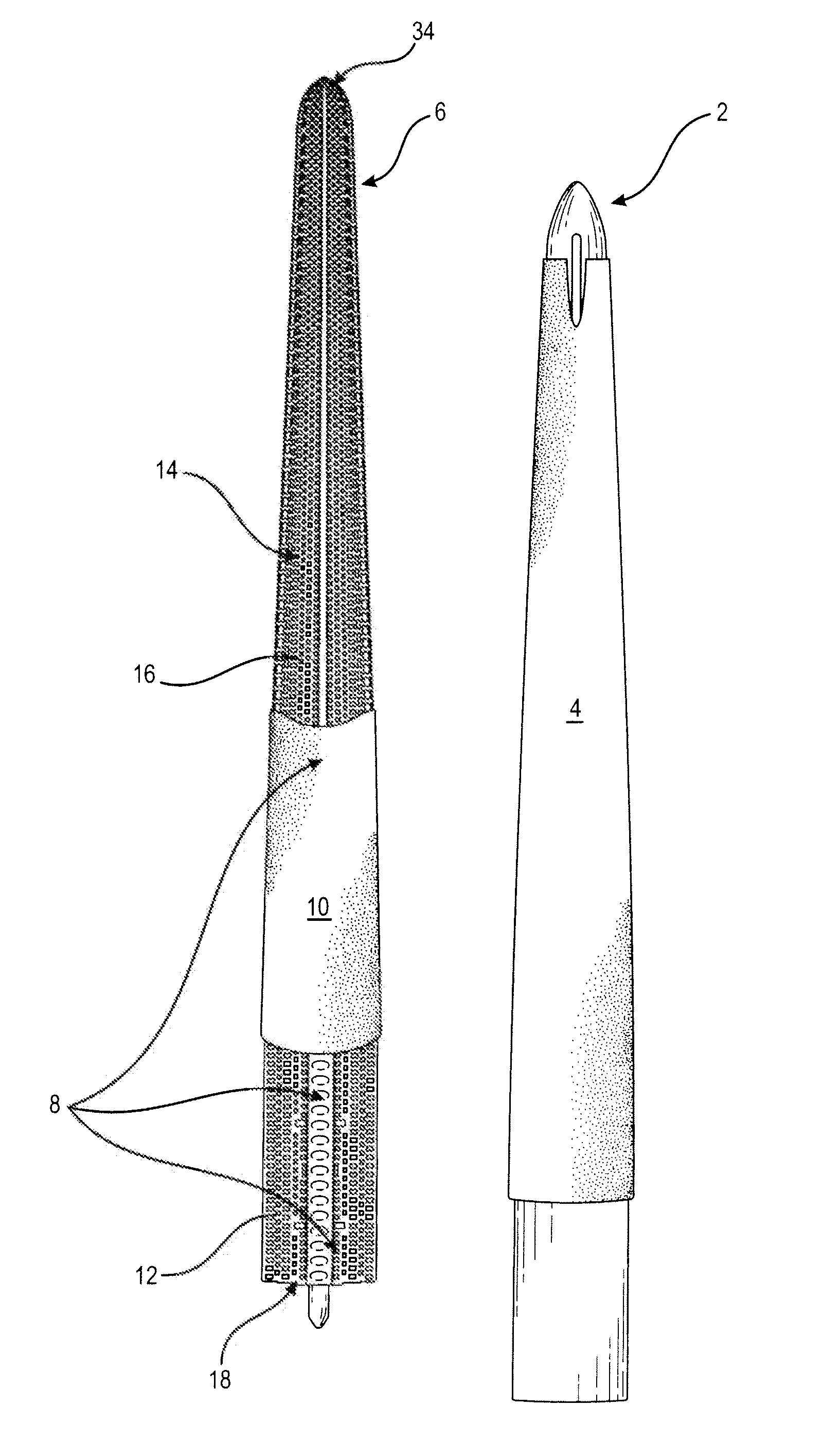

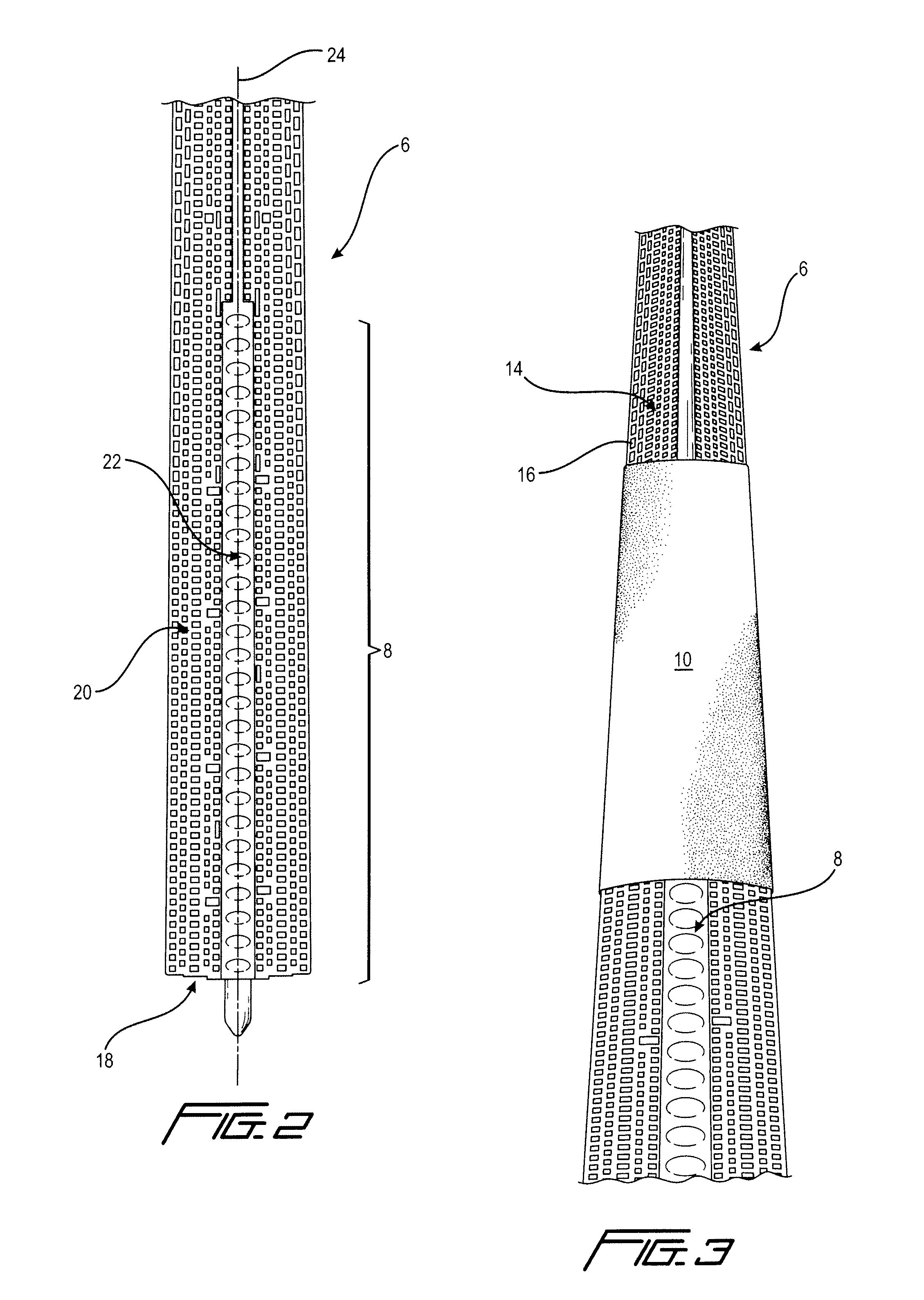

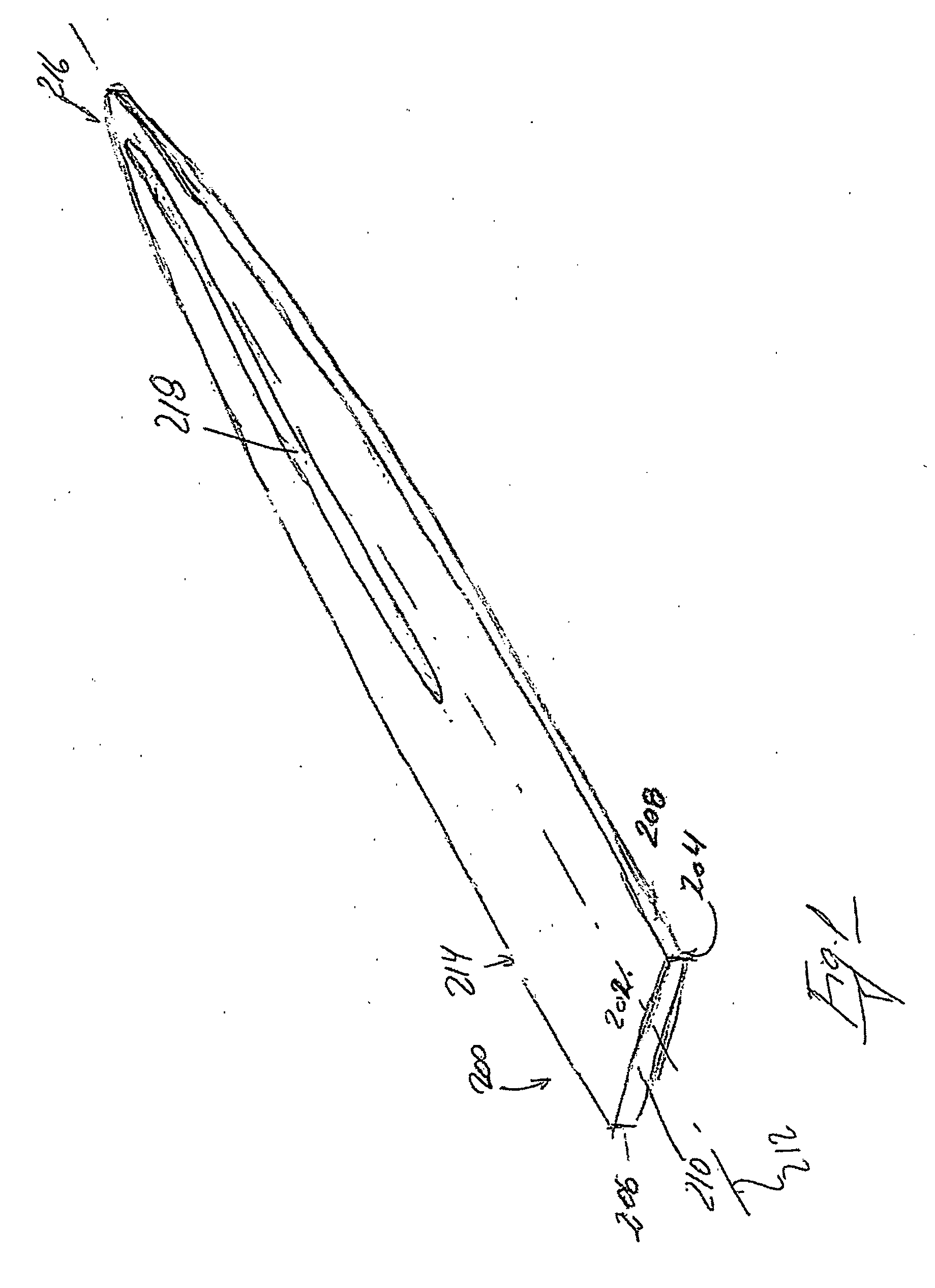

A pelt drying assembly having a pelt board used in the drying of the leather side of a pelt which, in use, is applied to, stretched and secured on the distension element in the stretched position during drying, and a sleeve / bag made of fat and moisture absorbing material for covering the pelt secured in the stretched position by having been drawn over the fur side of the pelt so as to press the pelt against a holding area of the distension element. The sleeve / bag is tubular for drawing onto the pelt board from a pointed end thereof until it covers at least a part of the holding area on the distension element, and has a length equal to at least 1 / 3, preferably 1 / 2, of the length of the holding area of the distension element.

Owner:MINKPAPIR

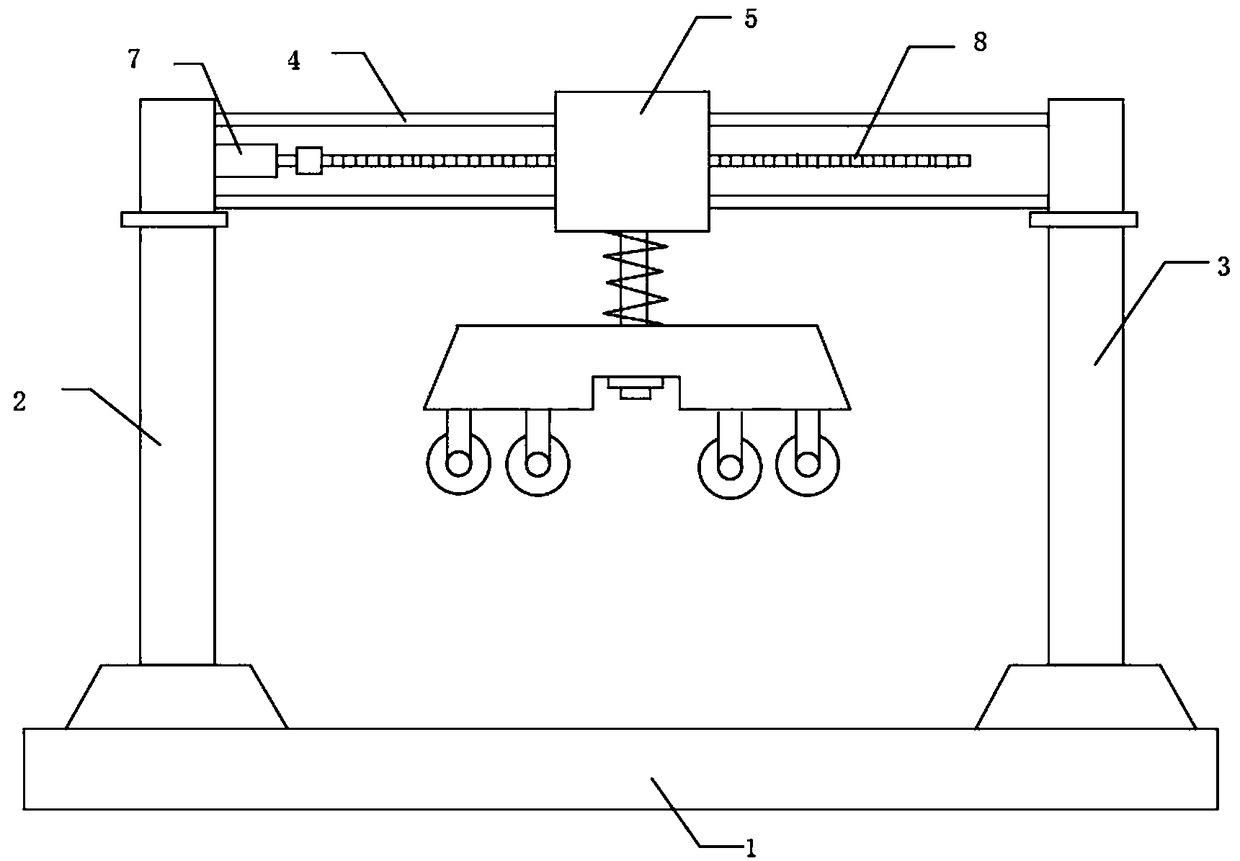

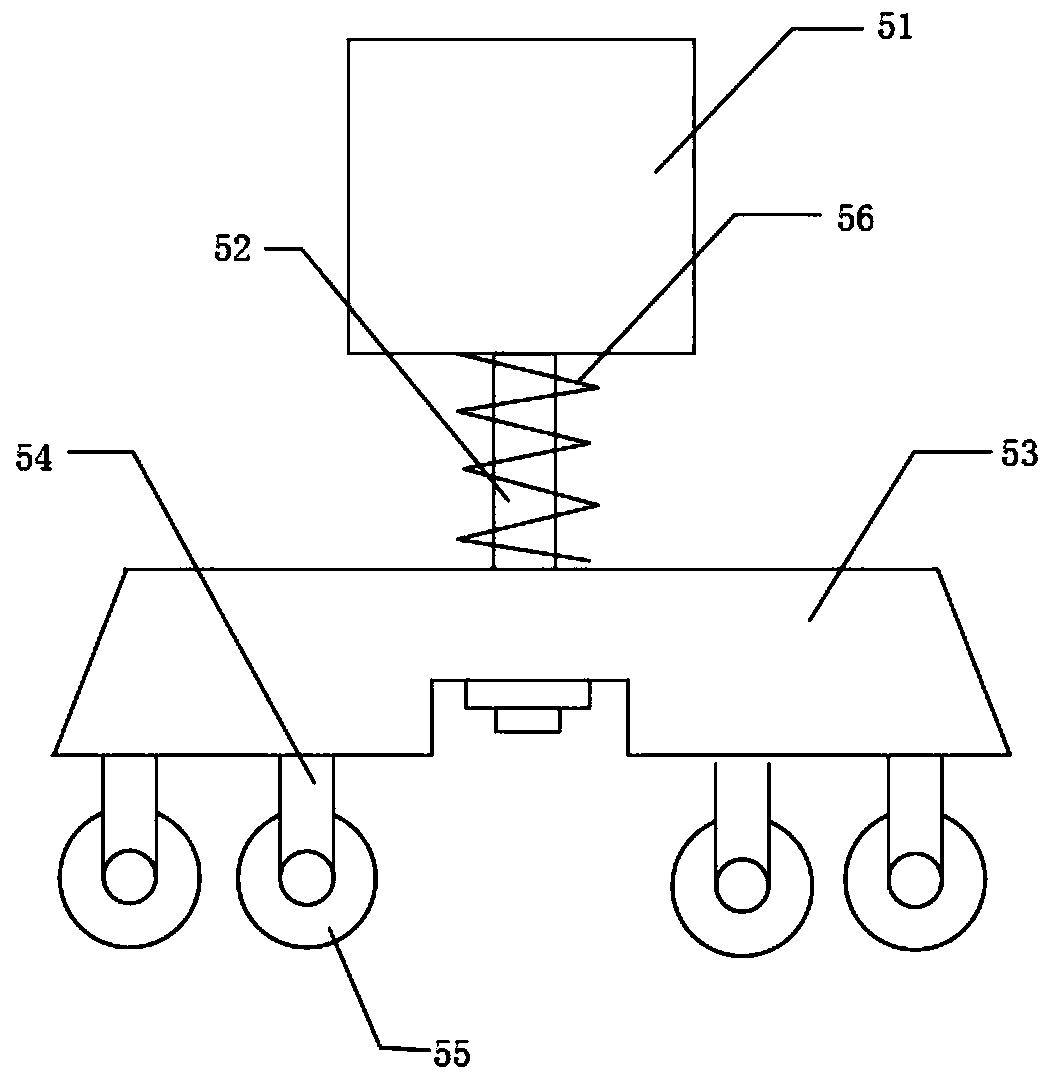

Automatic oil edge production line

ActiveCN105936949AImprove work efficiencyEasy to grabFur dressingSkins/hides/leather/fur manufacturing apparatusProduction lineRobot hand

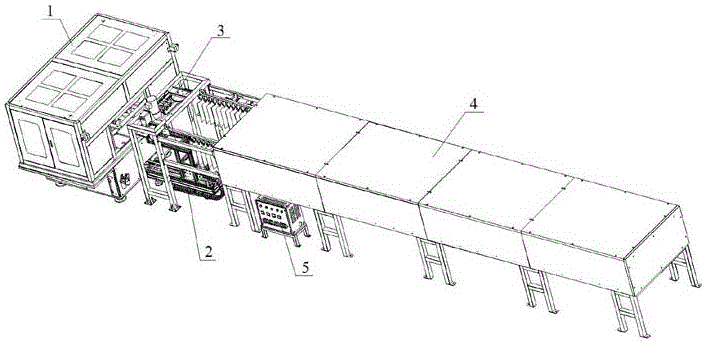

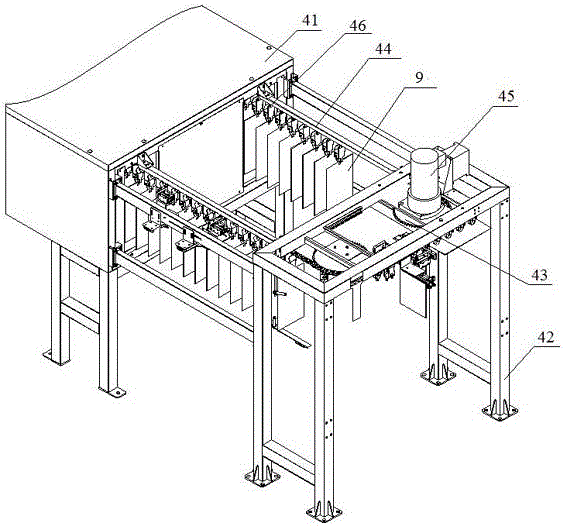

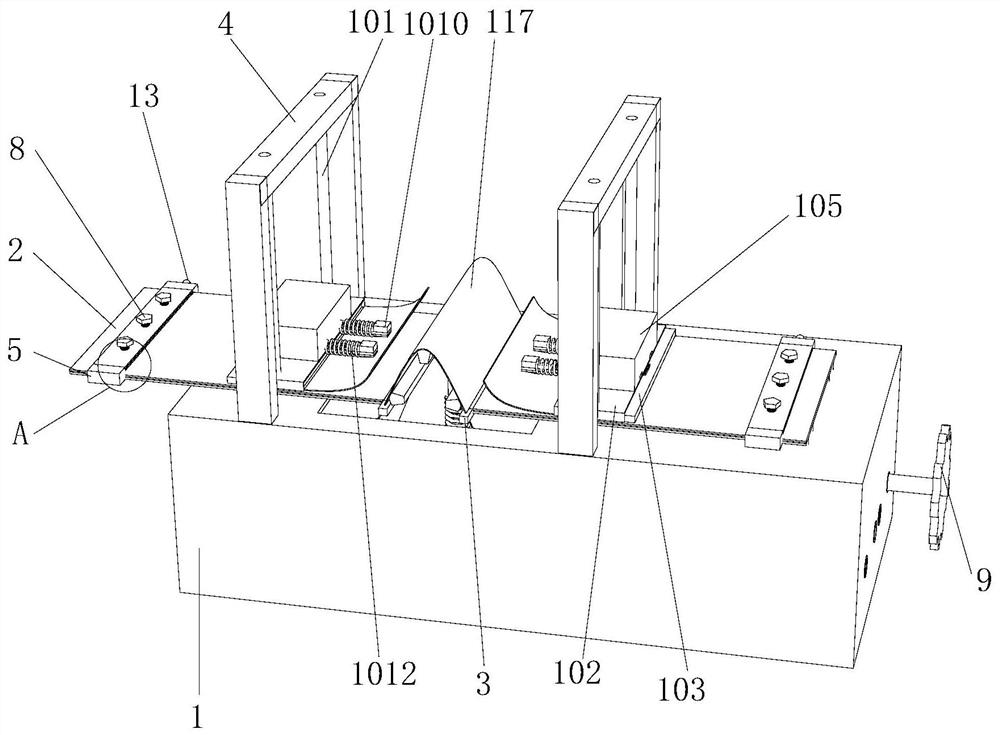

The invention discloses an automatic oil edge production line which comprises a control mechanism, an oil edge machine, a material hanging mechanism and a drying mechanism. The oil edge machine, a material hanging mechanism and a drying mechanism are sequentially connected. A clamping mechanism and a discharging mechanism are arranged on the connecting portion between the drying mechanism and the material hanging mechanism. The oil edge machine comprises a feeding mechanism, a shaping mechanism, an oil edge mechanism and a rotary mechanical arm. The rotary mechanical arm is of a four-station structure arranged in a cross mode. The feeding mechanism, the shaping mechanism, the oil edge mechanism and a material receiving end of the material hanging mechanism are arranged under the four stations of the rotary mechanical arm in the rotating direction of the rotary mechanical arm respectively. The control mechanism is connected with the controlled end of the rotary mechanical arm, the controlled end of the feeding mechanism, the controlled end of the shaping mechanism, the controlled end of the oil edge mechanism, the controlled end of the material hanging mechanism, the controlled end of the clamping mechanism, the controlled end of the drying mechanism and the controlled end of the discharging mechanism. Under control of the control mechanism, all the mechanisms are coordinated to cooperate to work, the whole oil edge operation is finished automatically under the circumstance without manual interference, and the working efficiency is improved greatly.

Owner:张志军

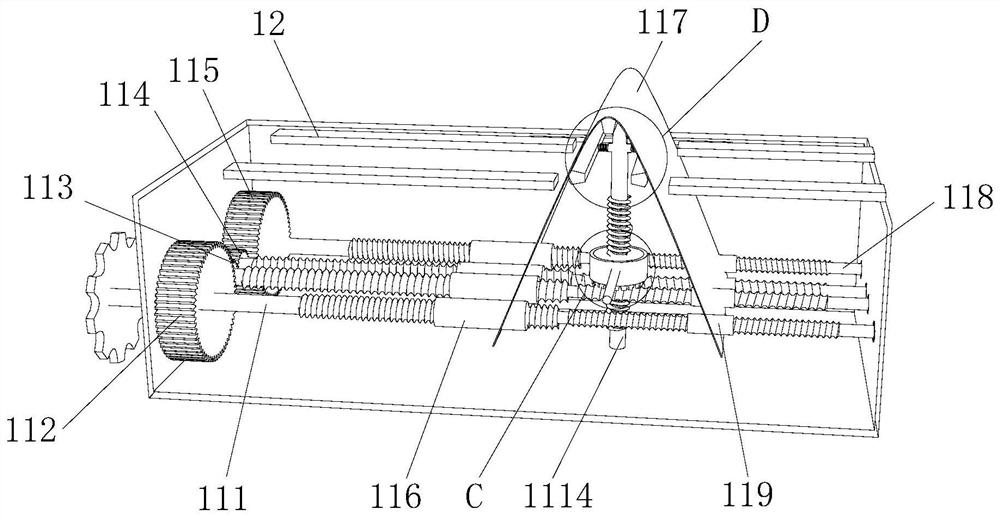

Automatic oil edge machine and positioning device thereof

ActiveCN105923390AAccurateAgileFur dressingSkins/hides/leather/fur manufacturing apparatusPulp and paper industryPositioning system

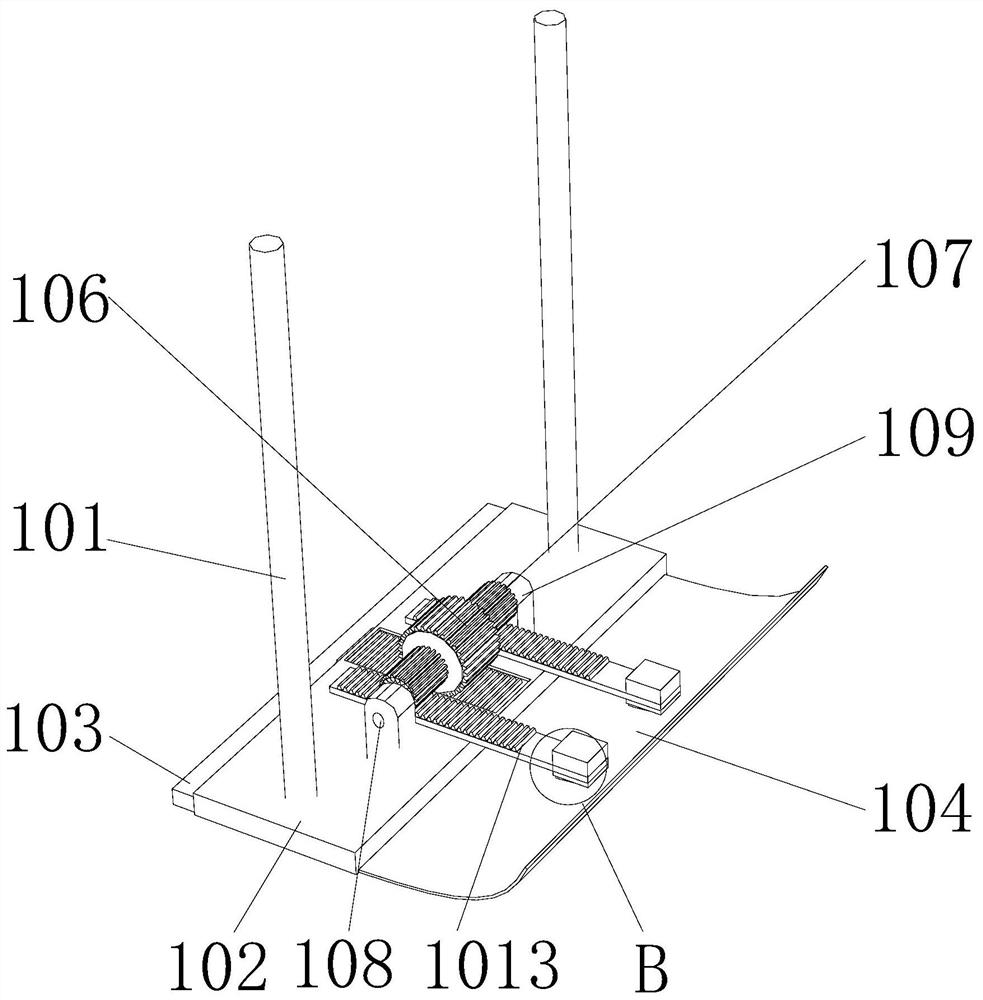

The invention belongs to the technical field of automatic oil edge machines, in particular to a positioning device of an automatic oil edge machine. The positioning device comprises a frame, a positioning plate and a template; the frame includes a stand; the stand is fixedly provided with a lifting cylinder; the template is molded with a mold hole corresponding to an oil edge material in shape; the template is detachably connected to the lifting cylinder; the positioning plate is provided with a sucking nozzle capable of absorbing the oil edge material; a steering cylinder is arranged on the frame; and the positioning plate is connected to the steering cylinder through a main shaft. The positioning device is simple in structure, convenient and safe in operation, relatively lower in manufacturing cost and capable of precisely positioning and loading, improves the oiling working efficiency of the oil edge machine, and saves the time.

Owner:台州市惠联机械有限公司

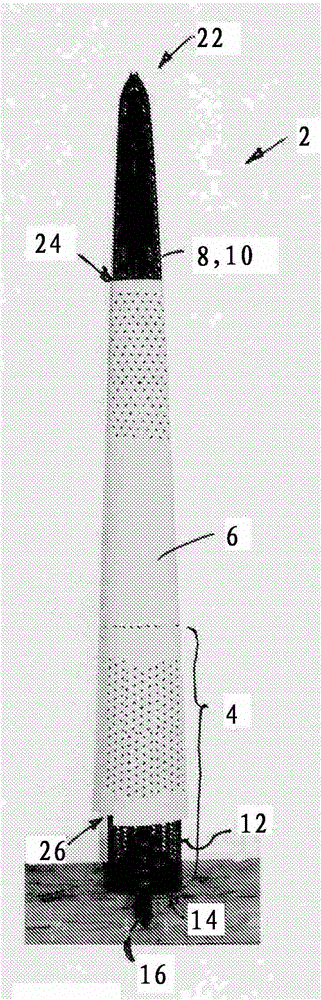

Sleeve/bag item of fat and moisture absorbing material for pelt boards

InactiveCN1977054AIncrease frictionThe problem of sucking out moisture is avoidedFur dressingLeather stretching/tensioningEngineeringAbsorbent material

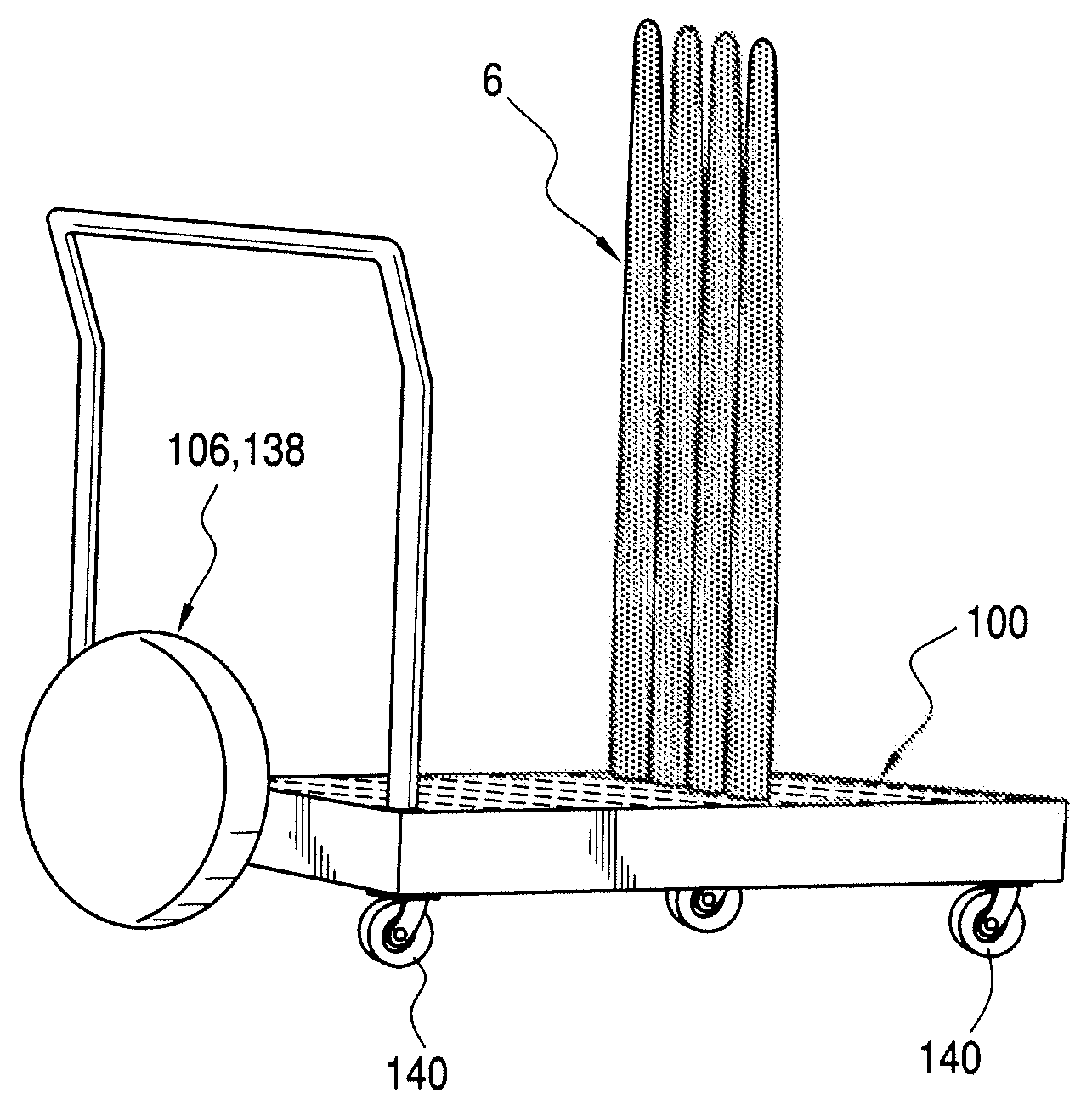

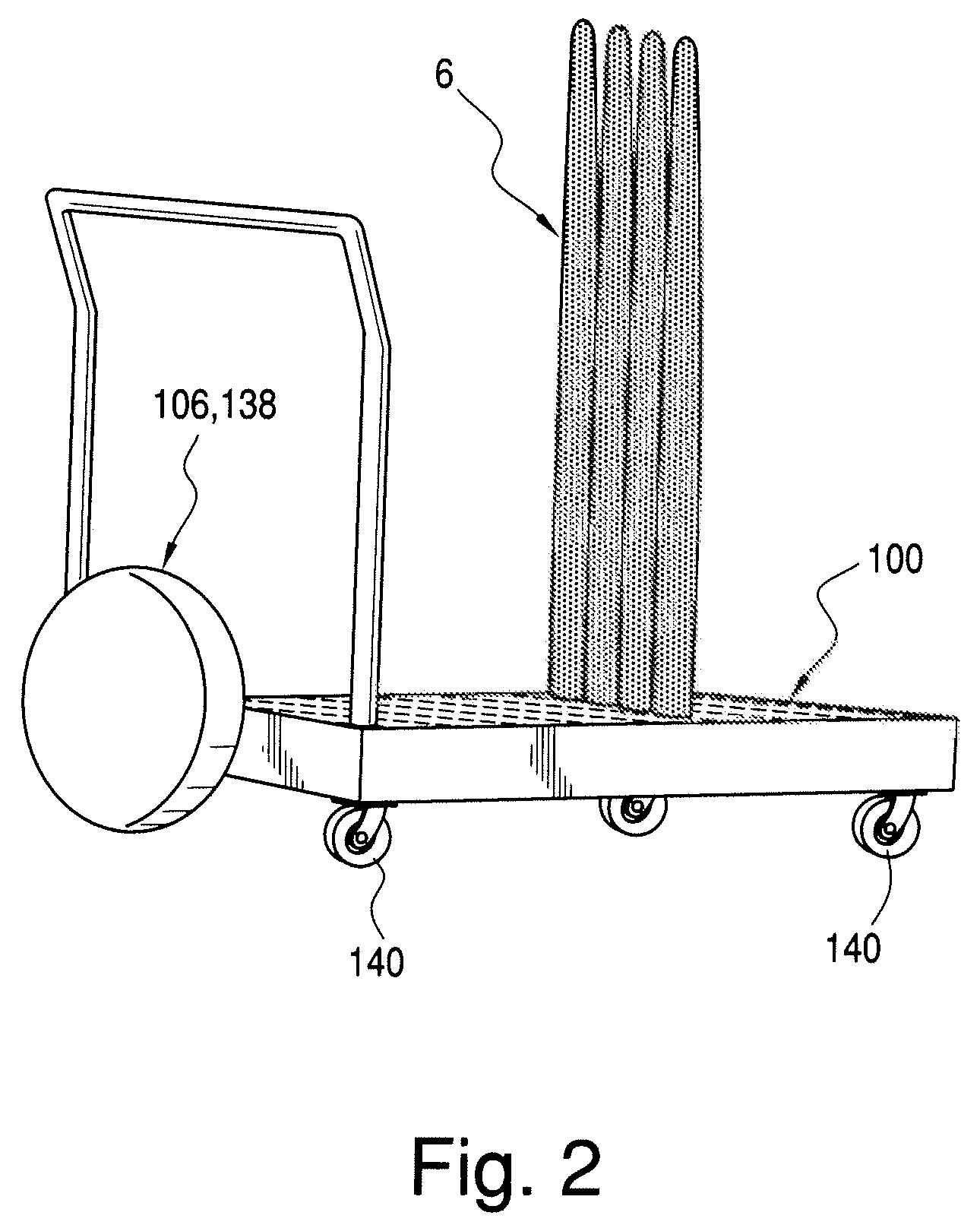

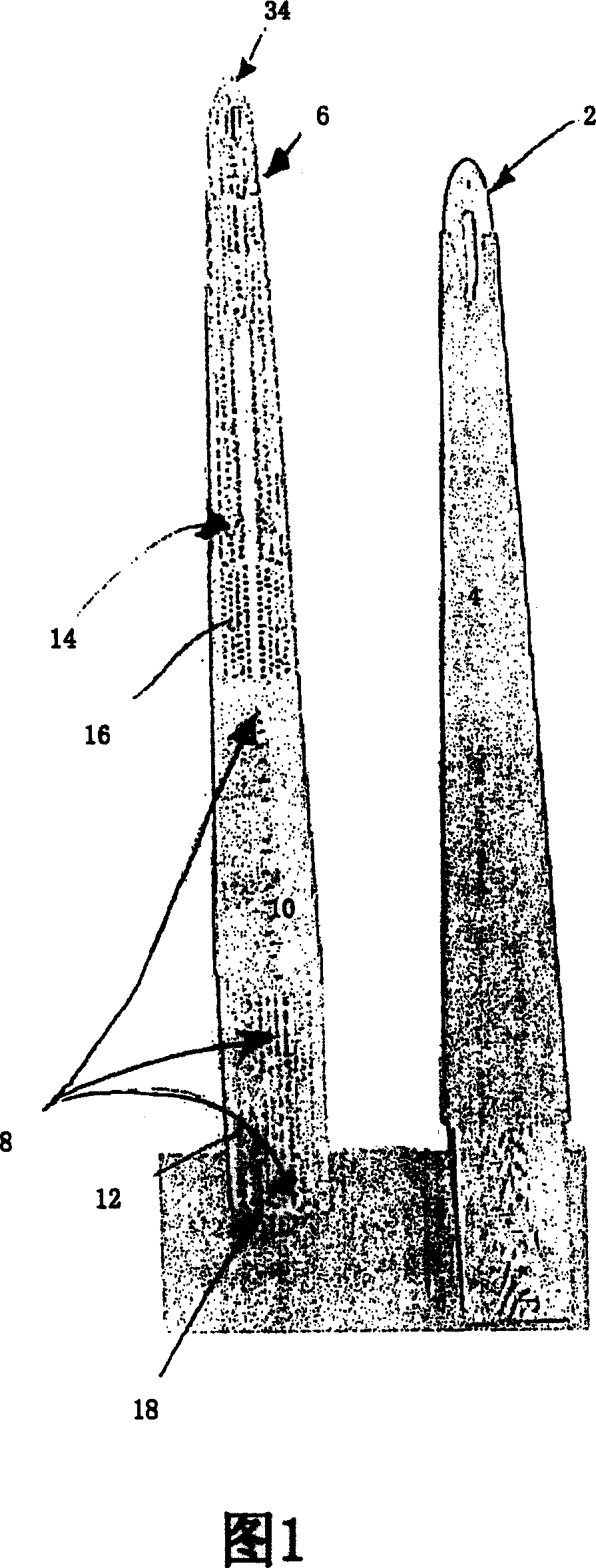

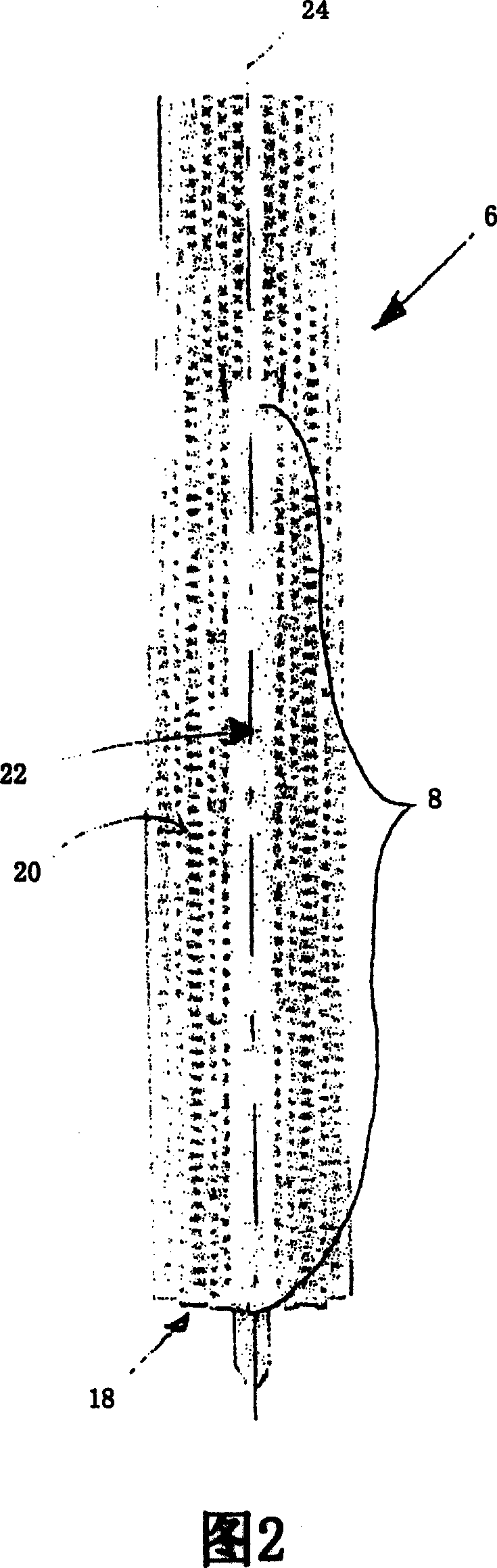

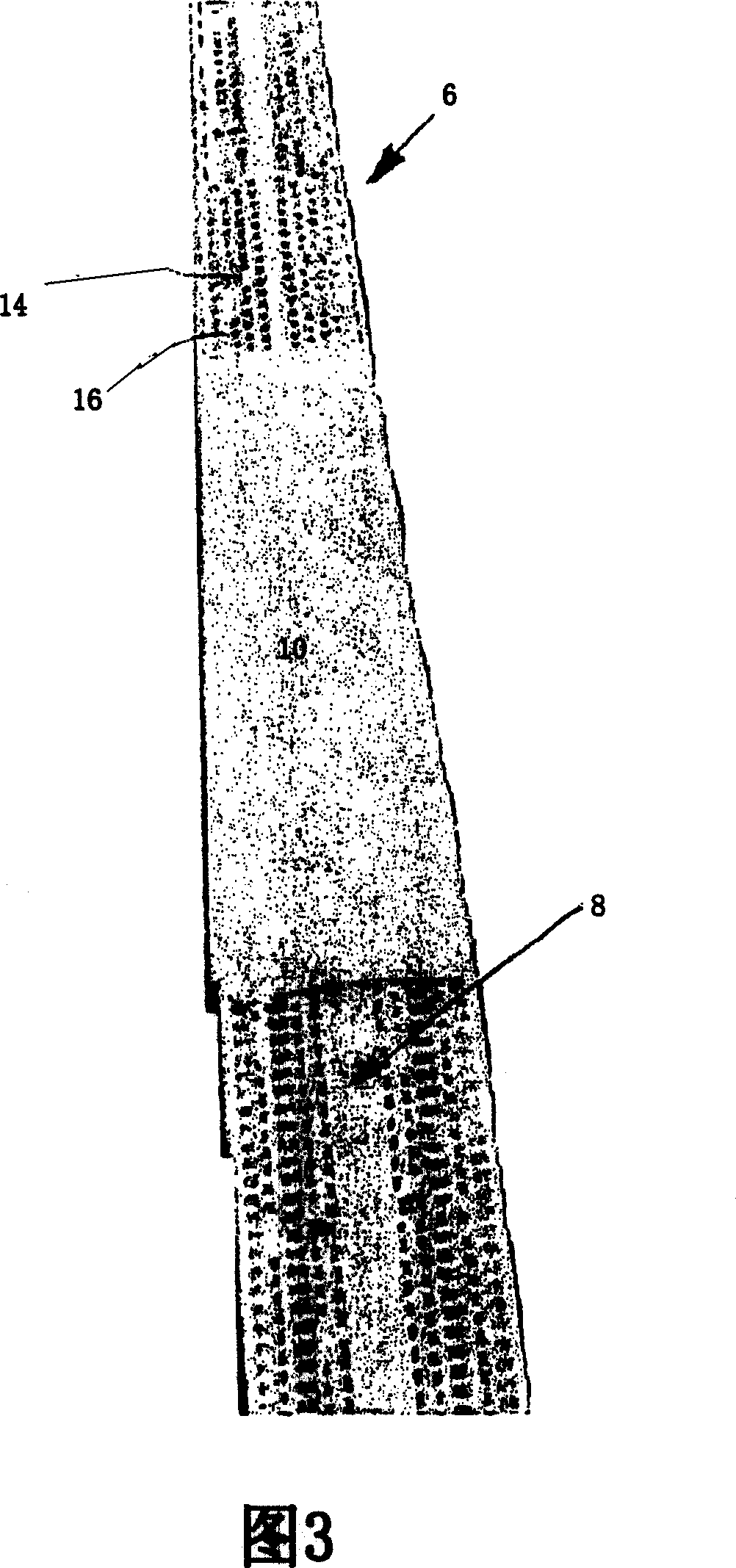

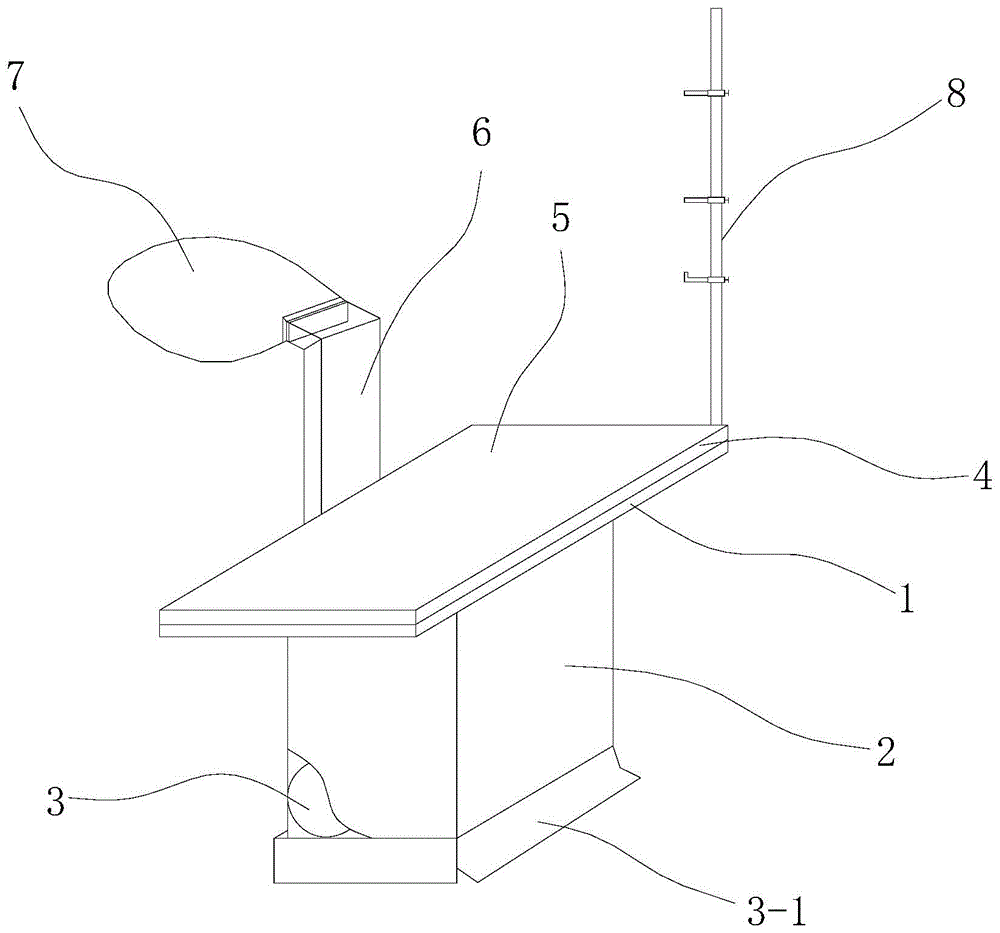

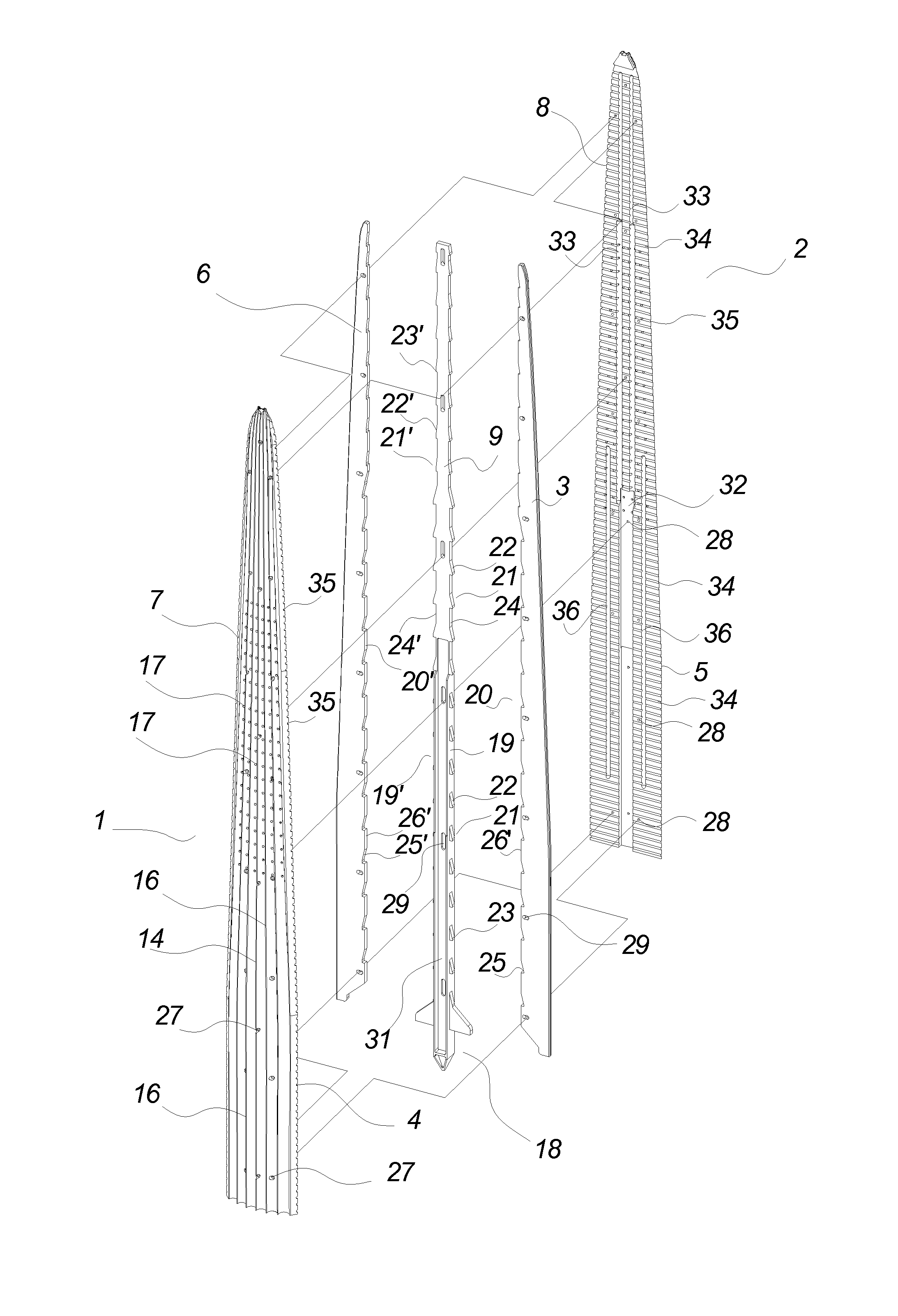

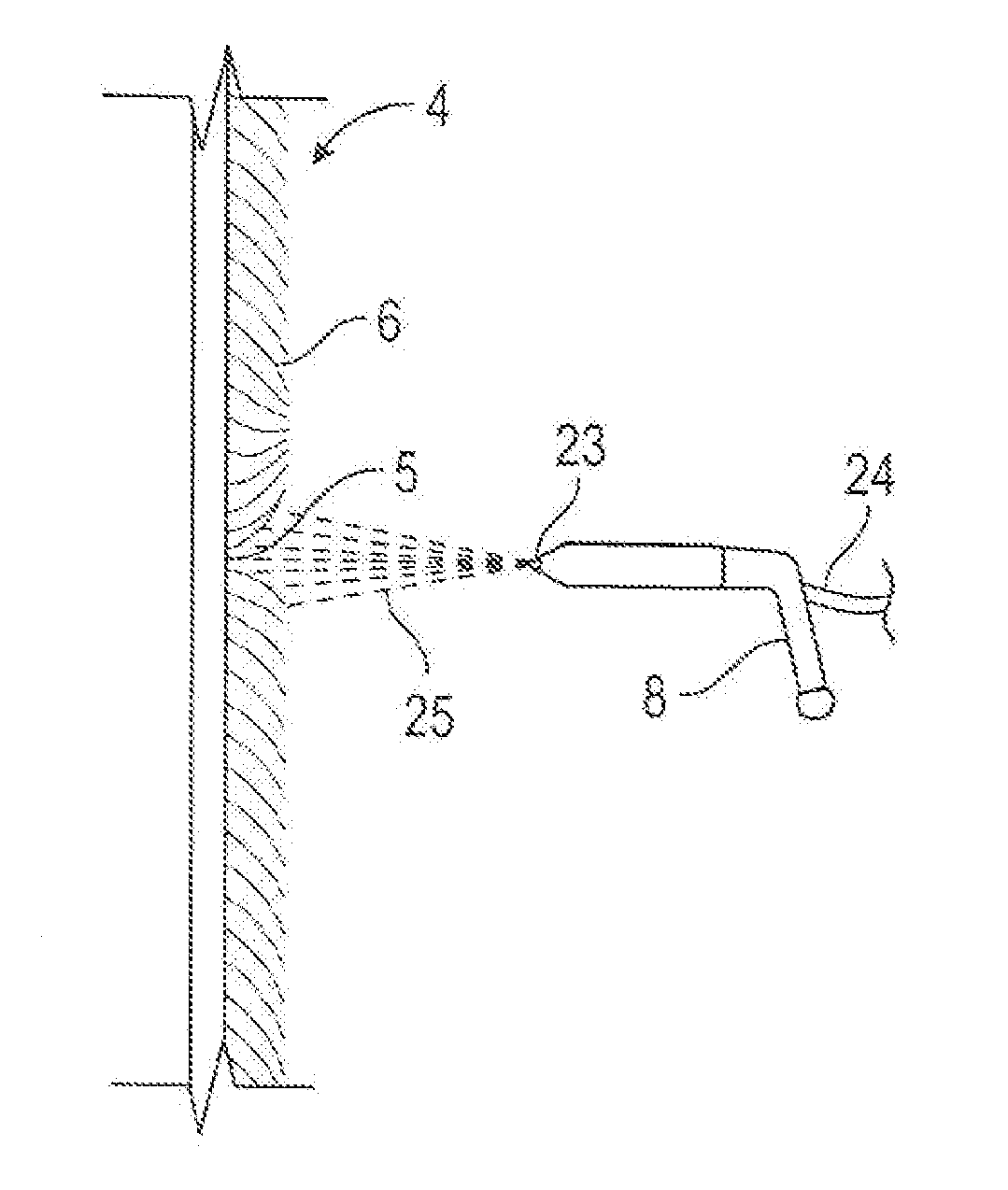

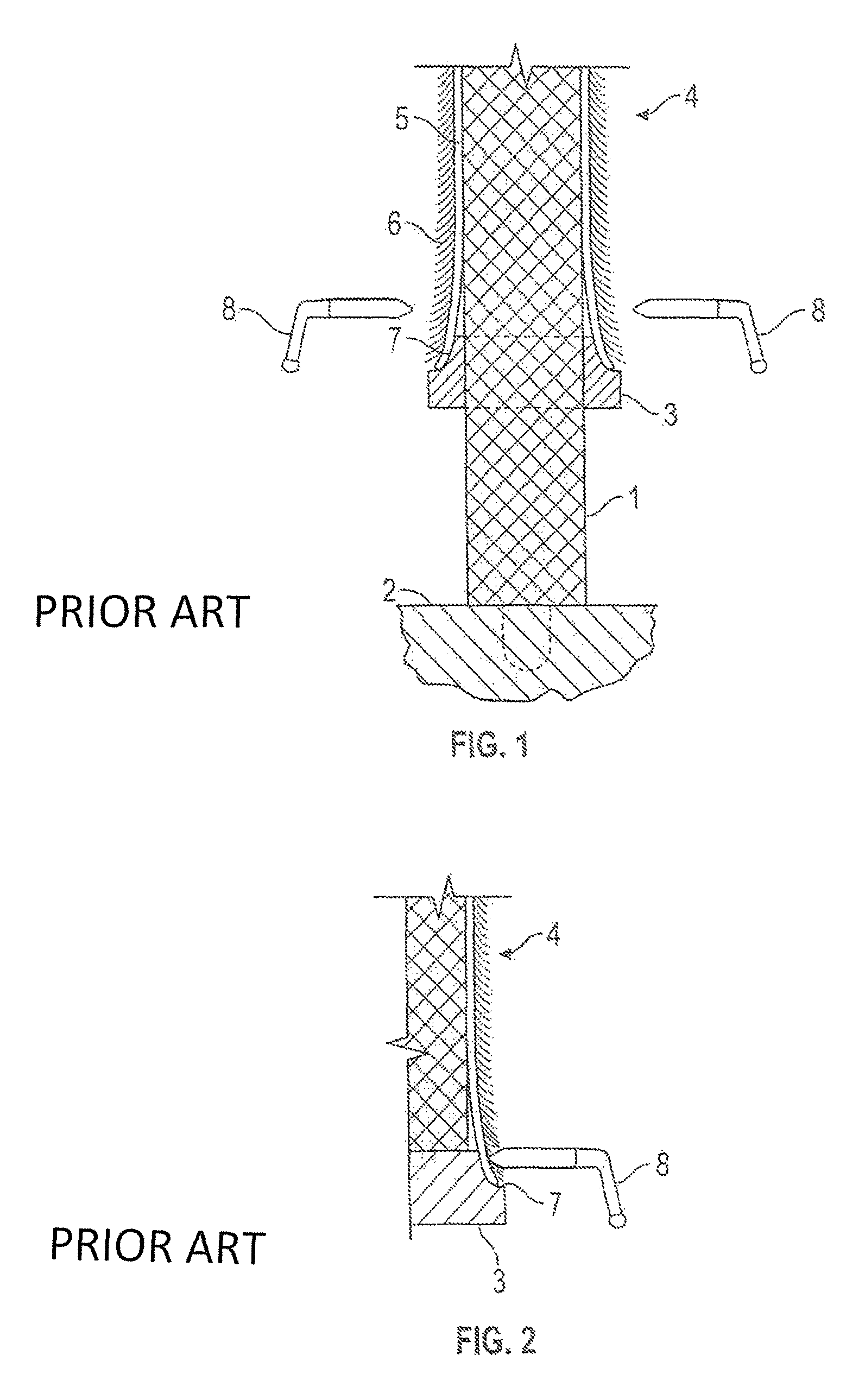

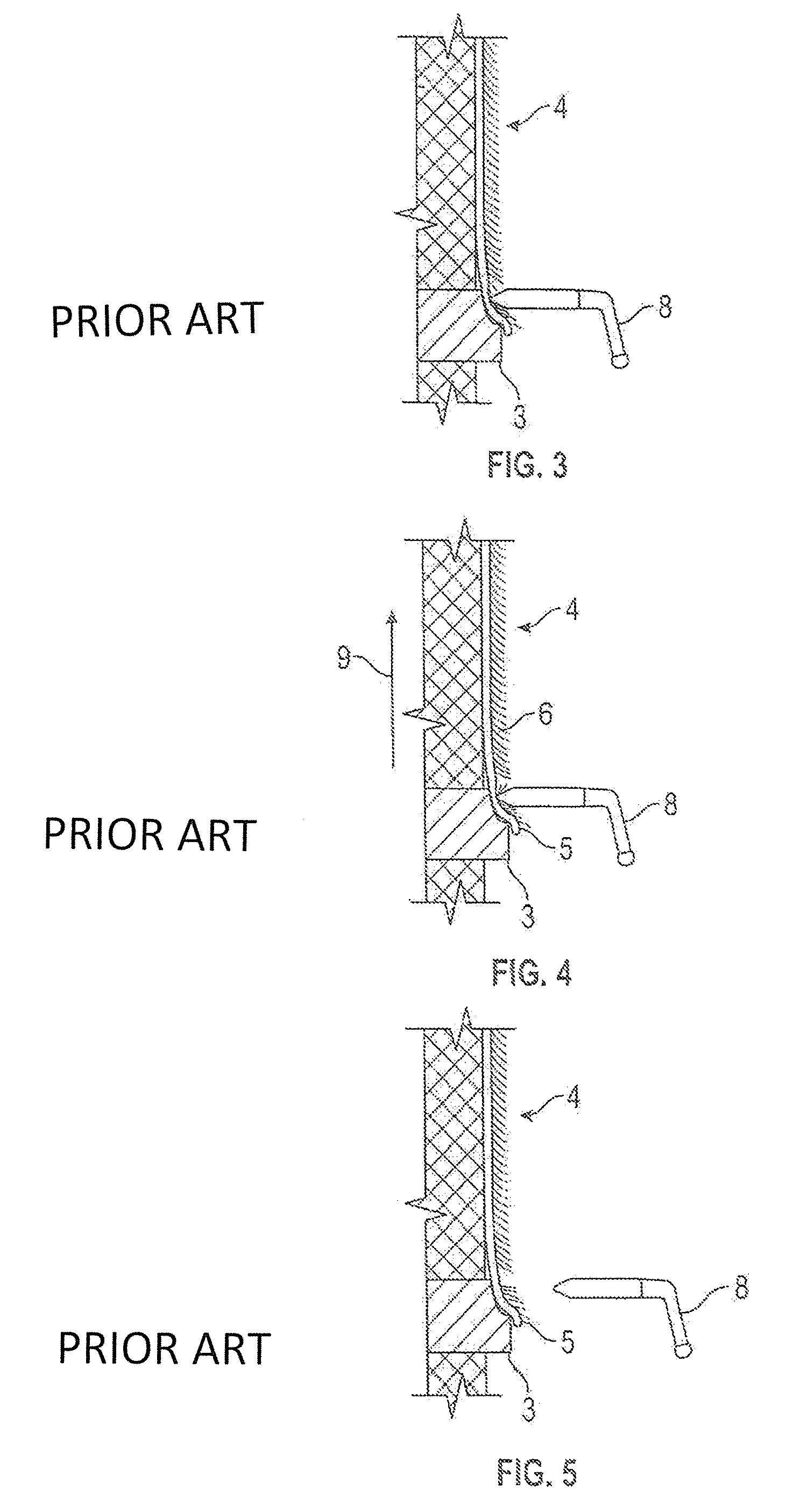

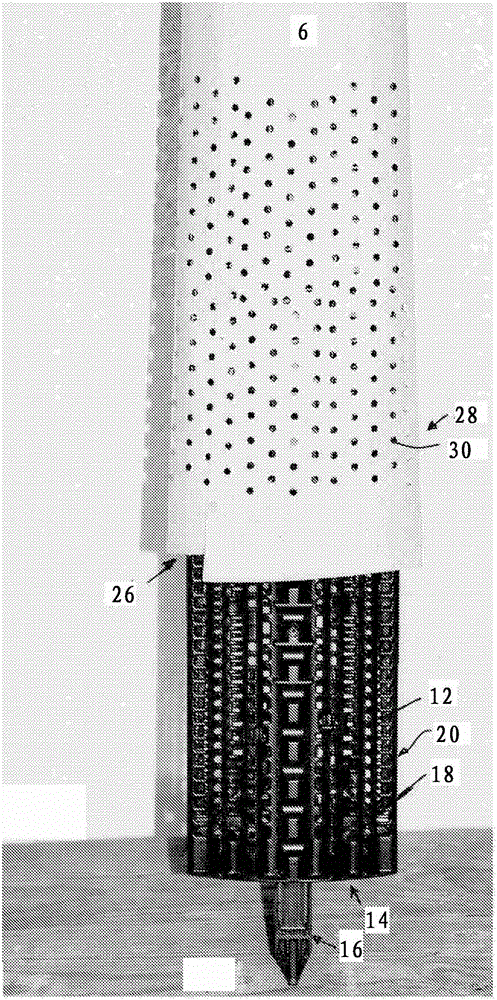

With the use of modern distension elements / pelt boards (6) consisting of two half-parts with surfaces (14) with open structure (18) in connection with the drying of pelts (26), where the pelt is secured in the stretched position during the drying procedure by means of a holding bag (28) which, in an area at the tail end of the pelt, presses the pelt against a special holding area (8) on the surface of the distension element / pelt board, there can appear areas of the pelt where this has not been sufficiently dried, and where the pelt therefore turns mouldy / decays. Moreover, as a consequence of the pelt slipping on the surface of the board, it can be difficult to obtain a straight measuring line for the measurement of the length of the pelt. In order to relieve these problems, there is disclosed a sleeve / pelt bag item of fat and moisture absorbing material which is characteristic in that the pelt bag (10) consists of a tubular bag item to be drawn over the outside of the distension element / pelt board from the pointed end of the board for the covering of at least a part of the holding area on the distension element, the extent of said pelt bag corresponding at least to 1 / 3 but preferably1 / 2 of the extent of the holding area (8) on the distension element (6).

Owner:MINKPAPIR

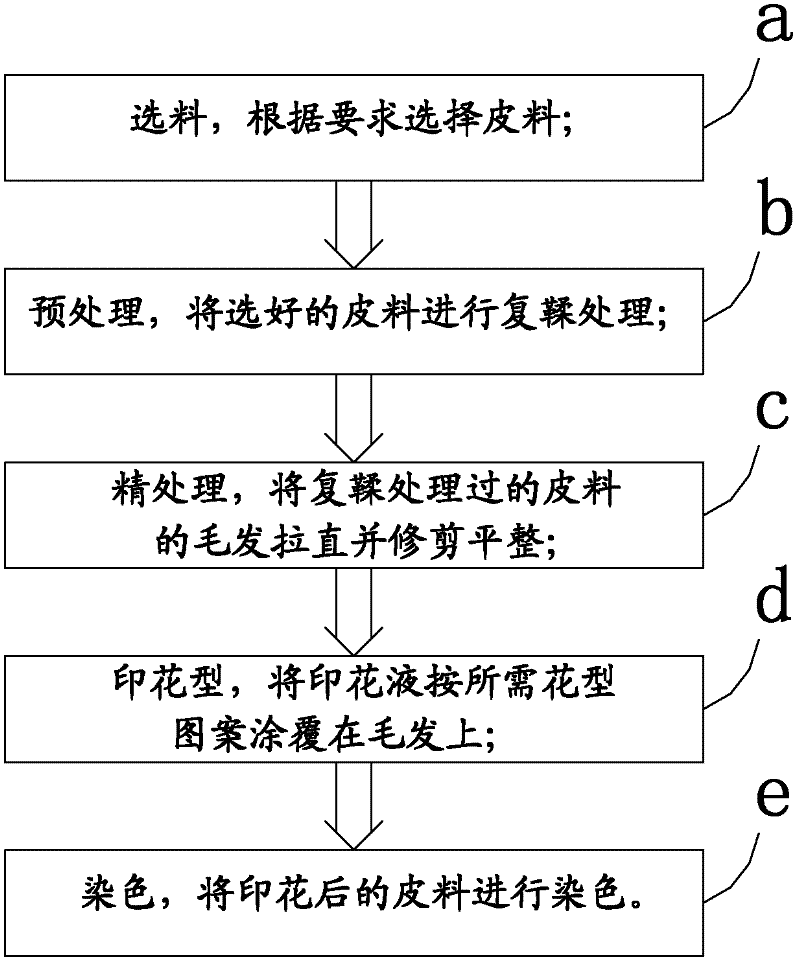

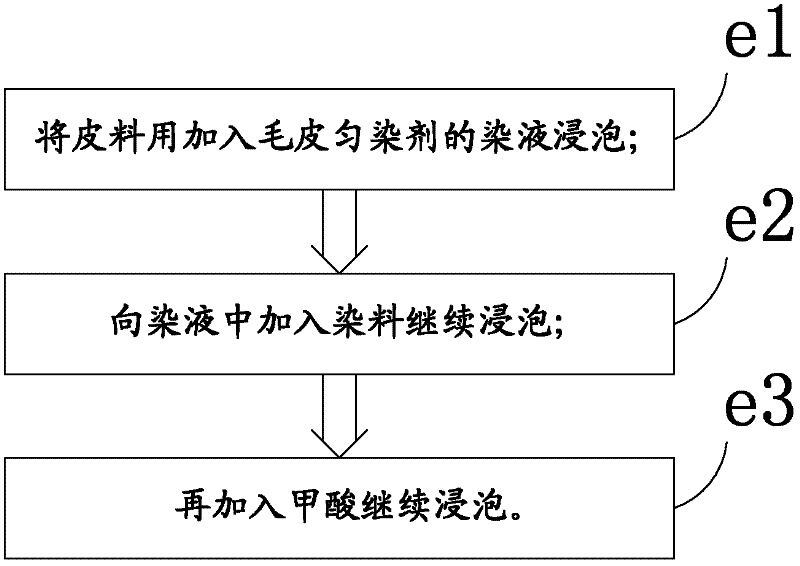

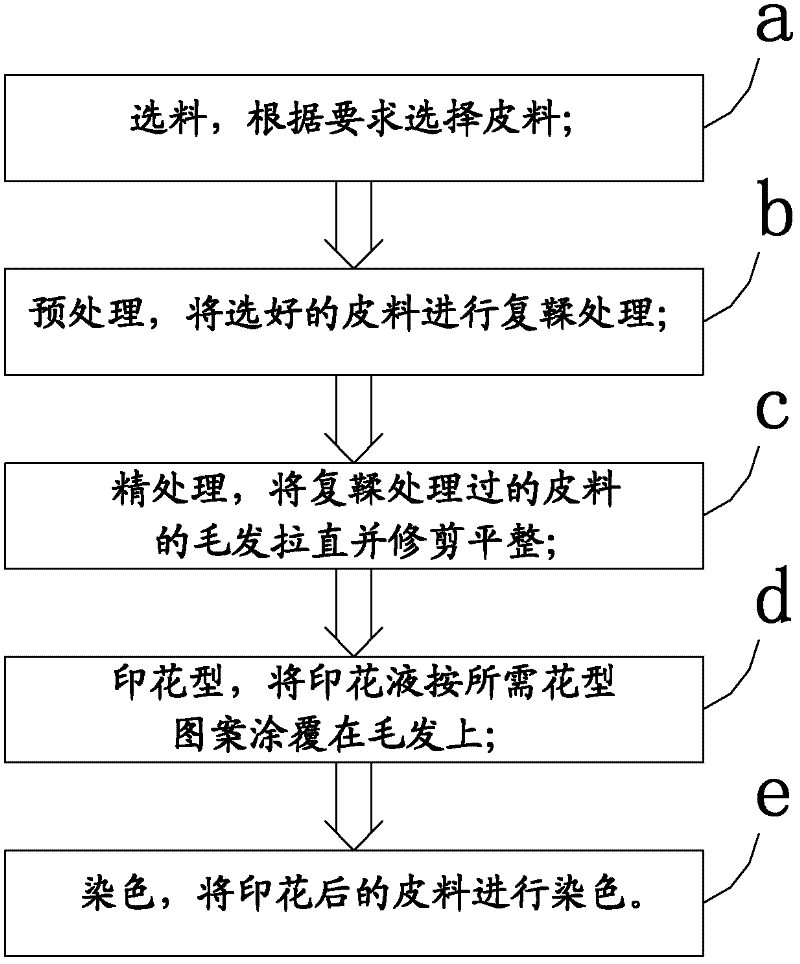

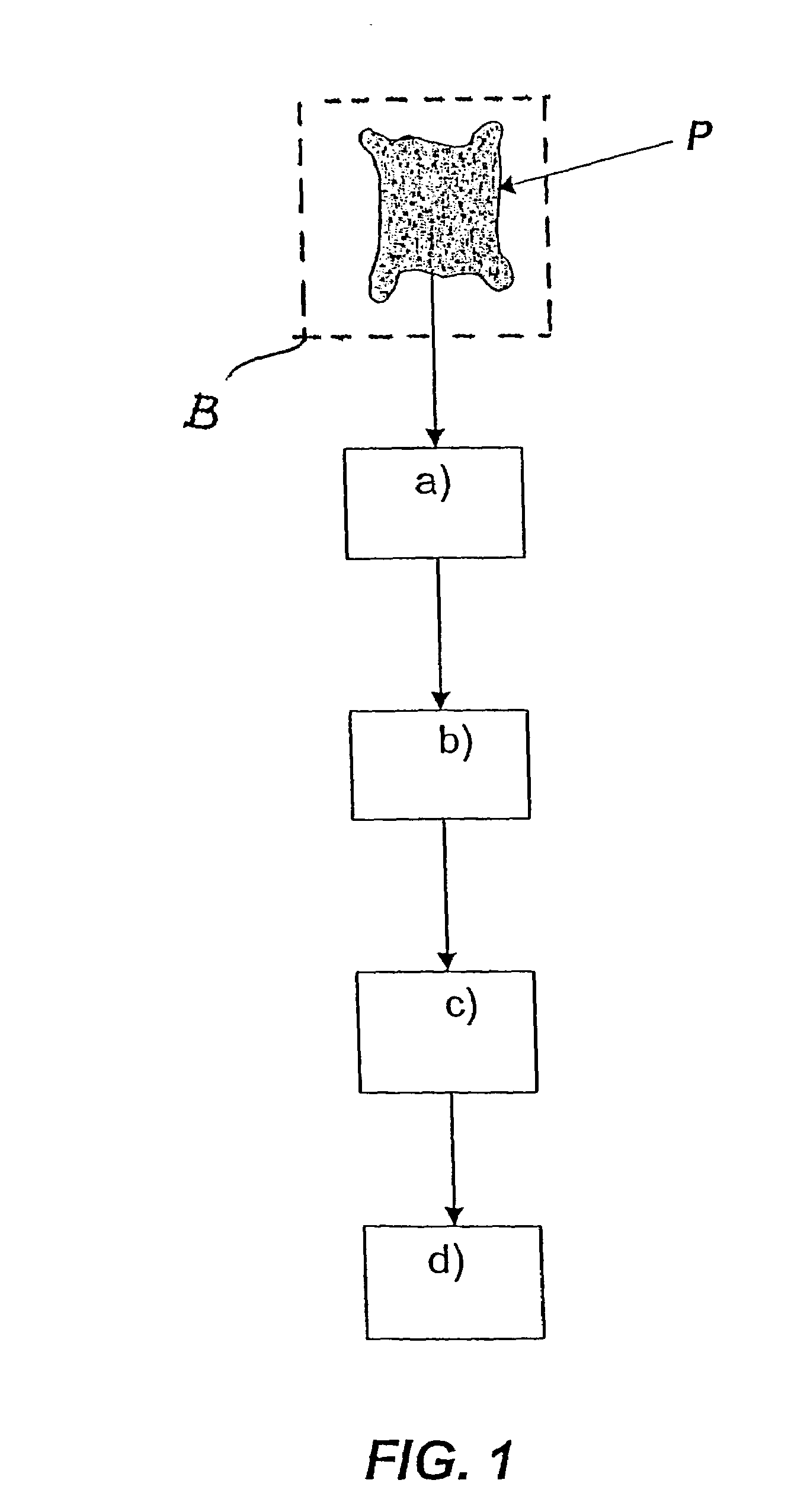

Printing and color developing method of fur

ActiveCN102493229AReduce complexityReduce manufacturing stepsTanning treatmentFur dressingEngineeringTwo step

The invention relates to the leatherworking field, and specifically relates to a printing and color developing method of fur. The method comprises the following steps of: a) material choosing: choosing a fur material according to requirements; b) pretreatment: subjecting the chosen fur material to retanning treatment; c): fine treatment: straightening the hairs on the retanned fur material, and trimming as well as flattening the hairs; d): pattern printing: coating a printing solution on the hairs according to a needed pattern design; and e) dyeing: dyeing the printed fur material. The printing and color developing method of fur in the invention reduces the realization of a bicolor effect of single hair from two-step dyeing in traditional making processes to just one-step dyeing, thus reducing making steps and lowering the complexity degree of the making method. Based on the dye adsorption ability of a printing and color developing agent, the method in the invention depends on the difference between the dye adsorption degrees of a part coated with the printing and color developing agent and a part not coated by the color developing agent to realize the bicolor effect of single hair. Transition between the two dyed colors is more natural, and the effect is better than that of traditional methods.

Owner:BEIJING FANBO CHEM

Pelt Board with Expansion Means

InactiveUS20150191802A1Reduction in cross-sectional circumferenceEasy to disassembleFur dressingLeather stretching/tensioningEngineeringMechanical engineering

Owner:EIKON TECH HLDG

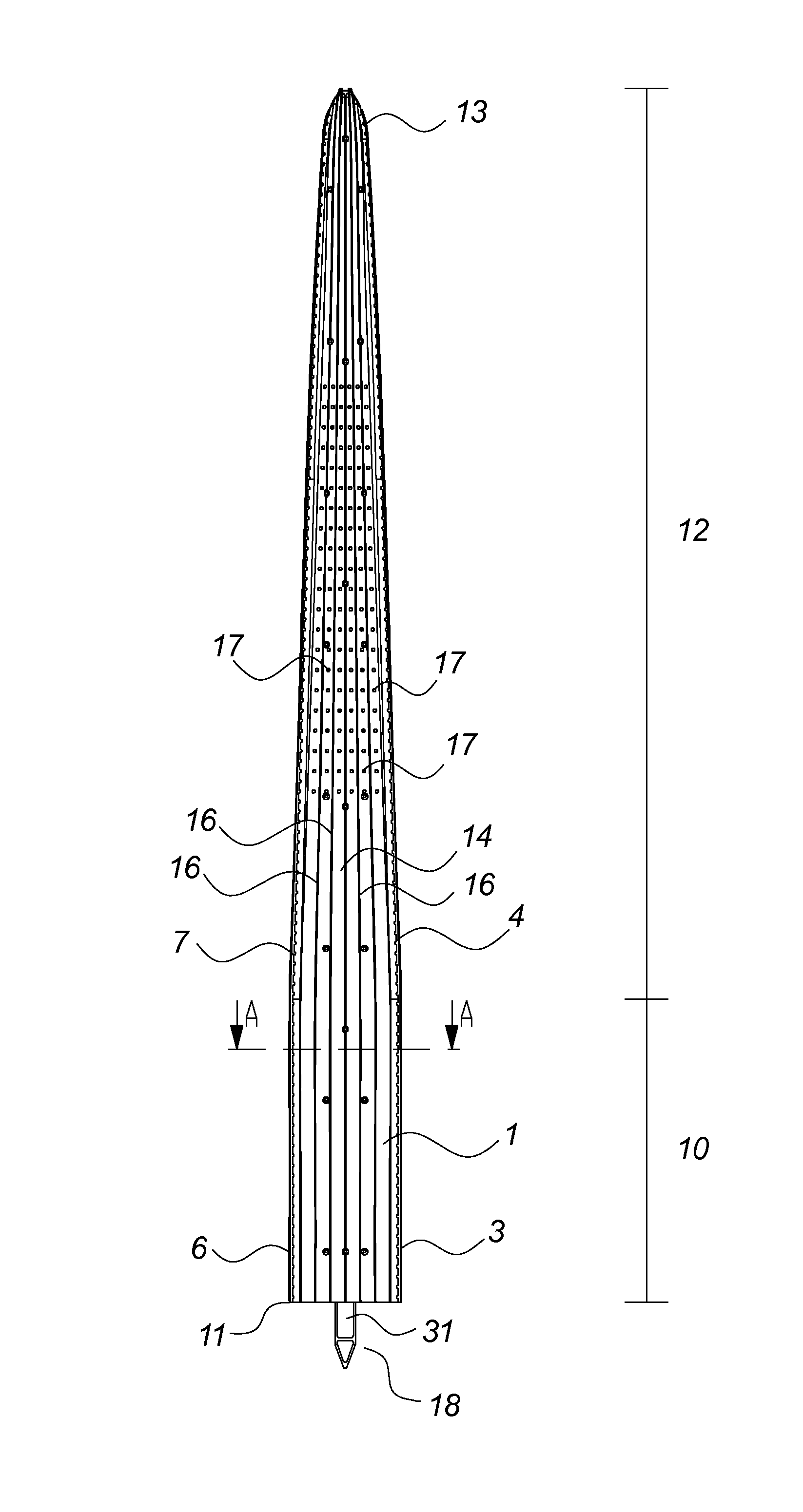

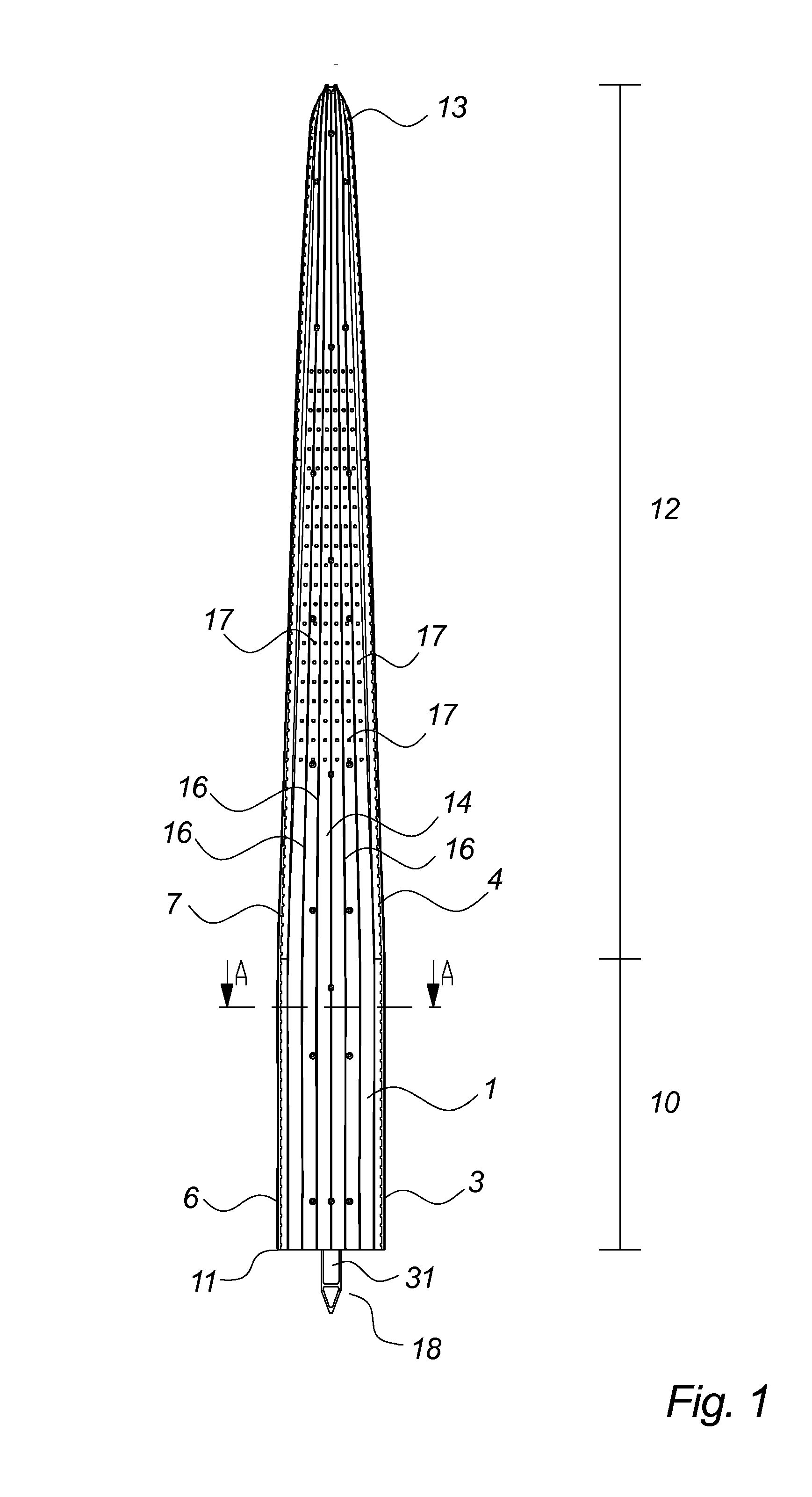

Method and system for drying out the leather side of a pelt stretched out and fixed in this position on a pelt board

ActiveUS20070061979A1Eliminate useThe process is fast and efficientPre-tanning chemical treatmentFur dressingBlack spotEngineering

A method, a system and a pelt board for the drying of the leather side of pelts from furred animals, in which the pelt board is a hollow distension element, the surface of which has an open structure. The the leather side is dried by changing the air within the distension element. The distension element is is lockable in a position in which it has a first circumference, and can also assume a position or be force controlled to a position in which it has a circumference which is smaller than the first, which results in a considerably easier removal of the pelt from the pelt board. A quicker, more uniform and more effective drying of the pelts is achieved, so that “black spots” on the leather side are avoided, and the pelt is fixed in its stretched position on the pelt board without the use of clips / staples.

Owner:MINKPAPIR

Machine and method for stretching a pelt before fastening to a pelt board

Owner:EIKON TECH HLDG

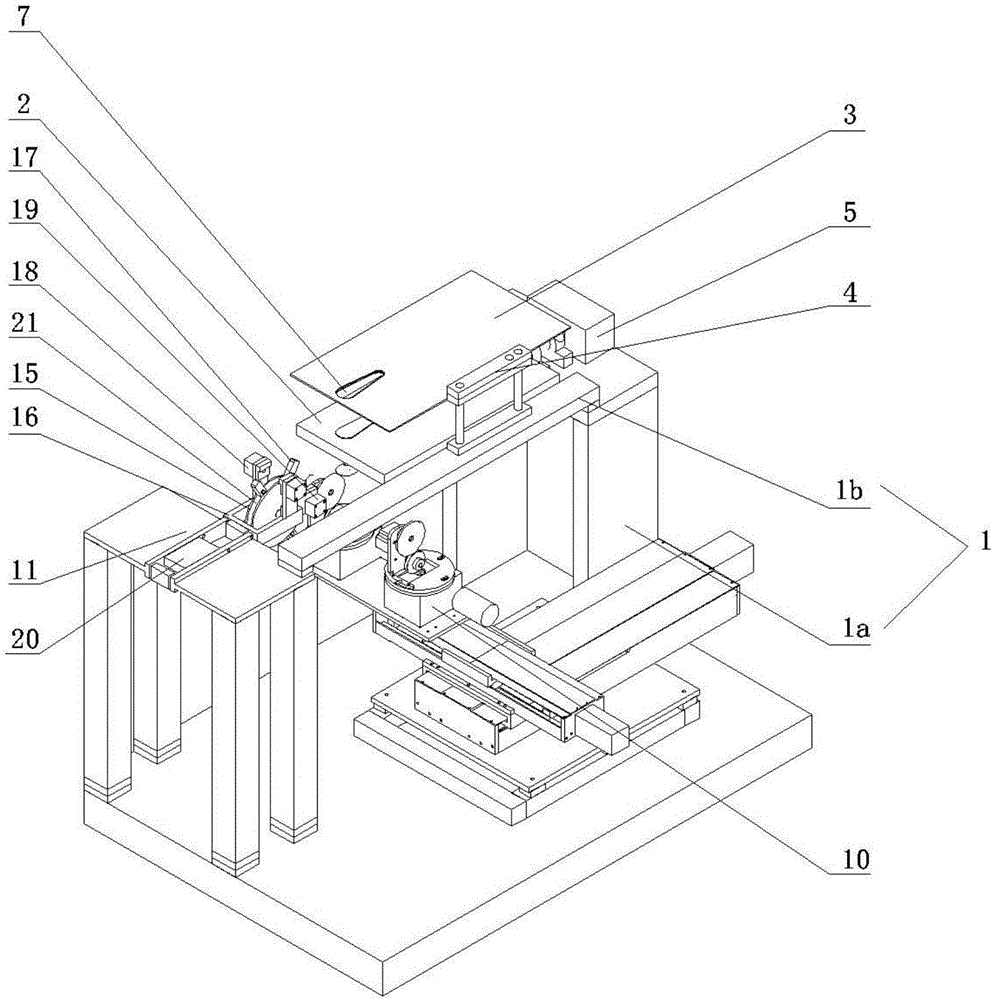

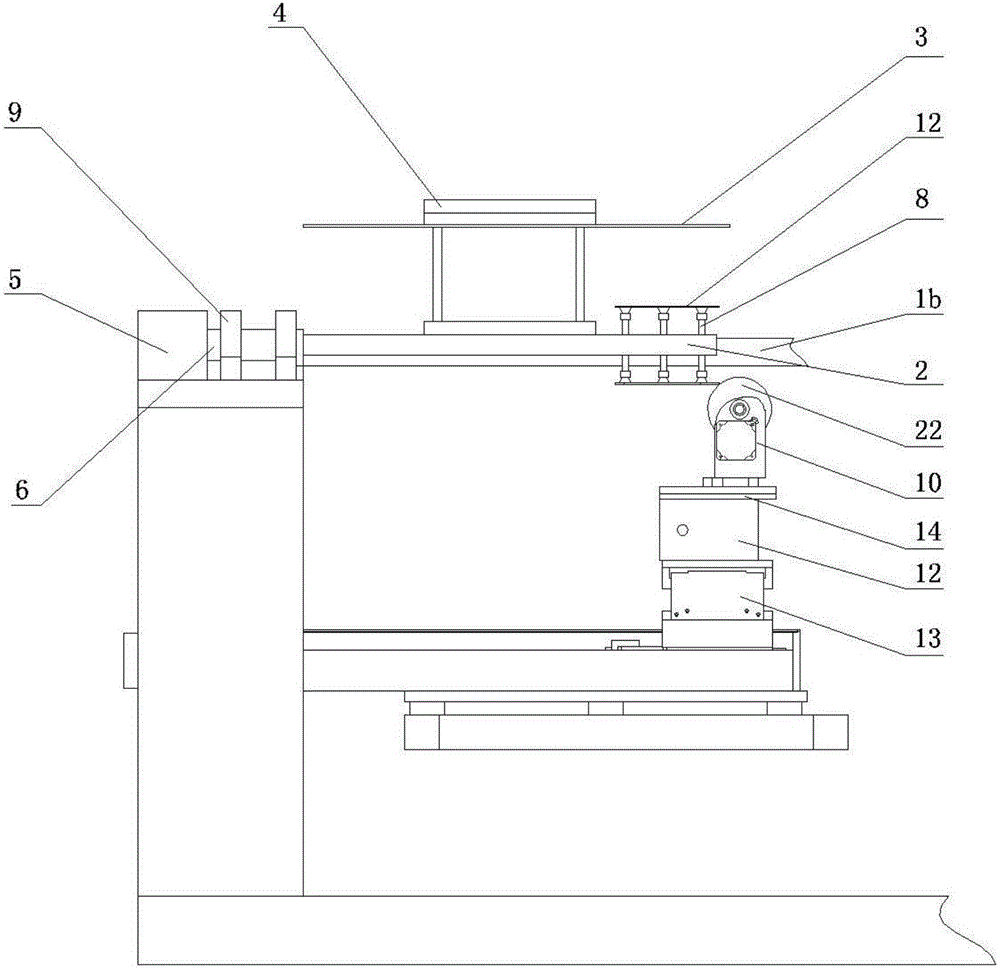

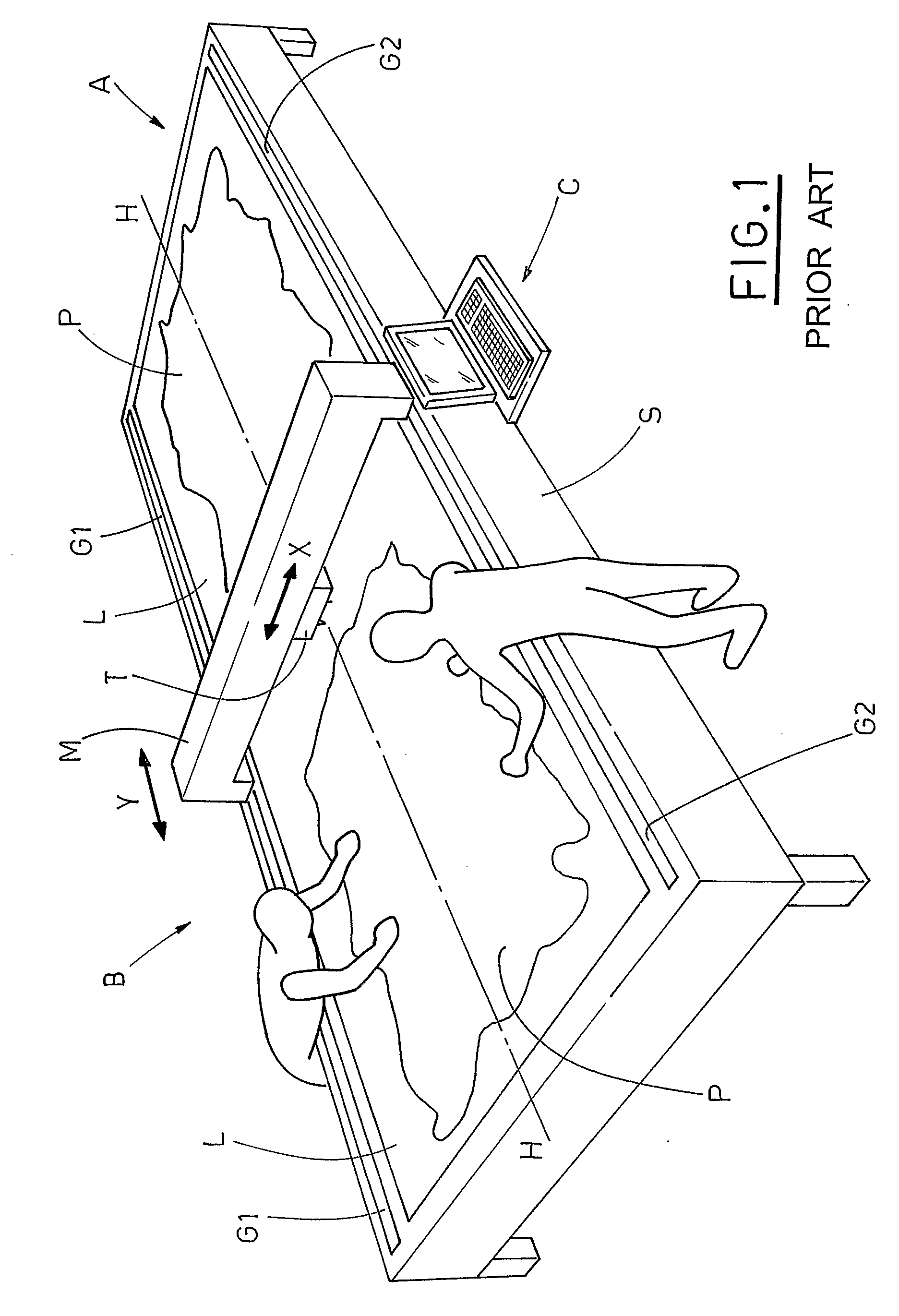

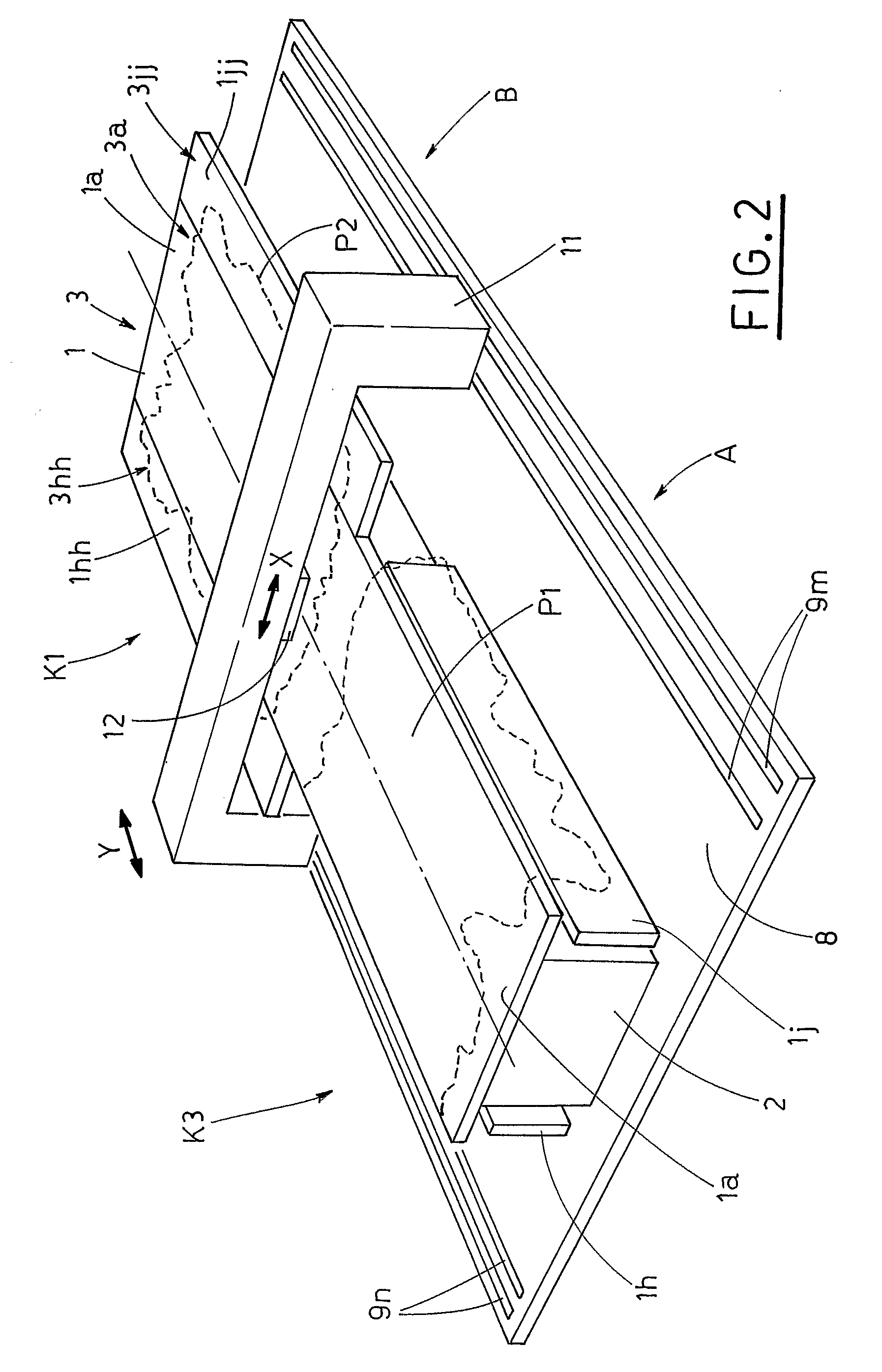

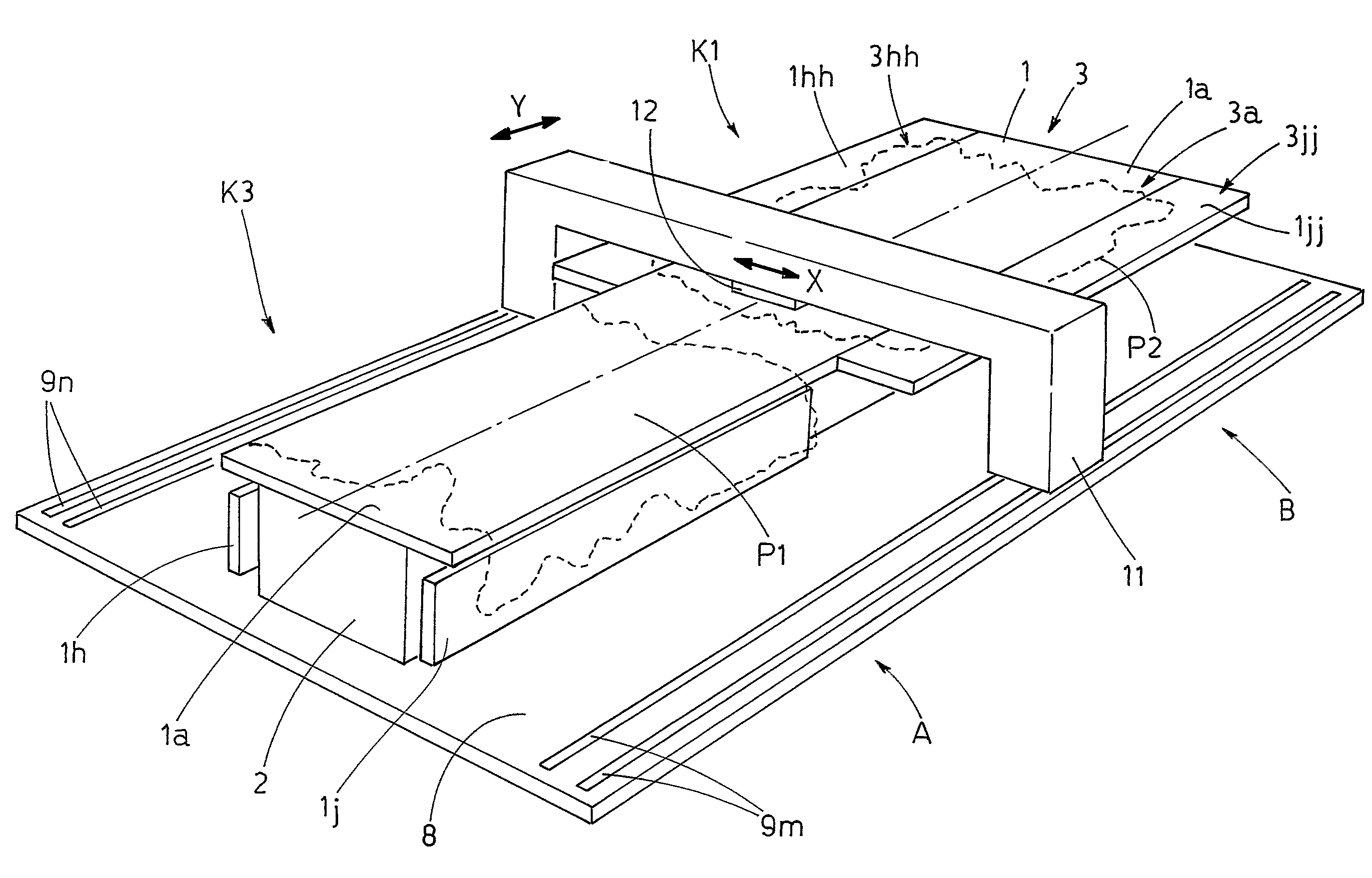

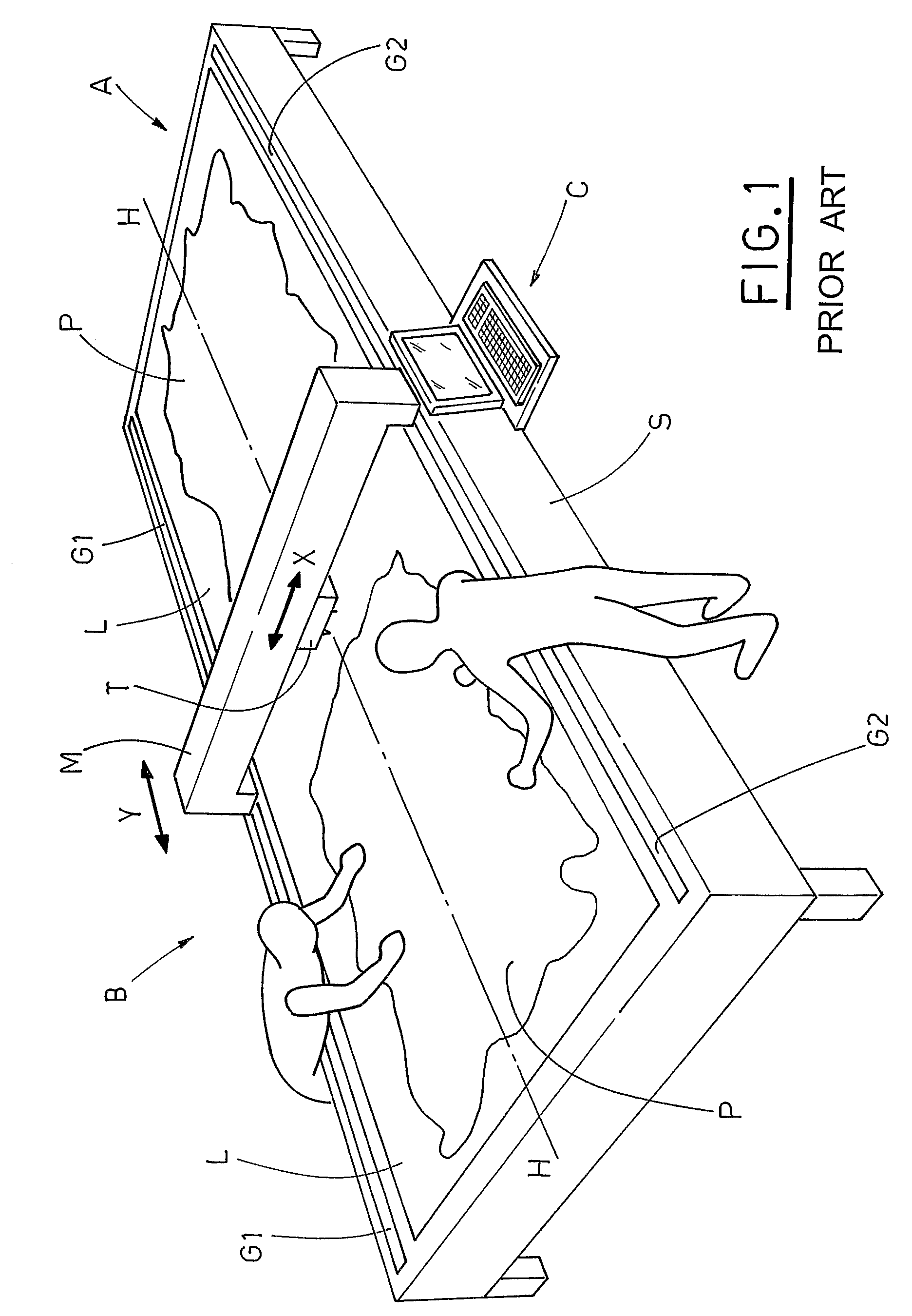

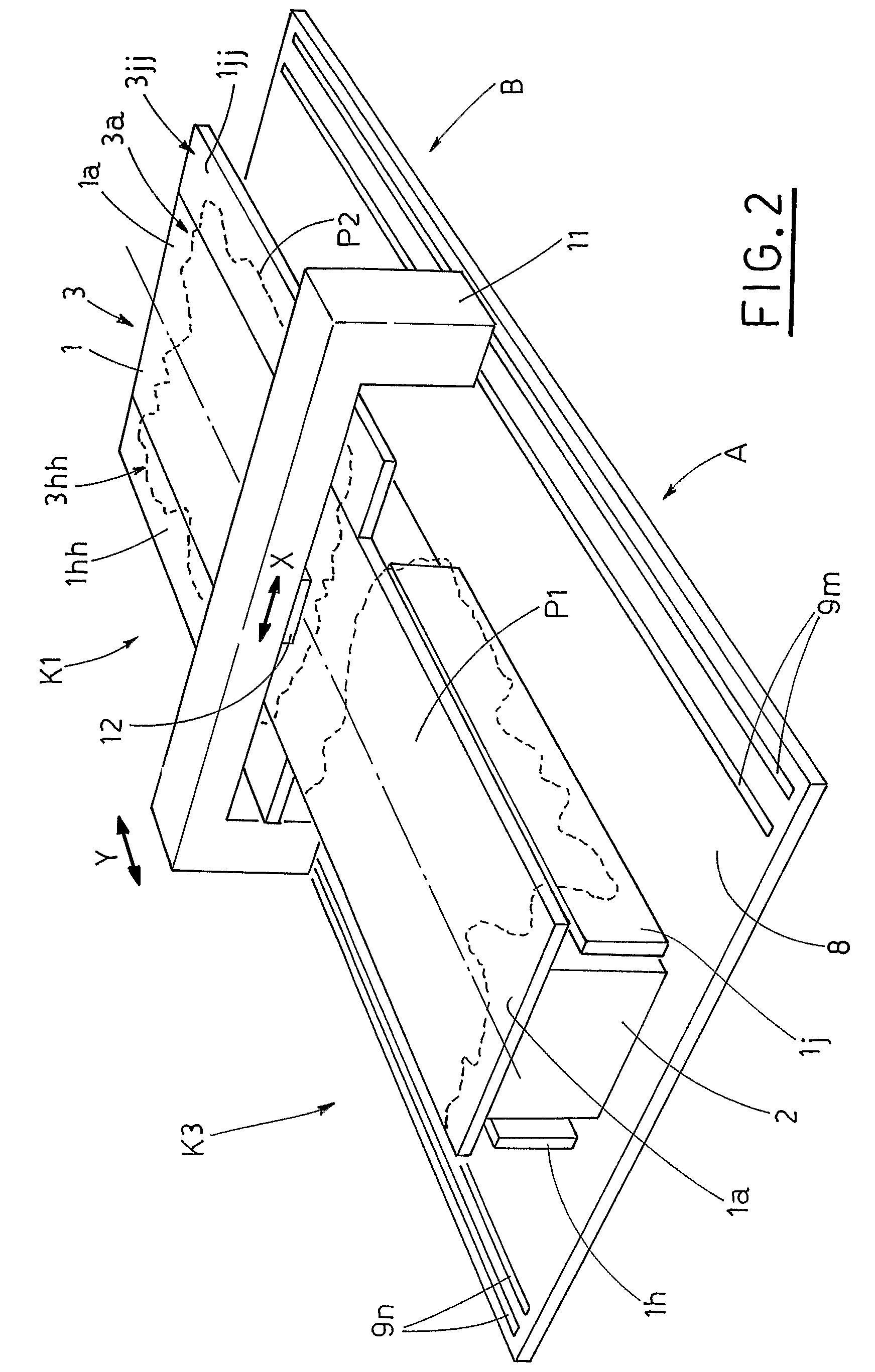

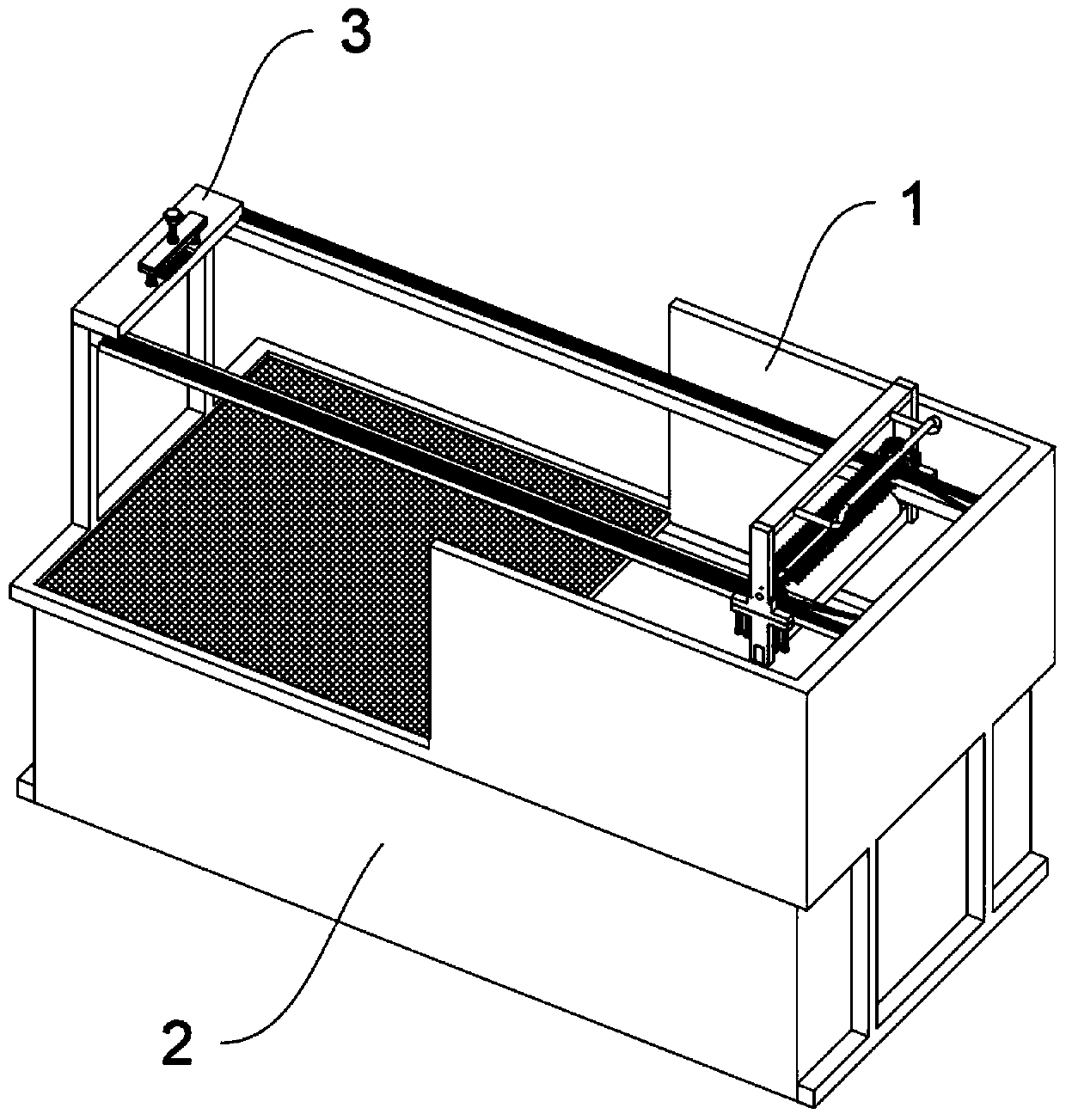

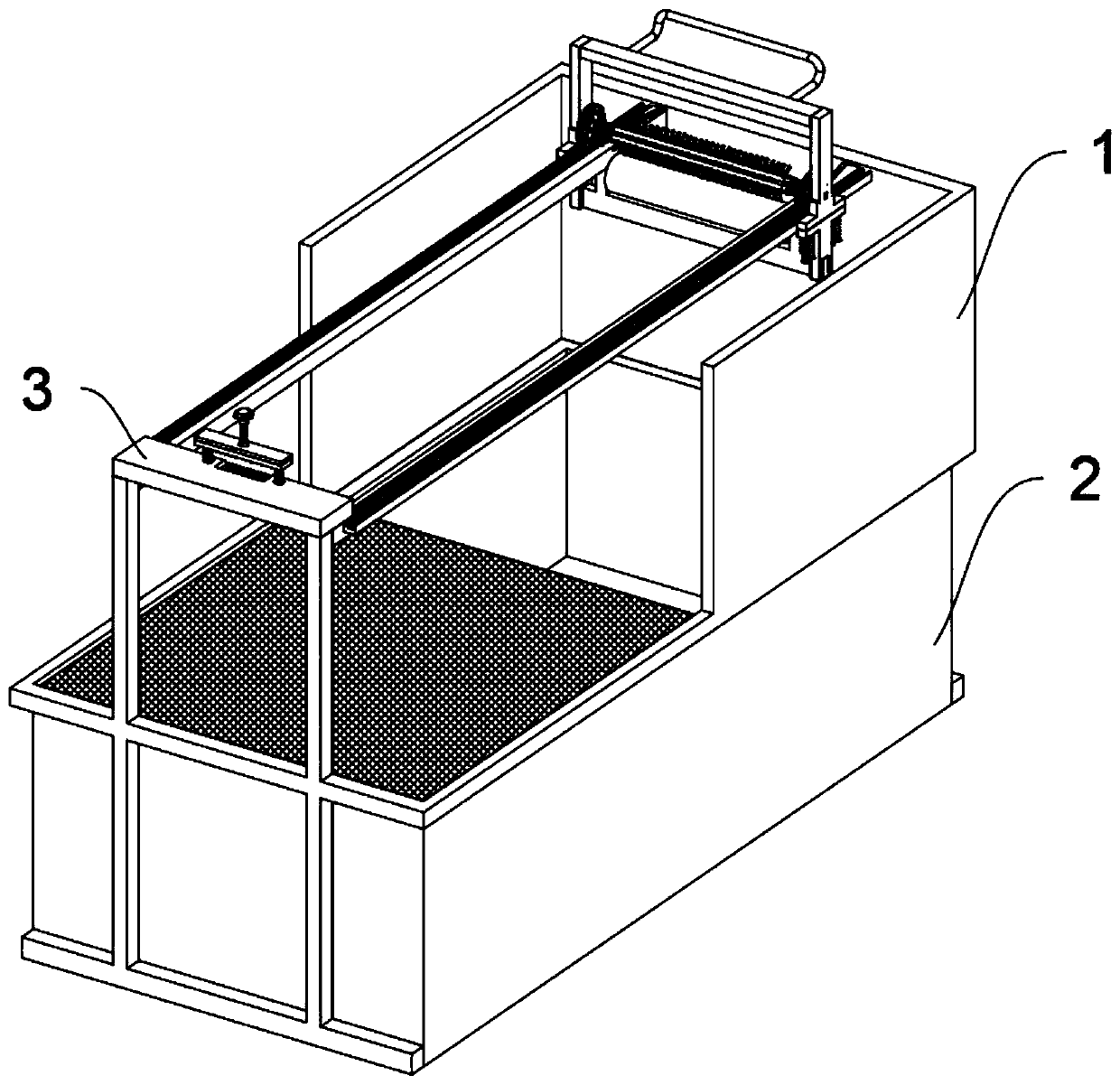

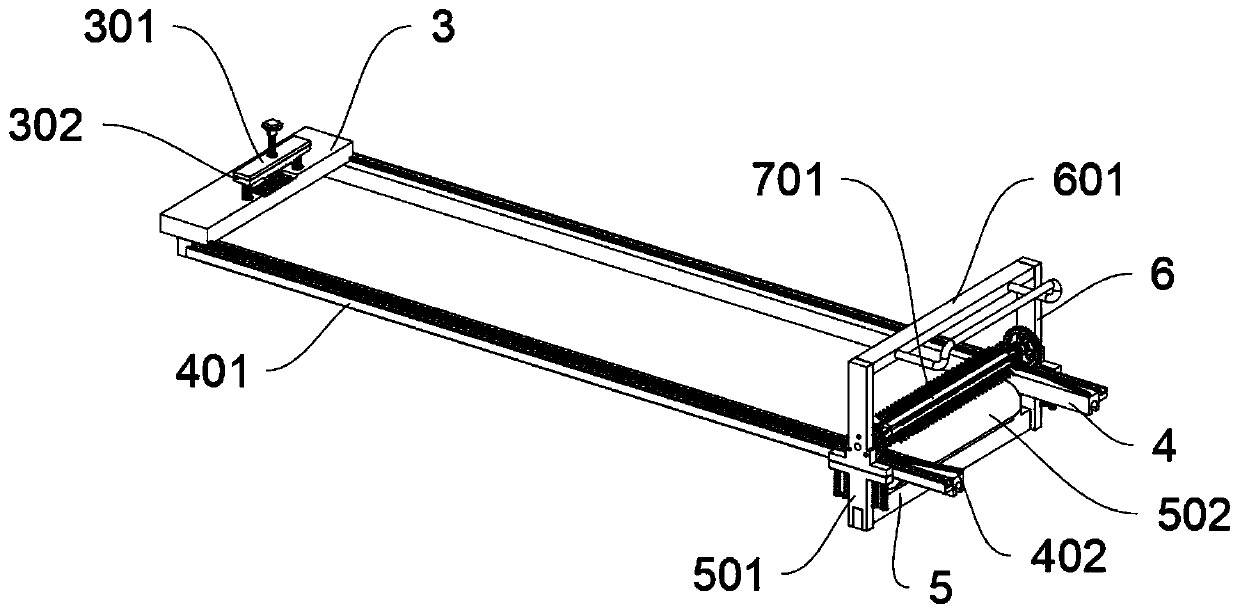

Work Table For an Automatic Machine For Cutting Leathers and the Like

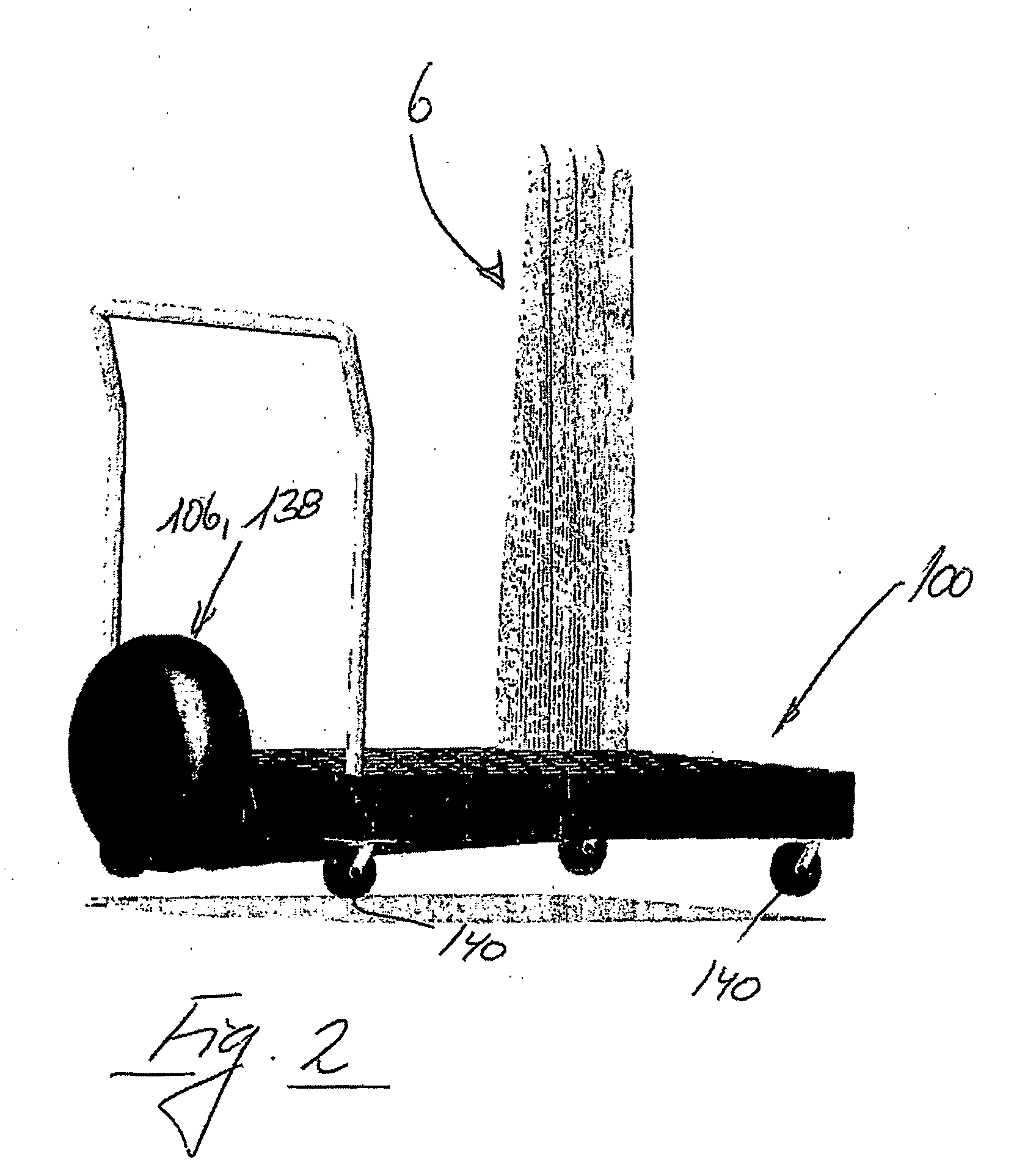

ActiveUS20080149003A1Shorten the timeIncrease of machine production rateLeather clicking/perforating/clickingFur dressingMachineAutomaton

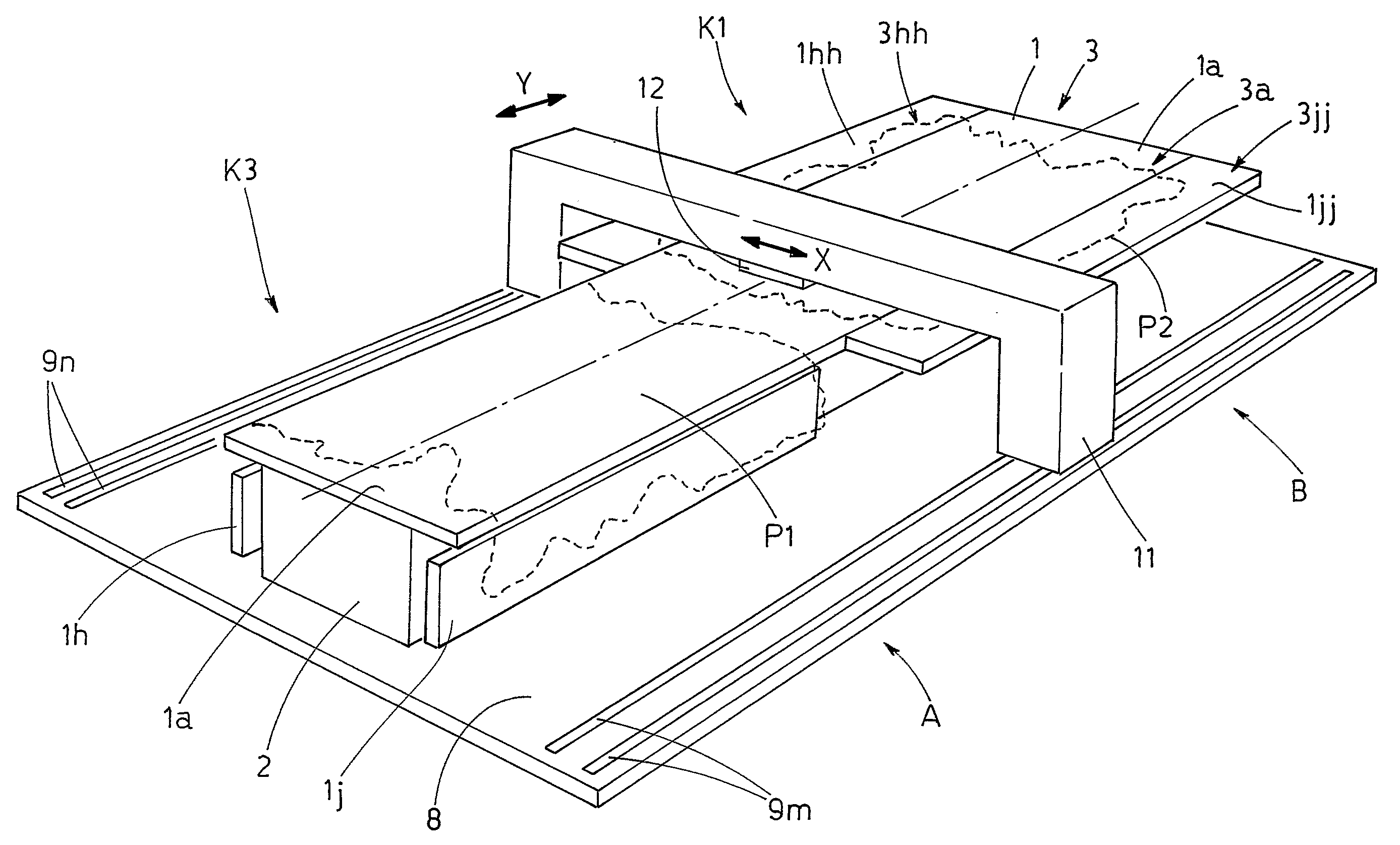

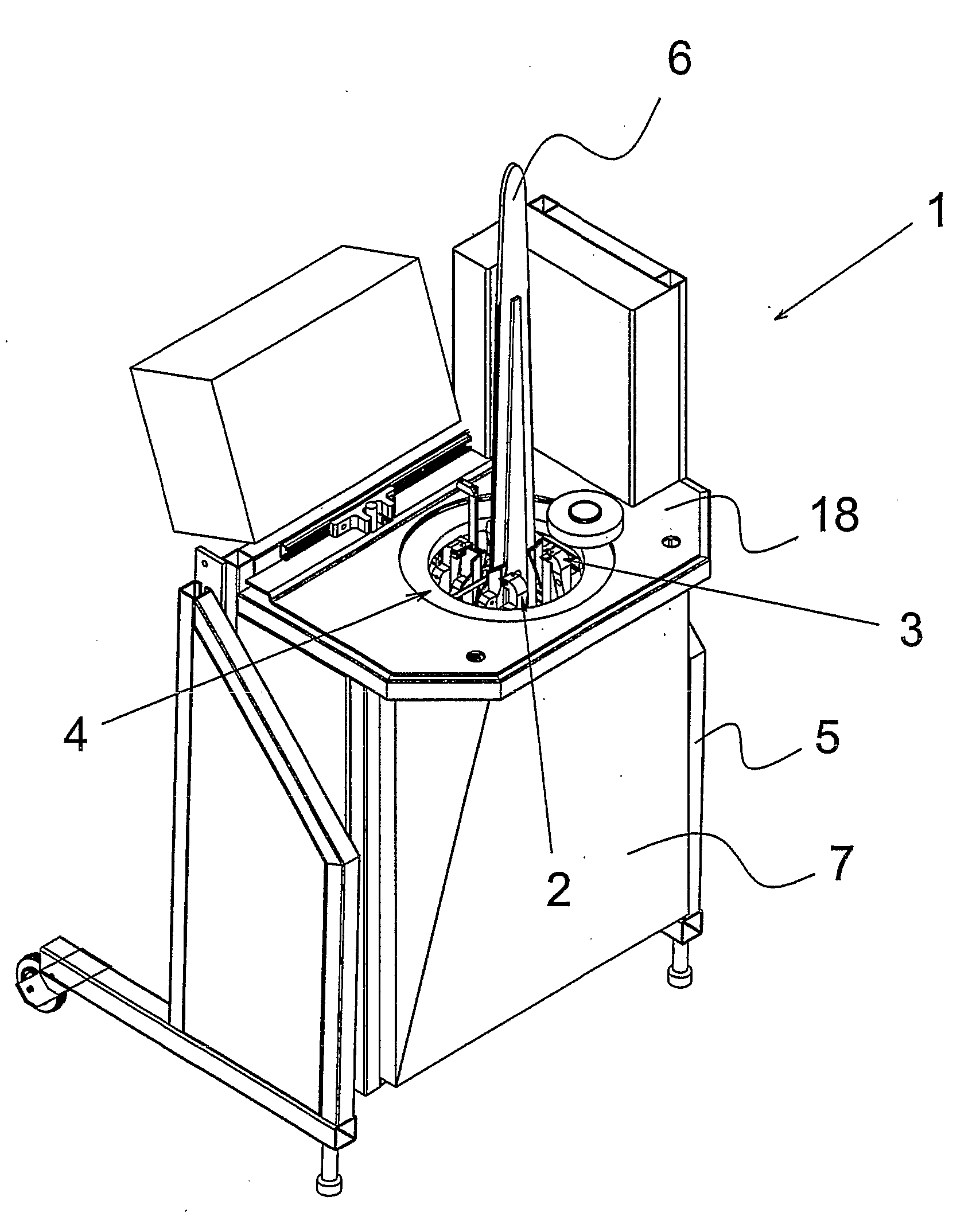

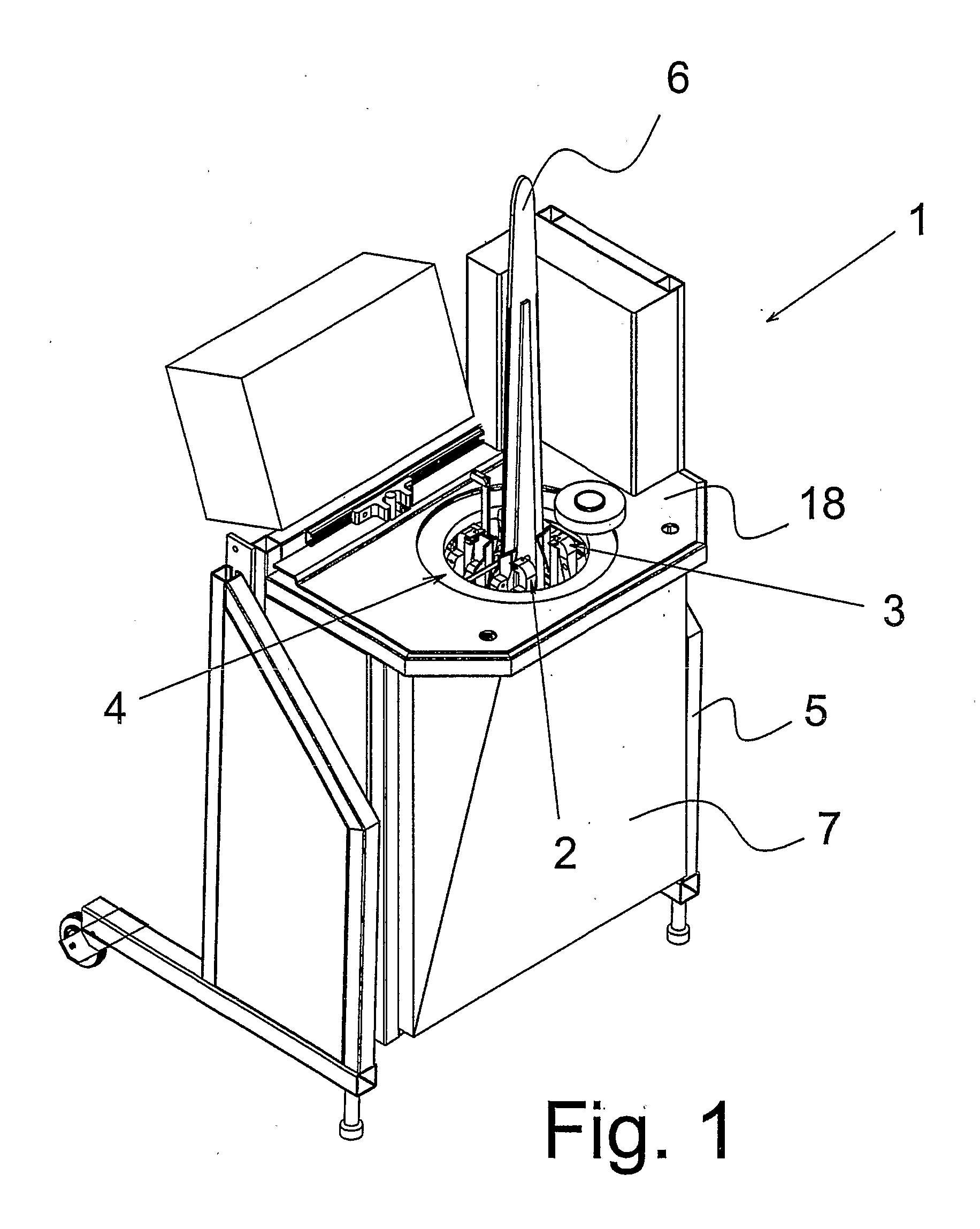

A work table for an automatic machine for cutting leathers and the like, includes a plurality of holes opening outwards and communicating with a vacuum source, to make portions of leathers to adhere to the active surface (3) of the work table (1). The work table (1) includes a central body (1a), supported by a fixed structure (2). At least one lateral portion (1h, 1j), connected to the fixed structure (2), is moved by first motion means (10h, 10j) between at least one work configuration (K1), in which its active surface (3h, 3j) is aligned with the active surface (3a) of the central body (1a), to define the active surface (3) of the work table (1), and a rest configuration (K2) of reduced dimension, in which the active surfaces (3a, 3h, 3j) of the central body (1a) and the lateral portion (1h, 1j) are arranged at an angle with respect to each other.

Owner:TESEO SPA

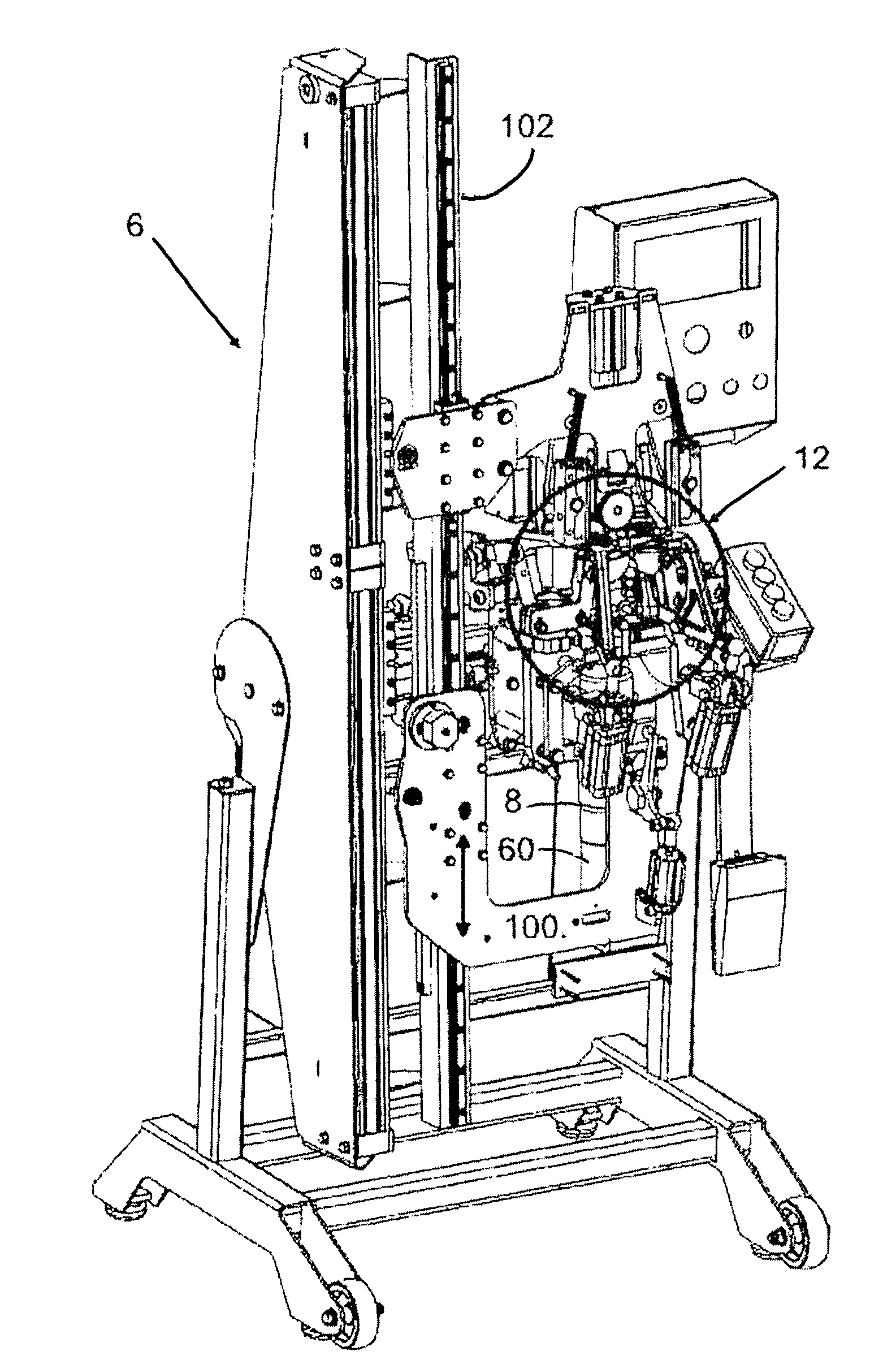

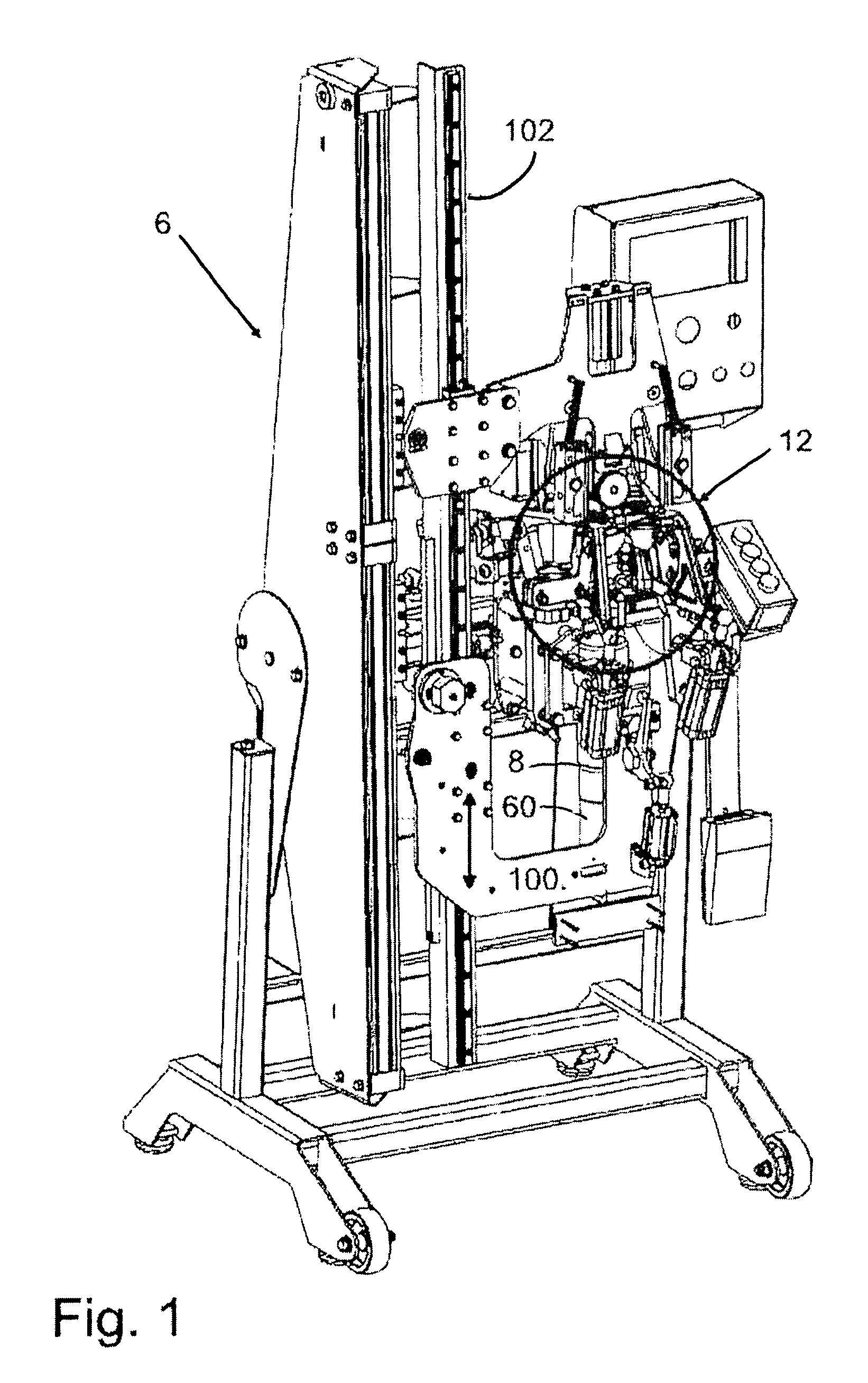

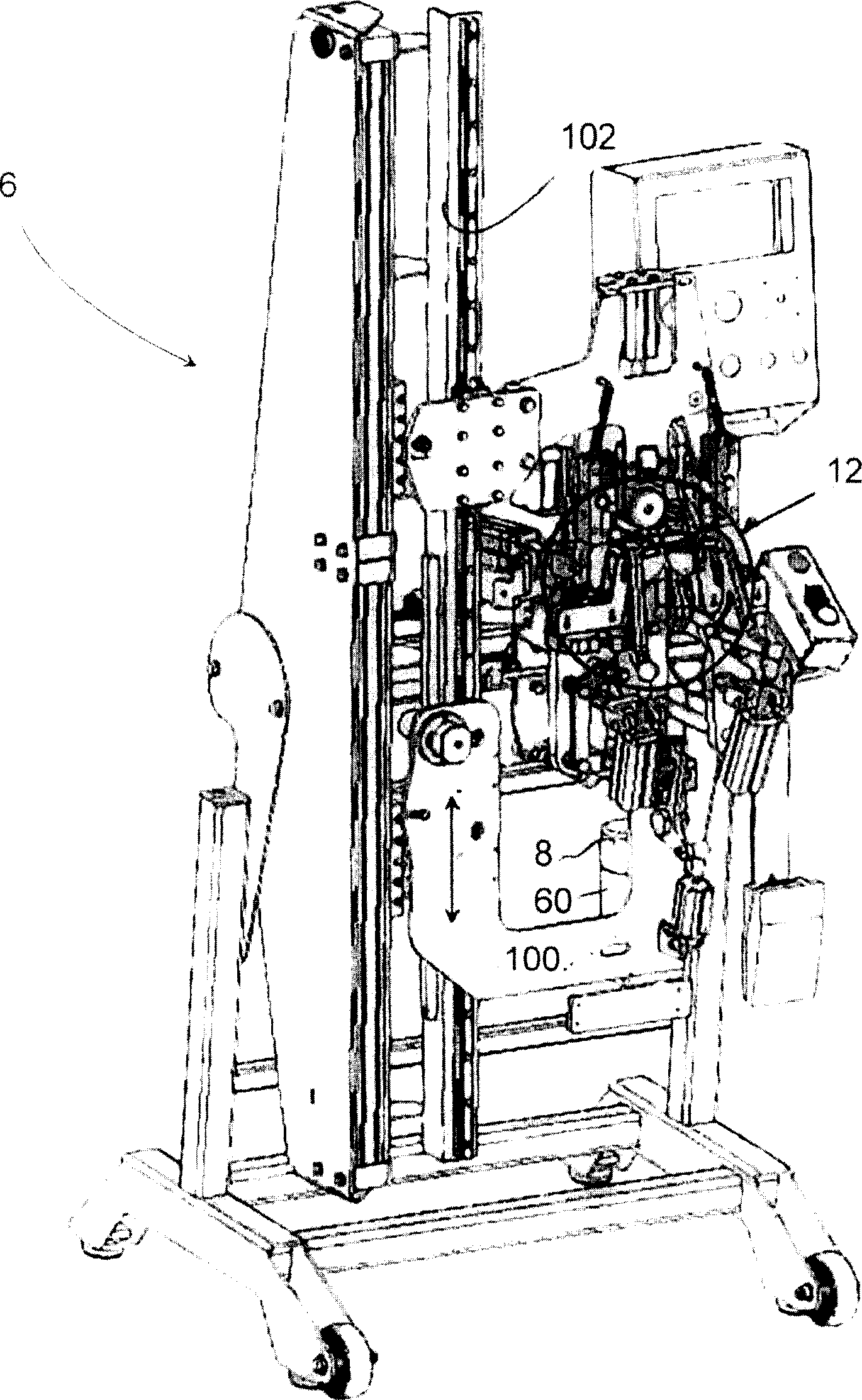

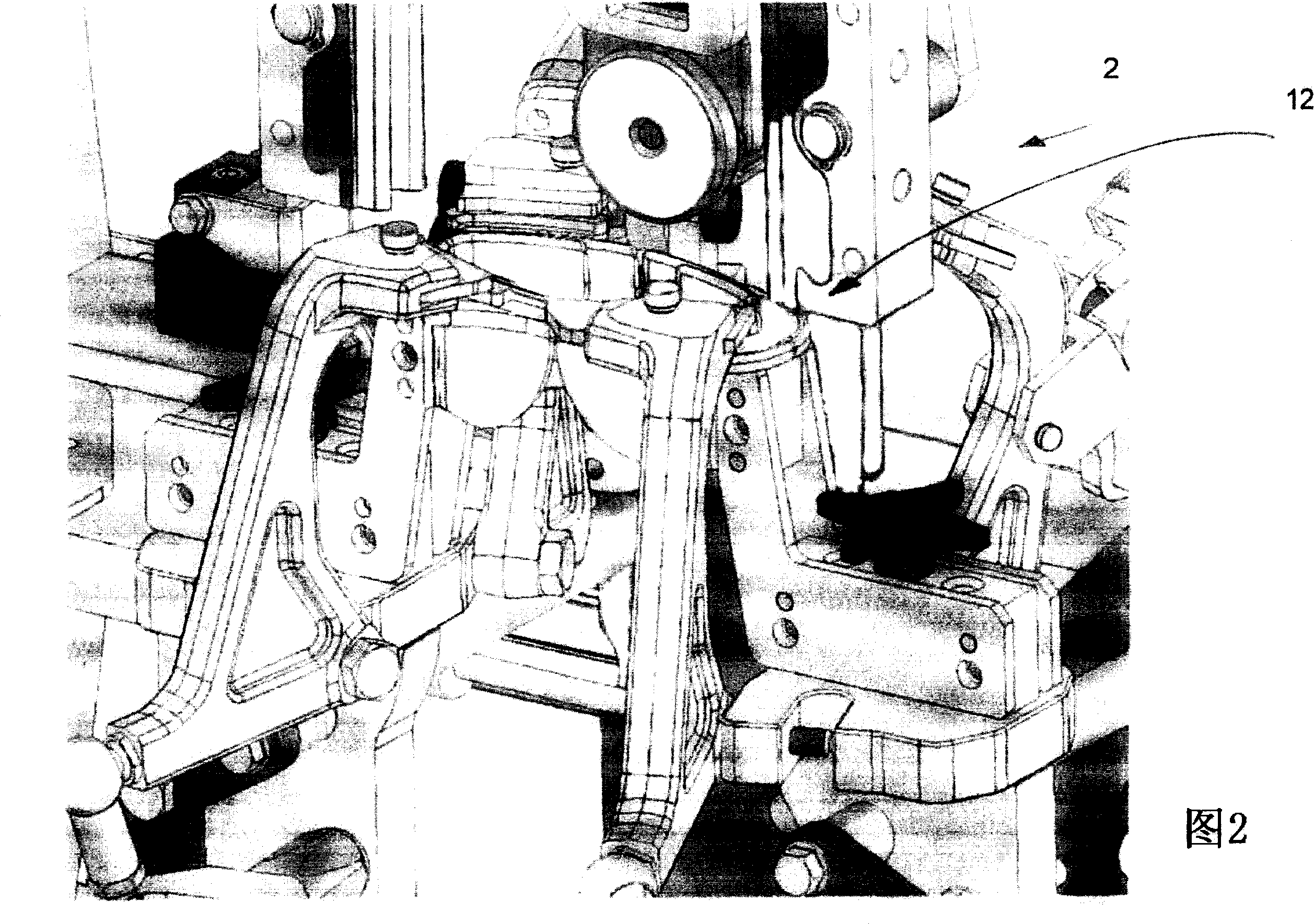

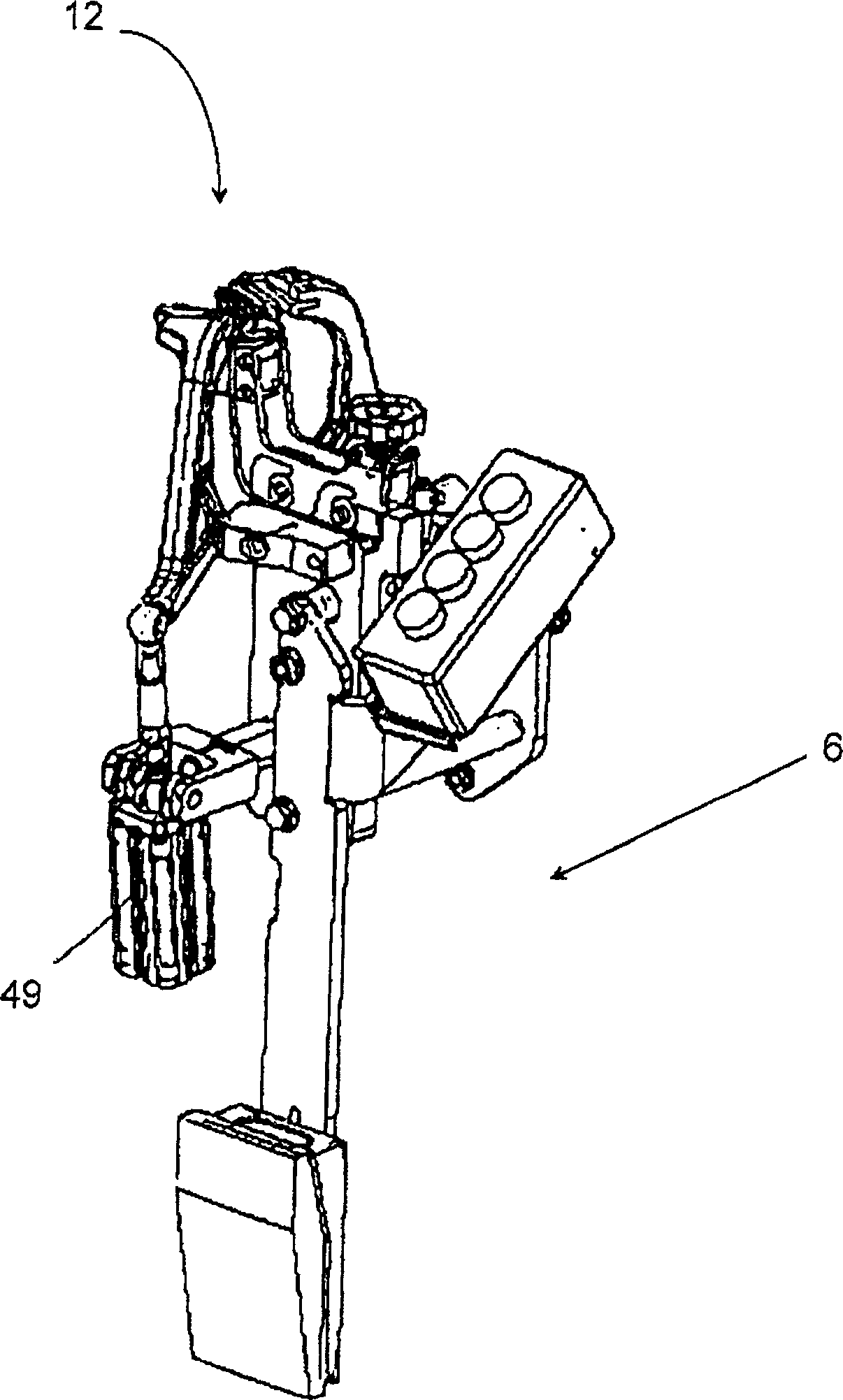

Method and machine for non-destructive stretching and fastening of a pelt on a pelt board

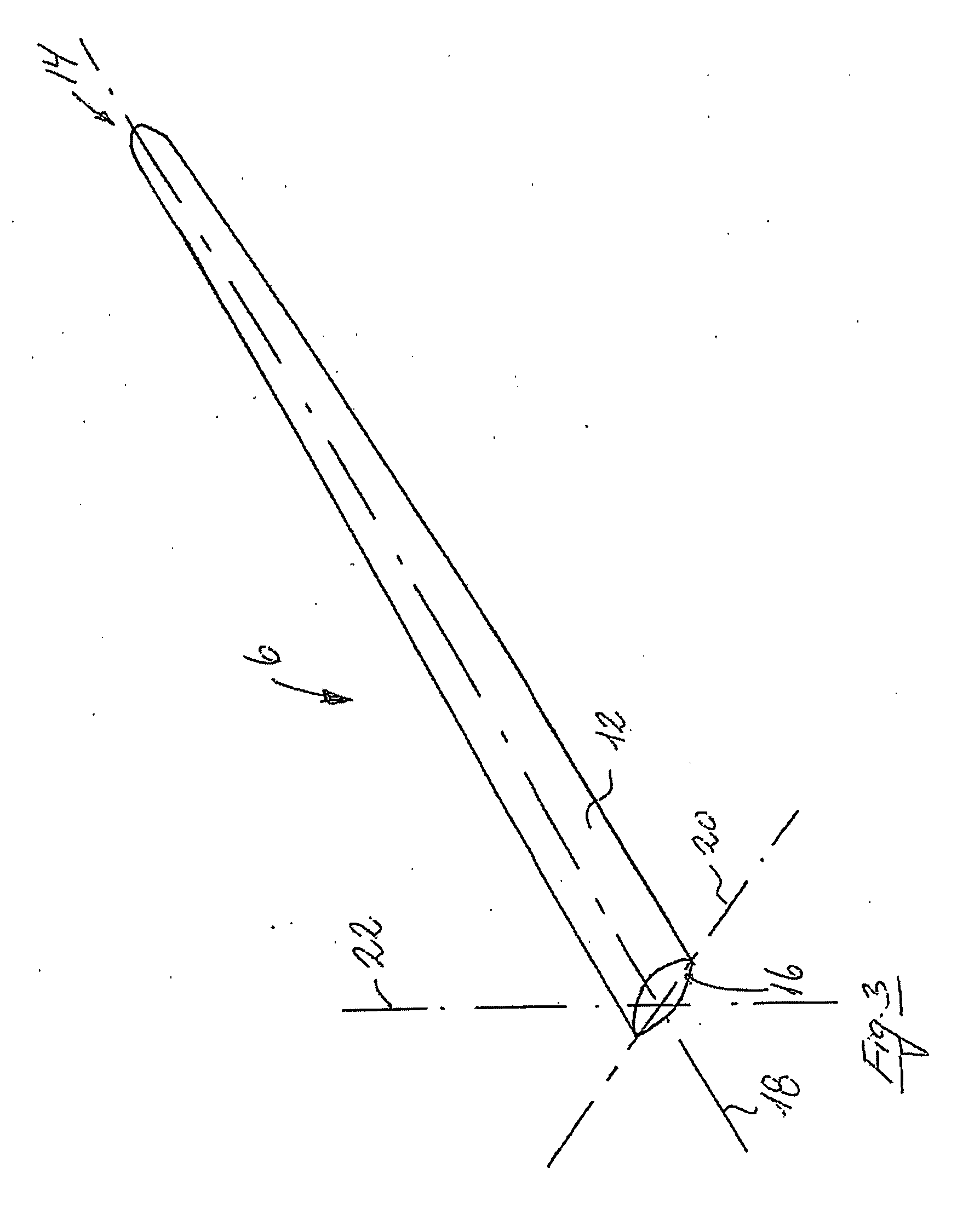

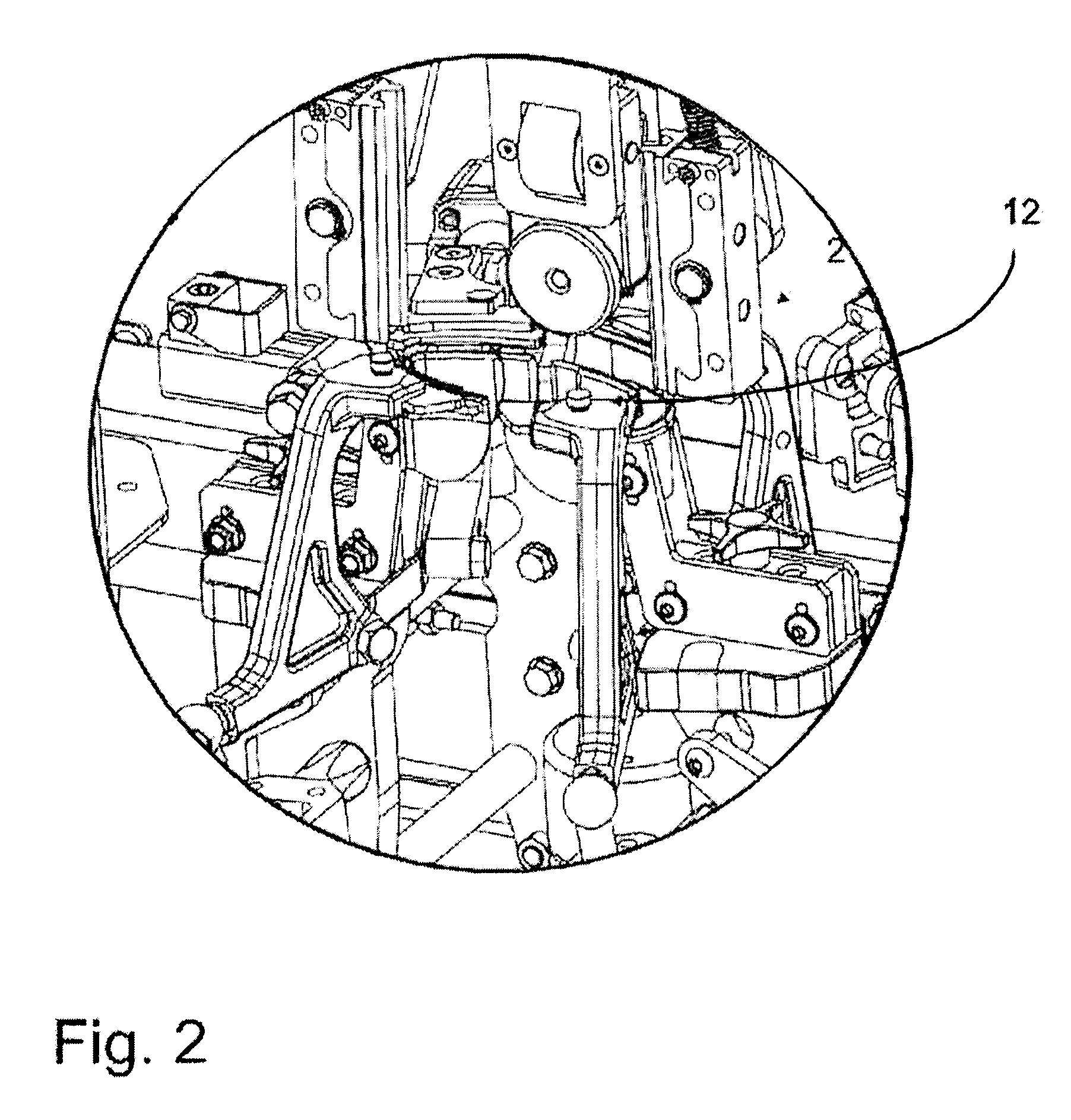

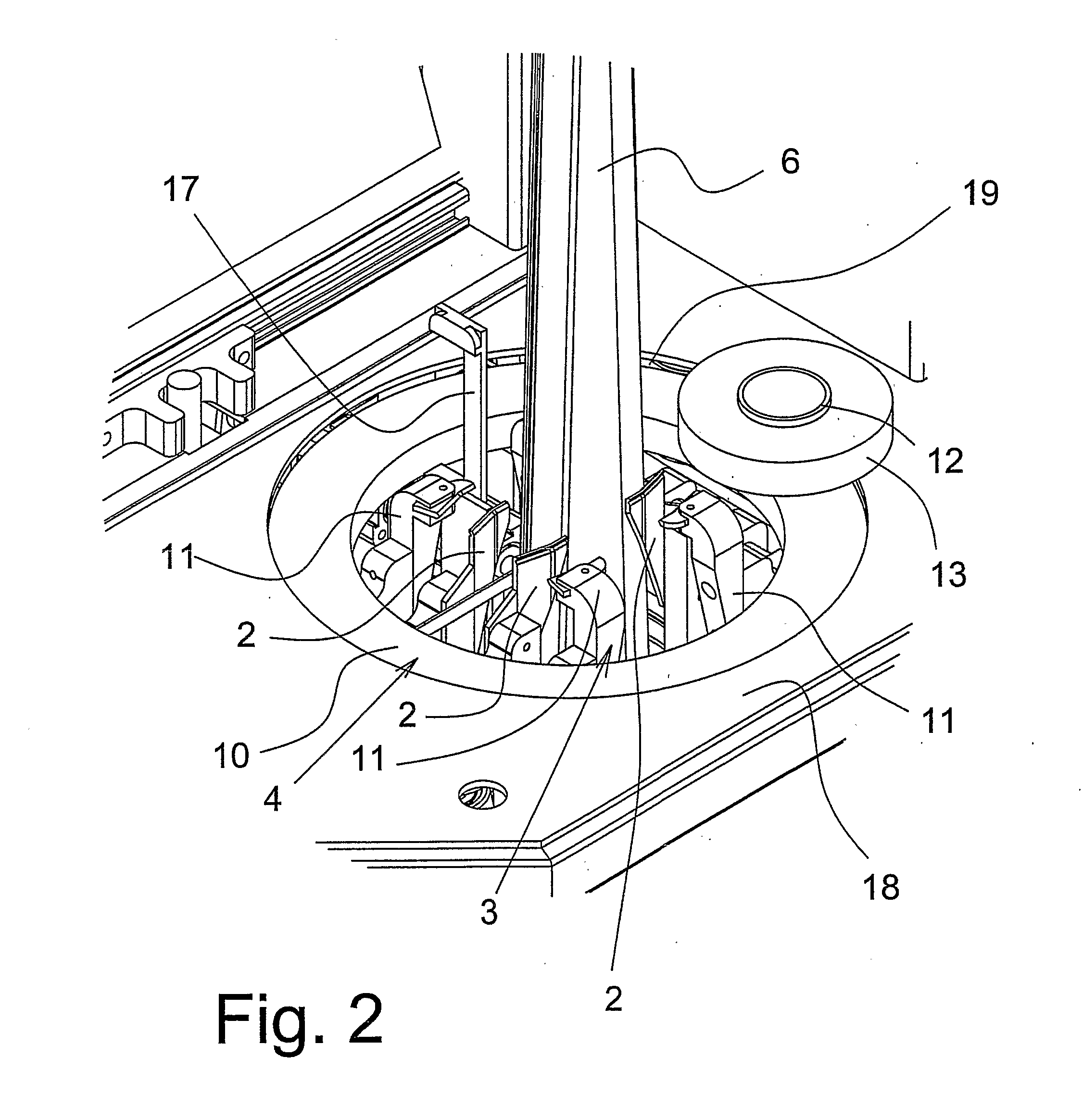

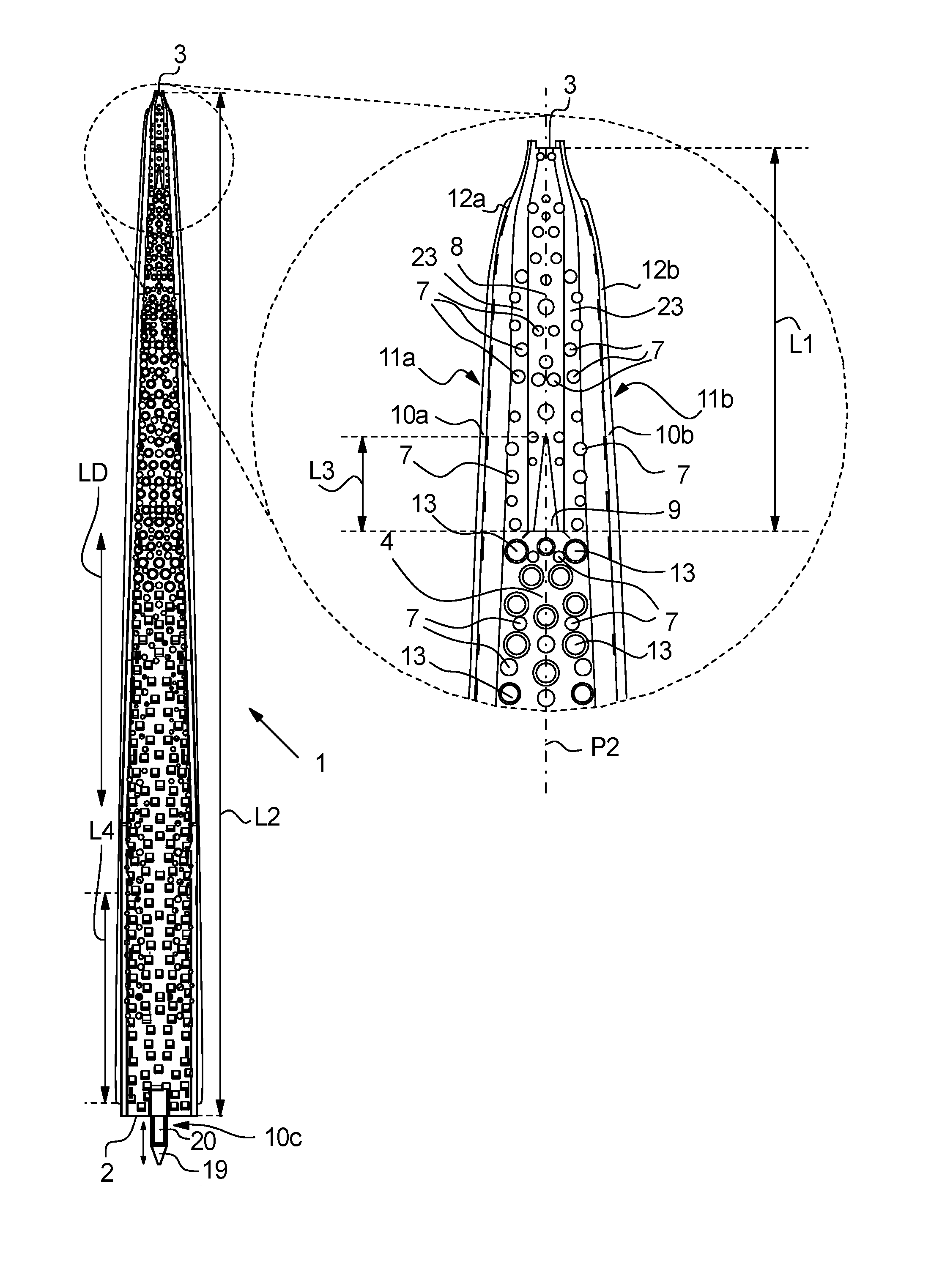

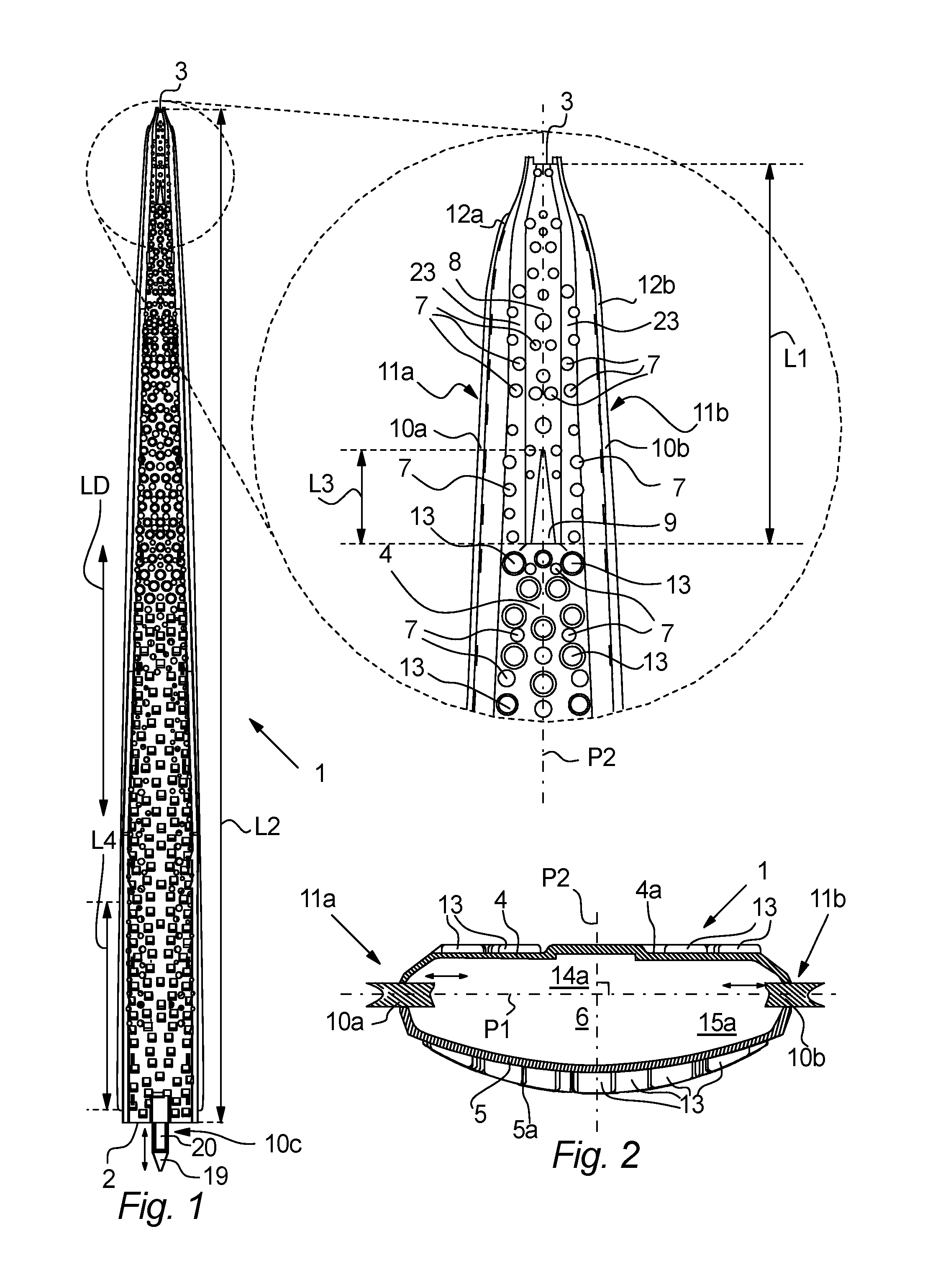

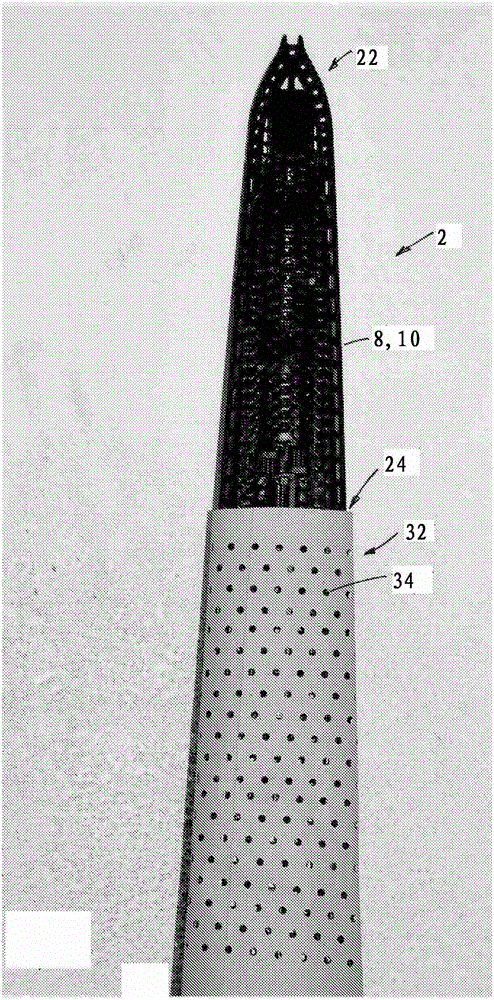

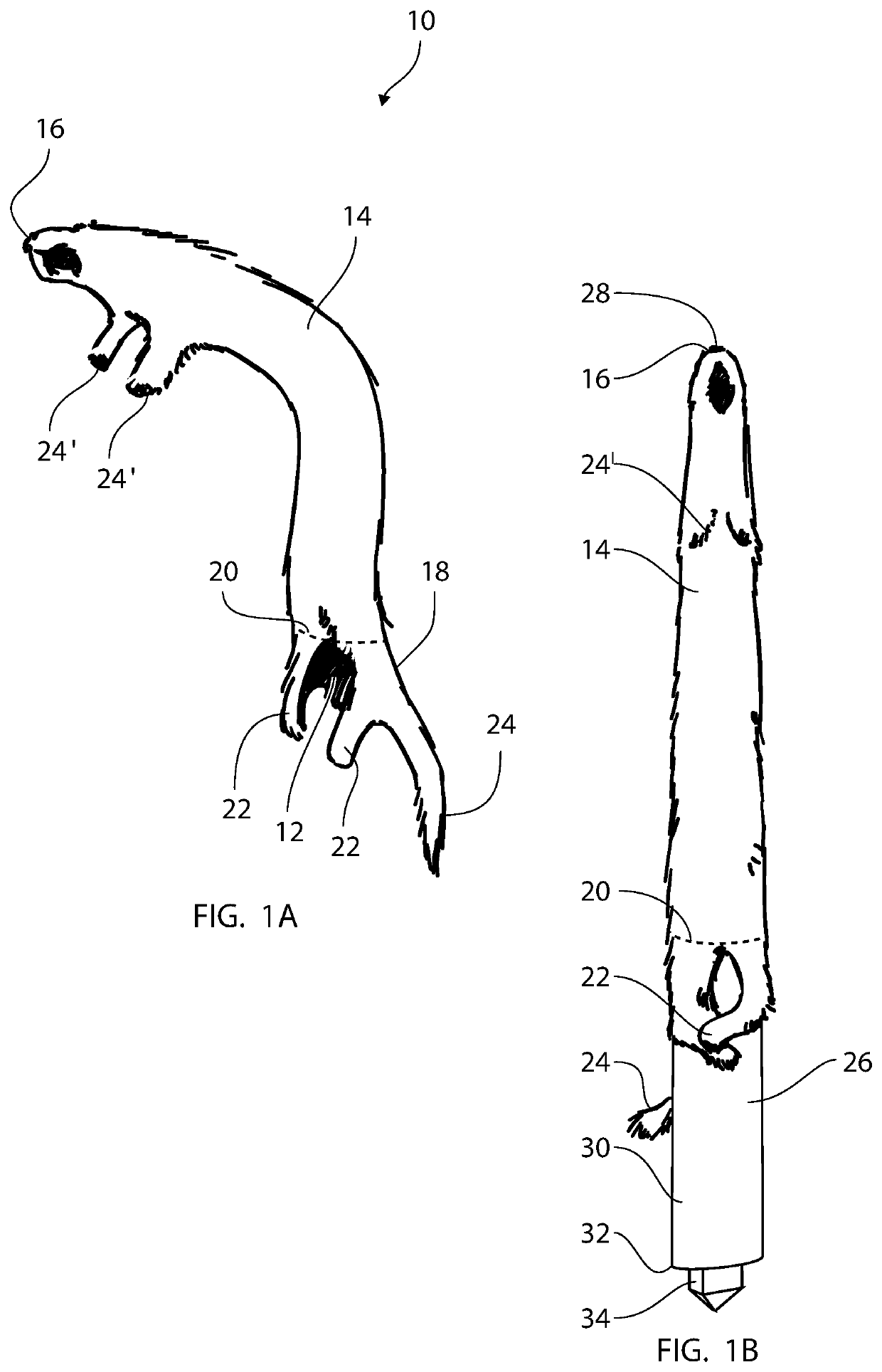

In connection with the non-destructive stretching and fastening of pelts (2) on distention elements / pelt boards (4), where the pelt is stretched and fastened in the stretched position during the drying process by means of a fixing bag, it has shown that the pelts give way (shrink) on each side of the tail root of the pelt, with the result that use is made of a number of staples for the fastening of these places on the stretched pelt. Since it is not at all desirable to use staples, a development of the pelt boards (4) has taken place, so that these have an arched extent around two transverse axes in relation to their longitudinal axes. Moreover, it has long been desirable to be able to stretch the pelts to a greater degree, which has not been possible with the use of the known stretching machines. This development has led to the development of a method and a stretching machine for the execution of the method, where the gripping elements are configured to correspond with the shape of the pelt board, and where the pelt is engaged by the gripping elements along the whole of the lower periphery of the pelt, so that the counter-hold force in the pelt is distributed over the whole periphery of the pelt, whereby the pelt can be stretched to a greater degree without any damage to the pelt in the areas of engagement for the gripping elements.

Owner:MINKPAPIR

Method And Apparatus For Fastening Fur On A Pelting Board And Winding Material Therefor

InactiveUS20070277564A1Without damaging quality of furFur dressingLeather stretching/tensioningEngineeringElectrical and Electronics engineering

Owner:EIKON TECH HLDG

Carding operating platform for floating hair on surface of fur

InactiveCN104531910AImprove the operating environmentImprove portabilityFur dressingEngineeringStart up

The invention relates to a carding operating platform for floating hair on the surface of fur. The carding operating platform is characterized by comprising an operation panel and a bellow, wherein an induced draft fan is fixedly arranged in the bellow; an air inlet communicated with the induced draft fan is formed in the operation panel, and a breathable sponge mat is arranged on the upper surface of the operation panel; a breathable placemat is laid on the breathable sponge mat, and the periphery of the placemat is wrapped on the sponge mat; an air outlet of the induced draft fan is connected with an exhaust duct, and the tail end of the exhaust duct is provided with a dust bag; a hanging rack for hanging a steam iron head and a cleaning hairbrush is arranged at one side end of the operation panel. With the technical scheme, the fur is laid on the breathable placemat on the upper surface of the operation panel, and the induced draft fan is started up, so that the fur is adsorbed on the upper surface under the action of the induced draft fan, and thus a hand can be freed up, the brushing and ironing can be simultaneously performed, and the probability is improved; fine hair suspended in air and brushed off by the hairbrush can be adsorbed due to the design of the induced draft fan, so that the operating environment of operators is improved.

Owner:TIANJIN YINGDAK

Method and machine for non-destructive stretching and fastening of a pelt on a pelt board

InactiveCN1852993AAchieve stretchIncrease valueLeather stretching/tensioningFur dressingMedicineEngineering

In connection with the non-destructive stretching and fastening of pelts (2) on distention elements / pelt boards (4), where the pelt is stretched and fastened in the stretched position during the drying process by means of a fixing bag, it has shown that the pelts give way (shrink) on each side of the tail root of the pelt, with the result that use is made of a number of staples for the fastening of these places on the stretched pelt. Since it is not at all desirable to use staples, a development of the distension elements / pelt boards (4) has taken place, so that these have an arched extent around two transverse axes in relation to their longitudinal axes. Moreover, it has long been desirable to be able to stretch the pelts to a greater degree, which has not been possible with the use of the known stretching machines. This development has led to the development of a method and a stretching machine for the execution of the method, where the gripping elements are configured to correspond with the shape of the distension element / pelt board, and where the pelt is engaged by the gripping elements along the whole of the lower periphery of the pelt, so that the counter-hold force in the pelt is distributed over the whole periphery of the pelt, whereby the pelt can be stretched to a greater degree without any damage to the pelt in the areas of engagement for the gripping elements.

Owner:MINKPAPIR

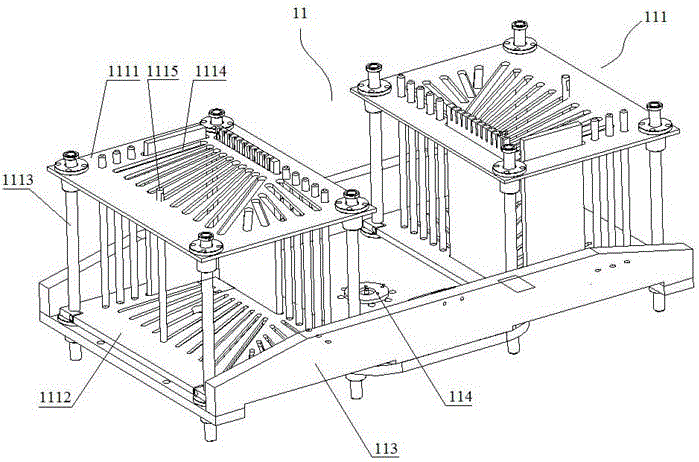

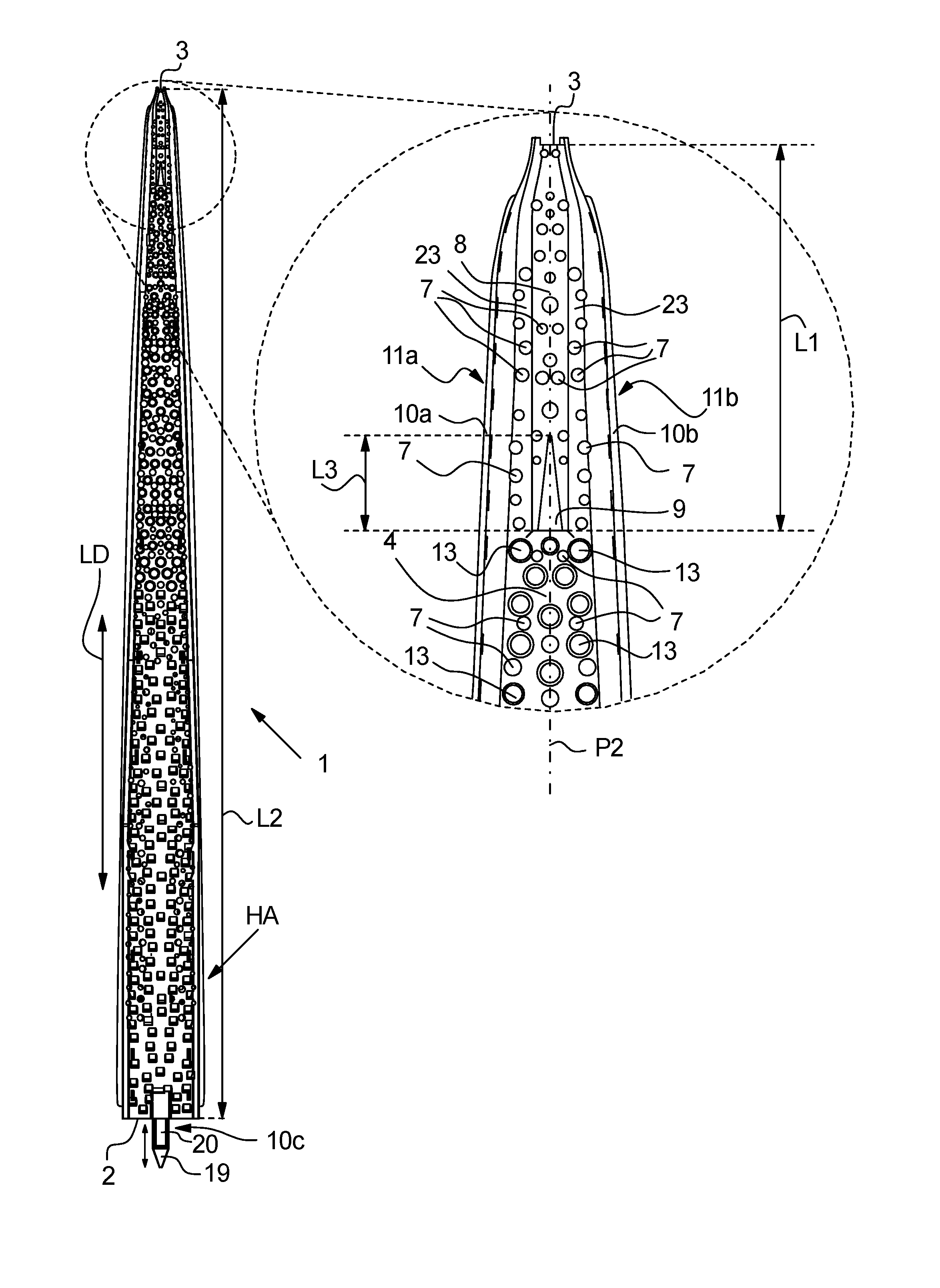

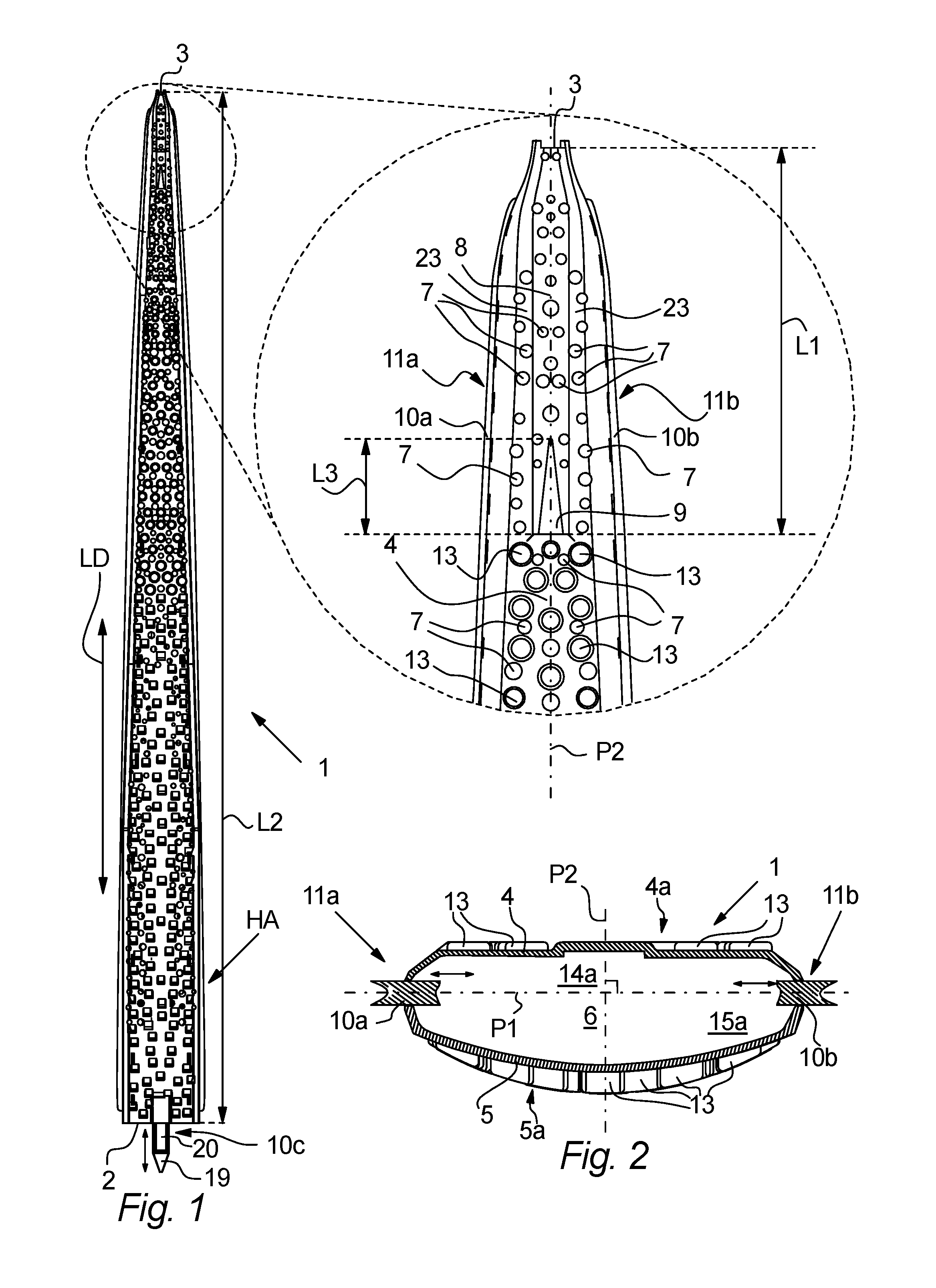

Pelt board

InactiveUS20160102373A1Small sizeRetain its shapeLeather stretching/tensioningFur dressingEngineering

A pelt board (11) is disclosed for stretching and drying of tubular pelts (5), the pelt board (11) having a tip end (4) from which the pelt is drawn onto the pelt board (11) and a foot end (2), wherein the pelt board (11) has a lower part (8) nearest the foot end (2) where the outer cross-sectional circumference of the pelt board (11) is substantially constant and an upper part (9) between the lower part (8) and the tip end (4), where the outer cross-sectional circumference of the upper part (9) gradually decreases towards the tip end (4), wherein the longitudinal extent (L1) of the lower part (8) is in the range of 36 to 50 cm, more preferably in the range of 40 to 45 cm. Furthermore is disclosed an extension piece for connecting with a standard pelt board and fat-absorbing inner bags (13, 19) for use with the pelt board (11).

Owner:EIKON TECH HLDG

Production process for preparing leather by virtue of numerical control cutting machine

ActiveCN106591504AImprove stabilityHigh glossFur dressingSkins/hides/leather/fur manufacturing apparatusNumerical controlEconomic benefits

The invention relates to the technical field of leather processing, and specifically relates to a production process for preparing leather by virtue of a numerical control cutting machine. The production process comprises the following steps: (1) material selection: using sheepskin leather, pigskin leather or calfskin leather as a crust; (2) pattern drawing: drawing a pattern through a computer of the numerical control cutting machine, and outputting the pattern; and (3) numerical control cutting: cutting the lines of reptiles in the nature on the surface of the leather through the output pattern by the numerical control cutting machine, so as to prepare the leather. The production process disclosed by the invention has simple steps, and is convenient to operate and control, stable in quality and high in production efficiency; the raw materials are low in price and easily available; and the leather is high in utilization rate, low in production cost, and capable of realizing large-scale industrialized production. The quality of the prepared finished leather is similar to that of top-layer leather, the additional value of the finished leather is greatly increased, and the finished leather is wide in application range and high in economic benefit.

Owner:DONGGUAN TIANYI LEATHER TECH CO LTD

Pelt board with expansion means

InactiveUS9499871B2Reduction in cross-sectional circumferenceEasy to disassembleLeather stretching/tensioningFur dressingEngineeringBiological activation

Owner:EIKON TECH HLDG

Pelt board

InactiveUS20170051368A1Improve abilitiesSurface roughnessFur dressingLeather dryingEngineeringMechanical engineering

A pelt board for drying of tubular pelts has a tip end from which the pelt is drawn onto the pelt board and a foot end. The pelt board has at least one inlet and an air conducting arrangement that includes openings in broad side surfaces connected to the inlet. At least one of the broad side surfaces within at least a holding area is provided with protrusions, which are arranged in a staggered manner in the longitudinal direction of the pelt board so as to deflect the air flow between the broad side surfaces and a tubular pelt arranged on the pelt board from a flow path parallel to the longitudinal direction of the pelt board. The holding area is positioned in the half part of the pelt board nearest the foot end and extends at least 25 or 30 cm in the longitudinal direction of the pelt board.

Owner:EIKON TECH HLDG

Hair controller for a pelt stretching machine

Owner:MINKPAPIR

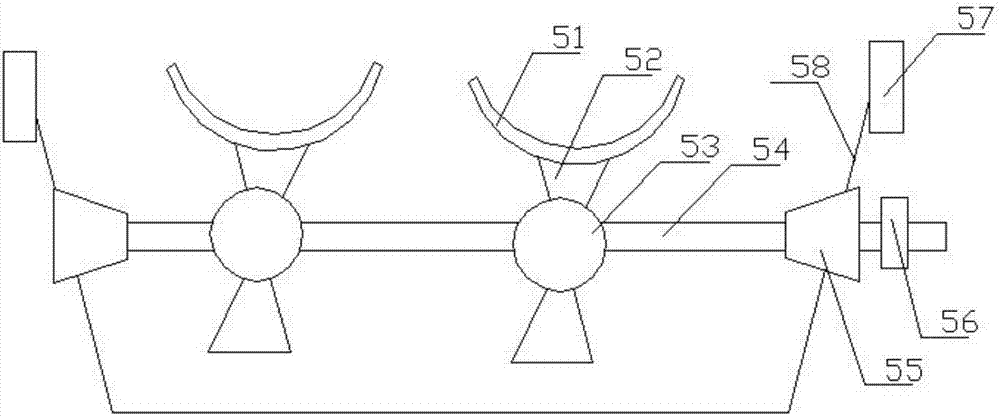

Leather teasing equipment

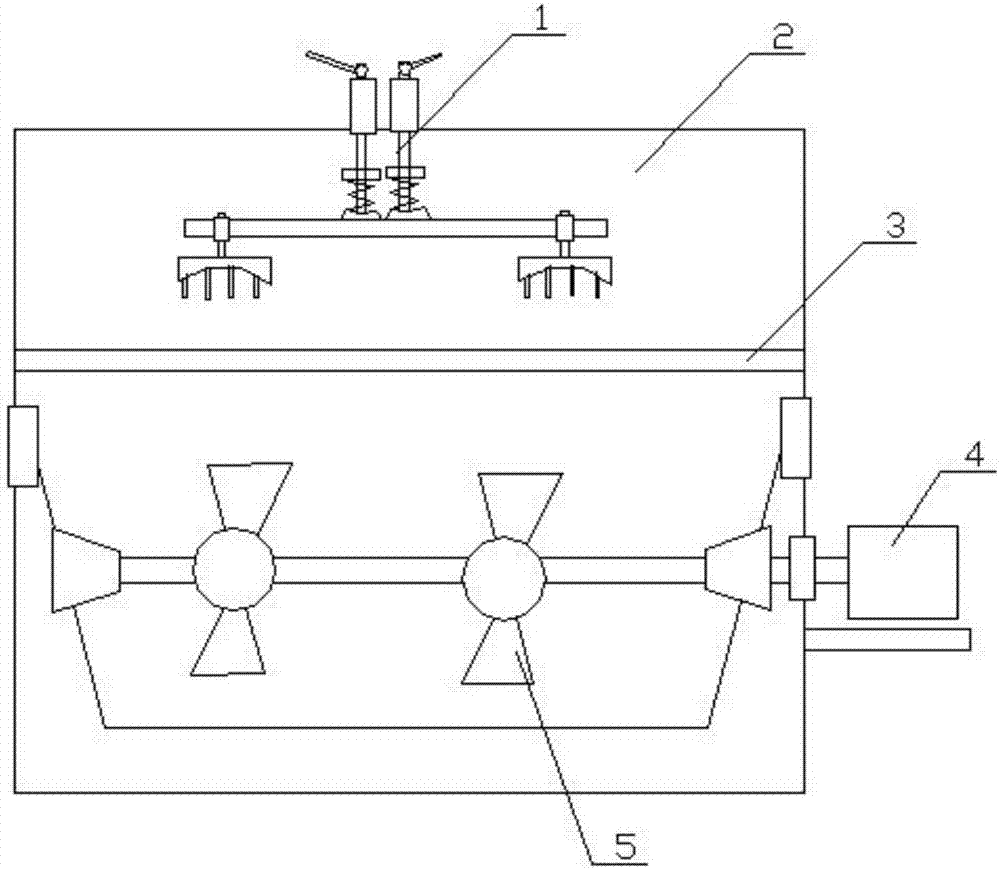

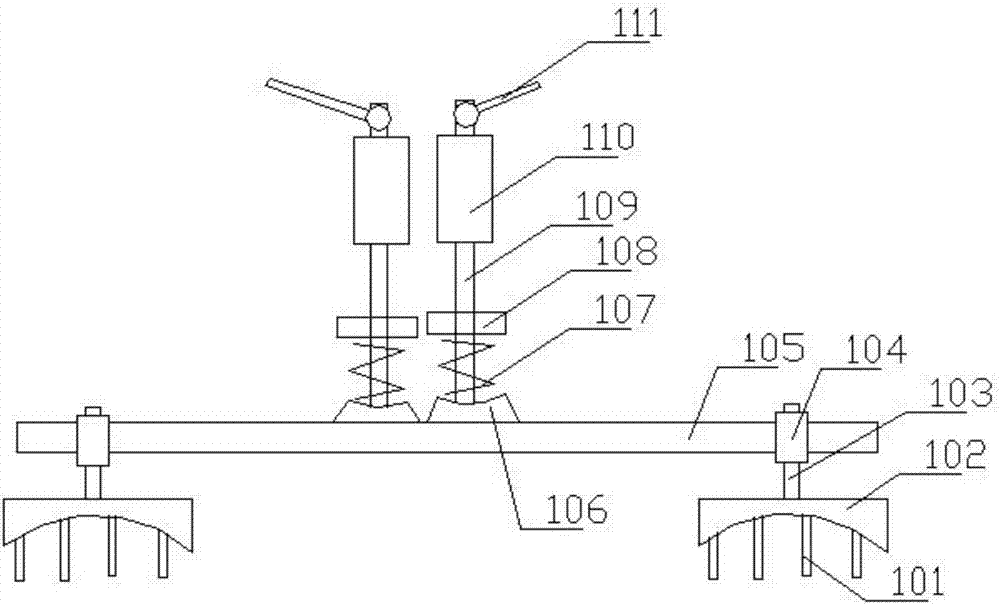

The invention relates to the technical field of leather processing, in particular to leather teasing equipment. The leather teasing equipment comprises a machine box, a loading shelf, a first teasing part, a second teasing part and a motor, wherein the loading shelf is connected in the middle of the machine box in a clamped mode, the first teasing part is arranged at the upper portion of the machine box in a penetrating mode and located at the upper side of the loading shelf, and the motor is arranged at the end portion of the second teasing part in a rotating mode; and the first teasing part comprises a cross beam, mounting cylinders, operating rods, operating discs, teasing rods, supporting seats, lifting rods, compressing pieces, springs, lifting guide cylinders and handles, wherein the mounting cylinders are arranged on the end portion of the cross beam in a penetrated mode, the teasing rods are arranged at the lower portions of the operating discs in a clamped mode, the supporting seats are connected with the upper portion of the cross beam in a clamped mode, the springs are arranged on the lifting rods in a sleeving mode and compressed between the supporting seats and the compressing pieces, and the handles are arranged at the upper ends of the lifting rods in a rotating mode. According to the leather teasing equipment, the two surfaces of leather can be teased simultaneously through the first teasing part and the second teasing part, and therefore the teasing efficiency is high.

Owner:JIASHAN LONGXIANG ARTIFICIAL FUR

Preparation method for chenille oar leather product

ActiveCN107338338AImprove processing efficiencyImprove efficiencyFur shearingFur dressingWaxColor changes

The invention provides a preparation method for a chenille oar leather product. The preparation method comprises the following steps that (1) chenille fur after retanning and dyeing is neatened for the first time; (2) the fur after processing in the first step is subjected to staking and leather buffing and then is neatened for the second time; (3) a top side of the fur after processing in the second step is subjected to bottom oar spraying, color paste spraying and top oar spraying in sequence; (4) after the fur after processing in the third step is milled, wax change effect leather is obtained. A wax color change effect glaze can be obtained from a chenille flesh side. The product has good color fastness to light, dry and wet rubbing color fastness and PVC transfer resistance.

Owner:HENAN PROSPER SKINS & LEATHER ENTERPRISE

Tubular pelt board inner bag

InactiveCN103069013ALarge diameterFur dressingLeather stretching/tensioningAbsorbent materialEngineering

Using modern pelt boards (2) with surface (10) with open structure (12) in connection with drying out pelts (36), where the pelt is retained in stretched position during the drying procedure with a holding bag (44), which in an area near the tail part of the pelt is pressing the pelt against a special holding area (4) n the surface of the pelt board, there may occur areas of the pelt where it can't be retained sufficient during the drying procedure, to maintain the stretched size, and further the occurs areas where the pelt is not dried out sufficient and thus becomes moldy or rot. To solve this problem there is indicated a tubular pelt board inner bag (2) of perforated, fat-and moisture absorbing material which is peculiar in, that the pelt board inner bag (6) at least nearest to the first end boundary (26) and / or the second end boundary (24) comprises a number of removals in the bag material in shape of holes (30, 34), and / or rows of holes (28, 32), where the holes (30, 34) has a larger diameter than the perforations. The rows of holes ensures an improved retaining of the pelt in the stretched out position, and further a better drying out of the pelt in the areas where the rows of holes occurs.

Owner:MINKPAPIR

Fur stretching device

InactiveCN111826477AAffect processing and productionChange heightFur dressingSkins/hides/leather/fur manufacturing apparatusEngineeringSupport plane

The invention provides a fur stretching device, and relates to the technical field of fur processing. The fur stretching device comprises a shell, a placement plate, a limit plate, a support frame, slide blocks, a connection plate, a pressing plate, a rotary knob, a rotary disc, a pressing mechanism, a stretching mechanism, a fixed plate and a fixed knob, wherein the fixed plate is fixedly connected to the top end of the shell; the placement plate is fixedly connected to the top end of the fixed plate; the slide blocks are slidably connected to the left side and the right side of the placementplate; the connection plate is fixedly connected between the slide blocks; the pressing plate is arranged between parts below the connection plate, of the slide blocks; the rotary knob penetrates through the top end of the connection plate; the pressing mechanism is arranged at a part close to the middle part, of the top end of the placement plate; the support frame is arranged above the pressingmechanism; the bottom end of the support frame is fixedly connected with the shell; the limit plate is fixedly connected to one side of the placement plate; the rotary disc is arranged at the left side of the shell; and the stretching mechanism is arranged in the shell. According to the fur stretching device, the problem of a poor fur stretching effect due to excessive stretching and non-uniformstress on fur in a fur stretching process, is solved.

Owner:闻平

Leveling mechanism for fur processing

InactiveCN108893565AClear structureIngenious designFur dressingSkins/hides/leather/fur manufacturing apparatusLeveling mechanismEngineering

The invention provides a leveling mechanism for fur processing. The leveling mechanism for fur processing comprises a substrate, a first mounting base connected to the left side of the upper end of the substrate in a clamping manner and a second mounting base connected to the right side of the upper end of the substrate in a clamping manner. The leveling mechanism for fur processing further comprises a first guide bar connected to the first and second mounting bases and a roller pressing part slidably arranged at the first guide bar. The leveling mechanism for fur processing is clear in structure, skillful in design, good in leveling effect and high in leveling efficiency.

Owner:JIASHAN SHENGLAISI CASHMERE

Work table for an automatic machine for cutting leathers and the like

ActiveUS7726159B2Shorten the timeImprove productivityLeather clicking/perforating/clickingLeather stretching/tensioningEngineeringMechanical engineering

A work table for an automatic machine for cutting leathers and the like, includes a plurality of holes opening outwards and communicating with a vacuum source, to make portions of leathers to adhere to the active surface (3) of the work table (1). The work table (1) includes a central body (1a), supported by a fixed structure (2). At least one lateral portion (1h, 1j), connected to the fixed structure (2), is moved by first motion means (10h, 10j) between at least one work configuration (K1), in which its active surface (3h, 3j) is aligned with the active surface (3a) of the central body (1a), to define the active surface (3) of the work table (1), and a rest configuration (K2) of reduced dimension, in which the active surfaces (3a, 3h, 3j) of the central body (1a) and the lateral portion (1h, 1j) are arranged at an angle with respect to each other.

Owner:TESEO SPA

Pelt board for drying tubular pelts

InactiveUS20170051366A1Durable peltReliable and efficient peltLeather stretching/tensioningFur dressingDistensionInternal cavity

A pelt board for tubular furs such as mink, includes a foot end and a tip end, and also includes half parts extending between opposite longitudinal edges, and an internal cavity for distributing drying air between the half parts. A distension system is configured to reduce or increase the circumference of the pelt board dependent on the setting of said distension system. The half parts include ventilation openings, which provide a flow of drying air between the internal cavity and the outer surface of the half parts. The outer surface of at least one of the half parts includes an outer guiding recess for receiving an air exchange part. The guiding recess extends substantially from the tip end of the pelt board in a direction towards the foot end, and ends substantially at a drying air supply opening to the internal cavity.

Owner:EIKON TECH HLDG

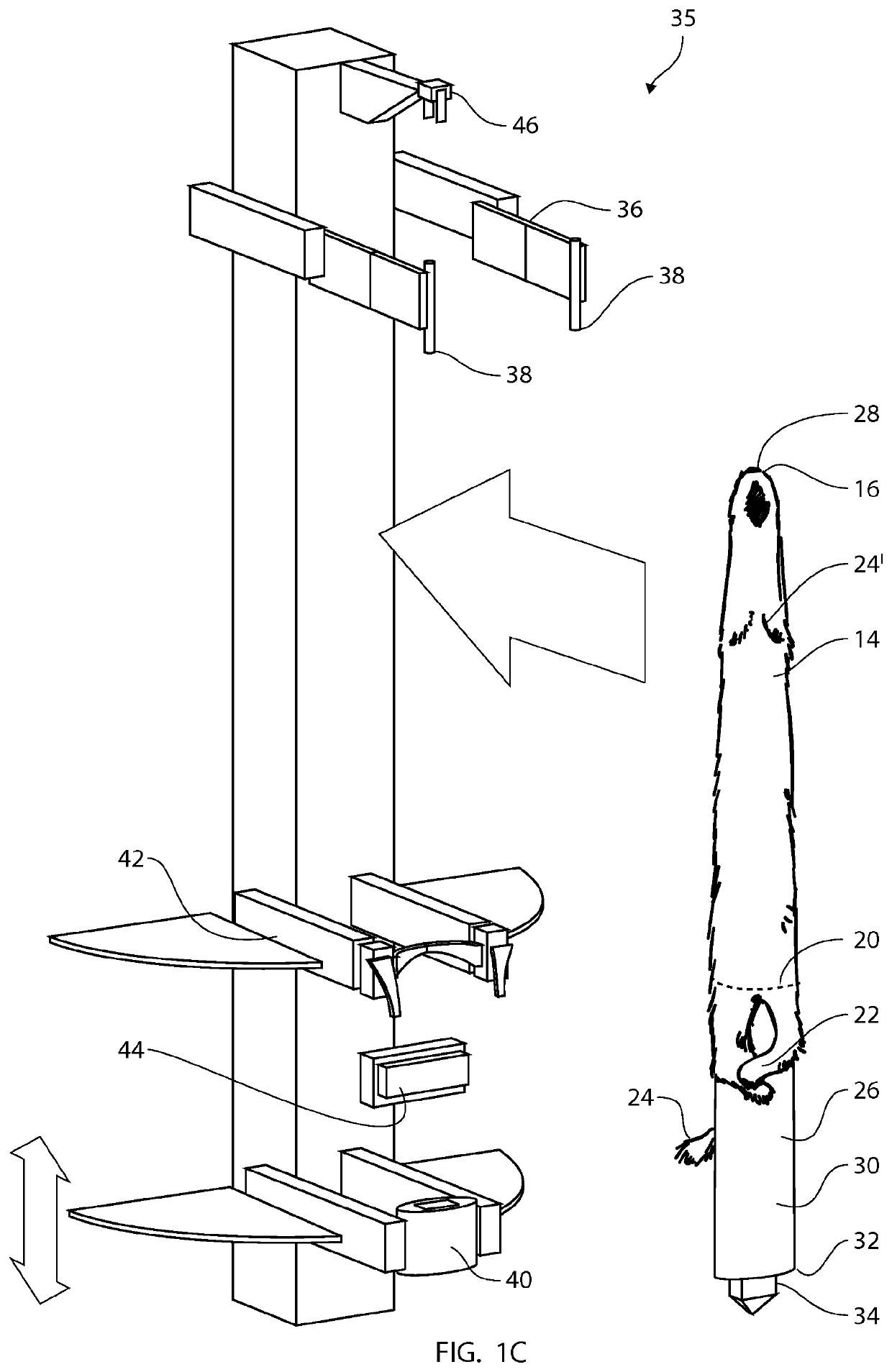

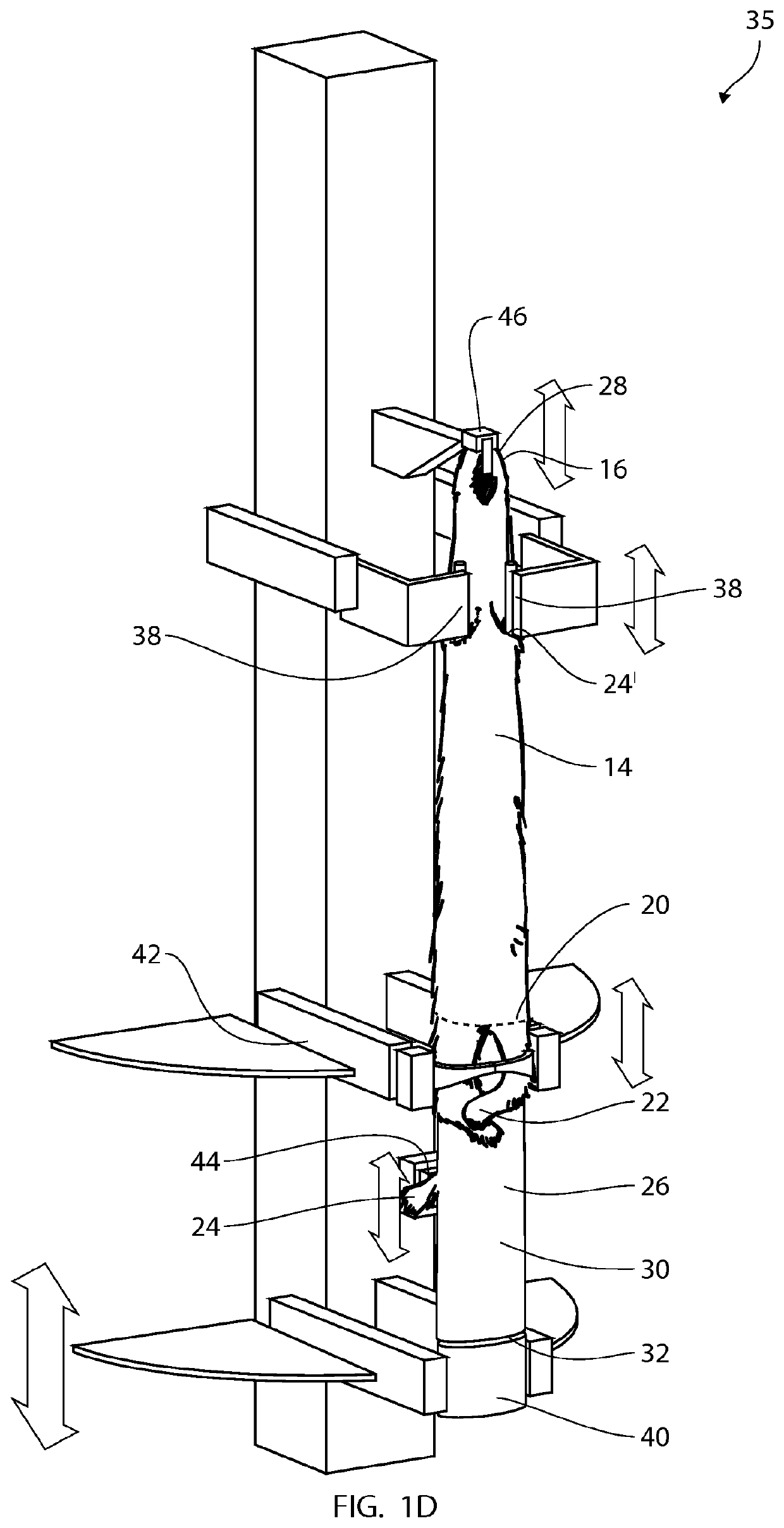

Apparatuses and methods for stretching a pelt on a pelt board

A stretching apparatus for stretching a pelt on a pelt board and a method of stretching a pelt on a pelt board, where the pelt has a substantially tubular shape defining an inwardly oriented leather side, an outwardly oriented fur side, a nose end and a rear end. The pelt board defines a top end for accommodating and fixating the nose end of the pelt, a circumferential wall for facing the inwardly oriented leather side of the pelt and a base end located opposite the top end. The method comprises the steps of providing a stretching apparatus comprising a holding device, a fastening device comprising a gripping mechanism, and a drive mechanism connected between the holding device and the fastening device. The method further comprises holding the base end of a pelt board by the holding device so that the pelt board extends outwardly along a longitudinal direction from the holding device. Furthermore, the method comprises the fastening of the rear end of the pelt by using the gripping mechanism of the fastening device. The method also comprises moving the holding device and the fastening device relative to each other in the longitudinal direction by using the drive mechanism for applying a stretching force onto the pelt by the drive mechanism corresponding to an estimated maximum stretching force value or more during a total time period.

Owner:MINKPAPIR

Fox fur combing device based on fur processing

The invention discloses a fox fur combing device based on fur processing, and relates to the technical field of fur processing. The problems that a manual combing manner is low in work efficiency, andnot beneficial to large-amount processing, a mechanical combing device carries out cleaning mainly through an air flow, a large amount of electric appliances are needed for finishing combing, cost expenses are high, control is not easy, and rapid processing is not facilitated are solved. The fox fur combing device based on fur processing comprises a frame body, the bottom of the frame body is ofan empty frame structure, a collecting box capable of being placed in a length and width matching manner is mounted at the bottom of the frame body, a fixing device is fixedly mounted on the top of the other end of the frame body through a bolt, a planetary gear and a brush shaft are mounted, the fur can be continuously cleaned, meanwhile, in the moving process, the brush shaft is in the reverse rotation state, the fur can be tensioned, fur combing is ensured to the maximum degree, the combing efficiency is improved, the combing process can be manually finished, and cost is saved.

Owner:李承红

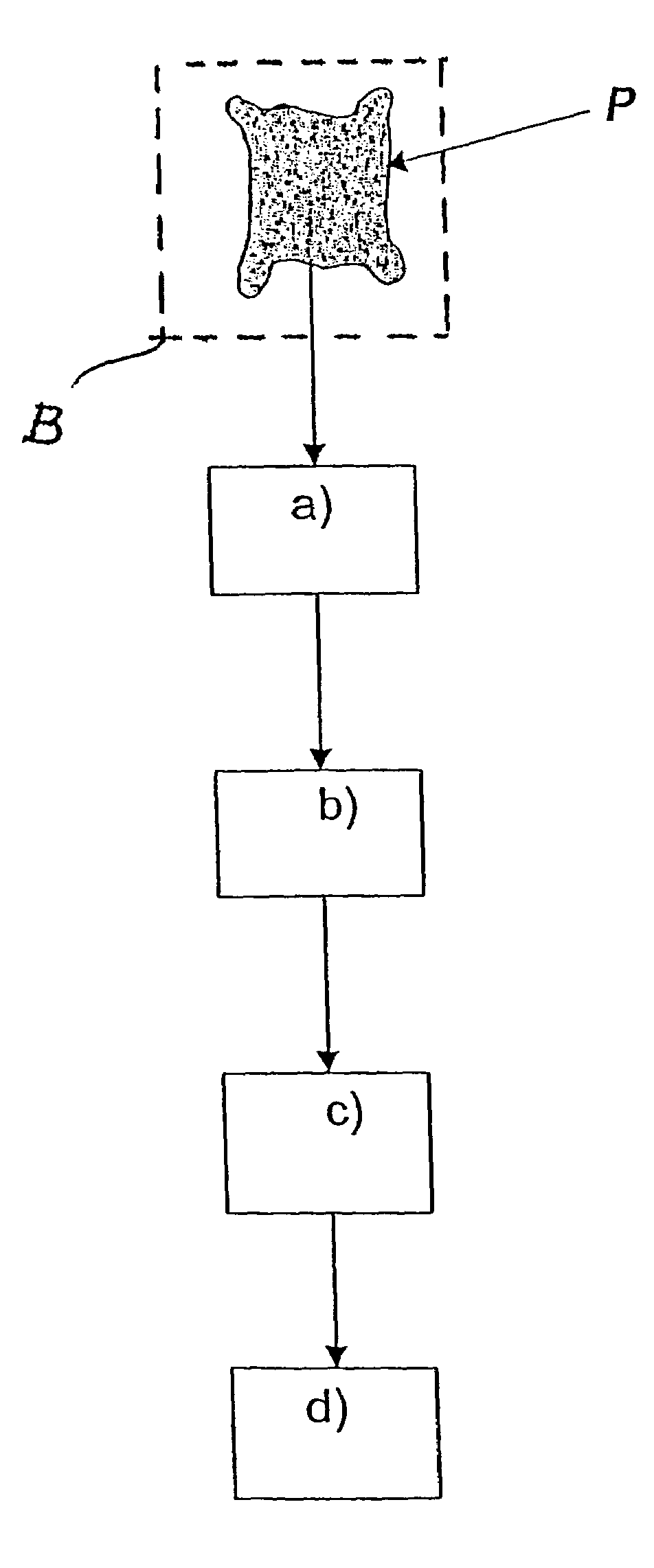

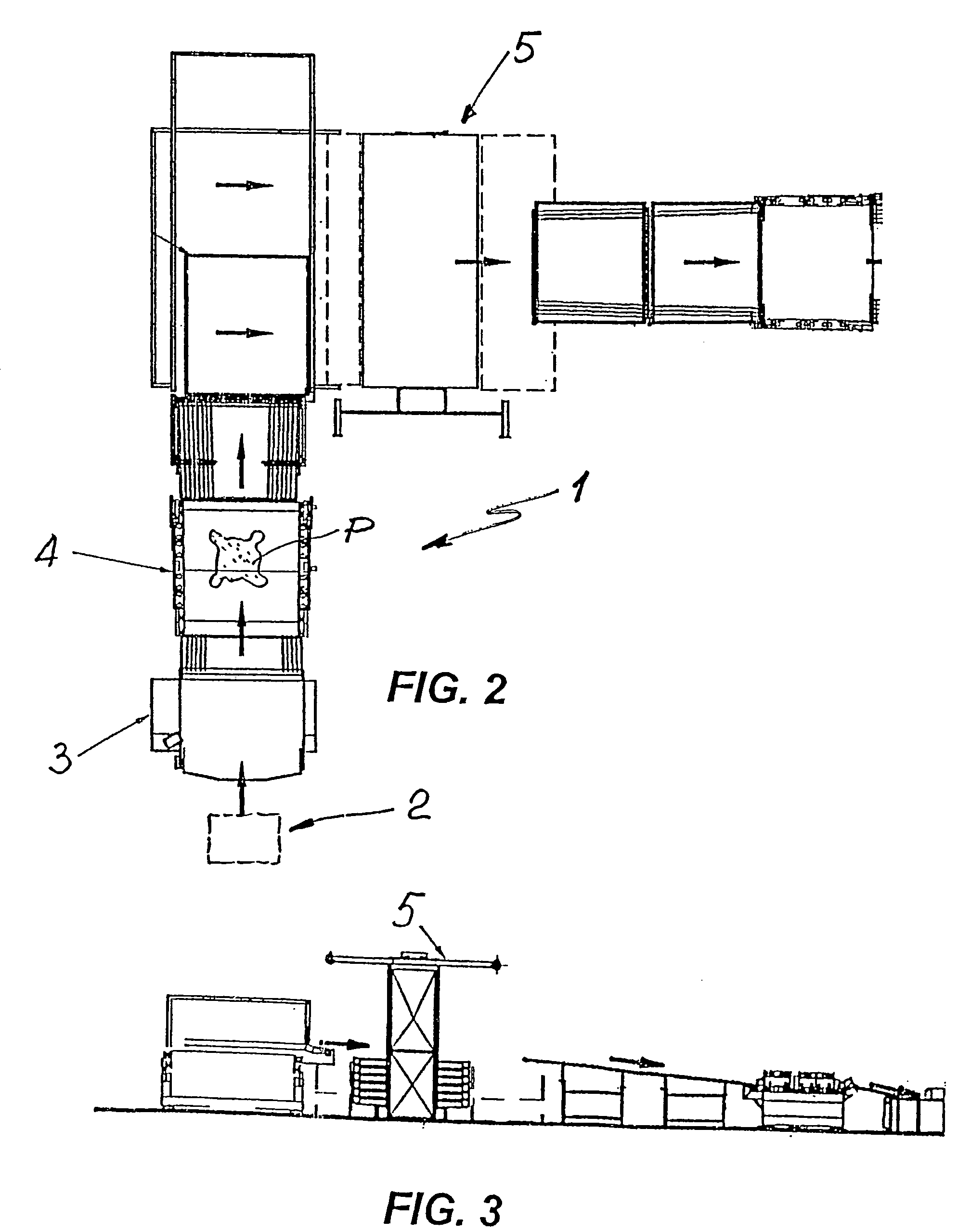

Method and line for the continuous stretching of hides and other similar products

InactiveUS6957553B2Increase surface areaConstant thicknessPre-tanning chemical treatmentFur dressingProduction lineEngineering

A method for the continuous wet stretching of industrial hides and other similar products comprises the following steps: a) removal of uniformly wetted hides following a treatment with liquids, such as tanning, re-tanning or the like, b) partial pre-drying of the wetted hides so as to reduce their residual relative moisture to a value of between 35% and 65%, c) stretching of the moist hides by means of localized mechanical stresses applied in directions which are substantially perpendicular to the plane of lie of the hides so as to achieve a predetermined increase in surface area, d) drying of the stretched hides until they have a residual relative moisture of between 7% and 30% so as to stabilize and thermally fix the stretched hides. The hides are kept in substantially constant relative humidity conditions with the mechanical stresses distributed uniformly over the entire surface area of the hides.

Owner:OFFICINE DI CARTIGLIANO SPA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com