Patents

Literature

88results about How to "Improve carding efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

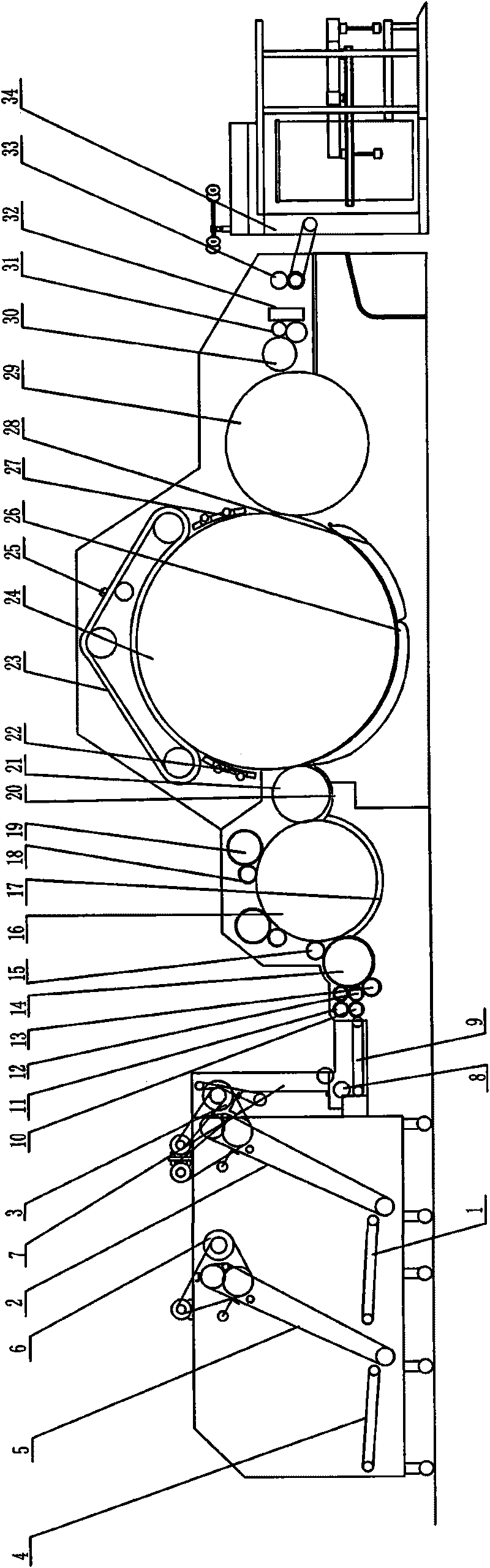

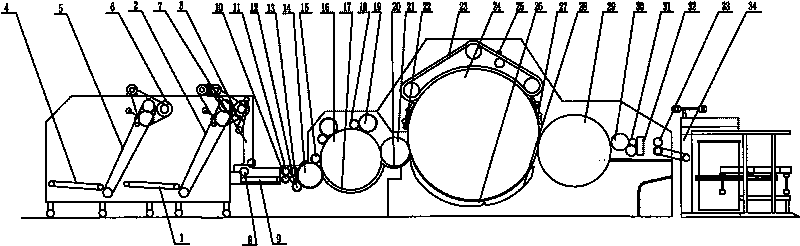

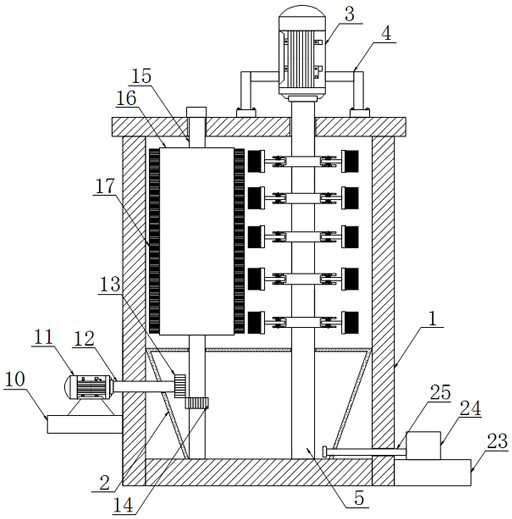

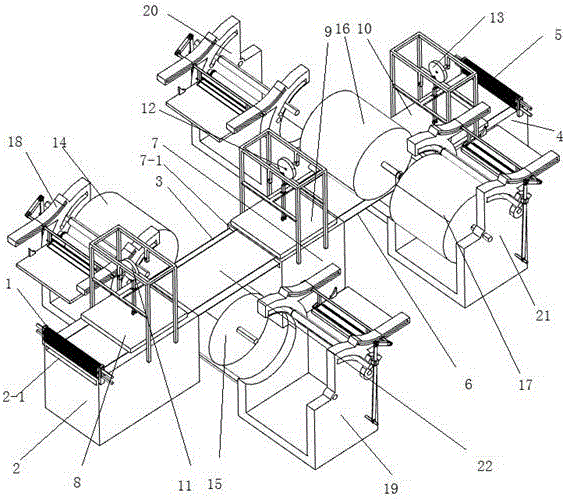

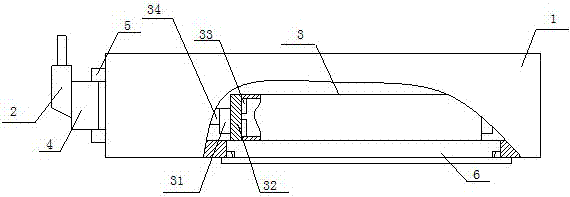

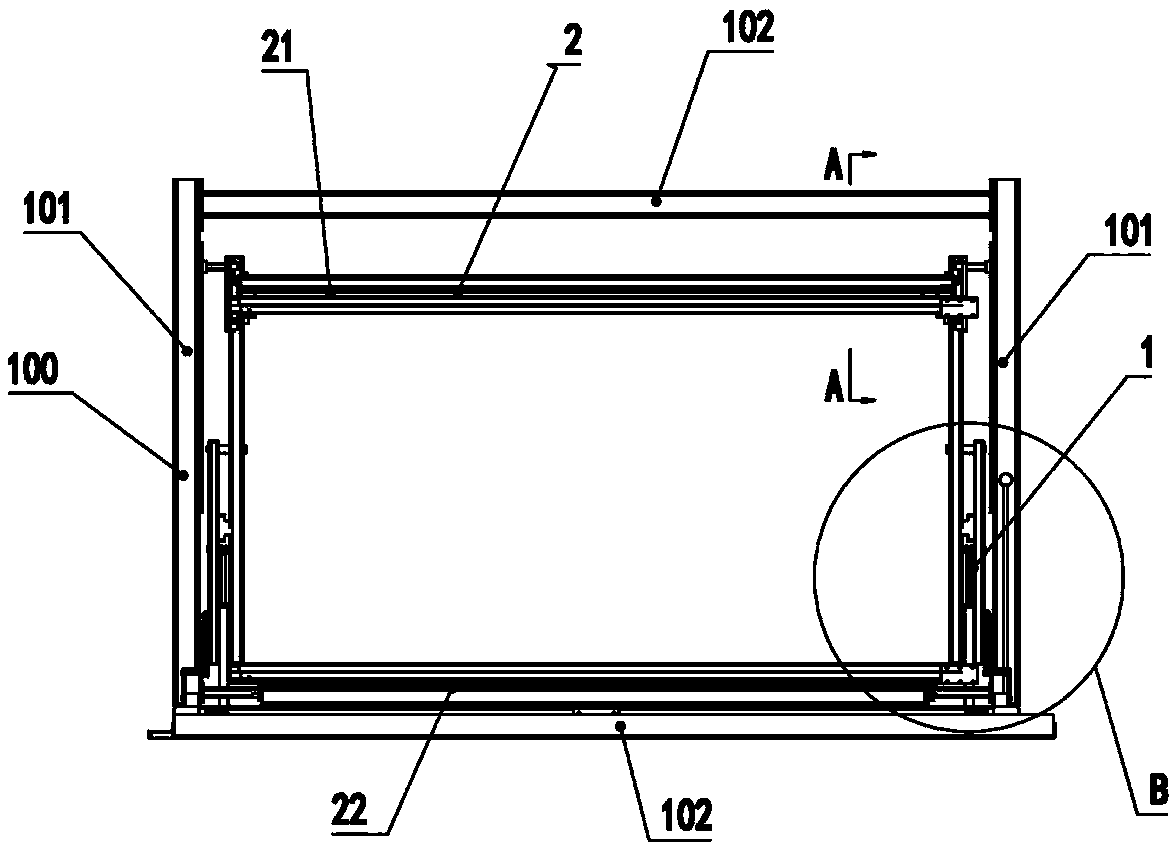

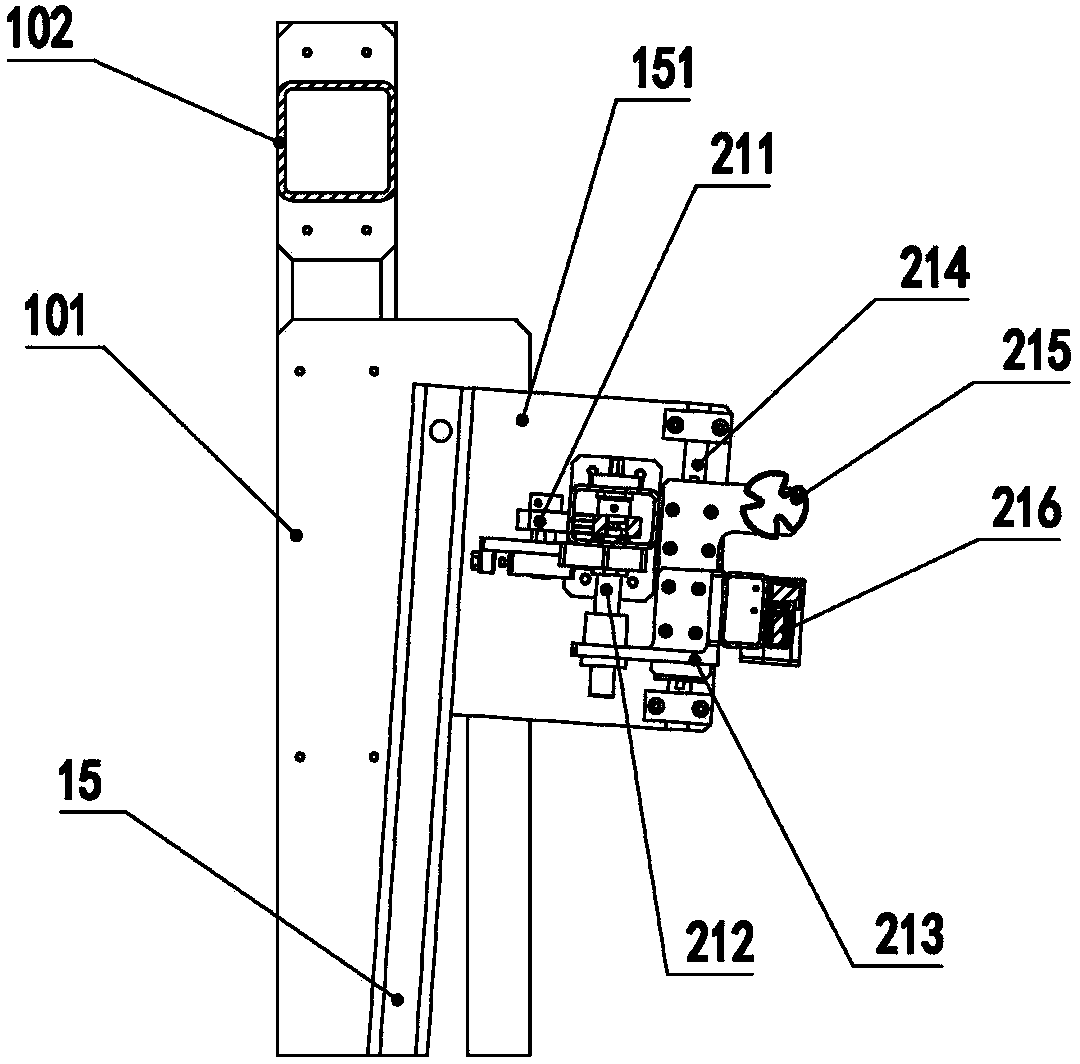

Novel semi-spinning specialized equipment

InactiveCN101709521AEasy to changeImprove the initial opening effectCarding machinesWorstedEngineering

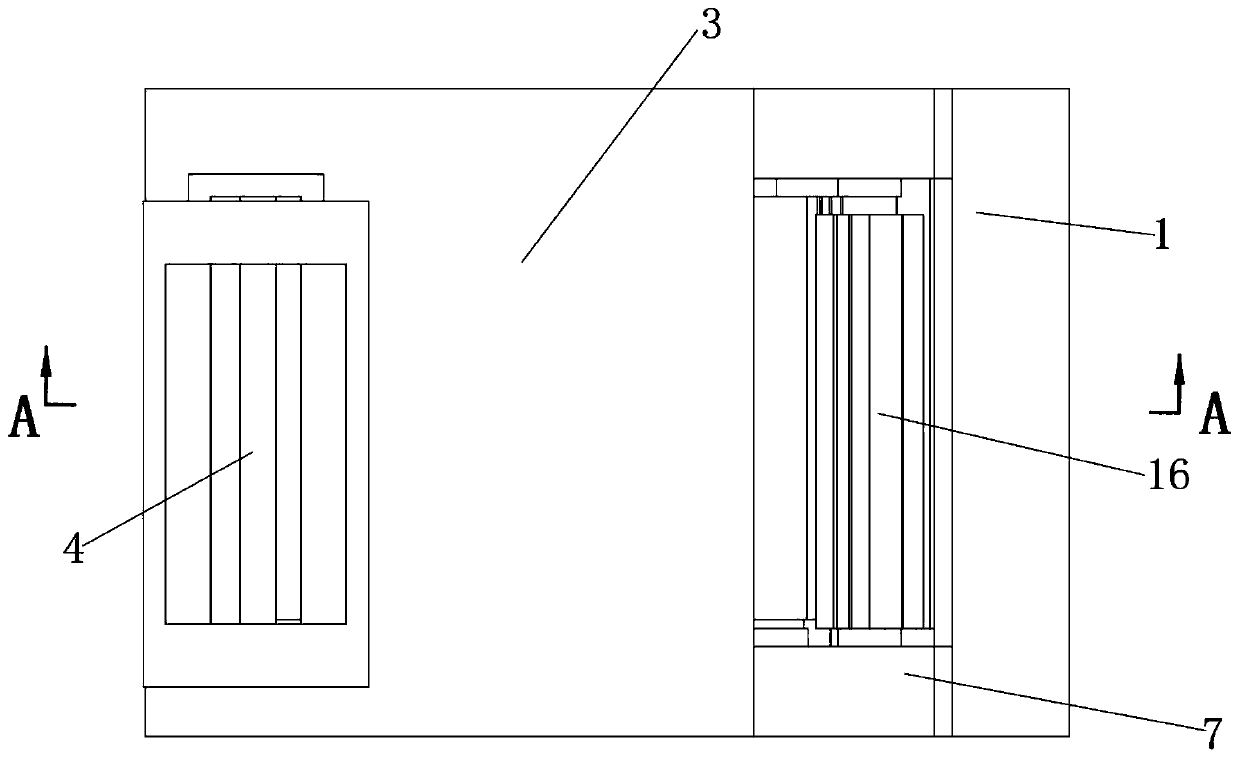

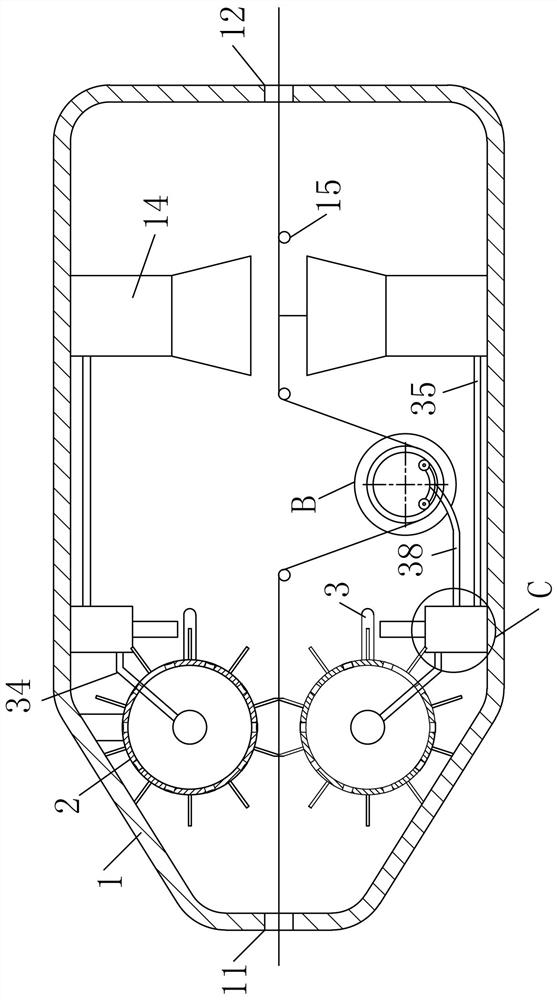

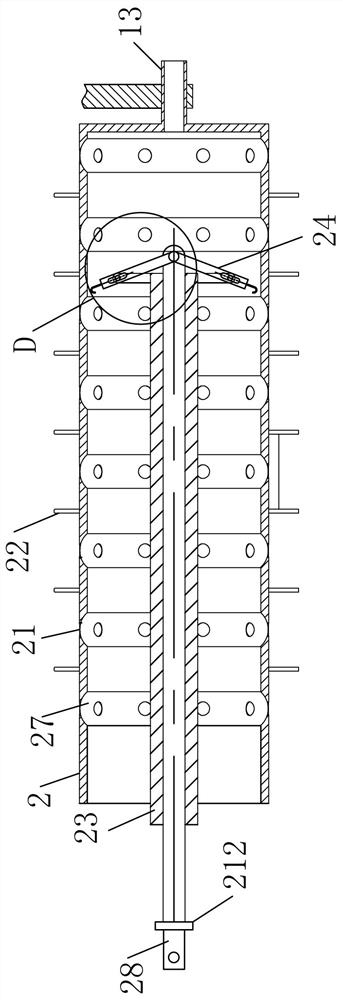

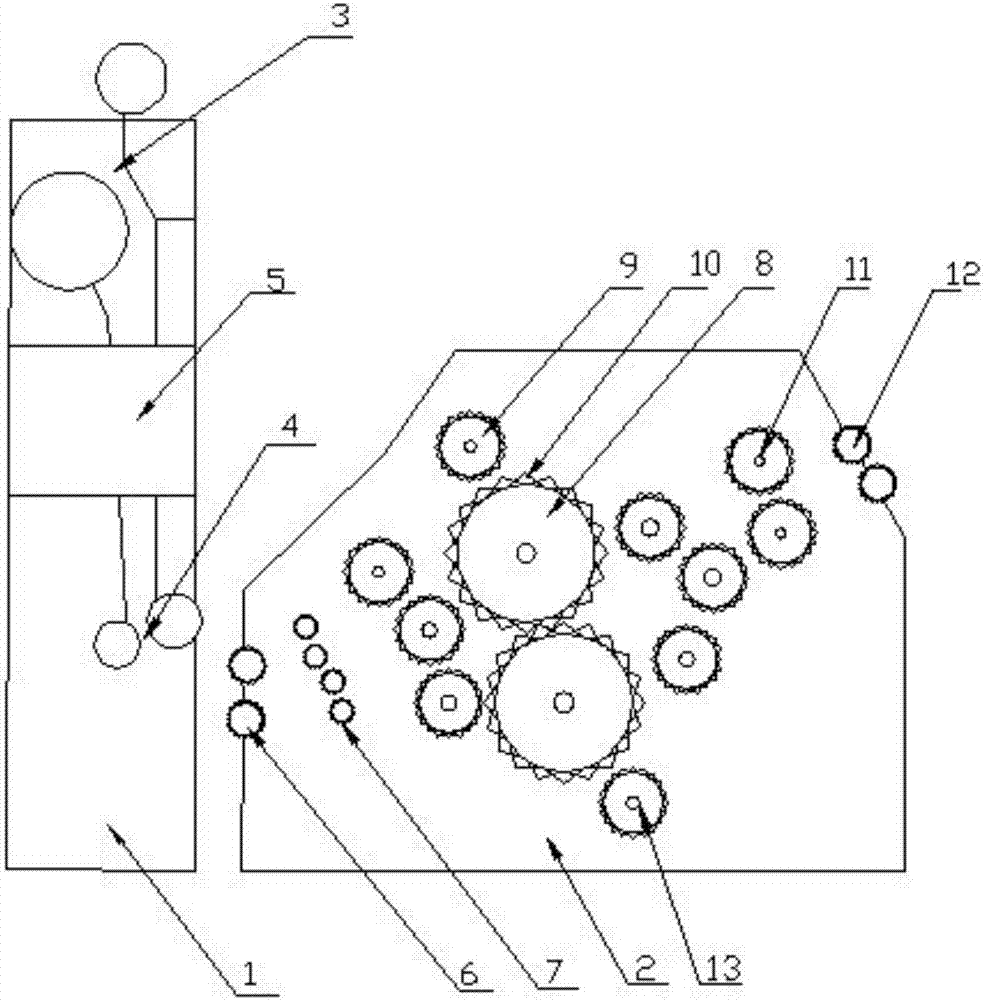

The invention discloses novel semi-spinning specialized equipment, comprising a feeding mechanism, a carding mechanism, a stripping and taking mechanism and a strip forming and coiling mechanism; the rear part of the feeding mechanism is provided with a second flat-bottom lattice and a second inclined-spike lattice in sequence; the rear side of the upper part of the second inclined-spike lattice is provided with a second hair uniformizing roller and a second hair uniformizing rake; the front side of the upper part of the second inclined spike lattice is provided with a second hair stripping roller, the lower part of which is provided with a first flat-bottom lattice; the carding mechanism comprises a big cylinder; a rotary cover plate is arranged above the big cylinder, the front part of which is provided with a front fixed cover plate; four fixed cover plate bars are arranged on the front fixed cover plate; the rear part of the big cylinder is provided with a rear fixed cover plate; two fixed cover plate bars are arranged on the rear fixed cover plate; a front fixed cover plate carding region, an upper rotary cover plate carding region and a rear fixed cover plate carding region are formed on the big cylinder; and a card wire type structure is adopted to the fixed cover plate bars. The novel semi-spinning specialized equipment of the invention is beneficial to uniform feeding and further improves the carding effect.

Owner:青岛东佳纺机(集团)有限公司

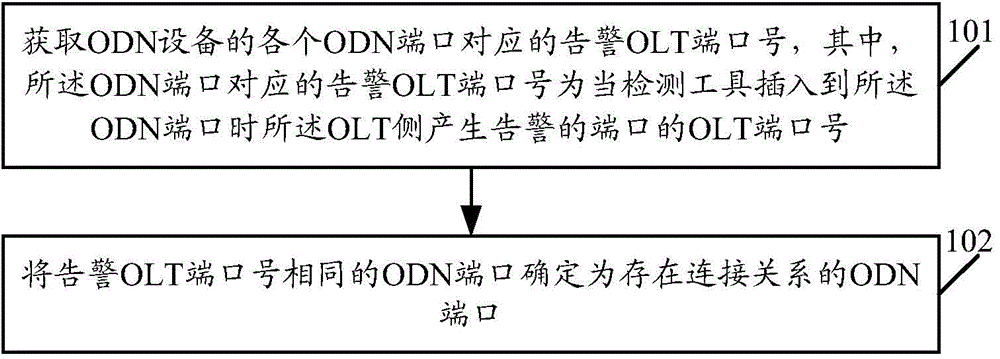

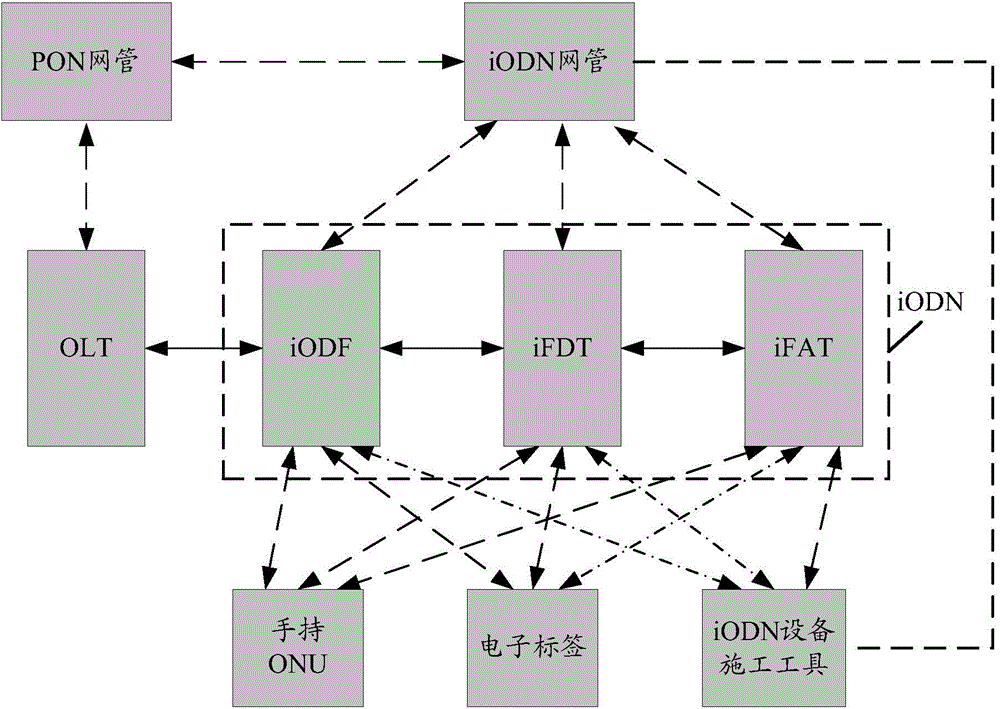

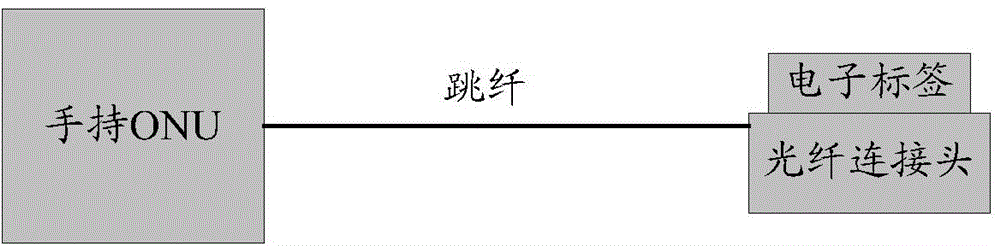

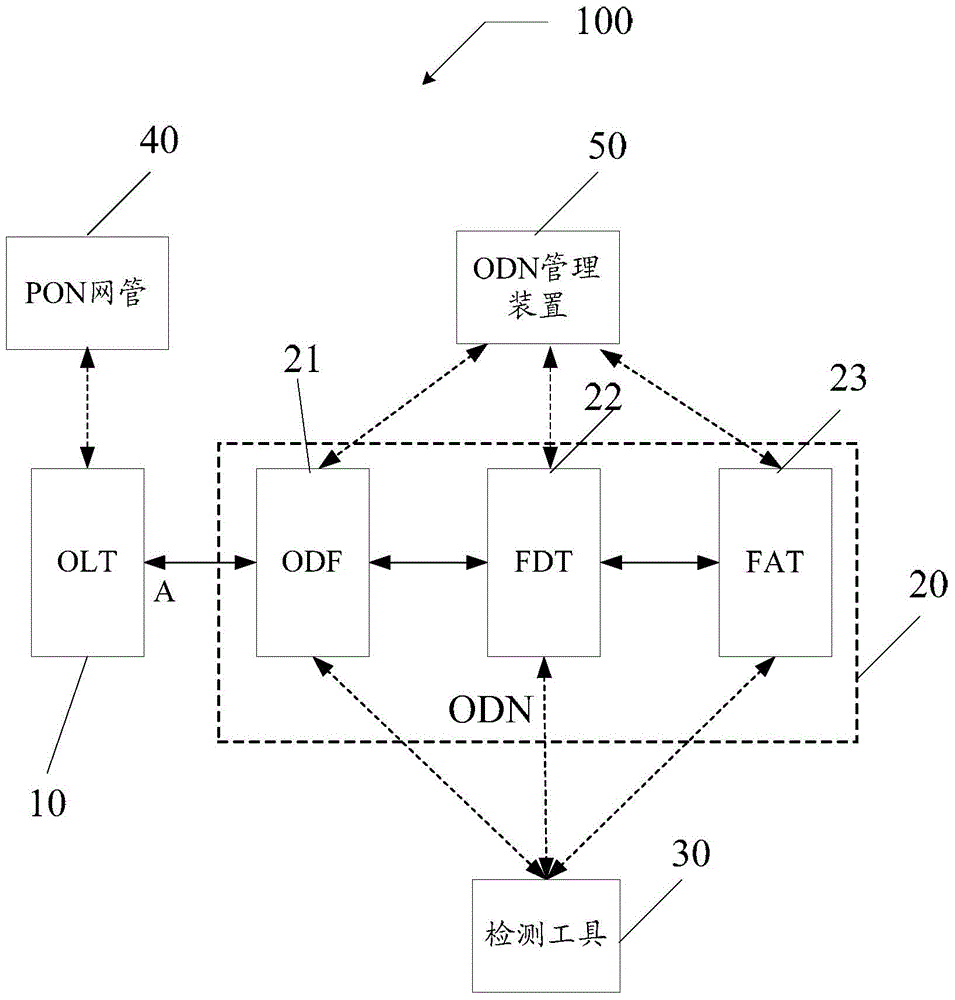

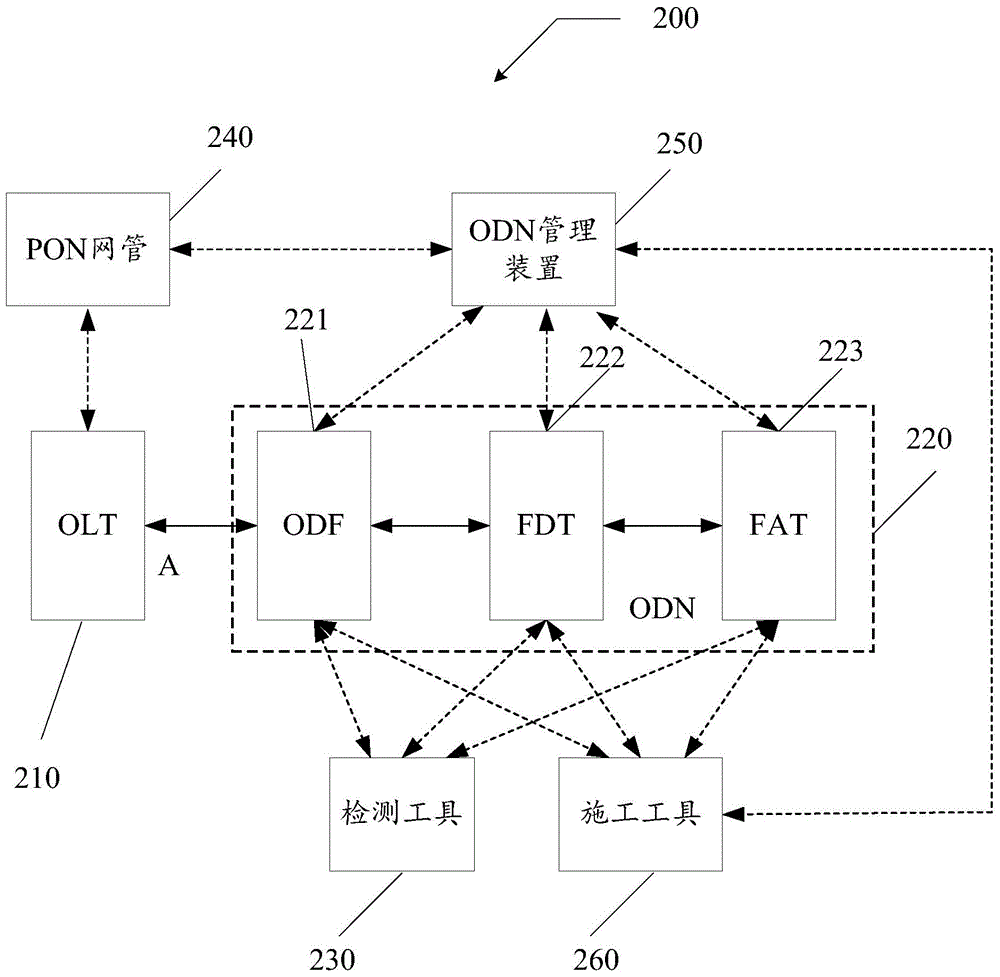

Method and apparatus for determining ODN connection relation

ActiveCN105721186AImprove carding efficiencyImprove reliabilityMultiplex system selection arrangementsElectromagnetic transmissionEngineeringComputer terminal

Owner:HUAWEI TECH CO LTD

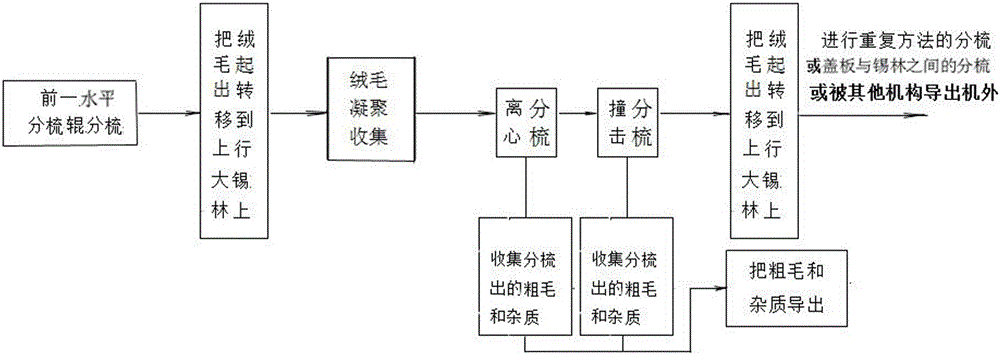

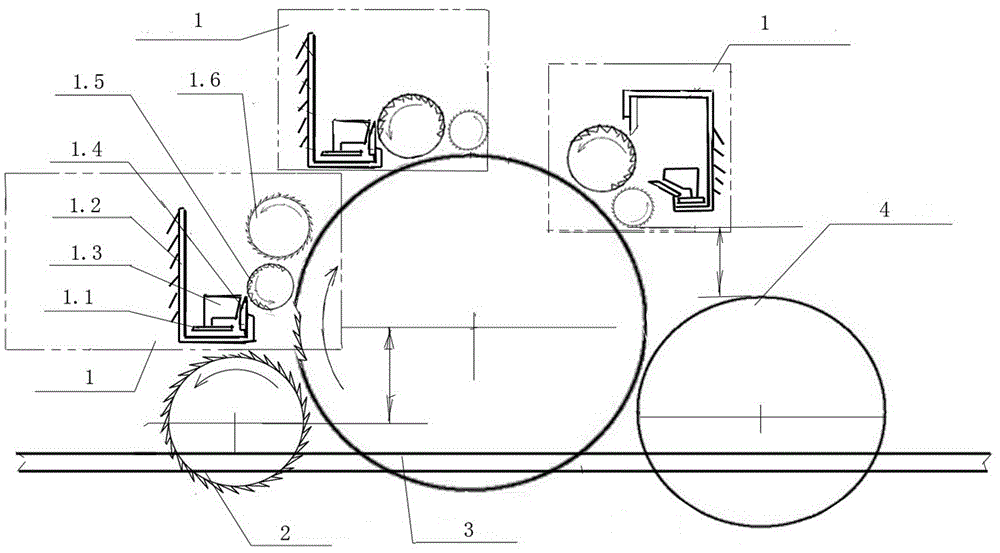

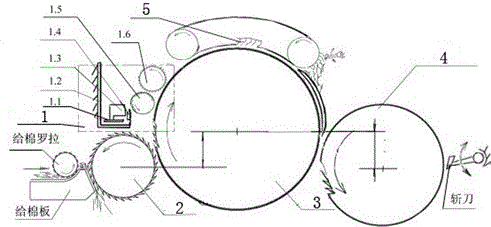

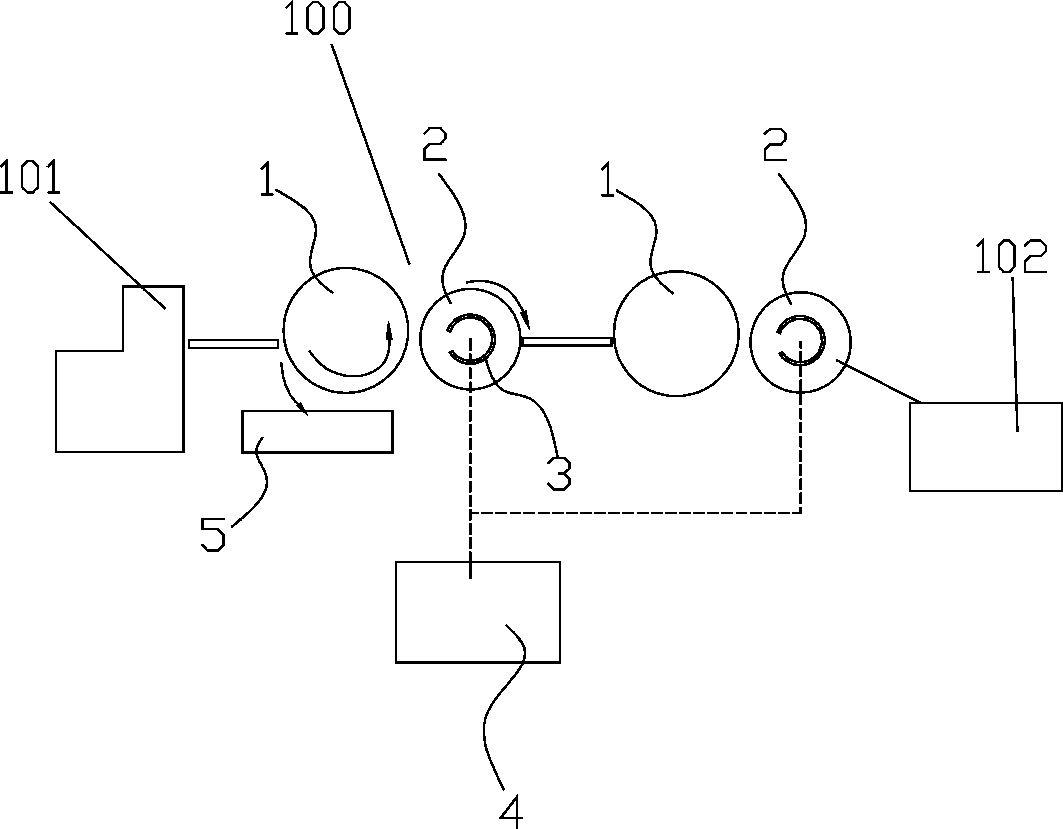

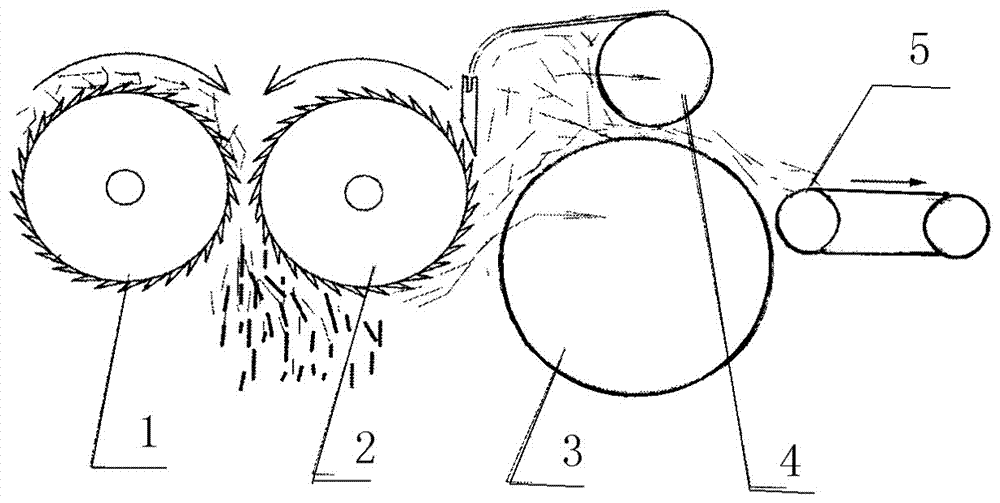

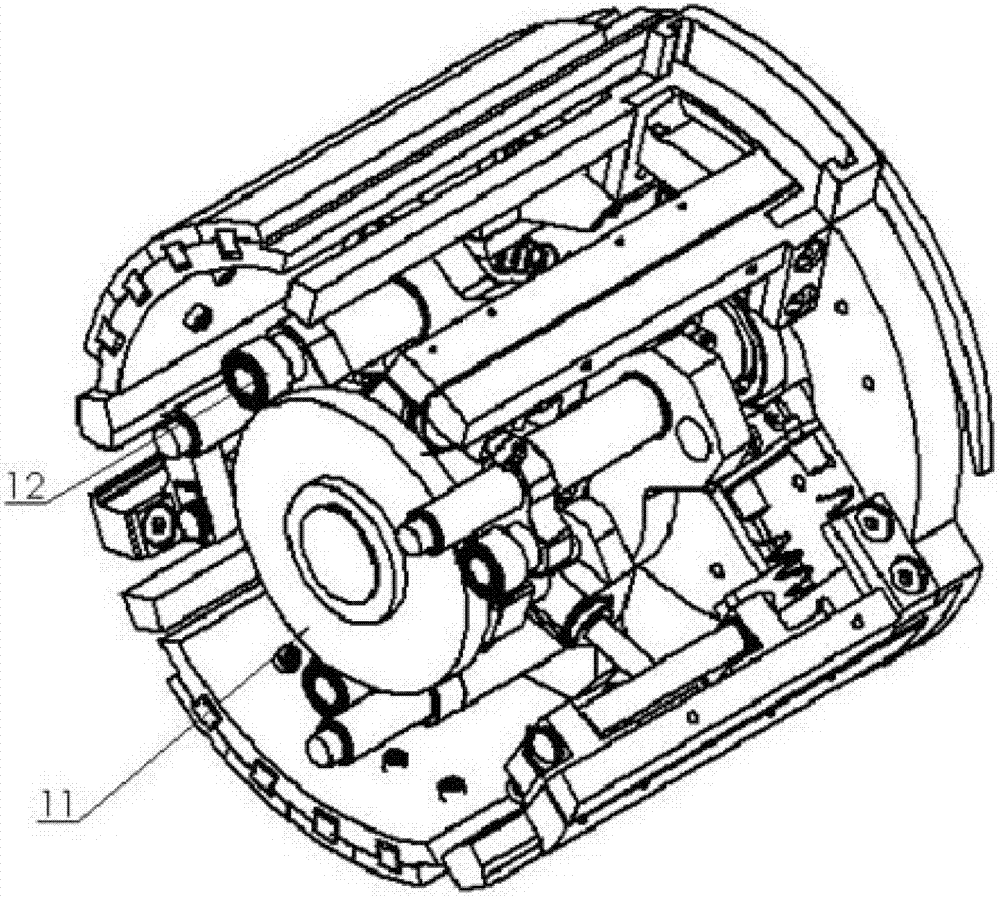

Three-dimensional multi-point coarse wool and impurity removing and carding method and device

The invention provides a three-dimensional multi-point coarse wool and impurity removing and carding method and device. The method comprises the steps that by installing a large upward-running cylinder behind a carding roller of a carding machine and installing 1-4 carding mechanisms each composed of a combing condensing roller, a fluff stripping carding roller, a wool cutter and the like at the appropriate positions on the circumferential surface of the upper half portion of the large cylinder, roller carding on the upward circumference of the cylinder is achieved, coarse wool and impurities in fluff clusters are jointly removed, and then fluff obtained after carding is guided out of the machine through a fluff guiding mechanism. The device comprises a taker-in roller, the large cylinder arranged behind the taker-in roller, the 1-4 carding mechanisms installed on the circumferential surface of the upper half portion of the large cylinder and the fluff cluster transferring and guiding mechanism arranged behind the large cylinder. The method and device have the advantages of being less in damage to fibers, higher in carding efficiency, smaller in floor area and higher in adaptability.

Owner:苗宇 +1

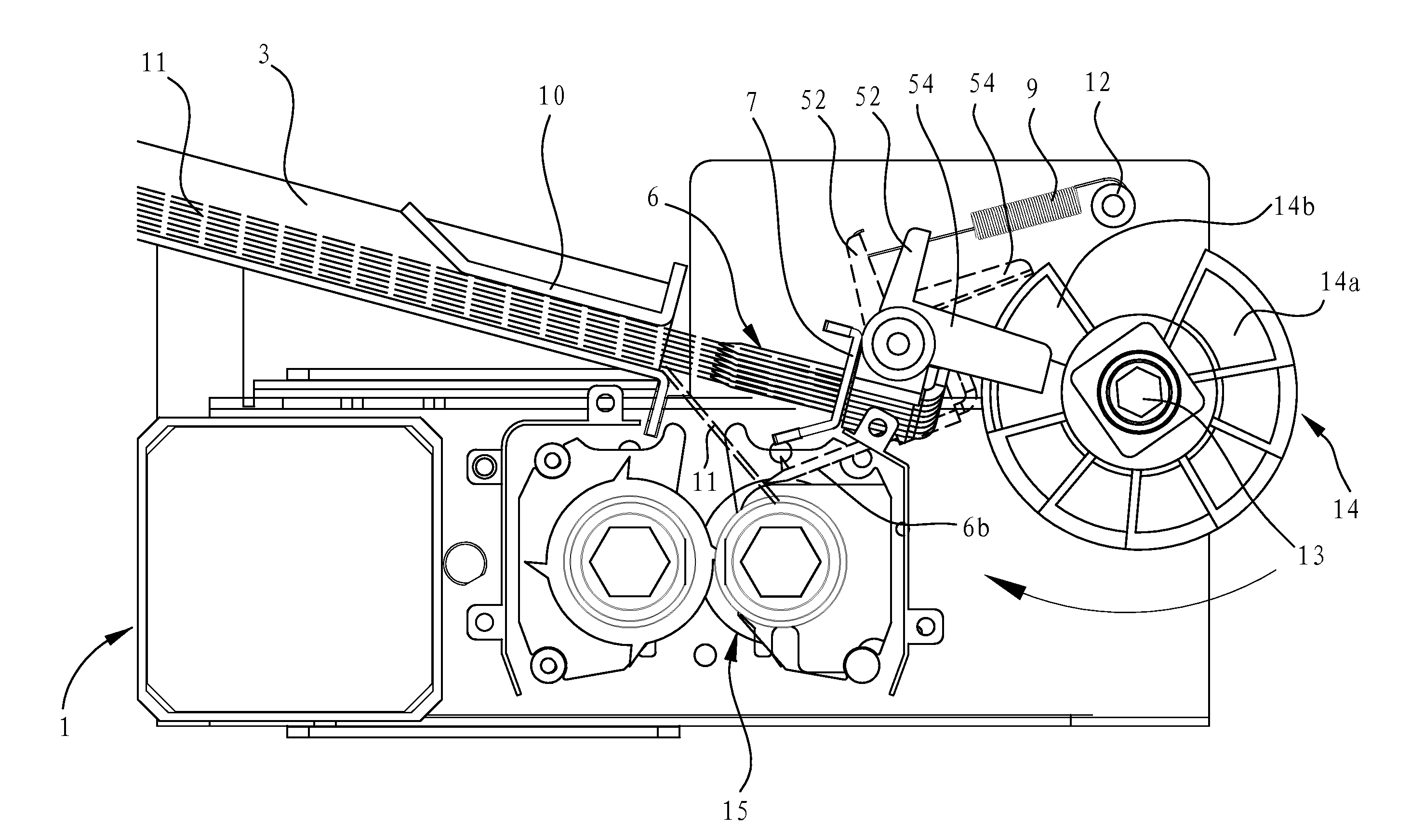

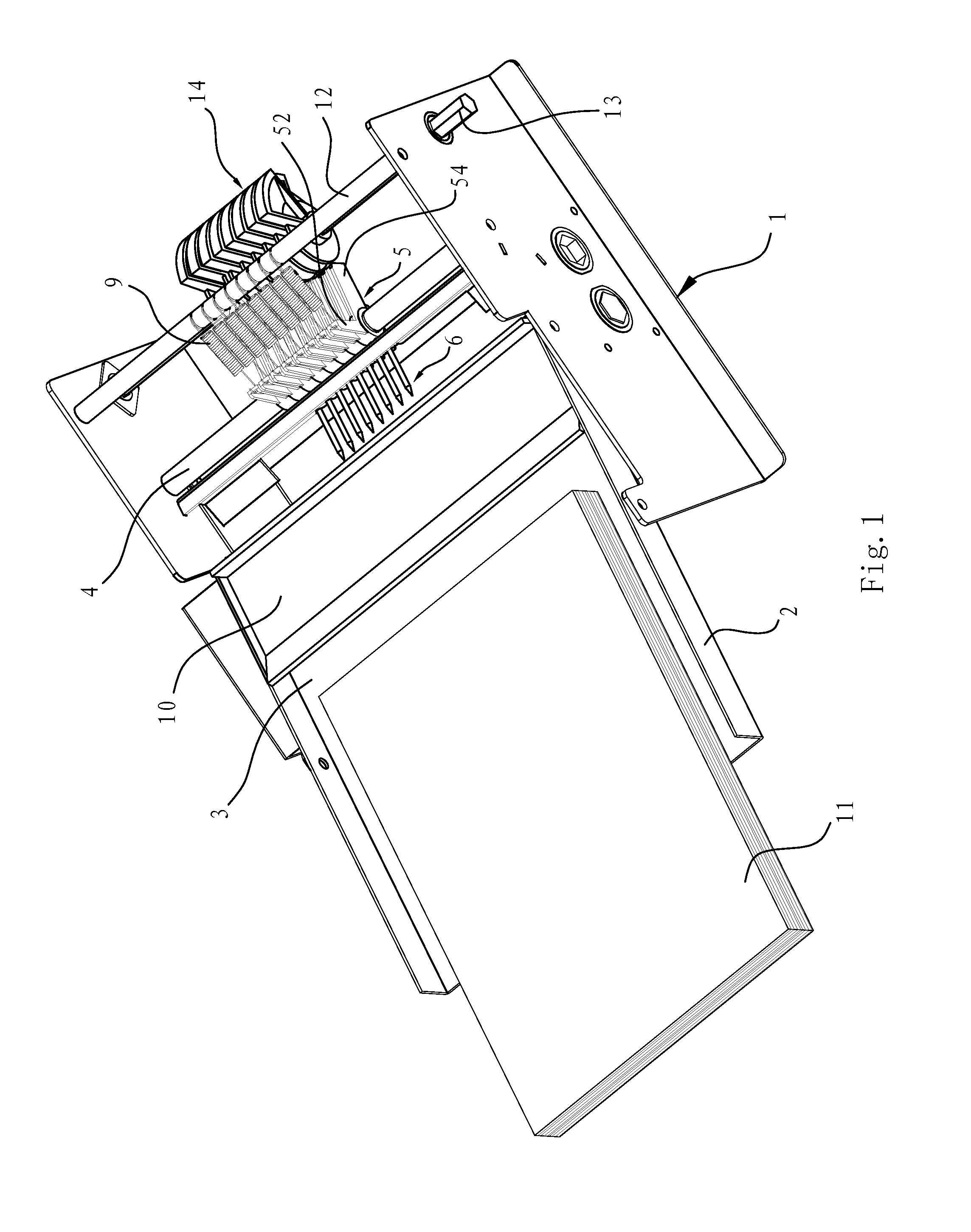

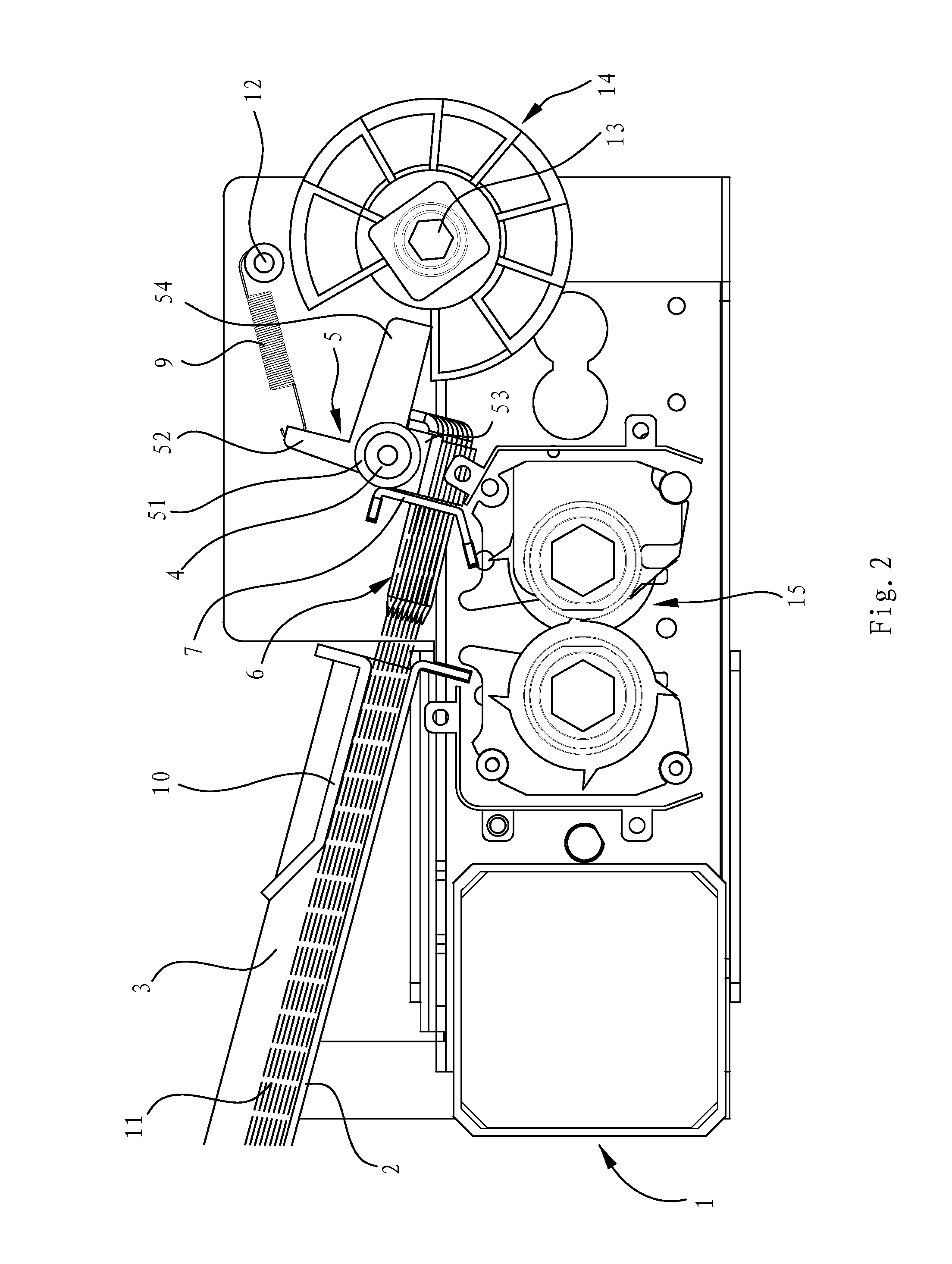

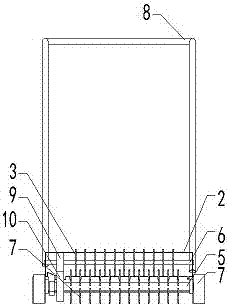

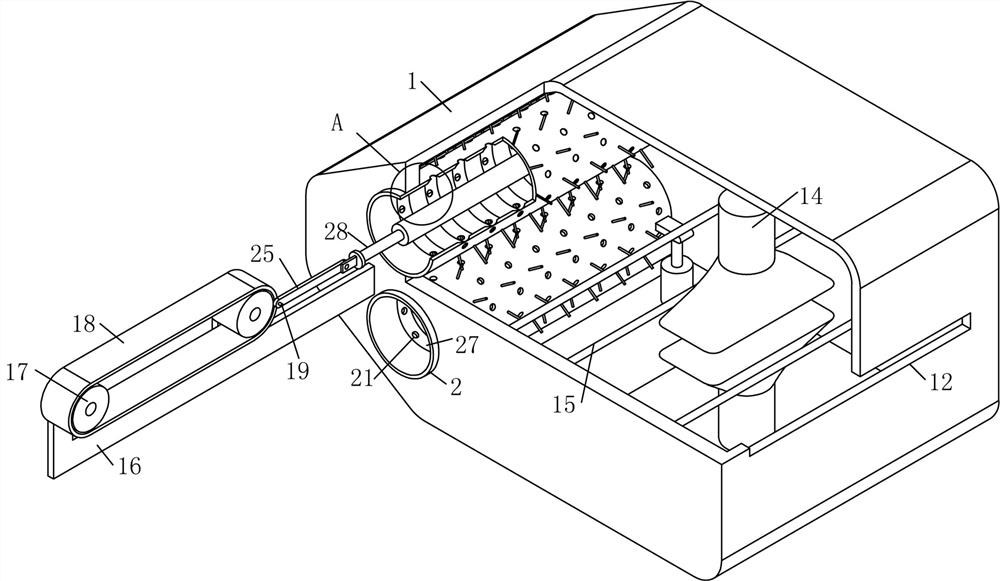

Auto Paper-Combing Mechanism and an Auto Paper-Feeding Mechanism of a Paper Shredder

InactiveUS20130134244A1Improve efficiencyHigh feeding reliabilityCocoaGrain treatmentsCombingEngineering

The present invention provides an auto paper-combing mechanism of a paper shredder, comprises a frame which is formed with a feeding channel and a fixing shaft, and a feeding salver; a plurality of combing needle beds are disposed on the fixing shaft along the axial direction in sequence, a combing needle is respectively inserted on the bottom of each combing needle bed, the needlepoint of each combing needle heads towards the outlet of the feeding channel, and the height of combing needles are in ladder-like distribution and along the axial direction of the fixing shaft in sequence, furthermore, the vertical distances between the needlepoint of each combing needle and the lower edge of the outlet of the feeding channel are equal. The present invention also provides an auto paper-feeding mechanism of a paper shredder. Compared with the prior art, the height of the combing needles are in ladder-like distribution and in sequence, which can realize auto paper-combing. The whole mechanism is relatively simple. Moreover, the paper can touch the needlepoint of each combing needles at the same time when the paper enters into the feeding channel and closes the combing needles, therefore, the synchronous paper-combing will be realized and the paper-combing efficiency will be increased.

Owner:NINGBO OFITECH BUSINESS MACHINES

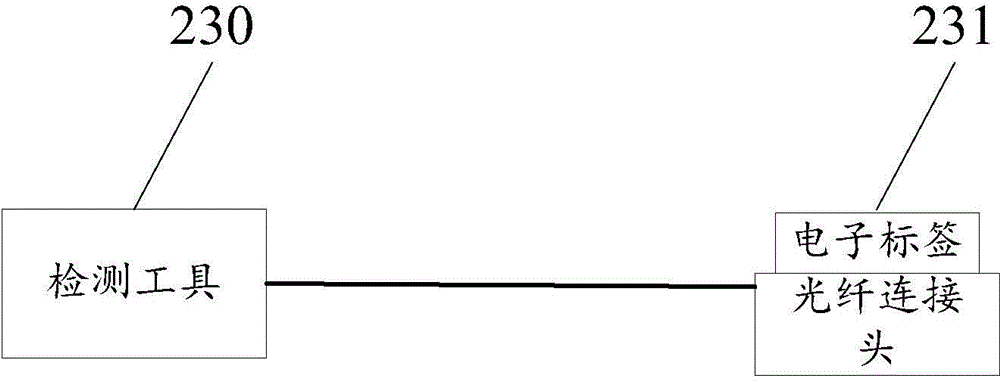

ODN resource organizing method and system

ActiveCN105656648ALower skill requirementsImprove carding efficiencyTransmission monitoring/testing/fault-measurement systemsData switching networksEngineeringDistribution networks

An ODN (Optical Distribution Network) resource organizing system comprises an ODN, an optical line terminal (OLT), a detection tool, a passive optical network (PON) administration and an ODN management device, wherein the OLT is used for realizing signal communication with the ODN via a port, and broadcasting a PON ID of the port to the ODN; the detection tool is used for receiving the PON ID sent by the OLT after accessing a port to be detected on the ODN; the PON administration is used for parsing the input PON ID to acquire a parsed second PON ID; and the ODN management device is used for receiving a port sequence number of the port to be detected currently and the corresponding parsed second PON ID, and binding the port sequence number with the corresponding parsed second PON ID. The ODN resource organizing system can perform resource organization on the ODN by automatically acquiring an organizing manner, and has the advantages of high construction efficiency, reliable result and the like.

Owner:HUAWEI TECH CO LTD

Rabbit fur carding machine

The invention discloses a rabbit fur carding machine which comprises a plurality of carding devices sequentially arranged. Each carding device comprises a licker-in and a net roll arranged on one side of the licker-in, a negative pressure roll with a hollow inner cavity is arranged in the net roll, a long-strip-shaped through hole facing the licker-in is formed in the negative pressure roll, and the negative pressure roll is connected with a fan through a pipeline. An air sucking rolling device is utilized to transfer carded soft fur, and the original transfer mode of card clothing fur hanging is changed. The staying time of fiber in the device is greatly reduced, fiber damage is reduced, carding efficiency is improved, the carded coarse fur does not contain the soft fur, and the fallen fur portion containing the coarse fur does not need to be carded repeatedly.

Owner:NINGBO ZHENHAI DEXIN RABBIT FUR PROCESSING FACTORY

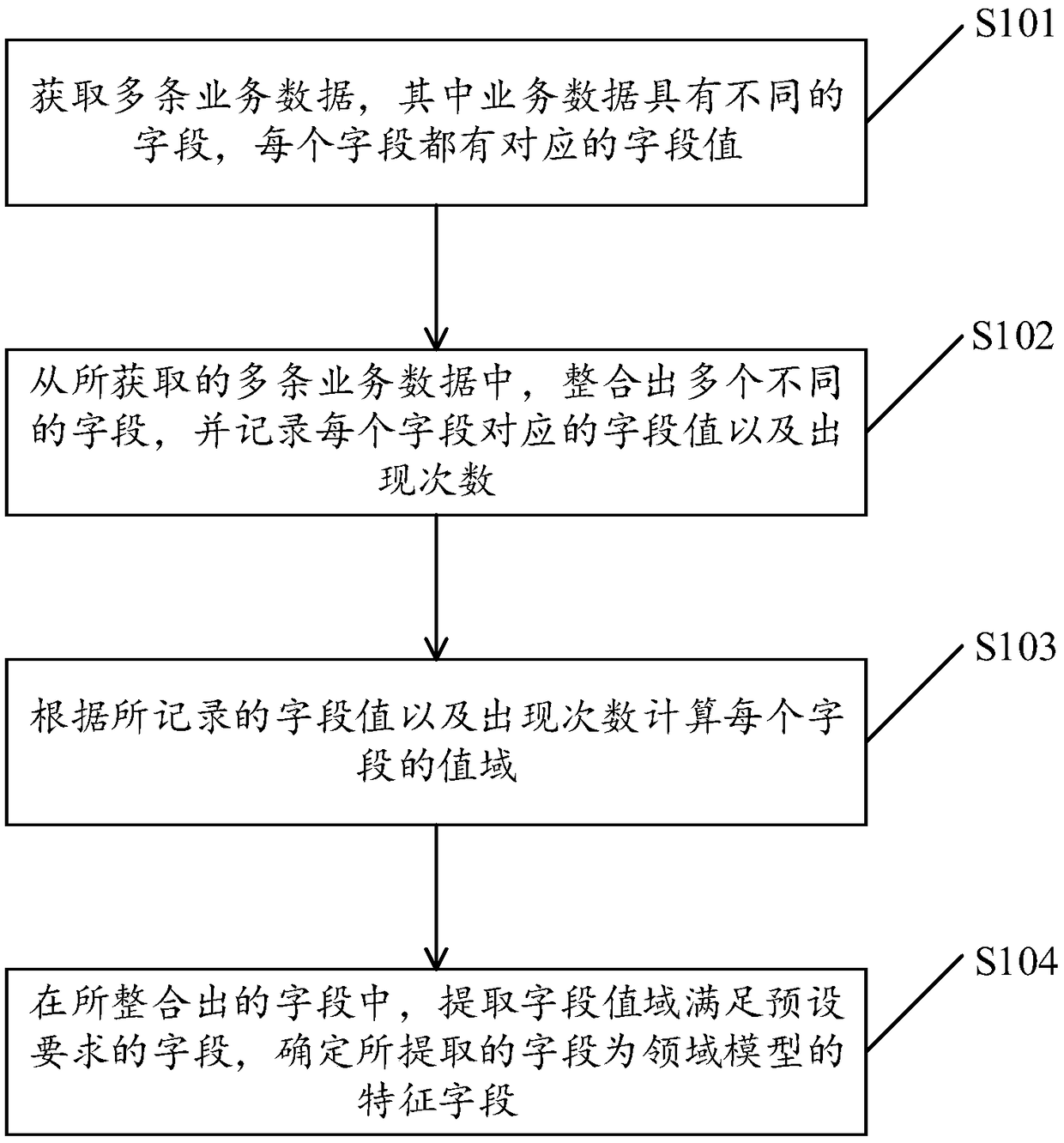

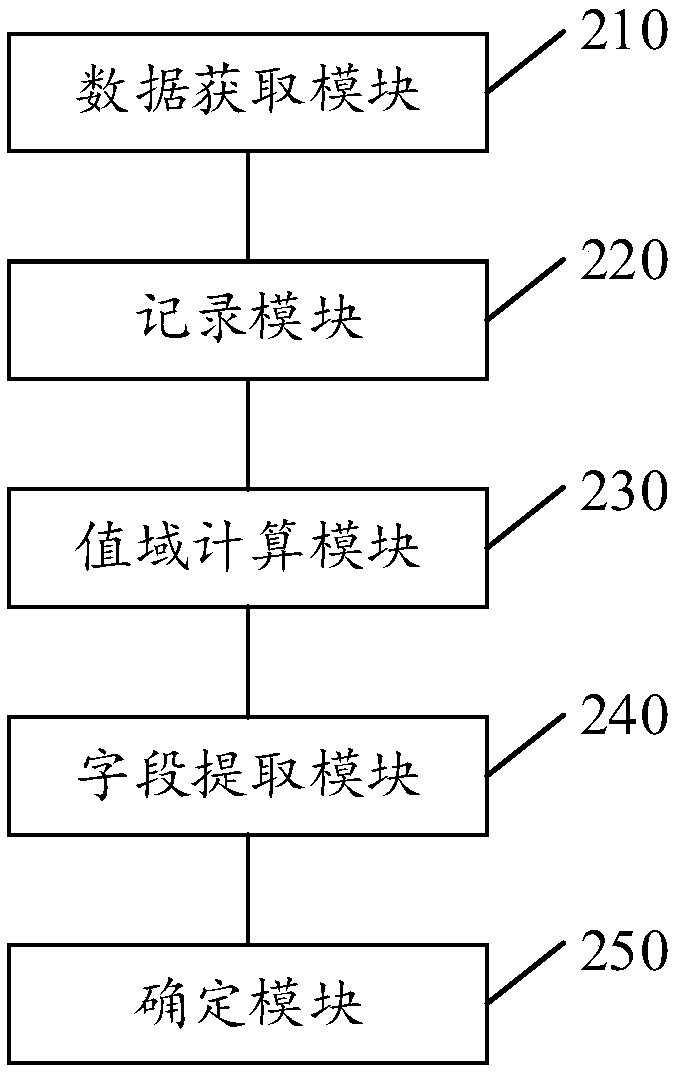

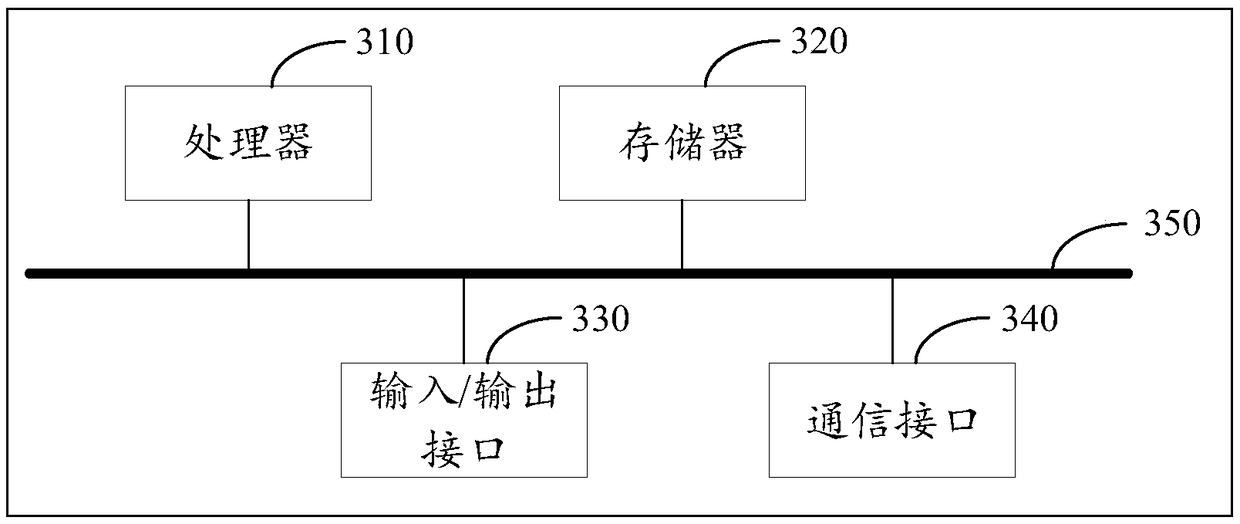

A method and apparatus for extracting the feature fields of a domain model

ActiveCN109325015AReduce grooming timeImprove carding efficiencyDatabase design/maintainanceDomain modelA domain

A method and apparatus for extracting the feature fields of a domain model is disclosed. The method for extracting the characteristic fields of the domain model comprises: acquiring a plurality of service data, wherein the service data has different fields and each field has corresponding field values; integrating a plurality of different fields from the obtained plurality of service data, and recording the field values and occurrence times corresponding to each field; calculating a value range of each field according to the recorded field value and the number of occurrences; in the integratedfield, extracting the field whose field value domain satisfies the preset requirements, and determining the extracted field to be the feature field of the domain model.

Owner:ADVANCED NEW TECH CO LTD

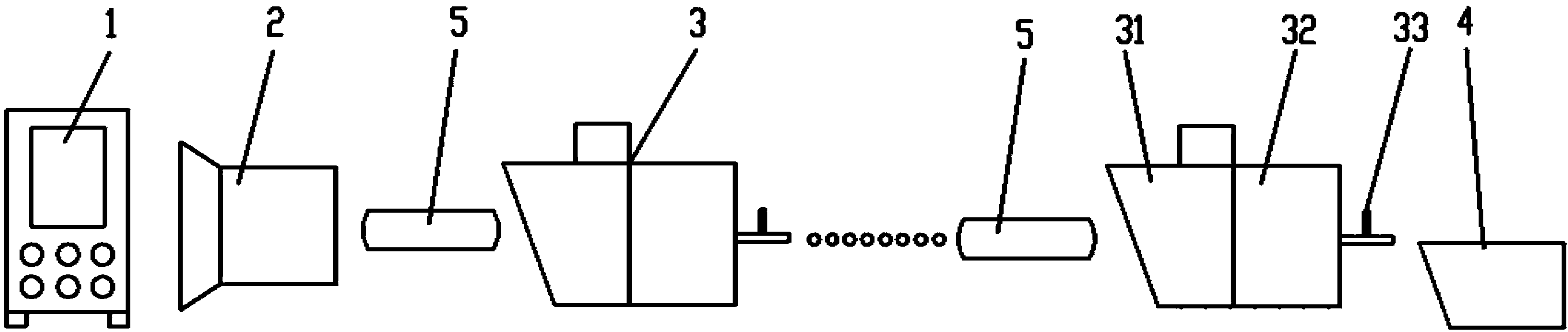

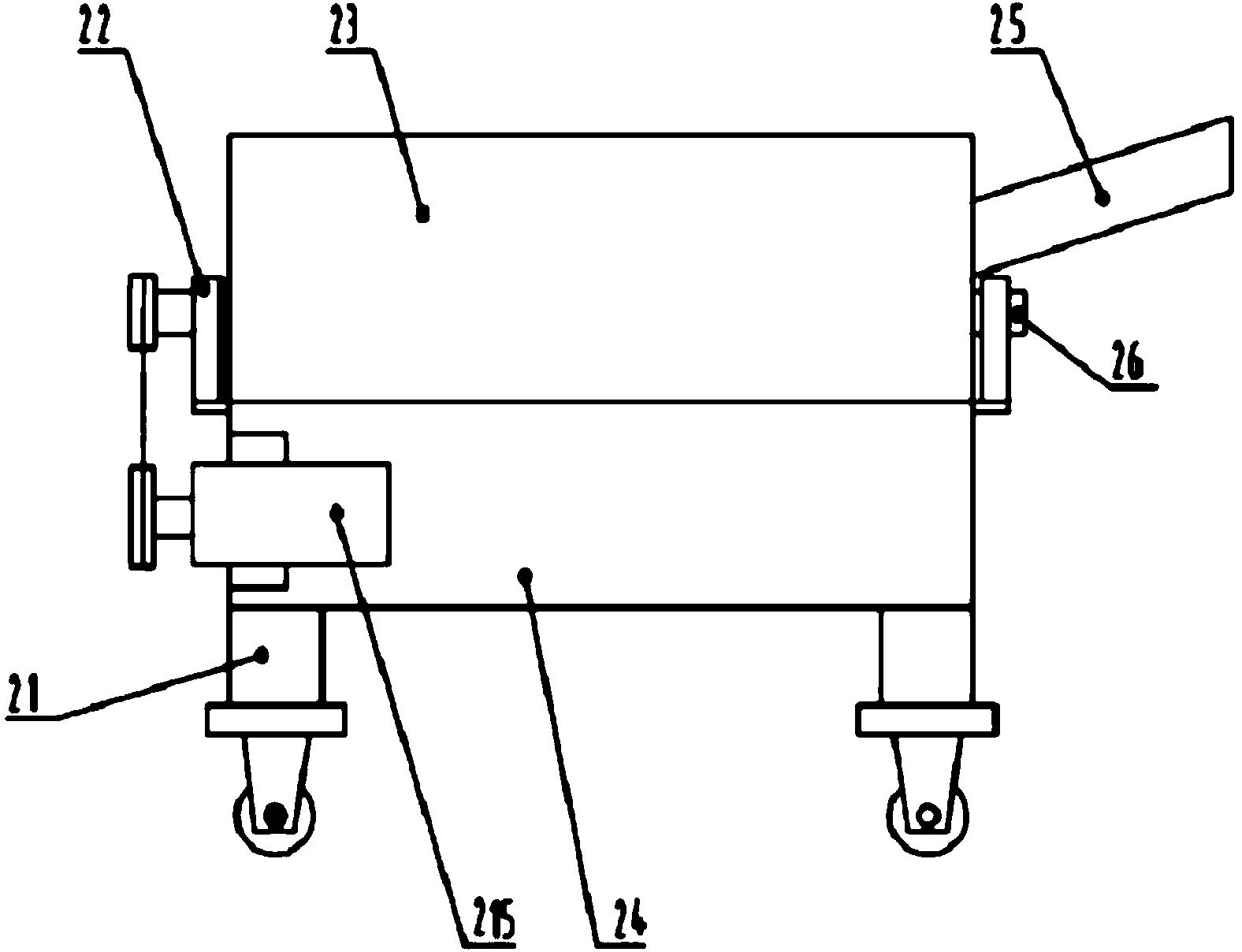

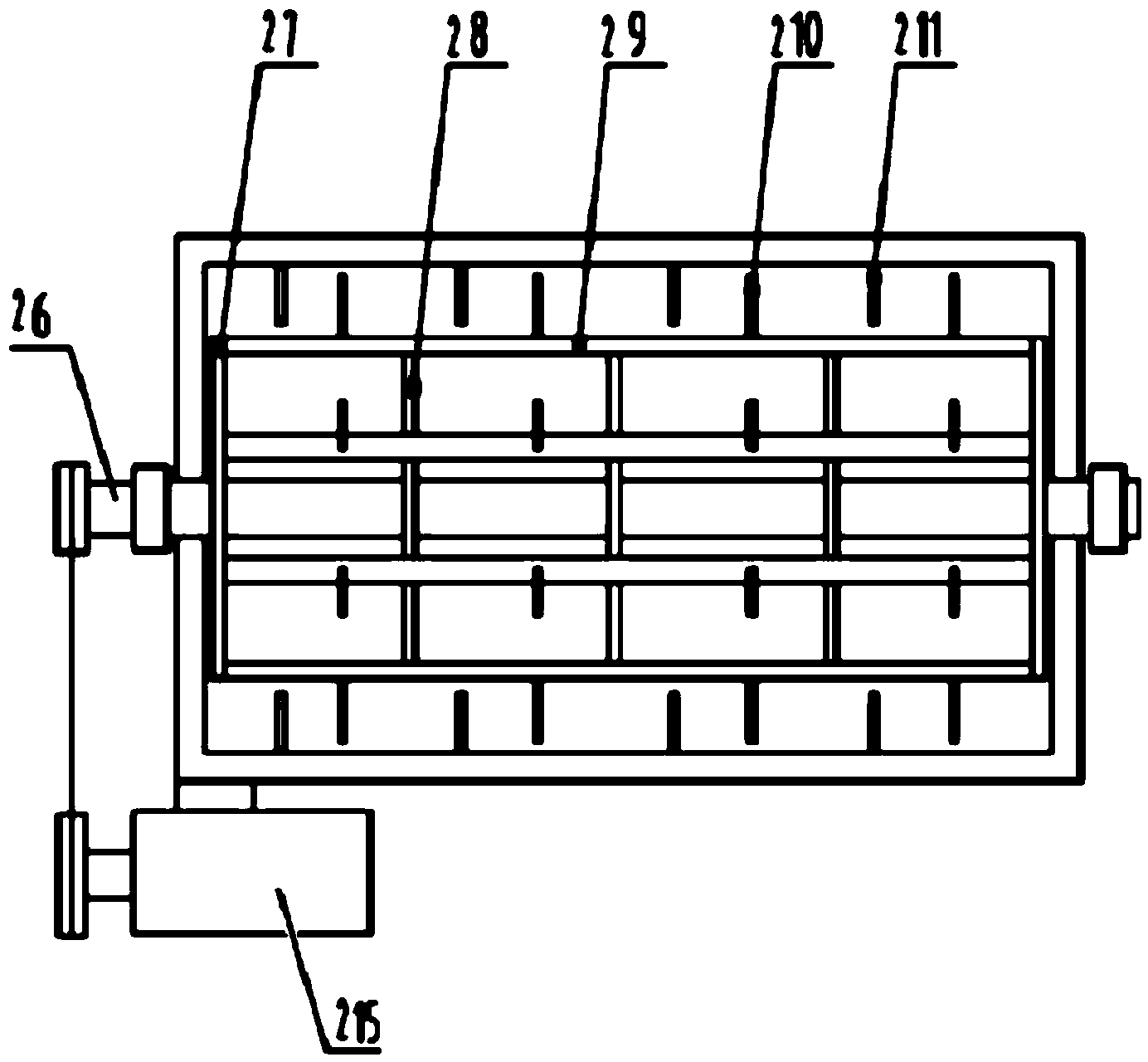

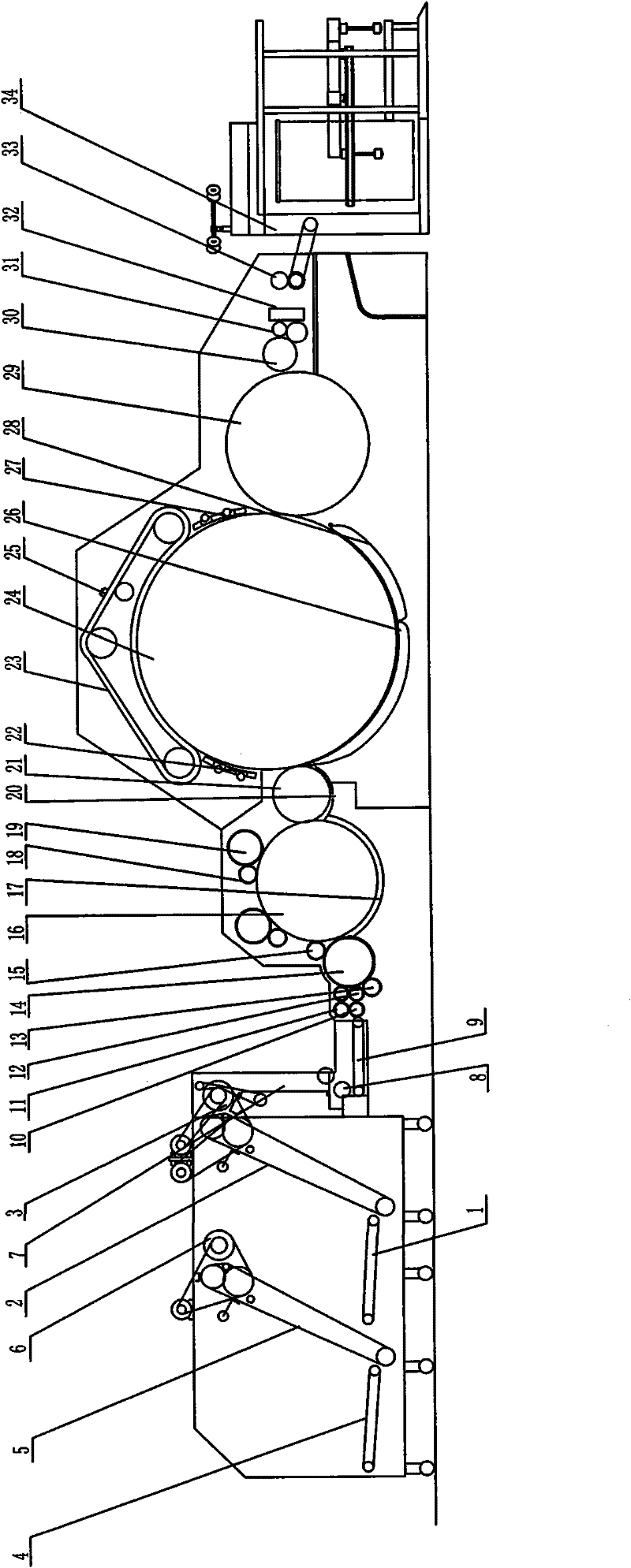

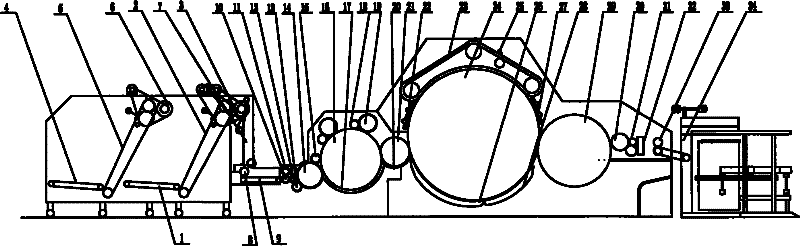

Cashmere opening and carding line production system and process thereof

ActiveCN103451781AImprove carding efficiencyImprove carding qualityContinuous processingFibre feedersAutomatic controlMoisture regain

The invention discloses a cashmere opening and carding line production system, which structurally comprises an industrial control computer, an opener and 8-16 carding machines sequentially, wherein the 8-16 carding machines are connected end to end and are arrayed in sequence, and the industrial control computer is used for monitoring the operation states of the opener and the carding machines in real time and performing automatic control; according to the line production sequence, each carding machine comprises a cashmere feeding mechanism used for conveying and feeding cashmere to a carding host, the carding host used for carrying out carding operation, and a moisture regain mechanism used for carrying out water spray moisture regain operation on carded cashmere sequentially. According to the cashmere opening and carding line production system and the process thereof, when opened and mixed cashmere enters each carding machine sequentially by virtue of conveying flat belts, the arrangement sequence of the carding machines are strictly controlled so as to ensure that the Xth carding machine is always used for carrying out the Xth carding operation, and the opening and carding operation can be efficiently finished. The feed quantity, the carding speed and the moisture regain rate of the carding machines can be automatically adjusted according to different properties of raw materials, and accordingly, the carding efficiency and quality of the cashmere can be improved.

Owner:HONGYE CASHMERE

Hair combing device for paint brush

The invention discloses a hair combing device for a paint brush, and particularly relates to the technical field of paint brushes; the hair combing device comprises a shell, a hair containing cylinderis arranged in the shell, a combing mechanism is arranged in the shell and located at the top of the hair containing cylinder, and the combing mechanism comprises a first driving motor arranged at the top of the shell; the first driving motor is externally sleeved with a fixing ring, the output end of the first driving motor is provided with a rotating rod, the rotating rod is externally sleevedwith a plurality of rotating discs, the two ends of each rotating disc are each provided with a fixing groove, a paint brush body is mounted in each fixing groove, and the tops and the bottoms of theplurality of rotating discs are each provided with a plurality of clamping grooves. According to the hair combing device, the plurality of paint brush bodies can be carded in a centralized mode, the operation efficiency is improved to a great extent, meanwhile, redundant hair can be adsorbed, the situation that the workload of workers is increased after the redundant hair is accumulated is prevented, and the practicability is high.

Owner:湖州菱创科技有限公司

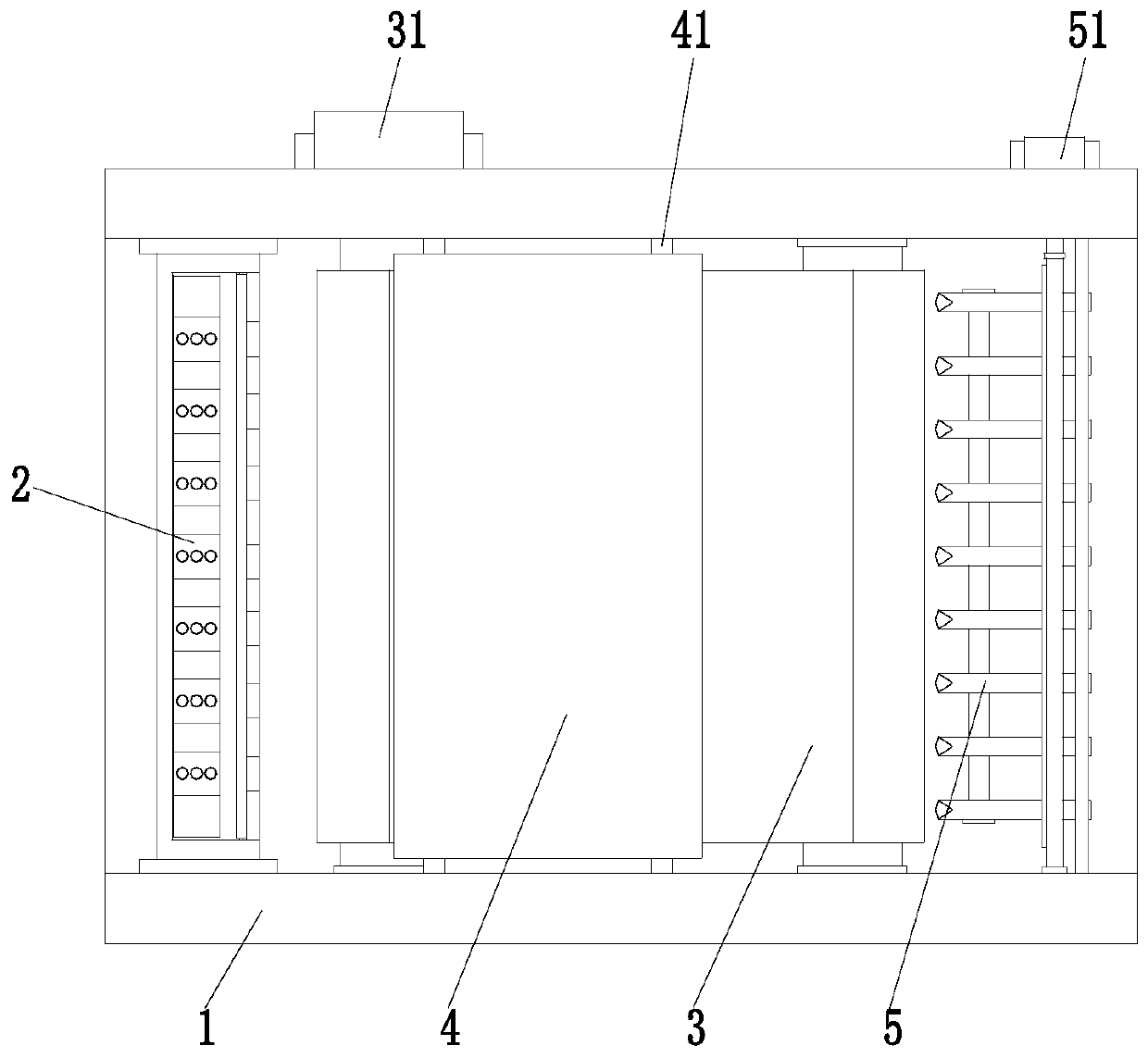

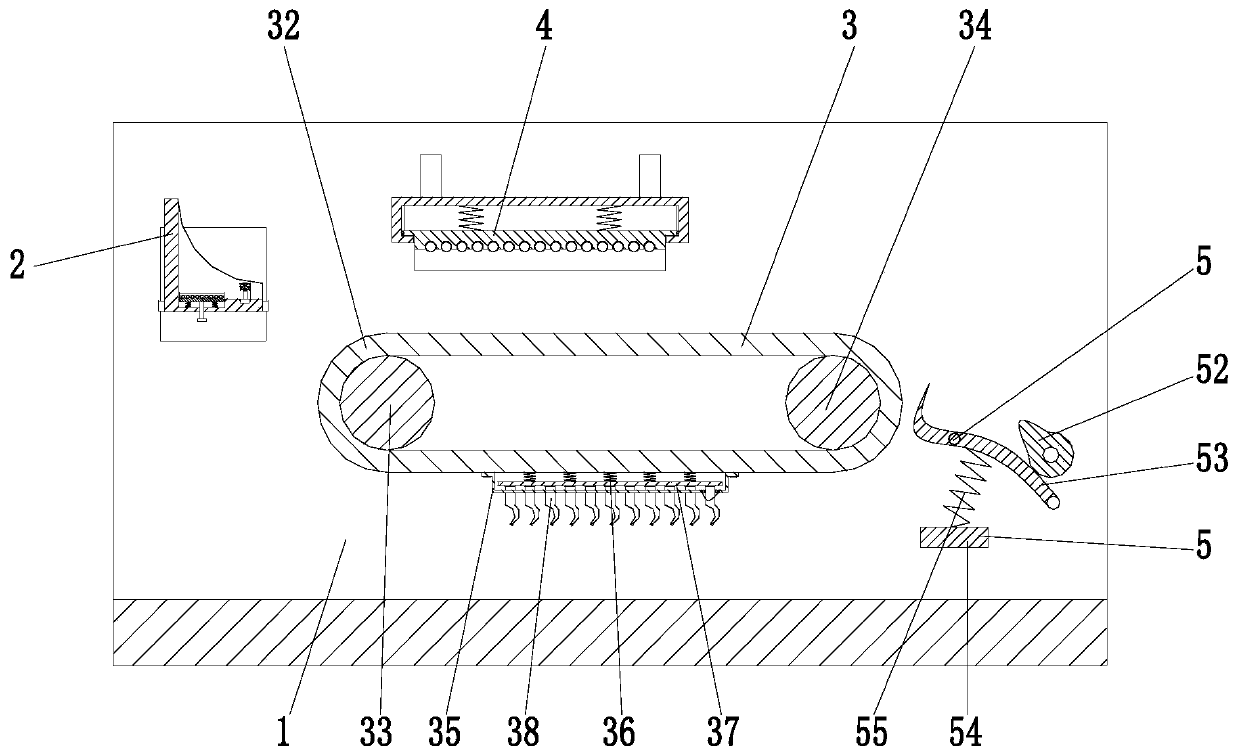

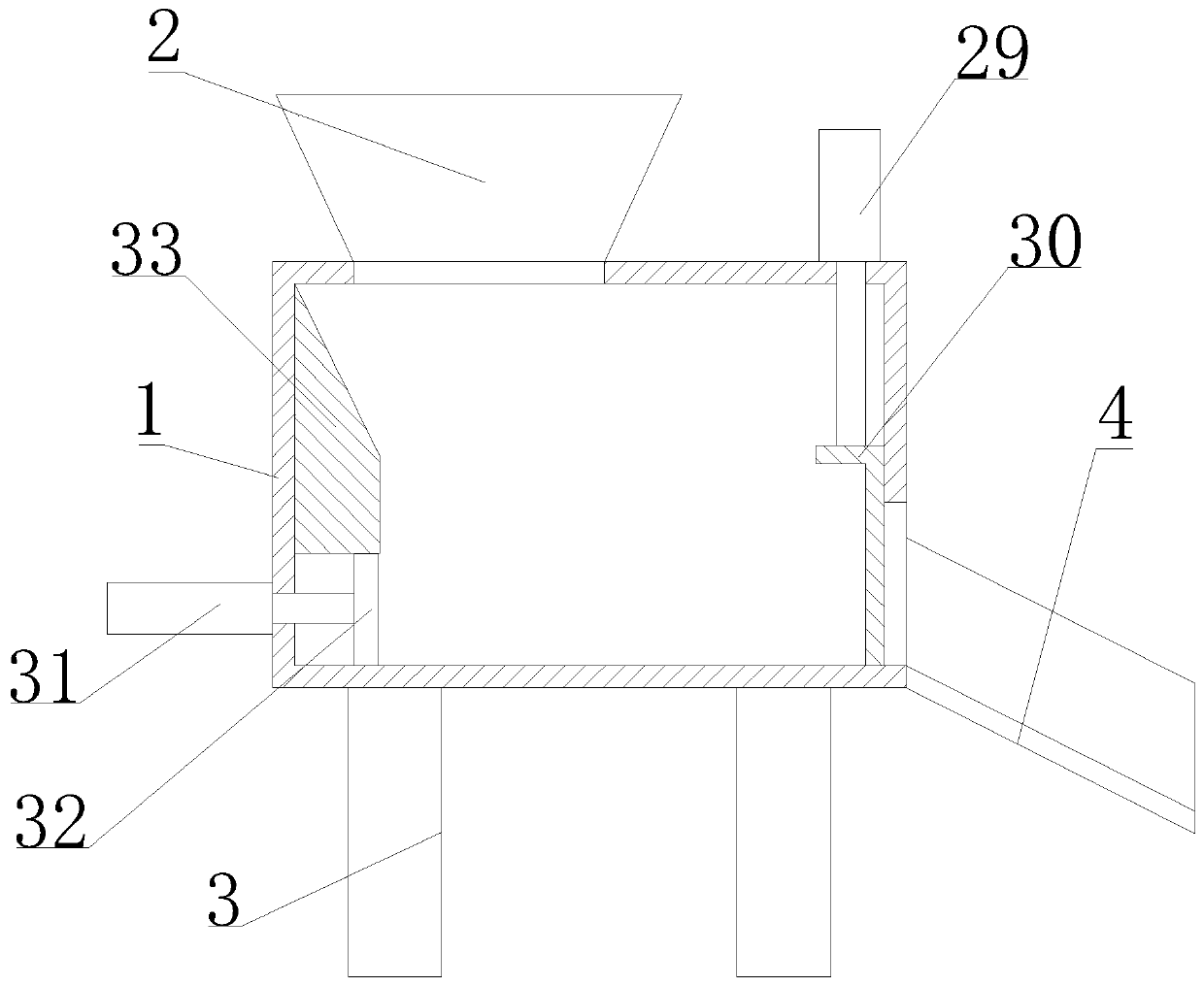

Carding machine for effectively cleaning cotton ball of cotton raw materials

InactiveCN109811430AFeeding safetyQuality improvementCarding machinesAgricultural engineeringCotton balls

The invention discloses a carding machine for effectively cleaning cotton ball of cotton raw materials. The carding machine comprises a carding machine shell, wherein the lower end surface of the carding machine shell is fixedly supported by supporting columns arranged at four corner positions, and a top plate is connected to the upper end surface of the carding machine shell through bolts; and afeed port is formed in the left end of the upper end surface of the top plate, and a visual window is connected to the right end of the top plate; and a first rotating shaft, a second rotating shaft and a third rotating shaft are arranged at the lower end of the top plate, and a feed funnel is fixedly welded to the upper end of the feed port. The carding machine peels off the cotton ball on the carded cotton raw materials, the quality of carded products is improved, meanwhile, a belt is used for forming a loop, the purpose of uninterrupted work is achieved, and the carding efficiency is improved.

Owner:南昌汇达知识产权有限公司

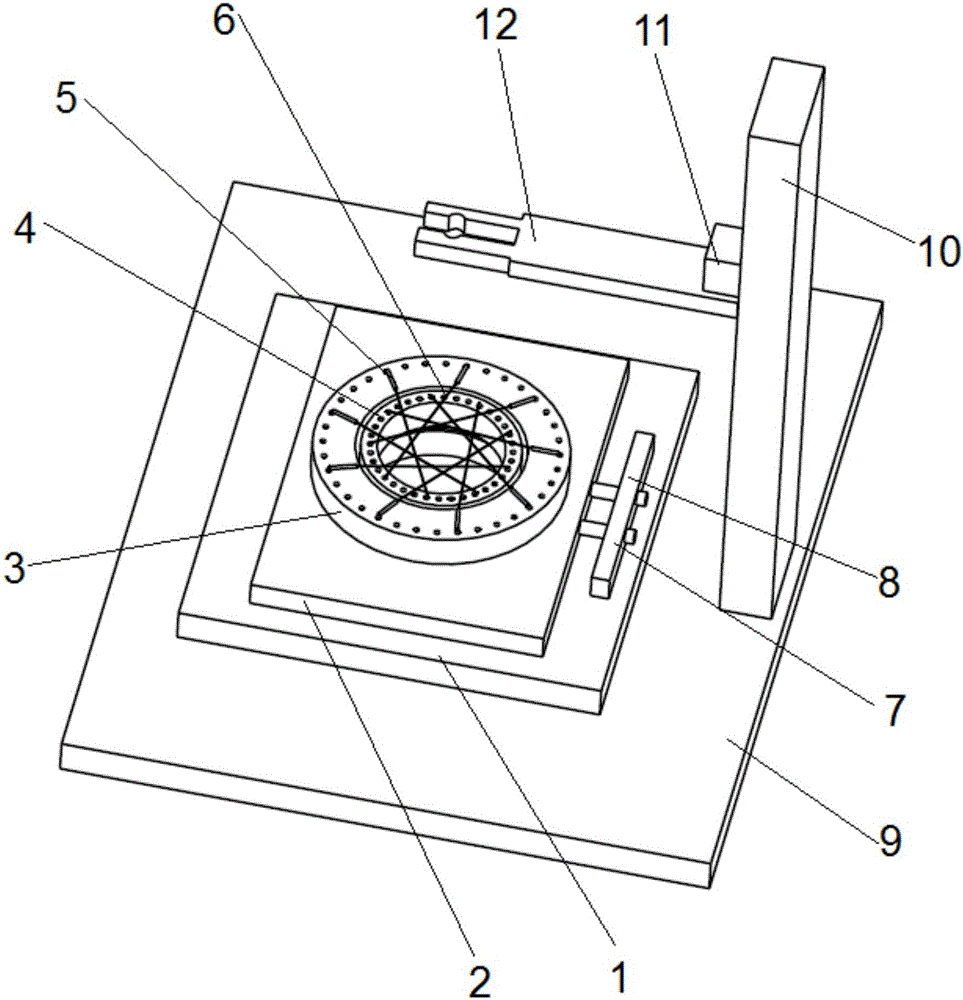

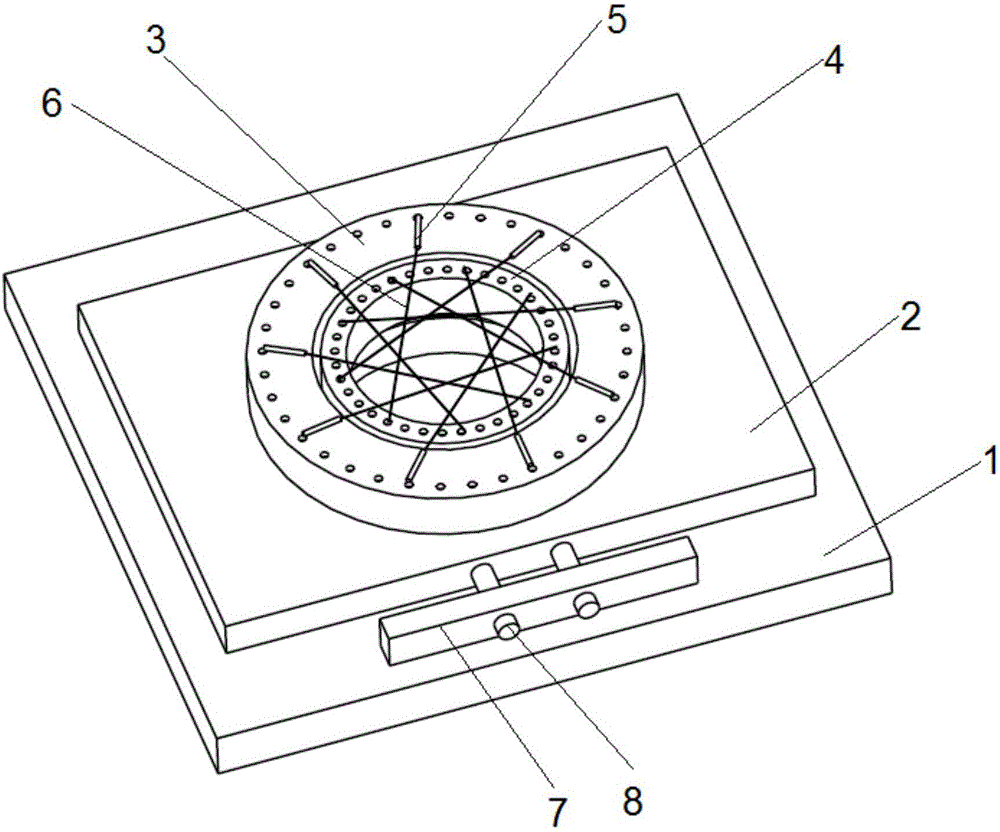

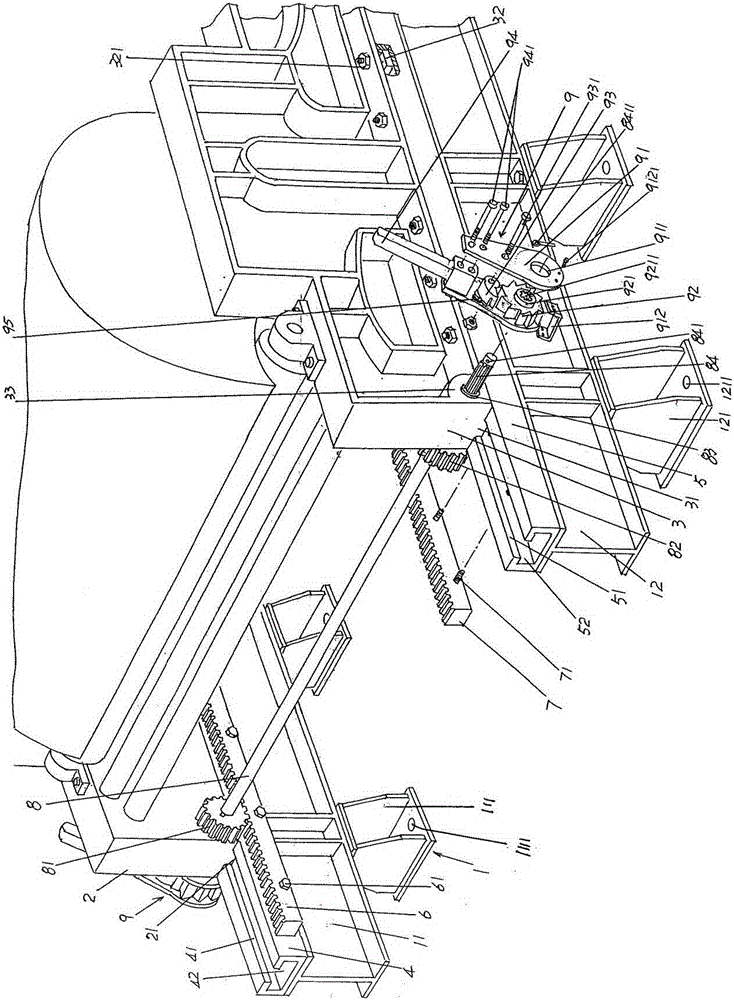

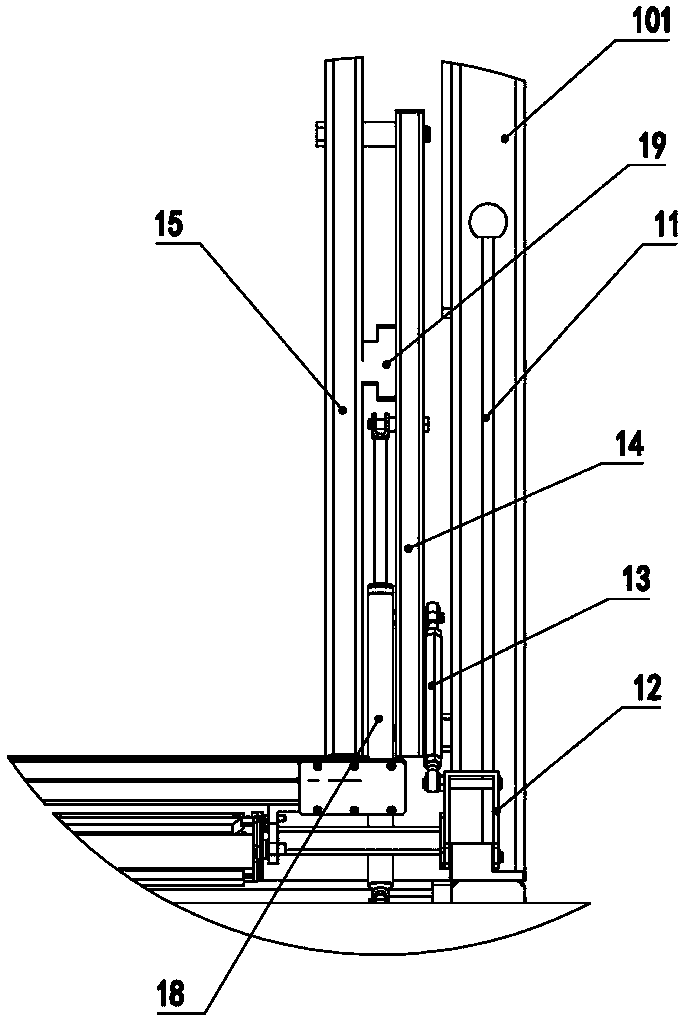

Pen point combing robot feeding mechanism

ActiveCN106166909APlay the role of squeezing the tip of the penImprove carding efficiencyPen repairingNibsEngineeringMechanical engineering

The invention discloses a pen point combing robot feeding mechanism which comprises a fixed disc, a rotary disc, at least three sets of combing belts and a conveying mechanism. The rotary disc is arranged in the middle of the fixed disc and can be rotated. Each set of combing belt comprises a spring and a rope, wherein one end of the spring is connected with one end of the rope, the other two ends are connected to the fixed disc and the rotary disc respectively, the three sets of combing belts are distributed at different positions on the periphery of the fixed disc, the conveying mechanism comprises a stand column, a sliding base capable of sliding up and down on the stand column and a clamping jaw arranged on the sliding base and capable of clamping a pen. The pen point combing robot feeding mechanism automatically combs a pen point, and is high in combing efficiency and uniform in combing.

Owner:ANHUI ZHONG XIN MOLD IND DEV CO LTD

Novel yarn organizing device for sock machine

The invention discloses a new type of wire management device on a hosiery machine, the structure of which comprises a support column foot, a wire barrel placement frame, a right side support plate, a transition plate, a winding barrel, a thread straightener, an upper support plate, and a left support plate , control panel, display screen, emergency stop button, virtual control keyboard, electric control cabinet, cooling fan. The layers are equally spaced and evenly distributed on the surface of the wire management column, the rotating shaft is mechanically connected to the inside of the wire management column, and the wire management column is movably connected to the right side of the connector. The beneficial effect of the present invention is that the multi-strand Multiple yarns are carded, which improves the efficiency of carding, makes the speed of carding yarns keep up with the speed of use of yarns, and improves the production efficiency of socks.

Owner:李歆怡

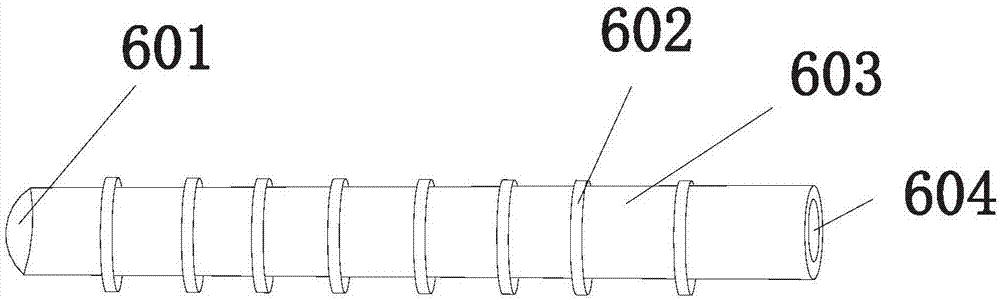

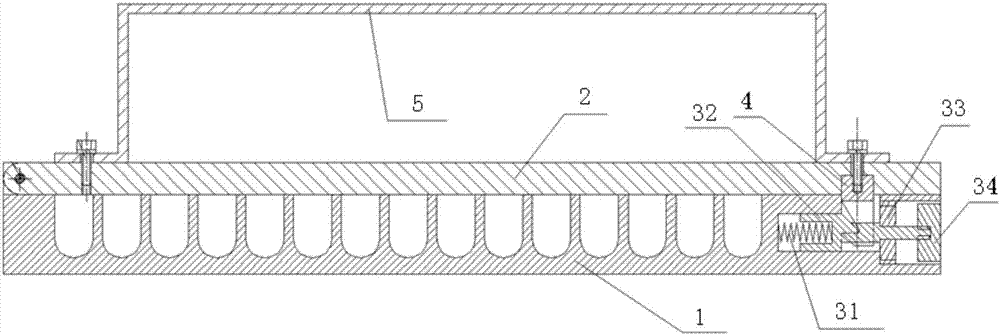

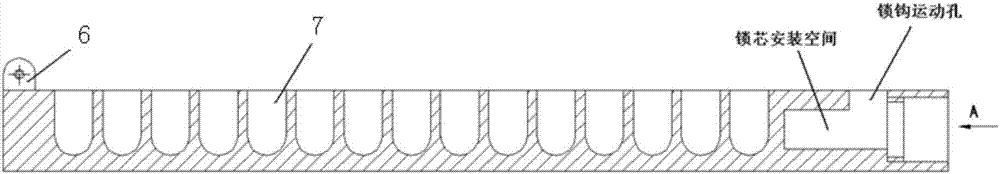

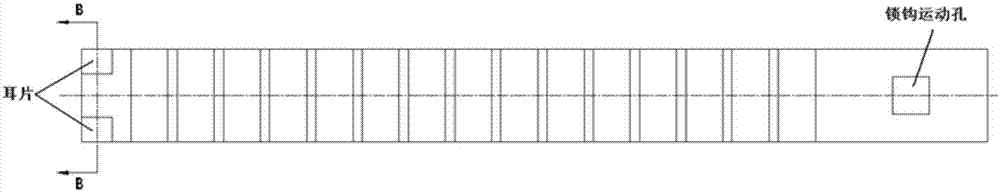

Parachute cord combing clamp with self-locking function

The invention discloses a parachute cord combing clamp with the self-locking function. The parachute cord combing clamp comprises a comb groove, a pressing plate and a locking structure. The parachutecord combing clamp with the self-locking function has the advantages that the comb groove, the pressing plate and the locking structure are coordinated with each other so that parachute cords can befixed in grooves, the parachute cords cannot be staggered in the combing process, the multiple parachute cords can be combed at a time, and therefore the combing efficiency of the parachute cords canbe greatly improved; and meanwhile, the locking structure is hidden inside the parachute cord combing clamp, and therefore damage to a parachute canopy can be effectively prevented in the combing process.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

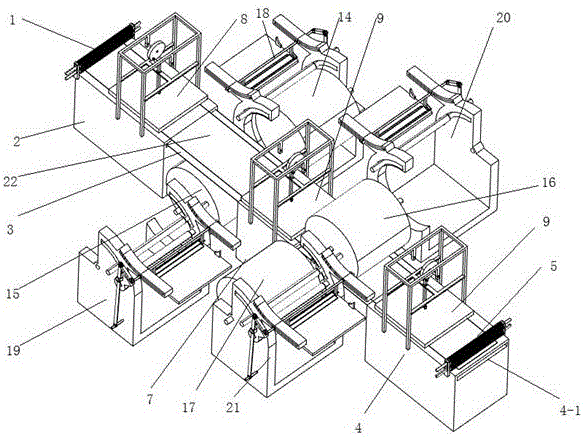

Streamlined equipment for silk spinning production

ActiveCN106835384ASmall footprintImprove carding efficiencySilk-dressing machinesContinuous processingEngineeringMechanical engineering

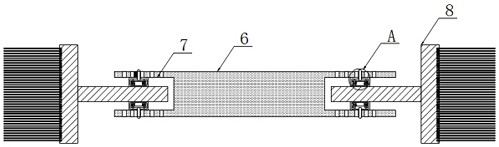

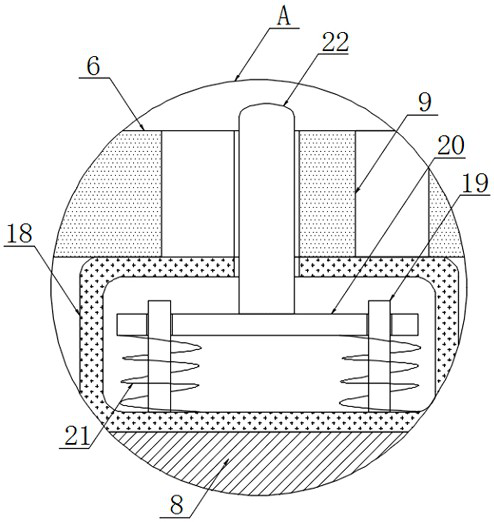

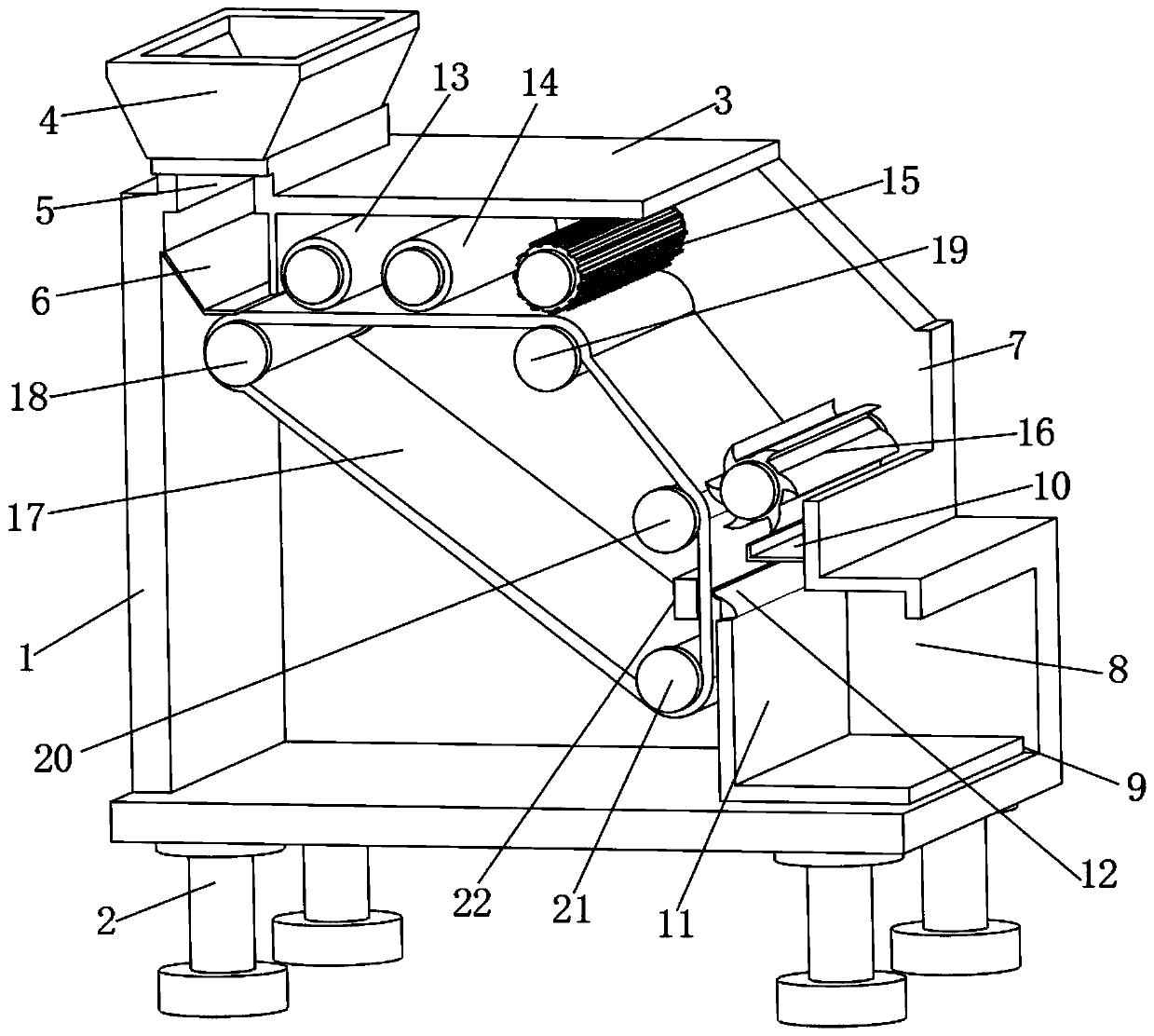

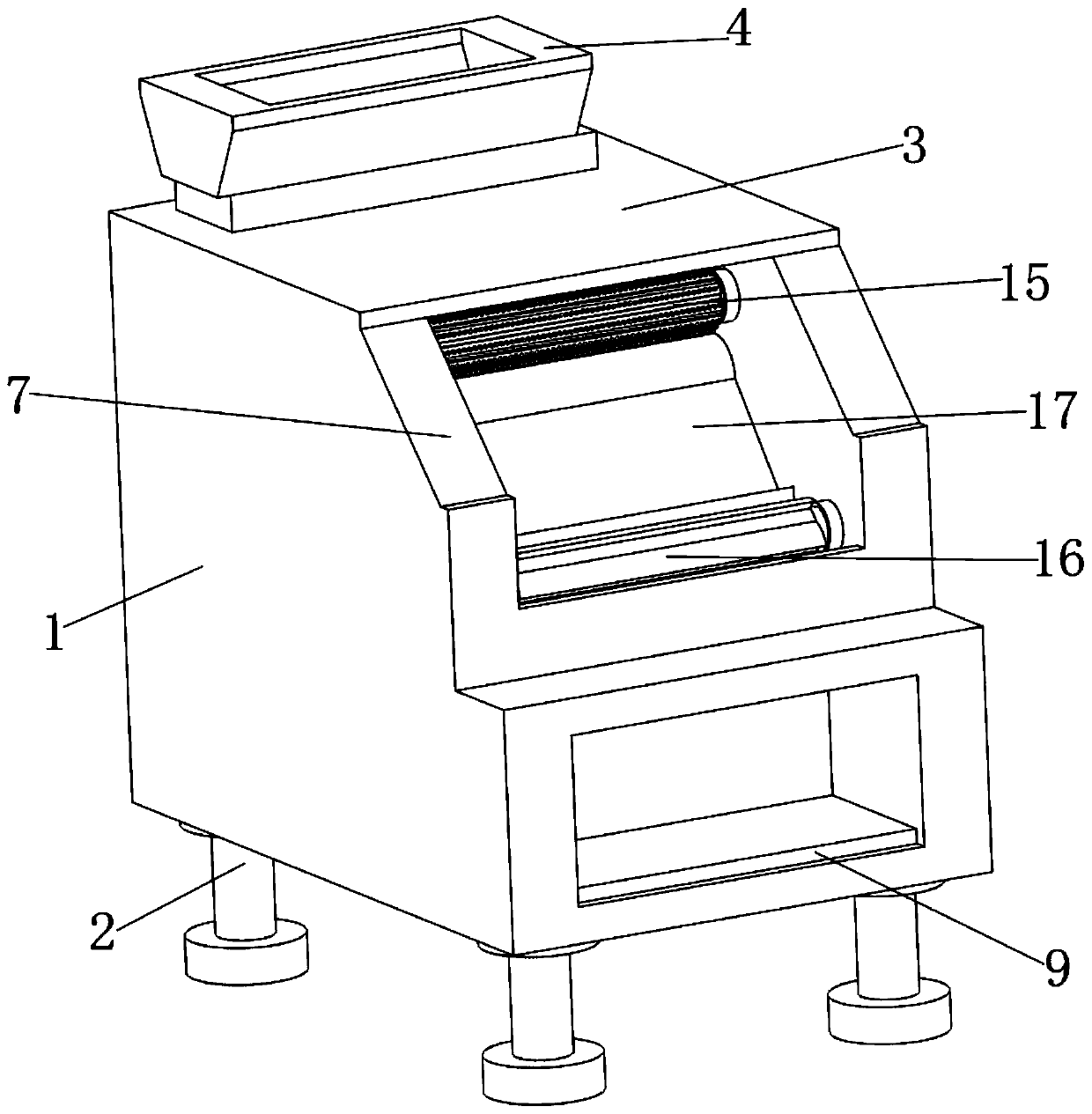

The invention relates to streamlined equipment for silk spinning production. A middle transfer table is arranged between a transfer table I and a transfer table II; an input roller is arranged above the front side of the transfer table I, an output roller is arranged above the back side of the transfer table II, a pressure plate lifting mechanism is arranged on the transfer table, a pressure plate is arranged at the lower end of the pressure plate lifting mechanism, a baffle plate placing groove is formed in the middle transfer table, a pre-posed smooth baffle plate is inserted into a pre-posed baffle plate working groove, a post-posed smooth baffle plate is inserted into a post-posed baffle plate working groove, a pre-posed automatic bourette taking device I and a pre-posed automatic bourette taking device II are separately arranged on two sides of a work station I, a post-posed automatic bourette taking device I and a post-posed automatic bourette taking device II are separately arranged on two sides of a work station II, and four combing rollers are separately a bottom combing roller I, a bottom combing roller II, a top combing roller I and a top combing roller II. According to the equipment provided by the invention, the original silk spinning mechanism is greatly simplified: a middle filling machine and an attaching clamp plate are cancelled and a round comb is simplified, so that the production efficiency is increased, and a manufacturer cuts and processes cotton of any length conveniently.

Owner:JINLING INST OF TECH

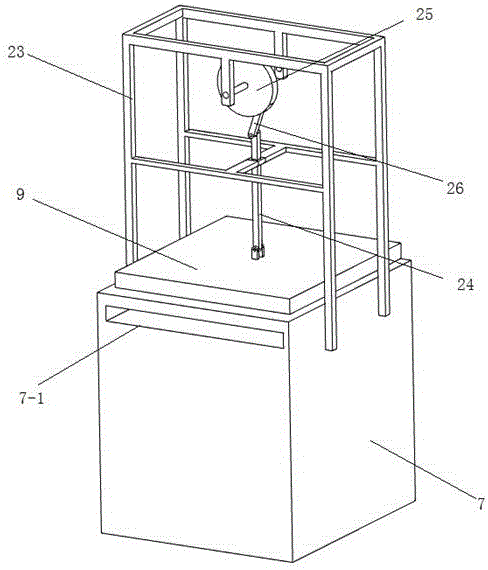

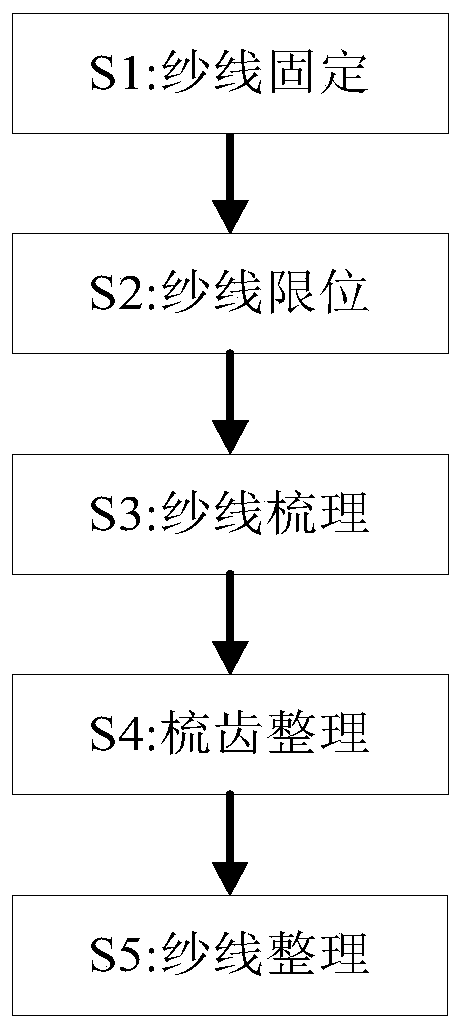

Method for quickly carding textile yarns

ActiveCN110644103AImprove combing effectImprove carding efficiencyFibre cleaning/openingTextile yarnEngineering

The invention provides a method for quickly carding textile yarns. A U-shaped frame, a fixing device, a carding device, a limiting device and an impurity removing device are matched to finish rapid carding operation of the textile yarns. The main problems that in an existing main process of carding yarns, continuous carding work in the same direction cannot be carried out for the yarns all the time, intermittent rotary carding operation is adopted, and low carding efficiency of the yarns is caused by the carding method; in the process of yarn carding, along with the lengthening of the cardingtime, a large amount of broken yarns and other impurities are wound on comb teeth, so that the carding work of the comb teeth on the yarns is influenced; and the quality of the carded yarns is low aresolved.

Owner:晋江恒升染织有限公司

Rabbit hair carding machine

ActiveCN104328535AAvoid damageGood effect of removing coarse and impurityContinuous processingCarding machinesFiberEngineering

The invention discloses a rabbit hair carding machine which comprises a feeding part, a carding part, a hair guide plate and a hair box which are connected orderly. The rabbit hair carding machine is characterized by further comprising an opening and thick throwing part which is connected between the carding part and the hair guide plate. The carding machine is simple in structure, convenient to operate, less in fiber damage, high in carding efficiency, good in thick and impurity removing effect, small in occupied space and low in energy consumption. After rabbit hair is processed by the carding machine, most of the hair lock and impurities in the rabbit hair can be removed.

Owner:吴孔希

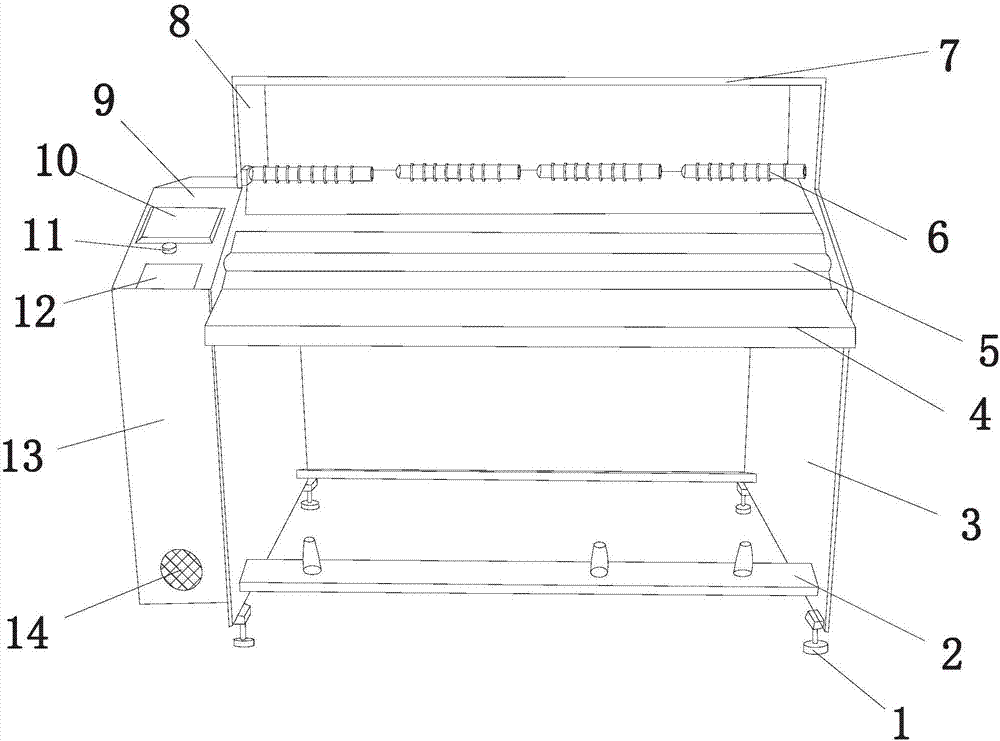

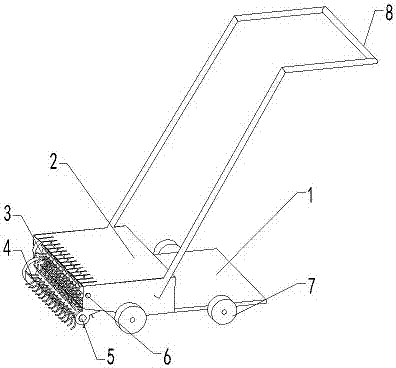

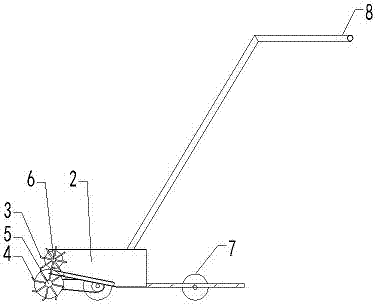

Hand push type grass comber

InactiveCN107996294AImprove carding efficiencyAvoid normal workHops/wine cultivationTurf growingEngineeringMechanical engineering

The invention discloses a hand push type grass comber which comprises a chassis. A collecting device is arranged at the portion, close to the front end, of the chassis. The front end of the collectingdevice is provided with a rotating device for grass combing and collecting, a wheel device for movement is arranged at the bottom of the chassis, the wheel device is in transmission connection with the rotating device, a push handle for pushing the grass comber to move is arranged at the portion, close to the rear end, of the collecting device, the push handle is pushed so that the grass comber can move forwards, and the wheel device rotates to drive the rotating device to convey sundries such as dead leaves into the collecting device. Due to the hand push type grass comber, lawn combing andsundry bagging can be completed, the manual later-period bagging work can be effectively performed, and the hand push type grass comber is suitable for being used in a small place, and the combing efficiency of lawn in the small space is improved.

Owner:李娜娜

Carding machine with cotton yarn not likely to adhere for cotton yarn processing

InactiveCN110453318AAvoid stickingImprove running fluencySafety devices for fibre treatmentCarding machinesYarnBristle

Owner:XUZHOU HUAYUN TEXTILE CO LTD

Combing machine with automatic feeding function

InactiveCN107190107AImprove carding efficiencyFur dressingSkins/hides/leather/fur manufacturing apparatusEngineeringMechanical engineering

The invention relates to the technical field of leatherworking, in particular to a combing machine with the automatic feeding function. The combing machine comprises a case, and further comprises a carrying frame clamped in the middle of the case, first combing parts which penetrate through the upper part of the case and are located on the upper side of the carrying frame, second combing parts which are arranged at the lower part of the case and located on the lower side of the carrying frame, and a motor rotationally connected to the end parts of the second combing parts; and a conveying assembly is further arranged at the front end of the carrying frame and comprises a conveying base, a conveying belt which is arranged outside the conveying base and rotates around the conveying base, a conveying motor arranged on the side face of the conveying base, and adjusting pieces arranged on the upper surface of the conveying belt.

Owner:JIASHAN LONGXIANG ARTIFICIAL FUR

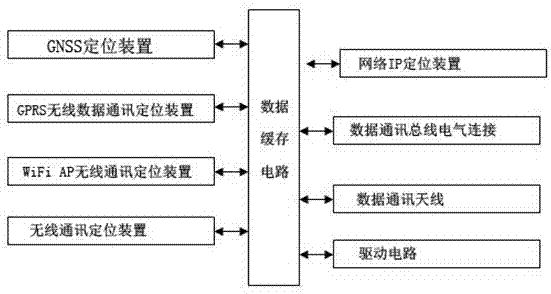

Financial mobile payment terminal with mobile high precision positioning capability

The invention relates to a financial mobile payment terminal with mobile a high precision positioning capability; the financial mobile payment terminal comprises a mobile payment terminal body with apositioning mechanism; the positioning mechanism comprises a communication data antenna and a control circuit; the data communication antenna is arranged on the outer surface of the payment terminal body through a slide block; the slide block is connected with the outer surface of the payment terminal body through a slide groove in a slide manner; the data communication antenna is connected with the slide block in a slide manner through a ratchet, and electrically connected with the control circuit; the control circuit comprises the positioning mechanism, a GNSS positioning device, a GPRS wireless data communication positioning device, a WIFI AP wireless communication positioning device, a network IP positioning device, a data buffer memory circuit, a data communication bus and a drive circuit. The financial mobile payment terminal can simultaneously satisfy the demands of various positioning tracking modes, is high in data sorting and communication efficiency, thus greatly improving the usage safety and management convenience of the financial mobile payment terminal equipment.

Owner:CHENGDU YUYA TECH

Roller adjustable frame structure of carding machine

ActiveCN103924328BMaintenance work intensityReduce standby timeCarding machinesEngineeringUltimate tensile strength

Owner:JIANGSU YINGYANG NONWOVEN MASCH CO LTD

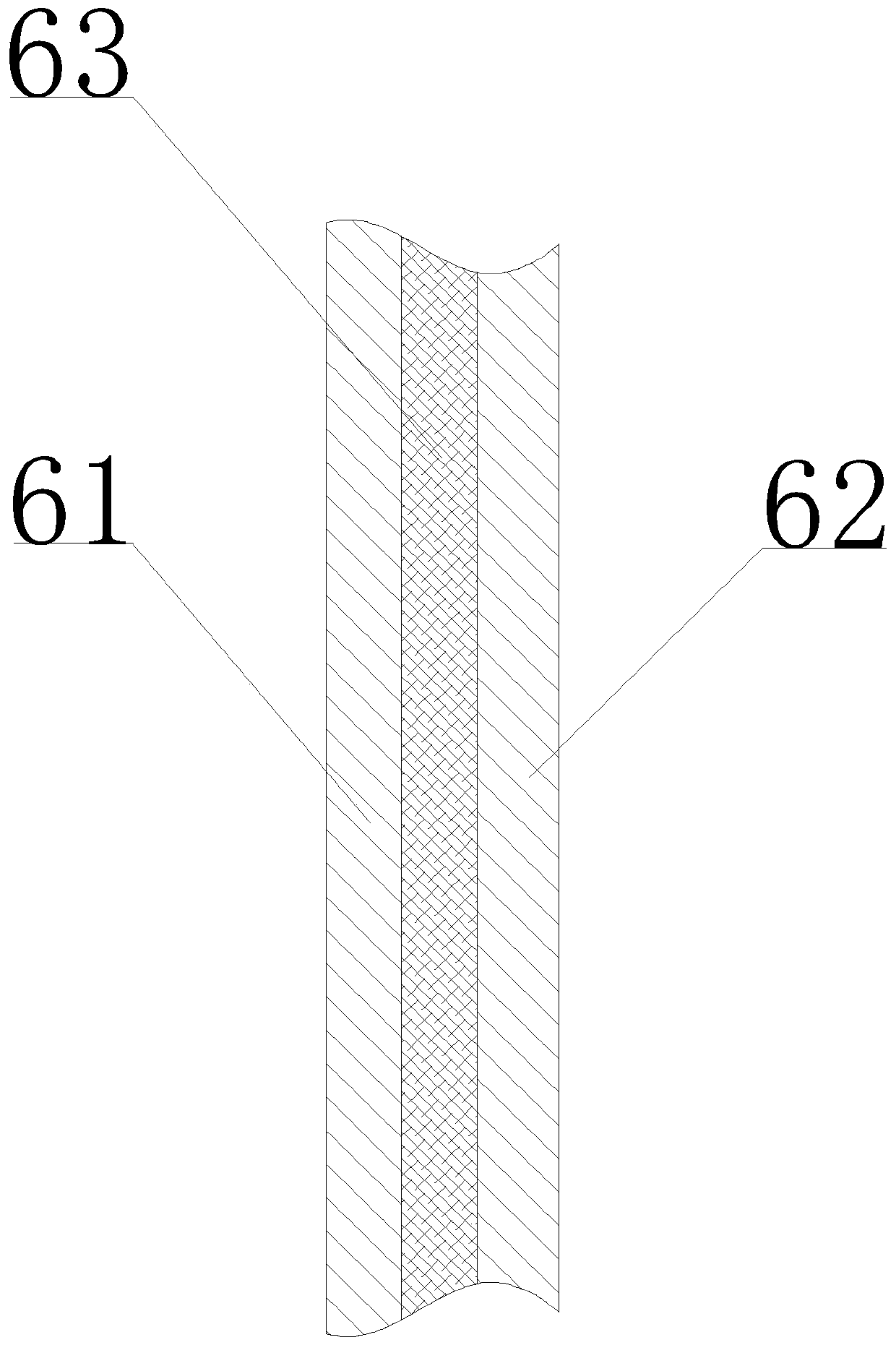

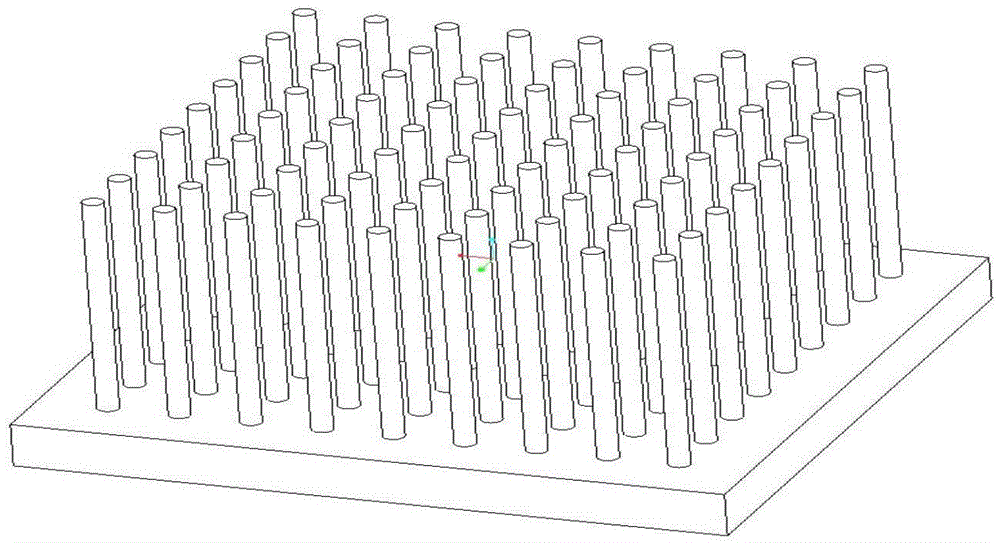

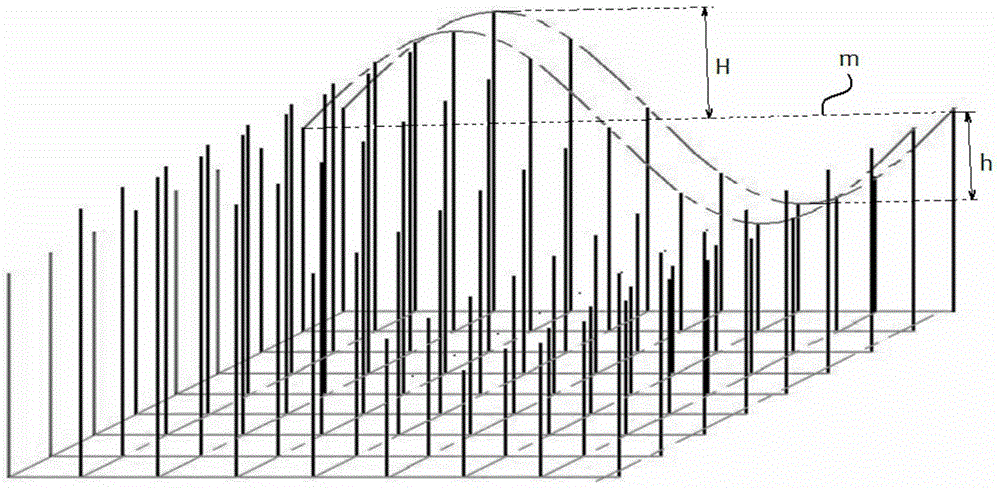

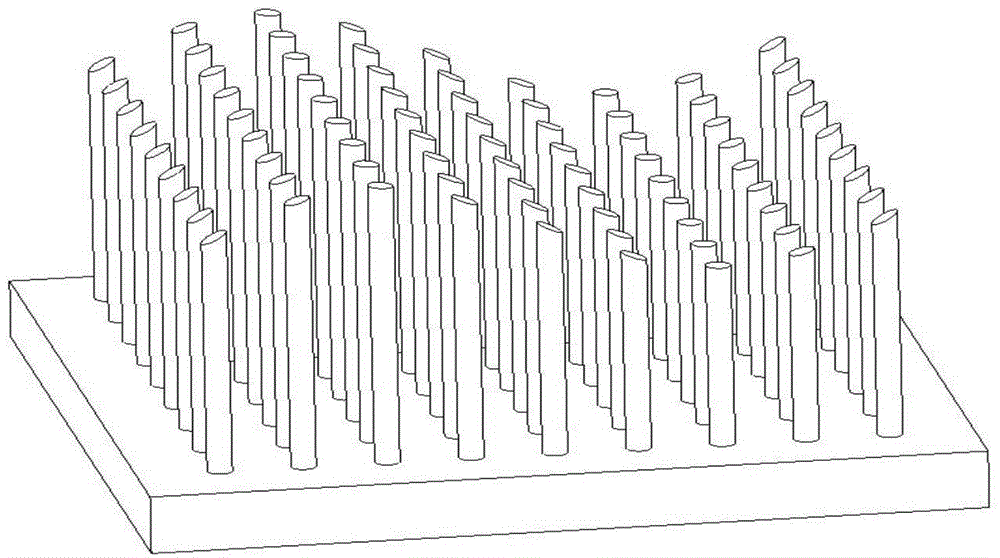

Unequal-height tooth carding cloth

ActiveCN104805542AMinimizes carding damageAffect quality efficiencyCarding machinesCardingEngineering

The invention provides an unequal-height tooth carding cloth, which consists of unequal-height tooth carding cloth units, wherein the surface of the tooth top of the carding cloth of each unequal-height tooth carding cloth unit is in a wavy way. By adopting the technical scheme, the unequal-height tooth carding cloth has the advantages that the carding and loosening functions are realized, the carding damage to fibers is reduced, the amount of short fibers is reduced, the carding quality is improved, the stereo multi-layer surface carding state is formed, and the technical purposes of high carding yield and high carding quality are realized.

Owner:EASTERN LIAONING UNIV

Textile fabric rapid carding equipment and working method thereof

InactiveCN112227047AImprove patencyImprove adsorption capacityMechanical cleaningPressure cleaningBristleStructural engineering

The invention belongs to the technical field of textile equipment, and particularly relates to textile fabric rapid carding equipment and a working method thereof. The textile fabric rapid carding equipment comprises a machine body; a feeding hole and a discharging hole are formed in the two sides of the machine body correspondingly; a pair of circular pipes are rotatably connected to the side, close to the feeding hole, in the machine body through a bracket; one end of each circular pipe is fixedly connected with a hollow clearing roller, and the other ends of the circular pipes communicate with negative pressure devices; and a group of negative pressure holes are uniformly distributed at the periphery of each clearing roller, and a group of bristles are circumferentially and uniformly distributed at the position, between the adjacent negative pressure holes, of each clearing roller. The ends, away from the circular pipes, of the clearing rollers penetrate through the machine body andextend out of the machine body, and pushing rods are arranged in the clearing rollers; brush plates are arranged at the ends, located in the clearing rollers, of the pushing rods; supporting seats are fixedly connected to the position, corresponding to the clearing rollers, of the machine body, and a pair of rollers is arranged on each supporting seat; and a conveying belt is arranged between theevery two rollers in a sleeving mode, one side of each conveying belt is fixedly connected with a rotating pin, and the rotating pins are hinged to the pushing rod through connecting rods. Accordingto the textile fabric rapid carding equipment, the brush plates are driven by the conveying belts to continuously scrape the inner walls of the clearing rollers, and the carding efficiency of cloth isimproved.

Owner:沈足金

Novel semi-spinning specialized equipment

The invention discloses novel semi-spinning specialized equipment, comprising a feeding mechanism, a carding mechanism, a stripping and taking mechanism and a strip forming and coiling mechanism; the rear part of the feeding mechanism is provided with a second flat-bottom lattice and a second inclined-spike lattice in sequence; the rear side of the upper part of the second inclined-spike lattice is provided with a second hair uniformizing roller and a second hair uniformizing rake; the front side of the upper part of the second inclined spike lattice is provided with a second hair stripping roller, the lower part of which is provided with a first flat-bottom lattice; the carding mechanism comprises a big cylinder; a rotary cover plate is arranged above the big cylinder, the front part of which is provided with a front fixed cover plate; four fixed cover plate bars are arranged on the front fixed cover plate; the rear part of the big cylinder is provided with a rear fixed cover plate; two fixed cover plate bars are arranged on the rear fixed cover plate; a front fixed cover plate carding region, an upper rotary cover plate carding region and a rear fixed cover plate carding region are formed on the big cylinder; and a card wire type structure is adopted to the fixed cover plate bars. The novel semi-spinning specialized equipment of the invention is beneficial to uniform feedingand further improves the carding effect.

Owner:青岛东佳纺机(集团)有限公司

High-efficiency main carding device of carding machine

The invention discloses a high-efficiency main carding device of a carding machine. The main carding device comprises a preparing device and a main carding device arranged on the right side of the preparing device. The main carding device is characterized in that the preparing device comprises a first cotton inlet and a first cotton outlet, a stirring and crushing barrel is arranged between the first cotton inlet and the first cotton outlet, a second cotton inlet is arranged in the position, horizontally corresponding to the first cotton outlet, of the main carding device, a plurality of cotton separating wheels are arranged on the right side of the second cotton inlet and distributed regularly, a primary carding wheel and secondary carding wheels which are cylinders are arranged on the right side of the cotton separating wheels, small carding teeth are arranged on outer walls of the cylinders, the secondary carding wheels are circumferentially and regularly distributed around the primary carding wheel, a cotton gathering wheel is arranged on the right side of the primary carding wheel, and second cotton outlets are arranged on the right side of the cotton gathering wheel. The carding efficiency can be greatly improved, treated broken cotton is finer and tidier, scattering and crushing of broken cotton are facilitated by the aid of the stirring and crushing barrel, and the primary carding wheel and the secondary carding wheels are high in adaptability.

Owner:郭林华

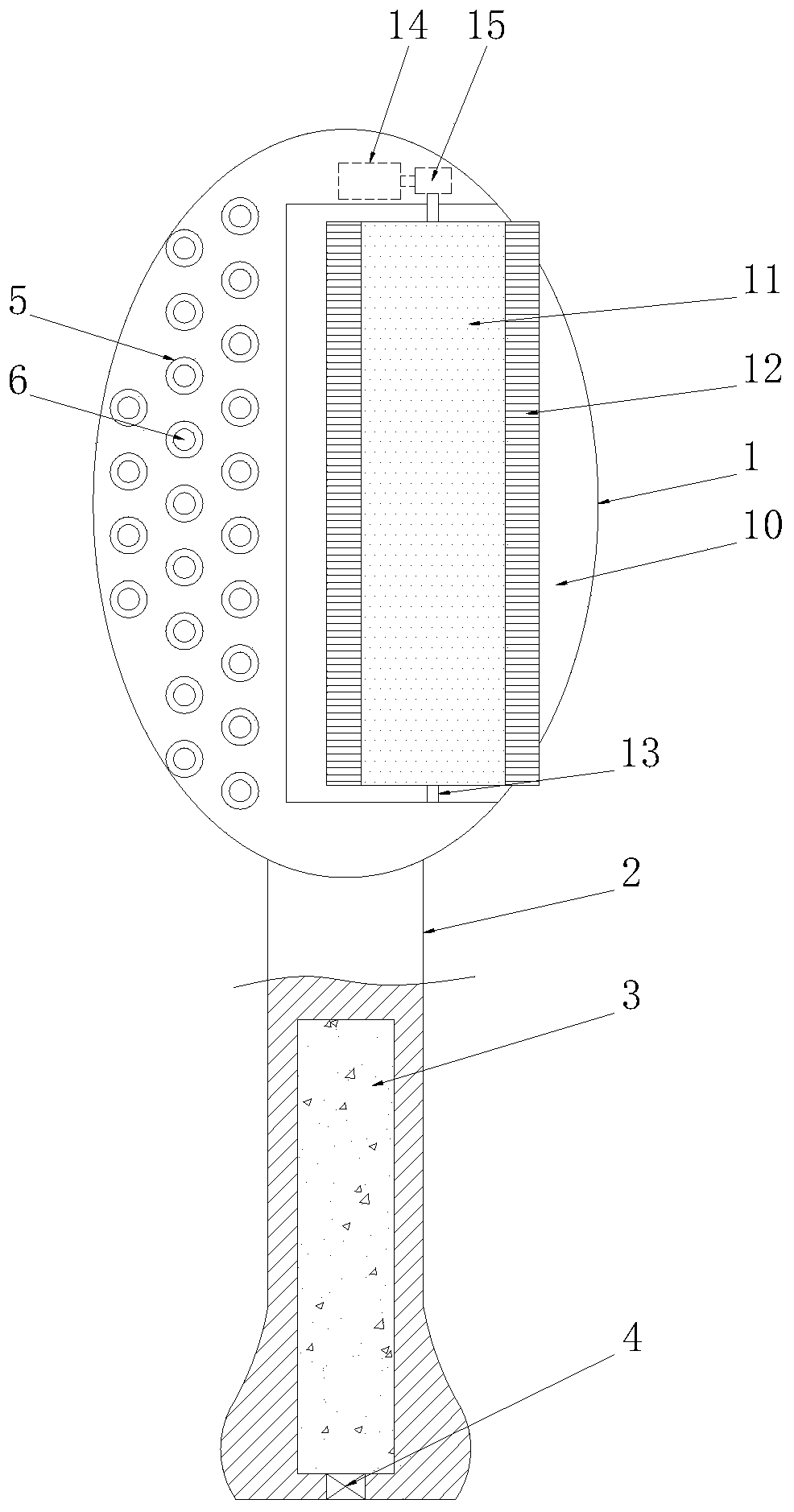

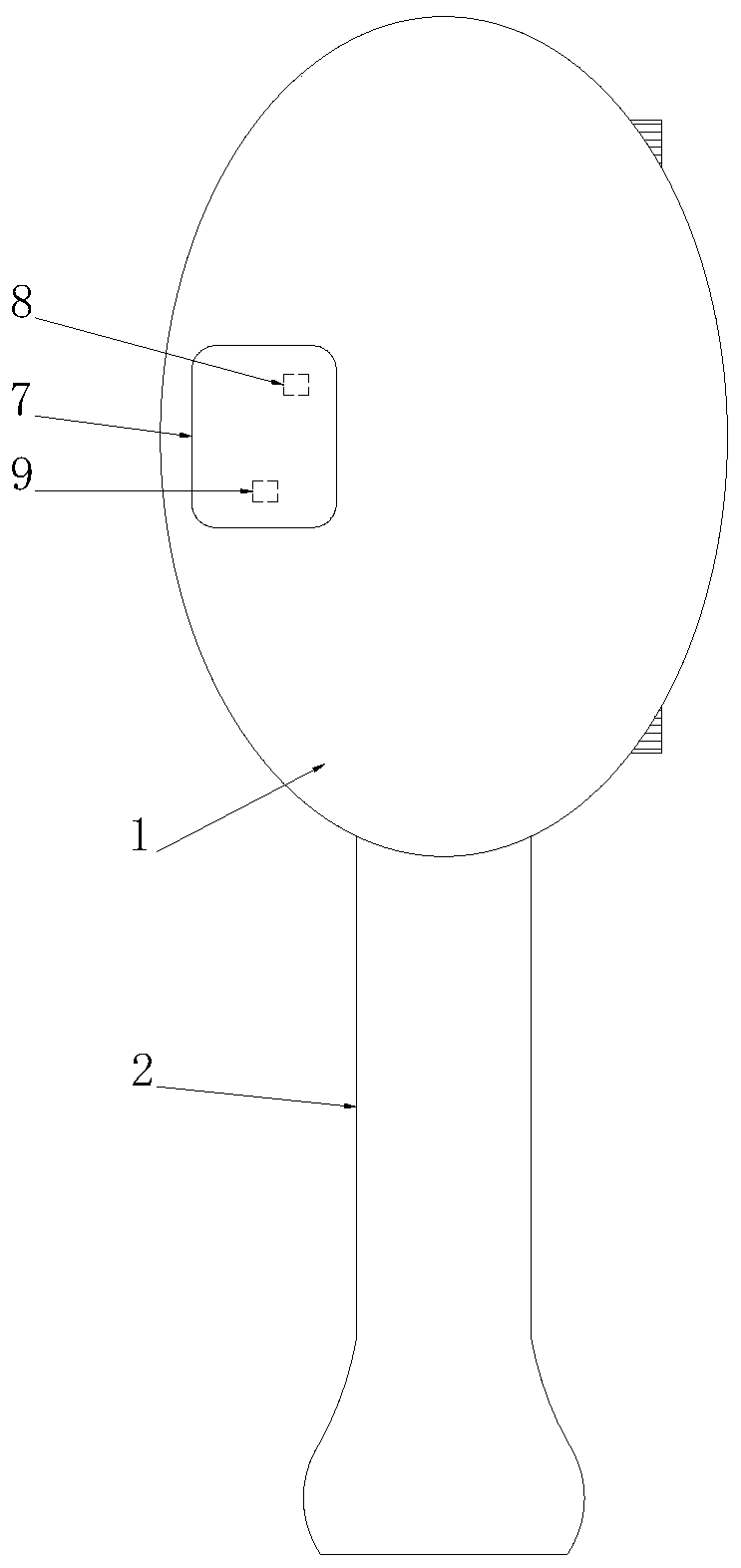

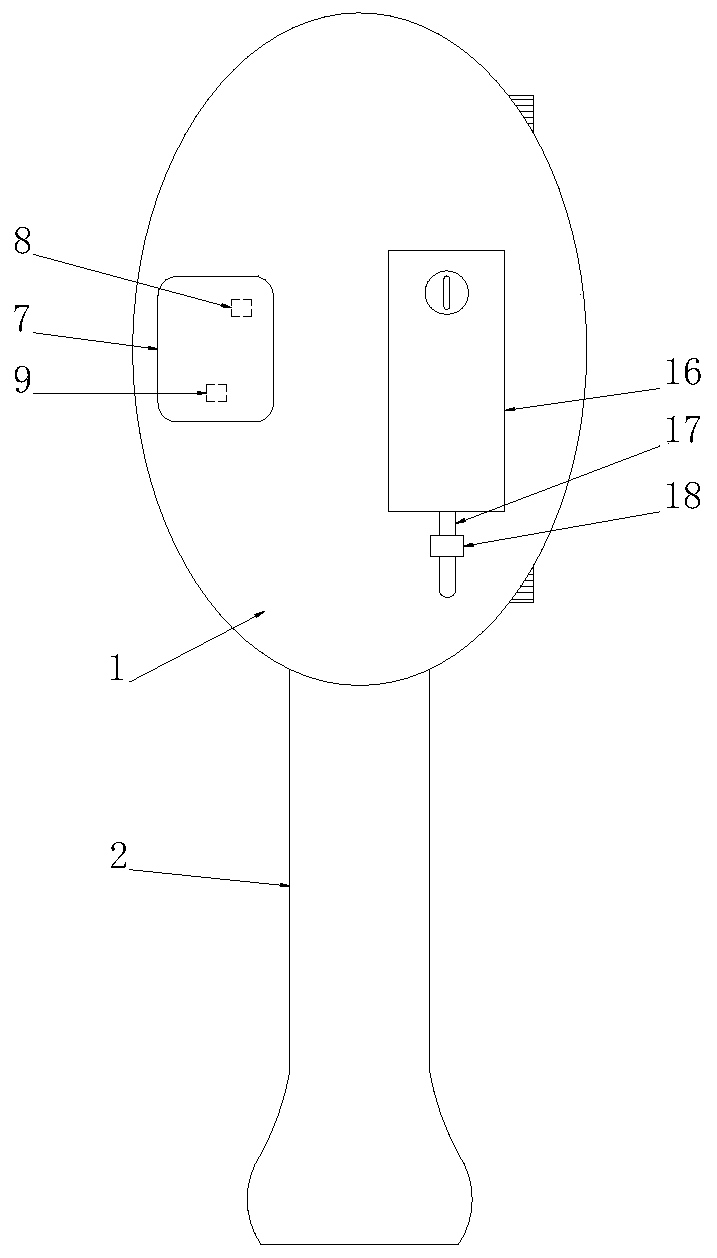

Animal parasite detection device

InactiveCN110301370AImprove carding qualityImprove carding efficiencyGeological measurementsGrooming devicesEngineeringBody surface

The invention discloses an animal parasite detection device. The animal parasite detection device comprises a comb head and a comb handle and is characterized in that one end of the comb head is fixedly connected with the comb handle, a storage battery is embedded into the comb handle, the front end face of the comb head is provided with a comb cavity and a plurality of fixed comb teeth, a detection probe is embedded into one end, away from the comb head, of each fixed comb tooth, and a touch display screen is arranged on one side of the back side of the comb head; a comb roller is arranged inthe comb cavity, the comb roller is rotatably connected to the comb cavity through a rotary shaft, a plurality of movable comb teeth are evenly arranged on the comb roller, and a motor and a reducerare arranged in one end, away from the comb handle, of the comb head. The animal parasite detection device has the advantages that whether parasites exist on the body surface of a pet or not is detected through the detection probes, an alarm module gives out a sound to remind a pet owner when parasites are detected, the number of the detected parasites is counted through a counting module, the conditions of the parasites are displayed through the touch display screen, and the pet owner can roughly observe the number of the parasites on the body surface of the pet through the touch display screen so as to decide whether to wash the pet with medicine and water or not to remove the parasites.

Owner:TARIM UNIV

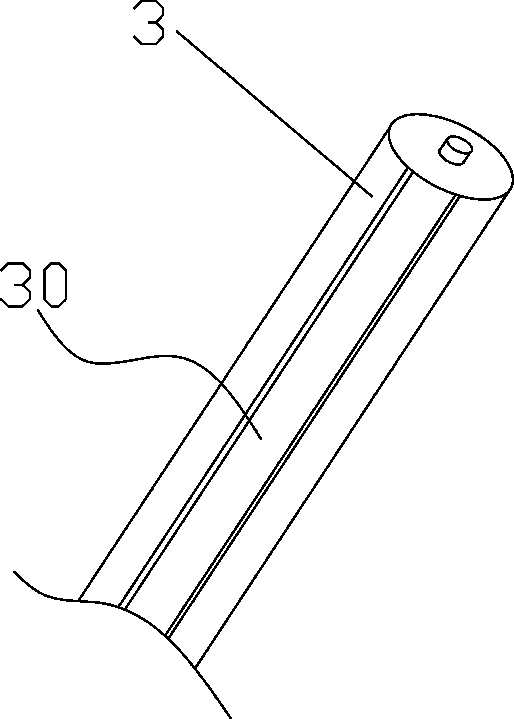

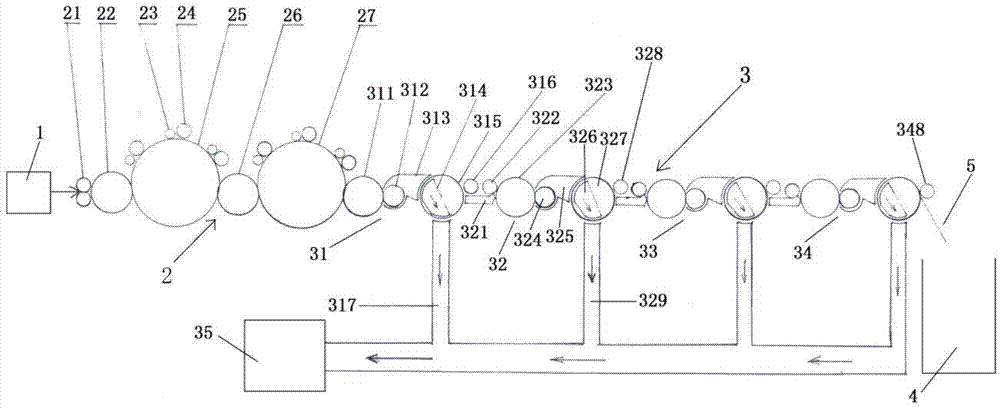

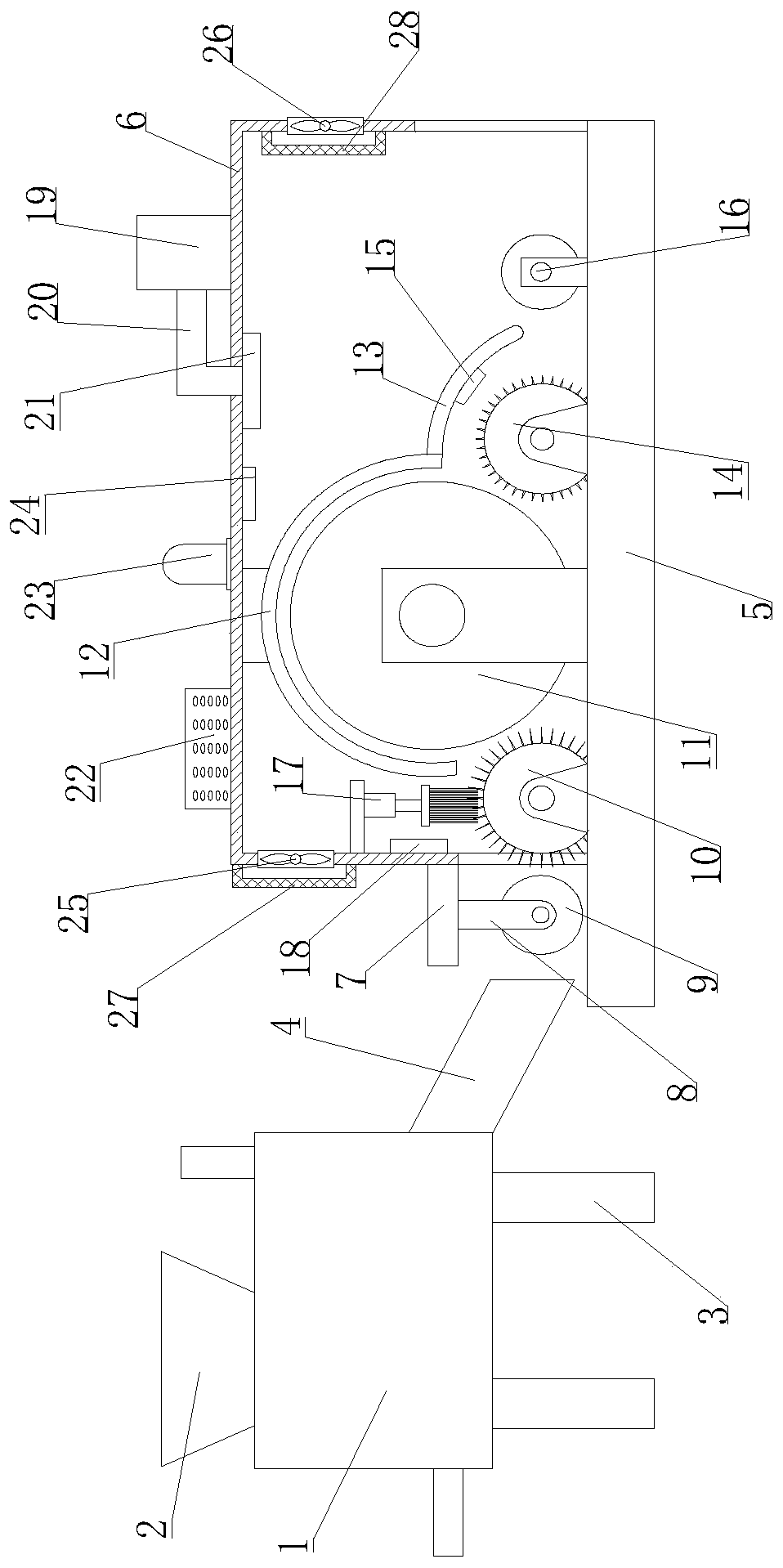

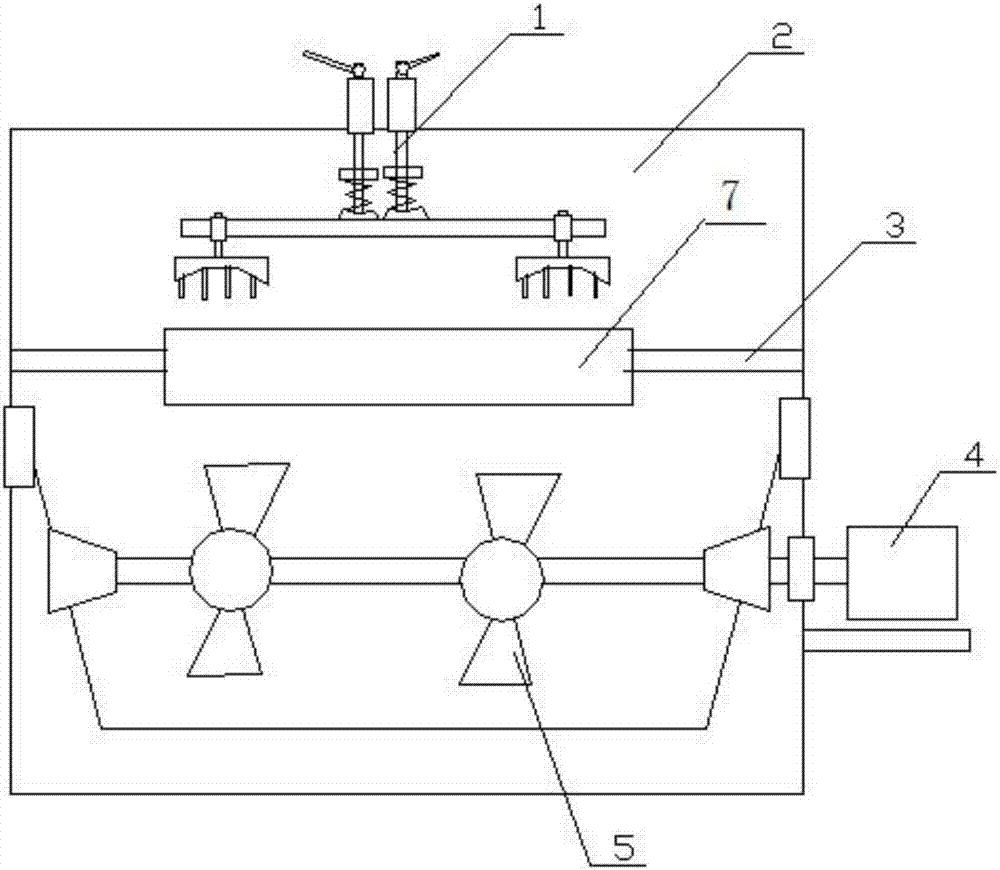

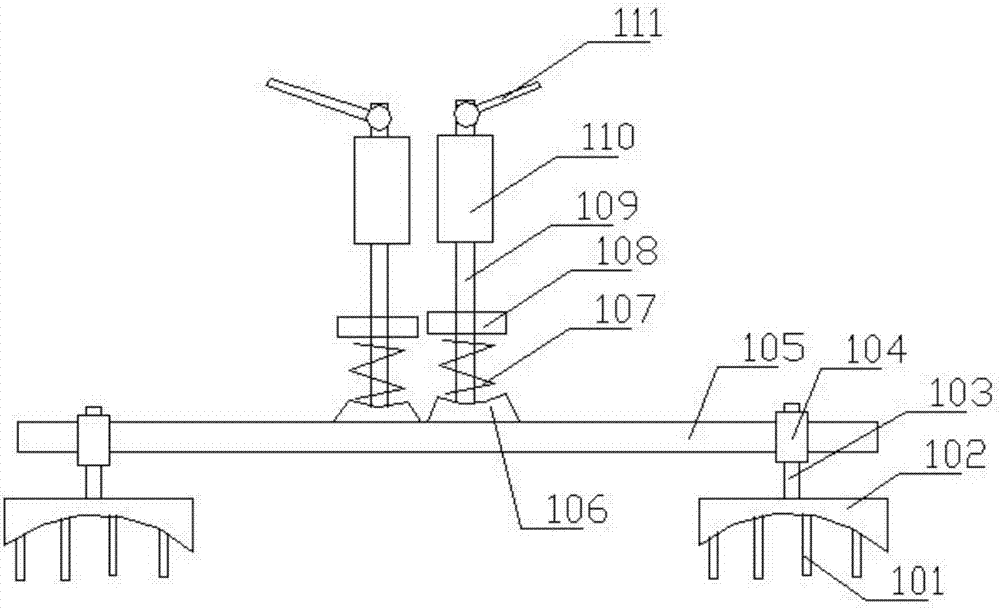

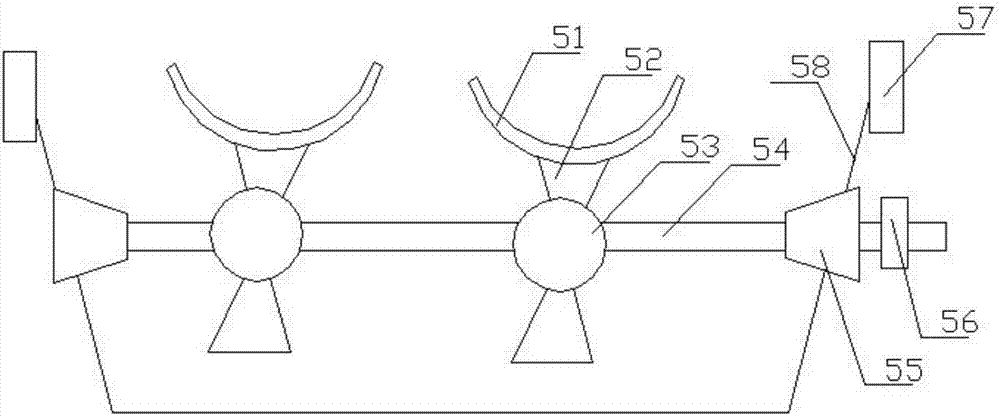

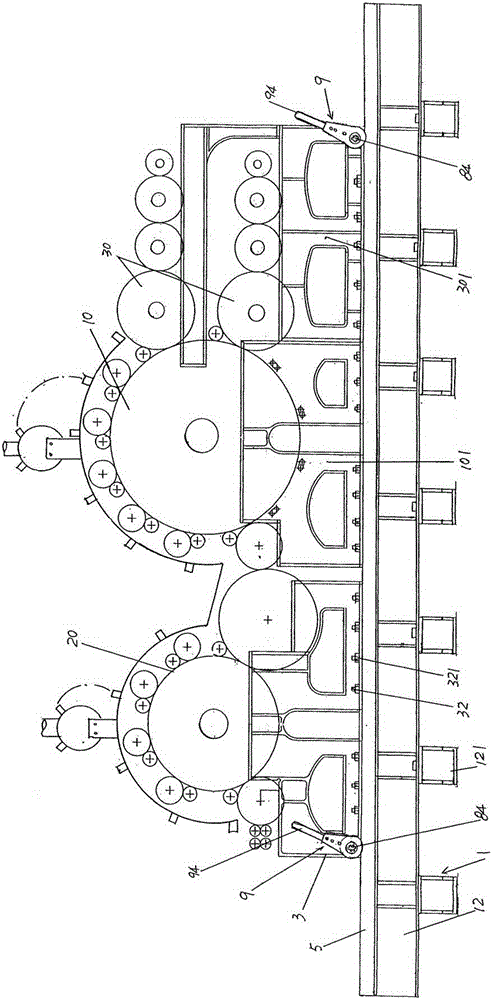

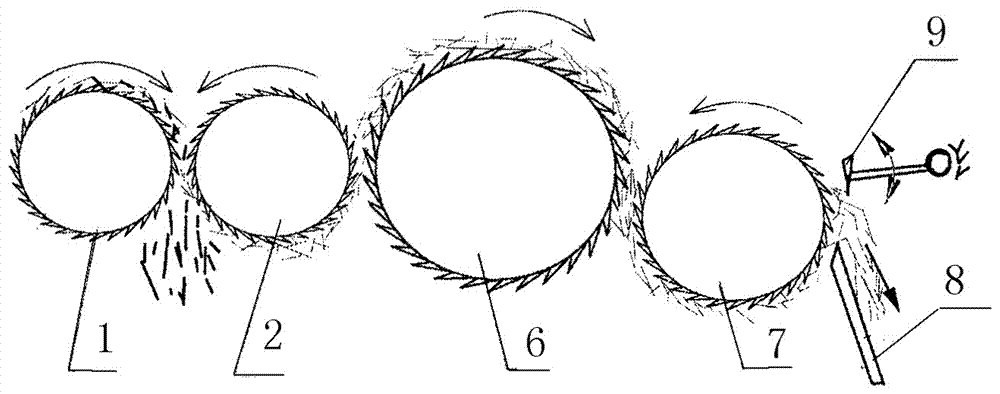

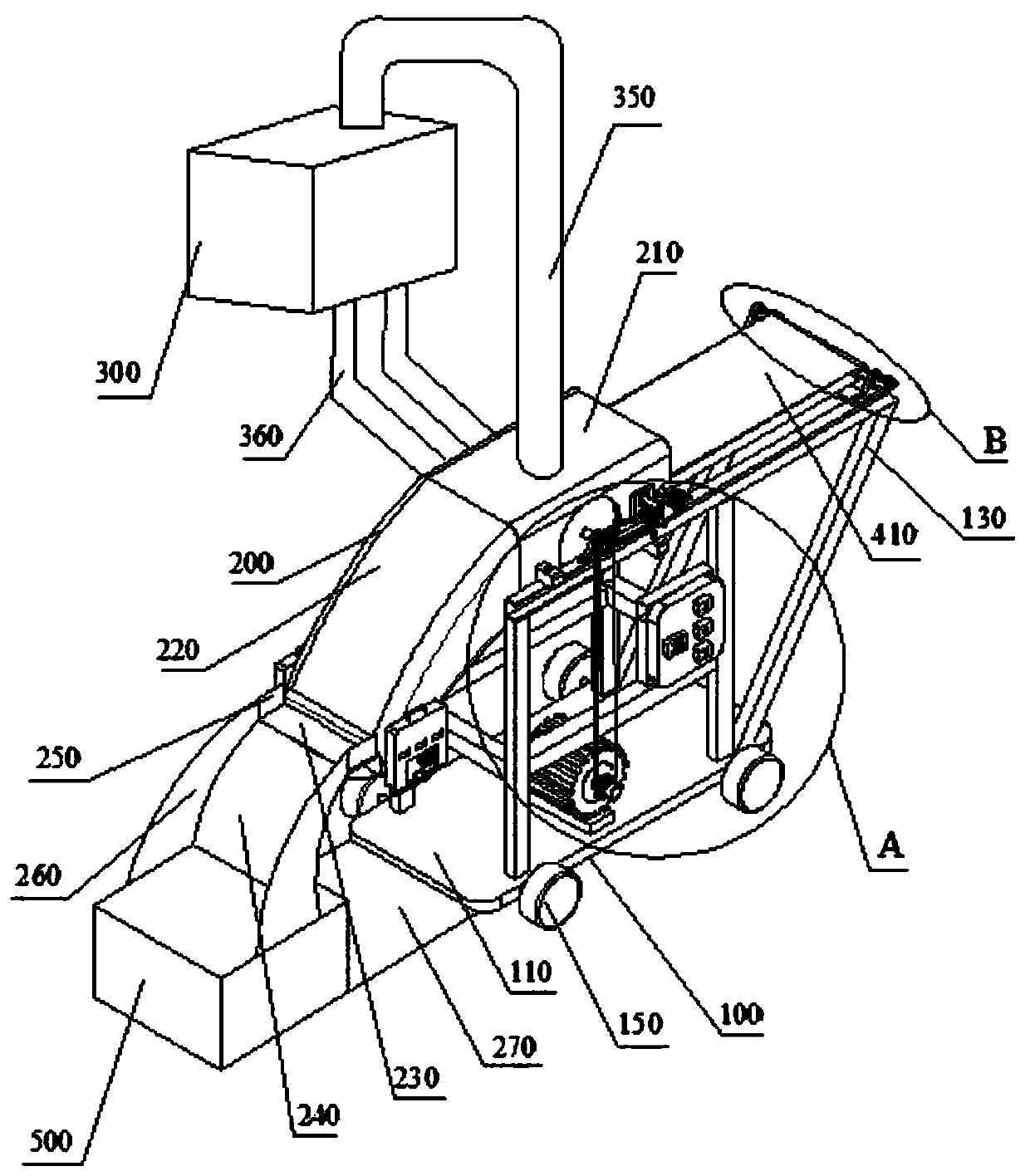

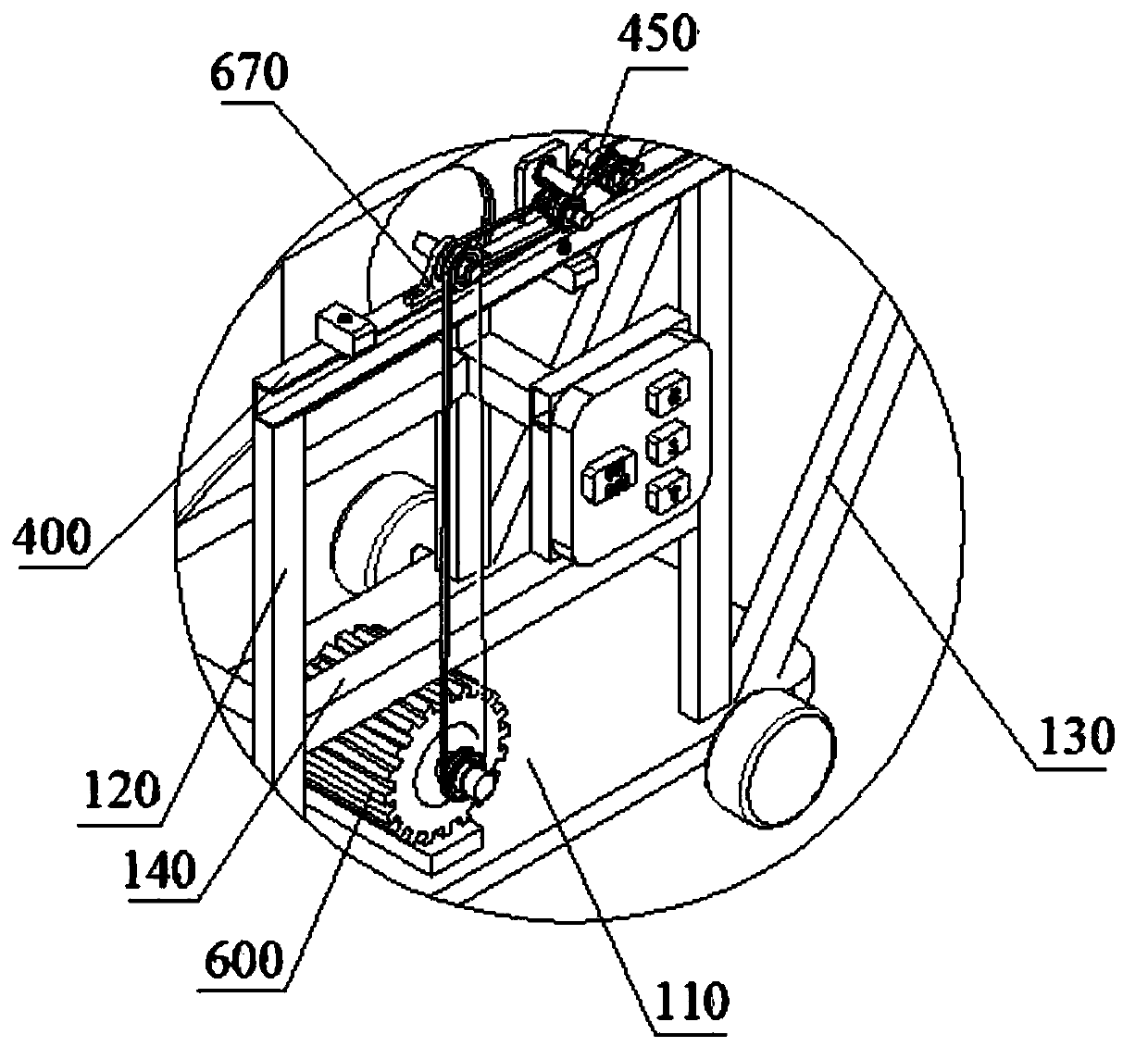

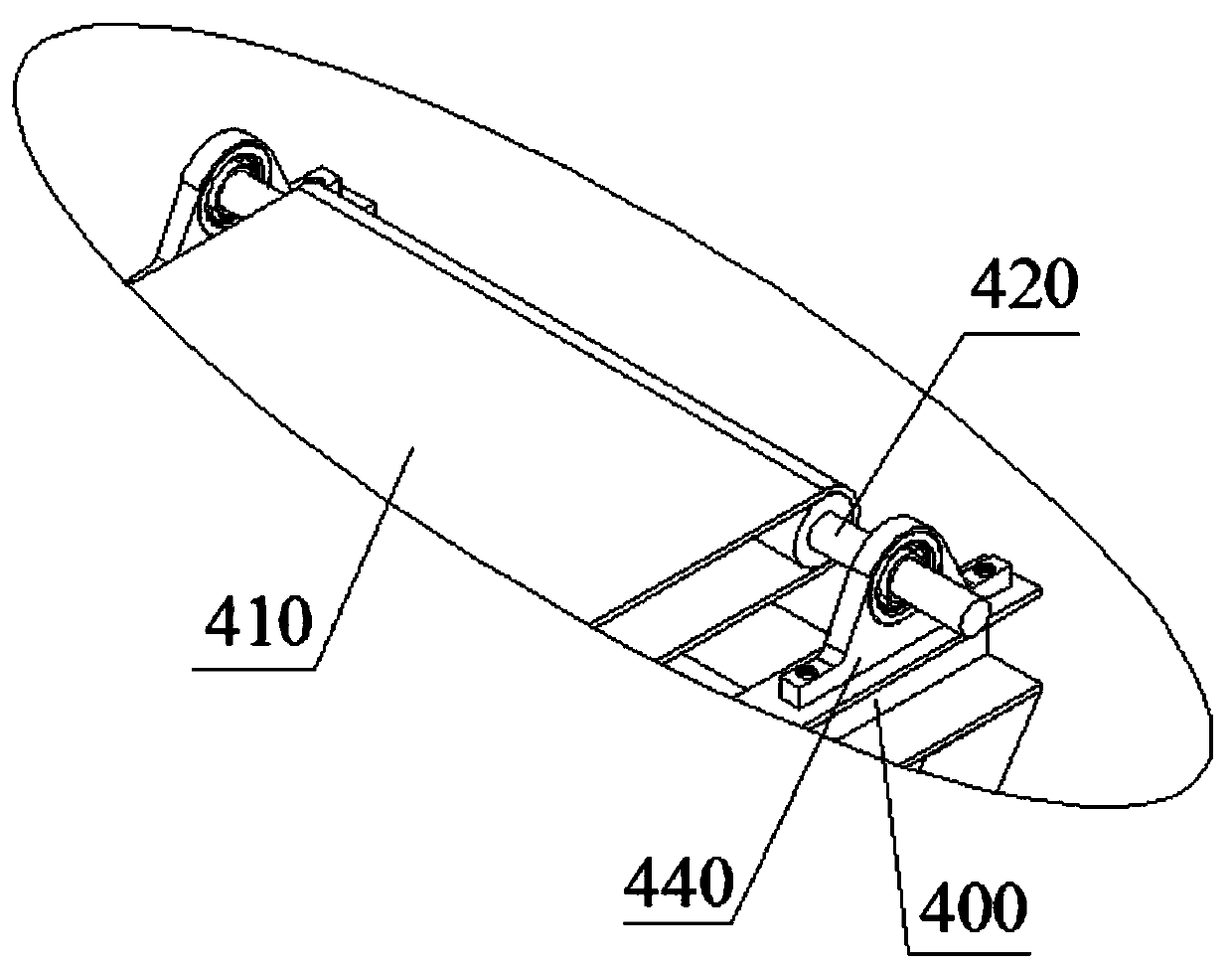

Double-path villus transfer carding method and equipment

The invention discloses a double-path villus transfer carding method and equipment. Villi are fed into a front-stage carding device through a feeding mechanism of the villi, the villi are transferred in two paths after being subjected to front-stage carding, one path is doffer transfer, and the other path is dust cage transfer. The villi transferred in two paths are separately collected and sequentially fed into carding regions formed by the villi and a rear-stage carding roller respectively for rear-stage carding, and the villi obtained after rear-stage carding are transferred through transfer equipment and then finally guided out. According to the method, front-stage carding and rear-stage carding are arranged, the carding speed is high, and the carding efficiency is far higher than that of traditional carding. According to the method, a double-path villus transfer and feeding mode is adopted for front-stage carding, the carded villi are more fully transferred, the villi returned after being hooked on card clothing are less, therefore, fiber damage is lower, the villus content in falling objects is smaller, and the situation that part of the falling objects contain more villi and pill is avoided. According to the equipment adopted for the method, the gauge of all parts is reasonable, and the selected card clothing can be bought on the market.

Owner:赤峰牧原绒毛制品有限责任公司 +2

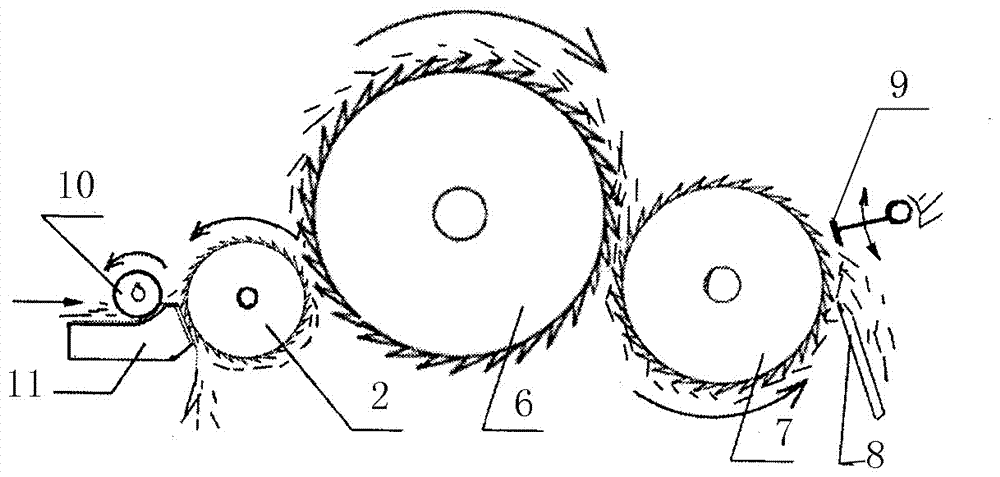

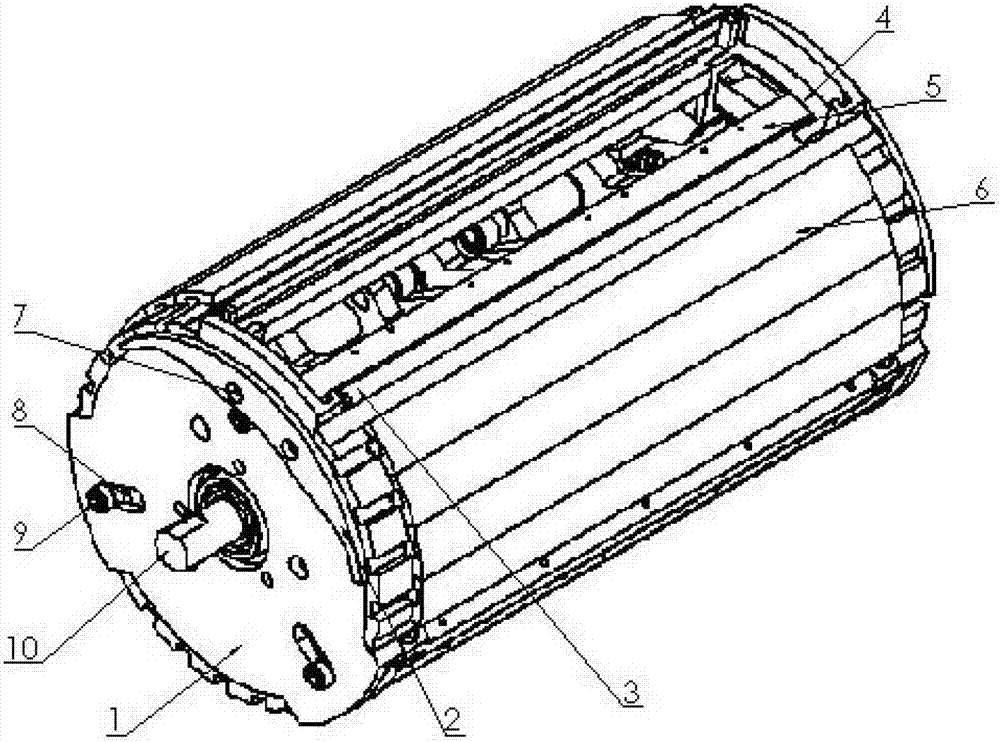

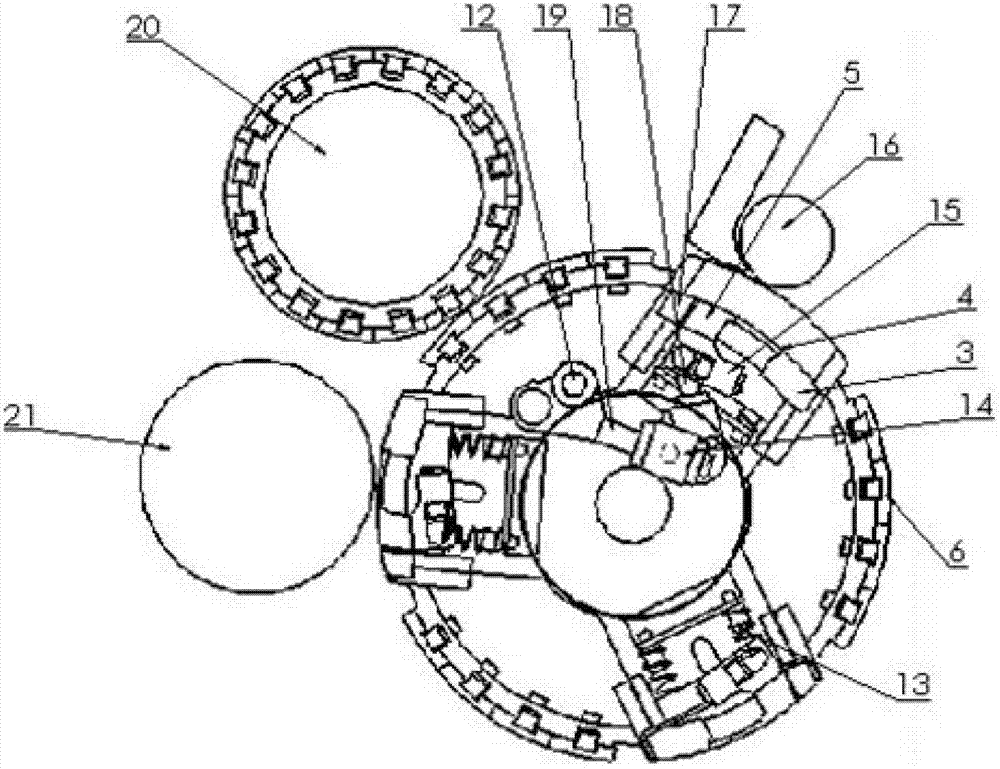

Combing machine cylinder structure with built-in nipper assemblies

The invention relates to a combing machine cylinder structure with built-in nipper assemblies. The combing machine cylinder structure comprises a cylinder shaft, a cylinder, cylinder end caps, the nipper assemblies and a cylinder card wire device, wherein the cylinder is movably sleeved on the cylinder shaft; the cylinder end caps are respectively fixed at two ends of the cylinder shaft; 1-4 nipper assemblies and the cylinder card wire device are peripherally distributed on the periphery of the cylinder uniformly; and each nipper assembly comprises a movable nipper, a fixed nipper, a nipper stretching and retracting mechanism, a nipper pressurizing mechanism and a nipper driving mechanism, the movable nipper is mounted on the nipper stretching and retracting mechanism and is connected with the nipper driving mechanism through the nipper pressurizing mechanism, and the fixed nipper is fixed on the nipper stretching and retracting mechanism. Combing and piecing modes finished in a narrow triangular region in the traditional combing process actions is changed into a mode that combing and piecing are simultaneously carried out on different portions of the surface of the periphery of the cylinder. After the cylinder rotates by a circle, a plurality of combing processes can be finished, and the combining efficiency of a combing machine is greatly improved. The combing machine cylinder structure is simple in motion mode, low in noise and suitable for popularization and application.

Owner:DONGHUA UNIV

Yarn-combing tensioning frame

ActiveCN104178866AEasy to operateEasy combing operationOther manufacturing equipments/toolsTextiles and paperYarnEngineering

The invention relates to spinning equipment, particularly to a yarn-combing tensioning frame used for being matched with a drawing-in machine in the spinning equipment. The yarn-combing tensioning frame comprises a support, a tensioning mechanism for tensioning yarn, and overturning mechanisms for overturning the tensioning mechanism, wherein the overturning mechanisms are arranged on the support and connected with the tensioning mechanism; each overturning mechanism comprises an overturning rod; the tensioning mechanism comprises a first tensioning mechanism and a second tensioning mechanism; the first tensioning mechanism is arranged at one end of each overturning rod; the second tensioning mechanism is arranged at the other end of each overturning rod; the first tensioning mechanism comprises a first tensioning roller, and a first tensioning adjusting mechanism for driving the first tensioning roller to conduct tensioning adjusting; the second tensioning mechanism comprises a second tensioning roller; the first tensioning roller is in parallel with the second tensioning roller. The yarn-combing tensioning frame has the benefits that the operation of operating staff is facilitated, the workload is reduced, and the yarn-combing efficiency is improved.

Owner:SHENZHEN HAYHON EQUIP TECH

Carding equipment for spinning easy to clean and application method thereof

ActiveCN110295417AReduce power consumptionImprove carding efficiencyCarding machinesCardingTransmission belt

The invention discloses carding equipment for spinning easy to clean and an application method thereof. The carding equipment for spinning is characterized in that a first pulley is driven to rotate through an output shaft of a first driving motor, the first pulley further drives transmission of a first transmission belt and rotation of a second pulley, the second pulley drives transmission of a second transmission belt, and a third pulley and a fourth pulley rotate along; rotation of a center spindle connected with the second pulley drives a licker-in to rotate. In use, the four pulleys, twotransmission belts and two roller shafts are driven by the first driving motor to engage in linkage, such that feeding, squeezing and carding are carried out for cotton at the same time; power consumption of the carding equipment is reduced greatly, and carding efficiency is improved. Impurities in a carding chamber can be dried and sorted, so that impurity cleaning cost is reduced.

Owner:安徽宜民新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com