Double-path villus transfer carding method and equipment

A carding and routing technology, used in deburring devices, textiles and papermaking, fiber processing, etc., can solve the problems of easy pilling of fluff, low carding efficiency, low carding speed, etc., and achieves less fiber damage and improved separation. The effect of high comb output and opening speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with accompanying drawing.

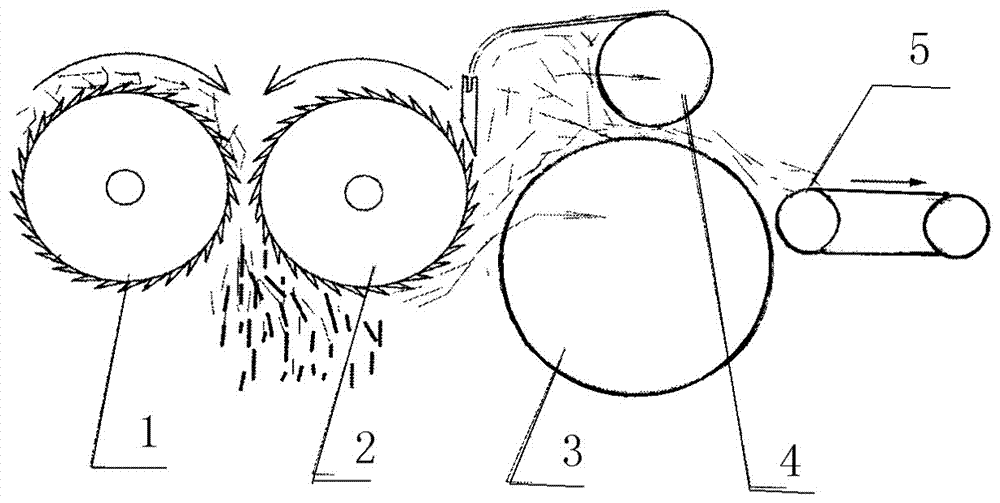

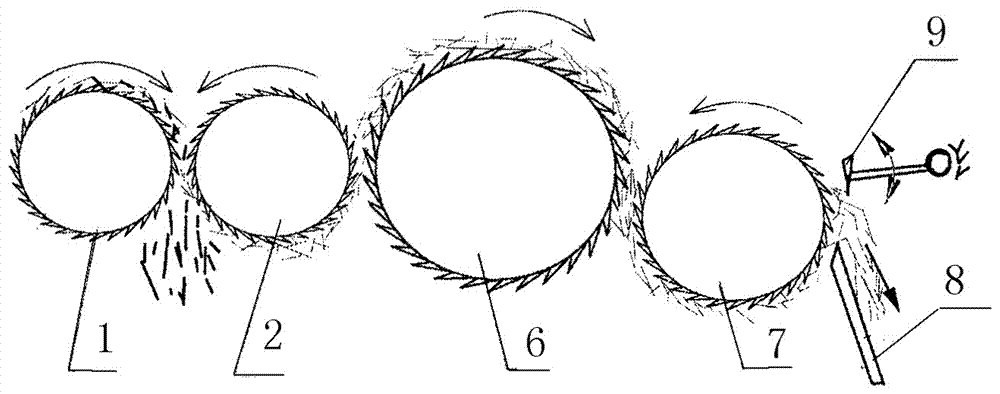

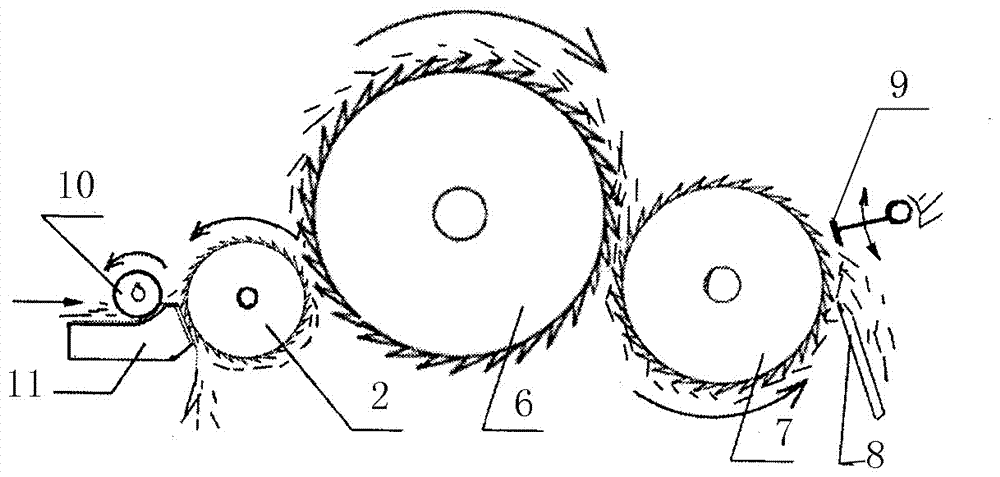

[0047] Figure 1-7 Middle, 1. Guide feeding roller; 2. Carding roller; 3. Large dust cage; 4. Small dust cage; 5. Transfer curtain; 6. Cylinder; 7. Doffer; 8. Deflector; 9. Cut Knife; 10. Feeder roller; 11. Feeder board; 12. Rear stage doffer; 13. Upper feed roller; 14. Upper stripping roller; 15. Front stage doffer; 16. Transfer cylinder; 17. Rear stage Carding roller; 18, the lower stripping roller; 19, the front stage carding roller; 20, the fed hair bundle transferred from other mechanisms; 21 gives the fleece board nose wide plane.

[0048] The following embodiments are used to illustrate the present invention, but not to limit the protection scope of the present invention.

[0049] Figure 1-3 are the three most commonly used methods in the prior art, figure 1 It is fed by the middle guide feed roller 1, and transferred by the carding roller 2, the large dust cage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com