Preparation method of three-dimensional graphene film and three-dimensional graphene-copper composite cable

A graphene film, graphene technology, applied in the direction of graphene, single-layer graphene, chemical instruments and methods, etc., can solve the problem of low softening resistance temperature of pure copper contact wire, low strength of pure copper wire, increased electrical wear, etc. problems, to achieve the effect of not easily broken and broken, less layers, and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

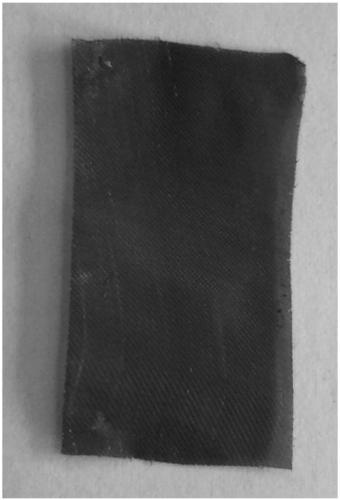

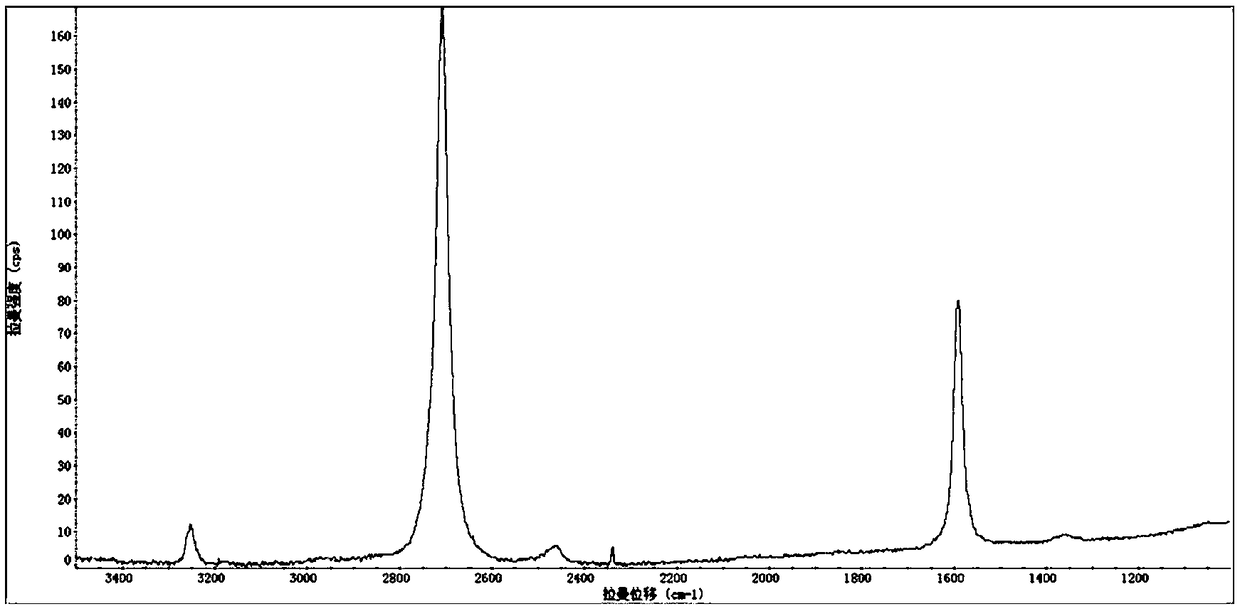

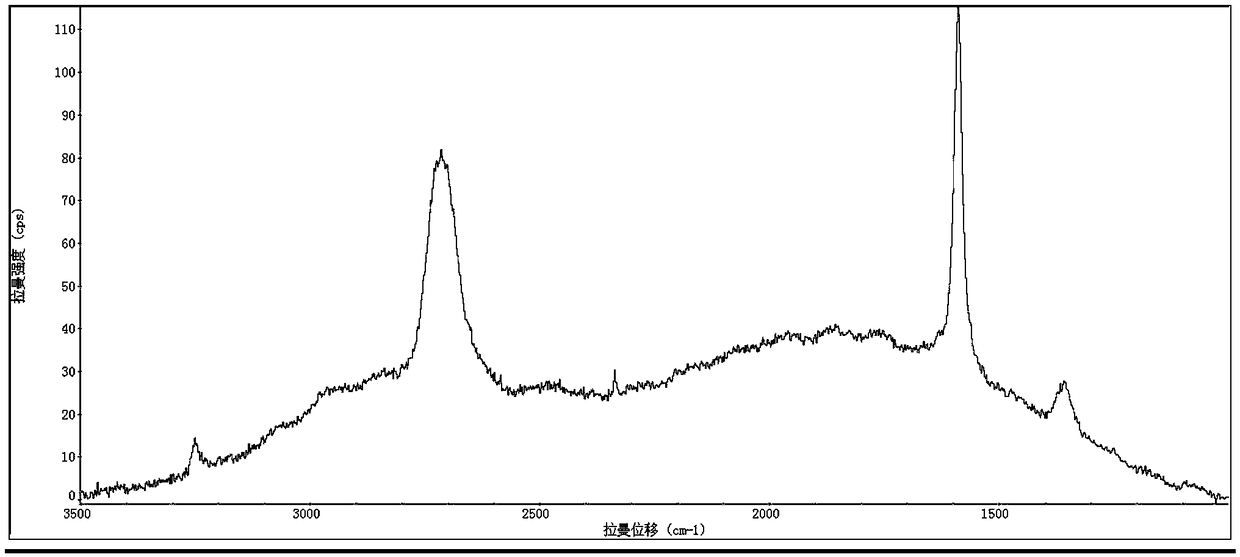

Image

Examples

Embodiment 1

[0052] Step a: Using a 30cm*20cm nickel mesh as the reaction substrate, decontaminate the surface of the nickel mesh, place the nickel mesh in a 2% glacial acetic acid solution for 5 minutes, and then place it in deionized water for ultrasonic washing 5 minutes, and finally blow dry with cold air.

[0053] Step b: Use the CVD method to grow graphene on the surface of the nickel mesh, place the nickel mesh in a quartz boat, and place it in the constant temperature zone of the tube furnace of the CVD system. First, the temperature of the tube furnace is heated to 15°C / min. At 1000° C., during the heating process, hydrogen gas was introduced at a flow rate of 50 sccm, and argon gas was introduced at a flow rate of 100 sccm; then, the temperature and gas flow rate were kept unchanged for 60 minutes, and annealing was performed. Then, methane as a carbon source gas was fed at a flow rate of 10 sccm for growth, and the growth time was 25 minutes. During the growth process, the tempe...

Embodiment 2

[0061] Step a: Using a 30cm*20cm nickel mesh as the reaction substrate, decontaminate the surface of the nickel mesh, place the nickel mesh in a 2% glacial acetic acid solution for 5 minutes, and then place it in deionized water for ultrasonic washing 5 minutes, and finally blow dry with cold air.

[0062] Step b: Use the CVD method to grow graphene on the surface of the nickel mesh, place the nickel mesh in a quartz boat, and place it in the constant temperature zone of the tube furnace of the CVD system. First, the temperature of the tube furnace is heated to 15°C / min. At 900°C, during the heating process, hydrogen gas was introduced at a flow rate of 50 sccm, and argon gas was introduced at a flow rate of 100 sccm; then, the temperature and gas flow rate were kept unchanged for 60 minutes, and annealing was performed. Then, methane as a carbon source gas was fed at a flow rate of 10 sccm for growth, and the growth time was 25 minutes. During the growth process, the temperat...

Embodiment 3

[0070] Step a: the same as step a of the first embodiment.

[0071] Step b: Use the CVD method to grow graphene on the surface of the nickel mesh, place the nickel mesh in a quartz boat, and place it in the constant temperature zone of the tube furnace of the CVD system. First, the temperature of the tube furnace is heated to 15°C / min. At 1100° C., during the heating process, hydrogen gas was introduced at a flow rate of 50 sccm, and argon gas was introduced at a flow rate of 100 sccm; then, the temperature and gas flow rate were kept unchanged for 60 minutes, and annealing was performed. Then, methane as a carbon source gas was fed at a flow rate of 10 sccm for growth, and the growth time was 25 minutes. During the growth process, the temperature was kept unchanged, and the flow rate of argon gas was 300 sccm, and the flow rate of hydrogen was 40 sccm. Finally, the temperature is rapidly cooled, so that the temperature of the tube furnace is reduced to room temperature within...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com