Controllable preparation method of high-oxidation-resistance high-purity single/double-wall carbon nanotube

A technology of double-walled carbon nanotubes and single-walled carbon nanotubes, applied to the controllable preparation method of single/double-walled carbon nanotubes, which can solve the problem of difficult large-scale production, high oxidation resistance, and purity of single or double-walled carbon nanotubes Low-level problems, to achieve controllable preparation, selectivity, and easy purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

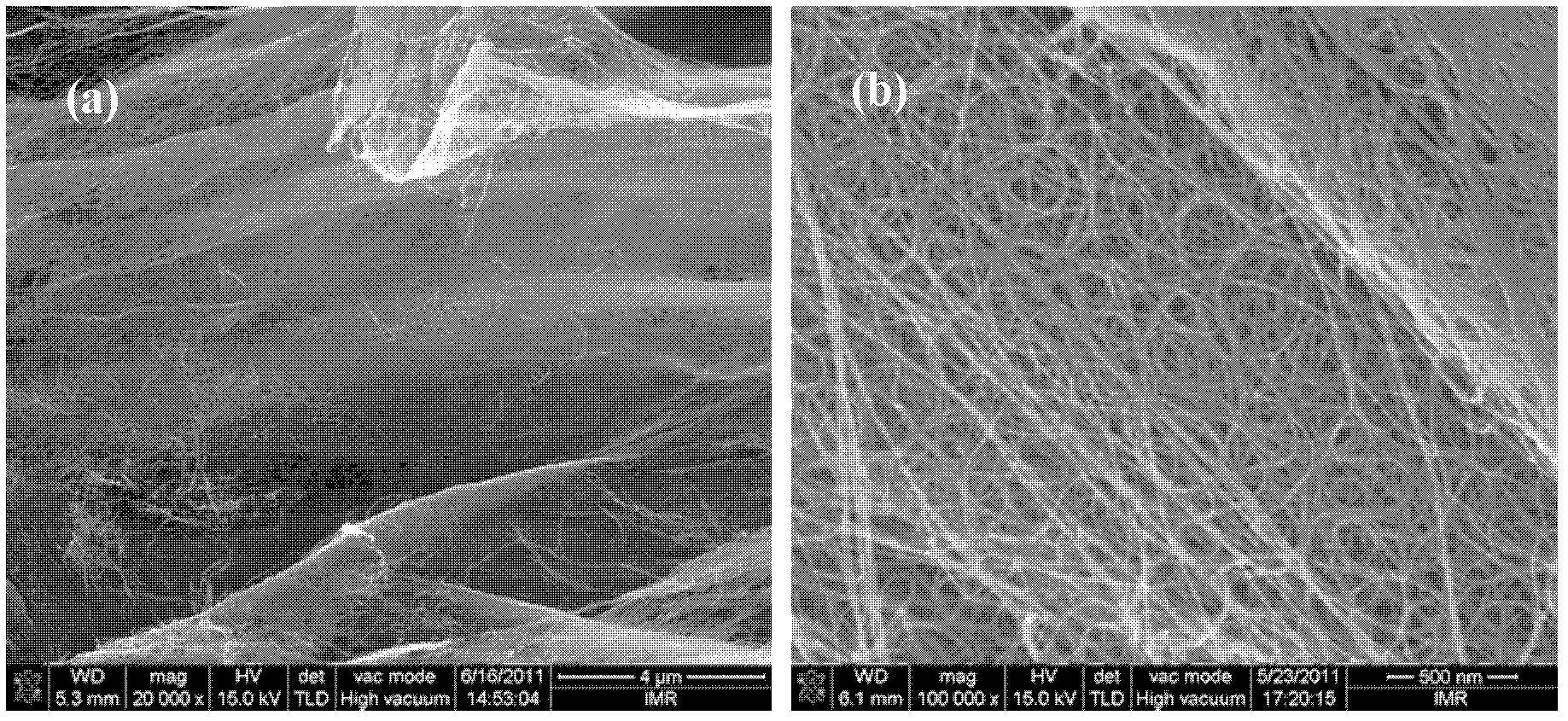

[0023] (1) A piece of ferrocene containing 0.5wt% sulfur powder is placed in the low-temperature zone of the chemical vapor deposition furnace (CVD furnace, the diameter is 50mm, and the length of the constant temperature zone is 8cm), and the temperature is raised at 30° C. / min under a hydrogen atmosphere. Raise the rate to 1100°C, increase the hydrogen flow rate to 12,000ml / min, inject 20ml / min of methane, and push the ferrocene containing sulfur powder to the furnace temperature of 215°C at the same time to grow carbon nanotubes. The growth time was 30 minutes. After the chemical vapor deposition is finished, turn off the methane, and drop to room temperature under the protection of low hydrogen flow rate (the hydrogen flow rate is 100ml / min).

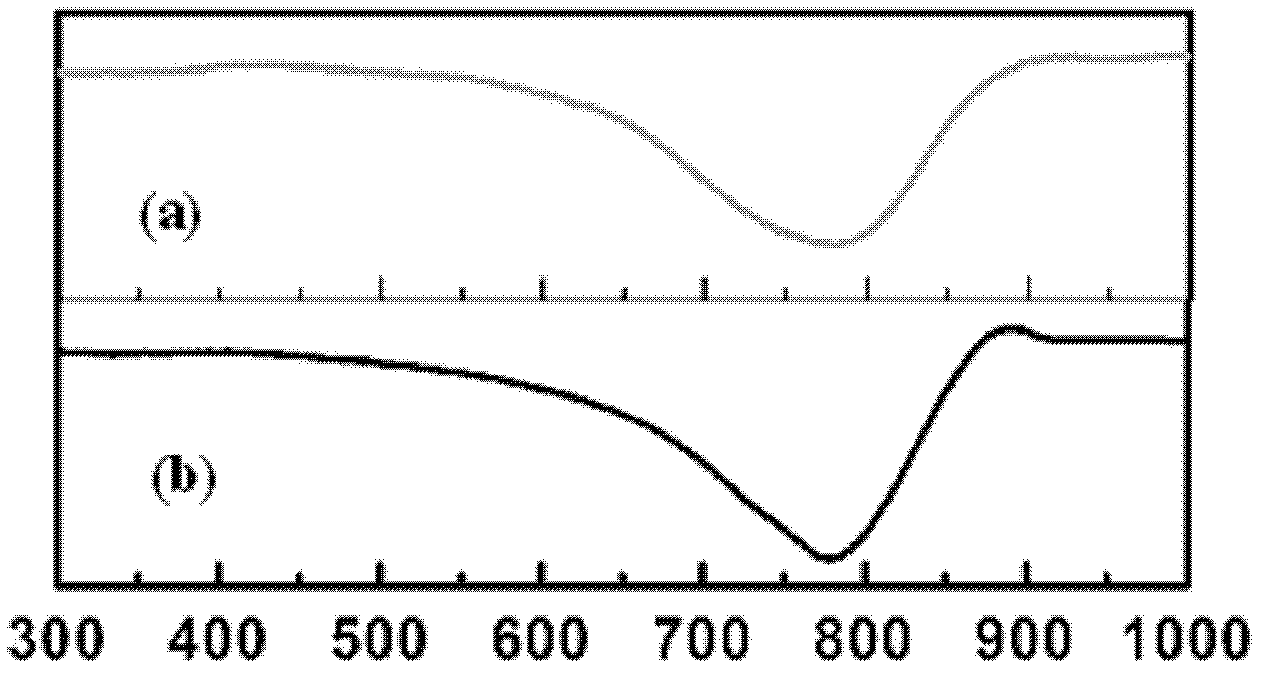

[0024] (2) 30 mg of carbon nanotubes prepared in step (1) were evenly placed in a heating furnace tube with a diameter of 50 mm and a constant temperature zone length of 8 cm, and oxidized at 370° C. for 10 h. After the sample was ...

Embodiment 2

[0027] (1) A piece of ferrocene containing 1wt% sulfur powder is placed in the low-temperature zone of the chemical vapor deposition furnace (CVD furnace, the diameter is 50mm, and the length of the constant temperature zone is 8cm), at a heating rate of 30°C / min under a hydrogen atmosphere Raise to 1100°C, increase the hydrogen flow rate to 10,000ml / min, feed 30ml / min of methane, and push the ferrocene containing sulfur powder to the furnace temperature of 180°C at the same time to grow carbon nanotubes. The time is 30 minutes. After the chemical vapor deposition is finished, turn off the methane, and drop to room temperature under the protection of low hydrogen flow rate (the hydrogen flow rate is 100ml / min).

[0028] (2) 30 mg of carbon nanotubes prepared in step (1) were evenly placed in a heating furnace tube with a diameter of 50 mm and a constant temperature zone length of 8 cm, and oxidized at 370° C. for 10 h. After the sample was cooled to room temperature, it was t...

Embodiment 3

[0031] (1) A piece of ferrocene containing 1wt% sulfur powder is placed in the low-temperature zone of the chemical vapor deposition furnace (CVD furnace, the diameter is 50mm, and the length of the constant temperature zone is 8cm), at a heating rate of 30°C / min under a hydrogen atmosphere Raise to 1100°C, increase the flow rate of hydrogen to 5000ml / min, feed 30ml / min of methane, and push the ferrocene containing sulfur powder to a furnace temperature of 180°C at the same time to grow carbon nanotubes. The time is 30 minutes. After the chemical vapor deposition is finished, turn off the methane, and drop to room temperature under the protection of low hydrogen flow rate (the hydrogen flow rate is 100ml / min).

[0032] (2) 30 mg of carbon nanotubes prepared in step (1) were evenly placed in a heating furnace tube with a diameter of 50 mm and a constant temperature zone length of 8 cm, and oxidized at 370° C. for 10 h. After the sample was cooled to room temperature, it was ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| anti-oxidation temperature | aaaaa | aaaaa |

| anti-oxidation temperature | aaaaa | aaaaa |

| anti-oxidation temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com