ZSM-5 molecular sieve and preparation method thereof

A technology of ZSM-5 and molecular sieve, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problem that the uniformity of ZSM-5 grain size is not very high, the degree of crystallinity is reduced, Small crystal grains and other problems, to achieve the effect of simplified particle size control means, wide range of silicon-aluminum ratio, and less structural defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

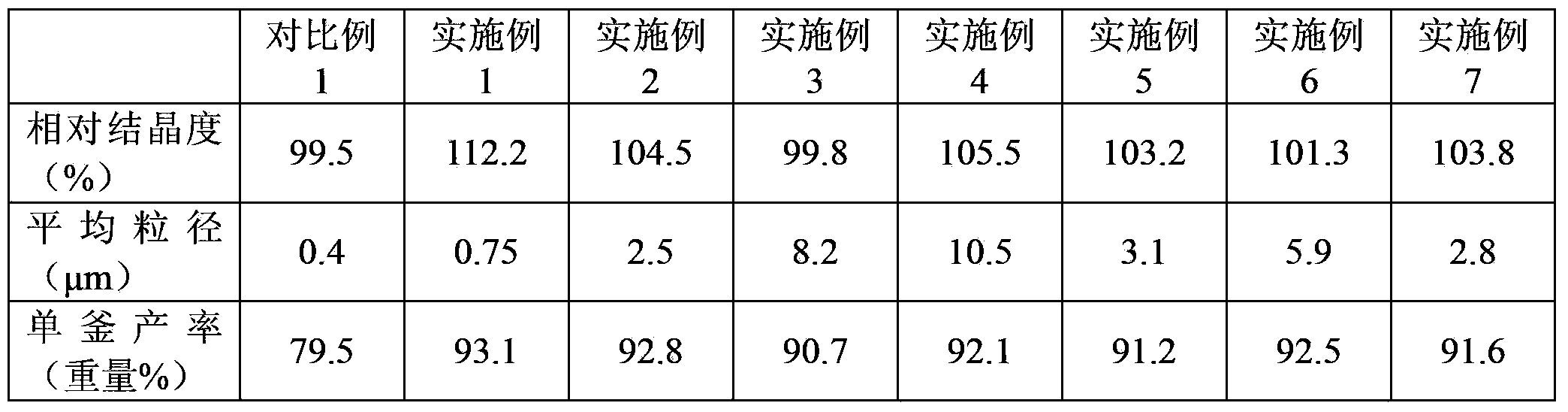

[0019] The invention provides a method for preparing ZSM-5 molecular sieves with different grain sizes and uniform grain sizes, different silicon-aluminum ratios and high crystallinity, characterized in that the molecular sieve shape remains unchanged, and the grain size is 500nm ~50μm, the ratio of silicon to aluminum can range from 27 to pure silicon, and the crystallinity is above 100%. Its preparation method comprises the following steps:

[0020] Using silicon source, aluminum source, template agent, potassium source and water as raw materials, it is synthesized under hydrothermal conditions. The specific steps are, the silicon source is SiO 2 Al 2 o 3 In terms of templating agent TPA + In terms of potassium source in K + The meter and water are mixed evenly according to the molar ratio of silicon source: aluminum source: template agent: potassium source: water = 1:0~0.075:0.02-1:0-5:5-100, at a temperature of 120-200°C Crystallize for 8-180 hours, and calcinate the...

Embodiment 1

[0024] This example is used to illustrate the preparation method of ZSM-5 molecular sieve.

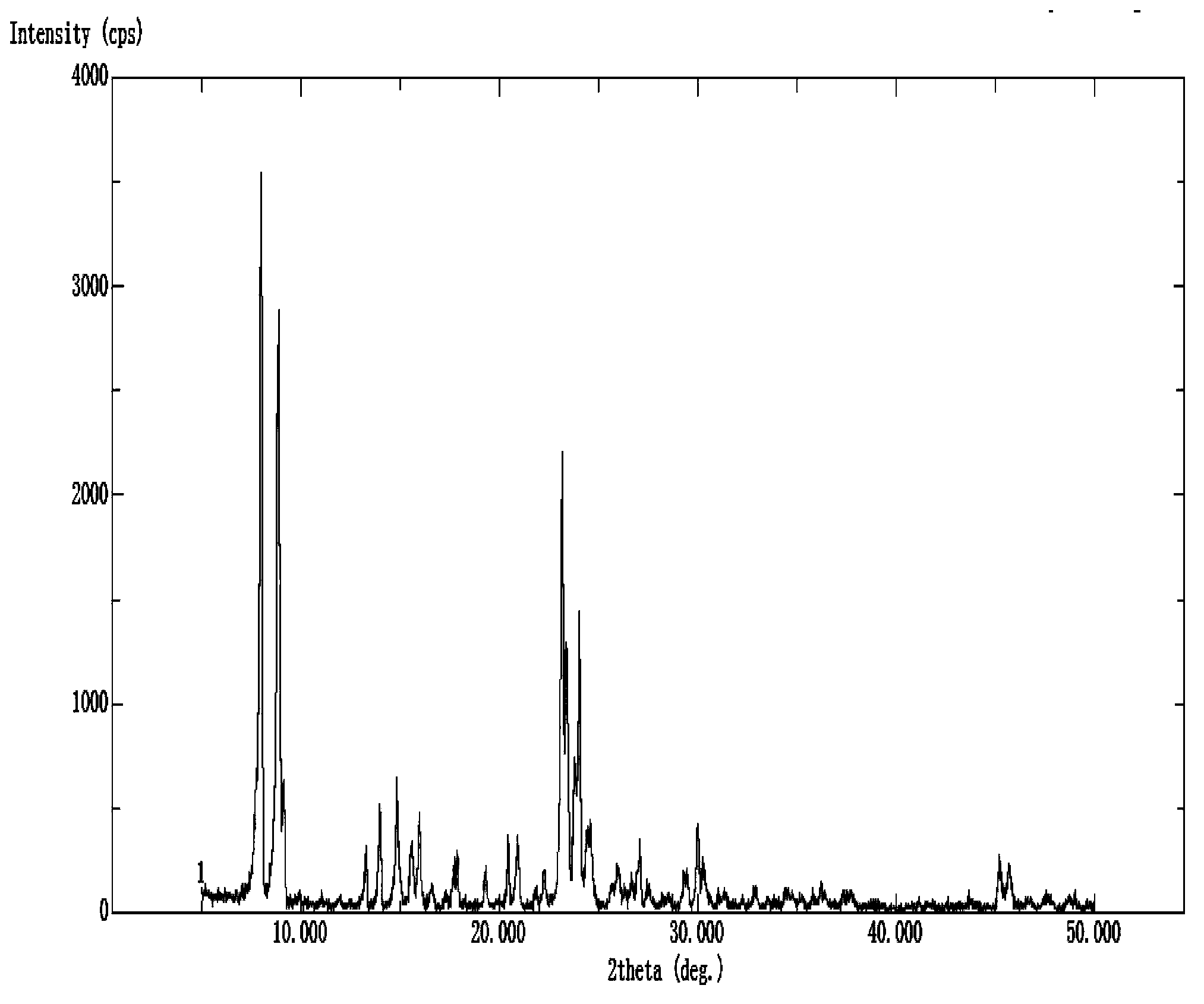

[0025] Silica gel (as SiO 2 in terms of), pseudoboehmite (in terms of Al 2 o 3 In terms of), template agent tetrapropylammonium bromide (TPA + In terms of), potassium hydroxide (in K + meter) with water in accordance with SiO 2 :Al 2 o 3 : TPABr: KOH: water = 1: 0.02: 0.5: 0.25: 35 molar ratio after mixing evenly, dynamic crystallization at 120°C for 3 days, take out and wash, dry at 100°C for 6 hours, then bake at 550°C for 6 hours, Product Z1 is obtained. Measure the relative crystallinity and average particle diameter of this product Z1, list in Table 1. For the XRD spectrum of Z1, see figure 1 ,pass figure 1 It can be seen from the XRD spectrum that Z1 is a ZSM-5 molecular sieve.

Embodiment 2

[0027] This example is used to illustrate the preparation method of ZSM-5 molecular sieve.

[0028] Silica gel (as SiO2 in terms of), pseudoboehmite (in terms of Al 2 o 3 Calculated), template agent tetrapropylammonium hydroxide (TPA + In terms of), potassium chloride (in K + meter) with water in accordance with SiO 2 :Al 2 o 3 : TPABr: KOH: water = 1: 0.02: 0.5: 5: 35 molar ratio after mixing evenly, dynamic crystallization at 140 ° C for 4 days, take out and wash, dry at 100 ° C for 6 hours, then bake at 550 ° C for 6 hours, Product Z2 is obtained. Determination of the relative crystallinity and average particle size of the sample is listed in Table 1. According to the XRD spectrum of Z2, Z2 is a ZSM-5 molecular sieve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com