Carding equipment for spinning easy to clean and application method thereof

A carding and equipment technology, applied in the field of cotton textile processing equipment, can solve problems such as easy adhesion of lint, lower carding efficiency, inability to disassemble and assemble, etc., to improve cleaning efficiency, improve carding efficiency, and facilitate centralized processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

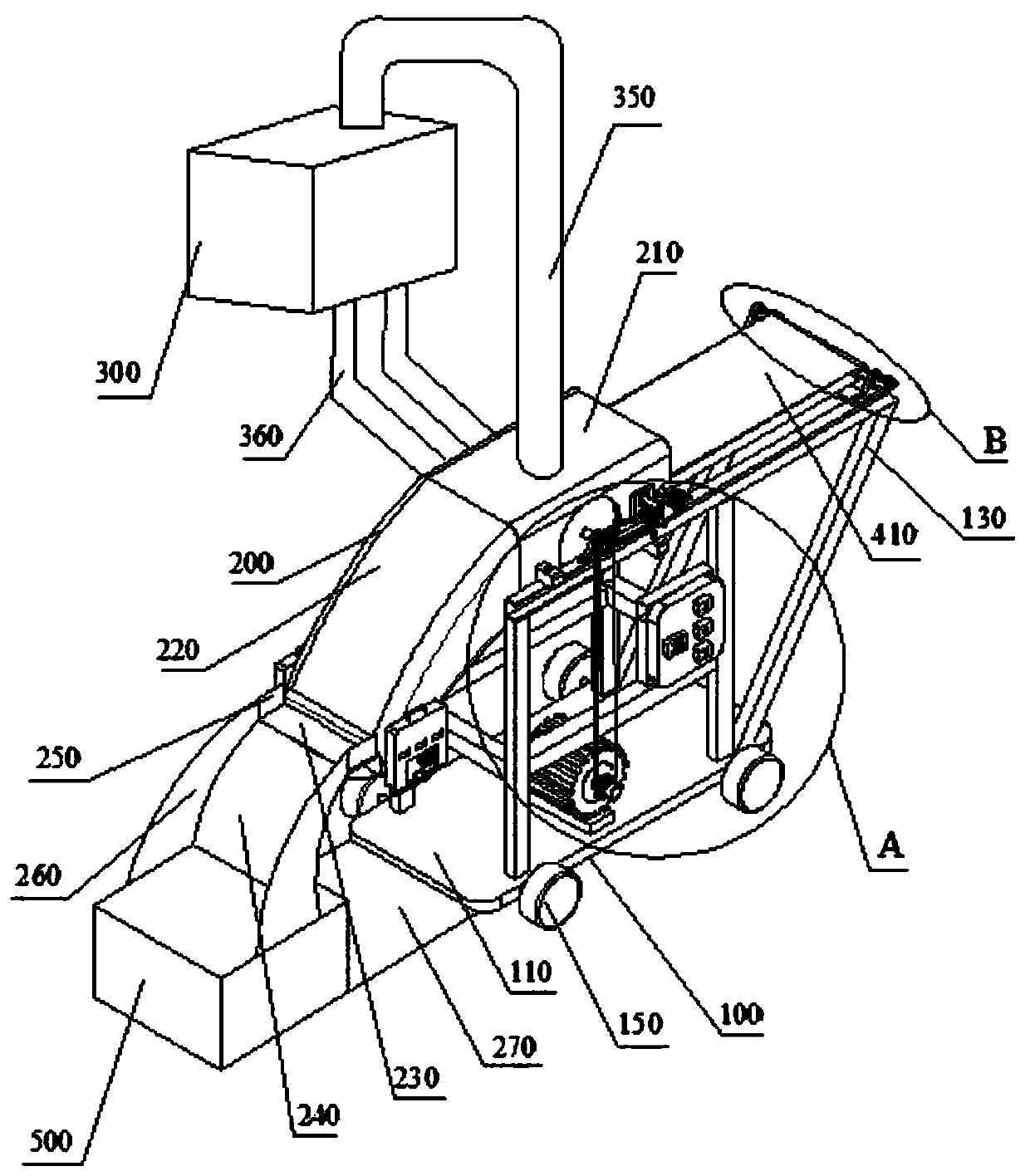

[0041] see Figure 1-9 As shown, the present embodiment provides a kind of carding equipment for spinning processing that is easy to clean, including a support 100, a feeding mechanism, a carding bin 200, a cleaning bin 300 for removing impurities, a carding mechanism, a collection box 500, and a support 100. For the support and installation of the feeding mechanism, the carding bin 200, the impurity removal and cleaning bin 300, the carding mechanism, and the collection box 500; Yarn raw material cotton provides space for extrusion, carding, and blanking; the impurity removal and cleaning bin 300 is used to absorb and classify the dust and impurities generated in the carding bin 200; The dough is extruded and carded to obtain cotton fiber strips.

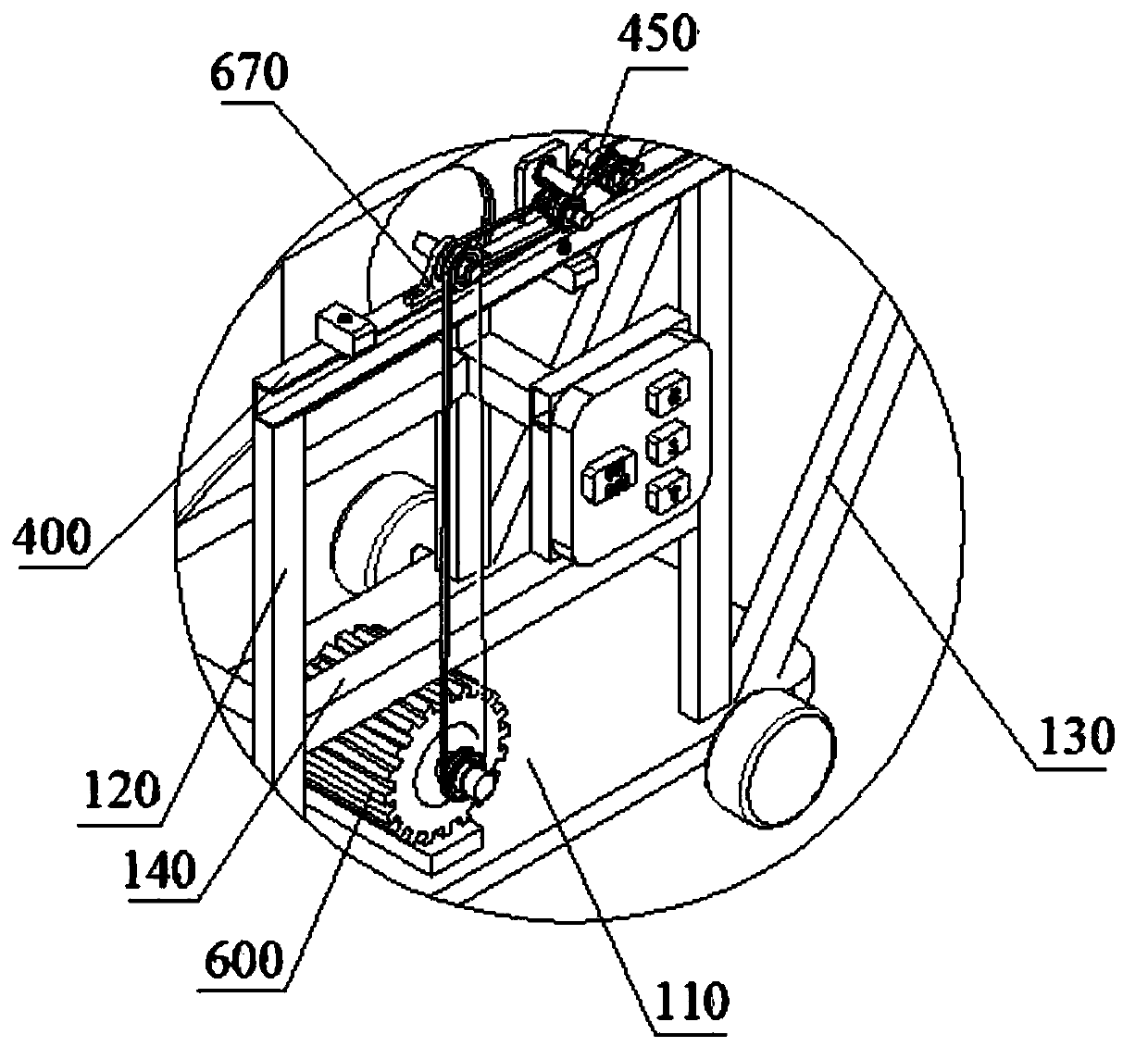

[0042] Specifically, the bracket 100 includes a base plate 110, a main support rod 120, an oblique support rod 130, and a secondary support rod 140. The main support rods 120 are vertically installed at the four corners of the bas...

Embodiment 2

[0051] refer to Figure 1-9 As shown, the present embodiment provides a method for using a carding device for spinning processing that is easy to clean, comprising the following steps:

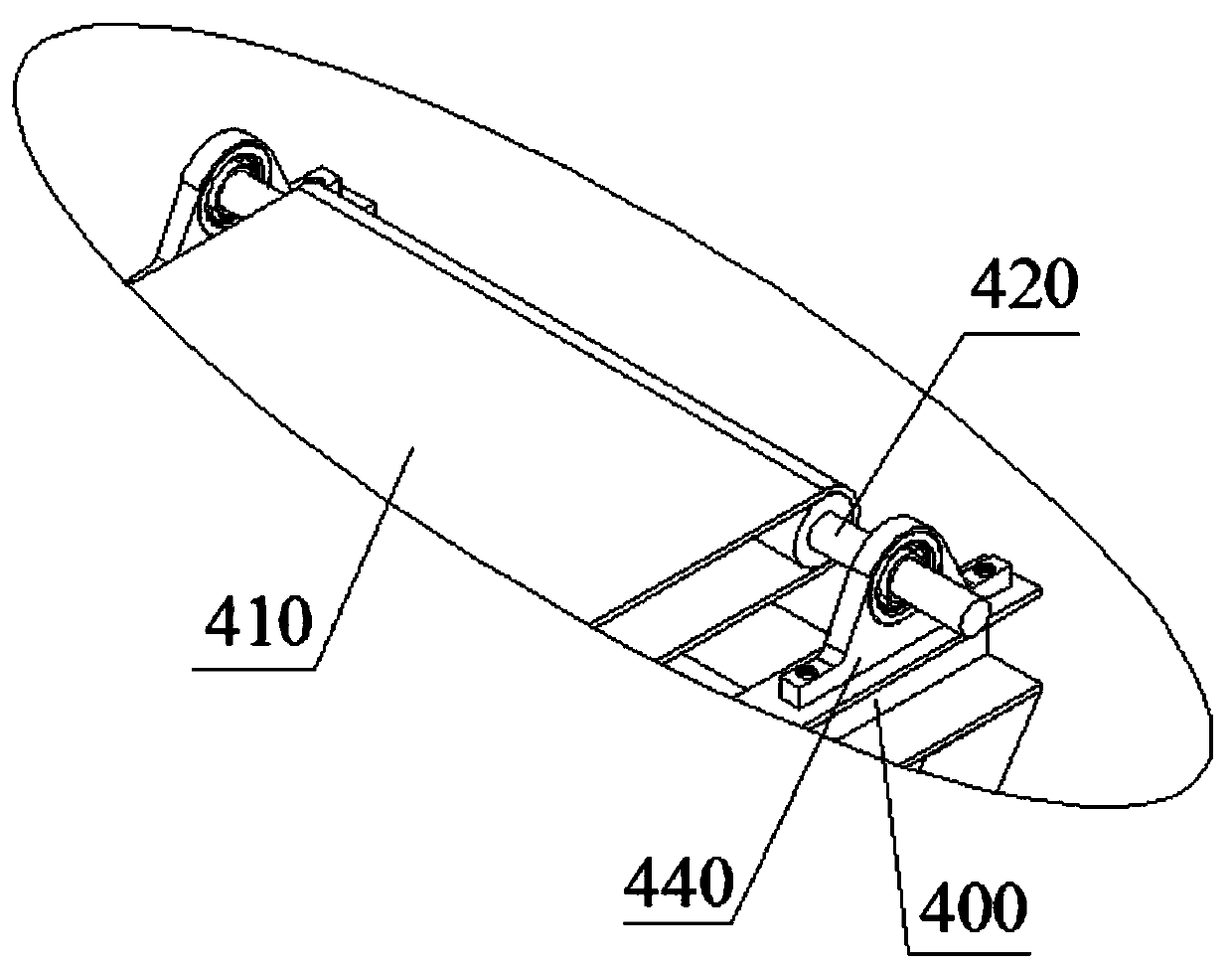

[0052] S1. Cotton feeding, extruding, and carding: start the first drive motor 600, the output shaft of the first drive motor 600 drives the first pulley 601 to rotate, and the first pulley 601 drives the first drive belt 640 and the second pulley 602 Rotate, the second pulley 602 drives the second transmission belt 650 transmission, the third pulley 603, the fourth pulley 604 rotate thereupon; the central shaft 680 connected with the second pulley 602 rotates, drives the rotation of the licker-in roller 610; the second roller shaft The rotation of 430 drives the transmission of the feeding belt 410 and the rotation of the first roller shaft 420; cotton wool is put into the feeding belt 410, and the cotton wool enters between the first squeeze roller 620 and the second squeeze roller 621 along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com