High-efficiency main carding device of carding machine

A high-efficiency, carding technology, applied in the field of carding, can solve the problem of low working efficiency of the carding machine, and achieve the effects of improving carding efficiency, strong adaptability and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

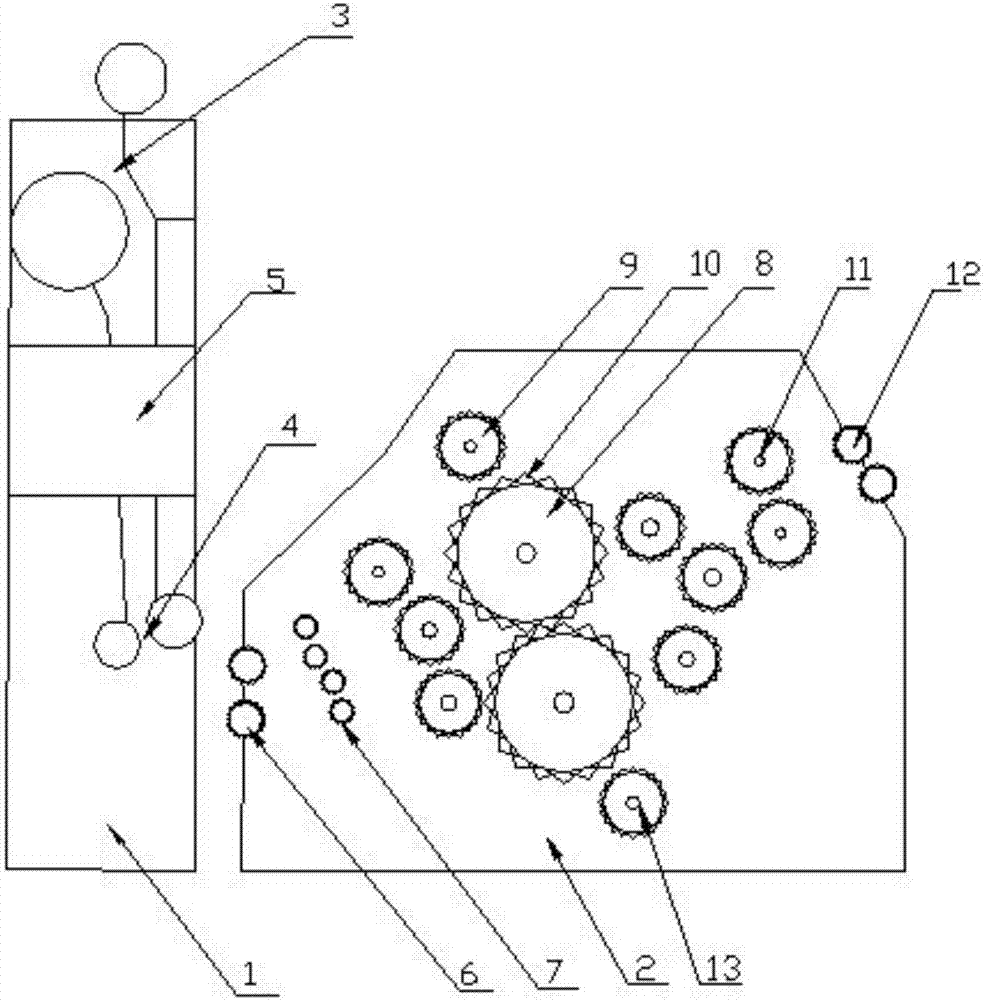

[0016] Example: such as figure 1 As shown, the present invention discloses a high-efficiency main carding device about a carding machine, including a pre-carding device 1 and a main carding device 2 on the right side of the pre-carding device 1, and the pre-carding device 1 includes a first cotton inlet 3 and a second carding device. A cotton outlet 4, the middle of the first cotton inlet 3 and the first cotton outlet 4 is provided with a crushing bucket 5, and the position corresponding to the first cotton outlet 4 on the main comb device 2 is provided with a second cotton inlet 6, the right side of the second cotton inlet 6 is provided with a number of cotton-distributing runners 7, the cotton-distributing runners 7 are regularly distributed, and the right side of the cotton-distributing runner 7 is provided with a primary comb wheel 8 and a secondary comb wheel 9. The primary comb wheel 8 and the secondary comb wheel 9 are cylindrical, and the outer wall of the cylinder is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com