Layered anti-static PVC coiled material and preparation method thereof

An anti-static and coiled material technology, applied in the field of building materials, can solve the problems of poor anti-aging ability, easy arching and blistering of anti-static floors, etc., achieve high fault tolerance, avoid local excessive humidity, and reduce losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

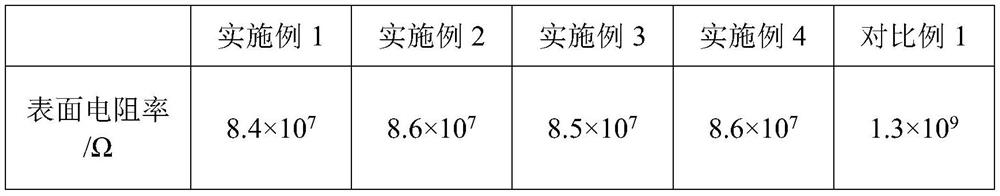

Examples

Embodiment 1

[0031] (1) Preparation of the first and second functional layers

[0032] Put lignin, copper nanowires, activated carbon, and porous polylactic acid fibers in water for 2 hours to mix thoroughly, then take out the mixed material and add it to a lipase solution at 45°C and let it stand for 6 hours. After standing, wash it with water and dry it in the air . Then put the dried material in a vacuum device, add a dilute acetic acid solution of chitosan to the device, vacuum and shake at 45 ° C for 60 min, then take it out and wash it, add an appropriate amount of water, and use the solvent casting method to load MgO nanoparticles. particles and obtain the first functional layer film. Wherein the dosage ratio of lignin, copper nanowire, activated carbon, porous polylactic acid fiber and lipase is 7g:2.5g:10g:15g:5g.

[0033] Put carbon nanotubes and carbon black in a ball mill for 2 hours, then filter through a 200-mesh sieve. After filtering, add the mixture and conductive carbon...

Embodiment 2

[0040] (1) Preparation of the first and second functional layers

[0041] Put lignin, copper nanowires, activated carbon and porous polylactic acid fibers in water for 3 hours and mix thoroughly by ultrasonic, then take out the mixed material and add it to lipase solution at 50°C and let it stand for 7 hours. After standing, wash it with water and dry it in the air . Then put the dried material in a vacuum device, add a dilute acetic acid solution of chitosan to the device, vacuum and shake it at 42°C for 70 minutes, then take it out and wash it, add an appropriate amount of water, and use the solvent casting method to load MgO nanoparticles. particles and obtain the first functional layer film. Wherein the dosage ratio of lignin, copper nanowires, activated carbon, porous polylactic acid fiber and lipase is 8g:4g:11g:17g:4.5g.

[0042] Put carbon nanotubes and carbon black in a ball mill for 2 hours, then filter through a 200-mesh sieve. After filtering, add the mixture and...

Embodiment 3

[0049] (1) Preparation of the first and second functional layers

[0050] Put lignin, copper nanowires, activated carbon and porous polylactic acid fibers in water for 3 hours and mix thoroughly by ultrasonic, then take out the mixed material and add it to lipase solution at 48°C and let it stand for 8 hours. After standing, wash it with water and dry it in the air . Then put the dried material in a vacuum device, add a dilute acetic acid solution of chitosan to the device, vacuumize and shake at 40°C for 80 minutes, then take it out and wash it, add an appropriate amount of water, and use a solvent casting method to load MgO nanoparticles. particles and obtain the first functional layer film. Wherein the dosage ratio of lignin, copper nanowire, activated carbon, porous polylactic acid fiber and lipase is 9g:3.5g:12g:16g:3g.

[0051] Put carbon nanotubes and carbon black in a ball mill for 3 hours, then filter through a 200-mesh sieve. After filtering, add the mixture and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com