Longitudinal axial flow belt cut-up type combined roller of combined harvester

A combine harvester and longitudinal axial flow technology, applied to cutting equipment, agricultural machinery and implements, threshing equipment, etc., can solve the problems of unsatisfactory effect, easy breeding of pathogenic bacteria, too concentrated distribution, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

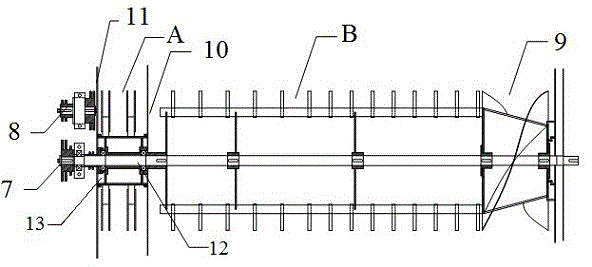

[0029] Below in conjunction with accompanying drawing and specific embodiment, further clarifies the longitudinal axial flow band chopping combined drum of this combine harvester:

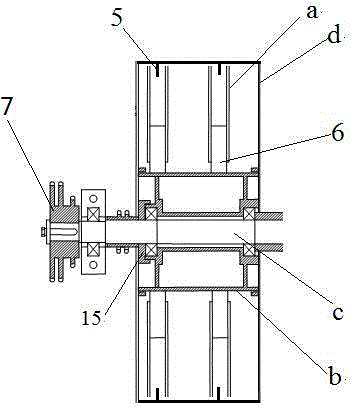

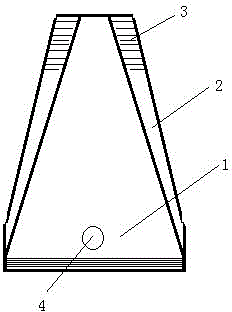

[0030] Such as figure 1 , a longitudinal axial flow belt chopping combination drum, including a threshing device and a threshing driving device, the threshing driving device is connected to drive the threshing device; it also includes a straw chopping and throwing device, and the feeding port of the straw chopping and throwing device is connected to The grass outlet of the threshing device; the straw chopping and throwing device is provided with a throwing outlet.

[0031] The threshing device includes a threshing cylinder, a threshing cylinder and threshing teeth; the threshing cylinder is inside the threshing cylinder, and the axes of the two are the same; the threshing cylinder is provided with threshing teeth; the grass outlet of the threshing device is at the tail end of the threshing cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com