Filtering and conveying integrated machine for feed processing

A feed processing and integrated machine technology, applied in feed, sieve, application, etc., can solve the problems of easy clogging of the filter screen, agglomeration and dispersal, large area, etc., and achieves the effect of small contact area and prevention of accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

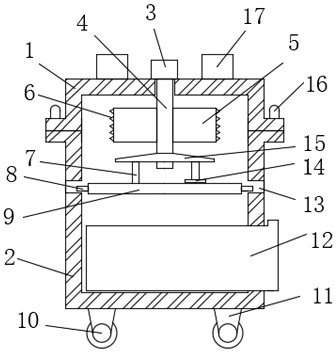

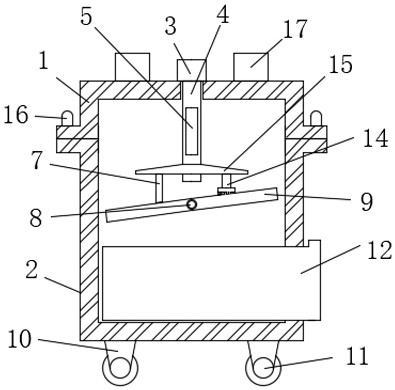

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0016] refer to Figure 1-2 , a filter and conveying integrated machine for feed processing, including a first casing 1 and a second casing 2 arranged below the first casing 1, a feed port 17 is symmetrically fixedly connected to the top of the first casing 1, and the first casing A servo motor 3 is arranged above the body 1, and a rotating shaft 4 is vertically arranged in the first casing 1. The first casing 1 and the second casing 2 are fixedly connected by positioning pins 16. The first casing 1 and the second casing The bodies 2 are all clamped with the positioning pin 16, the first housing 1 and the second housing 2 are connected through the positioning pin 16, the positioning pin 16 can make the first housing 1 and the second housing 2 align, and prevent the servo motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com