Grain combine harvester

A combine harvester and grain technology, applied to harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of unsatisfactory results, easy breeding of pathogenic bacteria, friction and fire, etc., so as to reduce the probability of accidents and benefit Dispersing and guaranteeing the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and specific embodiment, further clarify the structure of this combine harvester.

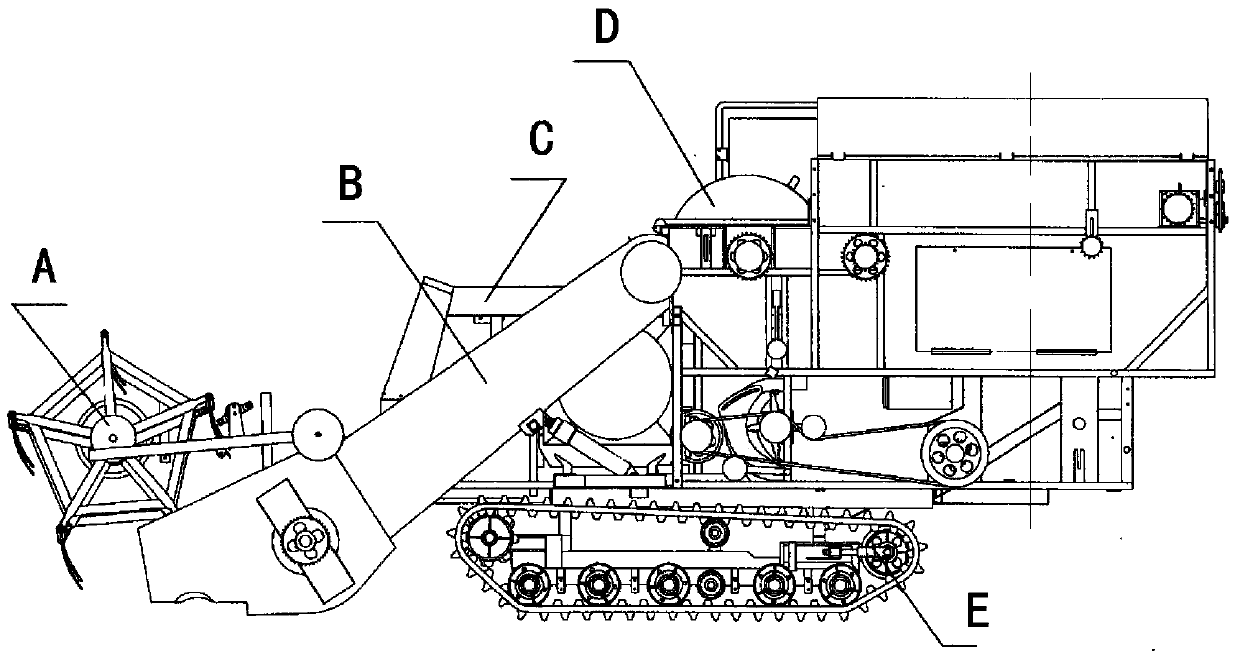

[0035] Such as figure 1 , a combine harvester comprising a frame, a header, a conveying chute, a frame and a threshing chamber located on the frame; , there is also an auger assembly connected between the conveying trough and the header; the auger assembly lies below the blanking place of the header, and the feed port of the conveying trough is connected below the outlet of the auger assembly; the threshing The chamber is behind the conveying trough, and the feed port of the threshing chamber is below the discharge port of the conveying trough; the frame is installed on the traveling chassis, and a console is also arranged on the traveling chassis.

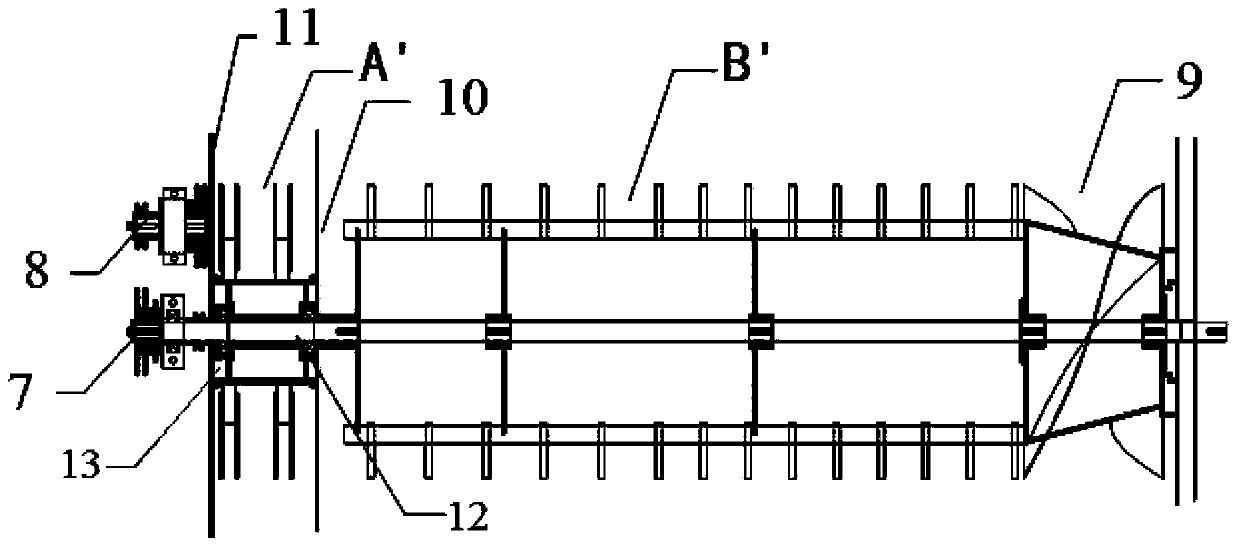

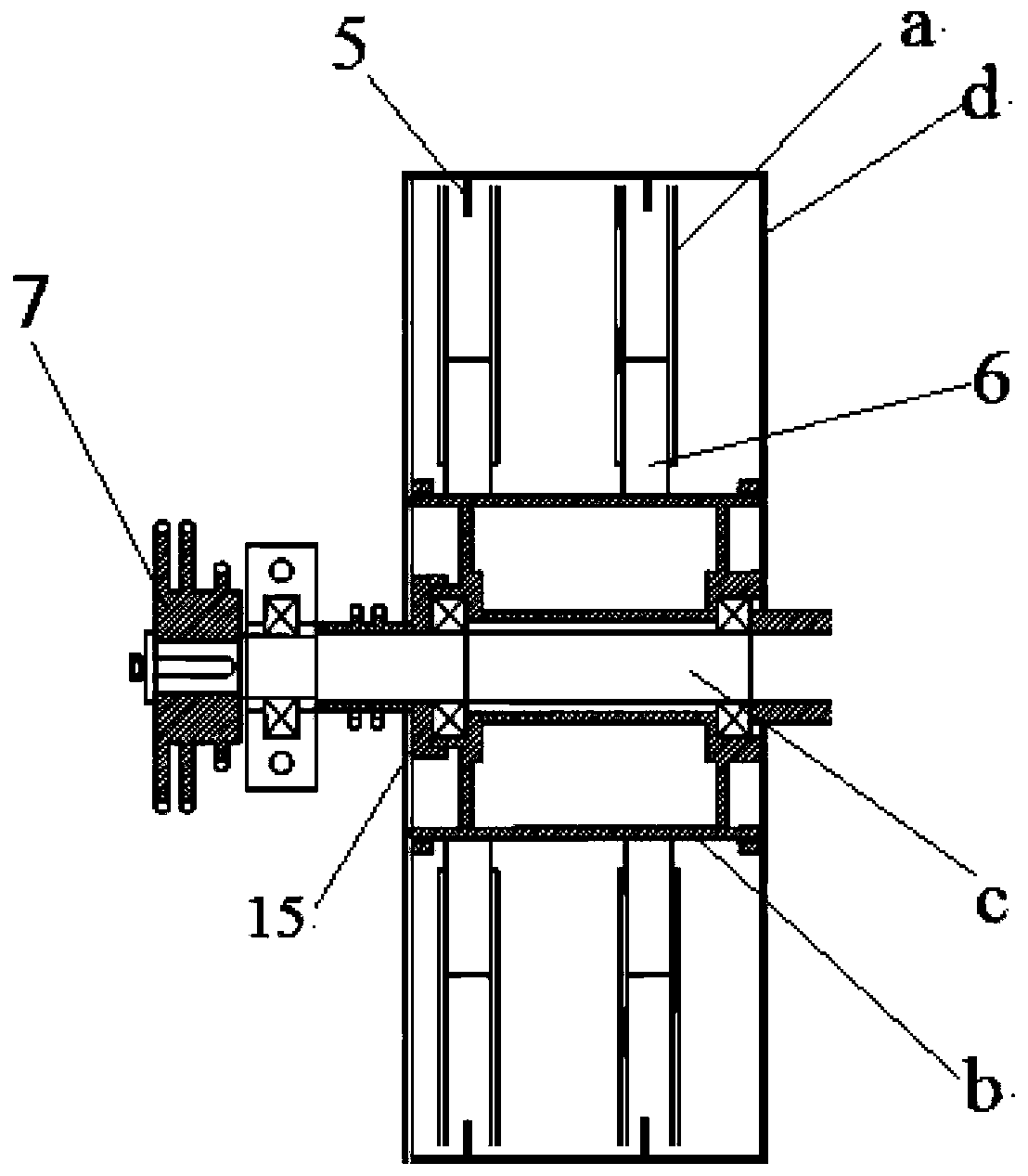

[0036] Such as figure 2 , the threshing chamber is a longitudinal axial flow belt chopping combination drum, including a threshing device and a threshing drive device, the threshing drive dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com